Page 1

VGF22

VGF21

VGF31

VGF32

VGF Flanged Globe Valves

SPECIFICATIONS

Models: See Tables 2 and 3.

Dimensions: See Fig. 3 and 4.

Action:

Mixing valves: Stem up to close port A-AB.

All others: Stem down to close port A-AB.

Controlled Media:

Water up to 50% glycol solution.

Saturated steam (2-way models) up to 100 psig.

Not suitable for open loop systems such as condenser

water or potable water.

Valve Body Temperature-Pressure Ratings:

Water: ANSI Class 125 and 250. See Table 1.

Steam: 337°F (170°C); 100 psig (689 kPa).

Flow Capacity: See Table 8.

Stroke and Mounting:

2-1/2 and 3 inch (DN65 and DN80): 3/4 in. (20mm)

APPLICATION

VGF Flanged Globe Valves are used for 2-position or

modulating control of steam, hot water, or chilled water in

closed loop HVAC systems. They can be operated by a

large variety of electric and pneumatic actuators. Threeway valves are available in mixing or diverting flow

patterns.

FEATURES

• ANSI Class 125 and Class 250 flanged cast iron

bodies.

• Face-to-face flange dimensions per ANSI/ISA S75.03

standard.

• Sizes from 2-1/2 to 6 inches (DN65 to DN150).

• Metal-to-metal seating for long life span.

• Differential pressure of 175 psi, ANSI Class IV

leakage on pressure-balanced models.

• Steam inlet pressure up to 100 psig (689 kPa).

• Self-adjusting packing.

• Equal percentage and linear flow characteristics to

ensure precise control in a variety of applications.

Related Literature

— 62-0213 VGF Installation Instructions

— 63-1301 VGF Specification Data

— 63-9271 Field Devices Catalog (for compatible

actuators)

stroke, 1-3/8 in. bonnet, 1/4-28 UNF stem thread and

button.

4 to 6 inch (DN100 to DN150): 1-1/2 in. (38mm) stroke,

1-7/8 in. bonnet, 7/16-20 UNF stem thread, and button.

Maximum Temperature Differential

(alternating hot/cold water): 108°F (60°C).

Flow Characteristic:

VGF2__E_: Equal percentage.

VGF2__L_: Linear.

VGF3_EM_ Mixing Valve: Equal percentage port A-AB, Lin-

ear port B-AB.

VGF3_LD_ Diverting Valve: Linear.

Rangeability: 50:1.

Close-Off Pressure (maximum):

VGF21_P pressure-balanced: 175 psi (1207 kPa).

All others: Proportional to actuator force. See Tables 4, 5.

and 6.

Leakage Rate (maximum):

VGF21_P pressure-balanced: 0.01% of Cv (ANSI Class IV).

VGF2__S: 0.05% of Cv (ANSI Class III).

Three-way:

VGF31EM and VGF32EM <.05% of CV A to AB (ANSI

Class III), <.1% of CV B-AB

VGF31LD and VGF32LD <.05% of CV AB to A (ANSI

Class III), <.1% of CV AB-B

PRODUCT DATA

63-2618-01

Page 2

VGF FLANGED GLOBE VALVES

Table 2. VGF2 2-way.

VGF2 Valve, Globe, Flanged, 2-way

1 ANSI 125

2 ANSI 250

EP Equal percent flow, pressure-balanced

a

ES Equal percent flow, standard

LP Linear flow, pressure-balanced

a

LS Linear flow, standard

a

25 2-1/2 in. ports

30 3 in. ports

40 4 in. ports

50 5 in. ports

60 6 in. ports

VGF2 1 EP 30

e.g.: 3 in. flanged, equal percent, pressure balanced, ANSI 125

a

ANSI 125 only

Table 3. VGF3 3-way.

VGF3 Valve, Globe, Flanged, 3-way

1 ANSI 125

2 ANSI 250

EM Equal percentage flow, mixing

LD Linear flow, diverting

25 2-1/2 in. (DN65) ports

30 3 in. (DN80) ports

40 4 in. (DN100) ports

50 5 in. (DN125) ports

60 6 in. (DN150) ports

VGF3 2 EM 40

e.g.: 4 in. (DN100) flanged mixing valve, ANSI

250

Valve Body:

End connections:

Face-to-face flange dimensions per ANSI/ISA 75.03.

Bolt holes conform to ANSI B16.1. VGF3 valves have

standard ANSI flange connections on A and AB

ports. B ports have lugged connections. See Table 7.

VGF3 B-Port Threads

Material: Cast iron, ASTM A126 Class B (GG25).

Trim:

Seat:

Mixing valve: body integrated (cast iron).

All others: Stainless steel.

Plug: Stainless steel, skirt guided.

Stem: Stainless steel.

Packing: Spring loaded PTFE cone rings.

Accessories:

43196000-001 High Temperature Kit. Fits 2 1/2 and

3" VGF valves.

43196000-038 High Temperature Kit. Fits 4 to 6" VGF

valves.

R43176754002 Packing Kit for 2-1/2 in. and 3 in. VGF21

and VGF31 valves.

R43176755004 Packing Kit for 2-1/2 in. and 3 in. VGF22,

VGF32, VGF21EP, and VGF21LP valves.

R43176755005 Packing Kit for all 4 in. to 6 in. VGF valves.

Replacement stem buttons:

2-1/2 to 3 in (DN65-80): 209117

4 to 6 in (DN100-150): 209116

NOTE: Packing kits include copper ring, spring, bearing,

packing, and gasket.

Table 1. Water Temperature and Maximum Pressure.

Temperature

°F (°C)

VGF21, VGF31 VGF22, VGF32

System Pressure

35 to 130 (2-66) 175 psig (1206 kPa) 400 psig (2758 kPa)

Up to 200 (< 93) 165 psig (1138 kPa) 370 psig (2251 kPa)

Up to 250 (< 121) 150 psig (1034 kPa) 340 psig (2344 kPa)

Up to 300 (< 149) 140 psig (965 kPa) 310 psig (2137 kPa)

Up to 337 (<170) 125 psig (862 kPa) 280 psig (1931 kPa)

63-2618—01 2

Page 3

VGF FLANGED GLOBE VALVES

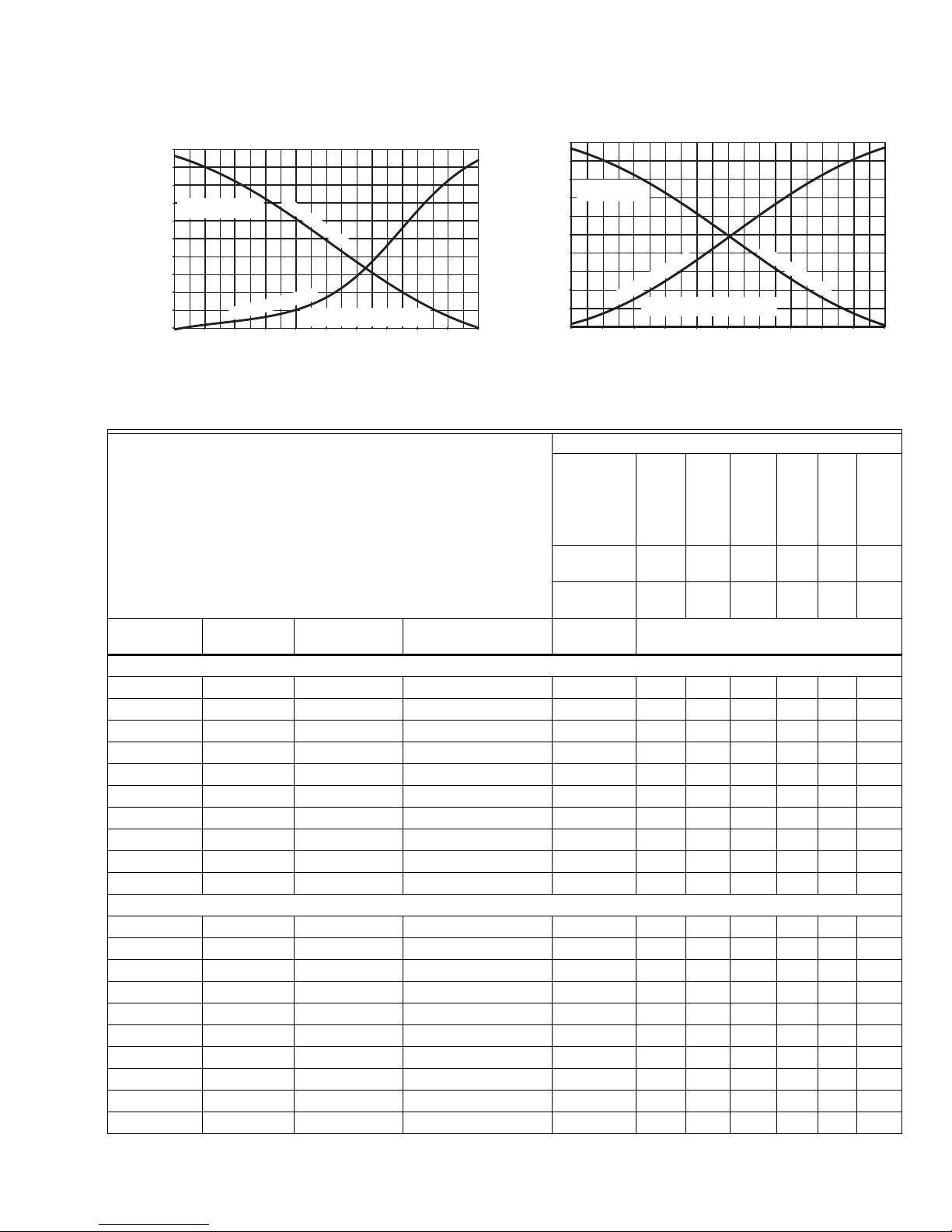

LINEAR FLOW

NORMALLY OPEN

A TO AB FOR 2 WAY LS AND LP MODELS

AB TO A FOR 3 WAY DIVERTING

70% 80% 90%

STEM TRAVEL (% OF STROKE)

60%

M22598A

FLOW

(% OF CV)

100%

90%

80%

70%

B TO AB FOR 3 WAY

MIXING VALVE

60%

50%

40%

30%

20%

10%

0%

EQUAL PERCENTAGE FLOW

NORMALLY OPEN

NORMALLY CLOSED

A TO AB FOR 2 WAY EP AND ES MODELS

A TO AB FOR 3 WAY MIXING

STEM TRAVEL (% OF STROKE)

100%10% 20% 30% 40% 50% 60% 70% 80% 90%

M22600A

100%

FLOW

(% OF CV)

90%

80%

AB TO B FOR 3

WAY DIVERTING

70%

60%

50%

40%

30%

20%

10%

0%

NORMALLY CLOSED

Fig. 1. Equal percentage flow diagram. Fig. 2. Linear flow diagram.

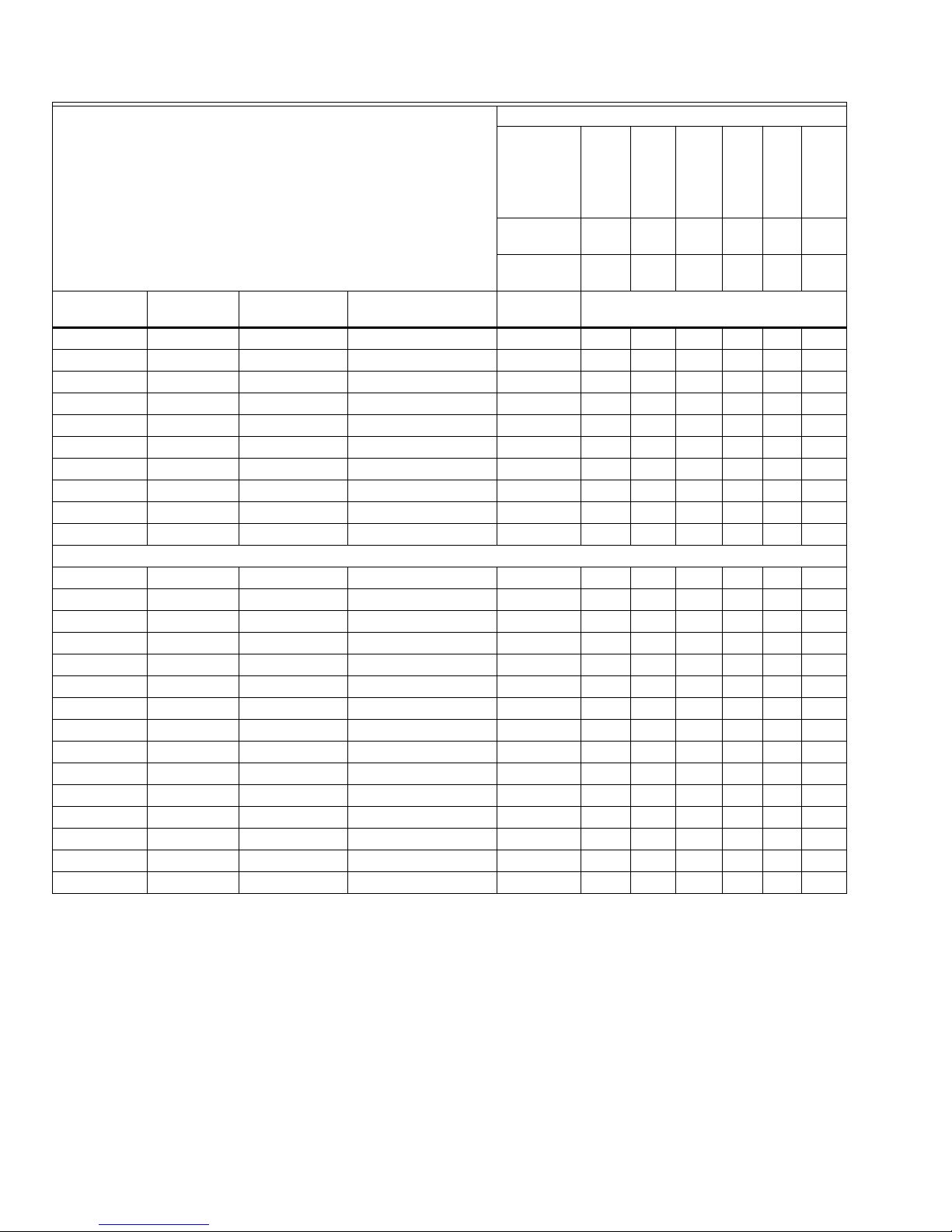

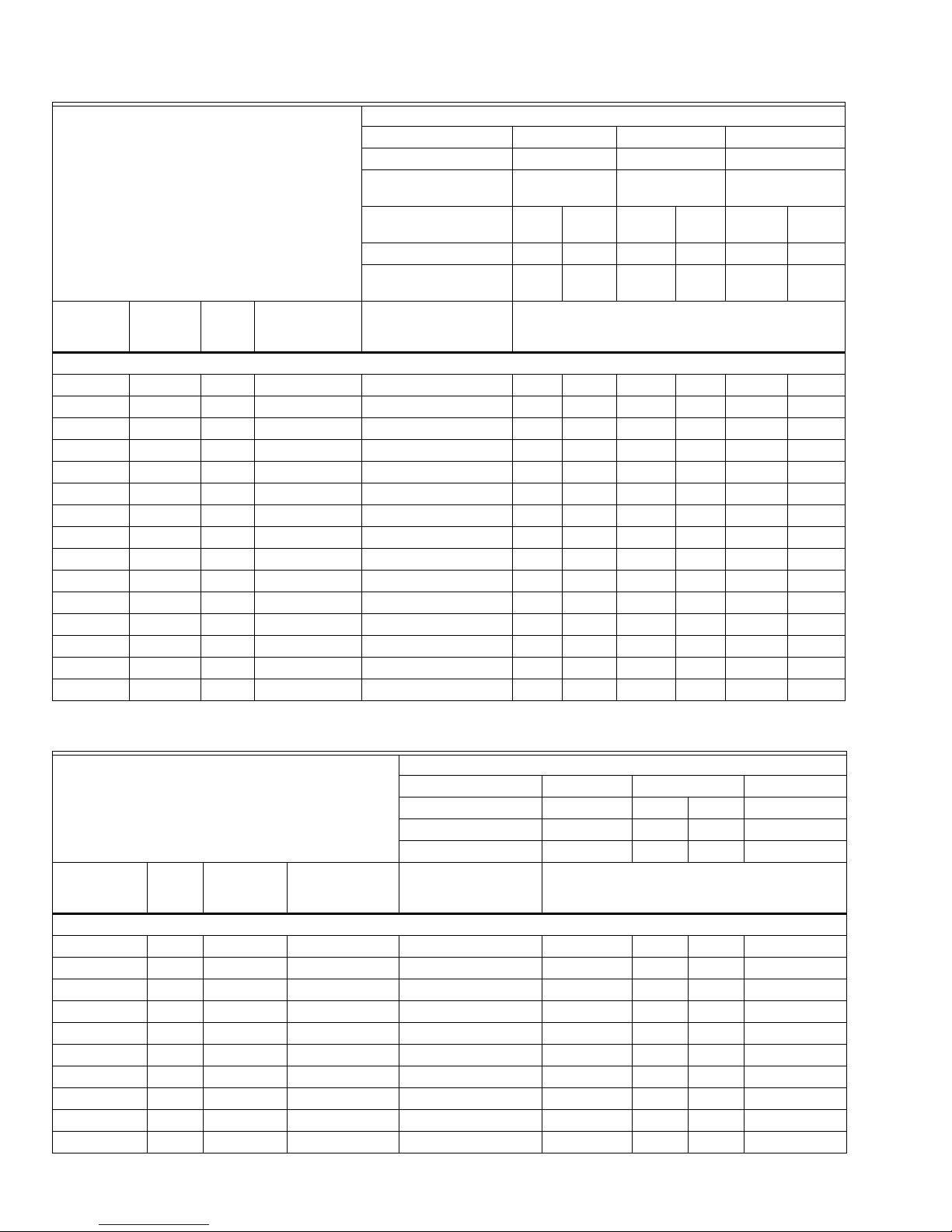

Table 4. Close-off Ratings for VGF valves and Linear Actuators.

Linear Globe Valve Actuator Models

Actuator Part

Number

ML6420A3049

ML6420A3056

ML7420A3055

ML7420A3063

ML6425A3022

ML7425A3013

ML6421A1017

ML6425B3013

ML7421A1032

ML7425B3012

Stem Force

(lbf) 135 135 135 135 404 404

Actuator

Stroke (inch) 3/4 3/4 3/4 3/4 3/4 1-1/2

Valve Part

Number Close-Off (psi)

Connection Size

(inch)

Valve Characteristics

Stem Travel

(inch) Body Pattern Flow Characteristics

Class 125 Pressure Balanced Globe Valves

2-1/2 3/4 2-Way Equal Percentage VGF21EP25 175 175 175 175 175

3 3/4 2-Way Equal Percentage VGF21EP30 175 175 175 175 175

4 1-1/2 2-Way Equal Percentage VGF21EP40 175

5 1-1/2 2-Way Equal Percentage VGF21EP50 175

6 1-1/2 2-Way Equal Percentage VGF21EP60 175

2-1/2 3/4 2-Way Linear VGF21LP25 175 175 175 175 175

3 3/4 2-Way Linear VGF21LP30 175 175 175 175 175

4 1-1/2 2-Way Linear VGF21LP40 175

5 1-1/2 2-Way Linear VGF21LP50 175

6 1-1/2 2-Way Linear VGF21LP60 175

Class 125 Standard Globe Valves

2-1/2 3/4 2-Way Equal Percentage VGF21ES25 17 17 17 17 68

3 3/4 2-Way Equal Percentage VGF21ES30 7 7 7 7 33

4 1-1/2 2-Way Equal Percentage VGF21ES40 33

5 1-1/2 2-Way Equal Percentage VGF21ES50 13

6 1-1/2 2-Way Equal Percentage VGF21ES60 13

2-1/2 3/4 2-Way Linear VGF21LS25 17 17 17 17 68

3 3/4 2-Way Linear VGF21LS30 7 7 7 7 33

4 1-1/2 2-Way Linear VGF21LS40 33

5 1-1/2 2-Way Linear VGF21LS50 13

6 1-1/2 2-Way Linear VGF21LS60 13

100%10% 20% 30% 40% 50%

ML6421B1040

ML7421B1023

3 63-2618—01

Page 4

VGF FLANGED GLOBE VALVES

Linear Globe Valve Actuator Models

Actuator Part

Number

ML6420A3049

ML6420A3056

ML7420A3055

ML7420A3063

ML6425A3022

ML6425B3013

ML7425A3013

ML7425B3012

ML6421A1017

ML7421A1032

Stem Force

(lbf) 135 135 135 135 404 404

Actuator

Connection Size

(inch)

Valve Characteristics

Stem Travel

(inch) Body Pattern Flow Characteristics

Stroke (inch) 3/4 3/4 3/4 3/4 3/4 1-1/2

Valve Part

Number Close-Off (psi)

2-1/2 3/4 Mixing Equal Percentage * VGF31EM25 23 23 23 23 94

3 3/4 Mixing Equal Percentage * VGF31EM30 15 15 15 15 58

4 1-1/2 Mixing Equal Percentage * VGF31EM40 33

5 1-1/2 Mixing Equal Percentage * VGF31EM50 13

6 1-1/2 Mixing Equal Percentage * VGF31EM60 13

2-1/2 3/4 Diverting Linear VGF31LD25 17 17 17 17 68

3 3/4 Diverting Linear VGF31LD30 7 7 7 7 33

4 1-1/2 Diverting Linear VGF31LD40 33

5 1-1/2 Diverting Linear VGF31LD50 13

6 1-1/2 Diverting Linear VGF31LD60 13

Class 250 Standard Globe Valves

2-1/2 3/4 2-Way Equal Percentage VGF22ES25 17 17 17 17 68

3 3/4 2-Way Equal Percentage VGF22ES30 7 7 7 7 33

4 1-1/2 2-Way Equal Percentage VGF22ES40 33

5 1-1/2 2-Way Equal Percentage VGF22ES50 13

6 1-1/2 2-Way Equal Percentage VGF22ES60 13

2-1/2 3/4 Mixing Equal Percentage * VGF32EM25 23 23 23 23 94

3 3/4 Mixing Equal Percentage * VGF32EM30 15 15 15 15 58

4 1-1/2 Mixing Equal Percentage * VGF32EM40 33

5 1-1/2 Mixing Equal Percentage * VGF32EM50 13

6 1-1/2 Mixing Equal Percentage * VGF32EM60 13

2-1/2 3/4 Diverting Linear VGF32LD25 17 17 17 17 68

3 3/4 Diverting Linear VGF32LD30 7 7 7 7 33

4 1-1/2 Diverting Linear VGF32LD40 33

5 1-1/2 Diverting Linear VGF32LD50 13

6 1-1/2 Diverting Linear VGF32LD60 13

* Mixing valves B-port have linear flow characteristics.

ML6421B1040

ML7421B1023

63-2618—01 4

Page 5

VGF FLANGED GLOBE VALVES

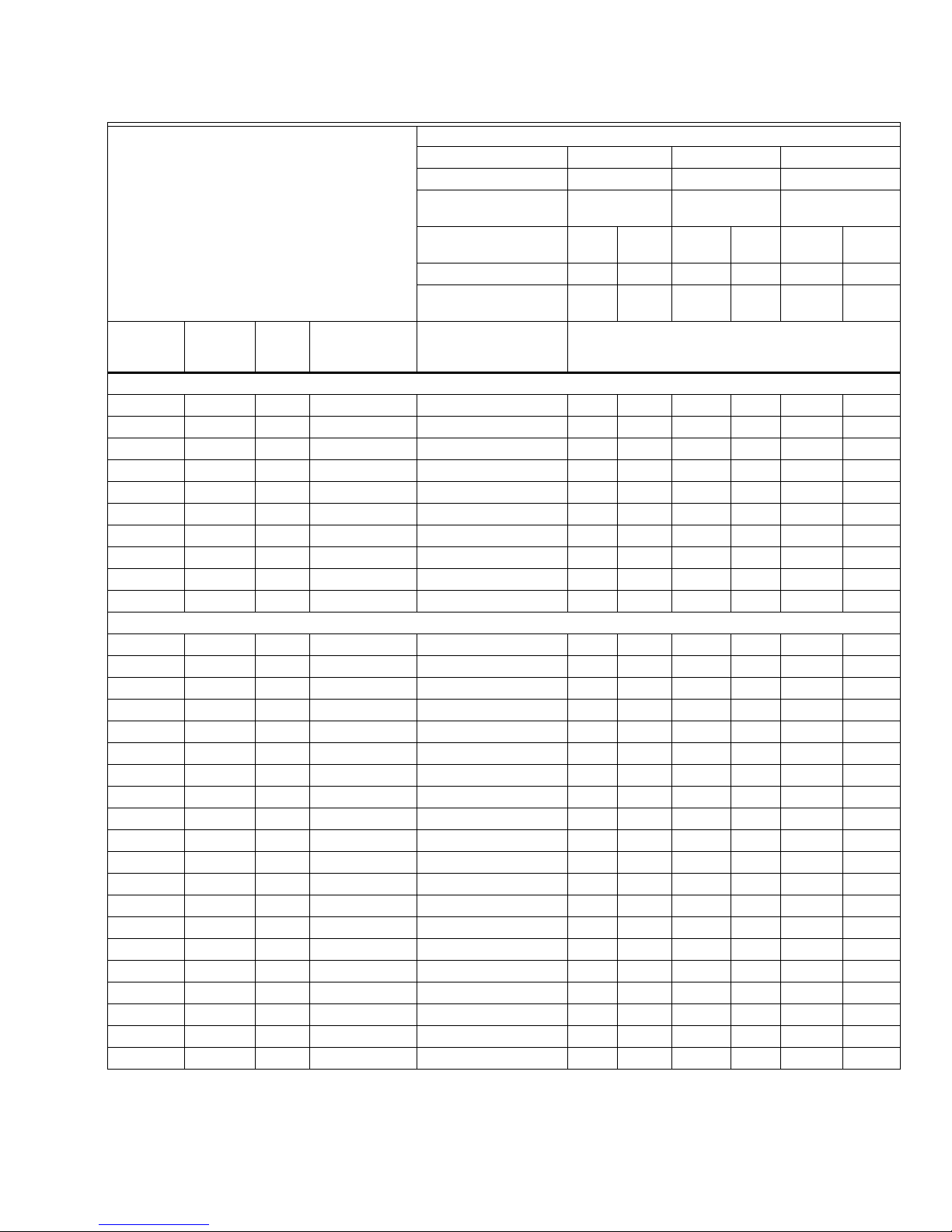

Table 5. Close-off Ratings for VGF valves with Direct Coupled Actuators and Linkages.

Rotary Direct Coupled Actuators with Globe Valve Linkage

Linkage Part Number Q5020A1003 Q5024B2230 Q5024B2240

Linkage Type Single actuator Dual actuator Dual actuator

Stem Adapter / Collar Part

Number N/A HU5024-001 HU5024-002

Actuator torque (lb-in) 175 300

350

(2x175)

600

(2x300)

350

(2x175)

(2x300)

Stem Force (lbf) 234 402 360 617 272 467

Effective Linkage Stroke

Valve Characteristics

(inch) 3/4 3/4 3/4 3/4 1-1/2 1-1/2

Connection

Size

(inch)

Stem Travel

(inch)

Body

Pattern

Flow

characteristics Valve Part Number Close-Off (psi)

Class 125 Pressure Balanced Globe Valves

2-1/2 3/4 2-Way Equal Percentage VGF21EP25 175 175 175 175

3 3/4 2-Way Equal Percentage VGF21EP30 175 175 175 175

4 1-1/2 2-Way Equal Percentage VGF21EP40 175 175

5 1-1/2 2-Way Equal Percentage VGF21EP50 175 175

6 1-1/2 2-Way Equal Percentage VGF21EP60 175 175

2-1/2 3/4 2-Way Linear VGF21LP25 175 175 175 175

3 3/4 2-Way Linear VGF21LP30 175 175 175 175

4 1-1/2 2-Way Linear VGF21LP40 175 175

5 1-1/2 2-Way Linear VGF21LP50 175 175

6 1-1/2 2-Way Linear VGF21LP60 175 175

Class 125 Standard Globe Valves

2-1/2 3/4 2-Way Equal Percentage VGF21ES25 39 68 61 105

3 3/4 2-Way Equal Percentage VGF21ES30 19 33 30 52

4 1-1/2 2-Way Equal Percentage VGF21ES40 22 39

5 1-1/2 2-Way Equal Percentage VGF21ES50 9 15

6 1-1/2 2-Way Equal Percentage VGF21ES60 9 15

2-1/2 3/4 2-Way Linear VGF21LS25 39 68 61 105

3 3/4 2-Way Linear VGF21LS30 19 33 30 52

4 1-1/2 2-Way Linear VGF21LS40 22 39

5 1-1/2 2-Way Linear VGF21LS50 9 15

6 1-1/2 2-Way Linear VGF21LS60 9 15

2-1/2 3/4 Mixing Equal Percentage * VGF31EM25 55 94 77 133

3 3/4 Mixing Equal Percentage * VGF31EM30 34 58 52 89

4 1-1/2 Mixing Equal Percentage * VGF31EM40 22 39

5 1-1/2 Mixing Equal Percentage * VGF31EM50 9 15

6 1-1/2 Mixing Equal Percentage * VGF31EM60 9 15

2-1/2 3/4 Diverting Linear VGF31LD25 39 68 61 105

3 3/4 Diverting Linear VGF31LD30 19 33 30 52

4 1-1/2 Diverting Linear VGF31LD40 22 39

5 1-1/2 Diverting Linear VGF31LD50 9 15

6 1-1/2 Diverting Linear VGF31LD60 9 15

600

5 63-2618—01

Page 6

VGF FLANGED GLOBE VALVES

Rotary Direct Coupled Actuators with Globe Valve Linkage

Linkage Part Number Q5020A1003 Q5024B2230 Q5024B2240

Linkage Type Single actuator Dual actuator Dual actuator

Stem Adapter / Collar Part

Number N/A HU5024-001 HU5024-002

Actuator torque (lb-in) 175 300

350

(2x175)

600

(2x300)

350

(2x175)

Stem Force (lbf) 234 402 360 617 272 467

Effective Linkage Stroke

Valve Characteristics

(inch) 3/4 3/4 3/4 3/4 1-1/2 1-1/2

Connection

Size

(inch)

Stem Travel

(inch)

Body

Pattern

Flow

characteristics Valve Part Number Close-Off (psi)

Class 250 Standard Globe Valves

2-1/2 3/4 2-Way Equal Percentage VGF22ES25 39 68 61 105

3 3/4 2-Way Equal Percentage VGF22ES30 19 33 30 52

4 1-1/2 2-Way Equal Percentage VGF22ES40 22 39

5 1-1/2 2-Way Equal Percentage VGF22ES50 9 15

6 1-1/2 2-Way Equal Percentage VGF22ES60 9 15

2-1/2 3/4 Mixing Equal Percentage * VGF32EM25 55 94 77 133

3 3/4 Mixing Equal Percentage * VGF32EM30 34 58 52 89

4 1-1/2 Mixing Equal Percentage * VGF32EM40 22 39

5 1-1/2 Mixing Equal Percentage * VGF32EM50 9 15

6 1-1/2 Mixing Equal Percentage * VGF32EM60 9 15

2-1/2 3/4 Diverting Linear VGF32LD25 39 68 61 105

3 3/4 Diverting Linear VGF32LD30 19 33 30 52

4 1-1/2 Diverting Linear VGF32LD40 22 39

5 1-1/2 Diverting Linear VGF32LD50 9 15

6 1-1/2 Diverting Linear VGF32LD60 9 15

* Mixing valves B-port have linear flow characteristics.

600

(2x300)

Table 6. Close-off Ratings for VGF valves with Modutrol IV Actuators and Linkages.

Modutrol IV Actuators with Q5001 Valve Linkage

Linkage Part Number Q5001D1000 Q5001D1018 Q5001D1026

Actuator torque (lb-in) 150 150 300 300

Stem Force (lbf) 160 160 320 320

Valve Characteristics

Linkage Stroke (inch) 3/4 3/4 3/4 1-1/2

Stem

Connection Size

(inch)

Tra vel

(inch) Body Pattern Flow characteristics Valve Part Number Close-Off (psi)

Class 125 Pressure Balanced Globe Valves

2-1/2 3/4 2-Way Equal Percentage VGF21EP25 175 175 175

3 3/4 2-Way Equal Percentage VGF21EP30 175 175 175

4 1-1/2 2-Way Equal Percentage VGF21EP40 175

5 1-1/2 2-Way Equal Percentage VGF21EP50 175

6 1-1/2 2-Way Equal Percentage VGF21EP60 175

2-1/2 3/4 2-Way Linear VGF21LP25 175 175 175

3 3/4 2-Way Linear VGF21LP30 175 175 175

4 1-1/2 2-Way Linear VGF21LP40 175

5 1-1/2 2-Way Linear VGF21LP50 175

6 1-1/2 2-Way Linear VGF21LP60 175

63-2618—01 6

Page 7

VGF FLANGED GLOBE VALVES

Modutrol IV Actuators with Q5001 Valve Linkage

Linkage Part Number Q5001D1000 Q5001D1018 Q5001D1026

Actuator torque (lb-in) 150 150 300 300

Stem Force (lbf) 160 160 320 320

Valve Characteristics

Linkage Stroke (inch) 3/4 3/4 3/4 1-1/2

Stem

Connection Size

(inch)

Tra vel

(inch) Body Pattern Flow characteristics Valve Part Number Close-Off (psi)

Class 125 Standard Globe Valves

2-1/2 3/4 2-Way Equal Percentage VGF21ES25 27 27 55

3 3/4 2-Way Equal Percentage VGF21ES30 13 13 27

4 1-1/2 2-Way Equal Percentage VGF21ES40 27

5 1-1/2 2-Way Equal Percentage VGF21ES50 10

6 1-1/2 2-Way Equal Percentage VGF21ES60 10

2-1/2 3/4 2-Way Linear VGF21LS25 27 27 55

3 3/4 2-Way Linear VGF21LS30 13 13 27

4 1-1/2 2-Way Linear VGF21LS40 27

5 1-1/2 2-Way Linear VGF21LS50 10

6 1-1/2 2-Way Linear VGF21LS60 10

2-1/2 3/4 Mixing Equal Percentage * VGF31EM25 34 34 69

3 3/4 Mixing Equal Percentage * VGF31EM30 23 23 46

4 1-1/2 Mixing Equal Percentage * VGF31EM40 27

5 1-1/2 Mixing Equal Percentage * VGF31EM50 10

6 1-1/2 Mixing Equal Percentage * VGF31EM60 10

2-1/2 3/4 Diverting Linear VGF31LD25 27 27 55

3 3/4 Diverting Linear VGF31LD30 13 13 27

4 1-1/2 Diverting Linear VGF31LD40 27

5 1-1/2 Diverting Linear VGF31LD50 10

6 1-1/2 Diverting Linear VGF31LD60 10

Class 250 Standard Globe Valves

2-1/2 3/4 2-Way Equal Percentage VGF22ES25 27 27 55

3 3/4 2-Way Equal Percentage VGF22ES30 13 13 27

4 1-1/2 2-Way Equal Percentage VGF22ES40 27

5 1-1/2 2-Way Equal Percentage VGF22ES50 10

6 1-1/2 2-Way Equal Percentage VGF22ES60 10

2-1/2 3/4 Mixing Equal Percentage * VGF32EM25 34 34 69

3 3/4 Mixing Equal Percentage * VGF32EM30 23 23 46

4 1-1/2 Mixing Equal Percentage * VGF32EM40 27

5 1-1/2 Mixing Equal Percentage * VGF32EM50 10

6 1-1/2 Mixing Equal Percentage * VGF32EM60 10

2-1/2 3/4 Diverting Linear VGF32LD25 27 27 55

3 3/4 Diverting Linear VGF32LD30 13 13 27

4 1-1/2 Diverting Linear VGF32LD40 27

5 1-1/2 Diverting Linear VGF32LD50 10

6 1-1/2 Diverting Linear VGF32LD60 10

* Mixing valves B-port have linear flow characteristics.

7 63-2618—01

Page 8

VGF FLANGED GLOBE VALVES

M22409

D

A

C

B

1

DOTTED LINE REPRESENTS ANSI 125

VALVE BONNET.

1

E

Stroke Y

Table 7. VGF3 B-Port Threads.

Model Thread # of Holes

VGF31EM25 0.625-11 4

VGF31EM30 0.625-11 4

VGF31EM40 0.625-11 8

VGF31EM50 0.750-10 8

VGF31EM60 0.750-10 8

VGF32EM25 0.750-10 8

VGF32EM30 0.750-10 8

VGF32EM40 0.750-10 8

VGF32EM50 0.750-10 8

VGF32EM60 0.750-10 12

VGF31LD25 0.625-11 4

VGF31LD30 0.625-11 4

VGF31LD40 0.625-11 8

VGF31LD50 0.750-10 8

VGF31LD60 0.750-10 8

VGF32LD25 0.750-10 8

VGF32LD30 0.750-10 8

VGF32LD40 0.750-10 8

VGF32LD50 0.750-10 8

VGF32LD60 0.750-10 12

Stroke Y

E

B

C

D

A

DOTTED LINE REPRESENTS ANSI 125

1

VALVE BODY.

M22420

Fig. 3. Dimensions for two-way models in inches (mm)

(See Table 8).

IMPORTANT

Valve sizing is important for correct system operation. Undersized valves do not have sufficient

capacity at maximum load. Oversized valves do not

have sufficient authority over the load in modulating applications.

Oversized valves can initiate hunting and the seat

and throttling plug can be damaged because of

the restricted opening. Some variables that must

be determined are:

•Medium (steam, water, glycol solution 50 percent

•Maximum temperature and pressure of the

•Pressure differential that exists across the valve

•Maximum capacity the valve must deliver.

•Maximum line pressure differential against which

maximum) to be controlled.

medium at the valve.

under maximum load conditions.

the valve actuator must close.

Fig. 4. Dimensions for three-way models in inches (mm)

(See Table 8).

63-2618—01 8

Page 9

VGF FLANGED GLOBE VALVES

Table 8. Valve Sizes, Flow Capacities, and Dimensions.

Dimensions, in. (mm)

Model

Number

Size

in. DN A B C D E

Cv (kvs)

See Fig. 3 (Two-way Valves) or Fig. 4 (Three-way Valves)

a

Y (stroke)

2-way valves, ANSI Class 125 Stem down to close. Equal percentage or Linear flow characteristic.

VGF21_S25 2-1/2 65 70 (60) 10-7/8 (276) 4-3/8 (112) 7 (178) —

VGF21_S30 3 80 125 (108) 11-3/4 (298) 6-3/8 (161) 7-1/2 (191) —

3-1/2 (89) 3/4 (19)

VGF21_S40 4 100 155 (133) 13-7/8 (352) 5-7/8 (150) 9 (229) —

5-1/4 (133) 1-1/2 (38)VGF21_S50 5 125 320 (275) 15-3/4 (400) 6-3/16 (157) 10 (254) —

VGF21_S60 6 150 370 (318) 17-3/4 (451) 6-3/16 (157) 11 (279) —

2-way valves, ANSI Class 250. Stem down to close. Equal percentage flow characteristic.

VGF22ES25 2-1/2 65 70 (60) 11-1/2 (292) 4-3/8 (112) 7-1/2 (191) —

VGF22ES30 3 80 120 (103) 12-1/2 (318) 6-3/8 (161) 8-1/4 (210) —

3-1/2 (89) 3/4 (19)

VGF22ES40 4 100 150 (129) 14-1/2 (368) 5-7/8 (150) 10 (254) —

5-1/4 (133) 1-1/2 (38)VGF22ES50 5 125 320 (275) 16-5/8 (422) 6-3/16 (157) 11 (279) —

VGF22ES60 6 150 370 (318) 18-5/8 (473) 6-3/16 (157) 12-1/2 (318) —

2-way valves, Pressure-balanced, ANSI Class 125. Stem down to close. Equal percentage or Linear flow characteristic.

VGF21_P25 2-1/2 65 70 (60) 10-7/8 (276) 4-3/16 (107) 7 (178) —

VGF21_P30 3 80 115 (99) 11-3/4 (298) 5-7/8 (150) 7-1/2 (191) —

3-1/2 (89) 3/4 (19)

VGF21_P40 4 100 150 (129) 13-7/8 (352) 5-7/8 (150) 9 (229) —

5-1/4 (133) 1-1/2 (38)VGF21_P50 5 125 285 (245) 15-3/4 (400) 6-1/8 (156) 10 (254) —

VGF21_P60 6 150 370 (318) 17-3/4 (451) 6-1/8 (156) 11 (279) —

3-way Mixing valves, ANSI Class 125. Stem up to close A-AB.

VGF31EM25 2-1/2 65 70 (60) 10-7/8 (276) 3-15/16 (100) 7 (178) 3-3/4 (95)

VGF31EM30 3 80 120 (103) 11-3/4 (298) 3-15/16 (100) 7-1/2 (191) 4-3/8 (111)

4-3/16 (107) 3/4 (19)

VGF31EM40 4 100 150 (129) 13-7/8 (352) 5-8/16 (140) 9 (229) 5-1/8 (130)

6-11/16 (170) 1-1/2 (38)VGF31EM50 5 125 320 (275) 15-3/4 (400) 5-3/8 (137) 10 (254) 5-3/4 (146)

VGF31EM60 6 150 370 (318) 17-3/4 (451) 5-11/16 (145) 11 (279) 6-5/8 (168)

3-way Mixing valves, ANSI Class 250. Stem up to close A-AB.

VGF32EM25 2-1/2 65 70 (60) 11-1/2 (292) 4-3/8 (112) 7-1/2 (191) 3-3/4 (95)

VGF32EM30 3 80 115 (99) 12-1/2 (318) 6-3/8 (161) 8-1/4 (210) 4-3/8 (111)

4-3/16 (107) 3/4 (19)

VGF32EM40 4 100 170 (146) 14-1/2 (368) 5-7/8 (150) 10 (254) 5-1/8 (130)

6-11/16 (170) 1-1/2 (38)VGF32EM50 5 125 320 (275) 16-5/8 (422) 6-3/16 (157) 11 (279) 5-3/4 (146)

VGF32EM60 6 150 370 (318) 18-5/8 (473) 6-3/16 (157) 12-1/2 (318) 6-5/8 (168)

3-way Diverting valves, ANSI Class 125. Stem down to close AB-A.

VGF31LD25 2-1/2 65 70 (60) 10-7/8 (276) 3-15/16 (100) 7 (178) 3-3/4 (95)

VGF31LD30 3 80 120 (103) 11-3/4 (298) 3-15/16 (100) 7-1/2 (191) 4-3/8 (111)

4-3/16 (107) 3/4 (19)

VGF31LD40 4 100 160 (138) 13-7/8 (352) 5-8/16 (140) 9 (229) 5-1/8 (130)

6-11/16 (170) 1-1/2 (38)VGF31LD50 5 125 285 (245) 15-3/4 (400) 5-3/8 (137) 10 (254) 5-3/4 (146)

VGF31LD60 6 150 380 (327) 17-3/4 (451) 5-11/16 (145) 11 (279) 6-5/8 (168)

3-way Diverting valves, ANSI Class 250. Stem down to close AB-A.

VGF32LD25 2-1/2 65 70 (60) 11-1/2 (292) 4-3/8 (112) 7-1/2 (191) 3-3/4 (95)

VGF32LD30 3 80 120 (103) 12-1/2 (318) 6-3/8 (161) 8-1/4 (210) 4-3/8 (111)

4-3/16 (107) 3/4 (19)

VGF32LD40 4 100 160 (138) 14-1/2 (368) 5-7/8 (150) 10 (254) 5-1/8 (130)

6-11/16 (170) 1-1/2 (38)VGF32LD50 5 125 285 (245) 16-5/8 (422) 6-3/16 (157) 11 (279) 5-3/4 (146)

VGF32LD60 6 150 380 (327) 18-5/8 (473) 6-3/16 (157) 12-1/2 (318) 6-5/8 (168)

a

With stem fully down.

9 63-2618—01

Page 10

VGF FLANGED GLOBE VALVES

12

(83)

13

(90)

14

(96)

15

(103)

16

(110)

17

(117)

18

(124)

19

(131)

20

(138)

21

(144)

22

(152)

23

(159)

24

(165)

25

(172)

12

(83)

11

(76)

13

(90)

14

(96)

15

(103)

16

(110)

17

(117)

18

(124)

12

(83)

11

(76)

13

(90)

14

(96)

15

(103)

16

(110)

17

(117)

18

(124)

19

(131)

20

(138)

21

(144)

22

(152)

23

(159)

24

(165)

25

(172)

19

(131)

20

(138)

21

(144)

22

(152)

23

(159)

24

(165)

25

(172)

7

(48)

8

(55)

9

(62)

10

(69)

0

(0)10(69)20(138)30(207)

40

(276)

60

(414)70(483)

50

(345)

80

(552)90(621)

100

(690)

110

(759)

120

(828)

130

(897)

140

(966)

150

(1035)

160

(1104)

2-7

(15-50)

4-11

(30-75)

8-12

(55-85)

SPRING RANGE

PSI (kPa)

SIZE 2-1/2 IN. AND 3 IN.

WITH 8 IN. D.A. PNEUMATIC ACTUATOR

(NORMALLY OPEN PORTS B TO AB)

AIR PRESSURE IN ACTUATOR PSI (kPa)

CLOSEOFF PRESSURE RATINGS PSI (kPa)

CLOSEOFF PRESSURE AT VARIOUS CONTROL AIR PRESSURES FOR VGF FLANGED VALVES AND MP953 PNEUMATIC ACTUATORS.

AIR PRESSURE REQUIRED TO OPERATE PRESSURE-BALANCED VGF FLANGED VALVES.

1

2

1

SIZE 2-1/2 INCH

SIZE 3 INCH

M36506

2 2

2

(15)

1

(5)

0

(0)

L*

U**

*L - LOWER SEAT

**U - UPPER SEAT

4

(30)

3

(20)

2

(15)

1

(5)

0

(0)

8

(55)

7

(50)

6

(40)

5

(35)

4

(30)

3

(20)

2

(15)

1

(5)

0

(0)

L*

U**

L*

U**

SPRING RANGE

2-7

(15-50)

7

2

(48)

(15)

1

8

(5)

(55)

9

0

(62)

(0)

10

(69)

11

(76)

12

(83)

13

(90)

AIR PRESSURE IN ACTUATOR PSI (kPa)

14

(96)

15

(103)

L*

U**

*L - LOWER SEAT

**U - UPPER SEAT

PSI (kPa)

(76)

(83)

13

(90)

(96)

(103)

(110)

(117)

(124)

(131)

1

SIZE 2-1/2 AND 3 IN. D.A. FLANGED BODIES

8-12

4-11

(55-85)

(30-75)

12

8

4

11

(83)

(55)

(30)

13

7

3

12

(90)

(50)

(20)

14

6

2

(96)

(40)

(15)

15

14

15

16

17

18

19

L*

5

1

(103)

(35)

(5)

4

0

16

(30)

(0)

(110)

17

3

(117)

(20)

2

18

(15)

(124)

1

19

(5)

(131)

0

20

(0)

(138)

0

(0)

L*

U**

U**

1

WITH 7 IN. R.A. PNEUMATIC ACTUATOR

(NORMALLY CLOSED)

SIZE 2-1/2 INCH

SIZE 3 INCH

25

(172)

30

(207)

35

(241)

40

(276)

10

5

(69)

(35)

USE 8-13 PSI (55-90 kPa) RANGE FOR DETERMINING CLOSEOFF OF VALVES

USED WITH MP953F ACTUATORS.

20

15

(138)

(104)

CLOSEOFF PRESSURE RATINGS PSI (kPa)

(310)

50

45

(345)

55

(379)

Fig. 5. Close-off pressures with 7 in. RA Pneumatic Actuator.

60

(414)

M36642

63-2618—01 10

Fig. 6. Close-off pressures with 8 in. D.A. pneumatic actuators.

Page 11

VGF FLANGED GLOBE VALVES

WARNING

SIZE 2-1/2 IN., 3 IN., 4 IN., 5 IN., 6 IN.

WITH 13 IN. D.A. PNEUMATIC ACTUATOR

(NORMALLY OPEN PORTS B TO AB)

CLOSEOFF PRESSURE RATINGS PSI (kPa)

SIZE 2-1/2 INCH

SIZE 3- AND 4-INCH

M36643

SIZE 5- AND 6-INCH

CLOSEOFF PRESSURE AT VARIOUS CONTROL AIR PRESSURES FOR

VGF FLANGED VALVES AND MP953 PNEUMATIC ACTUATORS.

AIR PRESSURE REQUIRED TO OPERATE PRESSURE-BALANCED VGF VALVES.

1

2

0

(0)10(69)20(138)30(207)

40

(276)

60

(414)70(483)

50

(345)

80

(552)90(621)

100

(690)

110

(759)

120

(828)

130

(897)

140

(966)

150

(1035)

160

(1104)

2 2 2

12

(83)

13

(90)

14

(96)

15

(103)

16

(110)

17

(117)

18

(124)

19

(131)

20

(138)

21

(144)

22

(152)

23

(159)

24

(165)

25

(172)

12

(83)

11

(76)

13

(90)

14

(96)

15

(103)

16

(110)

17

(117)

18

(124)

12

(83)

11

(76)

13

(90)

14

(96)

15

(103)

16

(110)

17

(117)

18

(124)

19

(131)

20

(138)

21

(144)

22

(152)

23

(159)

24

(165)

25

(172)

19

(131)

20

(138)

21

(144)

22

(152)

23

(159)

24

(165)

25

(172)

7

(48)

8

(55)

9

(62)

10

(69)

2-7

(15-50)

4-11

(30-75)

8-12

(55-85)

SPRING RANGE

PSI (kPa)

AIR PRESSURE IN ACTUATOR PSI (kPa)

1

2

(15)

1

(5)

0

(0)

L*

U**

*L - LOWER SEAT

**U - UPPER SEAT

4

(30)

3

(20)

2

(15)

1

(5)

0

(0)

8

(55)

7

(50)

6

(40)

5

(35)

4

(30)

3

(20)

2

(15)

1

(5)

0

(0)

L*

U**

L*

U**

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check ratings given in instructions and on the prod-

uct to ensure the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

Fig. 7. Close-off pressures with 13 in. D.A pneumatic actuators.

4. After installation is complete, check out product

operation as provided in these instructions.

Severe Burn Hazard.

Contact with hot liquid can lead to severe injury

or cause death.

Release system pressure and isolate or drain the

valve pipe section so the medium (steam, water or

glycol solution) does not leak out of the valve body

during installation (see Fig. 9).

11 63-2618—01

Page 12

VGF FLANGED GLOBE VALVES

CAUTION

M22590

M22592

133 IN-LB

(15 NM)

M22593

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply to the actuator to prevent

electrical shock and equipment damage, or

remove and cap the air line to the actuator.

IMPORTANT

• Before installing the valve, raise and lower the

valve stem to make sure that the valve stem operates freely. Impaired stem operation can indicate

that the stem was bent by rough handling. This

condition can require replacing the valve.

• Protect the stem from damage due to bending or

scratching.

NOTES:

• Some non-pressure balanced valves have stem travel

greater than the published 3/4 in. (20 mm) or 1-1/2 in.

(38 mm) control stroke. This is due to use of bodies

shared with pressure-balanced models.

• The first 3/4 inch (20mm) of the stroke is the control

stroke of the 2-1/2 and 3 inch valves.

• The first 1-1/2 inch (38 mm) of stroke is the control

stroke of the 4 to 6 inch valves.

Proper Use

These valves are only for use in cold, warm, hot water

systems and for steam applications. They are designed for

the medium temperature ranges listed in the

specifications. They are to be operated with the

appropriate Honeywell actuators only. Water should be

properly filtered, treated and conditioned according to

local conditions. The installation of a strainer is strongly

recommended.

IMPORTANT

The presence of iron oxide (red rust) in the system

voids the valve warranty. The use of rust inhibitors

is recommended.

Safety

The valves are to be installed by skilled personnel and in

strict accordance with the installation instructions and

local regulations. (See Fig. 8 for proper hoisting method.)

Honeywell assumes no responsibility for damages or

injuries resulting from non-compliance with installation

instructions or standard good practice when mounting,

operating, or maintaining the valves, even if not explicitly

mentioned in the installation instructions. (See Fig. 10 for

basic pipe orientation.) Observe all safety practices when

working with steam systems.

Fig. 10. Basic pipe orientation.

Fig. 8. Proper hoisting of VGF Valves.

M22591

Fig. 9. Piping must prevent leakage.

63-2618—01 12

Fig. 11. Basic proper bolt length.

Page 13

VGF FLANGED GLOBE VALVES

COMPANION

FLANGE

GASKET

GASKET

GASKET

BE SURE FACE OF COMPANION FLANGE IS FLUSH

WITH FACE OF VALVE-BODY FLANGE AND ALIGNED

SQUARELY BEFORE TIGHTENING MOUNTING NUTS.

OPTIONAL SERVICE FLANGE

COMPANION FLANGE

PIPE

M7977

Location

Select a location where the valve and actuator are

accessible. Allow sufficient space for servicing the valve

and actuator. See Fig. 3 and 4 for valve body dimensions.

7. Use mounting bolts long enough so the nuts can use

the full length of the nut threads. (See Fig. 11.) Use

bolts 1/8 in. smaller than the diameter of the bolt

hole to allow clearance for installing. (See Fig. 12.)

Mounting Actuator

For information on mounting, refer to the Product Data

literature for the actuator. It is important to have the

correct actuator available for the installation. See Table 9

for recommended installation clearance from valve

bonnet.

IMPORTANT

When using VGF valves with pneumatic MP953C

and MP953E direct acting actuators, the following

stroke limiting accessories are required to prevent

over-travel and damage to the diaphragm. See Fig.

21:

• VGF21ES25 - 272629A (stem collar, purchased

separately)

• VGF21ES30 - 272629A (stem collar, purchased

separately)

• VGF21LS25 - 272629A (stem collar, purchased

separately)

• VGF21LS30 - 272629A (stem collar, purchased

separately)

• VGF31EM25 - stem collar (provided with valve)

• VGF31EM30 - stem collar (provided with valve)

Fig. 12. Flanged valve body installation.

Mounting the Valve

See Fig. 12 for typical installation.

1. Hoist valve by its body only. Do not lift by stem, bon-

net, flanges, or flange holes. (See Fig. 8.)

2. Install the valve so the flow follows the direction of

3. Install the valve so the actuator is above the valve

4. When controlling steam, use appropriate high

5. Use companion flanges with the same number of

6. Use a gasket material recommended for the medium

the arrow indicated on the valve body.

body. The valve can be installed in any position

between vertical and horizontal. Do not install the

valve with the stem below horizontal or upside down.

temperature kit 43196000 and rotate valve body so

that actuator is not positioned directly above the

piping.

bolt holes and dimensions as the valve to be

installed. (See Table 7.) Use standard cast-iron

flanges for the two end ports.

to be handled.

Table 9. Installation Clearances (from Valve Bonnet).

Actuator Minimum Vertical Clearance in in. (mm)

ML6420, ML7420 12-11/16 (322)

ML6421A, ML7421A 14-1/4 (360)

ML6421B, ML7421B 16-7/8 (430)

ML6425A,B; ML7425A,B 14-5/16 (364)

MN/MS Series + Q5020 12 (305)

Modutrol IV + Q5001 14-1/2 (369)

MP953C (8 inch dia) 11-7/8 (302)

MP953C (13 inch dia) 17-11/16 (449)

MP953E (8 inch dia) 16-1/2 (420)

MP953E (13 inch dia) 25-13/16 (655)

MN/MS Series + Q5024 18 (457)

CHECKOUT

For instructions for operating the valve actuator, see the

Product Data sheet for the specific actuator.

1. Operate the control system and check valve opera-

tion to ensure the valve stem can position the valve

smoothly through full stroke without binding.

2. Verify that the actuator fully closes the A port.

3. Perform the checkout tests included with the actua-

tor instructions.

13 63-2618—01

Page 14

VGF FLANGED GLOBE VALVES

2

4

3

1

MP953E

MP953C

POSITIONER

ON MP953E ONLY

MINUMUM

CLEARANCE

MP953C, E

1 2 3

4

M7993B

OPERATION SIZE

NOMINAL DIA

8-INCH

13-INCH

8-1/4 (210)

13-1/2 (343)

11-1/8 (283)

18-1/8 (460)

6-1/2 (165)

10 (254)

5-3/8 (137)

7-11/16 (195)

2-1/2

(64)

7 (178 ) X 7 (178)

5-5/8

(142)

KNOCKOUTS

(2)

7/8 (22)

9-3/8

(239)

10-3/8

(264)

14-1/4

(360)

MINIMUM

CLEARANCE

ML6421A

YOKE DIAMETER 1-3/8 (35)

M7978

ML6421B

2-1/2

(64)

7 (178 ) X 7 (178)

KNOCKOUTS

(2)

7/8 (22)

8

(204)

11-7/8

(301)

CLEARANCE

12-3/4

(326)

16-7/8

(430)

MINIMUM

Fig. 13. MP953C-F Pneumatic Actuator

dimensions in in. (mm).

YOKE DIAMETER 1-7/8 (48)

M7979

Fig. 15. ML6421B and ML7421B Actuator (use with

4, 5, and 6 in. valves) dimensions in in. (mm).

Fig. 14. ML6421A and ML7421A Actuator (use with

2-1/2 and 3 in. valves) dimensions in in. (mm).

63-2618—01 14

Page 15

Fig. 16. ML6425A,B; ML7425A,B Actuator (use with

5-5/15

(135)

6-5/16

(161)

x

2-11/16 (67)

14-5/16 (364)

MINIMUM

CLEARANCE

11-1/4

(284)

7-5/8

(192)

M7892A

1/2 (13) FPT

YOKE

DIAMETER

1-3/8 (35)

4-5/8 (117)

9-1/2

(241)

6-9/16

(166)

1-7/8

(48)

11Q5020A,B,D: 4-7/16 (112)

Q5020C: 3-7/8 (98)

M16346A

2-1/2 and 3 in. valves) dimensions in in. (mm).

VGF FLANGED GLOBE VALVES

Fig. 17. Q5020 Actuator Linkage dimensions in in. (mm).

Q5024B2230/Q5024B2240

E

B

A

D

C

M36664

Linkage A B C D E Shaft Dia.

Q5024B2230

Q5024B2240

4-3/8” 4” 6” 11” 2-3/8” 19mm

Fig. 18. Q5024 Dimensions.

15 63-2618—01

Page 16

VGF FLANGED GLOBE VALVES

OPERATION

Two-Way Valves

Figs. 19 and 20 shows 2-way valves in the fully closed

position.

Pressure-Balanced Valve (Fig. 19)

The pressure-balanced design combines close-off

pressures comparable to a ball valve with traditional globe

valve flow control accuracy in large valve body sizes.

The pressure-balanced valve seat includes a sealed

pressure chamber. These valves operate as follows:

1. With the valve closed, pressure at the A port is pres-

ent in the chamber that forms the upper section of

the plug.

2. This equalizes the pressure above and below the

seat.

NOTE: As the valve opens/closes, the chamber pressure

equalizes in either direction.

3. As a result, the pressure of the medium does not

affect the ability of the actuator to open/close the

valve. The valve actuator works against only pressure

chamber seal friction.

4. This is particularly useful when the pressure of the

medium undergoes significant variation.

5. Regardless of pressure variation, valve operation is

relatively smooth throughout the travel of the stem.

PRESSUREBALANCED

VALVE

PLUG

A PORT

AB PORT

M22616C

Fig. 19. Two-way pressure-balanced valve operation.

STANDARD

VALVE

PLUG

NOTE: Both equal percentage (VGF21EP) and linear

(VGF21LP) flow characteristics are offered.

Standard Plug Valve (Fig. 20)

These valves have a metal-to-metal seat. As these models

share body castings with the pressure-balanced models,

the full stroke of the valve stem can be greater than the

control stroke dimension. (See dimension Y, in Table 8.)

Dimension Y is measured from the closure of the A port.

Honeywell actuators are constructed to this Y dimension,

and limit stem travel accordingly.

Flow does not increase with stem travel greater than 3/4

in. (20 mm) in 2-1/2 and 3 in. valves,

IMPORTANT

All VGF valves reference their flow and stroke to

the A port; actuators must be configured to provide positive closure of this port.

A PORT

AB PORT

M36096

Fig. 20. Two-way standard valve operation.

Three-Way Valves

Figs. 21 and 22 show 3-way valves in the fully closed

position, with no flow between the A port and AB port.

ELECTRIC CONTROL

Upon power failure:

• Spring return actuators return the valve to its normal

position. This position (open or closed to the A or the B

port) depends on the actuator installation.

• Non-spring return actuators hold the last commanded

position.

PNEUMATIC CONTROL

Upon loss of control air pressure:

• The actuator returns the valve to its normal position.

This position (open or closed to the A or the B port)

depends on the actuator model.

63-2618—01 16

Page 17

VGF FLANGED GLOBE VALVES

A

B PORT

AB PORT

A PORT

M36097

STEM

DOWN

Mixing Valve (Fig. 21)

• As the stem moves downward:

— Flow from port B to AB decreases linearly.

— Flow from port A to AB increases at an equal per-

centage rate.

• As the valve stem moves upward:

— Flow from port B to AB increases.

— Flow from port A to AB decreases.

NOTE: The B port seat of the VGF3_EM valves is con-

structed as a cage, not as a seat, and moves

through the B port. It does not offer tight closeoff. For leakage specifications, see Table 4. B port

flow is at a minimum when stem travel down is

3/4 in. (20 mm) in 2-1/2 and 3 in. mixing valves.

OUTDOOR RESET CONTROL (FIG. 24)

• Connect the A port to a boiler output.

• Connect the B port to the system return.

AIR HANDLING APPLICATIONS (FIG. 23)

• Connect the A port to the output of a coil.

• Connect the B port to the coil bypass.

BOILER/CHILLER BYPASS (FIG. 25)

• VGF mixing valves are not recommended for boiler or

chiller bypass due to B port close-off ratings. Use

diverting model instead.

IMPORTANT

VGF Mixing Valves are assembled through the

lower (B) port. The B port stop collar (see Fig. 21)

holds the stem and plug assembly in the bonnet.

Ensure the stem remains raised while servicing

the valve or installing stem extensions. The stem

collar provides a hard stop for direct-acting

MP953 pneumatic actuators, and should not be

removed.

AIR HANDLING APPLICATIONS (FIG. 26)

• Connect the A port to the coil supply.

• Connect the B port to the system return.

NOTE: The A and B connections may be reversed when

using pneumatic actuators.

STEM

UP

B PORT

STOP COLLAR

PORT

B PORT

1

B PORT STOP COLLAR IS SHIPPED ON VGF31EM25/30

AND VGF32EM25/30 VALVES.

1

AB PORT

M22410C

Fig. 21. VGF31EM mixing valve operation.

NOTE: B port stop collar is shipped on VGF31EM25/30

and VGF32EM25/30 valves.

Note that the full stroke of the valve stem can be greater

than the control stroke dimension, Y, in Table 8, which is

measured from the closure of the A port. Honeywell

actuators are constructed for this Y dimension, and limit

stem travel appropriately.

DIVERTING VALVE (FIG. 22)

• As the valve stem moves downward:

— Flow from port AB to A decreases linearly.

— Flow from port AB to B increases linearly.

• As the valve stem moves upward:

— Flow from port AB to A decreases.

— Flow from port AB to B increases.

OUTDOOR RESET CONTROL (FIG. 25)

• Connect the A port to the building supply.

• Connect the B port to the boiler return.

Fig. 22. VGF31LD diverting valve operation.

17 63-2618—01

Page 18

VGF FLANGED GLOBE VALVES

FULL

HEAT

PROPORTIONED

HEAT

SUPPLY

MAIN

RETURN

MAIN

NO

HEAT

HEATING COIL

VGF3

AB

5 GPM

A

B

5 GPM

AB

5 GPM

A

B

2.5 GPM

2.5 GPM

VGF3

VGF3

AB

5 GPM

A

B

5 GPM

NO FLOW

THROUGH COIL

A

B

C

M36098

VGF31EM

AAB

B

BOILER

Fig. 24. Supply mixing for reset control.

MIXED

DISCHARGE

WATER TO

HEAT LOAD

PUMP

M36099

Fig. 23. Three-way mixing valve operation with coil by-

pass.

BOILER

CHECK

VALVES

B

A

VGF31LD

BYPASS

AB

PUMP

M36100

Fig. 25. Boiler bypass for reset control.

AB PORT A PORT

SUPPLY

RETURN

B PORT

Fig. 26. Three-way valve flow orientation.

COIL

AB PORT A PORT

RETURN

SUPPLY

MIXINGDIVERTING

COIL

B PORT

M13737B

63-2618—01 18

Page 19

CHECKOUT AND TROUBLESHOOTING

VGF FLANGED GLOBE VALVES

Actuators

NOTE: For valve actuator operation instructions, see the

Valve does not move freely

Valve Leak-by • Damage to the plug or seat caused by particulate, wire draw, or steam corrosion requires valve replacement.

Valve stem leaks

Improper Control

Noisy Valve

Actuator Failure in Steam Applications

Product Data sheet for the specific actuator.

Table 10. VGF Valve Checkout and Troubleshooting.

Topic Information

• Possible cause: Contamination. Over time, scale, rust, magnetite, sand, and silt can cause wear of valve components.

• The presence of suspended rust in a hydronic system voids most industry warranties.

• Appropriate system flushing, filtration, and chemical treatment are required to maintain proper operating

conditions.

• Boiler and chiller manufacturers publish water quality guidelines. Specific conditioning regimens depend on system.

• Replace the stem packing using the matching repacking kit. (See the Specifications section for the proper

accessory.)

• If the valve stem is bent, the valve must be replaced.

• Pressure drop across the valve must be at least as great as the pressure drop across the controlled load. If not, valve

authority and control span are reduced.

• If necessary, use pipe transitions in order to use a valve body with the proper Cv rating. Transition should be installed

approximately 6 pipe diameters from valve.

• Limit differential pressure across valve seats to 20 psi.

• This recommendation is independent of published close-off ratings.

• Take care not to exceed valve temperature ratings. This can result in damage not covered by the Honeywell limited

warranty.

• To protect actuators from excess heat, orient the valve so the actuator is not directly over the piping, and/or use a

43196000 High Temperature Kit.

1. Operate the control system and check valve opera-

tion to ensure the valve stem can position the valve

smoothly through full stroke without binding.

2. Verify that the actuator fully closes the A port.

3. Perform the checkout tests included with the actua-

tor instructions.

TYPICAL SPECIFICATIONS

Valve housing shall consist of cast iron and shall be ANSIrated to withstand the pressures and temperatures

encountered. Automatic control valves shall have flanged

fittings, 2-1/2 in. through 6 in. size.

Valves shall have stainless steel plugs, seats, and stems,

and be constructed with replaceable spring-loaded

reinforced carbon-filled Teflon packing.

Straight through and diverting valves shall have a

maximum seat leakage rate of 0.05% Cv at the control

port and shall have 50:1 rangeability or better. Pressurebalanced valves shall have a maximum seat leakage rate

of 0.01% at 175 psi differential pressure.

All valves shall be provided with either linear or equal

percentage contoured throttling plugs for water, glycolwater, or steam service. Three-way valves shall be

available in either mixing or diverting configurations.

Valves shall be manufactured by the same company that

manufactures the direct coupled linear valve actuators or

linkages and rotary actuators.

19 63-2618—01

Page 20

VGF FLANGED GLOBE VALVES

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of

your use or modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries,

from and against any liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any

modification to the literature by you.

Home and Building Technologies

In the U.S.:

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422-3992

customer.honeywell.com

® U.S. Registered Trademark

© 2016 Honeywell International Inc.

63-2618—01 M.S. Rev. 12-16

Printed in United States

Loading...

Loading...