Page 1

VF 06

Filling valve

for closed heating systems

Product specification sheet

Application

The VF 06 filling valve permit simple and safe filling or refilling of

a closed heating system.

A pressure reducing valve, a check valve and a shutoff facility

are combined in one unit. The pressure gauge connection

enables fitting of a pressure gauge (available as an accessory)

to provide accurate checking of the pressure of a system after

filling.

Special Features

● Housing with internal and external threads

● One turn of the adjuster knob and the valve is set

● Setting directly readable on the adjuster knob

● Complett replaceable high grade synthetic material insert

● DIN/DVGW approved check valve

● Balanced-seat pressure reducing valve - inlet pressure

fluctuations do not influence outlet pressure

● Integral shutoff facility

● Alternative connections

Construction

The filling valve comprises:

● Housing

● Spring bonnet with setting scale

● Spring

● Pressure reducing valve

● Non return valve cartridge

● Shutoff insert with knurled knob

Materials

● Brass housing

● High grade, heat resistant synthetic material spring bonnet

● Springsteel spring

● High grade, heat resistant synthetic material non return

valve cartridge

● Fibre-reinforced NBR diaphragm

● NBR seals

Range of Application

Closed heating systems to DIN 4751

Technical Data

Operating temperature Maximum 70 °C

Inlet pressure Maximum 16.0 bar

Outlet pressure 0.5 bar to 3.0 bar adjustable

Set during manufacture to 1.5 bar

Connections Inlet R ½” internal and

R ¾” external threads

Outlet R ½” internal and

R ¾” external threads

Subject to change 03/99

217

Page 2

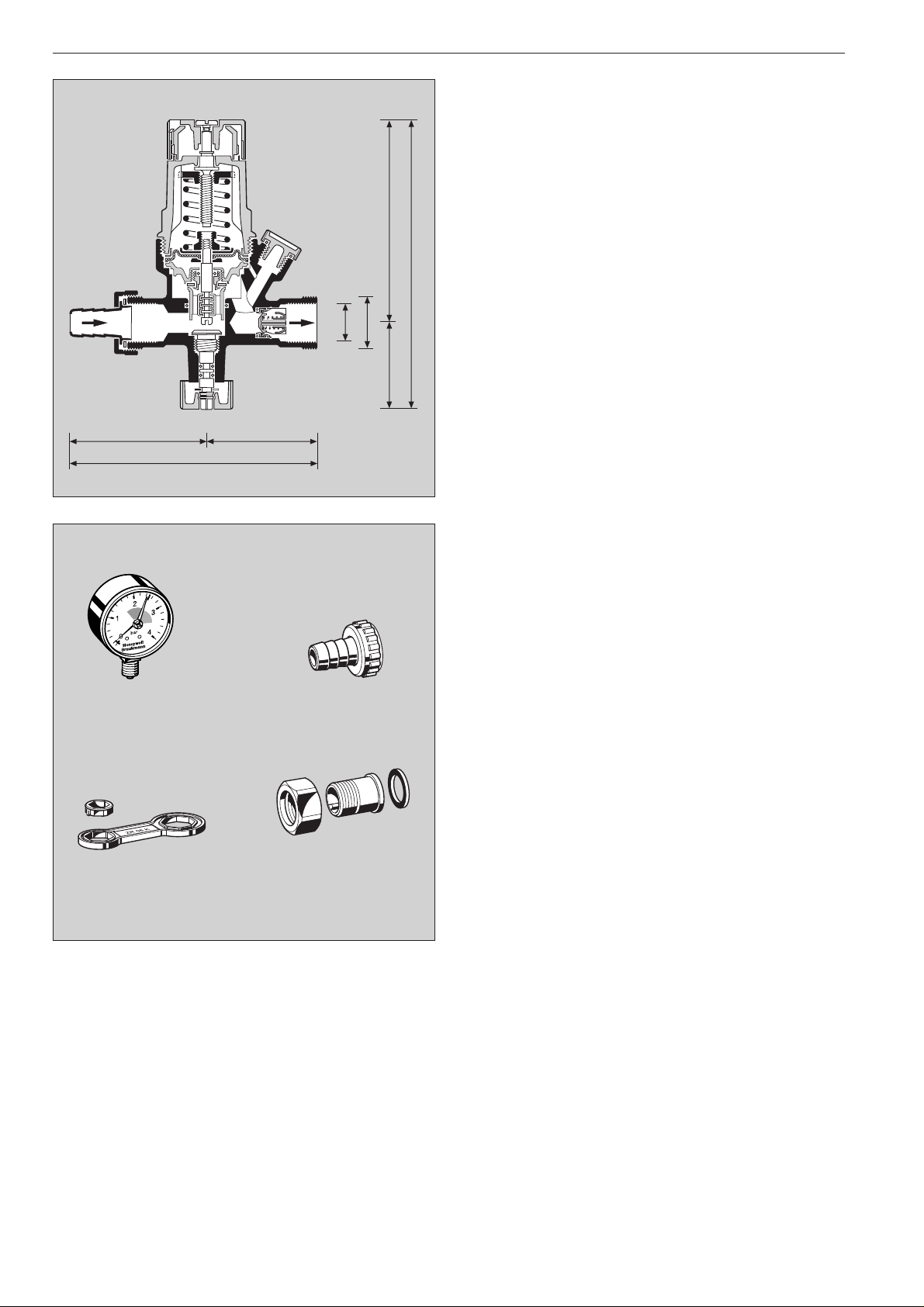

VF 06 Filling V alve

101

144

Method of Operation

The integral pressure reducing valve operates by means of a

force equalising system. The force of a diaphragm operates

against the force of an adjustment spring. The inlet pressure

does not influence either opening or closing of the valve. Inlet

pressure fluctuations do not therefore influence the outlet

pressure, thus providing inlet pressure compensation. An

integral check valve protects the drinking water supply by

allowing water to pass through in only one direction. In the flow

direction, a seal disc is pushed open against the force of a

spring by differential pressure.

(67,5)

MF 126

122,5

55

/2

0903454

3/41

43

Options

VF 06 VF 06 -

1

/2 A = With hose union connector

1

/2 B = With threaded union connector

Accessories

MF 126 Pressure gauge

63 mm diameter. Connection tapping at

bottom R ¼”, Range 0-4.0 bar, with red

hand at 1.5 bar, red mark at 2.5 bar and

green field between 1.5 and 2.5 bar

0903454 Hose connector union complete

With hose connector union, screw and

gasket ring

ZR 06 K

VST 06-½ A Connection set

With threaded union connector, screw and

gasket ring

VST 06 A

ZR 06 K Double ring wrench

For removal of the spring bonnet

218

Braukmann Water Control . Honeywell AG

Subject to change 03/99

Page 3

Installation Example (Heating system)

1

0

2

4

3

bar

6

4

10

8

2

bar

15

0

10

16

0

1

bar

4

2

3

VF 06 Filling V alve

2

3

1

4

bar

2

1

0

3

bar

4

2

1

0

3

b

a

r

4

0

Installation Guidelines

● Set adjuster scale to system filling pressure required

● Disconnect hose connection from filling valve after filling

● Check system pressure after every filling or refilling

● Ensure good accessibility

❍ Simplifies maintenance and inspection

Typical Applications

The VF 06 filling valve permit simple and safe filling or refilling of

a closed heating system.

Filling valves can be installed:

● Onto a heating circuit distributor manifold

● In combination with a water supply distributor manifold

● On a heating boiler via a fill hose

● In the supply to a heating boiler

● Directly onto a heating boiler

● As a filling set for trouble-free and safe initial filling of

a system

Subject to change 03/99 Braukmann Water Control . Honeywell AG

219

Page 4

VF 06 Filling V alve

Service Parts for VF 06 filling valves

1998 and after

Description Part Number

①

① Spring bonnet complete 0903445

1

② Valve insert complete D 06 FA-

/2

③ Check valve 2166200

1

④ Blanking plug with 'O'ring S 06 K -

/4

(Pack of 5)

②

④

③

Subject to change 03/99

Braukmann Water Control . Honeywell AG

P.O. Box 1347

D - 74819 Mosbach-Germany

Phone:

(49) 62 61/ 06261/810 · Fax: 06261/813 09 http://europe.hbc.honeywell.com

220

Loading...

Loading...