Page 1

Installation

Guide

VisionPRO®IAQ

Equipment Interface Module

English: Page 1 • Français: Page 6 • Español: Página 11

For up to 4 Heat/2 Cool systems with Honeywell TH9421C or equivalent.

System Types

• Gas, oil, or electric heat with air

conditioning

• Warm air, hot water, highefficiency furnaces, heat pumps,

steam, gravity

• Heat only — two-wire systems,

power to open and close zone

valves (Series 20), and normallyopen zone valves

• Heat only with fan

• Cool only

• Variable speed systems

Must be installed by a trained, experienced technician

• Read these instructions carefully. Failure to follow these instructions

can damage the product or cause a hazardous condition.

CAUTION: ELECTRICAL HAZARD

Can cause electrical shock or equipment damage. Disconnect power before

beginning installation.

MERCURY NOTICE

If this product is replacing a control that contains mercury in a sealed tube, do not

place the old control in the trash. Contact your local waste management authority for

instructions regarding recycling and proper disposal.

® U.S. Registered Trademark.

Copyright © 2006 Honeywell International Inc.

All rights reserved.

Page 2

VisionPRO®IAQ Equipment Interface Module

Installation

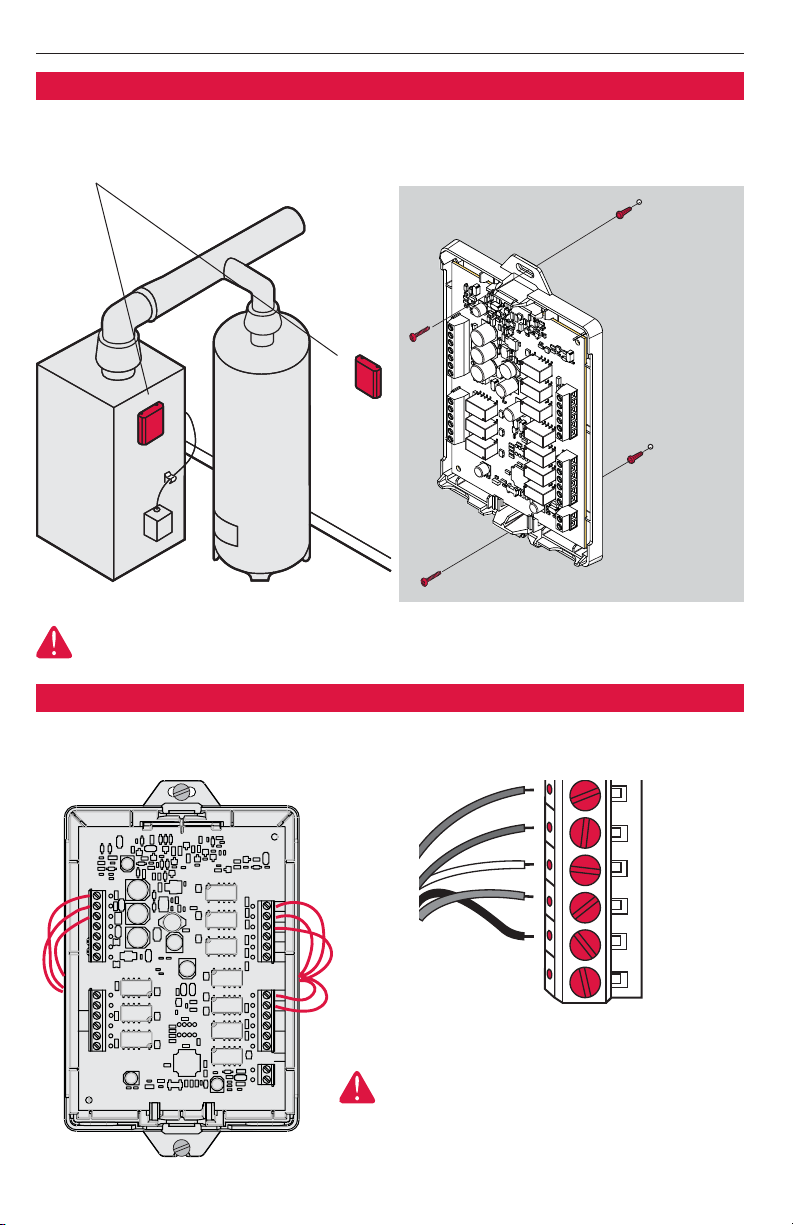

1 Remove cover from Equipment Interface Module (EIM).

2 Select location and mount EIM as shown below.

Wall anchor

Drill 3/16” holes

for drywall. Drill

7/32” holes for

plaster.

Furnace/air handler Water heater

CAUTION: This product may be damaged if mounted inside HVAC equipment. Install

only on the outside of HVAC equipment.

Mounting screw

Wiring

Connect wires as shown below (see wiring guides on following pages).

All wiring must comply with local electrical

codes and ordinances.

2

Page 3

English: Page 1 • Français: Page 6 • Español: Página 11

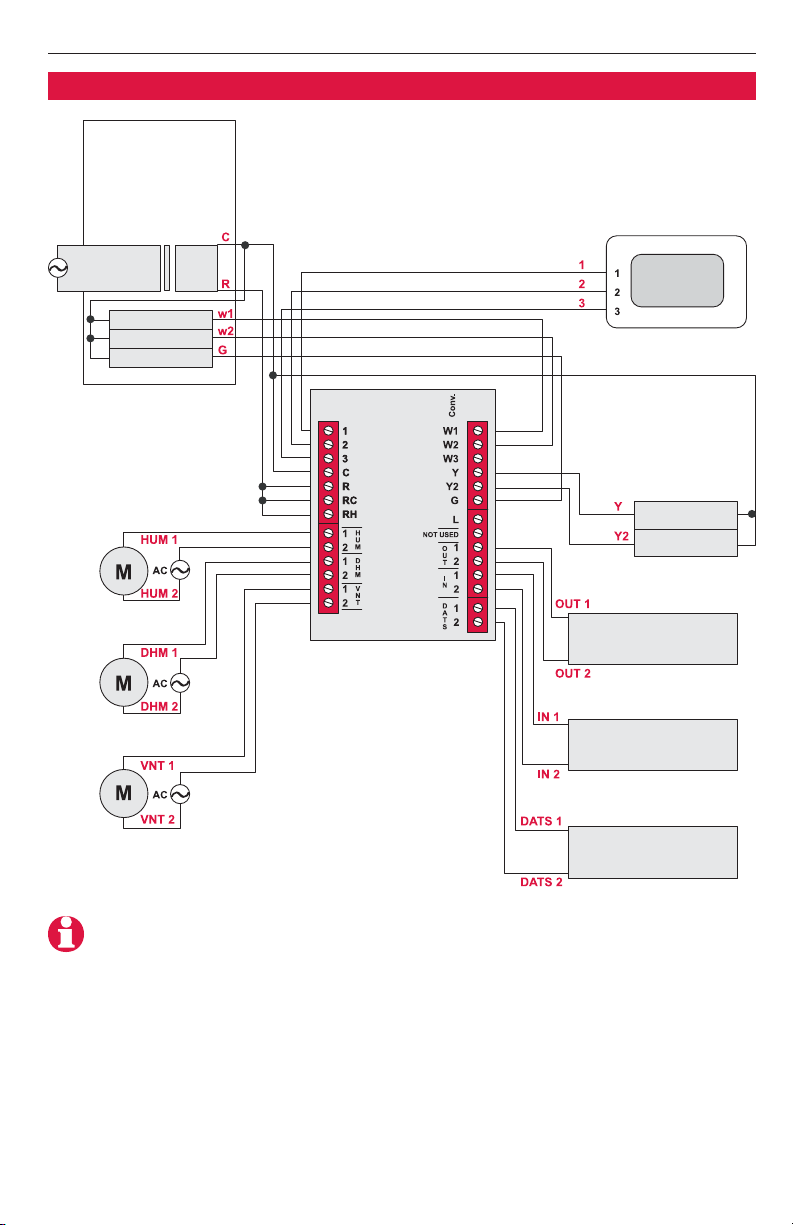

Wiring guide — conventional systems

FURNACE

Transformer

Stage 1 heat

Stage 2 heat

Fan

Humidifier

Dehumidifier

Ventilation

THERMOSTAT

24Vac120Vac

Air conditioning

compressors

Stage 1

Stage 2

Temperature sensor

EQUIPMENT INTERFACE

MODULE

(outdoor)

Temperature sensor

(indoor)

Discharge air

temperature sensor

NOTE: Check other equipment manuals to verify proper terminal connections.

3

Page 4

VisionPRO®IAQ Equipment Interface Module

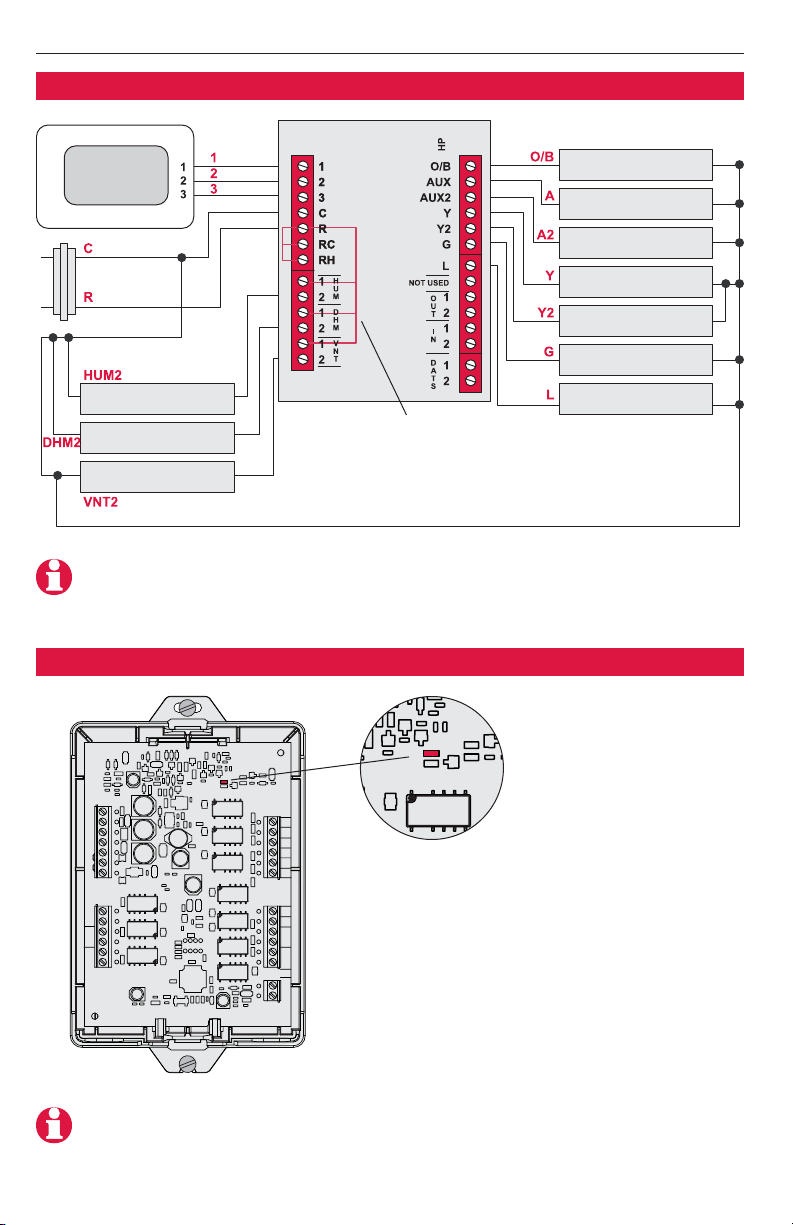

EIM wiring guide — heat pump systems

THERMOSTAT

Bypass humidifier

Low speed fan

Ventilator

EQUIPMENT INTERFACE

MODULE

Jumpers

NOTE: Check other equipment manuals to verify proper terminal connections.

Restore power & check operation

Changeover relay

Backup heat

(gas/electric)

Backup heat

(gas/electric)

Compressor

(stage 1)

Compressor

(stage 2)

Fan relay

System monitor

LED

Restore power and check LED:

• LED blinks rapidly: Normal information transfer.

• LED blinks once: Incoming message to EIM.

• LED blinks continuously: Wiring problem. Check

wiring to terminals 1, 2, 3.

• LED always off: Wiring problem. Check wiring to

terminals 1, 2, 3.

• LED always on: EIM may need replacement.

NOTE: It is normal for the LED to blink continuously during startup, and while checking

equipment status (Auto Discover mode).

4

Page 5

English: Page 1 • Français: Page 6 • Español: Página 11

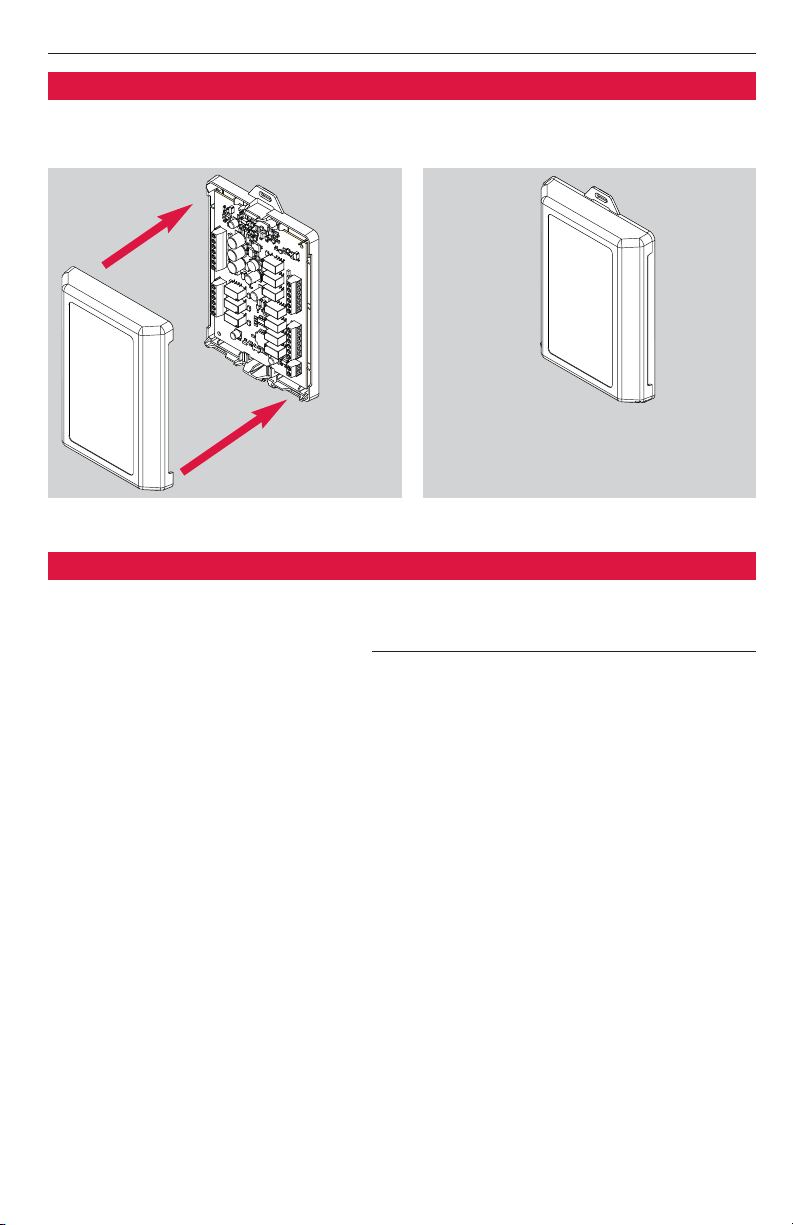

Replace EIM cover

Place cover on EIM, then push gently until it snaps into place.

Specifications

Temperature Ranges

• Heat: 40° to 90°F (4.5° to 32°C)

• Cool: 50° to 99°F (10° to 37°C)

Operating Ambient Temperature

• 0° to 120°F (-18° to 49°C)

Shipping Temperature

• -30° to 150°F (-34° to 66°C)

Operating Relative Humidity

• 5% to 90% (non-condensing)

Physical Dimensions

• 4-9/16” H x 6” W x 1-3/8” D

• 116 mm H x 152 mm W x 35 mm D

Electrical Ratings

Terminal Voltage (50/60Hz) Running Current

W Heating 20-30 Vac 0.02-1.0 A

W2 Heating 20-30 Vac 0.02-1.0 A

W3 Heating 20-30 Vac 0.02-1.0 A

Y Cooling 20-30 Vac 0.02-1.0 A

Y2 Cooling 20-30 Vac 0.02-1.0 A

Aux Auxiliary heat 20-30 Vac 0.02-1.0 A

Aux2 Auxiliary heat 20-30 Vac 0.02-1.0 A

G Fan 20-30 Vac 0.02-1.0 A

O/B Changeover 20-30 Vac 0.02-1.0 A

5

Page 6

Guide

d’installation

VisionPRO®IAQ

Equipment Interface Module

English: Page 1 • Français: Page 6 • Español: Página 11

Pour installations comportant 4 circuits de chauffage/2 circuits de climatisation

avec Honeywell TH9421C ou équivalent.

Types d’installations

• Chauffage au gaz, au mazout ou

électrique avec climatisation

• Chaudières à haut rendement à air

chaud, eau chaude, thermopompes,

vapeur, calorifères

• Installation à deux fils chauffage

seulement, alimentation pour ouvrir

et fermer les valves de zone (Série

20) et vannes de zone normalement

ouvertes

• Chauffage seulement avec ventilateur

• Climatisation seulement

• Systèmes variables de vitesse

Il est impératif de faire réaliser l’installation par un technicien chevronné

• Lisez attentivement les présentes consignes. La non observation de celles-ci

risque d’endommager le produit ou de présenter des dangers.

MISE EN GARDE : RISQUE ÉLECTRIQUE

Peut provoquer des secousses électriques ou endommager le matériel.

Coupez l’alimentation avant d’entreprendre l’installation.

AVIS CONCERNANT LE MERCURE

Si ce produit remplace un dispositif de régulation contenant une ampoule de

mercure, ne placez pas ce dernier dans les ordures. Contactez l'agence de gestion

des déchets de la localité pour connaître les règlements concernant le recyclage

et la mise au rebut.

Copyright © 2006 Honeywell International Inc.

® U.S. Marque déposée

Tous droits réservés

Page 7

English: Page 1 • Français: Page 6 • Español: Página 11

Installation

1 Enlevez la couverture de Equipment Interface Module (EIM).

2 Choisissez l'endroit et montez le EIM comme indiqué ci-dessous.

Chevilles murales

Percez des trous

de 3/16 po dans

une cloison

sèche. Percez

des trous de

7/32 po dans du

plâtre.

Chaudière/traiteur d'air Chauffe-eau

ATTENTION : Pour éviter des dommages, n'installez pas ce produit à l'intérieur

d'équipement de la HVAC. Installez seulement sur l'extérieur de l'équipement de la HVAC.

Vis de montage

Câblage

Reliez les fils comme montrés ci-dessous (voir les guides de câblage aux pages suivantes).

Tout le câblage doit être conforme aux codes

et aux ordonnances électriques locaux.

7

Page 8

VisionPRO®IAQ Equipment Interface Module

Guide de câblage — installations traditionnelles

CHAUDIÈRE

Transformateur

Chauff. étage 1

Chauff. étage 2

Ventilateur

Humidificateur

Déshumidificateur

Ventilation

THERMOSTAT

24Vac120Vac

Compresseurs

de climatisation

Étage 1

Étage 2

Sonde de température

EQUIPMENT INTERFACE

MODULE

(extérieure)

Sonde de température

(intérieure)

Vérifiez d'autres manuels d'équipement pour vérifier

les raccordements terminaux appropriés.

8

Sonde de température

de l'air de décharge

Page 9

English: Page 1 • Français: Page 6 • Español: Página 11

Guide de câblage — installations à thermopompe

THERMOSTAT

Humidificateur

de déviation

Ventilateur

à vitesse réduite

Ventilation

EQUIPMENT INTERFACE

MODULE

Vérifiez d'autres manuels d'équipement pour vérifier

les raccordements terminaux appropriés.

Vérifiez l'opération

Cavalier

Relais d’inversion

Chauff. de secours

(gaz/électrique)

Chauff. de secours

(gaz/électrique)

Compresseur

(Étage 1)

Compresseur

(Étage 2)

Relais ventilateur

Moniteur de système

LED

Reconstituerez l'énergie électrique &

vérifiez l'opération:

• La lumière clignote rapidement : Transfert de

l'information normal.

• Clignotements de lumière une fois : Message

entrant à EIM.

• La lumière clignote sans interruption :

Problème de câblage. Vérifiez le câblage aux

bornes 1, 2, 3.

• Lumière toujours au loin : Problème de câblage.

Vérifiez le câblage aux bornes 1, 2, 3.

• Lumière toujours dessus : EIM peut avoir besoin

de remplacement.

Il est normal que la LED clignote sans interruption pendant le démarrage,

et tout en vérifiant le statut d'équipement (le mode Auto Discover).

9

Page 10

VisionPRO®IAQ Equipment Interface Module

Remplacez la couverture d'EIM

Placez la couverture sur EIM, puis poussez doucement jusqu'à ce qu'il se

casse dans l'endroit.

Caractéristiques techniques

Gammes de température

• Chauffage : 40° à 90°F (4.5° à 32°C)

• Climatisation : 50° à 99°F (10° à 37°C)

Température ambiante de fonctionnement

• 0° à 120°F (-18° à 49°C)

Température d’expédition

• -30° à 150°F (-34° à 66°C)

Humidité relative de fonctionnement

• 5% à 90% (sin condensación)

Dimensions

• 4-9/16” H x 6” L x 1-3/8” Ép

• 116 mm H x 152 mm L x 35 mm Ép

Caractéristiques électriques

Borne Tension (50/60Hz) Courant

W Chauffage 20-30 Vca 0,02-1,0 A

W2 Chauffage 20-30 Vca 0,02-1,0 A

W3 Chauffage 20-30 Vca 0,02-1,0 A

Y Climatisation 20-30 Vca 0,02-1,0 A

Y2 Climatisation 20-30 Vca 0,02-1,0 A

Aux Chauffage aux. 20-30 Vca 0,02-1,0 A

Aux2 Chauffage aux. 20-30 Vca 0,02-1,0 A

G Ventilateur 20-30 Vca 0,02-1,0 A

O/B Inversion 20-30 Vca 0,02-1,0 A

10

Page 11

Guía de

instalación

VisionPRO®IAQ

Equipment Interface Module

English: Page 1 • Français: Page 6 • Español: Página 11

Para hasta 4 sistemas de calefacción/2 de refrigeración con Honeywell TH9421C o equivalente.

Tipos de sistemas

• Calefacción a gas, petróleo o

eléctrica con aire acondicionado

• Aire caliente, agua caliente, estufas

de alta eficiencia, bombas de

calefacción, vapor, gravedad

• Sólo calefacción, sistemas de

doble cableado, alimentación de

energía para abrir y cerrar válvulas

de zona (serie 20) y abrir normalmente válvulas de zona

• Sólo calefacción con ventilador

• Sólo refrigeración

• Sistemas variables de la velocidad

Debe instalarlo un técnico capacitado y con experiencia

• Lea atentamente estas instrucciones. Si las ignora, podría dañarse el

producto o generarse condiciones de peligro.

PRECAUCIÓN: PELIGRO ELÉCTRICO

Puede causar descarga eléctrica o daño del equipo. Desconecte la alimentación de

energía antes de iniciar la instalación.

AVISO DE MERCURIO

Si este producto reemplaza a un control que contiene mercurio en un tubo sellado,

no arroje el control viejo a la basura. Comuníquese con la autoridad local de disposición de desechos para recibir instrucciones sobre reciclado y eliminación correcta.

® Marca registrada en EE.UU.

Copyright © 2006 Honeywell International Inc.

Todos los derechos reservados.

Page 12

VisionPRO®IAQ Equipment Interface Module

Instalación

1 Quite la cubierta de Equipment Interface Module (EIM).

2 Seleccione la localización y monte EIM como se muestra a continuación.

Soportes de pared

Orificios de

taladro de 3/16”

para mampostería en seco.

Orificios de

taladro de 7/32”

para yeso.

Estufa/tratante del aire Calentador de agua

PRECAUCIÓN: Para evitar daño, no instale este producto dentro del equipo de la HVAC.

Instale solamente en el exterior del equipo de la HVAC.

Tornillos de montaje

Cableado

Conecte los cables según lo demostrado abajo (ver las guías de cableado

en las páginas siguientes).

Todo el cableado debe conformarse con

códigos y ordenanzas eléctricos locales.

12

Page 13

English: Page 1 • Français: Page 6 • Español: Página 11

Guía para el cableado — sistemas convencionales

ESTUFA

Transformador

Calor (etapa 1)

Calor (etapa 2)

Ventilador

Humidificador

Deshumidificador

Ventilación

TERMOSTATO

24Vac120Vac

Compresores

del aire

acondicionado

Etapa 1

Etapa 2

Sensor de temperatura

EQUIPMENT INTERFACE

MODULE

(exterior)

Sensor de temperatura

(interior)

NOTA: Consulte otros manuales del equipo para verificar

conexiones terminales apropiadas.

13

Sensor de temperatura

del aire de la descarga

Page 14

VisionPRO®IAQ Equipment Interface Module

Guía para el cableado — sistemas de bombeo de calefacción

TERMOSTATO

Humidificador

de puente

Ventilador bajo

de la velocidad

Ventilación

EQUIPMENT INTERFACE

MODULE

Empalme

NOTA: Consulte otros manuales del equipo para verificar

conexiones terminales apropiadas.

Verifique la operación

Relais del cambio

Calor de reserva

(gas/eléctrica)

Calor de reserva

(gas/eléctrica)

Compresor

(etapa 1)

Compresor

(etapa 2)

Relais del ventilador

Monitor del sistema

LED

Reactivaron corriente eléctrica y verifique la

operación:

• La luz centelleo rápidamente: Transmisión

informativa normal.

• Centelleos de la luz una vez: Mensaje entrante

a EIM.

• La luz centelleo continuamente: Problema del

cableado. Compruebe el cableado a los terminales

1, 2, 3.

• Luz siempre apagado: Problema del cableado.

Compruebe el cableado a los terminales 1, 2, 3.

• Luz siempre encendido: EIM puede necesitar

el reemplazo.

NOTA: Es normal para que la luz centelleo continuamente durante arranque,

y mientras que comprueba estado del equipo (el modo Auto Discover).

14

Page 15

English: Page 1 • Français: Page 6 • Español: Página 11

Reinstale la cubierta de EIM

Ponga la cubierta en EIM, luego presione suavemente hasta que la cubierta

calce en su lugar.

Especificaciones

Rangos de temperatura

• Calefacción: 40° a 90°F (4.5° a 32°C)

• Refrigeración: 50° a 99°F (10° a 37°C)

Temperatura ambiental de funcionamiento

• 0° a 120°F (-18° a 49°C)

Temperatura de envío

• -30° a 150°F (-34° a 66°C)

Humedad relativa de funcionamiento

• 5% a 90% (sin condensación)

Dimensiones físicas

• 4-9/16” H x 6” A x 1-3/8” P

• 116 mm H x 152 mm A x 35 mm P

Regímenes eléctricos

Terminal Tensión (50/60Hz) Corriente

W Calefacción 20-30 VCA 0,02-1,0 A

W2 Calefacción 20-30 VCA 0,02-1,0 A

W3 Calefacción 20-30 VCA 0,02-1,0 A

Y Refrigeración 20-30 VCA 0,02-1,0 A

Y2 Refrigeración 20-30 VCA 0,02-1,0 A

Aux Calefacción aux. 20-30 VCA 0,02-1,0 A

Aux2 Calefacción aux. 20-30 VCA 0,02-1,0 A

G Ventilador 20-30 VCA 0,02-1,0 A

O/B Cambio 20-30 VCA 0,02-1,0 A

15

Page 16

Need Help?

For assistance with this product please visit http://yourhome.honeywell.com

or call Honeywell Customer Care toll-free at 1-800-468-1502

Vous faut-il de l’aide ?

Pour obtenir de l’assistance concernant ce produit, visitez http://yourhome.honeywell.com

ou appelez gratuitement l’assistance client d’Honeywell au 1-800-468-1502

¿Necesita ayuda?

Para recibir asistencia con este producto visite http://yourhome.honeywell.com

o llame gratis al Servicio de Atención al Cliente Honeywell al 1-800-468-1502

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

http://yourhome.honeywell.com

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Scarborough, Ontario M1V 4Z9

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

® U.S. Registered Trademark.

© 2006 Honeywell International Inc. All rights reserved.

US Patent No. 6,208,263; 6,373,376; 6,448,901; H25192;

H25193 and other patents pending.

69-1823EFS • 06-2006

Loading...

Loading...