Page 1

PRODUCT HANDBOOK

UNIVERSAL GAS VALVES

VG SERIES

SAFETY SOLENOID VALVES

EN2R--9012 9412R0--NE

APPLICATION

Theseseries manually operated

safety solenoid valves are used in

gas leak detection systems.

CONTENTS

General

Description 2

Features 3

Model chart 4

Technical

Specifications 5

Performance characteristics 6

Capacitycurves 7--8

Dimensional drawing 1000 series 9

Dimensional drawing 3000 series 10

Installation and operation

Installation and final checkout 11

Construction and working principles 12

Various

Approvals and standards 13

Ordering information 14

Replacement parts and accessories 15

Subject to change without notice. Printed in the Netherlands.

Page 2

2

EN2R--9012 9412R0--NE

DESCRIPTION

The VG series safety solenoid valves

offerthe following func tionality:

Normally c losed valve. Manual opening

when energized.

The VG series safety solenoid valves

are suitable forthe control of g aseous

fluids in gas consuming appliances

according to international standards.

The VG series safety solenoid valves

meet the class A specification

according EN161.

The VG series safety solenoid valves

coverawiderangeofpipesize

connections.

From

3

/8” (DN 10) upto and including

3” (DN 80).

The VG series safety solenoid valves

are available withtreaded connection

from

3

/8” (DN 10) upto and including 3”

(DN 80).

The VG series safety solenoid valves

areavailablewith2

1

/2” (DN 65) and

3” (DN 80) flang ed connection.

The VG series safety solenoid valves

have 2 auxiliary pressure stops with

Rp

1

/4” threaded connection b oth at the

inletpressure side of the valve.

The VG series safety solenoid valves

have an inlet sc reen forprotecting the

valve against ingress of dirt.

Page 3

3

EN2R--9012 9412R0--NE

FEATURES

:

Class ” A” manually operated safety

solenoid valves for use in gas leak

detec tion systems.

:

The VGxxxxAseries safety solenoid

valves have a spring loaded valve

disc which closes when

de--energized.

:

All VGxxxx series safety solenoid

valves have an internal finemesh

screen.

:

Two inlet pressure stops at each side

of the valve.

:

The VGxxxx series safety solenoid

valves have incorporated in the valve

body a wrench boss as well at inlet

as at outlet side.

:

The VGxxxxx series safety solenoid

valves may be assembled on the

pipe line within

p

90 degrees of the

vertical axel.

:

The VGxxxxX3xxx (flanged

connection)series safety solenoid

valves have at inlet sid e two 1” ISO

7--1 connection tap s.

:

The VGxxxx series safety solenoid

valves have electrical connec tion by

terminal block with incorporated

rectifier board.

:

The VGxxxx series safety solenoid

valves have a field replacable

rectifier board.

:

The VGxxxx series safety solenoid

valves have coils turnable over

360

E

.

:

Cable strainrelief can be achieved

by Pg 11 cable gland.

:

The VGxxxx series safety solenoid

cover a wide rang e of pipe sizes

fromDN 10 up to and including

DN 80.

Electrical connection

:

Supply voltage 24, 110, 220 and 240

Volt 50/60 Hz.

:

Enclosureaccording to IP 54.

Page 4

4

EN2R--9012 9412R0--NE

MODEL CHART

Options 1000 series

(internal threaded)

3000 series

(flange connection)

Range: DN 103/8”

DN 15

1

/2”

DN 20

3

/4”

DN 25 1”

DN 32 1

1

/4”

DN 40 1

1

/2”

DN 50 2”

DN 65 2

1

/2”

DN 80 3”

VG.010

VG.015

VG.020

VG.025

VG.032

VG.040

VG.050

VG.065

VG.080

--

--

--

--

--

--

-VGX065

VGX080

Non regulated ON/OFF(VGxXXXA XXXX) Standard Standard

Page 5

5

EN2R--9012 9412R0--NE

SPECIFICATIONS

Models

The VG series consists of a series

manually operated safety solenoid

valves from

3

/8” upto and including 3”

connection.

VG series solenoid valves

VG.010A (DN 10)

VG.015A (DN 15)

VG.020A (DN 20)

VG.025A (DN 25)

VG.032A (DN 32)

VG.040A (DN 40)

VG.050A (DN 50)

VG.065A (DN 65)

VG.080A (DN 80)

Pipe sizes 1000 series

Inlet and outlet

3

/8” up to and inc luding

3” internalparallel pipe thread

according to

ISO 7--1

Pipe sizes 3000 series

Flanged connection 2

1

/2” and 3”

according to PN 16 UNI 2278--67

Torsion and bending stress

Pipe connections meet Group 2

according EN161 requirements.

Ambient temperature

--1 5

E

C ... 60EC

Supply voltage

24 V, 50/60 Hz

110 V, 50/60 Hz

220 V, 50/60 Hz

240 V, 50/60 Hz

The applicable voltage is led to the

solenoid coil via a rectified circuit.

Dimensions

1000 series: See pag e 9

3000 series: See pag e 10

Electrical connection

Wiring on terminalblock on box.

Cable entry Pg 11.

Coil insulation safety solenoid

valves

Insulation material according class F

Enclosure

IP 54

IP 65 on request

Capacity

See page 7 and 8

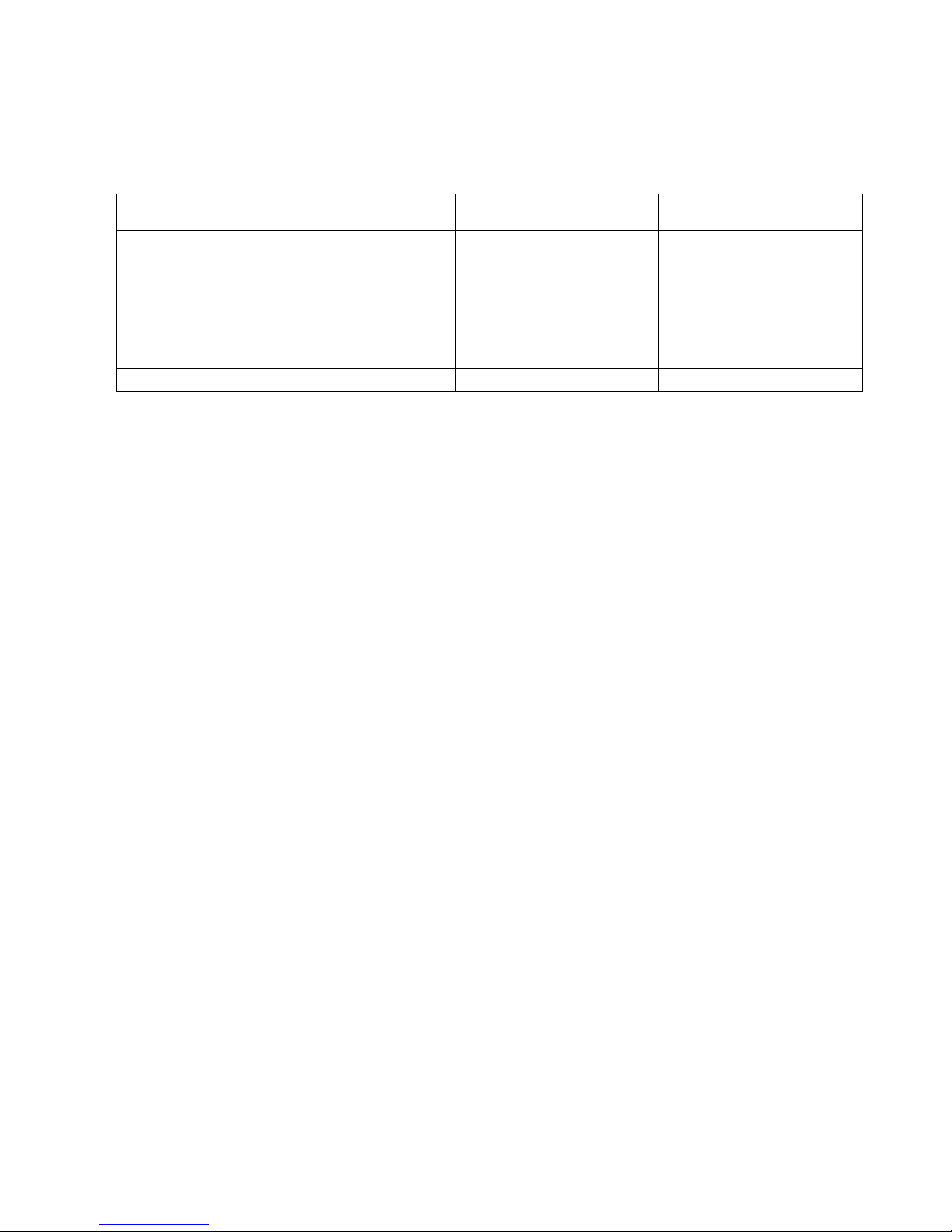

Maximum operating pressure

Model

Maximum operating

pressure (mbar)

VG.010 500

VG.015 500

VG.020 500

VG.025 500

VG.032 500

VG.040 500

VG.050 500

VG.065 350

VG.080 350

Power Consumption (W)

24 V, 50/60 Hz 110 V,50/60 Hz 220 V, 50/60 Hz 240 V,50/60 Hz

Model

number

At nominal

voltage

At 110% of

nominal

voltage

At nominal

voltage

At 110% of

nominal

voltage

At nominal

voltage

At 110% of

nominal

voltage

At nominal

voltage

At 110% of

nominal

voltage

VG.010 4 5 4 6 4,3 5 3 4

VG.015 4 5 4 6 4,3 5 3 4

VG .020 4 5 4 6 4,3 5 3 4

VG.025 4 5 4 6 4,3 5 3 4

VG.032 4 5 4 6 4,3 5 3 4

VG.040 4 5 4 6 4,3 5 3 4

VG.050 12,5 15 13 16 15,3 16 15 18

VG.065 12,5 15 13 16 15,3 16 15 18

VG.080 12,5 15 13 16 15,3 16 15 18

Page 6

6

EN2R--9012 9412R0--NE

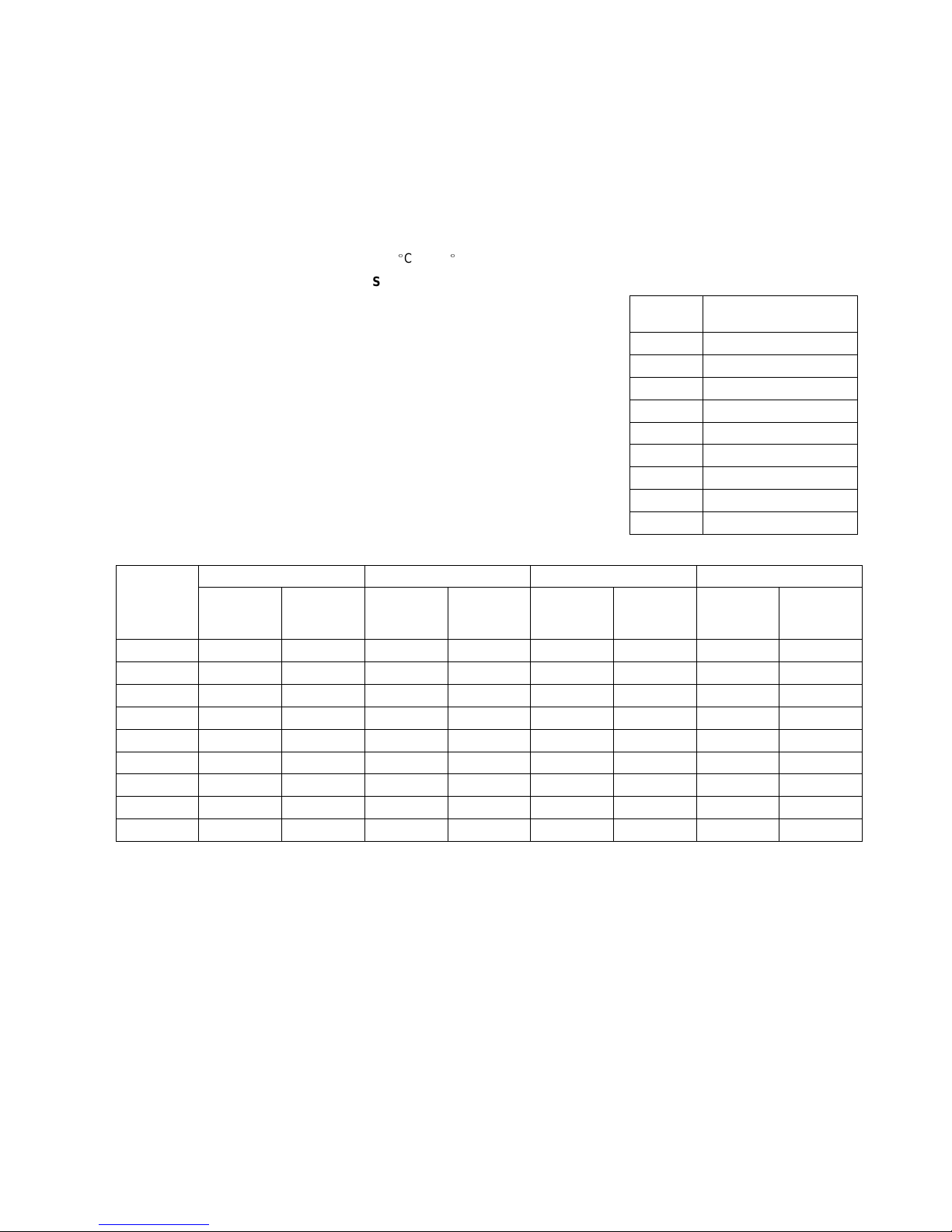

PERFORMANCE CHARACTERISTICS

Maximum allowable leakage

Model

Test pressure 1

Test pressure 2

Maximum allowable leakage rate (cm3/h)

(mbar) (mbar)

Internal External

VG.010 6 750 40 40

VG.015 6 750 40 40

VG.020 6 750 40 40

VG.025 6 750 60 60

VG.032 6 750 60 60

VG.040 6 750 60 60

VG.050 6 750 60 60

VG.065 6 525 60 60

VG.080 6 525 60 60

Opening time

Valves are manuallyopened

Closing time

Less than 1 second

Duty cycle

Coil suitable forpermanent

energization

Operationalvoltage range

The safety solenoid valve will funtion

satisfactory between 85% and 110% of

the rated voltage.

Rated voltage:

24 V, 50/60 Hz

110 V, 50/60 Hz

220 V, 50/60 Hz

240 V, 50/60 Hz

Design life

5.000 cycles

Page 7

7

EN2R--9012 9412R0--NE

CAPACITY CURVE DN10, DN15,DN 20,DN 25,DN 32 AND DN 40(THREADED

CONNECTION)

Capacity in m3/hair atap=2,5mbar

3

/8”DN10

1

/2”DN15

3

/4”DN20 1” DN 25 11/4”DN32 11/2”DN40

5 6,4 14,8 16,7 38,5 47,1

2

3

6

4

5

8

10

20

30

60

40

50

1

0,2

0,3

0,6

0,4

0,5

0,8

1

2

3

6

4

5

0,1

a

p(kPa)ap (mbar)

Vn(m3/h)

DN 25

DN 20

DN 32

DN 40

DN 15

DN 10

1 2 3 4 5 6 8 10 20 30 40 50 60 80 100 200 300

Air dv=1

Natural gas (G 25)

d

v

=0,612

Manufactured gas (G 110/120)

d

v

=0,45

Propane (G 31)

d

v

=1,562

Butane (G 30)

d

v

=2,09

0,8

2 3 4 5 6 8 10 20 30 40 50 60 80 100 200

2 3 4 5 6 8 10 20 30 40 50 60 80 100 200

1 2 3 4 5 6 8 10 20 30 40 50 60 80 100 200

1 2 3 4 5 6 8 10 20 30 40 50 60 80 100 200

0,8

300

300 400

Page 8

8

EN2R--9012 9412R0--NE

CAPACITY CURVE DN 50, DN 65, AND 80(TREADED ANDFLANGED

CONNECTION)

Capacity in m3/hair atap=2,5mbar

2”DN50

21/2”DN65 3” DN 80

66,7 94,2 131

2

3

6

4

5

8

10

20

30

60

40

50

1

0,2

0,3

0,6

0,4

0,5

0,8

1

2

3

6

4

5

0,1

a

p(kPa)ap (mbar)

Vn(m3/h)

10 20 30 40 50 60 80 100 200 300 400 500600 800 1000 2000 3000

Air dv=1

8

DN 65

DN 50

20 30 40 50 60 80 100 200 300 400 500600 800 1000 2000

20 30 40 50 60 80 100 200 300 400 500600 800 1000 2000

10 20 30 40 50 60 80 100 200 300 400 500600 800 1000 2000

10 20 30 40 50 60 80 100 200 300 400 500600 800 1000 2000

0,8

3000

3000 4000

DN 80

Natural gas (G 25)

d

v

=0,612

Manufactured gas (G 110/120)

d

v

=0,45

Propane (G 31)

d

v

=1,562

Butane (G 30)

d

v

=2,09

Page 9

9

EN2R--9012 9412R0--NE

DIMENSIONALDRAWING 1000 SERIES

Model Connec tion

Dimensions (mm)

Weight

A B C D

(kg)

VG.010 R

p

3

/8” 72 150 52 85 0,85

VG.015 R

p

1

/2” 72 150 52 85 0,85

VG.020 R

p

3

/4” 86 160 70 85 1

VG.025 Rp1” 150 160 75 85 1

VG.032 Rp11/4” 150 220 110 85 2

VG.040 Rp11/2” 150 220 110 85 2

VG.050 Rp2” 170 285 135 85 4,2

VG.065 Rp21/2” 225 330 170 120 7,5

VG.080 Rp3” 225 330 170 120 7,5

Page 10

10

EN2R--9012 9412R0--NE

DIMENSIONALDRAWING 3000 SERIES

Model Flanged

Dimensions (mm)

Weight (kg )

connection

A B C D

VG.065 21/2” 310 360 120 95 11

VG.080 3” 310 360 120 95 11,3

Page 11

EN2R--9012 9412R0--NE

11

INSTALLATION ANDFINAL CHECKOUT

Warning

:

Take c are thatinstaller is a trained

experienced service man.

:

Turn off gas supply before starting

installation.

:

Disconnect p ower supply to

prevent elec trical shock and/or

equip ment d amage.

Mounting position

The gas valve can be mounted plus or

minus 90 degrees fromthe vertical.

Mounting location

The distanc e between the gas valve

and the wall/ground, must be at least

30 cm.

Main gas connection threaded

valves

:

Take c are that dirt cannot enter the

gas valve during handling.

:

Ensure the g as flows in the same

direction as the arrow on the housing

of the gas valve.

:

Use a sound taper fitting with thread

according to ISO 7--1(BS21, DIN

2999) or a piece of new, properly

reamed pipe, free fromswarf.

:

Do not thread or tighten the pip e or

pipe fitting too far. Otherwise valve

distortion and malfunction could

result.

:

Apply a moderate amount of good

quality thread compound to the pipe

or fitting only, leaving the two end

threads bare.PTFEtape may be

used as an alternative.

:

Inordertotightenthepipeinthe

valve, d o not use the actuator as a

lever b ut use a suitable wrench

operating on the wrench bosses.

Main gas connection flanged valves

:

Take c are that dirt cannot enter the

gas valve during handling.

:

Ensure the g as flows in the same

direction as the arrow on the housing

of the gas valve.

:

Ensure thatinlet and outlet flanges

are in line and separated fromeach

other enoug h to allow the valve to be

mounted between them without

damaging the gasket.

:

Place gasket. If nec essar y grease it

slightly to keep it in place.

:

Mount gas valve between flanges

using the b olts for each flange.

Warning

Tightness test after installation

:

Paintall pipe connections and

gaskets with a strong soap and

water solution.

:

Start the appliance and check for

bubbles. If a leak is found in a p ipe

connection, remake the joint.

A gasket leak can usually be

stopp ed by tightening the mounting

screws. Otherwise, replac e the gas

valve.

Electrical connection

Caution

:

Switc h off p ower supply before

making electrical connections.

:

Take c are that wiring is in

accordance with local regulations.

Use lead wire which can withstand

105

E

C ambient.

The electric on/off operator is provided

with a terminalbloc k for elec trical

connections.

Wiring

Follow the instructions supplied by the

appliance manufacturer.

Final checkout

Setappliance in operation and observe

several complete c ycles to ensure that

components function correctly

Page 12

EN2R--9012 9412R0--NE

12

CONSTRUCTION AND WORKING PRINCIPLES

The VG series safety solenoid valves

are class A fail safe shutt--off valves.

The valve can be opened manually

afterenergizing the operator.

The operator consists of a coil and c oil

housing. Through this op erator moves

a shaft which is connected to the

closing member.On this shafta disc is

mounted which can be moved towards

the coil by pulling the setting knob and

will be kept in that position when the

operator is energized.

De--energizationwill cause the spring

loaded closing member to close.

A strainer made out of steel according

to AISI 303 is incorp orated in the valve.

Valve closing spring is mad e out of

steel ac cording to AISI 302.

Sealsand gaskets aremanufactured

out of hydrocarbon NBR resistantare

according to DIN 3535 and EN 291.

Setting knob

Coil

Gas flow direction

Valvehousing

Printed circuit

Shaft

Spring

Strainer

Shutter

Page 13

EN2R--9012 9412R0--NE

13

STANDARDS ANDAPPROVALS

Standards

The VG series safety solenoid valves

have been designed to meet the

Europ ean Standard EN 161.

The safety solenoid valve meets class

A requirements.

According to bending stress the safety

solenoid valve meets the highest

requirements.

Regarding electric safety, the VG series

safety solenoid valves can be used in

appliances acc ording to European

Standard for a household electrical

requirements EN60335 series and

industrial applications.

The VG series safety solenoid valves

also meet allElectro Magnetic

Compatability standards for

non--industrialand industrial

appliances.

Approvals

The VG series safety solenoid valves

confirm with the following

EC--directives:

:

Gas Appliance Directive

(90/396/EEC)

:

Low Voltage directive (73/23/EEC)

The fact thatthe VG series safety

solenoid valves are certified to

Europ ean Standard EN 161 means that

this series meets morestringent

requirementsthan laid down in the

essential requirementsstated in the

directives and thereforemeets the

requirements in all EC and EFTA

countries.

Details can be found in the approvals

list.

The registrationnumber specific for

each O.S.number is mentioned on the

label of the safety solenoid valve.

Page 14

EN2R--9012 9412R0--NE

14

ORDERING INFORMATION

When ordering specify:

:

Model number of VG series safety

solenoid valve required: see model

number chart below.

:

Order numbers of rep lacement p ar ts

and accessories required, i.e.

flanges, compression fittings: see

replacement parts/acc essoiries.

Note

Most mod els of valves, replacement

parts and accessories will be

available under ” TRADELINE” label.

Ask your wholesaler for details.

VG: Class ”A” manually operated safety

solenoid valve

VG

A: ON/OFF, normally closed

4: Linevoltage

8: Lowvoltage

401

A

odel number chart

9999

Valve size

010: DN 10

015: DN 15

020: DN 20

025: DN 25

032: DN 32

040: DN 40

050 DN 50

065: DN 65

080: DN 80

100: DN 100

Specification number

0

Ordering Specification number

1: Female threaded connection

3: Flange connection

Page 15

EN2R--9012 9412R0--NE

15

REPLACEMENT PARTSAND ACCESSORIES

Warning

Take c are that only qualified persons carry out the installation of p ar ts, accessories, and ad d on c omponents.

Follow the installation instructions included in the package.

Check that the selected part, accessor y or add on component is the correct one for the application in question.

Specifation of data is given in the instructionleafletin the pac kage.

Replace the old gaskets with the new ones supp lied in the p ackage and c heck forleakage when the supp ly is switc hed on

again.

Afterinstallation and/or replacement has been completed, a gas leak test mustbe carried out.

Also check the gas valve for satisfactory operation after fitting accessories

Coils

Descrip tion Order number Packing quantity

Coil for VG .010/.015/.020/.025/.032/.040A:

24 V, 50/60 Hz

110 V, 50/60 Hz

220 V, 50/60 Hz

240 V, 50/60 Hz

BB 020030

BB 020033

BB 020005

BB 020054

1

1

1

1

Coil for VG .050/.065/.080A:

24 V, 50/60 Hz

110 V, 50/60 Hz

220 V, 50/60 Hz

240 V, 50/60 Hz

BB 020027

BB 020031

BB 020006

BB 020055

1

1

1

1

Rectifier boards

Rectifierboard for 24/110/220/240 V, 50/60 Hz

model:

VE.010/.015/.020A

VE.032/.040/.050

VE.065/.080/4100

CS020065 10

Page 16

EN2R--9012 9412R0--NE

16

REPLACEMENT OFCOIL

:

Removesetting knob (1)

:

Unscrew cap (2)withsuitable

wrench and remove it from the coil

assy

:

Removecap of connection box

:

Disconnect c oil fromrectifier board

by releasing both wires from

connector (5)

:

Removecoil from exteria pipe (4)

:

Place new coil in exteria pipe (4)

:

Connect both wires to connector on

rectifier board (5)

:

Replace cap of connection box

:

Replace cap (2)

:

Replace setting knob (1)

REPLACEMENT OFRECTIFIER BOARD

:

Removecap of connection box.

:

Disconnect all electrical c onnections.

:

Remove selflocking nut in the center

of the board.

:

Removethe rectifier board

:

Place new board into the box

:

Replace selflocking nut

:

Reconnect all electrical connections

:

Replace cap of connection box

Loading...

Loading...