Honeywell Vigilon 4 loop, Vigilon 6 loop, Vigilon Compact, Vigilon Compact VA Generic Commissioning Instructions

Page 1

by Honeywell

Generic Commissioning Instructions

ISSUE 7

for Vigilon 4/6 loop & Compact range of fire panels & network nodes

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 2

Commissioning instructions

Contents

Preliminary information ----------------------6

Safety information ----------------------------- 6

Pre-visit checks ------------------------------- 6

Pre-commissioning ----------------------------- 6

Points to remember ----------------------------- 7

A typical commissioning process------------------8

Product Approval and Standards ------------------11

Fire detection and alarm control panel -------------------- 11

Interface Units ------------------------------- 11

Manual Call points ----------------------------- 11

S-Cubed Mark 3 ------------------------------ 12

S-Quad Sensors with Visual alarm device (VAD) - introduced post April 2014 - 13

S-Quad Sensors (Legacy product range) ------------------- 15

S-Cubed Mark 2 (Legacy product range) -------------------16

Fire Panels ----------------------------17

Vigilon 4/6 loop panels (EN/BS) ----------------------- 17

Vigilon Compact Panel (EN) ------------------------ 17

Vigilon Compact VA panel (EN) (Legacy panel) ---------------17

Controls and indications ----------------------18

Vigilon 4/6 loop Panels ----------------------23

Second fix parts------------------------------- 23

Remove the protective covers ------------------------ 23

Fitting the inner door ---------------------------- 24

Printer paper roll ------------------------------ 25

Setting the DKC card ---------------------------- 26

Card installation ------------------------------ 27

Terminals on Terminal Card -------------------------28

Pre power-up checks ---------------------------- 29

Mains supply wiring ---------------------------- 29

Battery installation ----------------------------- 30

PSU LED indications ---------------------------- 31

Write protect link on backplane ----------------------- 31

Fire Routing LEDs (Post Mid 2015) ---------------------32

Command Build LEDs CB253 and CB254 (Pre Mid 2015) ----------32

How to configure the 'U' buttons ----------------------- 33

Factory settings ------------------------------- 33

How to fit the outer door -------------------------- 33

Vigilon Compact Panel ----------------------34

Cards and internal cables of the panel -------------------- 35

Installing a replacement MCB in an older Vigilon Compact panel -------36

Terminals on the Master Control Board (MCB) ----------------37

Settings on the DKC ---------------------------- 38

Pre Power up checks ---------------------------- 39

Battery Installation ----------------------------- 39

Mains supply -------------------------------- 40

How to configure the monitored input --------------------41

Fire Routing LEDs (post mid 2015) --------------------- 42

How to configure the LEDs CB253 and CB254 (pre mid 2015) --------42

How to configure the U1 and U2 buttons ------------------- 43

External printer ------------------------------- 43

Factory settings ------------------------------- 44

Vigilon Compact Voice Alarm Panel - (legacy product) -------45

Cards and internal cables of the panel -------------------- 46

Terminals on the Audio Control Card -------------------- 47

Terminals on the Master Control Board-------------------- 48

Pre power up checks ---------------------------- 48

Battery Installation ----------------------------- 49

Mains supply -------------------------------- 50

External printer ------------------------------- 50

How to configure the monitored input --------------------50

How to configure the buttons U1 and U2 ------------------- 50

How to configure LEDs CB253 and CB254 (Legacy) -------------50

How to check and set the audio signal --------------------51

Factory settings ------------------------------- 51

Indications on power up ----------------------52

Initial tests ----------------------------52

Useful menu options -----------------------53

Panel Buzzer -------------------------------- 53

Software version check --------------------------- 53

Contents

2 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 3

Vigilon 4/6 loops & Compact (VA) panels & network nodes

Password or PIN code -----------------------53

How to create an Engineer PIN ----------------------- 54

How to change the Customer PIN ----------------------54

How to erase a PIN ----------------------------- 54

Address allocation ------------------------55

Address allocation with Loop circuit end 1 connected -------------55

Allocation faults ------------------------------ 56

How to re-allocate addresses to a loop circuit -----------------56

Address allocation with Loop circuit End 2 connected -------------56

Plexus Devices ------------------------------- 56

SAFE Addressing -------------------------57

To SAFE address a device --------------------------57

To convert from SAFE to soft address -------------------- 57

Checking a loop map -----------------------58

To find devices on a loop circuit -----------------------58

Non Volatile Memory (NVM) -------------------59

NVM Hardware Write protect ------------------------ 59

NVM Software - 'write protect' and 'unprotect' ----------------60

To back up loop data to NVM ------------------------60

To recover loop data from NVM ---------------------- 61

How to electrically erase the NVM ---------------------- 61

2km Loop circuit - tests using LDT ----------------62

Loop diagnostic tool ---------------------------- 62

How to [Repair] a loop circuit ------------------------ 62

Loop resistence measured by the panel -------------------- 62

1km Loop circuit - manual tests ------------------62

Loop resistance and capacitance ----------------------- 62

Loop circuit tests -------------------------63

Loop short circuit test ---------------------------- 63

Ground break test ------------------------------ 63

Positive line break test---------------------------- 64

Earth fault test ------------------------------- 64

Checking device STATUS---------------------65

Loop Device Status ----------------------------- 65

Plexus Device Status ---------------------------- 67

Device checks --------------------------68

Checking the time averages ------------------------- 68

Checking the Exception/Subfault codes-------------------- 70

Condition Codes for S-Quads (Exception / Sub Fault codes) ---------71

Pre Fire, Fire and Super fire --------------------72

S-Quad Sensor with VAD - STATES VAD (current range of devices) 73

S-Quad Sensor with Strobe - STATES (legacy devices) -------74

S-Quad Heat sensor STATES ------------------------ 75

S-Quad Dual Optical & Heat / Optical & Heat sensor STATES --------75

S-Quad Dual Optical, Heat & CO sensor STATES --------------76

S-Quad Optical sensor STATES ----------------------- 76

Beam sensor STATES-----------------------77

Interface Unit STATES ----------------------78

Single channel interface input STATES ------------------- 78

4 - Channel Interface Unit STATES --------------------- 78

34000 range of sensors STATES (legacy devices)----------79

Optical heat sensor (plus sounder) STATES (34000 range) ----------79

Heat sensor STATES (34000 range) --------------------- 80

Installed equipment tests----------------------81

Preparation --------------------------------- 81

Communication to site occupants ---------------------- 81

Commissioning Tool ---------------------------- 81

Plant equipment------------------------------- 81

Zone 'Test' mode (for EN panels only) -------------------- 81

'Commission' mode (for BS panels only) ------------------- 81

Fire Sensors -------------------------------- 82

Manual Call Points ----------------------------- 82

Interface Units ------------------------------- 82

S Cubed ---------------------------------- 83

Repeat panel (Loop connected) ----------------------- 83

Mimic Panel -------------------------------- 83

Mains powered DAU and micro DAU (Legacy devices) ------------83

VIGILON Compact VA system (Legacy system) --------------- 83

Deviations from standards -------------------------- 83

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 3

Contents

Page 4

Commissioning instructions

Vigilon Compact Network ---------------------84

Single Network ------------------------------- 84

Wiring the single network -------------------------- 85

Single network without domain bridge -------------------- 85

Network Card for VIGILON Compact - baud and node address switch settings - 86

Powering-up the Network --------------------------87

How to check a Network map ------------------------ 87

How to check Network Card status ---------------------- 88

Fault Finding -------------------------------- 88

High errors --------------------------------- 88

Single Vigilon Network ----------------------89

Single Network ------------------------------- 89

Wiring a Copper network -------------------------- 90

Wiring a Fibre network --------------------------- 90

Single network without domain bridge -------------------- 91

Powering-up the Network --------------------------91

How to check a Network map ------------------------ 91

How to check Network Card status ---------------------- 92

Fault Finding -------------------------------- 92

High errors --------------------------------- 92

Multiple Vigilon Networks --------------------93

Domain Bridge using Input Output card ------------------- 93

Two networks using Domain bridge IO card -----------------93

Star network using Domain bridge IO cards -----------------93

IO domain bridge network switch settings ------------------ 94

Message routing ------------------------------ 95

Domain bridge message passing tests--------------------- 96

Domain bridge using Fibre Optic network card ---------------- 96

FO Domain Network switch settings ---------------------97

Appendix A-1 - Menu maps for EN54 (V4) Vigilon panel ------98

Appendix A-2 - Menu maps for BS (V3+) Vigilon panel ------107

Appendix B - Message Action List -----------------116

Clearable fault events ---------------------------- 116

Latching fault events ---------------------------- 116

Repairable fault events --------------------------- 116

Message Action list ----------------------------- 117

Appendix C - Guidelines for standalone system commands -----139

Labels ----------------------------------- 139

Long labels --------------------------------- 140

Sectors ----------------------------------- 143

Integral sounder operation -------------------------- 144

Default fire plan ------------------------------ 145

Fail safe fire plan ------------------------------ 145

Site specific fire plan ---------------------------- 145

Delay Blocks -------------------------------- 146

Sound and Resound alarms options---------------------- 148

Time slots and Time blocks ------------------------- 149

Zones ----------------------------------- 150

Groups ----------------------------------- 150

Zone Tasks --------------------------------- 151

Command Builds ------------------------------ 152

Sounders Configuration --------------------------- 153

Auxiliary Relays ------------------------------ 154

Radio Device -------------------------------- 154

Fire Alarm Routing Equipment (FARE) ------------------- 155

Fire Protection Equipment (FPE)-----------------------156

S-Cubed Mark III or II and S-Quad ---------------------157

Voice and Sounder mode pluse VAD/Strobe action --------------158

Appendix D - Guidelines for Networked system commands -----159

Master Sectors ------------------------------- 159

Master Groups ------------------------------- 160

Appendix E - Cards ------------------------161

Contents

4 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 5

Vigilon 4/6 loops & Compact (VA) panels & network nodes

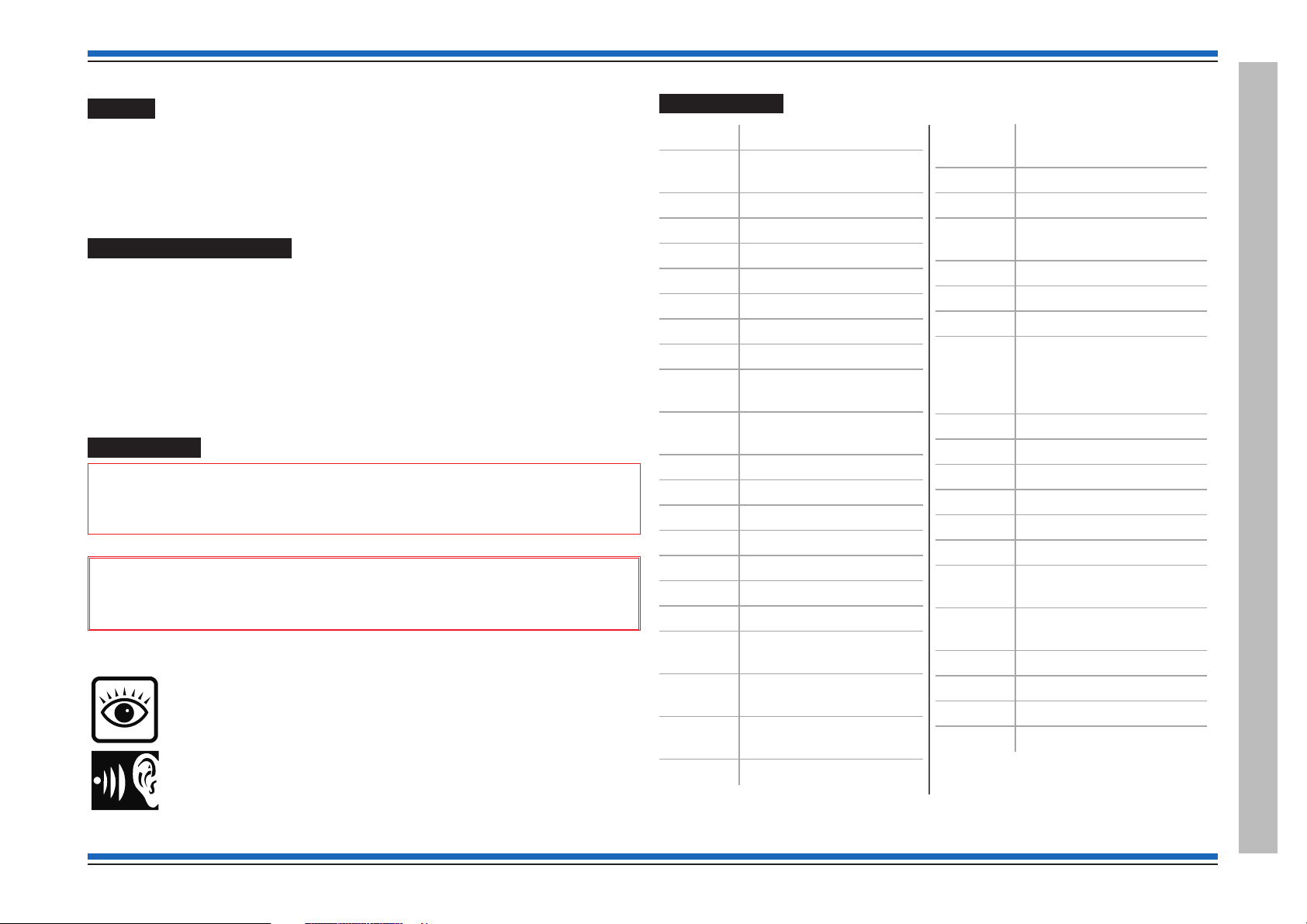

Preface

This is the seventh issue of the Commissioning instructions for the fire alarm system based on the

EN54/BS Vigilon 4/6 loop panels, Vigilon Compact panel (&VA) (with network capability)

and Vigilon Network nodes. This manual covers EN panels having Master Control Card / Master

Control Board software at version 4.53 or higher and BS panels having Master Control Card

software at version 3.97 or higher. It also covers FARE, FPE and Part 23 devices.

Associated documents

The Vigilon control panels and network nodes are supplied with respective copies of the operating

and installation instruction manuals:

EN54 Vigilon 4/6-loop panel based system - Installation instructions & Operating instructions

EN54 Vigilon Compact panel based system - Installation instruction & Operating instructions

EN54 Vigilon Compact Voice Alarm panel - Installation instructions & Operating instructions

Vigilon Compact Network node - Installation instructions

Vigilon Network Node - Installation instructions

Commissioning tool - User guide

Conventions

"

This is a note to highlight important text that is normally hidden in the main text.

&

warning to inform of dangerous conditions that may result in injury or death.

Symbol Keys

This is either a caution to prevent damage to the equipment or a

What you will see.

Abbreviations

ACC Audio Control Card

ADC Analogue to digital

converter

C Common

CH channel

CO Carbon monoxide

DAU Distributed Amplifier Unit

DEV Device

DIL Dual in line

DKC Display keyboard card

DPCO Double pole change over

(relay contacts)

EEPROM Electrically Erasable

Programmable ROM

EOL End of line

FAB First action byte

IO or I/O Input Output channels

IP Ingress protection

LED Light emitting diode

LRT Loop Radio Transceiver

LPC Loop processor card

LPCB Loss prevention council

certification board

MCB Master control board

(CARD 0)

MCC Main control card or Main

controller card (CARD 0)

MCP Manual call point

Mpeg Moving picture expert

group

N/C or NC Normally closed

N/O or NO Normally open

NVM Non Volatile Memory

(CARD14)

O/C or OC Open circuit

PA Public Address

PCB Printed circuit board

PIN Personal identification

number

(usercode, password,

access code)

PSU Power supply unit

PTT Press to Talk

PVC Polyvinyl chloride

QB Quick blow (fuse)

S/C or SC Short circuit

SAB Second action byte

SAFE Software addressed

firmware encoded

SPCO Single pole change over

relay contacts

SPL Sound pressure level

T Anti-surge (fuse)

USB Universal serial bus

VA Voice Alarm

What you will hear.

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 5

Page 6

Commissioning instructions

Preliminary information

34K Control Panels

This manual covers the Vigilon range of control

panels and does not specifically cover the

34K 4-Loop Control Panel.

For information on 34K 4-Loop Control panel refer

to Vigilon BS 4-Loop Control panel in this manual,

as both ranges of panels have version 3+ software

and the only difference is in the branding.

Safety information

&

1. Do not remove or replace printed circuit boards, fuses or attempt to wire the

control panel with the panel powered up. Always power down the mains supply

at the fused spur unit and disconnect the battery supply to the panel.

2. When powering up always power-up the mains supply first before the battery

supply. The power-down should be done in reverse order.

3. When installing the cards into the master control board or backplane always

use anti-static work procedures.

Pre-visit checks

Ensure there are accurate as fitted wiring drawings available, 2 copies are required.

¨

Any damaged equipment has been noted for replacement.

¨

Ensure access will be provided to system equipment installed in the protected

¨

premises.

The installer (electrical contractor) will be in attendance until the installation is

¨

proved.

Site contact or representative will be available during the visit.

¨

Ensure the commissioning tool along with the associated cables, printer and

¨

instructions are available.

Ensure spare parts are available, such as:

¨

MCP glasses

•

MCP test key

•

Printer paper roll

•

Equipment door keys.

•

Pre-commissioning

¨

Check the installation of fire alarm equipment with reference to the most recent as

fitted wiring drawings.

¨

Get the feel of the operating condition of areas on the site:

•

action the installer to carry out any rectification work plus

•

report discrepancies for administration purposes.

¨

Where the operating condition of an area is not right for the equipment installed, then

the appropriate replacement action must be taken.

¨

Ensure the fire system equipment is installed in accordance with the appropriate

standards and project specification.

4. Do not use anti-static procedures on live equipment.

Preliminary information

6 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 7

Points to remember

Earth leads

All earth leads supplied with the system equipment must be securely fitted to

¨

maintain earth continuity.

Parts for later installation

All unused parts should be retained in their respective container for safe keeping until

¨

required.

Loop wiring

The loop cable should have been connected to the appropriate terminals at each

¨

device, as shown in the installation manual in locations identified on the as fitted

wiring drawings.

Enclosure

Access into equipment enclosure is usually by means of opening an outer door/cover.

¨

A panel may also have an inner door which will also need opening.

Unattended equipment

Where equipment is to be left unattended, then it is important to close the door /cover

¨

for safety.

Copper fingers

¨

Copper fingers are conductive spring like strips fitted to metal assemblies. They are

fitted to shield against electromagnetic and radio frequency interferences.

Ensure the copper finger strips are intact and no damage has occurred. Damaged

fingers will reintroduce the gap to let in/out interferences.

Static precaution

¨

The discharge of static electricity can damage or degrade sensitive electronic

components on printed circuit boards. Anti-static procedures should be followed

when handling static sensitive boards.

&

It is important that anti-static procedures are NOT carried out on live equipment.

Removal and disconnection

¨

Any disconnection of cables or removal of parts from an assembly must be restored or

replaced.

Battery

¨

To prevent damage to batteries and equipment, the terminals of the battery must not

simultaneously touch any conductive part of the equipment enclosure.

Vigilon 4/6 loops & Compact (VA) panels & network nodes

Sealed lead acid battery can have a useful life of up to 5 years from the date of

¨

manufacture, it is strongly recommended that batteries are replaced after 4 years. The

batteries must be disposed of correctly by following national or local legislation and

battery manufacturers recommendations.

Powering up

When equipment is being powered up always connect the mains supply before the

¨

battery supply. Power-down should be done in reverse order.

&

powered equipment.

Panel Buzzer

It may be necessary during commissioning to switch Off the panel buzzer. It is

¨

possible to selectively switch the disablement, fault, fire, supervisory and command

build buzzer sound to Off or On. It is important to ensure that the buzzer is switched

On for normal operation after commissioning.

Fire plan

The system should be tested in accordance with the project specification.

¨

Sensor cover

¨

Each fire sensor installed in the system should have been fitted with a dust cover

during installation. The dust covers must be removed from all the fire sensors after the

panel loops have been satisfactorily powered-up and with addresses allocated to each

device ready for further checks and tests.

Site specific installation

¨

Plant equipment interfaced to the system should be tested to recommendations made

in the project specification.

Test mode (EN - V4) & Commission Mode (BS - V3+)

¨

During commissioning of the system you will need to switch On the Test/Commission

mode. It is important to switch Off the Test/Commission mode after the work is over,

to ensure the system operates normally.

Informing responsible persons

¨

It is important to inform the person(s) responsible for the fire alarm system that

the system is being commissioned.

Arcing may occur when the battery circuit is connected to mains

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 7

Preliminary information

Page 8

Commissioning instructions

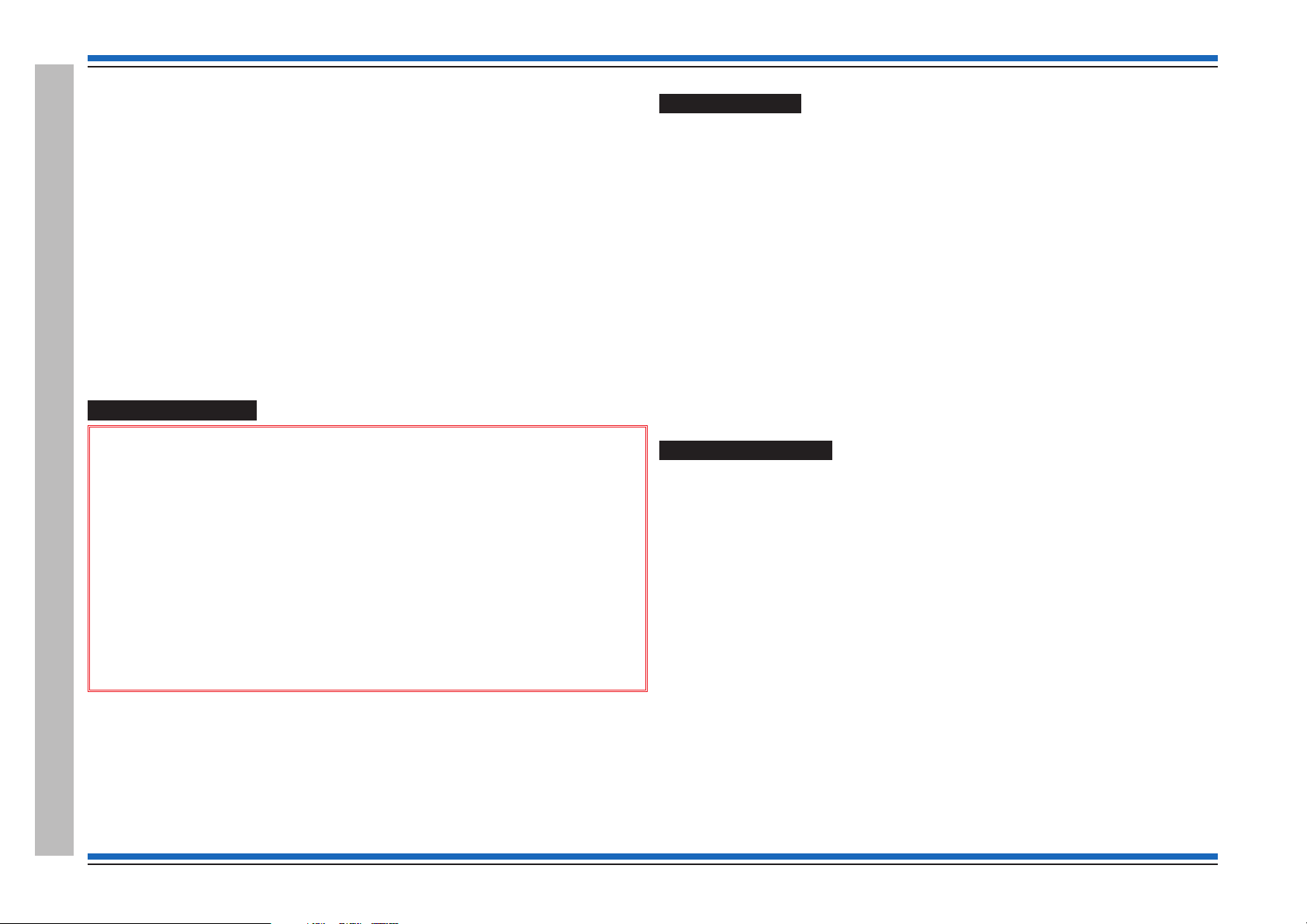

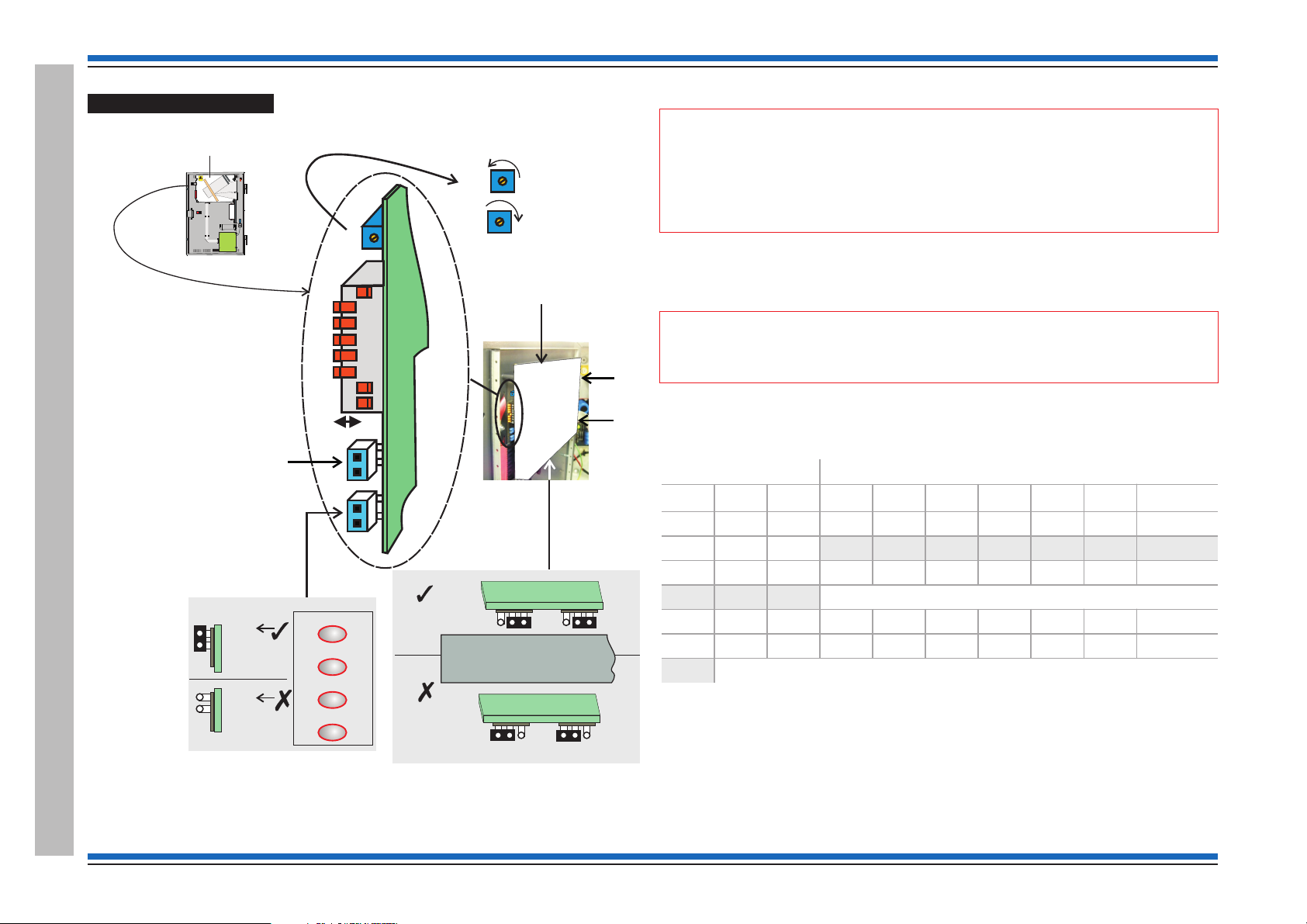

Before powering up the Panel

Open the outer cover and inner cover of the panel and:

– Check all the internal cables within the enclosure are securely fitted

– Ensure no external circuits are connected at this stage, except for

the mains supply which must be connected but not switched ON

–

– Fit the loop card(s) into the required location(s)

Fit the resistors to the master alarm circuits.

– Connect the external printer to the RS232 port, if required.

– Ensure the input - output lines of interface units on the loop are not

connected.

end of line

Inform responsible person(s)

Inform responsible person(s) that the fire alarm system is being

commissioned and occupants in the protected premises will hear

test alarms.

Ensure occupants are made aware of alternative site procedures

should there be a fire event while the system is commissioned.

Pre visit checks

Ensure you have:

shows installed system equipment

Installer will be present to rectify wiring faults

Tools and spare parts are available.

–

–

–

–

As-fitted-drawings that

Access will be available to protected areas having system equipment

Always power-down the panel when.working on the system,

for example when wiring or replacing parts

Survey the installation

Refer to the most recent and ensure that all the fire

system equipment has been installed in accordance with the

installation instructions, respective standards and project specification.

as-fitted-drawings

Power up

– Fit the batteries inside the panel enclosure and connect the battery

leads and then switch ON the mains supply.

Initial tests and set ups

– Carry out a display test and ensure DISPLAY and LEDs are working

– Set the system clock time and date

Configure the RS232 printer port, if an external printer is installed.

– Setup Access levels PIN codes, if required

–

Loop Devices

Configure the links on all LV 4-channel interface units connected to

the loop. Ensure links are set for either Input or Output application.

–

– Power up the mains powered interface unit on the loop.

Ensure all interface Input/Output external wiring remains

disconnected at this stage, unless otherwise instructed. This

action will prevent inadvertent operation of output/plant while

the system is being commissioned.

Loop device address allocation

– Connect only End 1 of a loop circuit and power-up the loop

– Allow address allocation to finish. Any fault(s) on the loop during

allocation must be rectified. Power-down the loop when correcting

loop wiring faults and the power-up to continue address allocation

– Connect only End 2 of the loop circuit and power cycle the loop and

ensure address allocation is complete from End 2.

– Connect both End 1 and End 2 of the loop and check the loop

allocation is complete with both ends of the loop connected.

– ‘Starting Loop n’ displayed after successful allocation of addresses.

– Check all the devices on the loop circuit are installed in their correct

location using the ‘ ’ function at the panel and by referring

to the ‘ ’

– Check to ensure correct devices are installed by viewing the

‘Device status’

– Repeat the allocation process on other loop circuits.

Find Device

as fitted wiring drawings

Continue on next page

Pre-allocate the wireless devices

– If the system has wireless devices then pre-allocate the

wireless devices and bind them to the respective LRT.

Then allocate loop again to allow panel to see the devices.

Radio

Devices

A typical commissioning process

A typical commissioning process

8 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 9

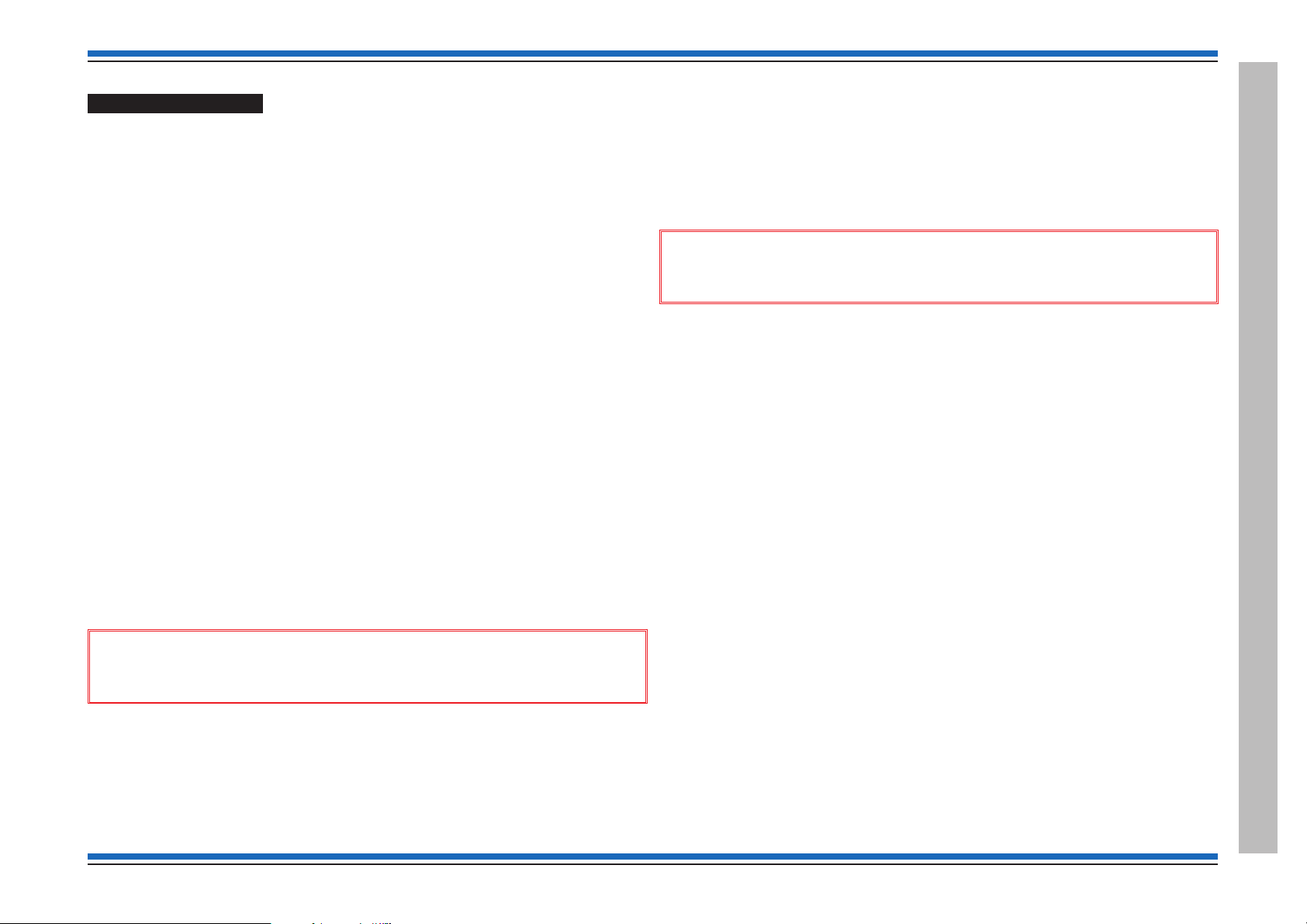

Installed system test

Put the panel in test mode and then carry out tests in accordance with

the recommendations of BS5839:Part 1 and also in accordance

with project requirements:

– Interface units

Prior to functional test on external equipment connected

to the I/O circuits, ensure the I/O circuits remain isolated.

After functional tests, reconnect the I/O circuits and where appropriate

test the I/O circuits to project recommendations.

S-Cubed - The output volume of an S-Cubed can be adjusted using:

[Set up] ->[Setup]-> [Device]-> [Loop]->[S-Cubed]->[Volume] and then

enter a value between 16 min to 100 max. command at the panel.

Repeat and Mimic panels

Check events are displayed and indicated

carrying out

– Fire sensors

Ensure a device fire causes alarms in the system to sound in

accordance with site specific requirement.

–

–

– Connect Master alarm and Monitored input circuits and move the

end-of-line resistor to the end of each circuit.

– Sounders - Conduct sound level tests to ensure the levels do not fall

below the requirements.

– VAD / Strobe - Check the appropriate S-Quad and S-Cubed devices

provide the visual alarm.

– Messages - Check the correct messages are announced from the

Speakers, S-Cubed and S-Quad devices where installed.

– Remove the Test mode and ensure any disablements are re-enabled.

Procedures for Vigilon Compact VA only

Background music and PA microphone

– Connect and test Background music system

– Connect and test PA microphone

– Test the emergency microphone.

Retrieve the system data to Commissioning tool

Connect the commissioning tool and retrieve the system data,

see Commissioning tools manual.

Devices set up

Ensure all devices on the loop circuits are correctly set up.

– Calibrate speaker circuits on micro DAUs

– Adjust volume of audio at each micro DAU and

Mains Powered DAU.

Audio loop wiring tests

Connect each audio loop and carry out tests to ensure live and

auxiliary messages are outputted to the DAU speaker circuits.

Backup

Back-up the system loop address allocation data to the memory.

Regularly back-up the configuration data during

commissioning, do this every 15 minutes to ensure the

changes made to the configuration is not lost.

Loop wiring tests

Repair

Carry out tests on each loop wiring by introducing open and short

circuit wiring faults. Ensure the panel provides an indication of each

fault. Run the ‘ ’ function at the panel after each wiring fault removal.

From previous page

Configure the system using the Commissioning Tool

Configure the system to site specific requirement using the

Commissioning tool.

Beam Sensor alignment

If there are beam sensors on the loop then commission the beam

sensor pair using the alignment and autogain function at the panel.

Transmit the configured system to the panel

Connect the commissioning tool to the panel and transmit the

system configuration.

Continued on next page

Vigilon 4/6 loops & Compact (VA) panels & network nodes

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 9

A typical commissioning process

Page 10

Commissioning instructions

Configuration data file

Ensure site file held at the Commissioning tool is the same as the

one held at the panel for future reference and for traceability.

PIN Codes

Change the user PIN code(s) and inform the new codes to the

respective users.

Final changes to configuration

Use the panel menu options to make minor adjustments if required to

the system configuration and then back up the work. All major changes

to the configuration must be done using the Commissioning tool.

From previous page

A typical commissioning process

10 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 11

Vigilon 4/6 loops & Compact (VA) panels & network nodes

Product Approval and Standards

Fire detection and alarm control panel

The following fire detection and alarm control panels are LPCB approved.

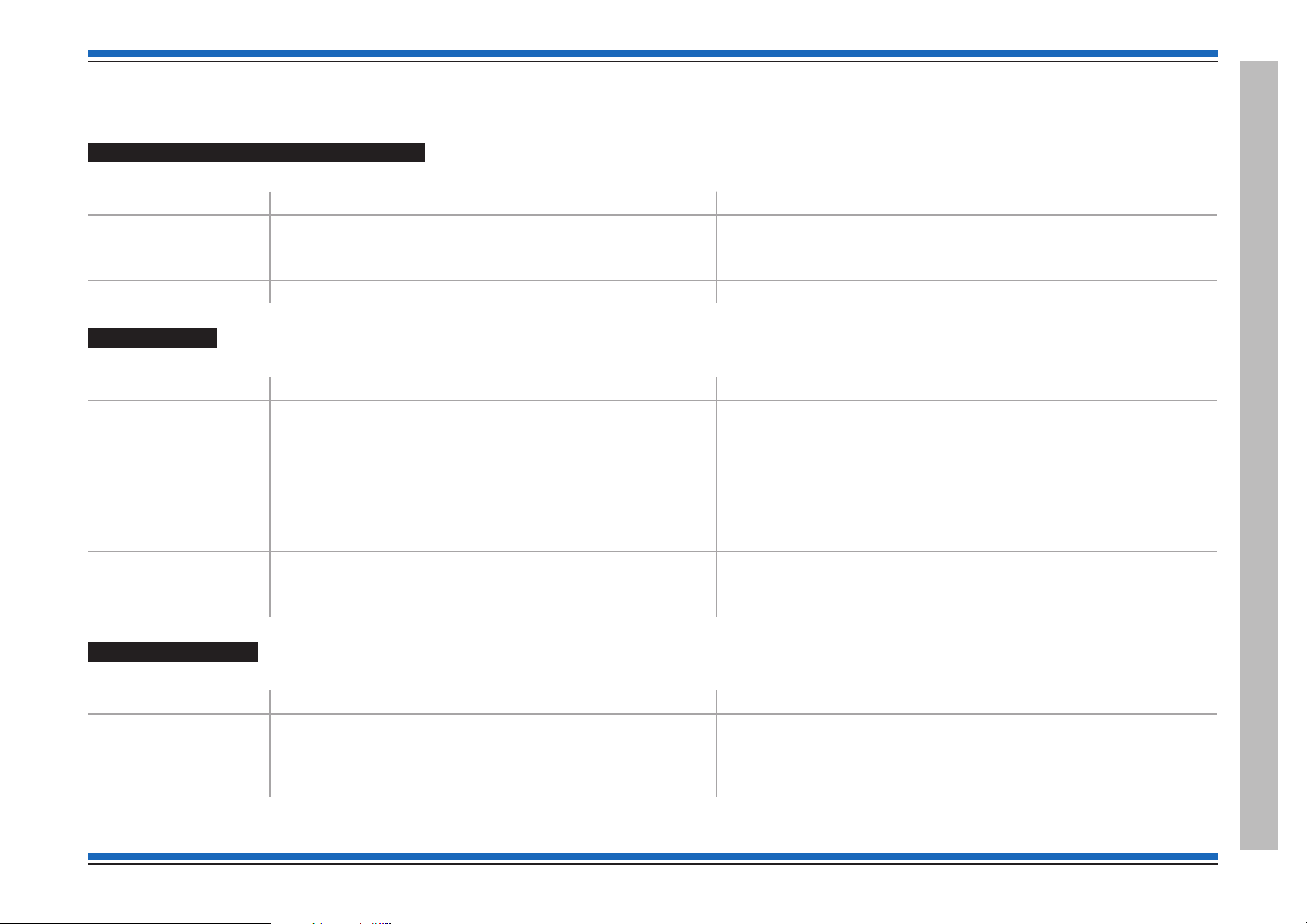

Product number Description Standard

VIG1-24

VIG1-72

COMPACT-24-N

COMPACT-VA EN Vigilon Compact VA 2-loop panel EN 54 Parts 2, 4 & 16. - a Legacy panel

Interface Units

The following interface units are LPCB approved.

Product number Description Standard

S4-34410

S4-34450

S4-34420

S4-34415

S4-34411

S4-34401

S4-34404

S4-34440-02 and

S4-34440-12

EN Vigilon 4-loop panel

EN Vigilon 4/6-loop panel

EN Vigilon Compact 2-loop panel

1 Input interface module (loop powered)

4 Input / output Interface module (loop powered)

1 Output & 1 input (confirmation) interface module (loop powered)

1 Output Interface

Single output interface (loop powered)

Single Channel Mains Switching Interface

Four Channel mains Switching Interface

Mains Powered Interface Units EN54-17: 2005

EN 54 Parts2&4

EN54-17:2005 and

EN54-18:2005

EN54-18: 2005 &

EN54-4:1997 + A1: 2002 + A2: 2006

Manual Call points

The following manual call points are LPCB approved.

Product number Description Standard

S4-34842

S4-34805

S4-34485

S4-34800

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 11

Manual Call Points EN54 Part 11: 2001

EN54 Part 17: 2005

Product Approval and Standards

Page 12

Commissioning instructions

S-Cubed Mark 3

The following S-Cubed Mark 3 devices are LPCB approved.

Product number Description Standard

Type A Devices

S3-S-R

S3-V-R

S3-S-W

S3-V-W

S3-VAD-HPW-R

S3-VAD-HPR-R

S3-S-VAD-HPW-R

S3-S-VAD-HPR-R

S3-S-VAD-HPW-W

S3-S-VAD-HPR-W

S3-S-VAD-LPR-R

S3-S-VAD-LPW-R

S3-V-VAD-HPW-R

S3-V-VAD-HPR-R

Environmentally protected Devices

S3EP-S-R

S3EP-VAD-HPW-R

S3EP-VAD-HPR-R

S3EP-V-VAD-HPW-R

S3EP-V-VAD-HPR-R

S3 Sounder/Red Body

S3 Voice Sounder/Red Body

S3 Sounder/White Body

S3 Voice Sounder/White Body

S3 VAD/High Perf. White VAD/Red body

S3 High Perf. Red VAD/Red Body

S3 Sounder/High Perf. White VAD/Red Body

S3 Sounder/High Perf. Red VAD/Red Body

S3 Sounder/High Perf. White VAD/White Body

S3 Sounder/High Perf. Red VAD/White Body

S3 Sounder/Standard Perf. Red VAD/Red Body

S3 Sounder/Standard Perf. White VAD/Red Body

S3 Voice Sounder/High Perf. White VAD/Red Body

S3 Voice Sounder/High Perf. Red VAD/Red Body

S3 Sounder/Red Body/EP

S3 VAD/High perform. White VAD/Red Body/EP

S3 VAD/High perform. Red VAD/Red Body/EP

S3 Voice Sounder/High perform. White VAD/Red Body/EP

S3 Voice Sounder/High perform. Red VAD/Red Body/EP

EN54-3 : 2001, A1:2002, A2:2006 (for Sounder)

EN54-23 : 2010 (for Visual Alarm Device VAD)

EN54-17 : 2005 (for Short circuit isolator)

EN54-3 : 2001, A1:2002, A2:2006 (for Sounder)

EN54-23 : 2010 (for Visual Alarm Device VAD)

EN54-17 : 2005 (for Short circuit isolator)

Product Approval and Standards

12 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 13

Vigilon 4/6 loops & Compact (VA) panels & network nodes

S-Quad Sensors with Visual alarm device (VAD) - introduced post April 2014

The following S-Quad with VAD sensors when operating in the STATES shown in table below are LPCB approved to the respective standard.

Part number Description Standard

S4-711-VAD-HPR S4 Dual Optical & Heat Sensors / Red VAD EN54-5 : 2000, A1 : 2002 (heat)

S4-720-V-VAD-HPR S4 Heat sensor / Voice Sensor Sounder / Red VAD

S4-711-V-VAD-HPR S4 Dual Optical & Heat Sensors / Voice Sounder / Red VAD

S4-911-V-VAD-HPR S4 Dual Optical & Heat & CO Sensors / Voice Sounder / Red VAD

S4-711-VAD-LPW S4 Dual Optical & Heat Sensors / White VAD

S4-711-VAD-HPW S4 Dual Optical & Heat Sensors / White VAD (HP)

S4-711-V-VAD-LPW S4 Dual Optical & Heat Sensors / Voice Sounder / White VAD (Std)

S4-711-V-VAD-HPW S4 Dual Optical & Heat Sensors / Voice Sounder / White VAD (HP)

S4-720-V-VAD-HPW S4 Heat / Voice Sounder / White VAD (HP)

S4-911-V-VAD-HPW S4 Dual Optical & Heat & CO Sensors / Voice Sounder / White VAD HP

Non VAD devices

S4-720 Heat sensor EN54 : Part 5 :2002* - (heat)

S4-715 Optical sensor EN54 : Part 7 : 2000* - (optical smoke)

S4-710 Optical Heat sensors EN54 : Part 7 : 2000* - (optical smoke)

S4-711 Dual Optical & Heat Sensors

S4-711-V S4 Dual Optical & Heat Sensors / Voice Sounder EN54-5 : 2000, A1 : 2002 (heat)

S4-770-S S4 Optical & Heat Sensors / Sounder

S4-771-S S4 Dual Optical & Heat Sensors / Sounder

S4-780-S S4 Heat Sensor Sounder

S4-901 S4 Dual Optical & Heat & CO Sensors

EN54-7 : 2000, A1 : 2002, A2 : 2006 (optical)

EN54-3 : 2001, A1 : 2002, A2 : 2006 (sounder)

EN54-23 : 2010 (visual alarm device VAD)

EN54-17:2005 (short circuit isolator)

EN54-18:2005 (input output devices)

EN54 : Part 5 : 2000* - (heat)

CEA 4021 : 2003-07 Class P heat multisensor detector

EN54-7 : 2000, A1 : 2002, A2 : 2006 (optical)

EN54-3 : 2001, A1 : 2002, A2 : 2006 (sounder)

EN54-17:2005 (short circuit isolator)

EN54-18:2005 (input output devices)

* - these standards are met when the sensor is operating LPCB approved STATES, see STATES table below. Sounder tone description - see next page

"

can be also configured using controls at the main panel.

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 13

If a S-Quad sensor is configured to operate a non LPCB STATE, then this will contravene the LPCB approval. The required STATE is configured during commissioning and

Product Approval and Standards

Page 14

Commissioning instructions

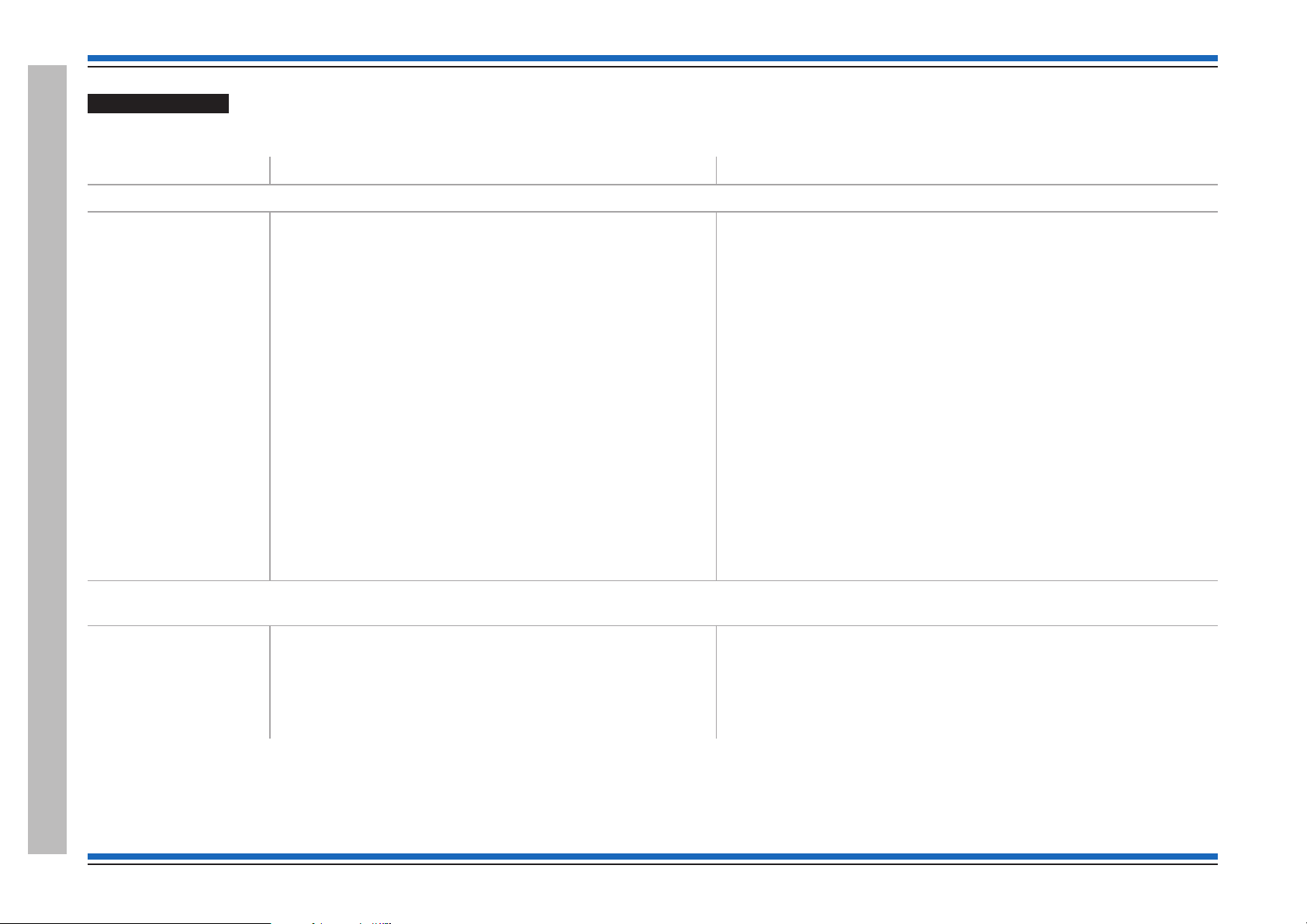

LPCB approved S-Quad Sensor with VAD device STATES

# - factory default settings

Device

Dual Optical & Heat sensor variant - S4-711

(With VAD) S4-711-VAD-HPR

(With VAD) S4-711-VAD-LPW

(With VAD) S4-711-VAD-HPW

(With Speech) S4-711-V

(With VAD & Speech) S4-711-V-VAD-HPR

(With VAD & Speech) S4-711-V-VAD-HPW

(With Sounder) S4-771-S

Dual Optical, Heat & CO sensor variant- S4-901

(With Speech & VAD) S4-911-V-VAD-HPR

(With Speech & VAD) S4-911-V-VAD-HPW

LPCB approved STATE Meets ~ EN54-7 : 2000, A1:2002, A2:2006

STATE 0 #

STATE 5

STATE 8

STATE 0 #

STATE 9

* EN54-5 : 2000, A1:2002

Medium optical smoke ~ / Class A1 heat *

Medium optical smoke ~ / Class B heat *

Delayed medium optical smoke ~ / Class A1 heat*

Medium optical smoke ~ / Class A1 heat *

Class A1 heat *

Optical & Heat sensor variant - S4-710

(With Sounder) S4-770-S

STATE 0 # Medium optical smoke ~ / Class A1 heat*

Heat sensor variant - S4-720

(With Speech & VAD) S4-720-V-VAD-HPR

(With Speech & VAD) S4-720-V-VAD-HPW

(With Sounder) S4-780-S

Optical sensor - S4-715

STATE 0 #

STATE 5

State 0 # Medium optical smoke

Class A1 heat *

Class B heat *

All S-Quad range of sensor sounder devices meet EN54-17:2005 Input/Output devices plus EN54-18:2005 Short circuit isolation for use on the transmission path of fire detection and alarm systems.

Sounder tone - Meets the following tone settings: High tone ( Continuous 933Hz) & Alternate tone (High 933Hz for 0.25s / low 700Hz for 0.25s)

When an S-Quad sensor is configured to operate a non LPCB approved STATE then this will contravene the LPCB approval.

# - these standards are met when the sensor is operating LPCB approved STATES.

All the LPCB approved STATES applicable to S-Quad fire sensors are shown. The required STATE is configured during commissioning. On initial power-up of the system all the sensors operate in

STATE 0.

Note sensor STATES are not applicable for wireless sensors.

Product Approval and Standards

14 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 15

Vigilon 4/6 loops & Compact (VA) panels & network nodes

S-Quad Sensors (Legacy product range)

The following S-Quad sensors when operating in the STATES shown in table below are LPCB approved to the respective standard.

Product number Description Standard

S4-720-ST-VO Heat sensor Strobe and Speech (Speech and Strobe - no approval) EN54 : Part 5 :2002* - (heat)

S4-780

S4-780-ST

S4-711-ST Dual Optical & Heat Sensors Strobe (Strobe - no approval) EN54 : Part 7 : 2000* (optical smoke)

S4-911 Dual Optical, Heat & CO Sensors (CO - no approval)

S4-711-ST-VO Dual Optical & Heat Sensors, Speech & strobe (Speech and Strobe - no approval) EN54 : Part 7 : 2000* (optical smoke)

S4-711-VO Dual Optical & Heat Sensors, Speech (Speech - no approval)

S4-771 Dual Optical & Heat Sensors & Sounder

S4-911-ST-VO Dual Optical, Heat & CO Sensors, Speech & Strobe

S4-770 Optical & Heat sensors and Sounder

* - these standards are met when the sensor is operating LPCB approved STATES, see STATES table below. Sounder tone description - see next page

Heat Sensor plus Sounder

Heat Sensor plus Sounder & Strobe (Strobe - no approval)

(Speech, Strobe & CO - no approval)

EN54 : Part 5 : 2002* - (heat)

EN54 : Part 3 : 2001 - (sounder)

EN54 : Part 5 : 2002* (heat)

CEA 4021 : 2003-07 Class P heat multisensor detector

EN54 : Part 5 : 2002* (heat)

EN54 : Part 3 2001 - (sounder tone)

CEA 4021 : 2003-07 Class P heat multisensor detector

"

can be also configured using controls at the main panel.

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 15

If a S-Quad sensor is configured to operate a non LPCB STATE, then this will contravene the LPCB approval. The required STATE is configured during commissioning and

Product Approval and Standards

Page 16

Commissioning instructions

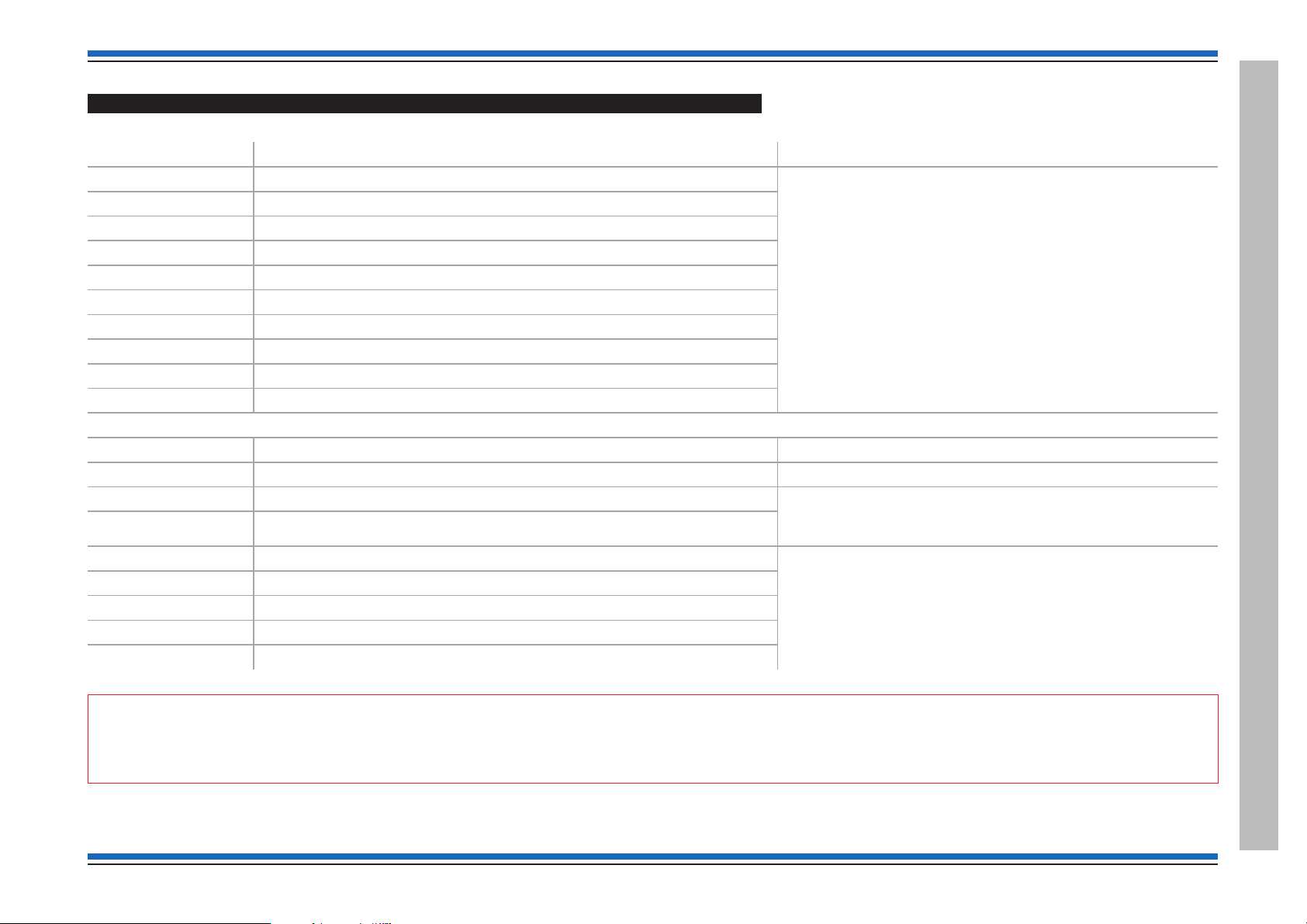

LPCB approved S-Quad Sensor STATES (Legacy product range)

Meets ~ EN54 : Part 7 :2000

* EN54 : Part 5 :2002

Device

LPCB approved STATE

# - default STATE

Dual Optical & Heat sensor variant -

(With Strobe) S4-711-ST

(With Speech) S4-711-VO

(With Strobe & Speech) S4-711-ST-VO

(With Sounder) S4-771

Dual Optical, Heat & CO sensor variant -

STATE 0 #

STATE 5

STATE 8

STATE 0 #

Medium optical smoke ~ / Class A1 heat *

Medium optical smoke ~ / Class B heat *

Delayed medium optical smoke ~ / Class A1 heat*

Medium optical smoke ~ / Class A1 heat *

S4-911

(With Speech & Strobe) S4-911-ST-VO

STATE 9

Class A1 heat *

Optical & Heat sensor variant -

(With Sounder) S4-770

STATE 0 # Medium optical smoke / Class A1 heat*

Heat sensor variant -

(With Speech & Strobe) S4-720-ST-VO

(With Sounder) S4-780

(With Strobe) S4-780-ST

STATE 0 #

STATE 5

Class A1 heat *

Class B heat *

All S-Quad range of sensor sounder devices meet CEA 4021: 2003-07, where applicable, and meet EN54-17:2005 Input/Output devices plus EN54-18:2005 Short circuit isolation for use on the

transmission path of fire detection and alarm systems.

Sounder tone - Meets the following tone settings: High tone ( Continuous 933Hz) & Alternate tone (High 933Hz for 0.25s / low 700Hz for 0.25s)

When an S-Quad sensor is configured to operate a non LPCB approved STATE then this will contravene the LPCB approval.

# - these standards are met when the sensor is operating LPCB approved STATES.

All the LPCB approved STATES applicable to S-Quad fire sensors are shown. The required STATE is configured during commissioning. On initial power-up of the

system all the sensors operate in STATE 0.

Note sensor STATES are not applicable for wireless sensors.

S-Cubed Mark 2 (Legacy product range)

The Sounders in the following S-Cubed Mark 2 range of products listed below are LPCB approved to EN 54 : Part 3

S3IP-VP-W, S3-VP-W, S3IP-VP-ST-WR, S3-VP-ST-WR, S3IP-VP-R, S3-VP-R, S3IP-VP-ST-RR, S3-VP-ST-RR, S2IP-VP-W, S2IP-VP-R, S3IP-SN-W-V2, S3-SN-W-V2, S3IP-SN-ST-WR-V2,

S3-SN-ST-WR-V2, S3IP-SN-R-V2, S3-SN-R-V2, S3IP-SN-ST-RR-V2, S3-SN-ST-RR-V2, S3IP-SN-ST-RW-V2, S2IP-SN-R-V2 and S2IP-SN-W-V2.

Product Approval and Standards

16 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 17

Fire Panels

VigilonFireSystem

GENT2015

DesignedtoEN54 Pt 2 & 4

15:45

Fault

SystemFault

Test

Fire

Power

PowerFault

Fault/Dis

Disablement

Previous Next

Delay

Verify

Active

12345678910111213141516

17 18 19 20 21 22 23 24 25 26 27 28 29 30 30 32

Zones

Sounder

FireRoutingO/P

Fault/Dis

Active

FireRoutingO/P

Indicators

Pocket for

Operating instructions

and Log Book

Message display

Access level 1

Controls to scroll events

Key lock for

outer door

Inner door

Printer

Outer door

Access level 2 & 3

Controls

Key lock for

outer door

Indications

Inner door

Operating instructions

and Log Book

Outer door

Message

Display

Access level 1

Controls

to scroll fire

events

Access level 2

Controls

Fault/Dis

Active

FireRoutingO/P

Fault/Dis

Active

FireRoutingO/P

VigilonCompactVoice Alarm System

GENT2010

DesignedtoEN54 Pts 2, 4 & 16

Panelhealthy

15:45

12345678910111213141516

17 18 19 20 21 22 23 24 25 26 27 28 29 30 30 32

Zones

Fault

Disablement

PowerFault

SystemFault

Delay

Test

Fire

Power

Verify

Sounder

CB253

CB254

AllZones

ClearZones

VoiceAlarmZones

SpeakNow

Auxiliarymessages

Emergencymessages

1423 5

6978

10

1

2

3

1

2

3

Previous

Next

ALERT

BOMB

EVACUATE

MIC

TESTSTART

STANDDOWN

TESTEND

byHoneywell

EN54Part2,4&

1

6

COMPACTVOICE

Vigilon

VAActivated

0XXXx

Access level 2 & 3

Controls

Indications

Pocket for

Operating instructions

and Log Book

Message display

Access level 1

Controls to scroll events

Key lock for

outer door

Inner door

Emergency

Microphone

Outer door

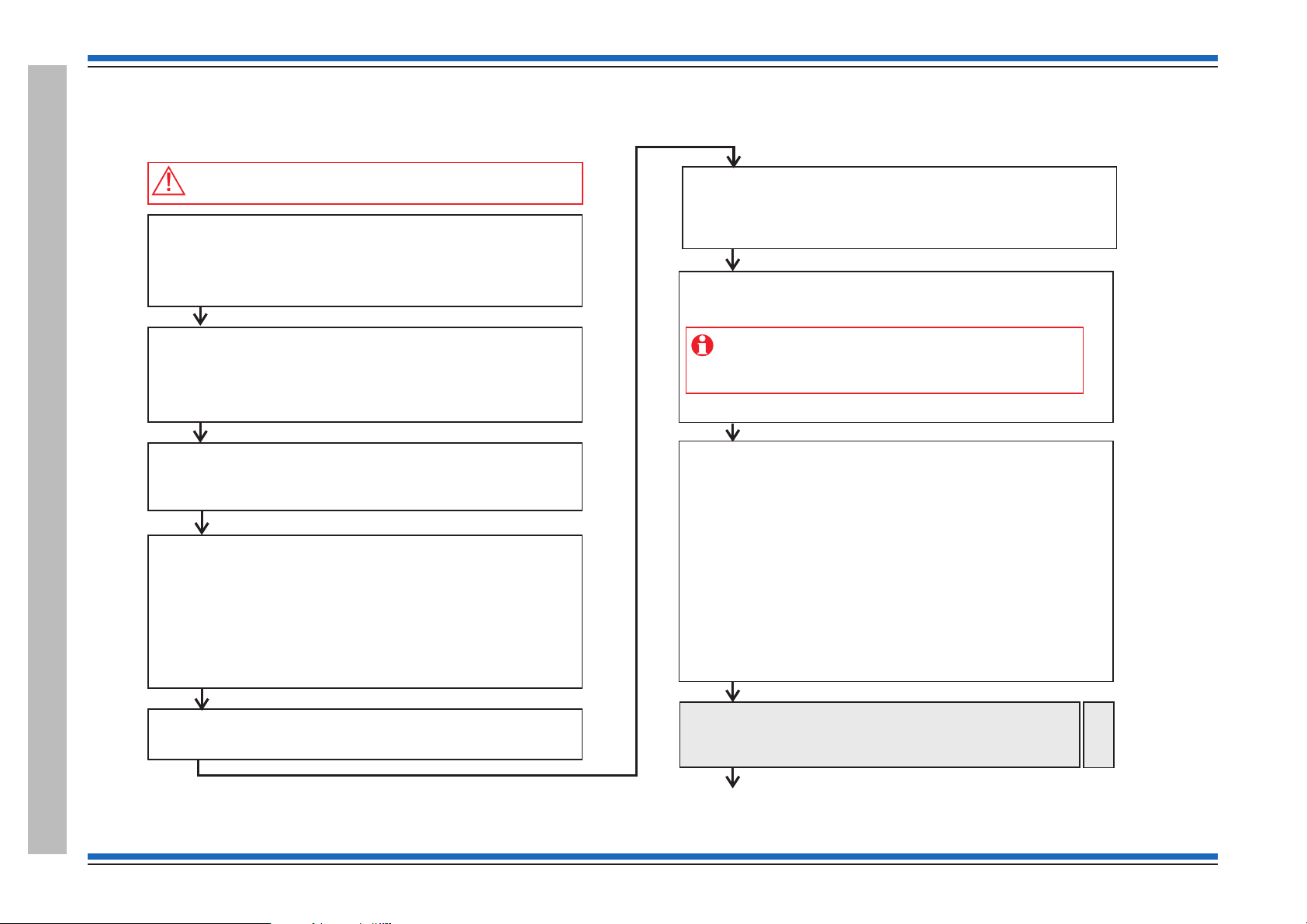

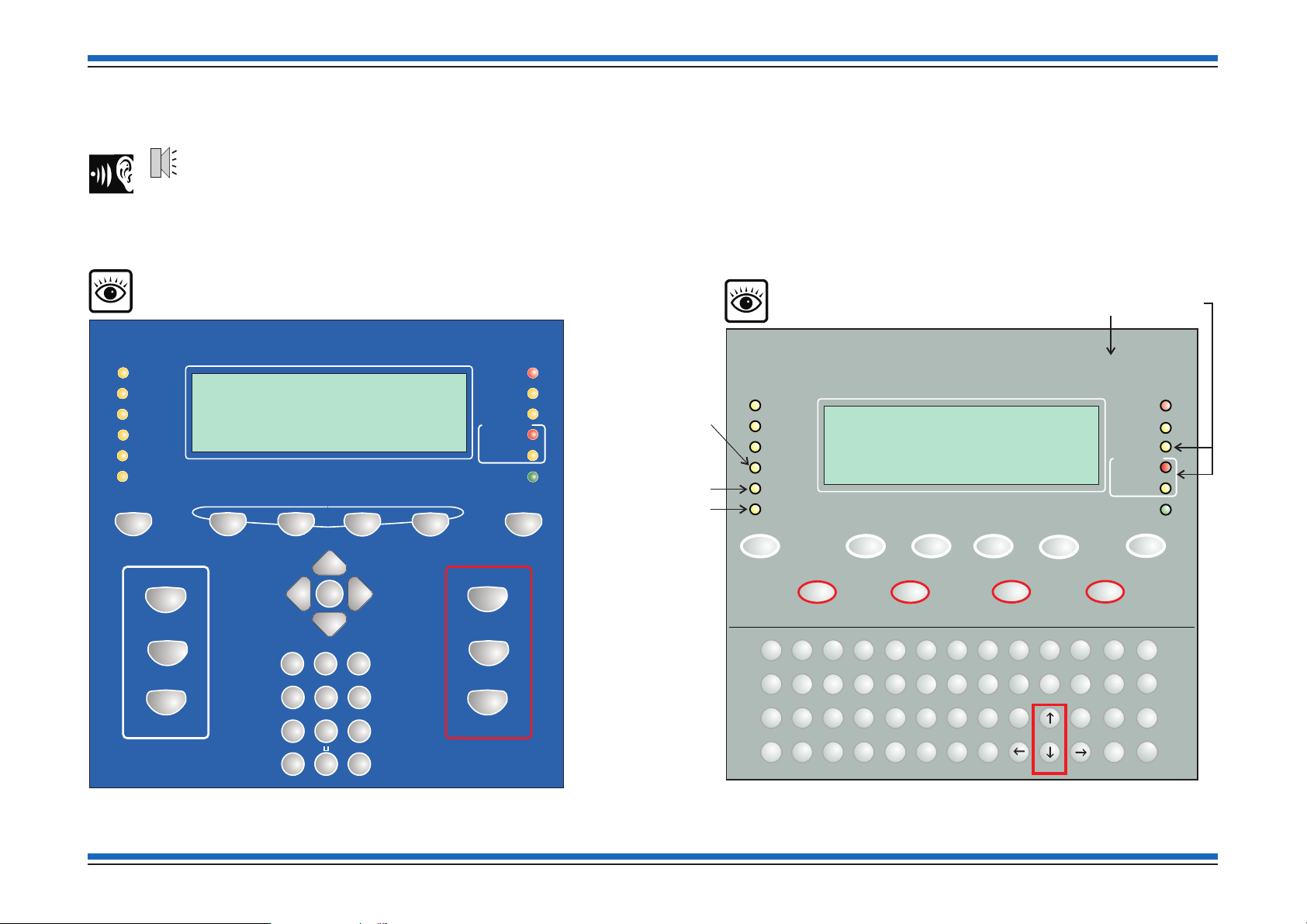

Vigilon 4/6 loop panels (EN/BS)

A BS panel is very similar to an EN panel:

Vigilon 4/6 loops & Compact (VA) panels & network nodes

Vigilon Compact VA panel (EN) (Legacy panel)

Vigilon Compact Panel (EN)

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 17

Fire Panels

Page 18

Commissioning instructions

Fault

System Fault

Test

Fire

Power

Power Fault

Disablement

Sounder

12345678910111213141516

17 18 19 20 21 22 23 24 25 26 27 28 29 30 30 32

Zones

Previous Next

Delay

Verify

1

23

4

5

6

7

890

"

#

$

%

^

& *

(

+

:

,

-

;

.

)

QW

ER

T

YU I OP

U1

U2

U3

U4

Fire

A

S

DF

GHJ KL

ZXC

VB

NM

Sound Alarms

Silence Alarms

Reset

Cancel Buzzer

Menu On/Off

F4

F3

F1 F2

!

Insert

Delete

SpaceShift

Enter

;

Verify

Panel

buzzer

Vigilon Compact panel or

Vigilon Compact Voice Alarm panel (legacy)

has CB253 / CB254 LEDs in place of Fire routing LEDs

EN Vigilon 4-loop panel or

BS Vigilon 4-loop panel

BS Vigilon 4-loop panel:

Commission

Warning

BS Vigilon 4-loop panel:

NOT USED

Not fitted on

BS Vigilon 4-loop

panel

Previous Next

ABC

DEF

GHI

JKL

MNO

Cancel Buzzer

Menu On/Off

Verify

1 2 3

4 5 6

PQRS

TUV WXYZ

7 8 9

0

Sound Alarms

Silence Alarms

Reset

Enter

THRU

BKSP

0

INS

DEL

F1 F2

F3 F4

U1

U2

12345678910111213141516

17 18 19 20 21 22 23 24 25 26 27 28 29 30 30 32

Zones

Fault

System Fault

Delay

Test

Fire

Power

Power Fault

Verify

Disablement

Sounder

Active

Fault/Dis

Fire Routing O/P

Active

Fault/Dis

Fire Routing O/P

Controls and indications

18 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 19

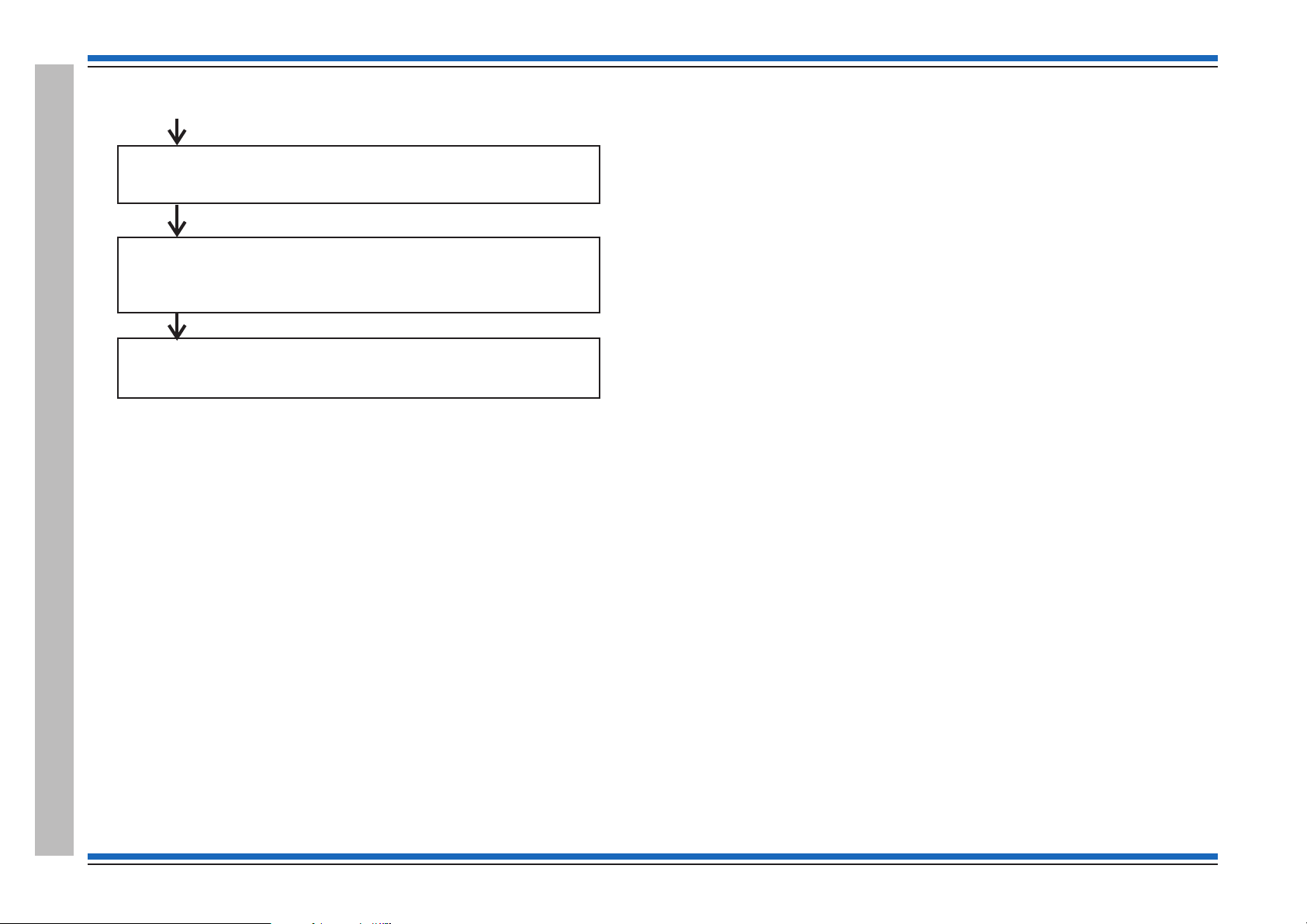

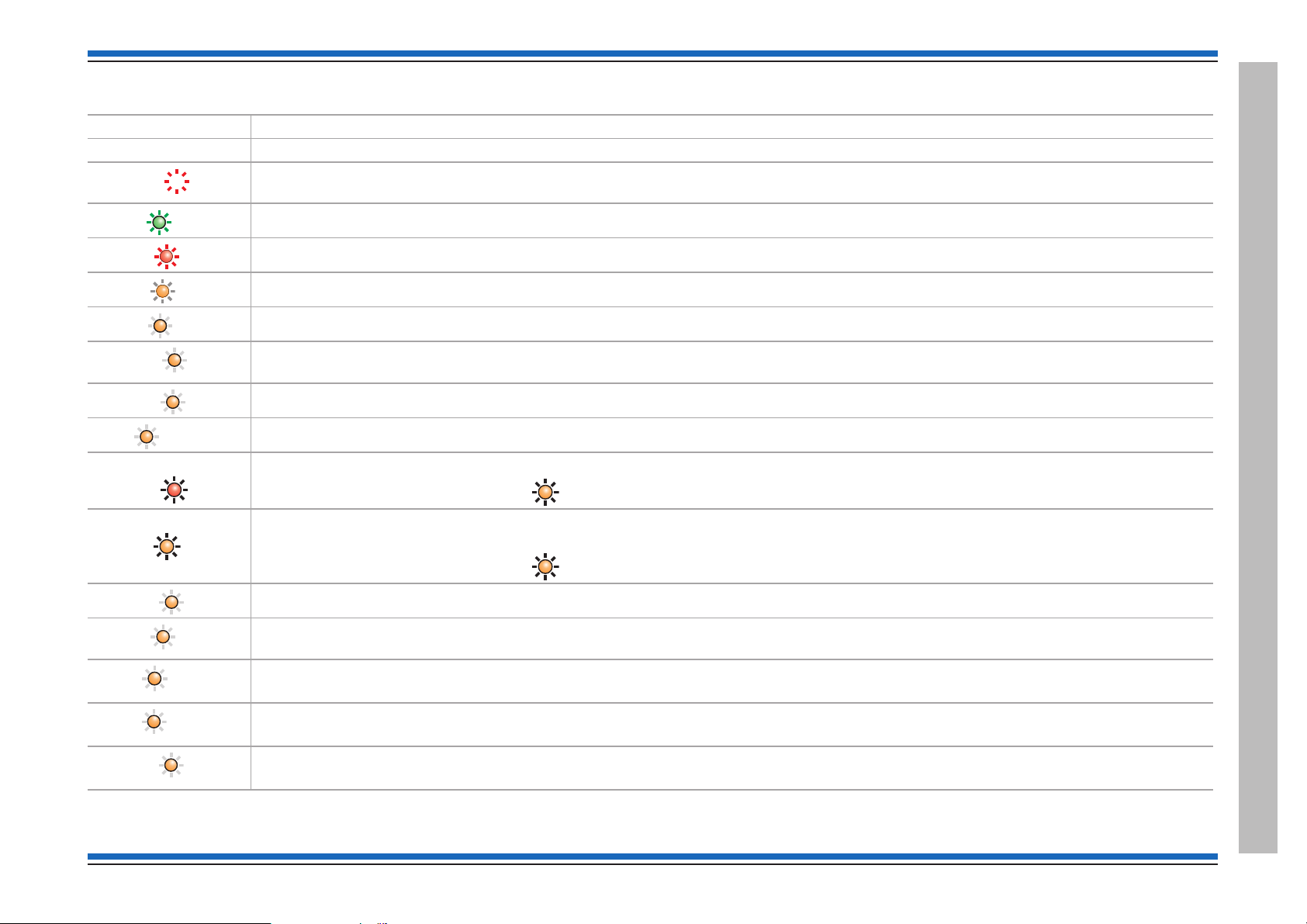

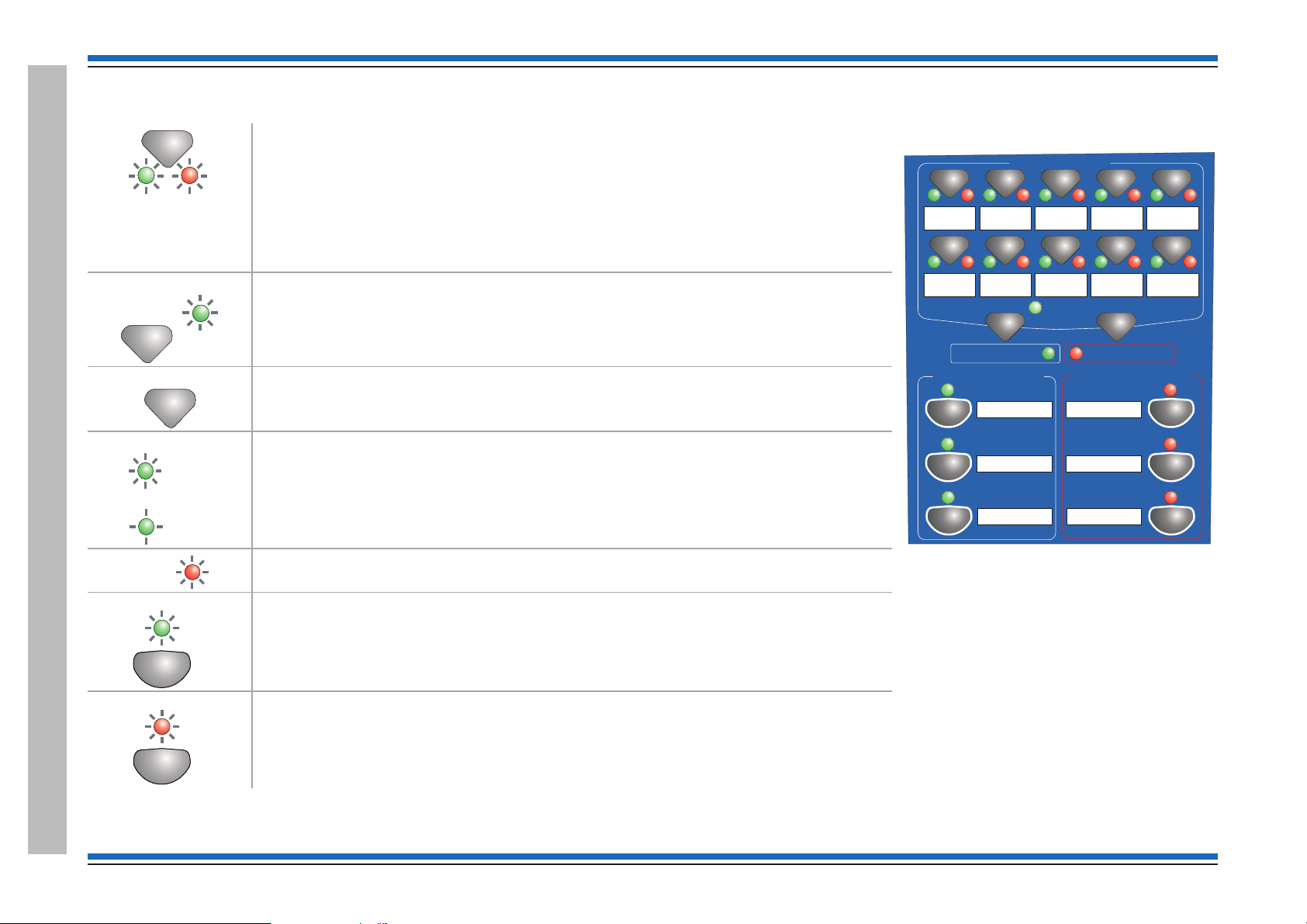

Indications applicable for all Vigilon panels

Zones 1

Power

Fire

Verify

Fault

System Fault

Disablement

Warning

Power Fault

Sounder

Delay

Test

Commission

Indicators Description

Display The Display provides messages of the system status / events by means of 8 lines by 40 characters per line display.

(red)

(green)

(red)

(amber)

(amber)

(amber)

(amber)

(amber)

Fire routing O/P

Hidden-until-lit fire zones indicators. When "Zones" text and number(s) are illuminated it indicates that a FIRE has been detected in the

specific zone(s). (Zone indicators are not applicable for BS Vigilon panels and Network Nodes)

When illuminated it indicates that a supply to the panel is present.

When illuminated it indicates that a FIRE has been detected in the protected premises.

When illuminated it indicates that the Verify button has been pressed and the alarm sounders in the system are delayed from sounding.

When illuminated it indicates that a FAULT has been detected in the fire detection and alarm system or in the audio system.

When illuminated it indicates that a fault has occurred with the system processor. It is important to investigate this fault because the

fire alarm system may not be able to detect fires.

Applicable for EN Vigilon panels only. When illuminated it indicates that a part of the system has been disabled.

Applicable for BS Vigilon panels only. When illuminated it indicates part of the system has been disabled, delayed or not functioning.

Applicable for EN panels only from mid 2015 onwards. When illuminated it indicates the Fire Alarm Routing Equipment is active.

Vigilon 4/6 loops & Compact (VA) panels & network nodes

Active

Fire routing O/P

(red)

Prior to mid 2015 this LED was

CB253 (amber) and it operates with Command Build 253.

Applicable for EN panels only from mid 2015 onwards. When illuminated and steady it indicates the Fire Alarm Routing Equipment is

faulty. When illuminated and flashing it indicates the Fire Alarm Routing Equipment is disabled.

Fault/Dis

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 19

(amber)

(amber)

(amber)

(amber)

(amber)

(amber)

Prior to mid 2015 this LED was

CB254 (amber) and it operates with Command Build 254.

When illuminated it indicates the battery or mains supply to the panel has failed.

Applicable for EN Vigilon panels only. When illuminated (always with either the FAULT light or the DISABLEMENT light) it indicates that

there is a sounder fault (flashing indication) or sounder disablement (steady indication).

Applicable for EN Vigilon panels only

When illuminated it indicates that one or more delay blocks are setup on the panel.

Applicable for EN Vigilon panels only

When illuminated it indicates one or more zones are in Test mode.

Applicable for BS Vigilon panels only

When illuminated it indicates panel is in commissioning mode.

Controls and indications

Page 20

Commissioning instructions

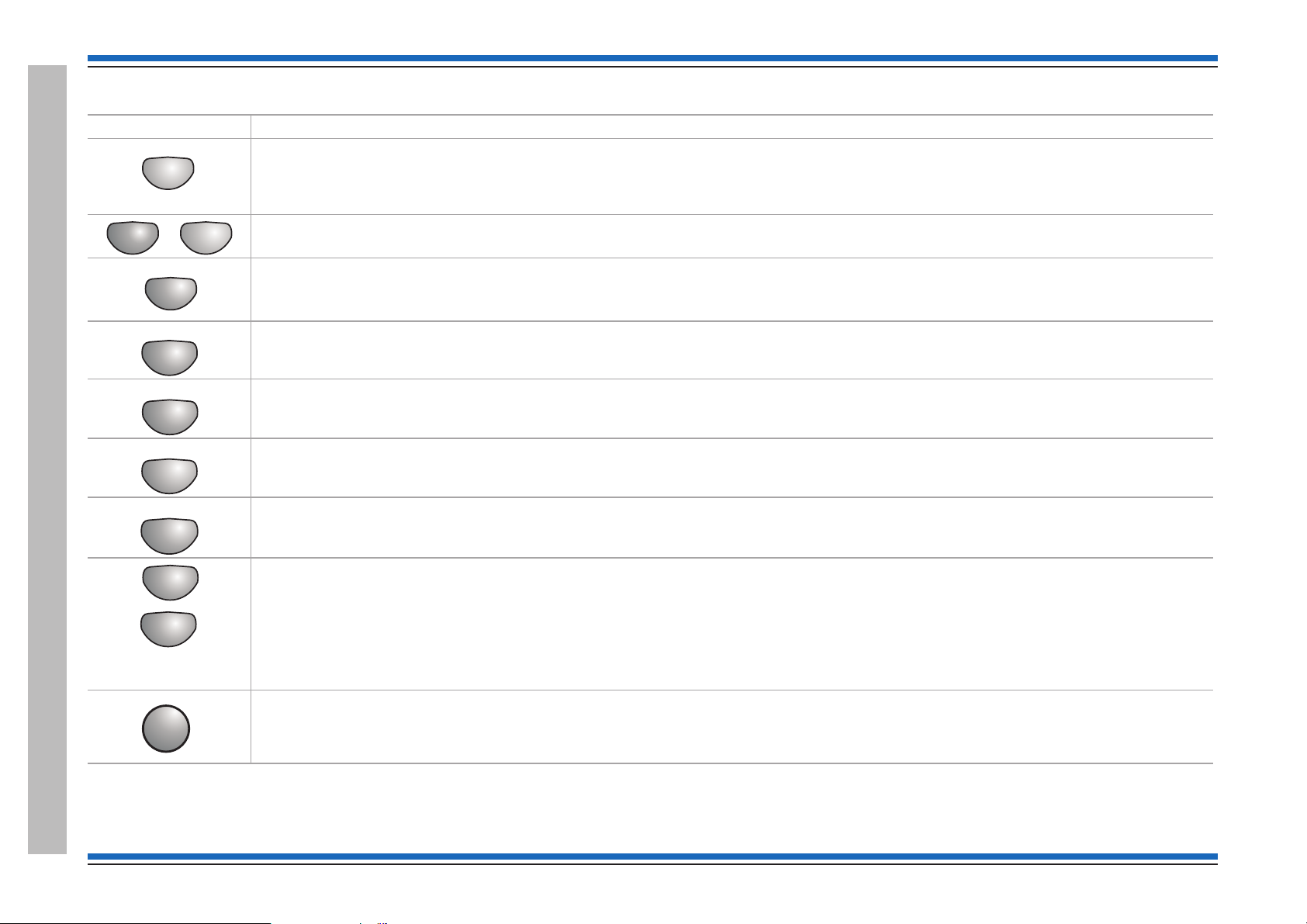

Menu On/Off

F1 F4

to

Next

Cancel Buzzer

Sound Alarms

Silence Alarms

Reset

Verify

U1

U2

Enter

Controls applicable for all Vigilon panels

Controls Description

Pressing Menu On/Off will enable/disable the on screen menu facility which gives access to the system menus.

The 'Fn' buttons are used to select functions and sub-functions of the system menus which appear on the display. Each option available at

a menu level has an associated function button and on pressing a function button will select the option described on the display.

The Cancel Buzzer button when pressed will stop the internal panel buzzer from sounding.

Note the local buzzer is automatically silenced when the emergency microphone is being used to announce live speech from a Vigilon

Compact VA panel.

Pressing the Sound Alarms button will announce 'evacuate message' and sound the evacuate alarms. This button is only pressed in an

emergency or at other agreed times, for example when conducting a system test or practice evacuation.

Pressing the Silence Alarms button will stop emergency message announcements and silence the system alarms.

Pressing the Reset button will clear any fires and return the panel to the condition seen before the fire event. If a fire condition should

reoccur immediately after a 'reset' then the indicated device should be investigated.

Controls and indications

If the Verify facility has been set up, then pressing the 'Verify' button soon after a fire detection will increase the time delay before the alarm

sounders are activated. This gives the user time to investigate the cause of the alarm and option to cancel the alarm within the delay time

period.

The 'U' buttons can be configured during commissioning to output user-defined actions, such as to disable devices in areas where smoke

may be generated and to activate a plant shutdown, for example during a fire condition.

The function of the 'U' buttons should be written on the label that is fitted on the back of the outer door.

Note: The Vigilon 4/6 loop panels have four configurable 'U' buttons.

At a Vigilon panel to operate a 'Un' key: press the 'Shift' key first then the 'Un' key.

This is pressed to acknowledge an entry of data or label text.

20 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 21

Controls applicable for Vigilon Compact (& VA) panels only:

ABC

DEF

GHI

JKL

MNO

1 2 3

4 5 6

PQRS

TUV WXYZ

7 8 9

0

THRU

BKSP

0

INS

DEL

Controls Description

These four buttons are used to scroll the displayed text.

These buttons allow data to be entered manually at the control panel.

When entering a label each press of a key will scroll the character string, for example:

key 2 will scroll

key 1 will scroll 1?,.;&*/

The bottom row of keys are explained here:

The button is used to enter a SPACE between characters

The INS key allows text to move one position to the right

The DEL key allows a character to be deleted

The BKSP button will delete previous character.

When entering a range data the THRU key is used to represent a '-', for example 1 THRU 5 equals 1-5.

ABC2abc.

Vigilon 4/6 loops & Compact (VA) panels & network nodes

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 21

Controls and indications

Page 22

Commissioning instructions

n

All Zones

(Green)

Clear Zones

Speak Now

Speak Now

VA Activated

Auxiliary messages

n

(green)

Emergency messages

n

(Red)

All Zones

Clear Zones

Voice Alarm Zones

Speak Now

Auxiliary messages

Emergency messages

1423 5

6978

10

1

2

3

1

2

3

ALERT

BOMB

EVACUATE

TEST START

STAND DOWN

TEST END

VA Activated

Controls applicable for Vigilon Compact VA panel only - (legacy product)

Pressing one or more of the 10 buttons selects the local Voice Alarm Zone(s) of the local

system to which emergency or auxiliary messages, or emergency microphone is to be

announced. The two LEDs beneath flash alternately to show the Voice Alarm Zone has

(green and red)

(green)

(green)

been selected.

On selecting the required emergency or auxiliary message only one of these LEDs changes

to steady or flashing indication determined by the type of audio to be outputted to the

selected Voice Alarm Zones. The left LED indicates auxiliary message selection while the

right LED indicates emergency message selection.

Pressing the 'All Zones' button allows quick selection of all Voice Alarm Zones

simultaneously. The accompanying LED gives a steady indication when the button is

pressed. Note all the VA Zones that have been setup in your system will give a flashing

indication and those not setup will give no indications.

Pressing 'Clear Zones' button will clear selected Voice Alarm Zones, also when auxiliary

messages are being announced pressing 'Clear Zones' will silence the announcements.

When 'Speak Now' light is illuminated the system is ready to allow live speech

announcement to selected Voice Alarm Zones via the Emergency microphone.

The indicator is lit following the selection of Voice Alarm Zones and on pressing the Press to

Talk (PTT) button on the Emergency microphone.

If the 'Press to Talk' button is released the 'Speak Now' indicator will flash and switch off

after 20seconds duration or immediately switch off on pressing the Clear Zone button.

When the 'VA Activated' LED is illuminated it indicates the voice announcements are being

made or emergency microphone is in use for speech announcement to Voice Alarms Zones.

(red)

When illuminated the system is announcing auxiliary message n to the selected Voice Alarm

Zones.

The indicator is lit following the selection of Voice Alarm Zone(s) and on pressing the

required Auxiliary message button.

Controls and indicationsControls and indicationsControls and indications

Controls and indicationsControls and indications

22 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

When illuminated the system is announcing emergency message n to the selected Voice

Alarm Zones.

The indicator is steady or flashing determined by the type of emergency message being

announced to Voice Alarm Zones.

Page 23

Vigilon 4/6 loops & Compact (VA) panels & network nodes

Earth to

inner door

Hinge

points for

inner and

outer doors

PSU

Hinge

points for

inner and

outer doors

Cardboard cover

over PSU

Cables of external circuits

Mains cable

Printer 0V

Transparent

cover over

backplane

Card guides

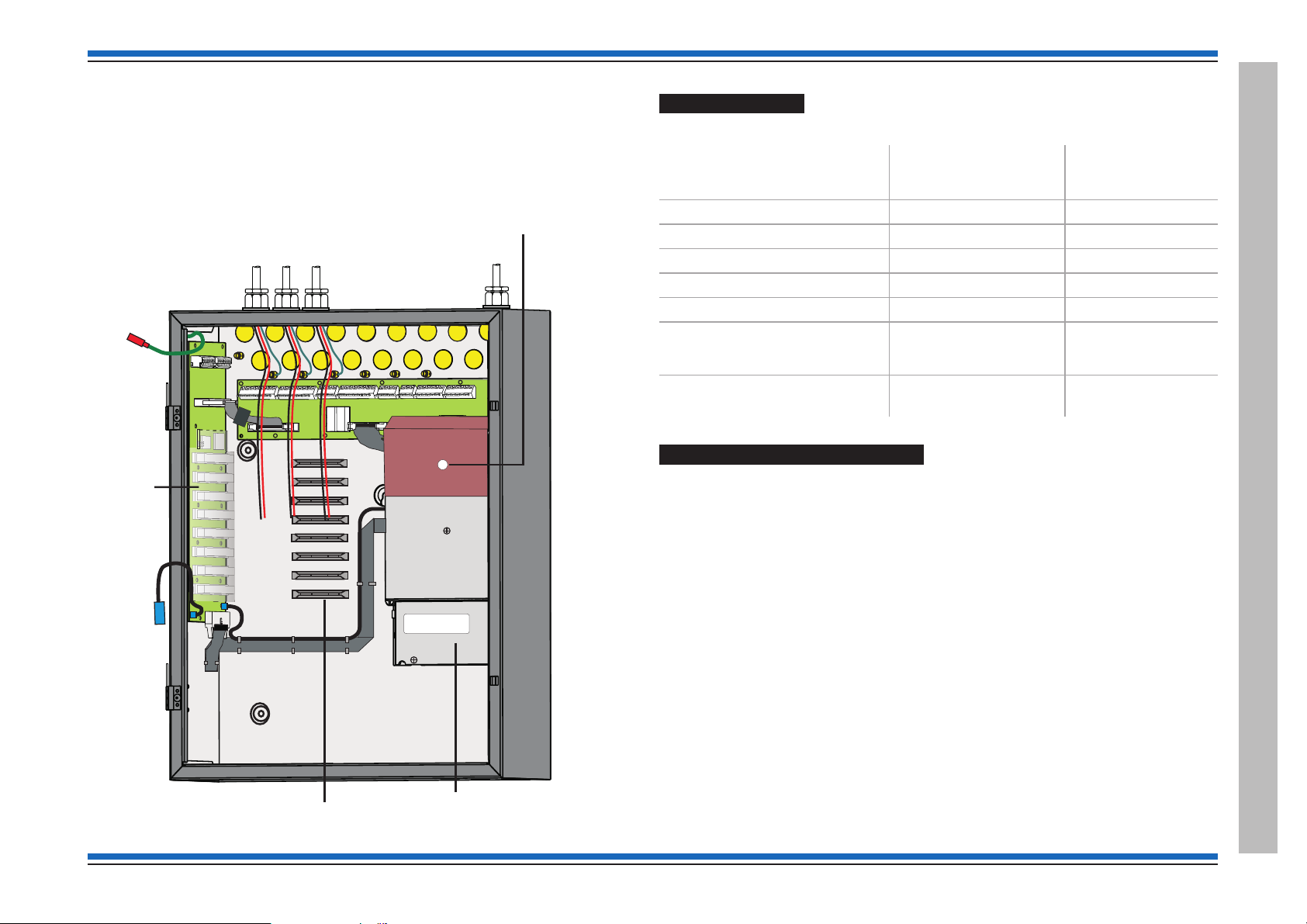

Vigilon 4/6 loop Panels

These procedures assume the respective 1st fix assembly of the Vigilon 4 loop (VIG1-24) / 6 loop

(VIG1-72) panel is already installed. The 1st fix backbox assembly may be surface or flush

mounted.

The second fix parts must now be installed before powering up the control panel.

¨

Second fix parts

Check that you have the second fix parts, which are supplied with the panel:

¨

Parts

Inner door assembly

Battery Pack (2 x 12V 21Ah)

Battery box

Outer door assembly

Main Control Card

Loop card

EN Vigilon 4 loop

Control panel

(VIG1-24)

11

12

11

11

1

(Option of

up to 4 maximum)

EN Vigilon 6 loop

Control panel

(VIG1-72)

1

1

(option of

up to 6 maximum)

Spares pack (see installation

manual for pack content)

1pack 1pack

Remove the protective covers

¨

Remove the cardboard protection cover fitted over the PSU. The cover is held in by a

retaining clip.

¨

Remove the transparent protection cover fitted over the backplane held together by an

elastic band.

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 23

Vigilon 4/6 loop Panels

Page 24

Commissioning instructions

Earth to

inner door

Cables of external circuits

Printer 0V

Transparent

cover over

backplane

WARNING

REMOVAL OF COVER

EXPOSES HIGHVH

VOLTAGES

Transit position of

printer paper roll

and holder pin held

together with an elasticband

Hinge point

Paper roll

holder bracket

Connector for

printer 0V

Earth spade

for connection from

backbox

Inner door

Preformed ribbon

cables held together

under masking tape

to be fitted during

commissioning

Card guide

Danger

Masking tape

BACKBOX (Part view)

Backbox

Inner

door

locating

the hinge pin

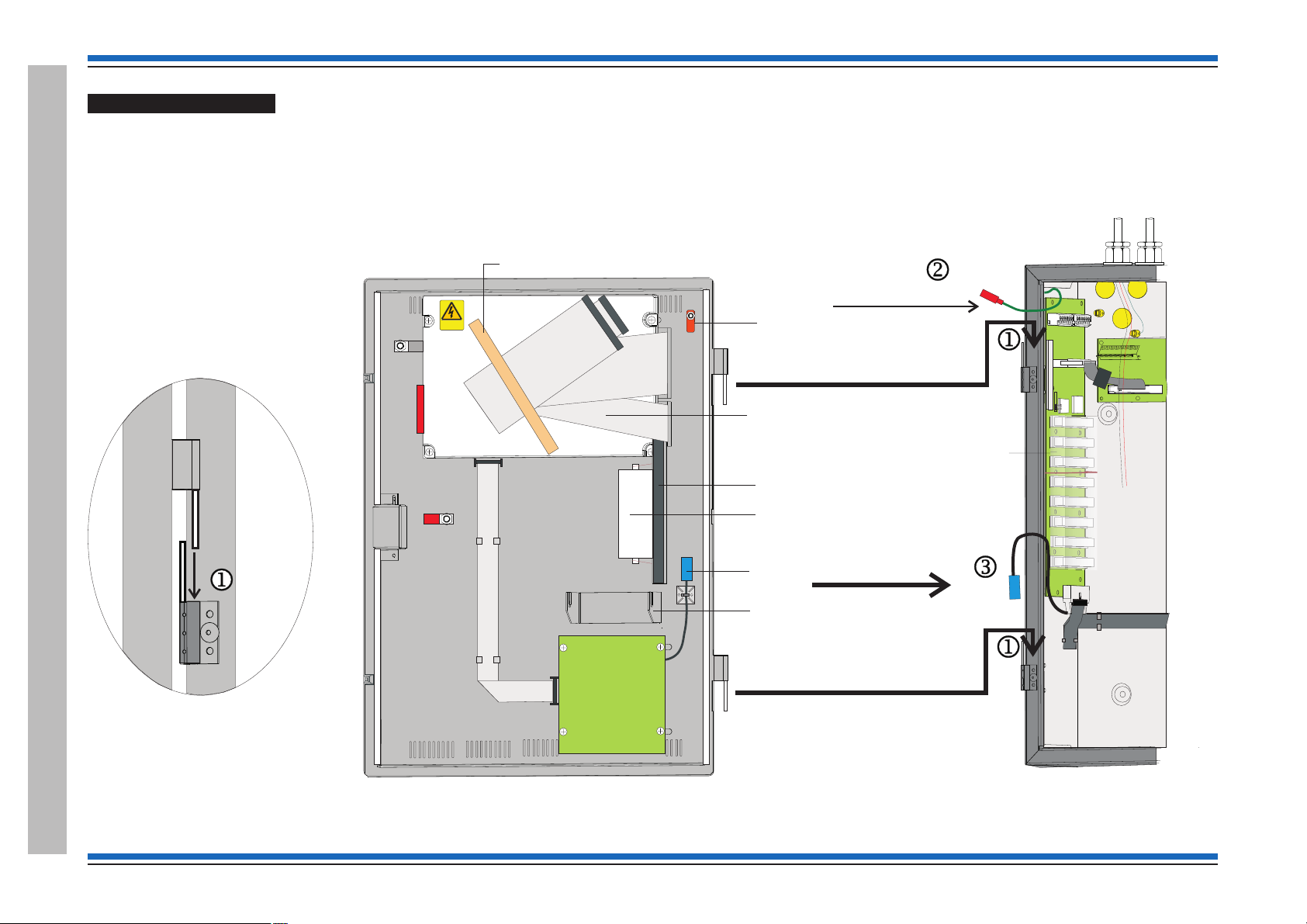

Fitting the inner door

Locate the hinge pins on the inner door assembly into the two hinge pin holes j on the backbox outer face.

¨

Fit the earth lead from the backbox to the inner door spade connector k.

¨

Fit together the two blue connectors of the printer 0V leads l, the leads are located at the inner door and backbox intersection.

¨

Vigilon 4/6 loop Panels

24 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 25

Vigilon 4/6 loops & Compact (VA) panels & network nodes

Fold paper end thus

before attempting to

feed it through printer

Printer

mechanism

Door

Paper

roll

Paper

feed knob

Printer paper roll

"

The printer paper roll is secured with an elastic band to the card guide on the inner door.

Remove the paper roll from the card guide and install paper into the printer mechanism. Ensure the paper roll enters the printer mechanism as shown.

¨

&

On the outside of the inner door there is a paper feed knob, DO NOT turn the knob in an upward direction as this may damage the integral printer.

¨

Upon completion of all commissioning work a new paper roll should be fitted.

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 25

Vigilon 4/6 loop Panels

Page 26

Commissioning instructions

DKC ASSEMBLY

WARNING

REMOVALOF COVER

EXPOSESHIGHVH

VOLTAGES

Inner door assembly

Danger

RV1

Sound Alarms

Silence Alarms

Reset

Verify

Control buttons

Inner door

1234

17 18 19 20

Zones

With Zone

indicators

(EN)

Display and

keyboard Card (DKC)

Without Zone

indicators

(BS) panel or

Network node

P6

P1

Buttons

enabled

Buttons

disabled

Factory setting

is with link fitted

8

7

6

5

4

3

2

1

ON

SW1

RV1

LCD Contrast adjust

OFF

Clockwise Darker

Anti-Clockwise Lighter

Link is NOT USED

leave link fitted.

It is for special use

with keyswitch

application

Setting the DKC card

The links, pot and switch on the DKC are factory configured as shown below.

Control buttons

"

The emergency control buttons must always be left in an enabled state, with the 'control

buttons' link fitted.

There is no indication given at the panel when the link is set for inactive controls.

Display Contrast

The display contrast is set using the Pot RV1 on the DAC, which is factory adjusted

¨

for optimum contrast. You can also adjust the contrast using the menu option under

[Test/Eng], see Appendix A menu maps.

"

applicable for some older build of panels.

Domain Address and baud rate settings

Typically the Baud rate set using these switches should be the same as the setting made using the

[TestEng] menu. The baud rate set must be backed up to the NVM. Where a baud rate value that

can only be achieved by [Test/Eng] menu, this must be set using the menu and backed up to NVM.

Baud Rate Domain address

1

Off Off 1200 Off Off Off Off Off Off 64

Off On 2400 Off Off Off Off Off On 1

On Off 9600 Off Off Off Off On Off 2

On On 19200 etc

Zone indicators

The Zone indicators are enabled for normal operation at an EN control panel and must NOT be

disabled.

The contrast adjustment function using the menu options may not be

2 Baud

3

4

5678Address

On On On On On Off 62

On On On On On On 63

Factory set domain address - 1 with 19200 baud (see SHADED cells)

Vigilon 4/6 loop Panels

26 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

The zone indicators are not applicable on a Network node nor on a BS Control panel. On these

products the 'zone indicator' links are set in the 'disable' position.

Page 27

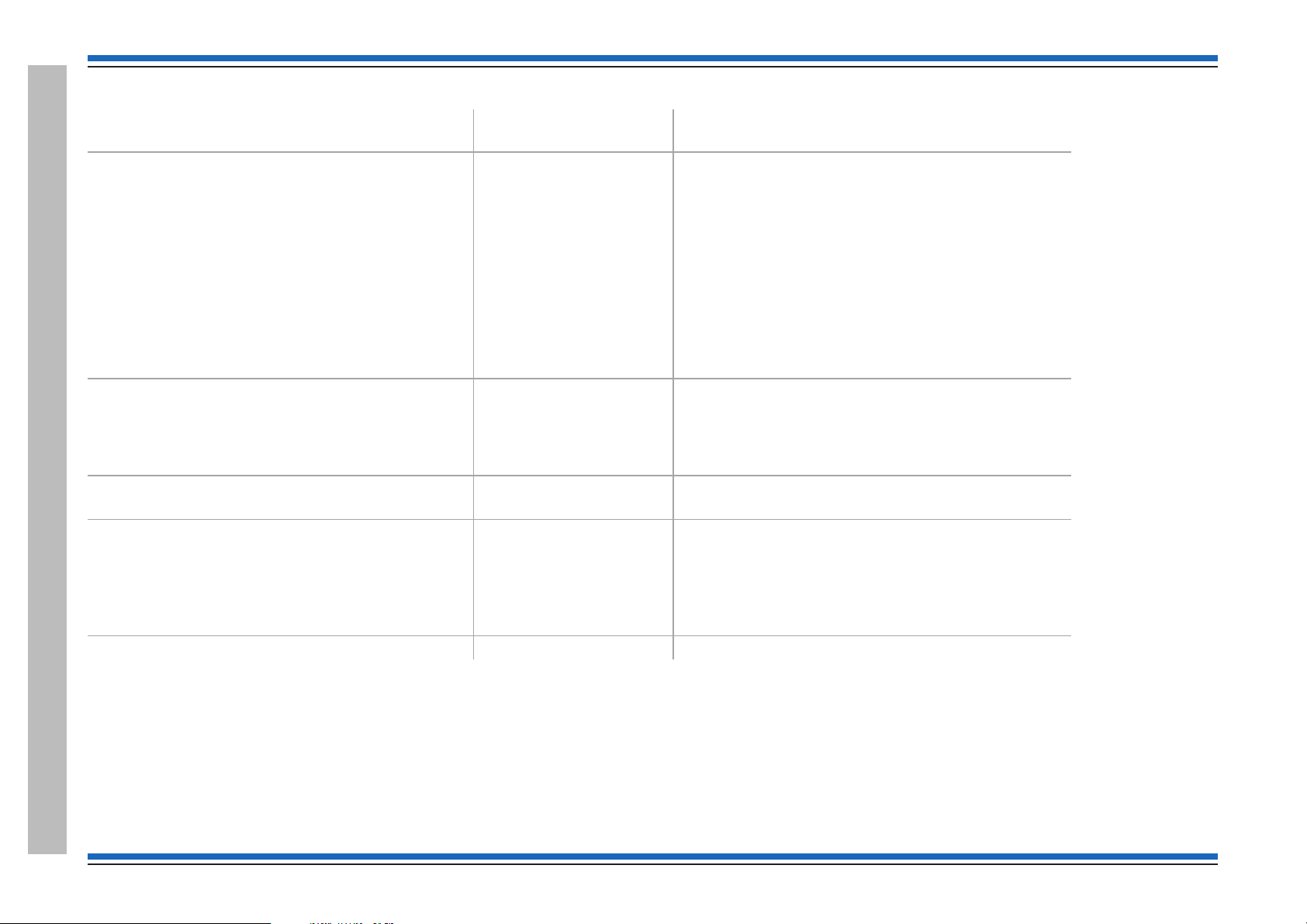

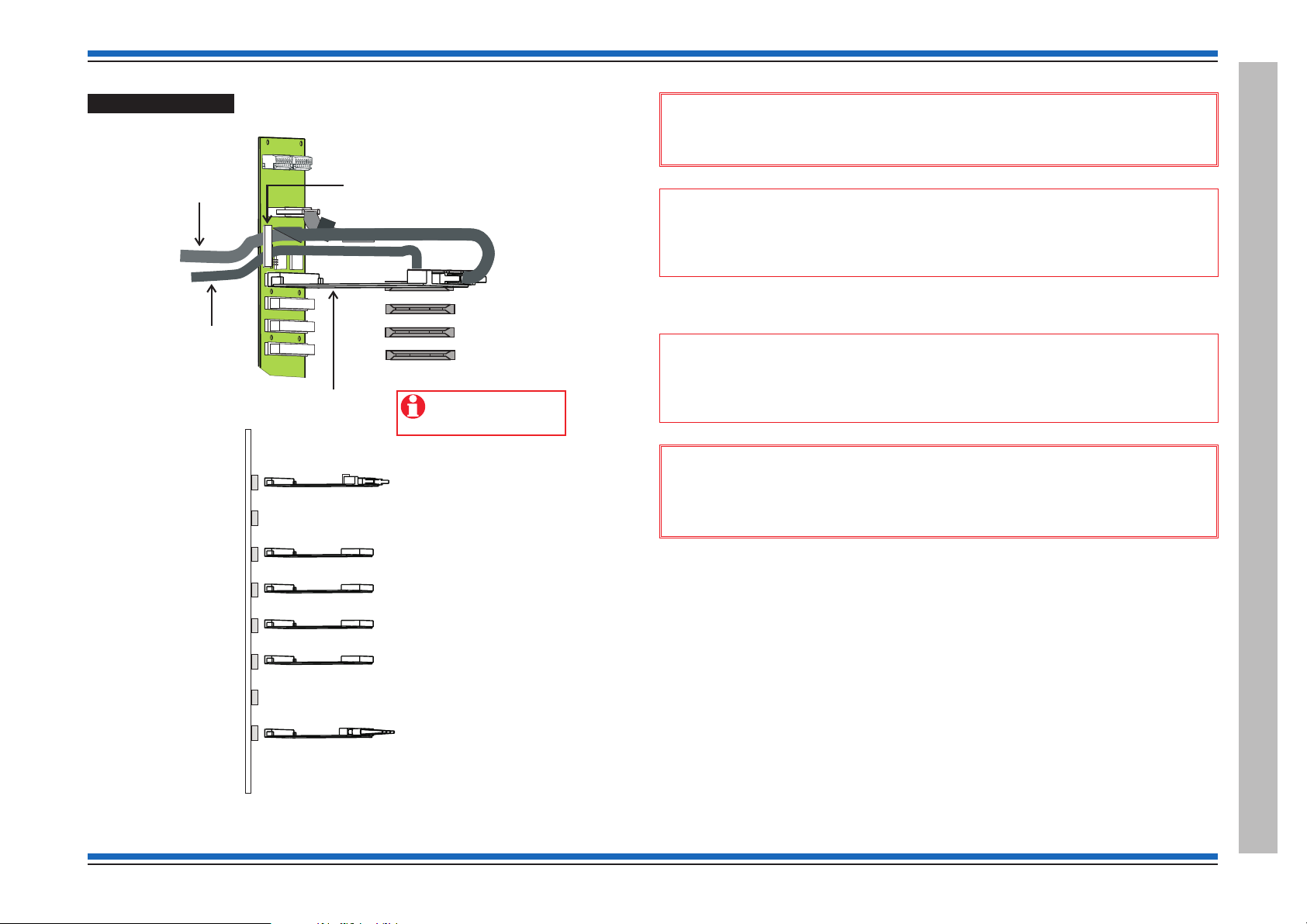

Card installation

Master Controller Card (MCC)

to be fitted to socket

P1 CARD 0 on backplane

Secure the two ribbon

cables (at the fold) under the clamp

located on the backplane

40 way ribbon

20 way ribbon

Card guides

Backplane

Main Controller Card

(SUPPLIED)

Network or IO Card (Optional)

Loop Processor Card (SUPPLIED)

or RS232

Loop Processor Card or RS232

(Option)

Loop Processor Card or RS232

(Option)

Loop Processor Card or RS232

(Option)

Fibre Network or RS232 or

Loop Card#

Network or RS232 or

Loop Card#

# for VIG1-72 only

P1 CARD 0

P2 CARD15

P3 CARD 1

P4 CARD 2

P5 CARD 3

P6 CARD 4

P7 CARD 5

P8 CARD 6

Backplane

Use the USB port on

the MCC to connect to

the Commissioning tool.

Vigilon 4/6 loops & Compact (VA) panels & network nodes

&

When installing cards into the backplane always use anti-static work

procedures. DO NOT use anti-static procedures on live equipment.

"

connect to the Commissioning tool. The DKC now connects directly to the MCC card. The

Commissioning tool connects directly to the USB port on the MCC.

The two ribbon cables held together under a masking tape on the DKC assembly must be routed

into the backbox to connect to the Main Controller Card.

"

backplane. Fit the Main Controller Card (MCC) into the backplane before the ribbon

cables are connected to the MCC.

&

An IO Card is not required for connection to DKC and neither is it required to

Ensure the two ribbon cables from DKC are secured under a clamp on the

Always ensure the panel is completely powered down before removal

or fitting of cards into the backplane. Power down the battery supply before the

mains supply. The power up should be done in reverse order.

¨

Ensure all the cards are installed in their correct location into the backplane and are

firmly seated into their respective slots.

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 27

Vigilon 4/6 loop Panels

Page 28

Commissioning instructions

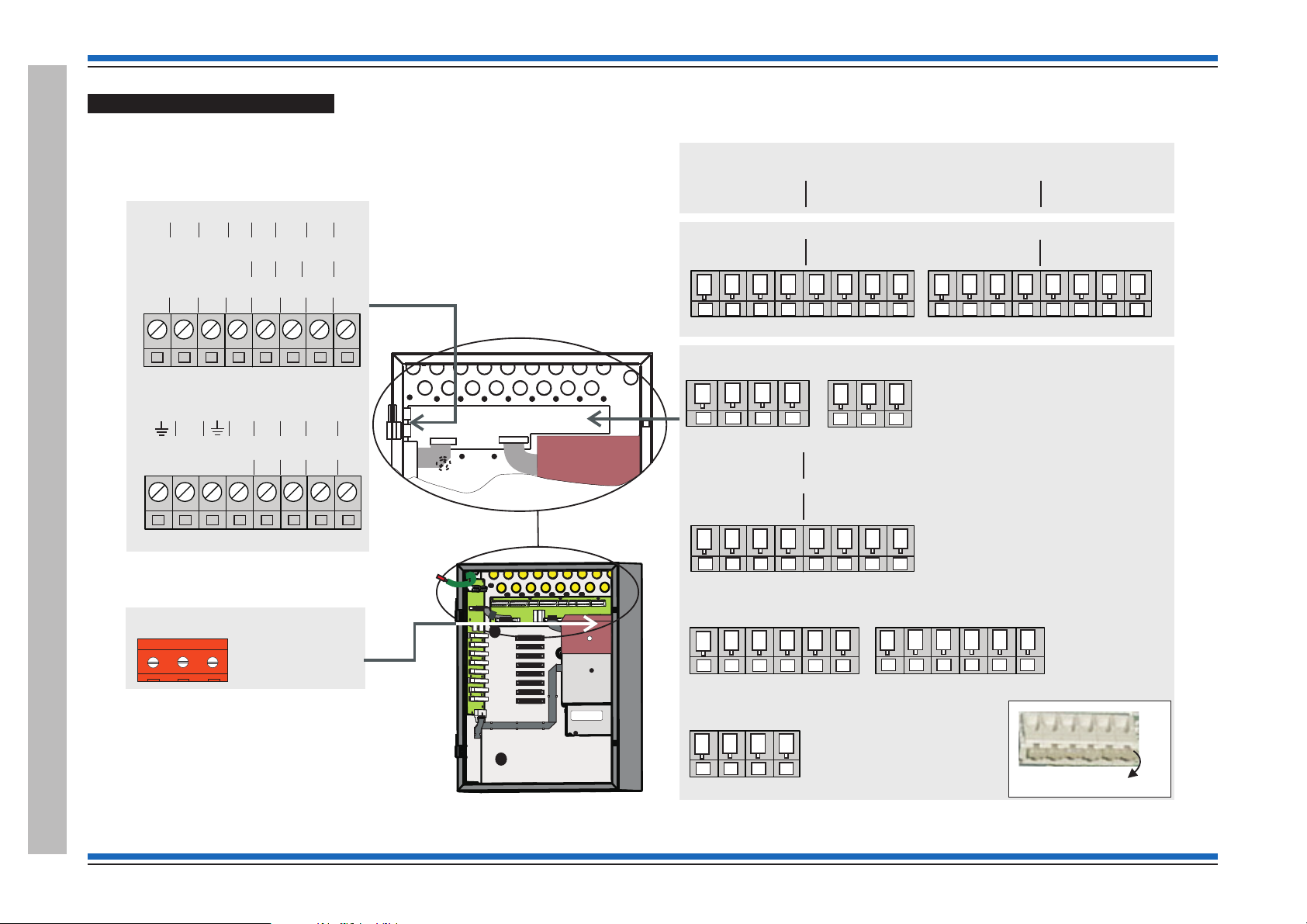

P2

L N

PSU board (located behind the

cardboard cover)

PB1

PB2

Backplane

NETWORK CARD IN SLOT P8

0V1 +VE1 -VE1 0V2 N/C +VE2 -VE2 N/C

LOOP CARD IN SLOT P8 (Loop 6)

L1 0V L2 0V

IO CARD IN SLOT P8

A 5V B 0V CTS Rx RTS TX

IO (RS232) CARD IN SLOT P7

N/C 0V CTS RX RTS TX

LOOP CARD IN SLOT P7 (Loop 5)

L1 0V L2 0V

LOOP 4

L1 0V L2 0V

LOOP 3

L1 0V L2 0V

LOOP 2

L1 0V L2 0V

LOOP 1

L1 0V L2 0V

RS485

A 5VB0V

RS232

TxCTSRxRTS

(WITH IO CARD IN SLOT P2 OF BACKPLANE)

P4

MA1+ MA1- MA2+ MA2-

Master alarm

P5

Clean C

NC C NO

P6

Auxiliary Relay 1

NCCNONCCNO

P7

Auxiliary Relay 2

NCCNONCCNO

P8

RS232 0V

0V 0V 0V 0V

P12

Terminal card

Quick release terminals

P2

P3

0V1 +VE1 -VE1 0V2

N/C N/C +VE2 -VE2

(WITH NETWORK CARD IN SLOT P2 OF BACKPLANE)

CTSRXRTSTX

CARD 4

RS232

CTSRXRTSTX

CARD 3

RS232

CTSRXRTSTX

CARD 2

RS232

CTSRXRTSTX

CARD 1

RS232

Terminals for Network node

These RS232 terminals

are for use with the RS232

wiring associated with IOC

fitted in Card slots 1 to 4.

0V

Terminals for Control panel

Terminals for Control panel and

Network node

Terminals on Terminal Card

Vigilon 4/6 loop Panels

28 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

Page 29

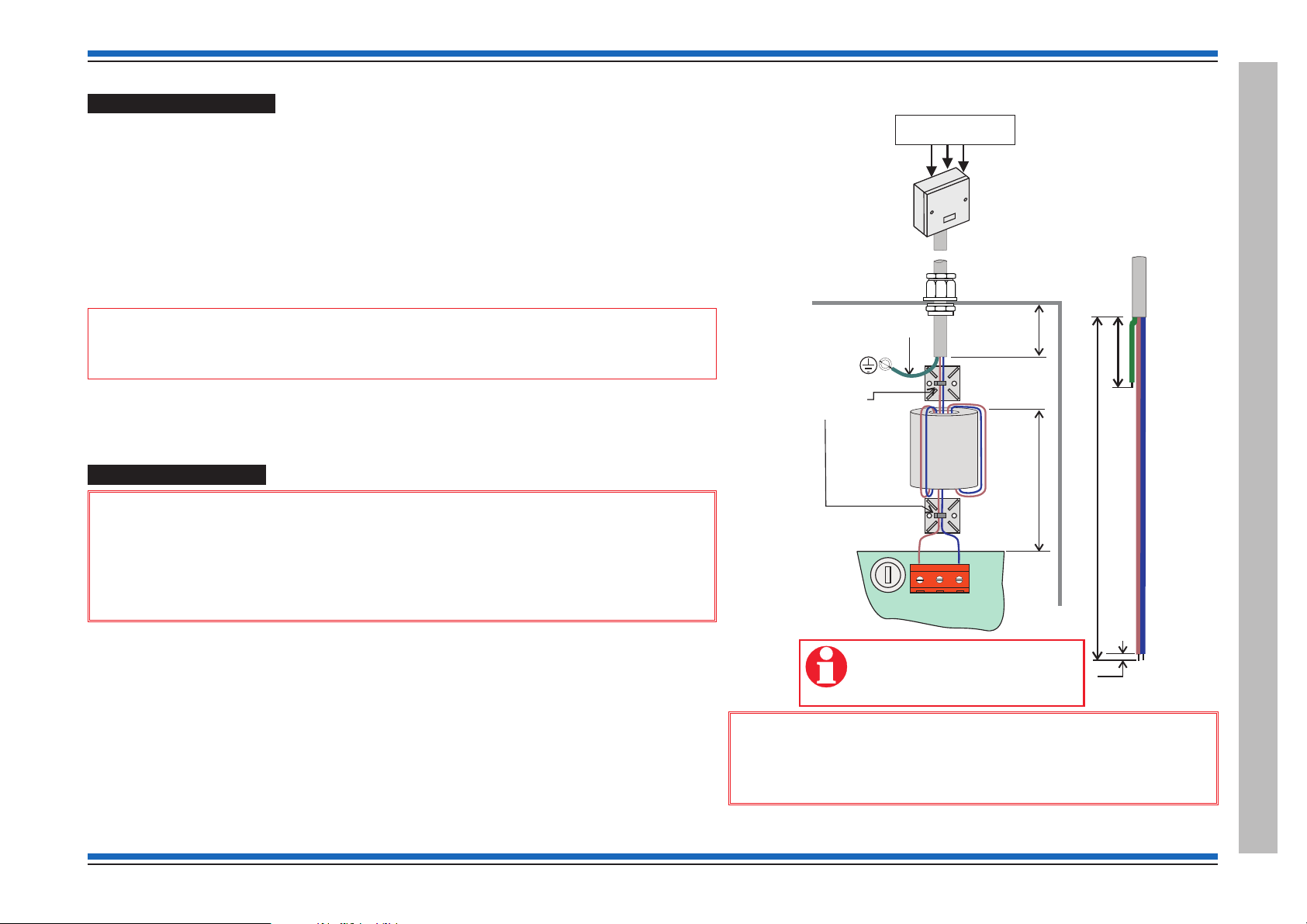

Pre power-up checks

P2

L

N

PSU PCB

The mains cable must be stripped

back to the length shown to allow

live and neutral wires to be wound

through the ferrite core.

Dedicated mains supply

from consumer unit

5A Unswitched

fused spur unit

max. 230V ac

Panel

must be sleeved

Use cable ties

(supplied)

ferrite

core

(supplied)

45mm

35mm

Gland

270mm

50mm

5mm

mains

cable

The mains cable is the only external cable that is required to be connected at this initial stage.

¨

Other external circuit cables are left disconnected, but are connected and tested later, they

include:

all loop circuits

•

clean contacts

•

auxiliary circuits

•

master alarm circuits, has the end-of-line resistors (22K Ohm) fitted to the terminals on the

•

terminal card to inhibit a master alarm circuit fault indication.

and RS232/RS485

•

"

commissioned.

Ensure all cards are securely fitted into their appropriate slots on the backplane.

¨

Ensure all ribbon cables are securely fitted into their respective sockets.

¨

A networked system is commissioned after all the individual standalone systems are fully

Vigilon 4/6 loops & Compact (VA) panels & network nodes

The Mains power is switched on after battery is installed and connected.

¨

Mains supply wiring

&

1. The fire alarm system products are NOT designed to be powered from

IT Power systems.

2. All mains powered equipment must be earthed.

Ensure the mains supply cable enters the equipment via a dedicated cable entry point, which is located

adjacent to the mains terminal block and is also segregated from other loop wiring.

¨

¨

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 29

Mains supply to any fire alarm control and indicating equipment must be via an unswitched 5A

fused spur unit. A disconnect device must be provided to disconnect both poles and must have a

minimum gap of 3mm. The 'disconnect device' should be available as part of the building

installation and must be easily accessible after installation is complete.

The fused spur isolator unit cover should be marked:

FIRE ALARM - DO NOT SWITCH OFF

&

Hazardous voltage remains after operation of a protection

fuse. Take appropriate action to guard against the risk of equipment

having exposed live mains supply.

Vigilon 4/6 loop Panels

Page 30

Commissioning instructions

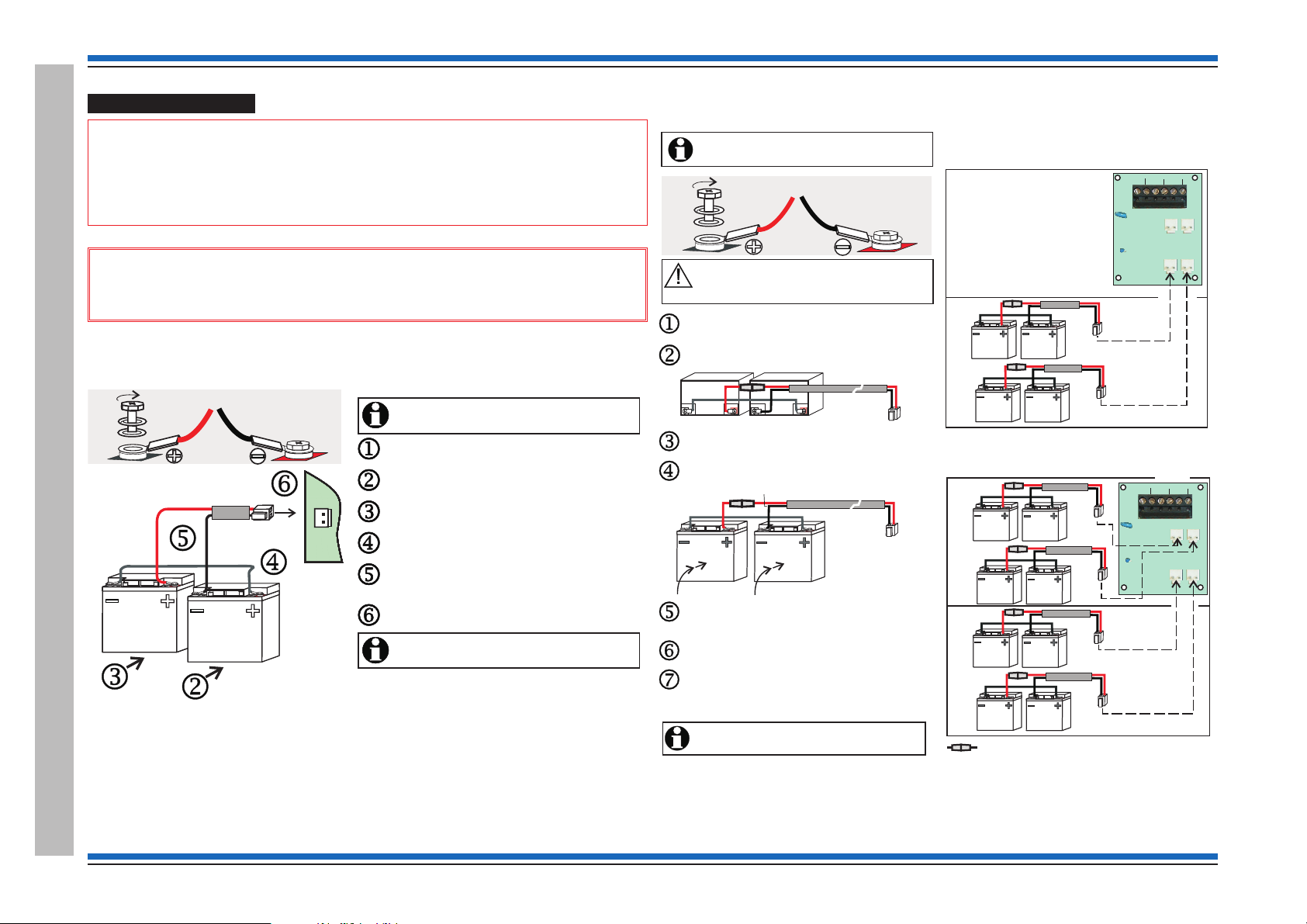

It is recommended that the mains supply to the panel

is switched during battery installation.Off

Fit the bolt, spade connector, washer, spring washer to

each battery terminal, as shown.

Insert the battery on the right into the back box.

Fit the ‘White’ link lead to outer + and - spade connectors

on the two batteries, as shown.

Fit the battery lead assembly (red & black) to the

remaining + and - spade connectors on the two

batteries, observe polarity.

Insert the battery on the left into the back box.

Plug the plug on the battery lead to connector P20 located

on the bottom left of power supply PCB.

The panel will only power up after the mains supply

is switched On.

P20

BT+ BT-

It is recommended that the mains supply to the panel

is switched during battery installation.Off

Fit the bolt, spade connector, washer, spring washer to

each battery terminal, as shown.

Insert the battery on the right into the back box.

Fit the ‘White’ link lead to outer + and - spade connectors

on the two batteries, as shown.

Fit the battery lead assembly (red & black) to the

remaining + and - spade connectors on the two

batteries, observe polarity.

Insert the battery on the left into the back box.

Plug the plug on the battery lead to connector P20 located

on the bottom left of power supply PCB.

The panel will only power up after the mains supply

is switched On.

Red Black

White

Black

Red

TH-

TH+

BT2-

BT2+BT1+

P4

P3

P2

P1

P6

TH1

BT1-

TH-

TH+

BT2-

BT2+BT1+

P4

P3

P2

P1

P6

TH1

BT1-

In-line fuse rated 10A QB ceramic 20mm x 5mm

8 - 12V 21Ah batteries

Battery Box

A

B

Lower

shelf

A

B

Upper

shelf

4 - 12V 21Ah batteries

Battery Box

Upper

shelf

B

A

Lower

shelf

The panel will only power up after the mains supply

is switched .

On

Route the battery red/black lead through hole in the shelf

of the battery box and fit the connector end of the lead

to the PCB, located on the top right side.

Place two more batteries 'B' onto the lower shelf and

repeat procedures to .

jn

Where required, add further four batteries onto the

upper shelf, use procedures to . The only

exception is that the red/black lead is directly connected

to the respective upper connectors on the PCB.

jo

Red

White.

Black

It is recommended that the mains supply is switched

during battery installation.Off

Fit the bolt, spade connector, washer and spring

washer to each battery terminal as shown above.

Place the two batteries on the lower shelf and lay them

horizontally with terminals facing outwards.

Fit the white link lead and then fit the red/black

fused lead to the battery terminals, as shown above.

White.

Red Black

Raise the two batteries to an upright position

and push them back into the enclosure.

Ensure the batteries are held in place while they

are being wired. Ensure the battery terminals

do not come into contact with the metal enclosure.

Black

Red

Battery installation

"

useful life of 5 years or more from the date of manufacture. It is strongly recommended

that batteries are replaced after 4 years of use. All batteries must be disposed of as per

recommendation made by battery manufacturer.

&

an explosion if incorrect batteries are used.

VIG1-24 panel battery installation

Vigilon 4/6 loop Panels

30 4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms.

The panel makes use of sealed lead acid type batteries which can have a

Always use the recommended replacement battery. As there is a risk of

VIG1-72 panel battery installation

Page 31

Vigilon 4/6 loops & Compact (VA) panels & network nodes

LD1

LD2

LD3

LD4

LD5

P7

P11

Indicates

communicating

with MCC

Ribbon cable

to Terminal Card

connector P10

Ribbon cable to

Backplane

connector P12

Spade connector

for 0V lead to printer

P5

LD1

LD2

LD3

LD4

LD5

Indicates Thermistor is O/C or

S/C or 43V boost test has failed.

RAM write/read

test failed

ROM checksum error

EEPROM checksum error

EEPROM stuck in

busy mode

EEPROM reinitialised

EEPROM read does

not match RAM copy

The above LEDs flash 1s on and 1s off.

When a LED is ON it indicates an error.

For more than one error the LEDs will flash in sequence.

PSU

ERROR

Steady indication

Flashing indication

LD1

LD2

LD3

LD4

LD5

Backplane

Protected

- write protected

LK1

Unprotected

- not write protected

(factory setting)

PSU LED indications Write protect link on backplane

The backplane assembly is fitted inside the left side of the backbox.

The backplane has the card slots to facilitate interconnection of plug-in cards, such as the Main

Controller Card (MCC), Loop Processor Cards, IO Cards and Network Cards.

The backplane also has the flash memory

(NVM) which is under the control of MCC and

is a shared memory to which the system

configuration data is saved.

The link header on the backplane marked

LK1 provides 'write' protection and will stop

the SAVE and BACKUP commands from the

panel controls modifying the memory.

Once the system is fully commissioned the

link LK1 should be configured to 'write

protected', this is important on sites where

customers require compliance to the EN54

Part 2 standard.

4188-856_issue 7_07/15_Generic Vigilon (Compact + VA) Comms. 31

The NVM should always hold the complete

system back up.

Vigilon 4/6 loop Panels

Page 32

Commissioning instructions

Fire

Power

CB253

Sounder

Pre mid 2015

Verify

CB254

Not on BS

panels

Not on BS

panels

Fire

Power

Sounder

Verify

Active

Fault/Dis

Fire Routing O/P

Post mid 2015

Fire Routing LEDs (Post Mid 2015)