Page 1

Vertex M Continuous Gas Monitor

Technical Handbook

• Table of Contents

• Introduction

• Installation

• Startup

• Operation

• Maintenance

• Troubleshooting

• Installation Drawings

• Specifications

• Detectable Gases

• Replacement and Consumable

Items

• Optional Relay Specifications

• Network Interface and Options

• 4-20mA Analog Output Option

• Line Integrity Test Option

• Warranty Statement

Page 2

Vertex MTM 24-Point Continuous Monitor

N OT I C E

WARNING

DANGER

!

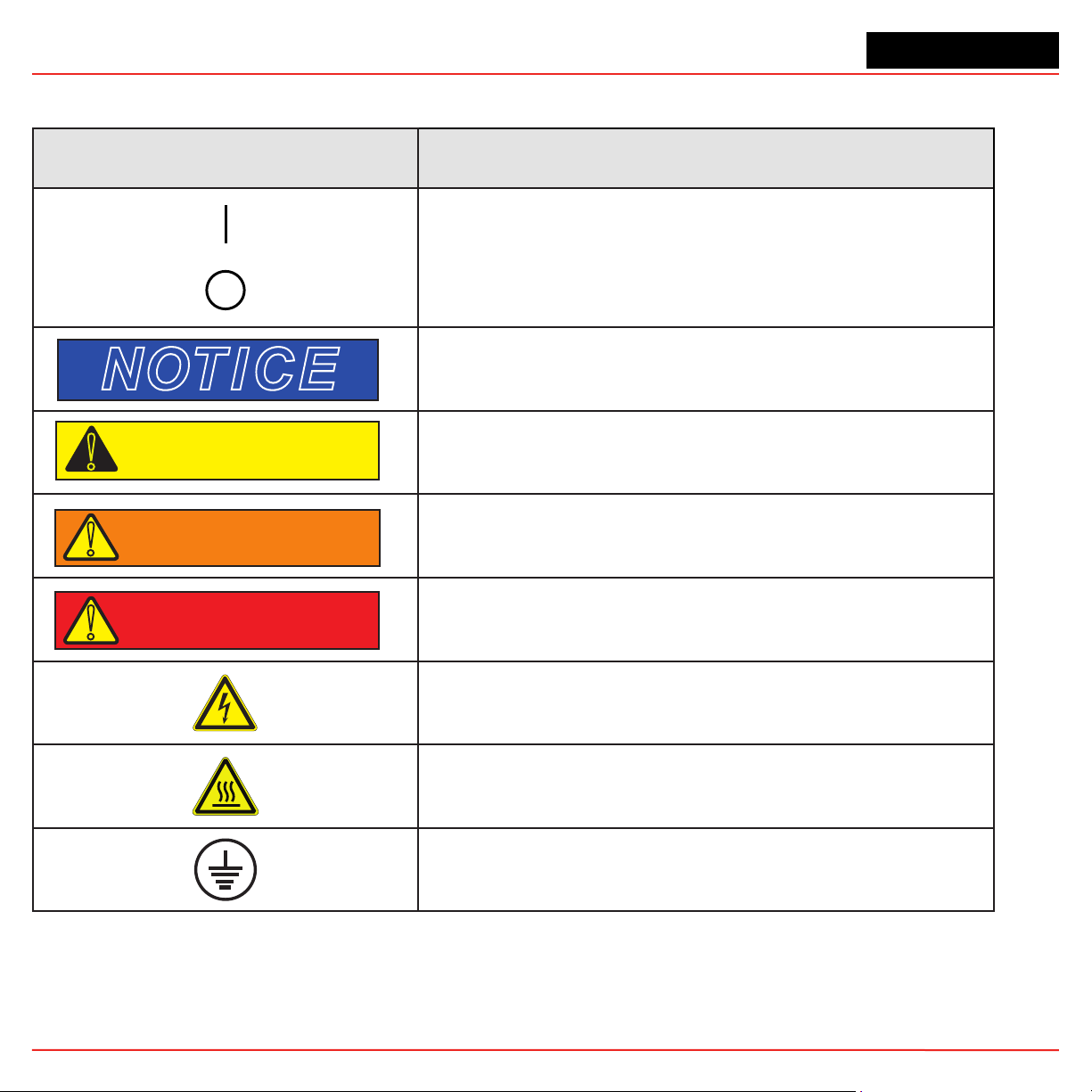

Vertex M Continuous Monitor Symbols

Symbol Description

Power on

Power off

Potential damage to the device or other property, maintenance

procedures, and “refer to manual” instructions.

Lifting instructions, low clearances, slipping/tripping hazards,

!

CAUTION

!

minor corrosive dangers. Also used when defining personal

protective equipment (gloves, dust masks, etc.)

Personal injury risk: machinery hazards around guarded

equipment, moving parts, crush/pinch hazards, flying debris, and

arc flash hazards.

Vertex M TM Technical Handbook

The most dangerous or potentially lethal hazards: unguarded

equipment, confined space entrances, and lockout labels.

Caution: possibility of electric shock

Caution: hot surface

Protective conductor terminal (ground terminal)

i

Page 3

Vertex MTM 24-Point Continuous Monitor

EMC Considerations

Your Honeywell Analytics monitor has been designed

to comply with applicable Electromagnetic Compatibility

(EMC) standards at the time of manufacture. The design

includes filtering, shielding and bypassing techniques.

At the time of certification, simulated customer Input/

Output (I/O) schemes were tested.

All methods used in your equipment for emission

suppression and reduction of susceptibility are

interactive. Modifications to the instrument could result

in increased emissions and higher vulnerability to other

radiated fields.

Following the guidelines in this EMC Considerations

section will ensure your instrument maintains the

highest degree of EMC integrity. The guidelines listed

apply only to I/O emissions and do not apply to A.C.

and D.C. instrument power connections.

Cabling

At a very minimum, all cables should include a braided

shield. Ideal results have been obtained with twisted

pair cabling which has a foil shield surrounding each

pair plus foil and 90% braid shielding around the b undle.

In addition, ensure local electrical code requirements

are met.

The following cable parameters must be considered:

Braid

Foil

Twisted Pair

Stranded Pair

Shield

Termination

Must have a minimum 90% coverage

When used with braid, provides 100% coverage

Do not use foil alone. It has a tendency to break.

Provides for cancelling of magnetic fields

Provides the greatest surface area

Continuation of the shield to the cabinet earth

ground is most important. For discrete wire

terminations, pigtails to the cabinet (connector)

ground should be extremely short (absolutely no

greater than three inches). For multiconductor

connector terminations, only 360° shielded

shells should be used.

Vertex M TM Technical Handbook

Note:

Honeywell Analytics product testing uses >90% braid

with foil (around the bundle); twisted pair; stranded 24

AWG (minimum wiring for all qualification and certification testing.)

Connectors

All qualification and certification of Honeywell Analytics

products were achieved with high quality connectors,

providing 360° shield coverage. These connectors

generally had metal shells.

Failure to properly secure the connector to the

equipment will result in high emission levels. Also,

poorly constructed or improperly assembled connectors

can be a high source of radiated noise and provide a

path for external signals into the monitor.

ii

Page 4

Vertex MTM 24-Point Continuous Monitor

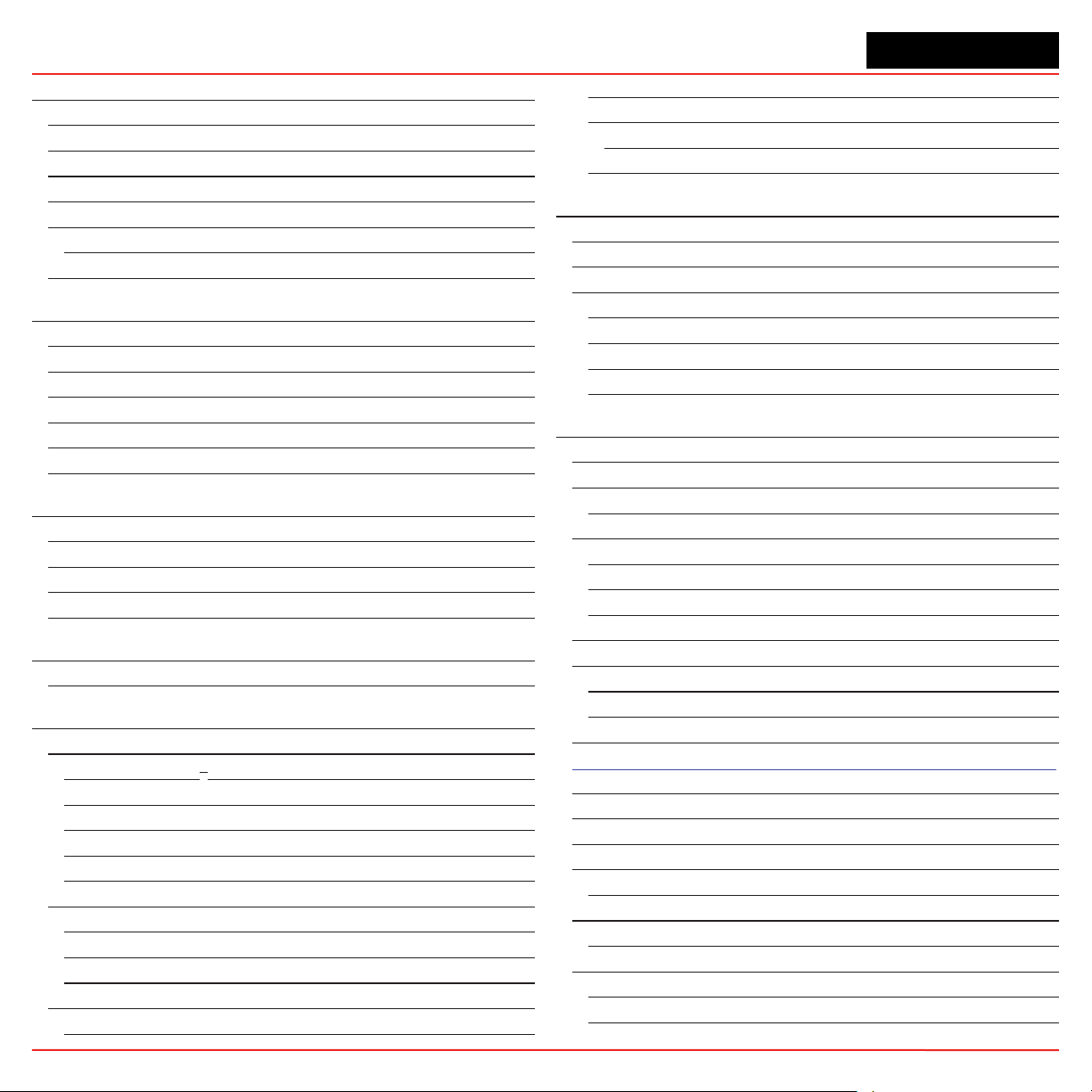

Table of Contents

Symbols Used on Your Instrument ..................................i

EMC Considerations

Cabling

Connectors

..........................................................................ii

....................................................................ii

.......................................................i

Introduction ................................................... 1-1

System Overview ........................................................1-2

Manufacturer

General Safety

System Components

Vertex M Front

Vertex M Back

Sample Tubing, Exhaust and Wiring Ports

Analyzer Side Panel

Analyzer Front

System Controls

Data Acquisition Computer (rear)

Back of Chemcassette

Main PLC

4-20mA Analog Output Option PLC

Menu Map

Analyzer Modules

Sampling System

Chemcassette

Detector Optics

Stain Pattern

Chemcassette

Optional ChemCam

Sample Filters

Pyrolyzer Module Detection System

Pyrolyzer Fan

Vacuum Pumps

Multiple Gas Monitoring

Control System

Data Acquisition Computer

Programmable Logic Controller

............................................................1-2

.........................................................1-2

..................................................1-2

.........................................................1-3

..........................................................1-4

...............1-5

................................................1-6

.........................................................1-7

......................................................1-7

............................1-8

®

Module ..............................1-9

...............................................................1-10

......................1-11

.................................................................1-12

.....................................................1-13

......................................................1-13

®

Detection System ............................1-14

......................................................1-14

..........................................................1-14

®

Tapes ............................................1-15

...............................................1-15

........................................................1-15

.........................1-16

.........................................................1-16

........................................................1-16

............................................1-16

.........................................................1-17

....................................1-17

.............................1-17

Installation ..................................................... 2-1

Introduction .................................................................2-2

Surveying the Installation Site

Placement of the Vertex M System

Exposure to Dust and Humidity

Sample Transport Time

Instrument Dimensions

Sample Locations

Sample Line Particulate Filter Use

Optional Floor Mounting

Installing Sample Lines/Filters

Sample Line Installation Requirements

Sample Line Connections

Installing Sample Line Particulate Filters

Installing Pump Exhaust Line

Exhaust Line Installation Requirements

Exhaust Line Connection

Electrical Power

Connecting AC Power

Power On/Off

Data Acquisition System

Printer

External Network Connection

Network Computer Security

Wiring Alarm Relays

Relay Contacts

Wiring Guidelines

......................................................................2-7

....................................................2-2

..........................................................2-5

...........................................................2-6

...................................................2-8

........................................................2-8

....................................................2-9

....................................2-2

..........................2-2

...............................2-2

............................................2-2

............................................2-2

..........................2-3

.............................................2-3

....................................2-3

...................2-3

........................................2-4

.................2-4

.....................................2-4

..................2-5

.........................................2-5

..............................................2-5

.............................................2-6

..................................2-7

.....................................2-8

Startup ........................................................... 3-1

Startup ........................................................................3-2

Initial Startup............................................................3-2

Factory Configuration

Getting Started

Verify Installation

Power Up

Start Program

...........................................................3-2

........................................................3-2

....................................................................3-2

.............................................................3-4

..............................................3-2

Table of Contents

iii

Page 5

Vertex MTM 24-Point Continuous Monitor

Configuration Utility ....................................................3-6

Define Gas Location

Configure Analyzers and Points

Set Analyzer Window

Configure Point

Define and Assign Relays

Configure PLC

Set Alarm Relays

Set Fault Relays

..............................................3-17

............................3-19

.............................................3-20

......................................................3-21

......................................3-28

.......................................................3-29

...................................................3-30

.....................................................3-32

Profile Management-File Menu..............................3-34

Other Menu

Load Tape

Verify Flow Rates and Supply Vacuum

Verify Flow Rates

Leak Checking Sample Lines

Reconfigure

Moving to a New Site

System Shut Down

............................................................3-34

.................................................................3-34

.....................3-35

...................................................3-35

...................................3-39

..............................................................3-39

................................................3-40

...................................................3-41

Operation ....................................................... 4-1

Introduction .................................................................4-2

Monitoring Mode Overview

Main Screen

...............................................................4-3

System Display Area

Point Detail Display Area

Function Buttons

Project Functions

....................................................4-10

......................................................4-10

Log In and Log Out

Changing Password

Updating Program..................................................4-12

Restore OnScreen Keyboard

Stopping Project

Review Functions

Event History

Data Trend

....................................................4-12

.....................................................4-12

.........................................................4-13

.............................................................4-20

Optional ChemCam

Event List

Menu Buttons

...............................................................4-24

...........................................................4-26

.........................................4-2

...............................................4-4

.........................................4-8

................................................4-11

...............................................4-11

.................................4-12

...............................................4-22

Run Time Options ..................................................4-26

Flow Calibration

Maintenance

Diagnostics

Service

...................................................................4-44

Security Access

Configuration

OnScreen Keyboard

Restore OnScreen Keyboard

....................................................4-32

..........................................................4-40

............................................................4-41

.....................................................4-47

.........................................................4-48

.................................................4-48

.................................4-48

Maintenance .................................................. 5-1

Introduction .................................................................5-2

Maintenance Schedules

Chemcassette

®

Analyzer Maintenance.......................5-3

Remove and Replace Analyzer Particulate Filters

Remove Filters

Replace Filters

.........................................................5-4

.........................................................5-4

Change Chemcassette

Replacing an Analyzer

Disconnecting Cables

Remove Analyzer

Install Analyzers.......................................................5-7

Remove and Replace Pyrolyzer Filters

Remove Filters

Replace Filters

.........................................................5-8

.........................................................5-8

Remove and Install Pumps

Remove Pump

.......................................................5-11

Install New Pump

Remove and Install Power Supplies

Remove Supply

Replace Supply

.....................................................5-12

.....................................................5-12

Clean the Touch Screen

PLC Module Battery Backup Check

File Maintenance

Optics Cleaning

......................................................5-14

........................................................5-15

.............................................5-2

..5-3

®

Tape ..................................5-5

................................................5-6

..............................................5-6

....................................................5-7

......................5-7

.........................................5-9

...................................................5-11

.........................5-12

...........................................5-12

.........................5-13

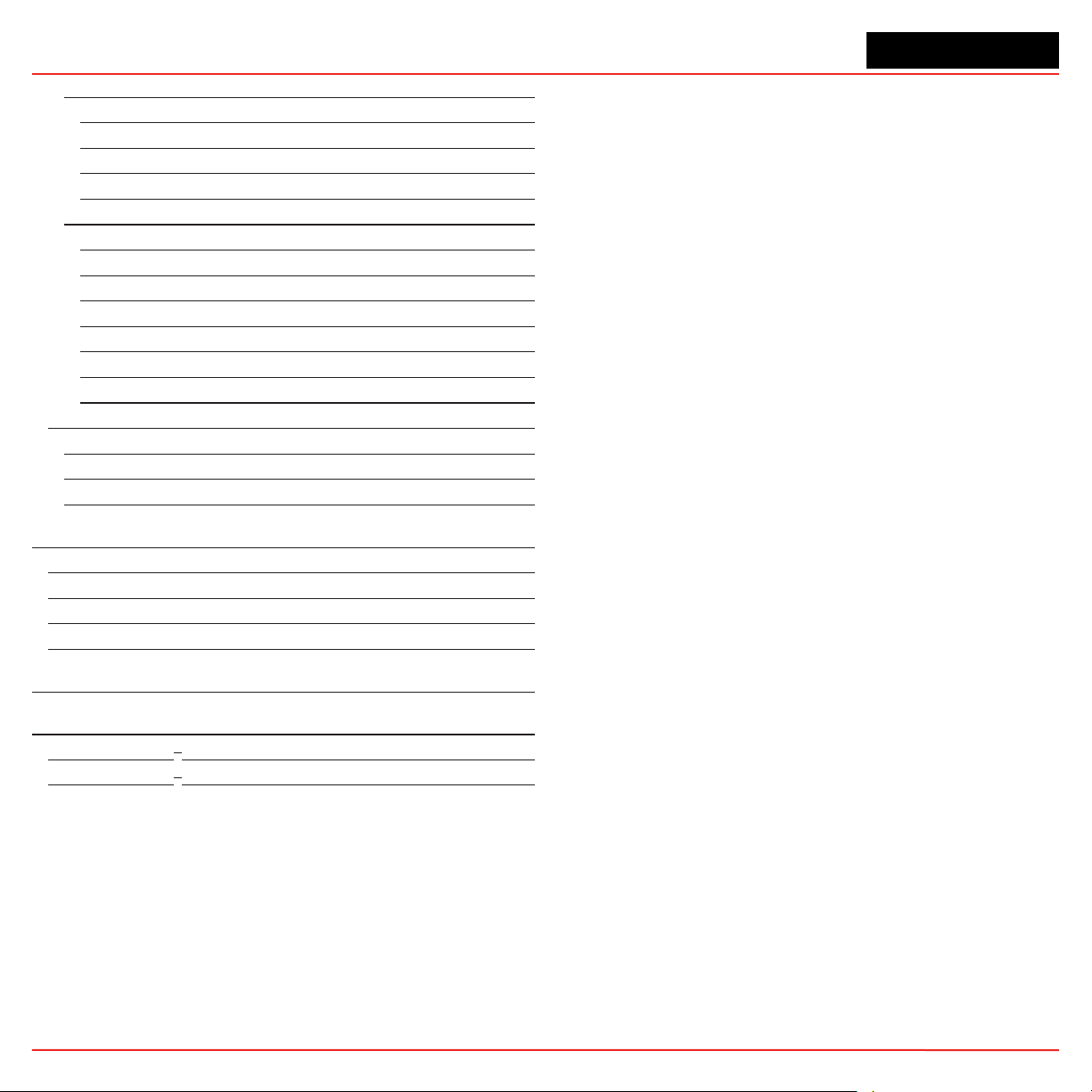

Table of Contents

iv

Page 6

Vertex MTM 24-Point Continuous Monitor

Troubleshooting ........................................... 6-1

Introduction .................................................................6-2

General System Problems

Maintenance Faults

Instrument Faults

Information Events

LIT-Related Informational Events

Manual Analyzer Override

....................................................6-5

......................................................6-10

....................................................6-16

..........................................6-2

...........................6-19

........................................6-20

Installation Drawings ...................................A-1

Introduction ................................................................A-2

Floor Space Requirements

General Considerations and Cooling

General Wiring

4-Port Manifold Option

Floor Mounting Option

...........................................................A-5

........................................A-3

.........................A-4

...............................................A-7

...............................................A-8

Specifications ...............................................B-1

Introduction ................................................................B-2

Filter Compatibility

Physical Dimensions..................................................B-3

Nominal Transport Times

.....................................................B-2

...........................................B-4

Detectable Gases..........................................C-1

Detectable Gases ......................................................C-2

Replacement and Consumable Items .........D-1

Consumables .............................................................D-2

Chemcassettes

End of Line Particulate Sample Filters

Analyzer Filters

Pyrolyzer Filters

Rack Filters

Printed Circuit Boards

Pyrolyzers

All Analyzers

Power Distribution Module

Components

All Analyzers

®

.....................................................D-2

..................D-2

.......................................................D-2

......................................................D-2

.............................................................D-2

................................................D-2

...............................................................D-2

...........................................................D-2

......................................D-2

..............................................................D-2

...........................................................D-2

Pyrolyzers ...............................................................D-3

Rack Systems

Power Distribution Module

Pump Modules

.........................................................D-3

...................................D-3

........................................................D-3

Optional Relay Specifications .....................E-1

Relay Output Contacts...............................................E-2

Relay Contact Ratings

Default Relay Assignments

Introduction

Main PLC

Terminal Assignment of 1746-OW16 Relay Module

Terminal Assignment of 1746-OX8 Relay Module

.............................................................E-3

................................................................E-3

...............................................E-2

........................................E-3

E-3

.E-4

Network Interface and Options ...................F-1

Network Interface and Options ..................................F-2

OLE for Process Control (OPC) Interface

Setting Up an OPC Client Application

Data Values Common to Fieldbus Networks

Alarms and Faults

Concentrations

Heartbeat

Data Map

Profibus Option (P/N 1295-275)

Termination

Profibus Module Configuration

DeviceNet Interface (P/N 1295-0329)

ControlNet Interface ............................................... F-14

DF1 Interface (P/N1295-0343)

Modbus Plus Interface (P/N 1295-0330)

LonWorks Interface (P/N 1295-0329)

Modbus/TCP (P/N1295-0520)

Configuring the IP Address

Ethernet/CIP (P/N1295-0519)

Configuring the IP Address

Vertex M Remote Display Setup

Checking Remote Session Count

Determining the IP Address

.............................................................. F-10

................................................................. F-11

........................................................... F-12

................................................... F-9

....................................................... F-9

.............................. F-12

............................. F-12

................................ F-15

................................. F-17

................................... F-17

................................. F-20

................................... F-21

.............................. F-21

.................................. F-22

.................. F-3

.................... F-3

............. F-9

...................... F-14

................. F-16

...................... F-16

......................... F-21

Table of Contents

v

Page 7

Vertex MTM 24-Point Continuous Monitor

Basic Desktop Station Setup ................................ F-22

Installing Java Runtime Environment Software

Install Adobe Reader Software

Create HMI account

Starting the Niagara Remote Display

Full Desktop Station Setup

Add Honeywell software to Desktop

Create a “Honeywell Analytics” account

Create Group “VertexDCOMUsers”

Disable Windows Firewall

Configure DCOM

Windows Firewall

Create matching Windows Accounts

Demonstrating Remote OPC Communication

Setup Procedure

Demonstration with Matrikon OPC Explorer

Demonstration with DAClient

.......................................... F-22

............................................... F-27

............................................... F-32

................................................... F-34

.......................... F-22

................ F-22

................................... F-25

.................. F-25

............ F-25

................... F-25

.................................. F-27

................. F-33

................................ F-38

4-20mA Analog Output Option ....................G-1

Overview ....................................................................G-2

Hardware Requirements

Configuration Requirements

Operational Description

............................................G-2

......................................G-2

.............................................G-3

. F-22

........ F-34

......... F-35

Line Integrity Test Option ............................H-1

Warranty Statement....................................... I-1

Chemcassette® Device Warranty Statement................I-2

Chemcassette

Table of Contents

®

Warranty .............................................I-3

vi

Page 8

Vertex MTM 24-Point Continuous Monitor

1 Introduction

Vertex M TM Technical Handbook

1-1

Page 9

Vertex MTM 24-Point Continuous Monitor

1.1 System Overview

The Honeywell Analytics Vertex M™ System

continuously monitors up to 24 remote locations

for toxic gases. It responds to gases that exceed

programmed levels by:

• Triggering alarms and opening event windows

to warn operators of high or low concentrations

• Triggering relays to external devices

• Displaying the location, gas type and gas

concentration

• Storing the alarm information in a database

The Vertex M System provides fast response to a wide

range of gases. Each location may be up to 400 ft

(122 m) from the Vertex M System. The system uses

one or more of Honeywell Analytics’ Chemcassette®

analyzers, with or without pyrolyzer, to provide a

monitoring system tailored to meet the requirements

of the facility.

The V ertex M System incorporates a range of redundant

and protective features for maximum uptime:

• Filters, Chemcassettes® and major

components in one of the analyzers can

be replaced while the remaining analyzers

continue to function

Operation can be through an LCD touch screen or

through a local area network (LAN).

Chemcassette® is a registered trademark of Honeywell Analytics, Inc.

1.1.1 Manufacturer

The Vertex M System is manufactured by:

Honeywell Analytics Inc.

405 Barclay Boulevard

Lincolnshire, IL 60069 USA

www.honeywellanalytics.com

1.1.2 General Safety

Follow all installation and operational instructions to

ensure the safe and reliable operation of this unit.

If this monitor is used in a manner not specified by

Honeywell Analytics Inc., the protection provided by

the equipment may be impaired.

• Intelligent analyzer modules allow one to stop

monitoring with no effect on the remaining

modules

• Power supplies are redundant

• Pumps are redundant

• The system powers up in the same state as

when powered down

Section 1 - Introduction 1-2

1.2 System Components

The following photos illustrate Vertex M System

components, ports, connections and controls. From

the main front and back photos, click on the labels to

see the detail photos.

Page 10

Vertex MTM 24-Point Continuous Monitor

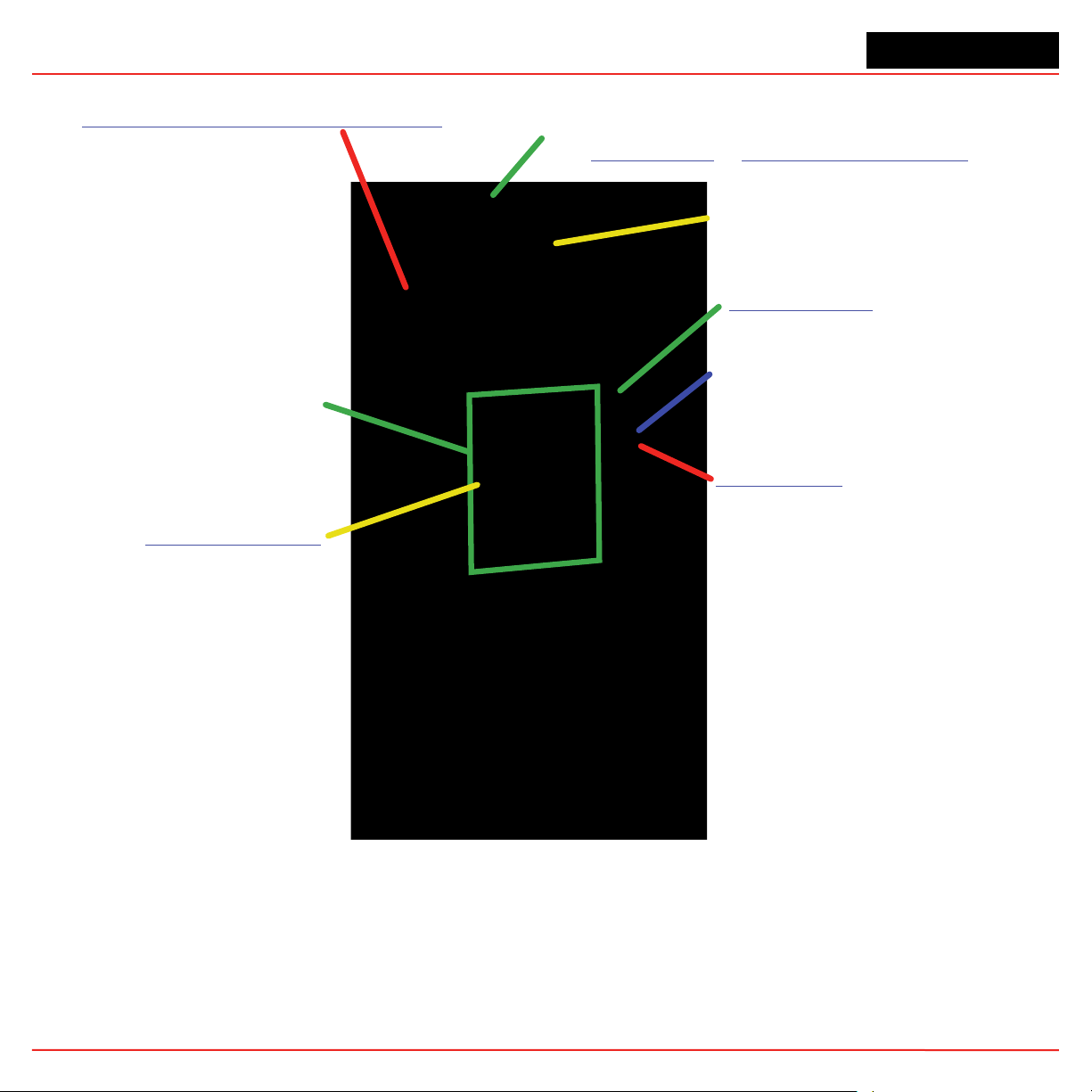

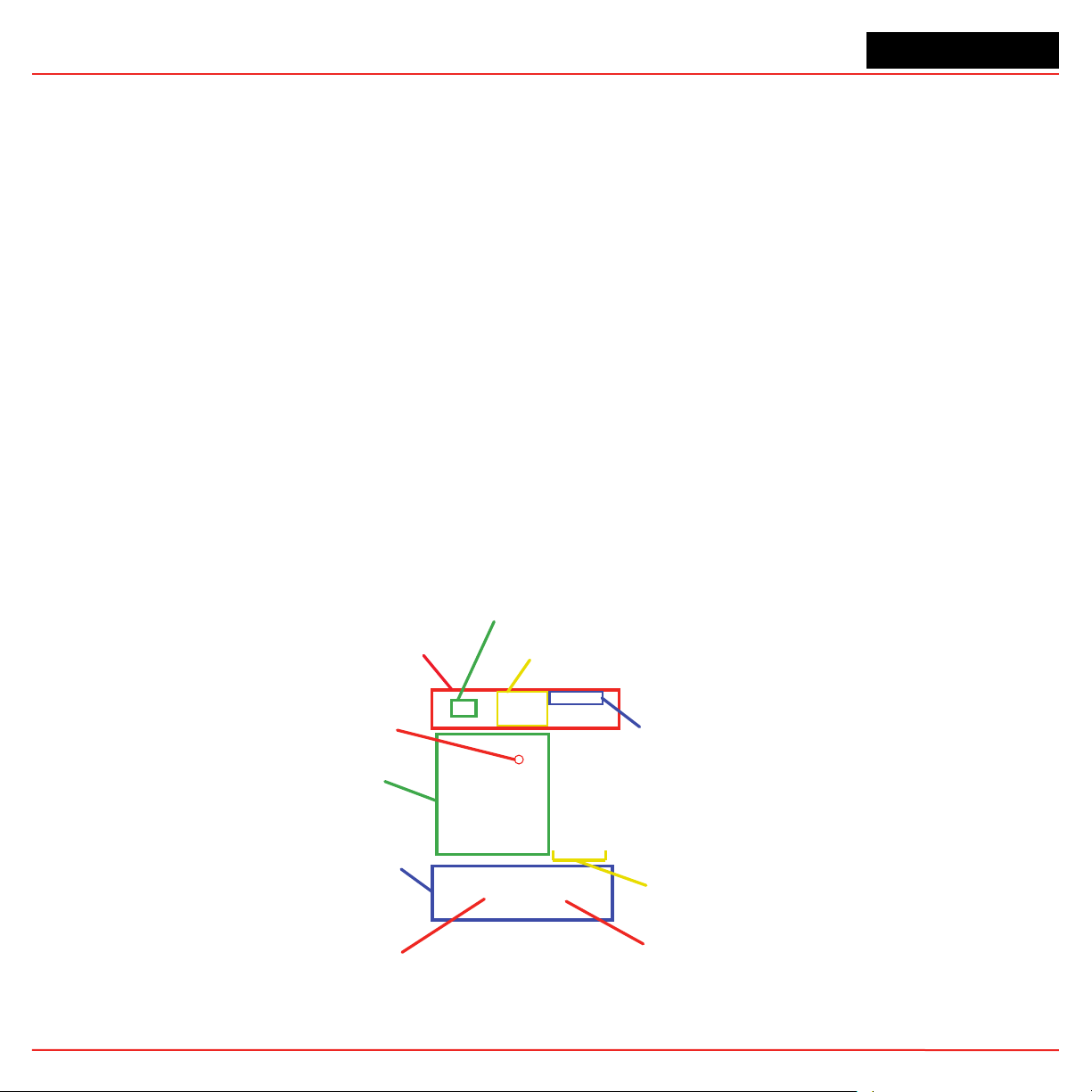

1.2.1 Vertex M Front

Sample Tubing, Exhaust and Wiring Ports

Relay PLC (behind monitor)

See Relay Options or Network Interface Options

Touch Screen

System Controls

Pyrolyzer Analyzer

Analyzer Side Panel

Universal Chemcassette

Analyzer

Analyzer Front

®

Section 1 - Introduction 1-3

Page 11

Vertex MTM 24-Point Continuous Monitor

1.2.2 Vertex M Back

Back of Pyrolyzing Chemcassette Analyzer

Data Acquisition

Computer (rear)

Pyrolyzer step-up/Isolation transformer

Section 1 - Introduction 1-4

4-20mA Option PLC

Page 12

Vertex MTM 24-Point Continuous Monitor

1.2.3 Sample Tubing, Exhaust and Wiring Ports

AC Input

0.75 in pipe thread

System Exhaust

0.5 in (12.7mm) tubing

Analyzer 3 Sample Ports

Alarm Wiring Conduit Plate

2 in (50.8mm)

Power Connection

Access Panel

3-Port Manifold for multiple gas sampling

See Section A.4 Nominal T r ansport Times for tubing

length limitations

Note:

The Alarm wiring conduit plate must remain in place if not used.

Analyzer 2 Sample Ports

Analyzer 1 Sample Ports

Points 1 thru 8 (Left to Right)

Section 1 - Introduction 1-5

Page 13

Vertex MTM 24-Point Continuous Monitor

1.2.4 Analyzer Side Panel

Exterior View

Slide Latch

Access Screws

Internal View

Analyzer CPU

ChemCam Option

Proportional Valv e Filters

Section 1 - Introduction 1-6

Sample Pressure

Transducers

Sample Flow

Transducers

Sensor Interface PCB

Page 14

Vertex MTM 24-Point Continuous Monitor

1.2.5 Analyzer Front

1.2.6 System Controls

Rack Power Switch and Circuit Breaker

Power Distribution Module

Analyzer Status LED

Pyrolyzer Analyzer

Data Acquisition

Computer (DAq)

Hot Swap

Hard Drives

Section 1 - Introduction 1-7

24VDC Power Supplies

2

Analyzer DC and Pyrolyzer AC

Power Switches with Indicators

3

Slot

CD-RW Drive

Page 15

Vertex MTM 24-Point Continuous Monitor

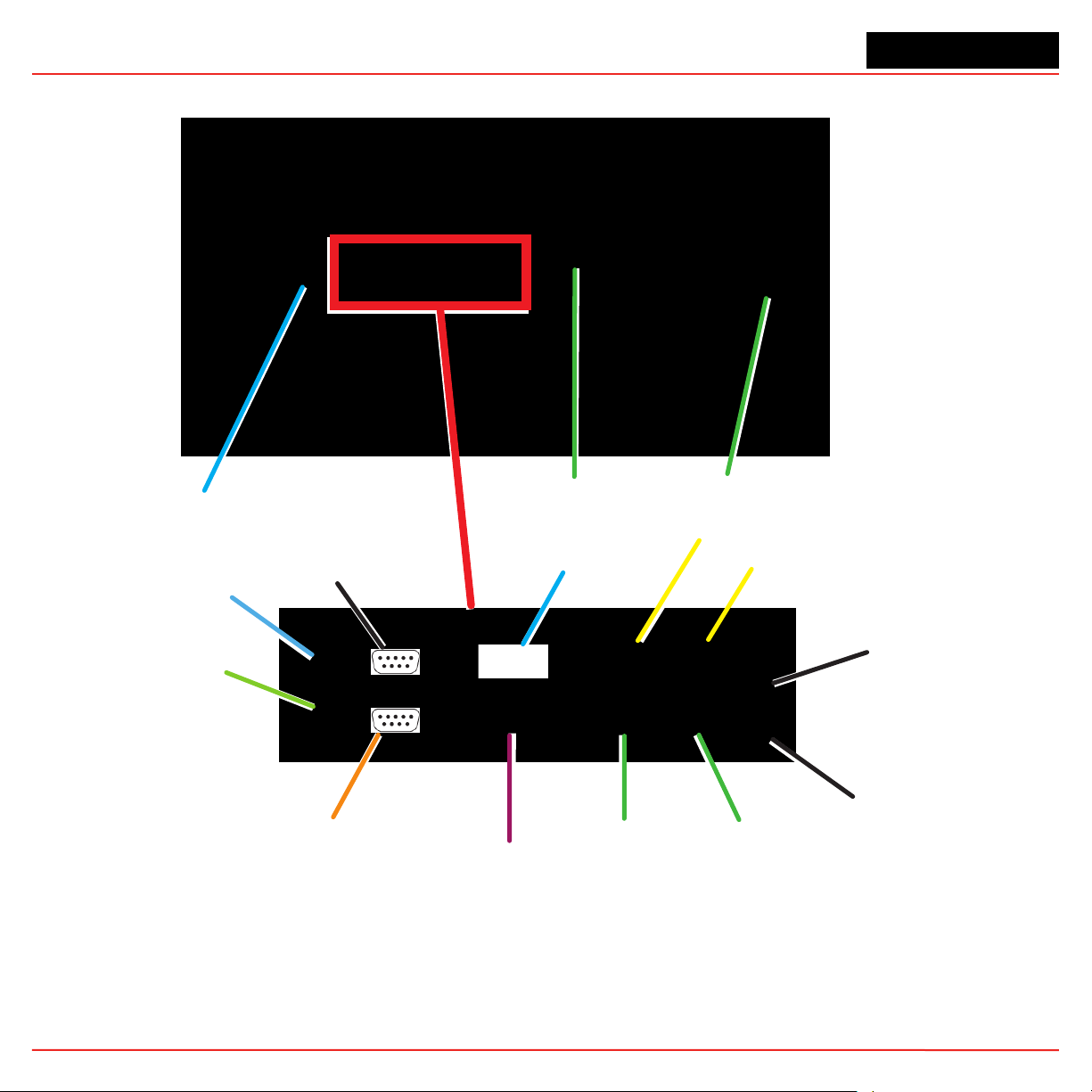

1.2.7 Data Acquisition Computer (rear)

Power

Mouse

Keyboard

Serial Com2

(not used)

Serial interface

for touchscreen

(COM 1)

USB (3)

Touchscreen

LCD

video

video

USB,

Chemcam

(3 ports)

USB Host Device

Internal Ethernet

External Ethernet

USB (Com8)

to PLC

(this port only)

Caution:

Restrict access to the USB port to reduce the risk of malicious software being introduced.

Note:

Speakers

(not used)

Microphone

(not used)

This photograph shows a typical port configuration. Port and slot locations vary from model to model.

Section 1 - Introduction 1-8

Page 16

Vertex MTM 24-Point Continuous Monitor

1.2.8 Back of Chemcassette® Module

ChemCam USB Connection

(Optional)

Analyzer Communications

(Ethernet)

Analyzer 24V

Power Supply

Multi-Function

Connector

Note:

Connection secured by slide latch. Push up to open. Push down to close.

Section 1 - Introduction 1-9

Circular Tubing Harness

Cable Carrier

Page 17

Vertex MTM 24-Point Continuous Monitor

1.2.9 Main PLC

PLC Processor

Module

DH485/RS232

Interface Module

Expansion slot for optional

Communications Interface

DH485 Link

Coupler

PLC Power Supply

Section 1 - Introduction 1-10

Advanced Interface

Converter

Optional Relay

Modules

Page 18

Vertex MTM 24-Point Continuous Monitor

1.2.10 4-20mA Analog Output Option PLC

Power Supply

4-20mA Output Modules (6X)

Section 1 - Introduction 1-11

Page 19

Vertex MTM 24-Point Continuous Monitor

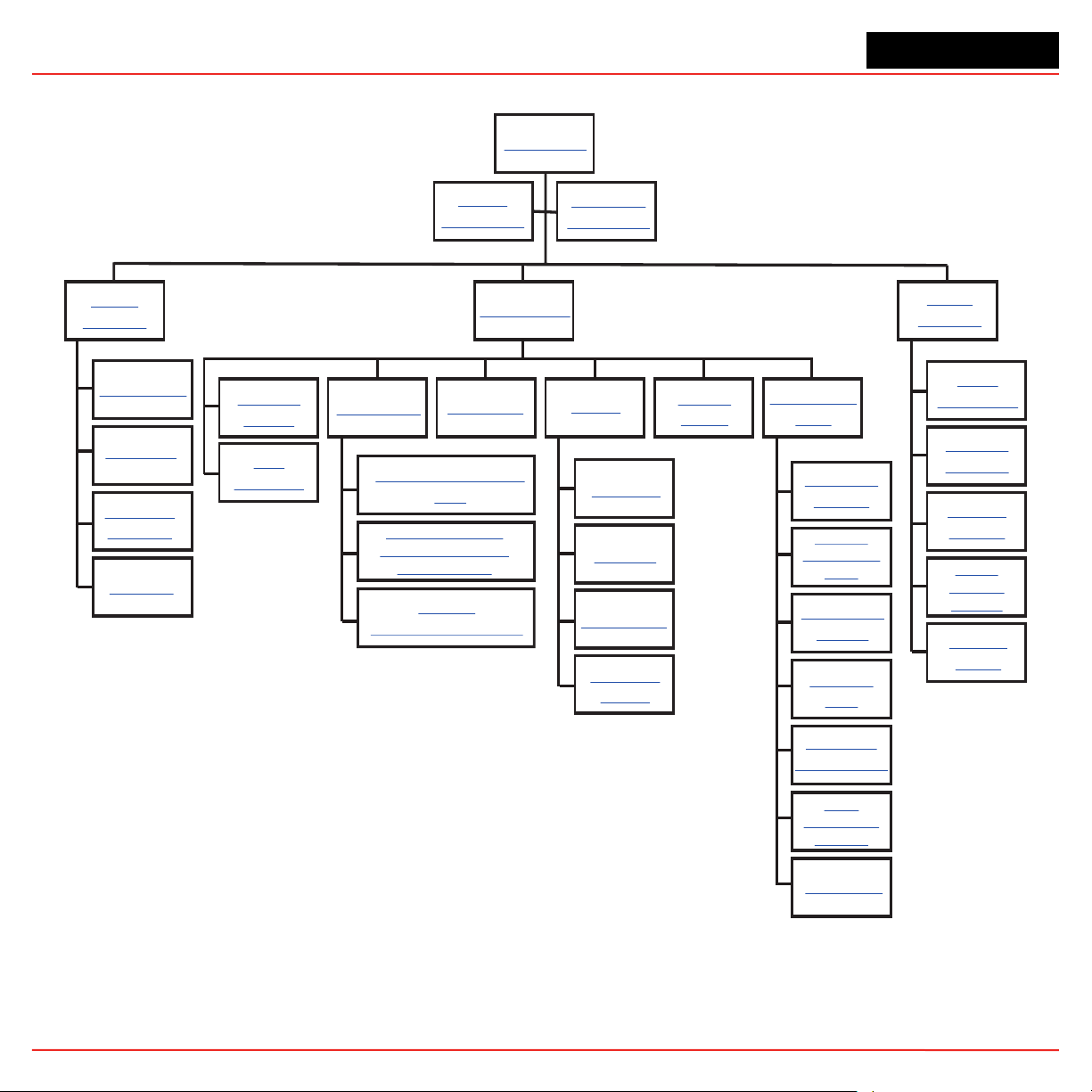

Review

Functions

Event History

Data Trend

ChemCam

(Optional)

Event List

Main Screen

System

Display Area

Point Detail

Display Area

Menu Buttons

Run Time

Options

Flow

Calibration

Maintenance

Analyzer

Operation/Maintenance

Remove and Replace

Chemcassette Analyzer

Particulate Filters

Change Chemcassette

Tape

Diagnostics

Service

Alarm Test

Fault Test

4-20 mA Test

Authorized

Service

Security

Access

Configuration

Utility

Project

Functions

Define Gas

Location

Configure

Analyzers and

Points

Set Analyzer

Window

Configure

Point

Define and

Assign Relays

Profile

Management-

File Menu

Other Menu

Log In

and Log Out

Changing

Password

Updating

Program

Restore

OnScreen

Keyboard

Stopping

Project

1.3 Menu Map

Section 1 - Introduction 1-12

Page 20

Vertex MTM 24-Point Continuous Monitor

1.4 Analyzer Modules

The Vertex M System is populated with one or more

types of analyzer modules. Each system may contain

Chemcassette® modules or Pyrolyzer modules.

Modules are installed in slots.

Tier 1

Table 1-1. Module Tier Structure

Chemcassette® modules occupy one slot each.

Howev er , Pyrolyzer Chemcassette® modules are to be

installed in slots 1 and 2. Pyrolyzer configuration and

status information will appear in slot 2.

Chemcassette

Pyrolyzer 8 1 and 2 Only 1

Examples of possible combinations in a Vertex M

System:

• One, Two or Three Chemcassette® modules

• One Pyrolyzer Chemcassette® module

• One pyrolyzer Chemcassette® module, one

Chemcassette® module

Your monitor will include only those modules specified

at time of ordering.

CC CC

PYRO

Slot 1 Slot 2 Slot 3

Number

of Points

®

8 1, 2 or 3 3

Table 1-2. Required Slots

Installed

into Slots

CC

Total

Possible

per Vertex

M System

1.5 Sampling System

Each Analyzer module is a monitoring center for

sampling lines from sample locations. As they apply to

the Vertex M System, the words point, line and location

require definition:

• A location is a place to be monitored

• Sample atmosphere runs from the location to

the Vertex M System via a line

• Each of the 24 sample tubing connections on

the Vertex M System corresponds to a point.

A sample line can be connected directly to

a single point or multiple points via a 4-port

manifold

The system draws air simultaneously from all l ocations.

Two different types of flow are:

• Transport flow: high-velocity, large-volume air

movement through the lines

• Sample flow: air admitted to the

Chemcassette® detection system

The high speed of transport flow allows rapid

monitoring and response time when using long lines

from monitored locations to the Vertex M System. A

small portion of the transport flow (sample flow) is

analyzed to determine concentration levels.

The complete sampling and monitoring system consists

of the following components:

• Sample lines to all monitored locations

• Flow connections through quick-connect ports

in bulkheads on top of unit

Section 1 - Introduction 1-13

• Moving cable and connectors

• Vacuum pumps

• Analyzers incorporating manifolds,

®

Chemcassette

and filters

• Flow controlling proportional valve

Page 21

Vertex MTM 24-Point Continuous Monitor

• Top exhaust port

There are 24 inlets, one for each monitored location.

One exhaust port is also located on top of the Vertex

M cabinet.

1.6 Chemcassette® Detection System

The Chemcassette® Analyzer module is a selfcontained, microprocessor controlled analyzer that

occupies one slot in a Vertex M. Sample lines and the

vacuum source are connected to the Chemcassette®

via a single 10-tube connector.

The system powers up in the same state as when

powered down. Data is stored in the module’ s memory

until the data acquisition computer retrieves it.

The Vertex M Analyzer modules use the Honeywell

Analytics’ Chemcassette® optical detection system.

Analyzer modules sample and detect a specific gas

or family of gases.

• Each eight-point Analyzer module:

detection system that measures a stain that develops

®

on the Chemcassette

target gas. Each eight-point Analyzer module has two

detection heads, each with four individual detectors.

tape in the presence of a

1.6.2 Stain Pattern

The following chart shows the stain pattern of sample

®

detection on the Chemcassette

tape.

• Manages Chemcassette® tape transport

• Provides optical detection of stain

• Directs sample flow through the

Chemcassette

®

• Stores data for retrieval by the data acquisition

computer

Components of the detection system include:

• Chemcassette® detection tape

• Optics and electronics for the detection system

• Chemcassette® tape transport mechanism

• Self adjusting proportional valves

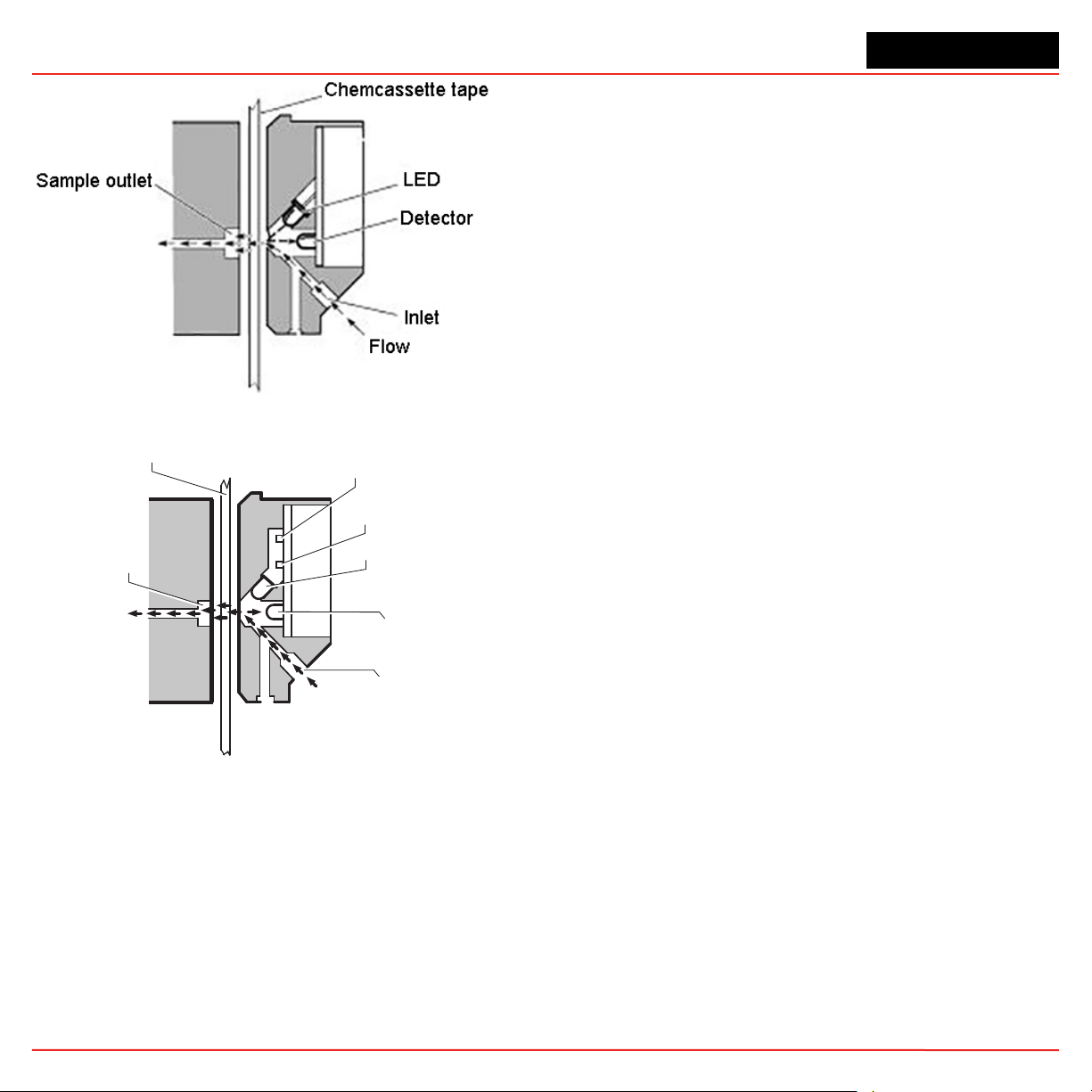

1.6.1 Detector Optics

The heart of the Chemcassette® module is an optical

Section 1 - Introduction 1-14

When monitoring a location, the system detects and

measures a specific gas or a family of gases in the

sample. The microprocessor in the analyzer module

interprets the data and responds appropriately.

In the legacy detection system, the sample enters

the inlet and passes through the Chemcassette

tape to the sample outlet. The target gas in the

sample flow reacts with the tape and produces a

stain density proportional to the gas concentration.

An LED in the detector head illuminates the sample

stain and the detector then optically measures the

stain.

Page 22

Vertex MTM 24-Point Continuous Monitor

Surface mount LED

1.6.3 Chemcassette® Tapes

Chemcassette® tapes are tagged with a radio frequency

identification (RFID) tag to automatically identify the

following:

• Serial number

• Gas family/ tape type

• Revision level

• Expiration date of the tape

• Chemcassette® leader parameters

The module uses a leader on the Chemcassette

to allow calibration of the optics e very time a new tape

Legacy Detection System

is installed. This feature can be bypassed.

®

tape

Chemcassette tape

Sample outlet

CLO Detection System

Reference detector

Light pipe

Detector

Flow

Inlet

In the Closed Loop Optics (CLO) detection system,

a reference detector monitors and controls the

intensity of the LED.

The microprocessor in the Chemcassette analyzer

module interprets the stain. It then calculates and

stores a precise concentration level in the module’s

memory. Gas concentrations are reported in

parts-per-million (ppm), parts-per-billion (ppb) or

milligrams-per-cubic-meter (mg/m3).

1.6.4 Optional ChemCam

The ChemCam is a small video camera located

between the take-up reel and the optic head on the

module. It provides a means to observe alarm level

stains.

1.6.5 Sample Filters

The Chemcassette® module includes three types of

filters in the sample flow system. Particulate filters

protect the internal precision orifice from dust particles.

An acid filter is used on the common line to the pumps.

Both types of filters are located in a removable filter

block on the side of the Chemcassette® module. An

internal particulate filter protects each proportional

valve.

Section 1 - Introduction 1-15

Page 23

Vertex MTM 24-Point Continuous Monitor

1.7 Pyrolyzer Module Detection

System

The pyrolyzer module is similar to the standard

Chemcassette

trifluoride (NF

temperature heater (pyrolyzer) which converts the

NF

to hydrogen fluoride (HF). The hydrogen fluoride

3

is then detected with a standard or XPV mineral acids

Chemcassette® tape. Detection is identical to the

Chemcassette

The correlation algorithm between HF and NF3 is

programmed into the module so the monitor displays

the NF

concentration.

3

The Vertex M pyrolyzer module detects NF3 only and

cannot be bypassed to detect mineral acids.

The right filter compartment houses eight par ticulate

filters and one acid scrubber, which are identical

to the standard Chemcassette

compartment houses eight charcoal filters which

remove the following compounds:

Freon® is a registered trademark of E.I. du Pont de Nemours &

Company (DuPont).

The charcoal filters may also remov e other compounds.

Contact Honeywell Analytics for a complete list.

Charcoal filters have a part number (P/N 1874-0139)

unique to the pyrolyzer module.

The Vertex M Pyrolyzer requires two adjacent slots on

one tier and always occupies Slot 1 and 2. The bottom

rail and latch must be removed from slot 1 to install

pyrolyzer.

®

module except that it detects nitrogen

). The sample passes through a high

3

®

module.

®

filters. The left filter

Freon 12 Freon 113 HF

Freon 13 Freon 114 HCl

Freon 21 Freon 116 Cl

2

1.7.1 Pyrolyzer Fan

The Pyrolyzer has a fan that provides cooling to the

pyrolyzer.

1.8 Vacuum Pumps

Two field-replaceable pumps provide a redundant

vacuum source for the transport and sample flow

system. One pump in the system dra ws v acuum while

the other is idle. The pump exhaust connects to the

manufacturing facility central toxic exhaust system.

Note:

The exhaust line from the Vertex M should not exceed 50 feet.

The pumps are located in the bottom of the Vertex M

System cabinet inside a sound-deadening enclosure

to reduce noise. Three cooling fans circulate air over

the pumps.

The Vertex M System draws cooling air in through a

filter mounted on the pump module access door.

Pump Status Indicator

See Pump Status Indicator under Section 4.3.1 System

Display Area.

1.9 Multiple Gas Monitoring

A Vertex M System equipped with two or more types

of Analyzer modules can monitor more than one gas

(or groups of gases such as hydrides or mineral acids)

at a location.

Each Vertex M Analyzer module can monitor only one

gas family (such as hydrides or mineral acids).

Section 1 - Introduction 1-16

Page 24

Vertex MTM 24-Point Continuous Monitor

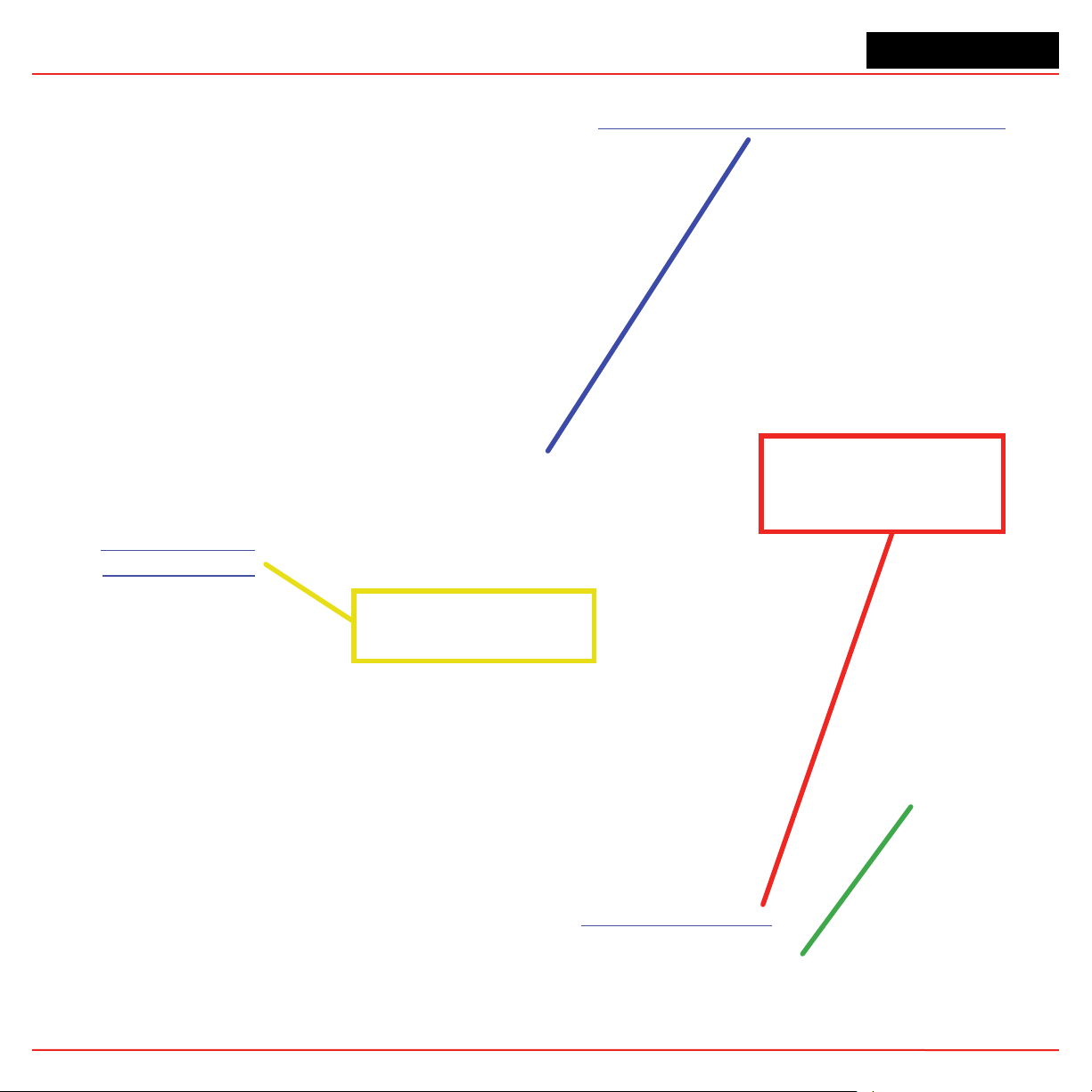

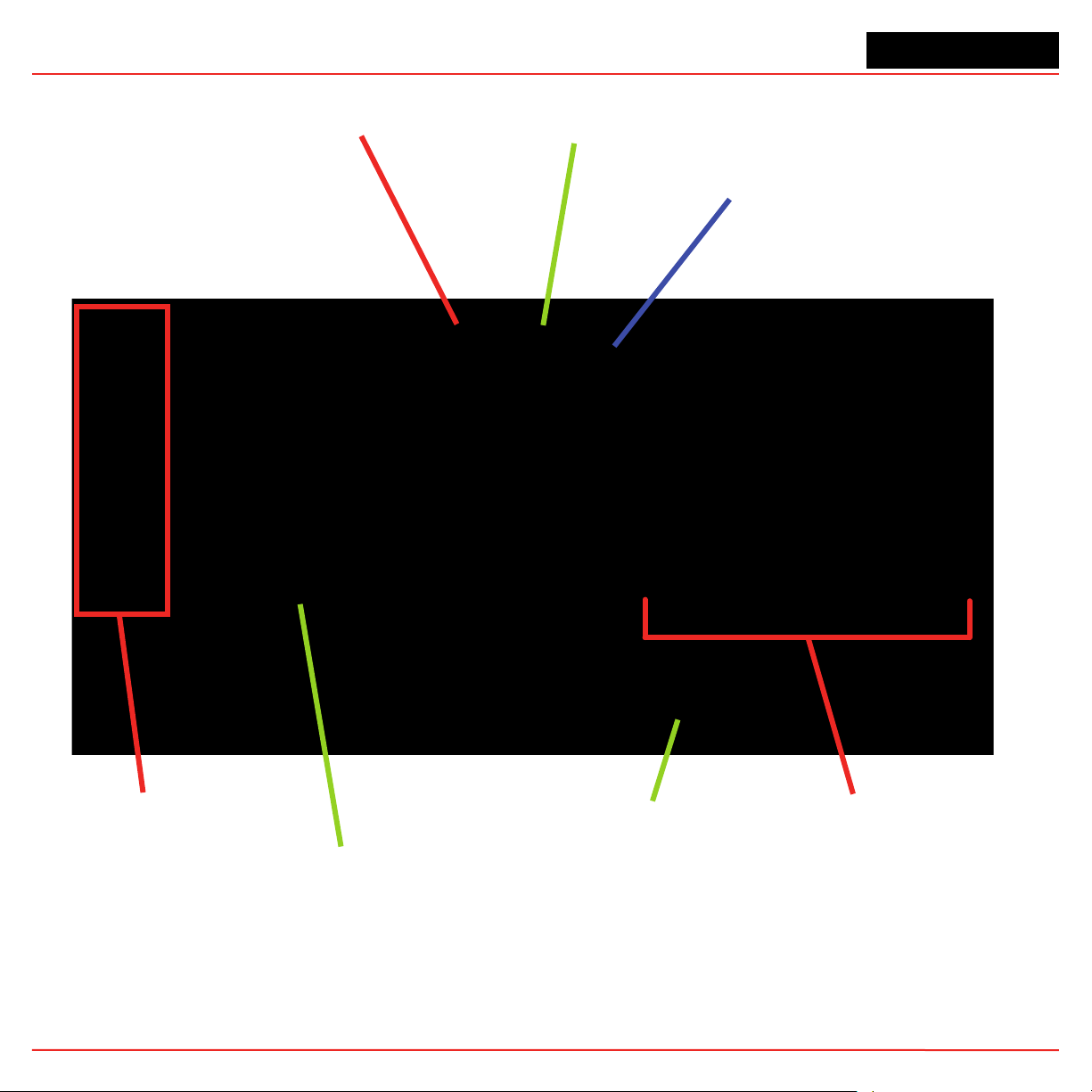

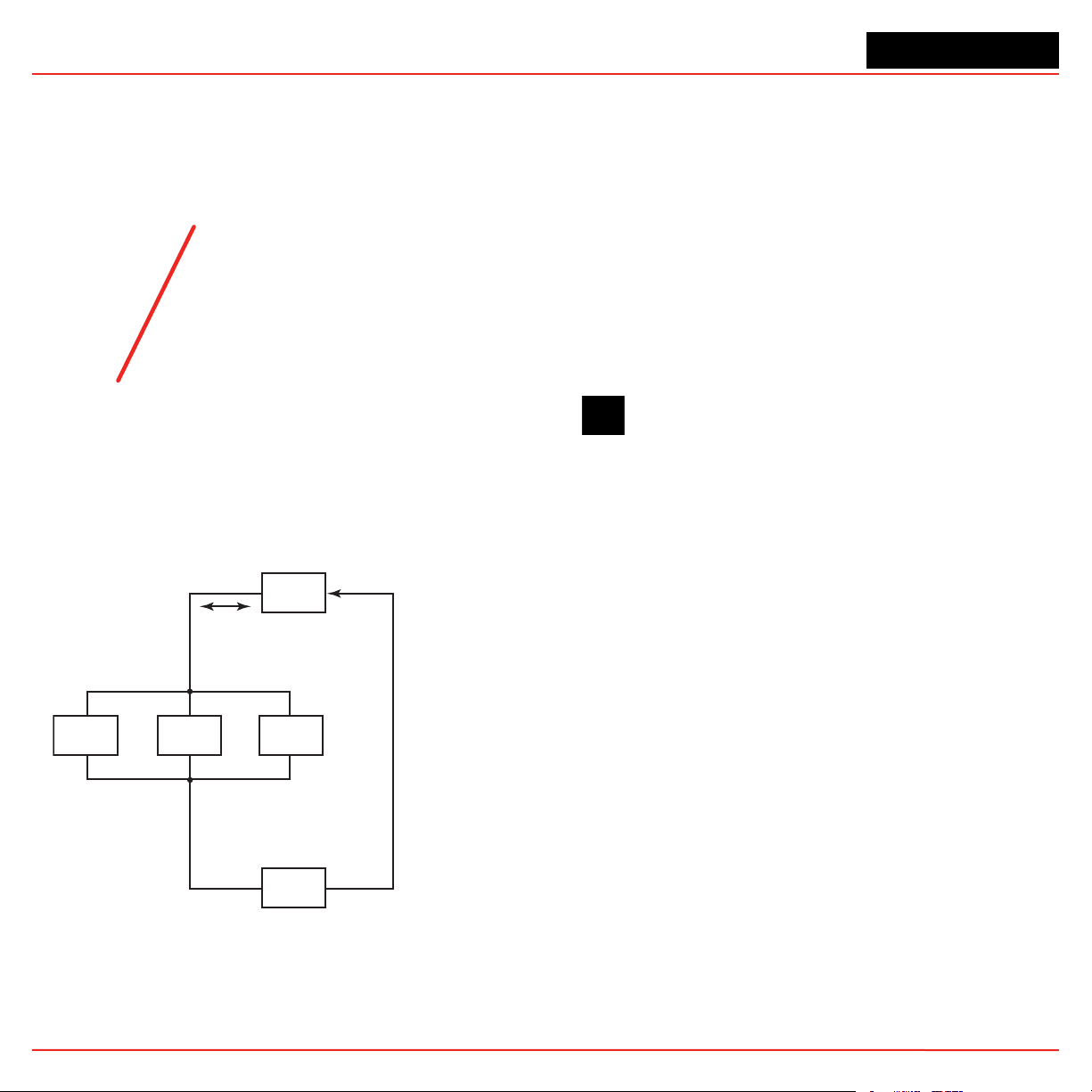

Communications

Above is a simplified block diagram of the communications

path of the control system. The analyzer modules and

PLC are microprocessor controlled and contain nonvolatile memory.

1.10.1 Data Acquisition Computer

The data acquisition computer (DAq) is the central

processor for the Vertex M System. It configures the

analyzers, stores data and provides a netw ork interface

for data transfer to other computers. System display

and operator control is through an LCD touchscreen w/

on-screen keyboard or included external keyboard.

Optional manifold for multiple-gas monitoring.

CAUTION

1.10 Control System

The Vertex M control system is a redundant system

consisting of a central data acquisition computer (DAq),

a programmable logic controller (PLC) and one or more

analyzer modules.

PLC

Primary

Communications

Alarms and Faults

Secondary

Az

Data

Communications

Prgramming

and Display

AzAz

Alarms and

Faults Should

Primary Fail

OPC on TCP/IP via Ethernet not recommended for alarm annunciation.

1.10.2 Programmable Logic Controller

The Programmable Logic Controller (PLC) is the

control system path between the DAq and the

individual analyzers. The PLC polls the analyzers for

current information, activates relays which may be

connected to external alarms and provides external

communications.

DAq

Figure 1-1. Communications Path

Section 1 - Introduction 1-17

Page 25

Vertex MTM 24-Point Continuous Monitor

Section 1 - Introduction 1-18

Page 26

Vertex MTM 24-Point Continuous Monitor

2 Installation

Vertex M TM Technical Handbook

2-1

Page 27

Vertex MTM 24-Point Continuous Monitor

2.1 Introduction

The installation and initial start-up procedure for the

Ver tex M System consists of seven steps, described

in this and the following sections:

• 2.2 Surveying the Installation Site

• 2.3 Optional Floor Mounting

• 2.4 Installing Sample Lines/Filters

• 2.5 Installing Pump Exhaust Line

• 2.6 Electrical Power

• 2.7 Data Acquisition System

• 2.8 Wiring Alarm Relays

2.2 Surveying the Installation Site

A survey of the site helps you mak e important decisions

before installing your Ver tex M System. Topics in this

section assist you with appropriate placement of the

V ertex M System and in determining if you have special

filtering needs at the sampling location.

The site should:

• Be remote from the monitored location, not

sharing the atmosphere

• Have sufficient ventilation for cabinet cooling

• Have power available

• Be indoors in an area that is not subject to wide

variations in temperature and humidity.

Note:

The specified humidity is 20–65% RH and a temperature between 59°F to 95°F (15°C to 35°C).

2.2.1 Placement of the Vertex M System

Install the Vertex M System in an environmentallyprotected setting remote from the manufacturing or

storage locations that it monitors.

Note:

Refer to the installation drawing in Appendix A Installation

Drawings for lifting/mounting information.

Section 2 - Installation 2-2

You can place the V ertex M System up to 400 ft. (122 m)

from sample locations.

2.2.2 Exposure to Dust and Humidity

Exposure to corrosive gases or materials, excess

moisture, dust and other unusual environmental

conditions could seriously hamper the Vertex M’s

monitoring ability and could damage the monitor.

Allow room around the V ertex M System f or ventilation

and servicing.

2.2.3 Sample Transport Time

Install the Vertex M System central to all 24 sample

locations to achieve equal sample transport times

during monitoring. The shorter the sample line, the

shorter the response time. If monitoring a critical

location, it may be desirab le to place the monitor near

that critical area to reduce sample transport time for that

location. See Appendix B Specifications for transport

times.

2.2.4 Monitor Dimensions

Monitor dimensions are important factors in monitor

placement. The Vertex M System is 24. in. (61 cm)

wide, 36 in. (91.4 cm) deep and 57 in. (144.8 cm) in

height. The system with 3 analyzers weighs about 550

pounds (249 kg). Allow f or 24 in. (61 cm) door s wing; 5

in. (12.3 cm) at rear and 5 in. (12.3 cm) on sides. Allo w

clearance above monitor for installing sample lines.

2.2.5 Sample Locations

Before installing the Vertex M System, evaluate the

sampling locations to determine if excessive dust

or moisture are present. An external filter must be

used in all locations. Make sure you use the correct

filter. Dust may be a result of construction as well as

manufacturing activities. Moisture ma y occur from rain

entering a line at an outdoor sampling location or from

Page 28

Vertex MTM 24-Point Continuous Monitor

condensation caused by temperature fluctuations.

Water condensation in the sample lines could cause

false alarms.

Note:

Variables such as airflow, the molecular weight and

temperature of the sample gas, and the physical

conditions of the areas being monitored influence

the placement of the sampling locations. You may

need to consult your company’s industrial hygienist or safety officer before installing sample lines to

determine your company’s policy related to sampling

locations and monitoring of the desired sample gas.

2.2.6 Sample Line Particulate Filter Use

See Appendix B Specifications to determine which filter

type should be used at the location.

2.3 Optional Floor Mounting

For added protection with optional floor mounts, prepare

floor anchors to secure the base of the cabinet and

prevent tipping. See Appendix A Installation Drawings

for floor mounting instructions.

2.4 Installing Sample Lines/Filters

Use only FEP Teflon® tubing to assure proper

sample transport. Other types of tubing are not

sufficiently inert. See Appendix B Specifications for

tube specifications. FEP tubing can be ordered from

Honeywell Analytics. This tubing is manufactured to

our own strict specifications, and has been purged

of all by-products of the manufacturing process. On

occasion, users have supplied their own FEP type

tubing. Should y ou choose to use y our own tubing, be

advised that some brands of FEP tubing off-gas small

amounts of HF, which can be detected on start up by

monitors configured for detecting mineral acids gases

(HBr, HCl, HF, NF3). Before enabling building alarm

systems, make certain that 1) you have installed the

correct Chemcassette® and 2) your monitor reads zero .

Install sample lines from each location to the top of the

Vertex M System. This procedure involves:

• 2.4.1 Sample Line Installation Requirements

• 2.4.2 Sample Line Connections

• 2.4.3 Installing Sample Line Particulate Filters

Teflon® is a registered trademark of E.I. du Pont de Nemours & Company

(DuPont).

2.4.1 Sample Line Installation Requirements

Follow the general requirements listed below when

installing sample lines.

• Sample lines should not exceed 400 ft. (122 m)

in length.

• Route all lines as direct as possible to improve

transport time. See Appendix B Specifications

for transport times.

• Avoid running sample lines through areas of

great temperature extremes, such as adjacent

to steam or chiller lines.

• Sample lines should not be crimped, bent to

less than a 12 in. (30.5 cm) radius, or placed

in an area where weight could collapse

the tubing. Sample lines should be easily

accessible for periodic inspection.

• Where possible, leave as many bends exposed

for periodic visual inspection of the line for

kinked or damaged tubing.

• Check each sample line installation for seal

integrity after completing installation of the

Vertex M System. See Section 3.8 Leak

Checking Sample Lines for the leak check

procedure. Also use this procedure to detect

leaking or severed tubing after events, such

as construction, which may have affected the

Section 2 - Installation 2-3

Page 29

Vertex MTM 24-Point Continuous Monitor

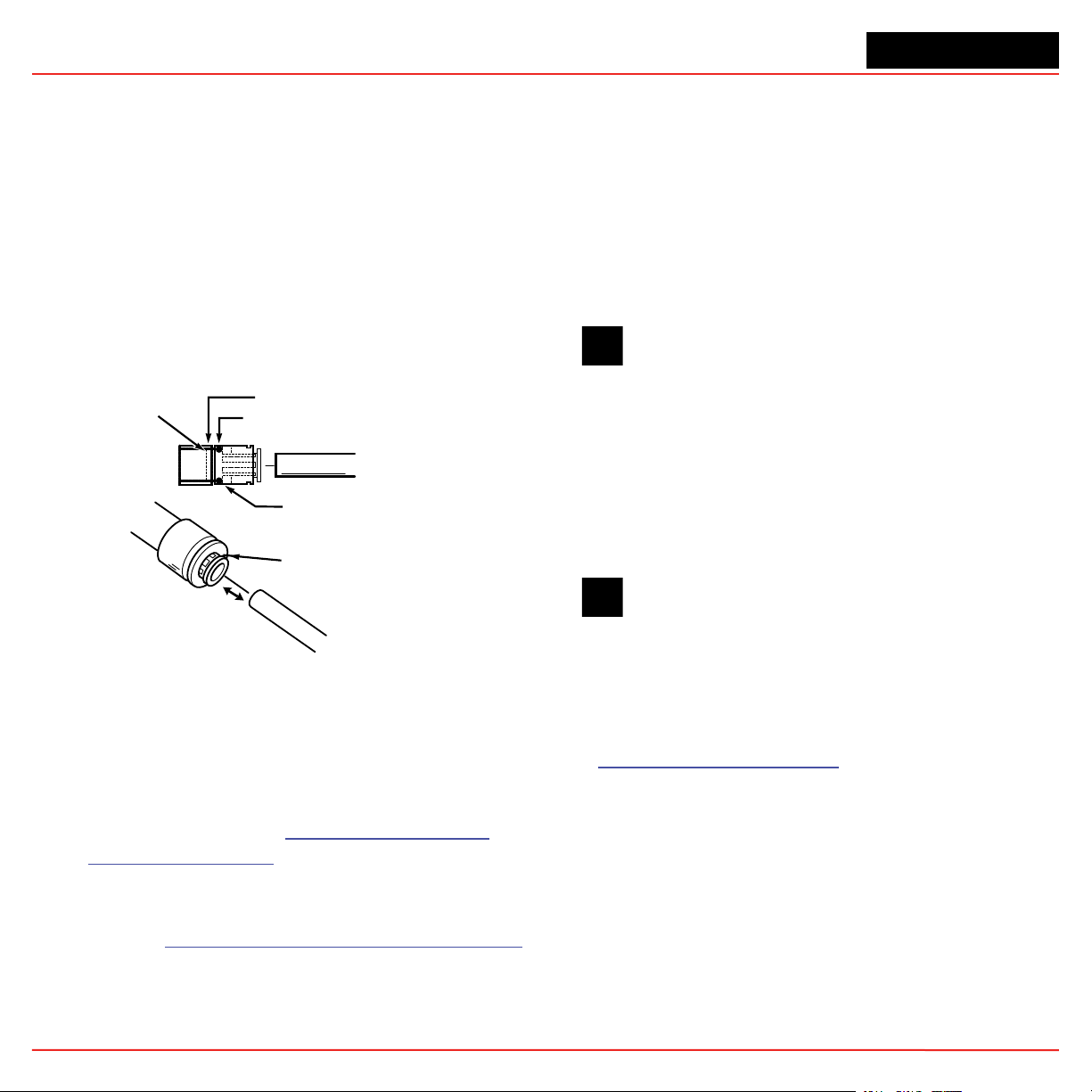

Correct - Fully Inserted

Incorrect - Not Fully Inserted

Tubing

Stop

integrity of the tubing.

• Unused sample line ports may be blocked by

the user with a plug, or a particulate filter may

be installed to keep the system clean. If using

a plug, make sure the system vacuum level is

adjusted.

• If an analyzer is installed in the Vertex with

a Chemcassette tape, the optics may need

cleaning before activating a previously unused

point.

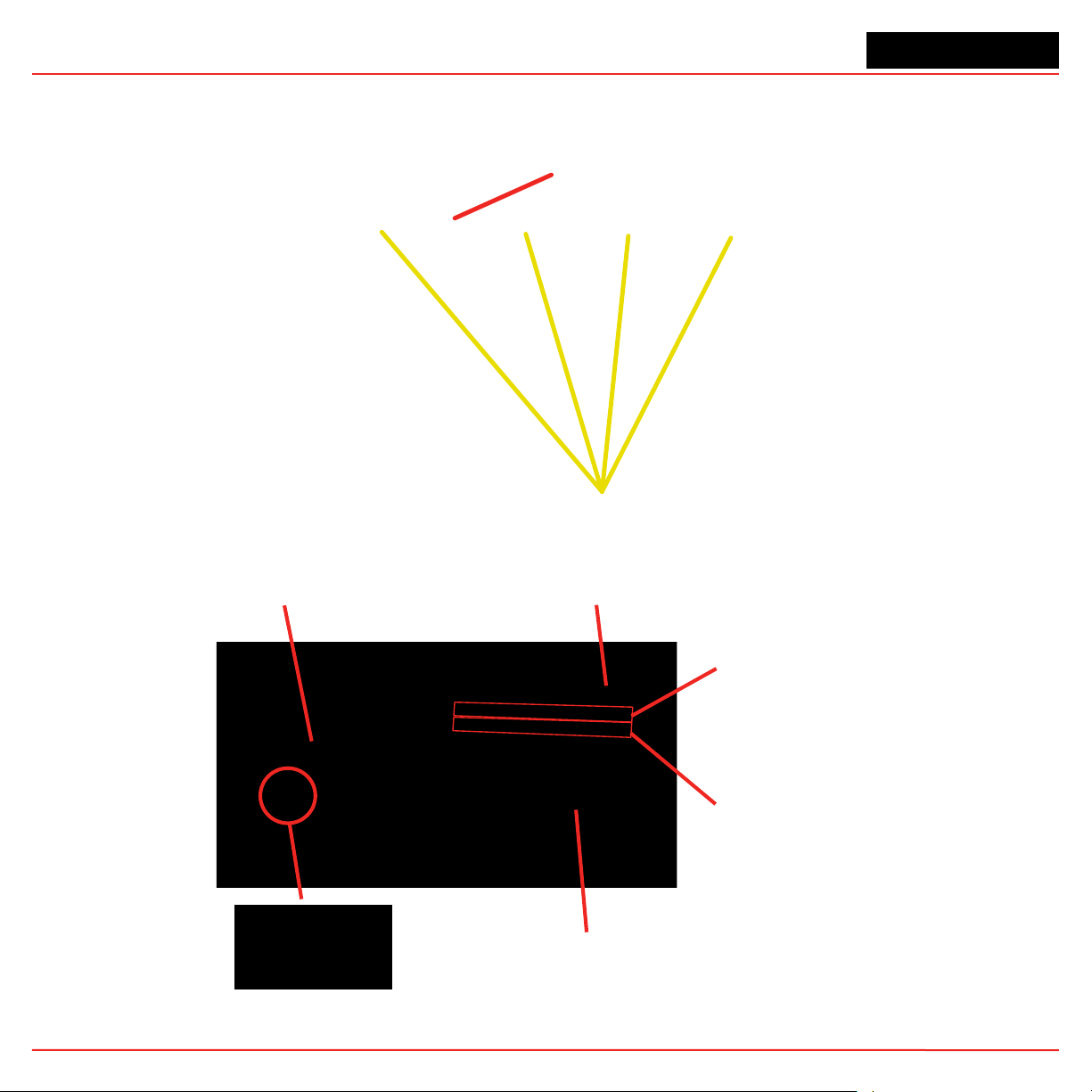

2.4.2 Sample Line Connections

O-Ring

Grey Locking Insert

install a tube into a sample line inlet, insert the tube

far enough into the fitting to ensure that the tube has

passed through both the external grab ring and the

internal O-ring and is firmly seated against the stop. The

insertion depth for a correctly installed sampling line is

1/2 in. to 5/8 in. (12 mm–16 mm). Verify the inser tion

depth by holding the tube and marking with your thumb

where it emerges from the fitting. Remove the tube to

measure the insertion depth.

CAUTION

Improper installation of the tube into the connector results in dilution of the sample.

2.4.3 Installing Sample Line Particulate

Filters

Attach a sample line filter to the sampling end of the

line for all locations.

Figure 2-1. Sample Line Inlet Connections

To prepare for installation of sample lines, remo ve the

FEP Teflon tubing from the installation kit. The top of

the unit includes 25 connections:

• 24 Sample Inlets

• Exhaust Outlet (See Section 2.5 Installing

Note:

Always perform a leak check after installing sample

lines. See Section 3.8 Leak Checking Sample Lines

for the leak check procedure.

Pump Exhaust Line for connection.)

Each inlet has a quick connect/disconnect fitting

with an internal O-ring and an external grab ring. To

Section 2 - Installation 2-4

CAUTION

Keep in mind that excess amounts of dirt in

the lters reduces the sample ow, raises

sample vacuum and may affect concentration

readings of the analyzer.

See Appendix A Specifications to determine the proper

filter type to use with each target gas.

2.5 Installing Pump Exhaust Line

This section describes exhaust connections and

installation. The Vertex M System is equipped with a

vacuum pump that is located in the bottom of the V ertex

M System cabinet. The pump exhaust line connects

to the manufacturing facility central toxic exhaust

system.

Page 30

Vertex MTM 24-Point Continuous Monitor

2.5.1 Exhaust Line Installation Requirements

Follow the general requirements listed below when

installing exhaust lines.

The length of the line should not exceed 50 ft. (15 m).

If longer distances are required, contact Honeywell

Analytics.

Do not crimp exhaust lines, or place them in an area

where weight could collapse the tubing, or bend them

to less than a 12 in. (30.5 cm) radius.

Where possible, leave as many bends exposed for

periodic visual inspection of the line for kinked or

damaged tubing.

Var ying exhaust pressure can induce pump failure or

flow faults.

2.5.2 Exhaust Line Connection

The monitor includes 20 ft. (6m) of 3/8 in. (10 mm) I.D .

x 1/2 in. (13 mm) O.D. Teflon tubing. Insert the tubing

into the exhaust port on the top of the unit to the depth

of 0.9 in. (23 mm).

System Exhaust

0.5 in (12.7mm) tubing

To ensure a leak-free installation:

• Use a polypropolene tube with outside

diameter 0.375 in. (9.525mm) +/-.005 in. (0.127mm).

• Verify that the external surface of the tube

is free of score marks and scratches that could

compromise the O-ring seal used in the fitting over

the insertion depth.

• Cut the tube end perpendicular to its length

0.062 inches (1.5 mm) from its end.

• Insert the tube in the fitting to a depth of 0.95

in. (24.13mm) ±0.05 inches (1.27mm)

With the system running, verifty the leak integrity with

a small amount of leak test fluid.

2.6 Electrical Power

The Vertex M System requires a connection to a

source of electrical power . An easil y accessible service

disconnect/power switch must be installed near the

instrument, and the switch must be marked as the main

disconnect for the V ertex M unit. The f ollowing warning

must be displayed at the switch:

CAUTION

Leaks in the exhaust tubing connection can cause

exposure to toxic gases from remote sample areas.

Section 2 - Installation 2-5

WARNING

Hazardous voltages may exist at the Alarm

Contacts in this unit with the power switch

turned off. Ensure power is disconnected at

the source prior to servicing alarm contacts.

Page 31

Vertex MTM 24-Point Continuous Monitor

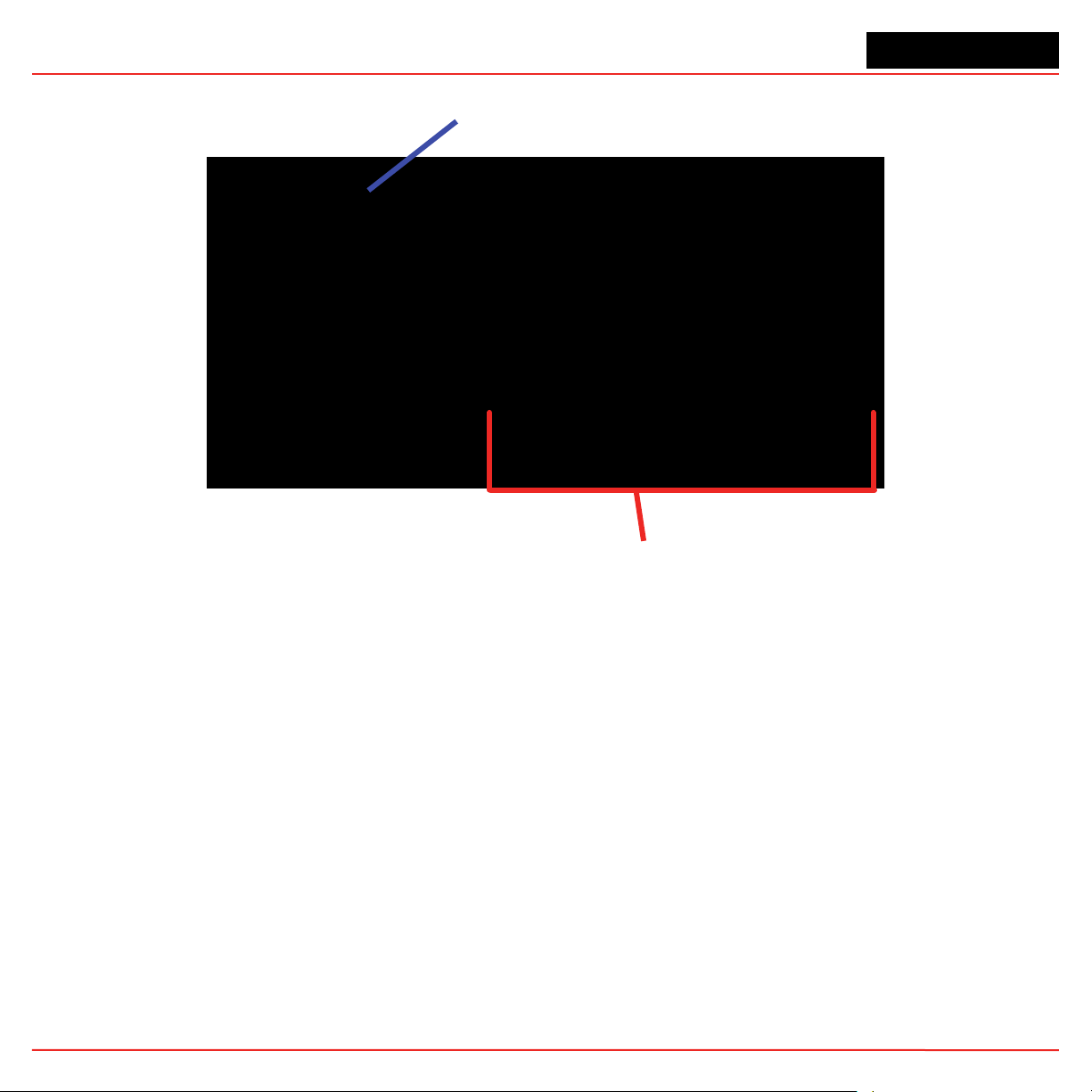

2.6.1 Connecting AC Power

AC Source Requirements:

• Operating Voltage: 110 or 230 VAC ± 10%

(under load) @ 50/60 Hz; 15 Amps maximum,

single phase.

The Vertex M System requires a dedicated AC circuit

rated at either 110 or 230 volts , 50/60 Hz, 15 Amp single

phase. Line voltage should fluctuate no more than

± 10%. The e xternal switch must be clearly labeled and

installed in accordance with local electrical codes. Input

power cable should be #14 A WG minimum. The saf ety

ground wire must be the same or larger gauge as the

line wires. Connect A C pow er connection to the threeposition terminal block in the side panel of the rack.

See Figure 2-2.

AC Input

2.6.2 Power On/Off

An internal rack power switch is located behind the

door.

After performing self-diagnostics, the V ertex M System

main screen opens and the system returns to the same

state it was in prior to power down.

Analyzer / Pyrolyzer

Power Switches and Indicators

Rack Power Switch

Line

Figure 2-2. AC Power Connection

Section 2 - Installation 2-6

Neutral

Ground

Figure 2-3. Rack Power Switch

WARNING

Hazardous voltages may exist at the Alarm

Contacts in this unit with the power switch

turned off. Insure power is disconnected at

the source prior to servicing alarm contacts.

2.7 Data Acquisition System

The data acquisition computer or DAq is the main

computer in the Vertex M System. System displa y and

operator control are through an LCD touch screen with

on-screen keyboard or the exter nal keyboard on top

of the unit.

Page 32

Vertex MTM 24-Point Continuous Monitor

The on-screen keyboard operates similar to a standard

keyboard e xcept when using modifier keys (CTRL, ALT,

or SHIFT).

To use modifier keys:

1. Touch the modifier key. The key changes to

show the modifier key is locked down.

2. Press the second key of the key combination.

Figure 2-4. On-screen Keyboard

2.7.1 Printer

The Vertex M System software can be programmed

to print to either a network or local printer. To install a

local printer, connect it to the parallel printer port as

shown. You may also use the USB port. The correct

printer driver must also be installed.

2.7.2 External Network Connection

The Vertex M System can be connected to an external

Ethernet network at the port shown.

External Ethernet Connection

Figure 2-6.

CAUTION

Do not connect an external network to the

Vertex M Ethernet hub. Use only the external

Ethernet connection (as shown in Figure 2-6)

on the back of the data acquisition computer.

Connecting an external network to the hub

will impair monitoring capability.

Parallel Printer Port

Figure 2-5. Printer Connection

Section 2 - Installation 2-7

USB Port

Figure 2-7. Ethernet cable

1. When using an Ethernet output, the conduit

must be connected to Earth ground.

2. The Vertex M comes with a Ferrite. Four wraps

of the Ethernet cable is needed as close to the

Vertex M as possible.

Page 33

Vertex MTM 24-Point Continuous Monitor

2.7.3 Network Computer Security

The Vertex M relies on the HMI system of accounts

and passwords to prevent unauthorized tampering

as described in Section 4.6.6 Security Access of this

manual. Microsoft® Windows® provides its own system

of accounts and passwords. However RSView32

requires that Windows be run in an account with

administrator privileges. Attempting to run the V ertex M

RSView32 application in a Windows® account without

administrator privileges will cause error messages to

be displayed. The Vertex M should be treated and

secured as any other networked PC by maintaining

the appropriate virus protection. Contact your local

Honeywell Analytics field service representative prior

to installing Microsoft updates or Service Packs

Use an external hardware firew all to isolate the monitor

from malicious Ethernet traffic.

2.8 Wiring Alarm Relays

This section describes relay:

• Contacts

• Ratings

2.8.1 Relay Contacts

The Vertex M System has form-A, single-pole, singlethrow relays that activate external alarm devices.

Contacts are availab le for each circuit to accommodate

installation of external devices.

Relay panels are located behind the Vertex M LCD

screen. See Appendix A Optional Relay Specifications

for more information.

• Wiring guidelines

WARNING

Use caution when servicing the PLC terminal

blocks. Power to contacts is supplied exter-

nally. See Appendix A Optional Relay Speci-

cations for alarm relay voltage and contact

rating guidelines.

Section 2 - Installation 2-8

Page 34

Vertex MTM 24-Point Continuous Monitor

2.8.2 Wiring Guidelines

To wire the alarm relays:

• Use agency approved wire (such as NRTL in

the U.S.) with 300 volt insulation.

CAUTION

Make sure there is proper separation between the mains power supply and alarm

wiring.

• Route relay wiring through raceway and out

through the top of the cabinet.

• Use shielded cable or conduit.

• Conduit must be earth grounded.

CAUTION

Failure to replace and retighten hardware

after servicing can adversely affect monitor

performance and EMC compliance. Make

certain all fasteners are reinstalled and rmly

tightened. This will ensure a proper ground.

• Use a single, solid or stranded wire (not

exceeding 14 gauge or 2.5 mm2) per

terminal block connection.

• Do not switch DC current with the relay

contact unless you are using counter

electromotive force (CEMF) protection such

as a suppression diode.

• Do not use the Vertex M System power

supply for external alarm power.

Note:

Make sure all connections comply with applicable

RFI/EMI standards.

Alarm Wiring Conduit Plate

2 in (50.8mm)

Note:

The Alarm wiring conduit plate must remain in place

if not used.

Validating the System

The Vertex M and Chemcassette products’ design,

manufacture, and recommended maintenance ensure

the correct operation of the system. For validation

or commissioning after installation by gas exposure,

these Technical Notes are available upon request from

Honeywell Analytics:

1998-0837

1998-0219

Calibration and Verification

Detector Testing Protocols

Section 2 - Installation 2-9

Page 35

Vertex MTM 24-Point Continuous Monitor

Section 2 - Installation 2-10

Page 36

Vertex MTM 24-Point Continuous Monitor

3 Startup

Vertex M TM Technical Handbook

3-1

Page 37

Vertex MTM 24-Point Continuous Monitor

3.1 Startup

This section describes the Vertex M System startup

sequence.

• Sample lines

• Exhaust line

• AC power connection

3.1.1 Initial Startup

Use this section to turn on your Vertex M System and to

configure the analyzer modules f or specific gas locations.

There are six parts to this startup procedure:

• 3.3 V erify Installation

• 3.4 Power Up

• 3.5 Start Program

• 3.6 Configuration Utility

• 3.7 Load T ape

• 3.8 Leak Checking Sample Lines

• 3.9 Verify Flow Rates and Supply Vacuum

3.1.2 Factory Conguration

Honeywell Analytics loads all software on the DAq at

®

the factory . The Univ ersal Chemcassette

configured for the mineral acid f amily of gases and the

Pyrolyzer Analyzers f or NF

each point for the target gases at your facility.

. You will need to configure

3

Analyzers are

• Relay wiring

See Section 2 Installation for connection details.

3.4 Power Up

Use the rack power switch behind the front door to

power up the Vertex M System.

1. Open front door.

2. Turn on rack power switch.

3. Turn on power switch to appropriate analyzers.

4. Close and latch front door.

After 15 seconds, the analyzer status LEDs sequence

four times through all colors.

Analyzer / Pyrolyzer

Power Switches and Indicators

Rack Power Switch

3.2 Getting Started

Before startup and configuration, gather the following

information:

• The location to which each point is connected

• Target gas at each location

• Alarm levels

• Relay configuration

3.3 Verify Installation

Ahead of the startup sequence, make sure that the

following installation steps have been completed:

Section 3 - Startup 3-2

Page 38

Vertex MTM 24-Point Continuous Monitor

Mon State Alarm State Fault State

none black green

500 400 100

time in millesconds

idle

pyrolyzer

warmup

monitoring

0

1 any red black

2 any red black

0

1 any green black red

0

1

2 red green

primary program invalid amber black amber black amber black amber black amber black

unpowered black

lockup

maintenance amber black

instrument amber black

none green black

m or i green black amber

none green black

maintenance amber green

instrument amber green

red green

any

green

amber

Table 3-1. Analyzer Status LEDs

Section 3 - Startup 3-3

red

Page 39

Vertex MTM 24-Point Continuous Monitor

3.5 Start Program

Upon power-up , the DAq automatically starts Windows

and loads the V ertex M progr am. After the two-to-three

minute startup sequence, the Vertex M main screen

opens.

Note:

Any time the Vertex M System is powered up, loss

of communications may cause maintenance faults.

See Section 4.5.4 Event List for instructions to clear

faults.

Note:

Use the Windows Date/Time Properties dialog box

to change the time zone, time and date on your

Vertex M System. Stop project if adjusting time and

time zone. Once complete restart project. See Sec-

tion 4.4.5 Stopping Project on how to stop the project.

CAUTION

Do not change language in Windows setup.

Section 3 - Startup 3-4

Page 40

Vertex MTM 24-Point Continuous Monitor

Figure 3-1. Vertex M Main Screen

Section 3 - Startup 3-5

Page 41

Vertex MTM 24-Point Continuous Monitor

3.6 Conguration Utility

Before the Vertex M System can begin monitoring, you must create a configuration profile. The configuration

profile stores all of the monitor settings in a single file on the hard drive. Configuration profi les include system level

information, point settings and analyzer information. Use the Configur ation menu to create a new configur ation

profile or modify an existing profile.

To open the Configuration Menu, touch Main Screen, Menu and then Configuration.

Set Initial Conguration

Enter information and set parameters

common to all points and modules.

Congure Analyzer / Points

Defines the type of analyzer module installed in each slot.

Designates the target gas. Sets alarm levels for each point.

Dene Gas Location Names

Enter the short and long names for each monitored location.

Section 3 - Startup 3-6

Page 42

Vertex MTM 24-Point Continuous Monitor

Dene and Assign PLCs

Associate relays with software alarms and faults.

Information and Options

A display of key parameters about

the Vertex M system.

See Summary Information

A tabular listing of the

configuration profile

Section 3 - Startup 3-7

Options

Select a tab to enter information and set

parameters common to all points and modules.

Page 43

Vertex MTM 24-Point Continuous Monitor

Install Profile Status

During the installation process,

a dialog box will be shown

indicating the status and final

result of the installation.

Open Profile...

Opens a previously saved profile.

File Save/Save As...

Saves current profile on disk.

Vertex M will prompt you to save

changes when closing the

Configuration window.

Install Current Profile

Not active while creating configuration

profiles on a computer other than the

one running the Vertex M system. Loads

the current configuration settings into the

appropriate analyzers and PLCs. If the

Vertex M System is in a monitoring state,

the program will open a dialog box to verify

that it is okay to take the Vertex M System

out of monitor during the profile installation.

Close Window/Done

Exits Configuration setup

Section 3 - Startup 3-8

Page 44

Vertex MTM 24-Point Continuous Monitor

All events require User Ack

When selected, non-latching alarm

events will not be removed from the

event list until an authorized user

acknowledges the event. Fault and

latching alarm events are not affected

by this option, since an authorized

user must reset these events and a

reset also serves as an acknowledgement.

Inverted Gas Alarm Relays

Vertex M alarm relays, by default, are normally open (de-energized)

when no alarm condition exists. If this option is checked, the alarm

relays will be normally closed (energized) when there is no alarm.

Fault relays are not affected by this option and are always normally

closed (energized) unless a fault condition exists.

Non-Latching Gas Alarm Relays

A latching gas alarm relay activates when a

gas concentration reaches a level 1 or

level 2 alarm setting. The relay remains

activated until an authorized operator resets

the alarm. Non-latching gas alarm events

clear themselves as soon as the gas

concentration drops below the alarm setting.

Section 3 - Startup 3-9

Page 45

Vertex MTM 24-Point Continuous Monitor

response to the event. When utilizing data output options, it is highly

Disabled Alarm Action - Gas Relays Disabled or Full (No Gas Events)

This setting effects the operation when alarms are disabled using

the Runtime Options screen. If “Full” is selected, Vertex M will not

generate an alarm event for the affected point(s) and none of the

associated actions such as relay actuation will occur. Otherwise,

the alarm events will be generated normally when using data

output options but, the alarm relays ONLY will not be activated in

Ignore Low ChemC. Alert

Vertex M software tracks the amount

of Chemcassette

the supply reel and triggers a low tape

event when less than 24 hours of tape

remain.

Choosing “Ignore Low ChemC. Alert”

disables the low tape event.

®

tape remaining on

Section 3 - Startup 3-10

Page 46

Vertex MTM 24-Point Continuous Monitor

Set the number of days the filters will last

before they need to be replaced. When the

target is reached, this setting will trigger a

Internal Filter Life (in Days)

maintenance fault to replace filter.

Set Timeout Values

Authorized users may temporarily disable

alarms from activating and points from

monitoring. A point or alarm that is disabled

longer than the timeout limit will cause a

maintenance fault which will call attention to

locations excluded from monitoring. Enter a

period of time up to displayed minutes or 0

to disable the maintenance fault.

User Specified Auto Logout

Users remain logged in until the auto logout period lapses.

The auto logout period ranges from 30 minutes to 24 hours.

A warning displays prior to auto logout.

Section 3 - Startup 3-11

Page 47

Vertex MTM 24-Point Continuous Monitor

1st TWA Time

Use to set times for the beginning and end of each 8-hour, Time Weighted Average (TWA)

period. Use this option to associate the TWA periods with shifts or any other regular event.

The system calculates and displays the TWA after each 8-hour TWA cycle.

The default setting is 04:00 indicating that the Vertex M will run three successive TWA

periods from 04:00 to 11:59, 12:00 to 19:59, 20:00 to 03:59. Remember, the Vertex M

System uses a 24-hour clock. For example, to set the first TWA to 3:00 P.M., enter 15:00.

If you view the profile information for this example, you will see the TWA End At Time is

07:00/15:00/23:00. The system automatically sets the beginning times of the second and

third TWA periods at 8-hour intervals from the time entered for the first TWA period.

Section 3 - Startup 3-12

Page 48

Vertex MTM 24-Point Continuous Monitor

Sets the time period to maintain historical

event and concentration data before purging.

Set the purge period in Database Management

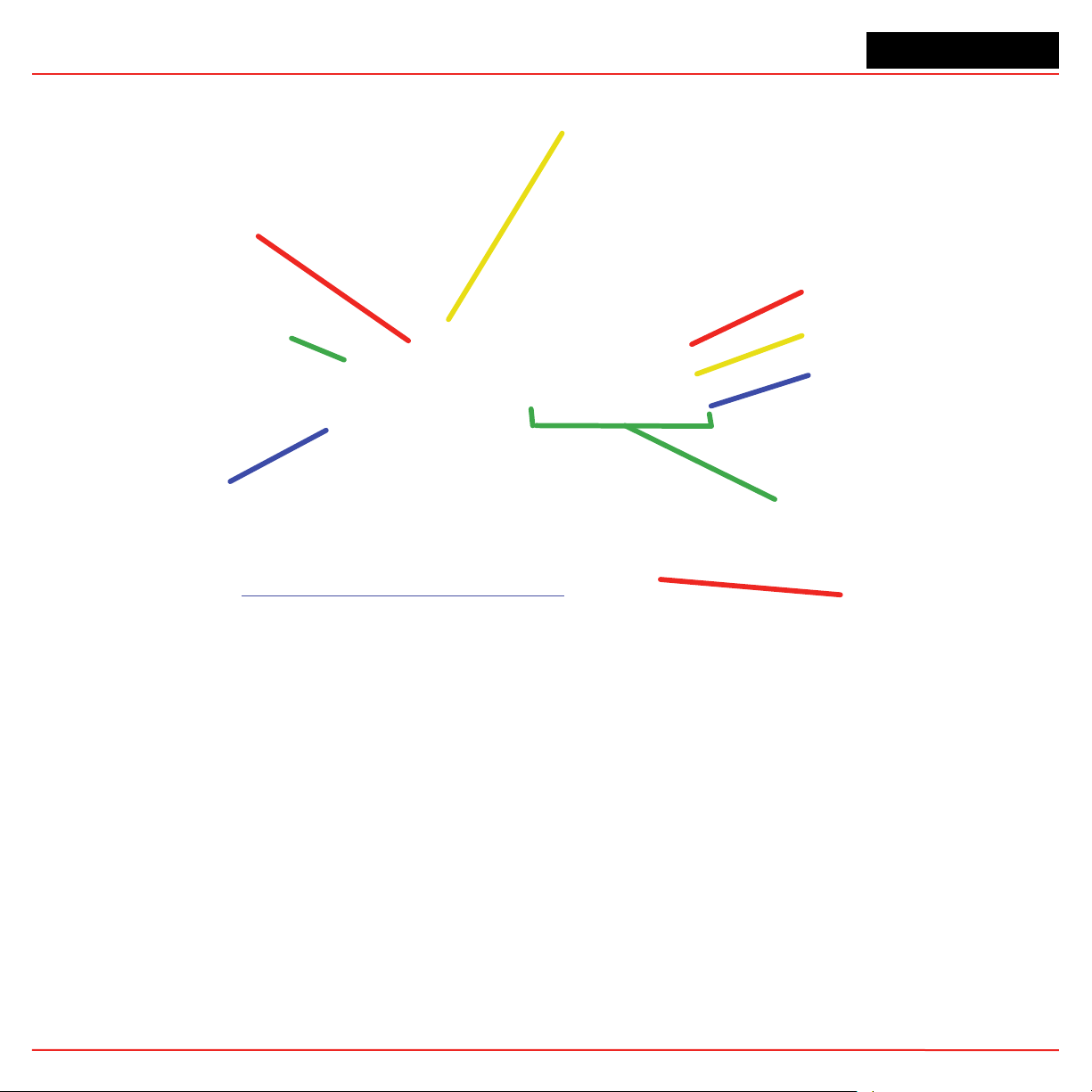

to prevent a large number of records to accumulate.

Logging Rate

The Logging Rate option sets the

frequency that Vertex M enters gas

concentration data into the

database. The system logs data at

a slow rate unless a gas concentration

rises above the threshold set in the

point configuration window. Once the

concentration reaches the threshold,

Vertex M logs at a faster rate. Logging

period options are 5, 10, 30, 60, or 120

seconds for the slow rate and 5, 10, 15,

20, 30, or 45 seconds for the fast rate.

(See Section 3.5.4, Configure Point, for

instructions to set logging frequency.)

Note:

DB Management

Setting the Vertex M System to continuously log concentration data on a 3-analyzer system requires approximately 15 megabytes of disk storage per day at the fastest logging rate of once every 5 seconds. Purge data often to

avoid filling available disk space.

Section 3 - Startup 3-13

Page 49

Vertex MTM 24-Point Continuous Monitor

Database Management-Retention Periods

Retention periods are selected as either days or weeks. Valid entries for the period are positive numbers from

1-99. Vertex M will not recalculate the values when the unit is changed. For example, if the purge period is 14

days and you change “da ys” to “weeks”, V ertex M will set the period to 14 weeks. Vertex M performs the record

purge as the data acquisition computer clock passes midnight.

Event Record Retention Period

When selected, Vertex M automatically purges

events from the database after the designated

period.

Logged Data Record Retention Period

When selected, Vertex M automatically purges

concentration records from the database after

the designated period.

Section 3 - Startup 3-14

Page 50

Vertex MTM 24-Point Continuous Monitor

Leave this box UN-checked regardless of whether a 4-20mA PLC is installed.

See Appendix G for Analog Output option configuration.

20 mA PLC Installed

Fieldbus

Use this setting to select the

PLC network interface that is installed.

Section 3 - Startup 3-15

Fieldbus Parameters

These settings allow the user to change

network specific parameters such as

address and baud rate.

Page 51

Vertex MTM 24-Point Continuous Monitor

Use mg/m3 units

Select to display concentrations in milligrams

per cubic meter. If this option is not selected,

Vertex M displays concentrations in

parts-per-million (ppm) or parts-per-billion (ppb).

User File Rev

Allows the user to assign a revision number

to a configuration profile. The profile revision

number is not associated with software

version numbers.

Profile Description

Enter a descriptive name for the

configuration profile. You may use

up to 32 characters.

Section 3 - Startup 3-16

Page 52

Vertex MTM 24-Point Continuous Monitor

3.6.1 Dene Gas Location

Use Define Gas Location to edit the list of locations. Assign a long and a short name for each location.

Clear All Entries

Clears every entry in the list.

Short names

Enter up to 12 characters. Vertex M

displays the short name where space

does not permit the display of the

long name.

Add New Entry

Creates a new entry in the gas location

list using the entered short and long names.

Long names

Enter up to 35 characters.

Replace Selected Item

Replaces the selected line in the gas

location list with the information in the

short and long name text boxes.

Delete Selected Item

Removes the selected line from the

location list.

Map Location To Point

Brings up Location Map window.

Section 3 - Startup 3-17

Page 53

Vertex MTM 24-Point Continuous Monitor

Gas Location List

Select desired gas location from this list.

For points with no assigned location,

select (default). Points assigned to default

location will automatically be given location

names based on the point’s position in the

Vertex M.

Point Map

Select point to add or remove it from the

selected location. Up to 3 points can be

assigned to each location.

Section 3 - Startup 3-18

Page 54

Vertex MTM 24-Point Continuous Monitor

3.6.2 Congure Analyzers and Points

Press “Configure Analyzer/P oints” to change the right side of the Configuration window to a display representing

physical layout of the Vertex M System. Each slot is represented by a two-part button.

When you have configured an analyzer, the top of the button displays the type of analyzer and the gas family.

The bottom of the button is a second button for configuring each point within the analyzer.

Note:

Only analyzers on tier one should be configured. Configuring analyzers on tiers 2 or 3 will result in errors and

faults.

Two-part Button

Section 3 - Startup 3-19

Page 55

Vertex MTM 24-Point Continuous Monitor