Page 1

Verifier Integration Interface

For PX940V Printer

Command Reference

Page 2

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other information contained in

this document without prior notice, and the reader should in all cases consult HII to determine whether any such changes

have been made. The information in this publication does not represent a commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained herein; nor for incidental or consequential

damages resulting from the furnishing, performance, or use of this material. HII disclaims all responsibility for the selection and use of software and/or hardware to achieve intended results.

This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this document may be photocopied, reproduced, or translated into another language without the prior written consent of HII.

Copyright 2020 Honeywell International Inc. All rights reserved.

Web Address:

www.honeywellaidc.com

Patents

For patent information, refer to www.hsmpats.com.

Page 3

TABLE OF CONTENTS

Customer Support ....................................................................................................................... vii

Technical Assistance ............................................................................................................ vii

Product Service and Repair ............................................................................................... vii

Limited Warranty ................................................................................................................... vii

Chapter 1 - Get Started ....................................................................................1

Features ............................................................................................................................................. 1

About this Manual.......................................................................................................................... 1

Interface Diagram ..........................................................................................................................2

Data Protocol ................................................................................................................................... 2

Network Interface...........................................................................................................................2

Chapter 2 - Printer and Host PC Setup.........................................................3

Set Up Printer................................................................................................................................... 3

Access the Printer Web Page............................................................................................... 3

Configure VII.............................................................................................................................. 3

Execution Mode................................................................................................................. 5

Verifier Mode.......................................................................................................................5

Command Channel, Feedback Channel, and Image Channel........................6

Set Up Host PC................................................................................................................................6

Command Channel.................................................................................................................7

Configure Command Channel.....................................................................................7

Feedback Channel................................................................................................................... 7

Configuring Feedback Channel .................................................................................. 8

Image Channel.......................................................................................................................... 8

VII Command Reference iii

Page 4

Configuring Image Channel..........................................................................................8

Chapter 3 - Commands and Responses ........................................................9

Commands ........................................................................................................................................9

Response.........................................................................................................................................10

GetPrinterInfo ...............................................................................................................................11

CancelAllJobs................................................................................................................................12

GetLabelImage .............................................................................................................................13

GetPrinterStatus ..........................................................................................................................14

ImageTransfer...............................................................................................................................15

PausePrintJob...............................................................................................................................16

PrinterError ....................................................................................................................................17

PrintJobStatus..............................................................................................................................18

ReprintPrintJob ............................................................................................................................ 19

ResetVerificationResult.............................................................................................................20

ResumePrintJob...........................................................................................................................21

RetractLabel ..................................................................................................................................22

ReverifyLabel.................................................................................................................................23

SendVerificationResult.............................................................................................................. 24

SetCommandChannelPort.......................................................................................................25

SetExecutionMode......................................................................................................................26

SetFeedbackChannelPort ........................................................................................................27

SetImageChannelPort ...............................................................................................................28

SetVerifierMode............................................................................................................................ 29

VerificationResult ........................................................................................................................30

VoidLabel ........................................................................................................................................31

Error Codes.....................................................................................................................................32

Chapter 4 - Troubleshooting........................................................................ 33

Problems and Possible Solutions..........................................................................................33

Chapter 5 - Use Case Sequence Diagram .................................................. 35

Printer Error ...................................................................................................................................35

iv VII Command Reference

Page 5

Print Job - Pause, Resume, Cancel .......................................................................................36

Appendix A - Verification Report .................................................................37

Sample Verification Report ......................................................................................................37

VII Command Reference v

Page 6

vi VII Command Reference

Page 7

Customer Support

Technical Assistance

To search our knowledge base for a solution or to log in to the Technical Support

portal and report a problem, go to www.hsmcontactsupport.com.

For our latest contact information, see www.honeywellaidc.com/locations.

Product Service and Repair

Honeywell International Inc. provides service for all of its products through service

centers throughout the world. To obtain warranty or non-warranty service, return

your product to Honeywell (postage paid) with a copy of the dated purchase record.

To learn more, go to www.honeywellaidc.com and select Service and Repair at the

bottom of the page.

Limited Warranty

For warranty information, go to www.honeywellaidc.com and click Get Resources >

Product Warranty.

VII Command Reference vii

Page 8

viii VII Command Reference

Page 9

CHAPTER

1

GET STARTED

The PX940V is a rugged label printer with ANSI Grade (ISO15415/15416)

verification for label printing.

The Verifier Integration Interface of the PX940V printer allows you to communicate

with the printer through a host PC setup. Using the Verifier Integration Interface

(VII), verification data can be collected as images and XML reports.

A TCP/IP connection needs to be configured between the printer and host PC for

communication.

Features

The verifier identifies and verifies the printed barcode using supported command

languages.

The VII can be used for the following:

• Label validation

• Secondary Grading

• Grading Barcodes

• Storing Audit Trails

• Label Duplication Detection

• Label Serialization Detection

About this Manual

This command reference provides you information about the interface between the

printer with the verifier and a host PC and a set of commands to help you create

applications for the PX940V Printer.

The following abbreviations are used in this guide:

• VII - Verifier Integration Interface

VII Command Reference 1

Page 10

• TPH - Thermal PrintHead

(ANSI GRADING)

Printing

VII

Printjob

DAEMON PROCESS

VII DAEMON

PROCESS

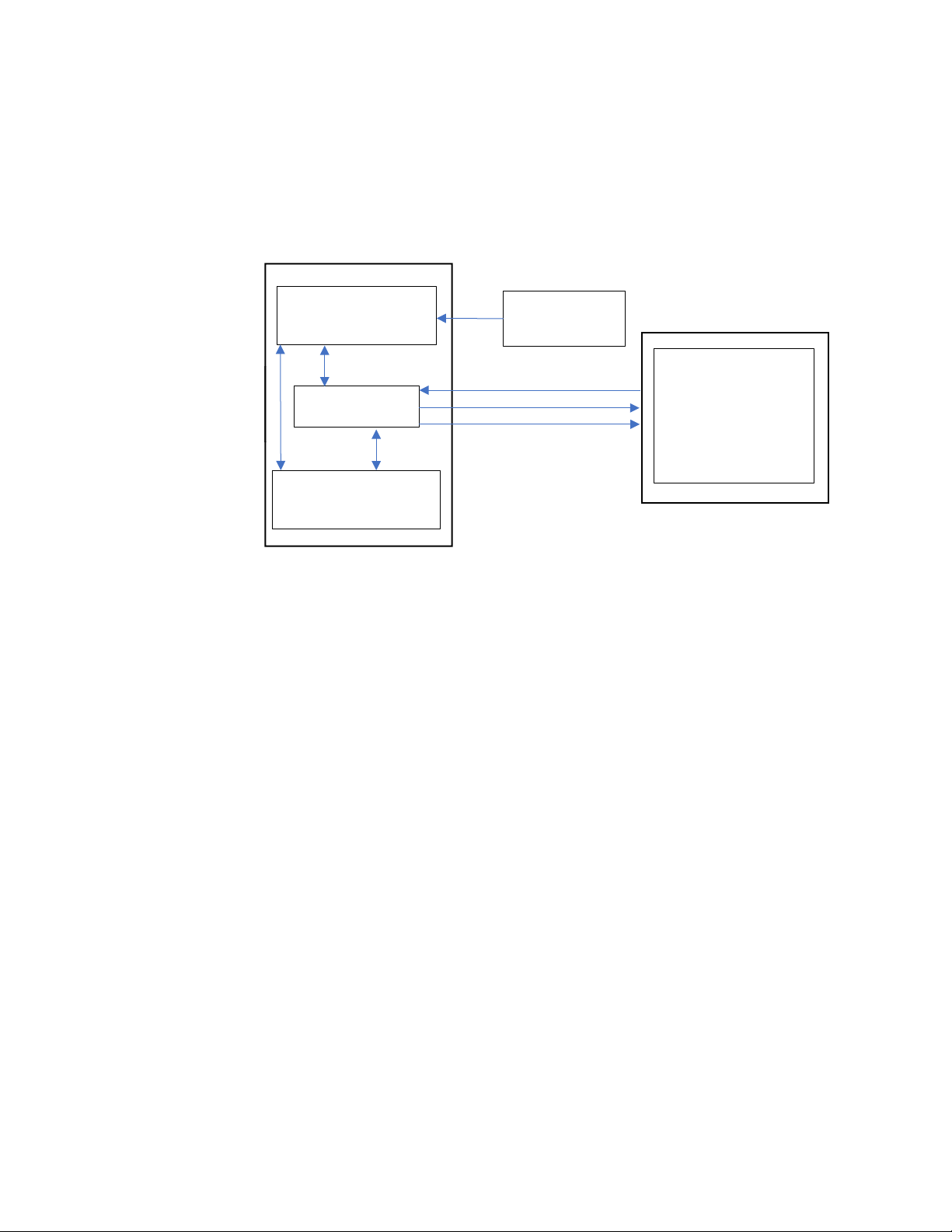

Interface Diagram

The interface between the VII and the host PC is illustrated below:

SYNC

Verification

PRINTER

HOST PC

Feedback

Command Channel

Image Channel

Feedback Channel

Image/Result

:

Data Protocol

XML is the data format set for the host PC to communicate with Verifier Integration

Interface.

Network Interface

A TCP/IP network interface is set up for the host PC to access the printer.

Note: While one host can be connected to multiple printers, each printer can only be

connected to a single host at a time.

2 VII Command Reference

Page 11

CHAPTER

PRINTER AND HOST PC SETUP

2

This chapter provides details to set up communication between VII and Host PC.

Set Up Printer

User can set up the printer through a web page or the printer LCD.

Access the Printer Web Page

1. Open a browser window on your PC.

2. In the location or address bar, type the printer IP address and press Enter.

3. Click Login. The login page appears.

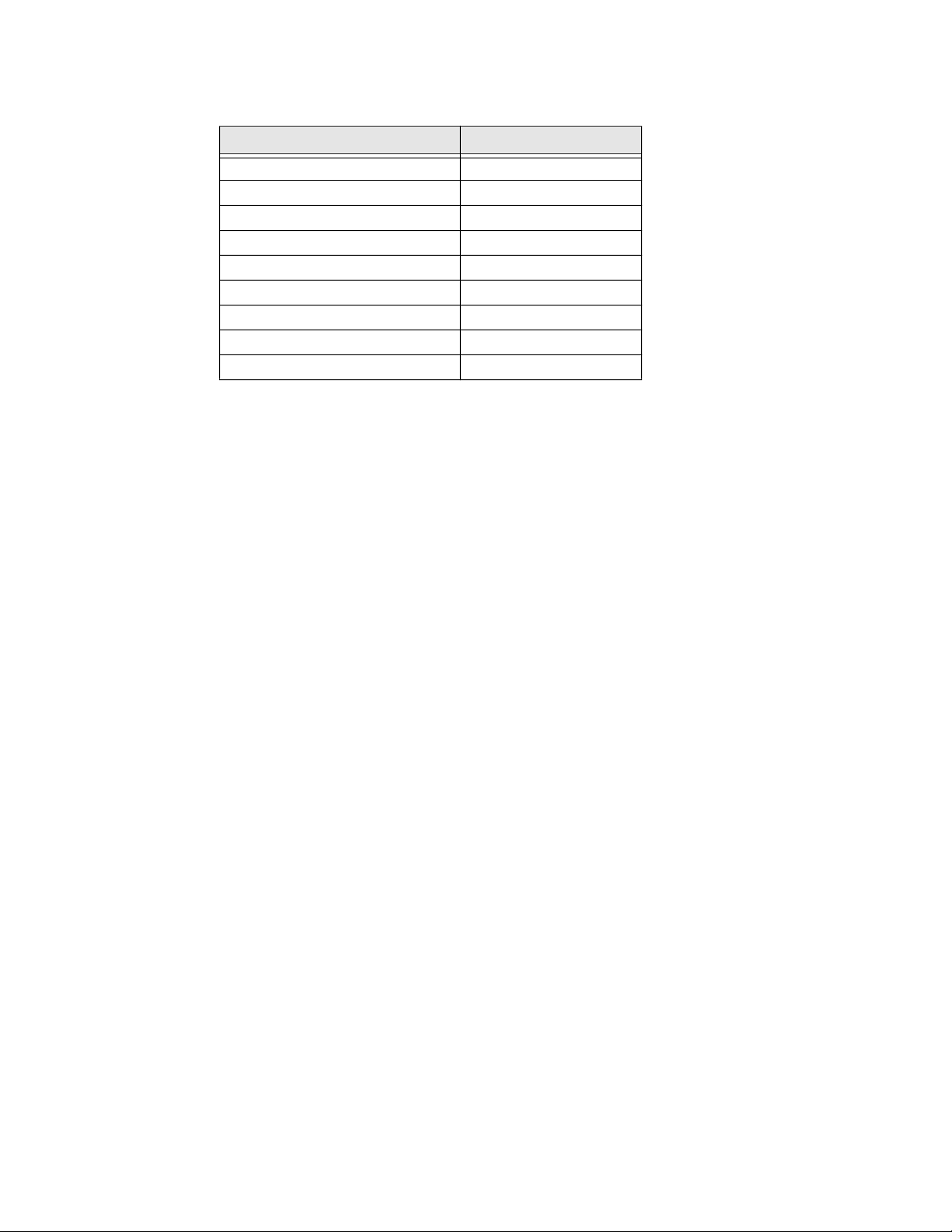

You will be prompted to enter a username and password. The defaults are:

After logging In, you will be prompted to change the password.

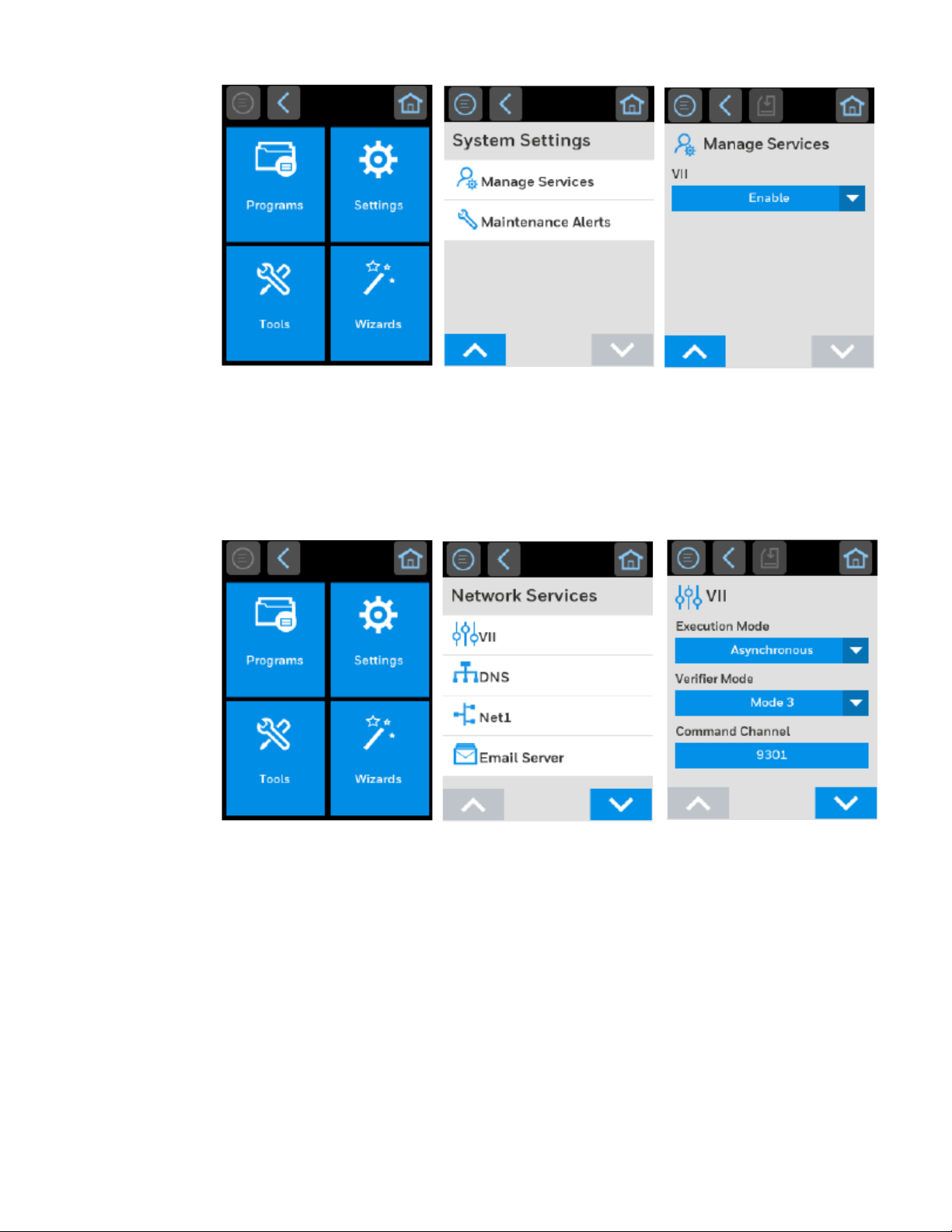

Configure VII

Before being able to configure the verifier integration interface service, it must be

enabled in the Manage service configuration.

To enable the verifier integration interface service through the web page, click

Configure > System Settings > Manage Services.

or

Through the front touch panel.

• User Name: itadmin

• Password: pass

VII Command Reference 3

Page 12

Once the VII is enabled in the Manage services section, you can configure VII in

detail through the web page.

Click Configure > Network Services > VII.

or

Through the front touch panel.

The options for the VII are as follows:

• Execution Mode

• Verifier Mode

• Command Channel

• Image Channel

• Feedback Channel

4 VII Command Reference

Page 13

Execution Mode

The Execution Mode allows you to control the synchronization between label

printing and printed label capture and verification.

Asynchronous Mode

One label is inspected while the next label is being printed and/or having its image

scanned.

Synchronous Mode

A single label is printed, image scanned and fully inspected before any other labels

are printed.

The default value is Asynchronous.

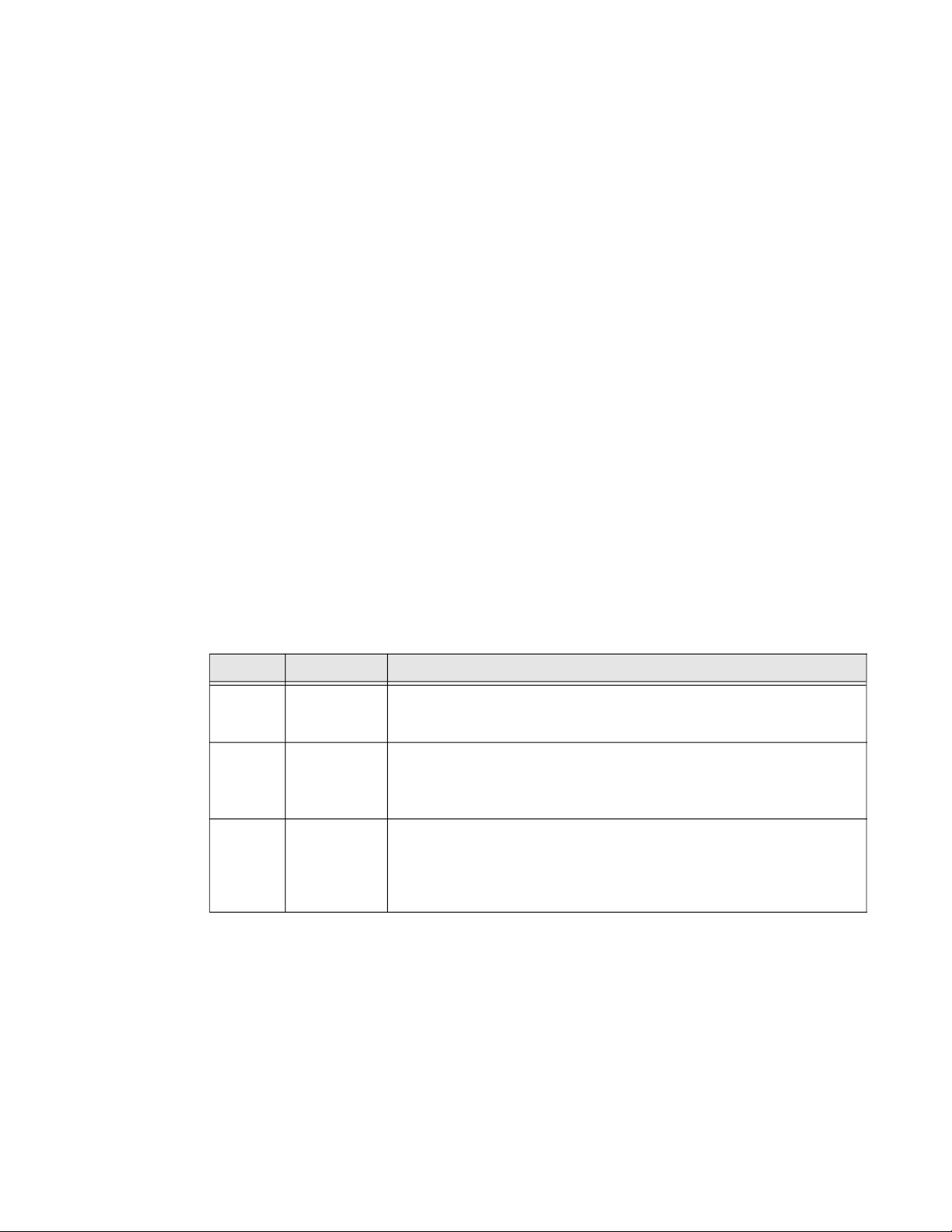

Verifier Mode

The verification modes define the types of the verification process.

For the VII, there are three types of verification modes:

1. Mode1 - Scan

2. Mode2 - Scan and grade

3. Mode3 - Scan, grade and control

Verifier Modes and Description

Modes Operation Description

Mode1 Scan The verifier will only scan the printed image, it will not do barcode

inspection. The host retrieves the image, analyzes it and control the

printer action.

Mode2 Scan and

grade

Mode3 Scan, grade

and control

The verifier will inspect the barcode. The host controls the printer action

and could also analyze the image. If the image channel is enabled from

host, the label image will be sent to host, otherwise the label image will

not be sent to host.

The verifier inspect barcode and do failure action handling. The host

captures reports and images for storage. The barcode verification result

will be sent to host via feedback channel. If image channel is enabled

from host, the label image will be sent to host, otherwise the label image

will not be sent to host.

For verifier modes 1 and 2, the printer will wait for the verification result from host.

In Synchronous Mode on page 5, if printer does not receive verification result from

host, printer will stop after printing 1 label.

In Asynchronous Mode on page 5, printer will stop after printing X number of labels

depending on the label length as indicated in the table below.

VII Command Reference 5

Page 14

Label number and Label Length range

Label Length Range (inches) Number of labels (X)

> 4.00 3

> 0.68 4

> 0.52 5

> 0.41 6

> 0.35 7

> 0.30 8

> 0.26 9

> 0.24 10

> 0.00 11

Command Channel, Feedback Channel, and Image Channel

Defines the port used for the host to connect to the printer. The range of the port

number is 9301 - 65535.

Note: Your firewall must be configured to allow these ports to be accessible otherwise a

failure may occur.

All the three communication channels must be opened to send or receive any data

from the printer. For example, if the image channel is closed, the printer cannot

send raw image data to the host.

Set Up Host PC

Verifier Integration interface allows you to transfer data between printer and host

and control the printer from the host.

The host PC communicates with the printer using certain commands. To send the

commands, user has to set up the communication channel and configure

accordingly.

The communication channels are,

• Command Channel

• Feedback Channel

• Image Channel

Command Channel

The command channel is used to issue commands from host to printer. The

commands can be sent based on the feedback result received from the printer to

host or to get printing information.

6 VII Command Reference

Page 15

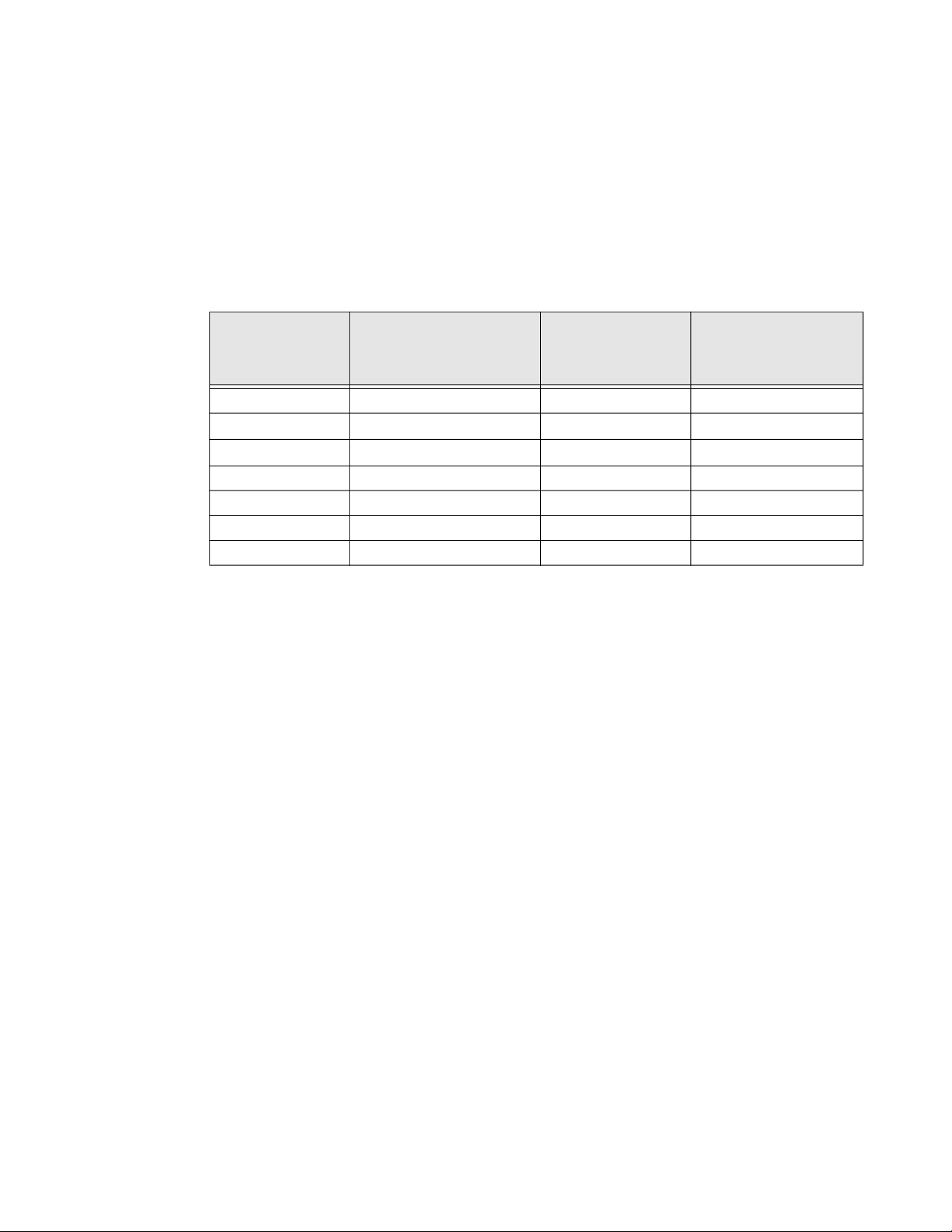

There are four types of commands that can be sent through command channel,

namely,

• Query Information Command

• Configuration Command

• Printing Control Command

• Update Command

The types of commands that can be sent through the command channel from the

host PC to the printer are detailed here.

Query

Information

command

GetPrinterInfo

GetPrinterStatus

GetLabelImage

Configure Command Channel

Setup a TCP/IP connection between host PC and printer to open the command

channel.

Command channel need to be connected before connecting Feedback channel.

The Feedback channel will only accept connection from Command channel's Host

(same IP), else, even if it shows connection OK, there won't be any output from this

channel.

Configuration

command

SetExecutionMode CancelAllJobs SendVerificationResult

SetVerifierMode PausePrintJob

SetCommandChannelPort ResumePrintJob

SetFeedbackChannelPort ReprintPrintJob

SetImageChannelPort VoidLabel

ResetVerificationResult RetractLabel

Printing

control

command

ReverifyLabel

Update command

Feedback Channel

The feedback channel is used by the printer to send the print job status, verification

result, or error result to host. These are sent by the printer automatically.

The responses from the feedback channel are:

• PrintJobStatus

• VerificationResult

• PrinterError

Configuring Feedback Channel

Setup a TCP/IP connection between the host PC and printer to open the feedback

channel.

VII Command Reference 7

Page 16

The command channel must be open before the feedback channel as both the

channel share the same IP address.

Note: Command channel need to be connected before connecting Feedback channel,

Feedback channel will only accept connections from Command channel's Host

(same IP).

Image Channel

The image channel is used to send the label images from printer to host. The

images can be BMP or raw image data. The image data is automatically sent from

the printer without any request from the host.

The responses for the image channel are,

• ImageTransfer

Configuring Image Channel

Setup a TCP/IP connection between the host PC and printer to open the image

channel.

The Image channel must be configured if the host PC expects to receive raw image

data from the printer. If the raw image data is not needed, then the image channel

need not be configured.

8 VII Command Reference

Page 17

CHAPTER

3

This chapter provides details about the Commands and Responses of all the

functionality of the verifier integration interface.

Commands

COMMANDS AND RESPONSES

Command Name Purpose

GetPrinterInfo Returns the printer information such as printer serial number, printer

model etc.

CancelAllJobs To instruct the printer to cancel all the pending print jobs.

GetLabelImage Returns label image based on label ID.

GetPrinterStatus Returns the printer status such as busy or available.

PausePrintJob To instruct the printer to stop printing.

ReprintPrintJob To instruct the printer to reprint the label specified by the host.

ResetVerificationResult To reset the verification result database stored in printer.

ResumePrintJob To instruct printer to resume from a printer pause mode.

RetractLabel To instruct printer to retract the label specified by the host using Label ID.

PausePrintJob To instruct the printer to stop printing.

ReprintPrintJob To instruct the printer to reprint the label specified by the host.

ResetVerificationResult To reset the verification result database stored in printer.

VII Command Reference 9

Page 18

Response

The feedback channel and image channel returns response automatically without any request from

host.

Command Name Purpose

ImageTransfer To send label image from the printer to host.

PrinterError To send the printer error information to host.

PrintJobStatus To send print job status from the printer to host.

VerificationResult To send Barcode verification result from the printer to the host.

10 VII Command Reference

Page 19

GetPrinterInfo

This command returns printer information such as printer serial number, printer

model etc.

XML Request

<VII Action=“GetPrinterInfo”>

</VII>

XML Response

<VII Action="GetPrinterInfo" Status="00">

<PrinterName>[printer name]</PrinterName>

<ModelName>[model name]</ModelName>

<SerialNumber>[serial number]</SerialNumber>

<VerifierResolution>[resolution]</VerifierResolution>

</VII>

Parameter

Elements Description

PrinterName

ModeName

SerialNumber

VerifierResolution

In case of error, the XML response will be,

<VII Action="GetPrinterInfo" Status=[error code]>

</VII>

For error codes, refer to Error Codes.

Name of the printer

Model name of the printer

Serial number of the printer

Verifier resolution of the printer.

The resolution is in dpi unit,

for example <VerifierResolution>600</VerifierResolution>

VII Command Reference 11

Page 20

CancelAllJobs

This command instructs the printer to cancel all pending print jobs.

XML Request

<VII Action="CancelAllJobs">

</VII>

XML Response

<VII Action="CancelAllJobs" Status="00">

</VII>

In case of error, the XML response will be,

<VII Action="CancelAllJobs" Status=[error code]>

</VII>

For error codes, refer to Error Codes.

12 VII Command Reference

Page 21

GetLabelImage

This command retrieves the label image based on the specified label ID.

XML Request

<VII Action="GetLabelImage">

<LabelID>[label ID]</LabelID>

</VII>

Elements Description

LabelID

XML Response

In case of successful command execution, the specified label image will be sent to

host via command channel.

<VII Action="GetLabelImage" Status="00" Type="BMP" ID="1"

Size="XYZ">

<Image>[Data Block]</Image>

</VII>

Unique identifier for the labels.

LabelID can be retrieved from PrintJobStatus, and

VerificationResult responses. The LabelID must be the LabelID

reported back in the last response by feedback channel.

Parameters

In case of error, the XML response will be,

<VII Action="GetLabelImage" Status=[error code]>

</VII>

For error codes, refer to Error Codes.

Name Description

Type

ID

Size

Data Block

Label image in BMP format

Label ID for each label

Data size of actual image

BMP data including BMP header

VII Command Reference 13

Page 22

GetPrinterStatus

This command is to check current printer status. It will help to check if the printer is

busy or available.

For all supported status, see “Error Codes section under Fingerprint Command

Reference Manual”.

XML Request

<VII Action="GetPrinterStatus">

</VII>

XML Response

<VII Action="GetPrinterStatus" Status="00">

<PrinterStatus>[status message]</PrinterStatus>

</VII>

Parameter

Elements Description

PrinterStatus Printer status message.

Status message does not support localization.

The status messages can be,

• Busy

• Available

• Out of media

• Printhead lifted

• Front arm lifted

• Out of ribbon

• Label not found

• Test feed not done

• Ribbon installed

• Printhead too hot

• Remove Label

In case of error, “GetPrinterStatus” XML response will be as listed below:

<VII Action="GetPrinterStatus" Status=[error code]>

</VII>

For error codes, refer to Error Codes.

14 VII Command Reference

Page 23

ImageTransfer

This is the response to send label image from printer to host.

XML Format

The XML format of image data transferred via image channel.

<VII Action="ImageTransfer" Type="RAW" ID="1" Width="XYZ">

<Image>[Data Block]</Image>

</VII>

Parameter

Name Description

Type

ID

Width

Data Block

Label image in raw format

Label ID for each label

Width of image data block

Raw image data block

VII Command Reference 15

Page 24

PausePrintJob

This command is to instruct the printer to pause from printing.

XML Request

<VII Action="PausePrintJob">

</VII>

XML Response

<VII Action="PausePrintJob" Status="00">

</VII>

In case of error, 'PausePrintJob' XML response will be,

<VII Action="PausePrintJob" Status=[error code]>

</VII>

For error codes, refer to Error Codes.

16 VII Command Reference

Page 25

PrinterError

This is the response to feedback any printer error, for example “Out of media”.

This is automatically sent from printer to host.

XML Response

<VII Action="PrinterError">

<PrinterError>[printer error]</PrinterError>

</VII>

Printer error can be as Follows:

• Printhead lifted

• Front arm lifted

• Next label not found

• Out of media

• Out of ribbon

• Ribbon installed

Note: For use case sequence diagram, refer to Printer Error.

VII Command Reference 17

Page 26

PrintJobStatus

This is a response to feedback print job status from printer to host. After each label

is printed, the label printing status will be sent to host.

XML Response

<VII Action="PrintJobStatus">

<LabelID>[label ID]</LabelID>

<PrintJobStatus>[print job status]</PrintJobStatus>

</VII>

Print job status can be “Printed” or “Printing Failed”.

18 VII Command Reference

Page 27

ReprintPrintJob

This command is to instruct printer to reprint the label specified by host. The label

can be specified by the label ID and option.

XML Request

<VII Action="ReprintPrintJob">

<LabelID>[label ID]</LabelID>

<Option>[option]</Option>

</VII>

Print job option should be either “Single” or “All”.

If option is “Single”, only the label specified by label ID will be reprinted.

If option is “All”, then the labels between the label specified by label ID and the last

printed label will be reprinted.

The reprint range will be from 3 to 11 which decrease when media length is

changing from small to big. Refer to Label number and Label Length range on

page 6.

For example, if the number of label is 3 and last label ID sent back to host is 5, the

host only can send back the label ID for reprint from 3 to 5.

XML Response

<VII Action="ReprintPrintJob" Status="00">

</VII>

In case of error, 'ReprintPrintJob' XML response will be as listed below:

<VII Action="ReprintPrintJob" Status=[error code]>

</VII>

For error codes, refer to Error Codes.

VII Command Reference 19

Page 28

ResetVerificationResult

This command is to reset verification result database stored in printer.

XML Request

<VII Action="ResetVerificationResult">

</VII>

XML Response

<VII Action="ResetVerificationResult" Status="00">

</VII>

In case of error, “ResetVerificationResult" XML response will be as listed below:

<VII Action="ResetVerificationResult" Status=[error code]>

</VII>

For error codes, refer to Error Codes.

20 VII Command Reference

Page 29

ResumePrintJob

This command is to instruct printer to resume printing from a printer pause mode.

XML Request

<VII Action="ResumePrintJob">

</VII>

XML Response

<VII Action="ResumePrintJob" Status="00">

</VII>

In case of error, “ResumePrintJob” XML response will be as listed below:

<VII Action="ResumePrintJob" Status=[error code]>

</VII>

For error codes, refer to Error Codes.

VII Command Reference 21

Page 30

RetractLabel

This command is to instruct the printer to retract the label specified by host using

label ID.

XML Request

<VII Action="RetractLabel">

<LabelID>[label ID]</LabelID>

</VII>

The range of how many labels can be retracted is between 3 and 11 which decrease

when media length is changing from small to big. Refer to Label number and Label

Length range on page 6.

For example, if the number of label is 3 and last label ID sent back to host is 5, the

host only can send back the label ID for retract from 3 to 5.

XML Response

<VII Action="RetractLabel " Status="00">

</VII>

In case of error, “RetractLabel ” XML response will be as listed below:

<VII Action="RetractLabel " Status=[error code]>

</VII>

For error codes, refer to Error Codes.

22 VII Command Reference

Page 31

ReverifyLabel

This command is to instruct printer to re-verify a single label specified by the

LabelID.

Note: When a label has been retracted through the TPH, the original grade (first time

verified) may not be accurate anymore. This command lets you regrade the label

again.

XML Request

<VII Action="ReverifyLabel">

<LabelID>[label ID]</LabelID>

</VII>

The range of how many labels can be reverified is from 3 to 11 which decrease

when media length is changing from small to big. Refer to Label number and Label

Length range on page 6.

For example, if the number of label is 3 and last label ID sent back to host is 5, the

host only can send back the label ID for reverify from 3 to 5.

XML Response

<VII Action="ReverifyLabel " Status="00">

</VII>

In case of error, “ReverifyLabel ” XML response will be as shown below:

<VII Action="ReverifyLabel " Status=[error code]>

</VII>

This response reply the status of reverify action. The verification result will be same

as normal printing verification sent from feedback channel.

For error codes, refer to Error Codes.

VII Command Reference 23

Page 32

SendVerificationResult

This command is to send barcode/image verification result from the host to the

printer.

In Synchronous Mode on page 5, printer will stop subsequent label printing and

wait for verification result from host. In Asynchronous Mode on page 5, printer will

stop print after all image buffer is used up.

Note: The SendVerificationResult is for verification modes 1 and 2 only.

XML Request

<VII Action="SendVerificationResult">

<LabelID>[label ID]</LabelID>

<VerificationResult>[verification result]</

VerificationResult>

</VII>

Verification result can be “Pass” or “Fail”.

XML Response

<VII Action="SendVerificationResult" Status="00">

</VII>

In case of error, “SendVerificationResult” XML response will be as listed below:

<VII Action="SendVerificationResult" Status=[error code]>

</VII>

For error codes, refer to Error Codes.

24 VII Command Reference

Page 33

SetCommandChannelPort

This command is to set the port number of the command channel. The default

value is “9301”. The range of the port numbers are 9301 - 65535.

XML Request

<VII Action="SetCommandChannelPort">

<PortNumber>[port number]</PortNumber>

</VII>

XML Response

In case of successful command execution, no response will be sent, as port will be

reset to new value.

In case of error, 'SetCommandChannelPort' XML response will be as listed below:

<VII Action="SetCommandChannelPort" Status=[error code]>

</VII>

Note: User can reconnect to a new port from the range 9301-65535.

For error codes, refer to Error Codes.

VII Command Reference 25

Page 34

SetExecutionMode

For Execution Mode, Refer to Execution Mode on page 5.

XML Request

<VII Action="SetExecutionMode">

<Option>[option]</Option>

</VII>

XML Response

<VII Action="SetExecutionMode" Status="00">

</VII>

In case of error, 'SetExecutionMode' XML response will be as listed below:

<VII Action="SetExecutionMode" Status=[error code]>

</VII>

For error codes, refer to Error Codes.

26 VII Command Reference

Page 35

SetFeedbackChannelPort

This command is to set the port number of the feedback channel. The default value

is "9302". The range of the port numbers are 9301 - 65535.

Note: Command port need to be connected before connecting Feedback channel. The

Feedback channel will only accept connection from Command channel's Host (same

IP), else, even if it shows connection OK, there won't be any output from this channel.

XML Request

<VII Action="SetFeedbackChannelPort">

<PortNumber>[port number]</PortNumber>

</VII>

XML Response

In case of successful command execution, no response will be sent as port will be

reset to new value.

In case of error, “SetFeedbackChannelPort” XML response will be as listed below:

<VII Action="SetFeedbackChannelPort" Status=[error code]>

</VII>

Note: User can reconnect to a new port from the range 9301-65535.

For error codes, refer to Error Codes.

VII Command Reference 27

Page 36

SetImageChannelPort

This command is to set the port number of the image channel. The default value is

"9303". The range of the port numbers are 9301 - 65535.

Note: Command port need to be connected before connecting the image channel. The

image channel will only accept connection from the same host (same IP) connected

by the command channel, else, even if it shows connection OK, there won't be any

output from this channel.

XML Request

<VII Action="SetImageChannelPort">

<PortNumber>[port number]</PortNumber>

</VII>

XML Response

In case of successful command execution, no response will be sent, as port will be

reset to new value.

In case of error, 'SetImageChannelPort" XML response will be as listed below:

<VII Action="SetImageChannelPort" Status=[error code]>

</VII>

Note: User can reconnect to a new port from the range 9301-65535.

For error code, refer to Error Codes.

28 VII Command Reference

Page 37

SetVerifierMode

This command is to set verifier mode.

XML Request

<VII Action="SetVerifierMode">

<Option>[option]</Option>

</VII>

Verifier option can be below value:

1. Scan

2. Scan and grade

3. Scan, grade and control

Note: The default value is "3".

XML Response

In case of successful command execution, 'SetVerifierMode' XML response will be

as listed below:

<VII Action="SetVerifierMode" Status="00">

</VII>

In case of error, “SetVerifierMode” XML response will be as shown below:

<VII Action="SetVerifierMode" Status=[error code]>

</VII>

For error codes, refer to Error Codes.

S

VII Command Reference 29

Page 38

VerificationResult

This is the response to feedback barcode verification result from printer to host. If

the barcode inspection is performed by printer verifier, the verification result will

be sent to host after each label is inspected.

Note: The verification mode applicable are mode 2 and 3.

XML Response

<VII Action="VerificationResult">

<LabelID>[label ID]</LabelID>

<VerificationResult>[verification result]</

VerificationResult>

<VerificationReport>[verification report]</

VerificationReport>

</VII>

Verification result can be "Pass" or "Fail".

The verification report will be XML format, and use UTF-8 as character encoding.

For a sample of verification report, refer to Appendix A.

30 VII Command Reference

Page 39

VoidLabel

This command is to instruct printer to mark up VOID on printed label.

XML Request

</VII>

VoildLabel option should be either "Single" or "All".

If option is "Single", only the label specified by label ID will be VOID.

If option is "All", then the labels between the label specified by label ID and the last

printed label will be VOID.

The range of how many labels can be VOID will be based on the Label number and

Label Length range on page 6.

For example, if the number of label is 3 and last label ID sent back to host is 5, the

host only can send back the label ID for voiding from 3 to 5.

<VII Action="VoidLabel">

<LabelID>[label ID]</LabelID>

<Option>[option]</Option>

XML Response

In case of successful command execution, 'VoidLabel ' XML response will be as

listed below:

<VII Action="VoidLabel " Status="00">

</VII>

In case of error, 'VoidLabel ' XML response will be as listed below:

<VII Action="VoidLabel " Status=[error code]>

</VII>

For error codes, refer to Error Codes.

VII Command Reference 31

Page 40

Error Codes

The following table details the possible causes or error and its description.

Error Codes Command Possible Cause Description

00 NA NA Command status is OK

01 NA Invalid XML Wrong syntax for the respective XML

02 NA Label ID Not Found The specified label ID cannot be found in

03 NA Command Error Error in command handling

04 NA Unknown Error Invalid command/other errors

commands used

printer

32 VII Command Reference

Page 41

CHAPTER

TROUBLESHOOTING

4

Problems and Possible Solutions

Problems Possible Solution

The Ethernet or wireless

network connection is not working

correctly

Printing stops May happen on VII mode 1/2 due to missing command from

Printer does not print label in batch

mode for batch printing

Missing result/Image files Try these possible solutions:

Printer is not voiding the full label Try these possible solutions:

Try these possible solutions:

• Make sure your network cable is securely connected to

your printer and is straight pin-to-pin cable, not a

crossover cable.

• Make sure your PC is correctly configured for and

connected to your network.

• Make sure your printer is correctly configured for your

network.

Host to printer. Drop the current connection and force the

printer to discard its current state.

Try these possible solutions:

• Lower the printing speed.

• Reduce the network route (move the printer and host pc

to the same network).

• Use Ethernet connection instead of Wireless

connection.

• Reset Verification result by UI/Webpage/VII command.

• Lower the printing speed.

• Reduce the network route (move the printer and host pc

to the same network).

• Use Ethernet connection instead of Wireless

connection.

• Change the Host application implementation dedicated

process/thread for receiving data rather than using the

same thread/process for receiving and data handling.

• Set the correct void length in printer setting

• Adjust the TPH pressure to avoid media slipping.

VII Command Reference 33

Page 42

Problems Possible Solution

Not able to connect to printer Try these possible solutions:

• Check network status, and make sure your host PC is

able to ping the printer IP address.

• Check your printer setting, and make sure your printer

VII service is enabled.

• Check your printer setting, and make sure the expected

VII ports are used.

• Printer might be connected to another Host PC,

disconnect the current connection.

• Check your Host PC port, and make sure VII ports are

not being used by other processes.

• Check your firewall setting, make sure VII ports are not

blocked by firewall.

Image data is not received • Try these possible solutions:

• Check network status, and make sure your host PC is

able to ping the printer IP address

• Check your printer setting, and make sure your printer

VII service is enabled.

• Check your printer setting, and make sure the expected

VII ports are used.

• Printer might be connected to another Host PC,

disconnect the current connection.

• Check your Host PC port, and make sure VII ports are

not being used by other processes.

• Check your firewall setting, make sure VII ports are not

blocked by firewall.

Report data is not received Try these possible solutions:

• Check network status, and make sure your host PC is

able to ping the printer IP address.

• Check your printer setting, and make sure your printer

VII service is enabled.

• Check your printer setting, and make sure the expected

VII ports are used.

• Printer might be connected to another Host PC,

disconnect the current connection.

• Check your Host PC port, and make sure VII ports are

not being used by other processes.

• Check your firewall setting, make sure VII ports are not

blocked by firewall.

Image data is not received in real

time

Try these possible solutions:

• Reduce print speed

• Reduce traffic congestion on network

34 VII Command Reference

Page 43

CHAPTER

USE CASE SEQUENCE DIAGRAM

5

Printer Error

The use case show when printer error happen before/during printing.

VII Command Reference 35

Page 44

Print Job - Pause, Resume, Cancel

This use case displays the host request to Pause/Print/Cancel print job.

Note: The pause will be executed on the next label.

36 VII Command Reference

Page 45

APPENDIX

VERIFICATION REPORT

A

Sample Verification Report

<Label ID="4">

<PrintJobID>4</PrintJobID>

<VerificationType>ISO 15415/15416</VerificationType>

<PassingGrade>1.5 (C)</PassingGrade>

<HardwareAperture>4.8 mils</HardwareAperture>

<Date>20190507</Date>

<Time>125652</Time>

<CalibrationDate>20190221</CalibrationDate>

<LabelGrade>3.3 (B)</LabelGrade>

<LabelStatus>Pass</LabelStatus>

<FailureReason></FailureReason>

<Image>PX940V_18333B24D8_4_20190507_125652.jpg</Image>

<Barcodes>3</Barcodes>

<Barcode ID="1">

<Symbology>CODE39</Symbology>

<Size>19.7 mils</Size>

<Data>1234</Data>

<EncodedData><Start>1234<Stop></EncodedData>

<Grade>3.3 (B)/10/660</Grade>

<Status>Pass</Status>

<ScanLineDataCheck>Pass</ScanLineDataCheck>

<XPos>213</XPos>

<YPos>396</YPos>

<Width>1530 pixels</Width>

<Height>682 pixels</Height>

<OverallParameter>

<RMax>80.5%</RMax>

<RMin Grade="4.0">18.2%</RMin>

<ECMin Grade="4.0">47.2%</ECMin>

<SymbolContrast Grade="3.4">62.3%</SymbolContrast>

<Modulation Grade="4.0">75.9%</Modulation>

<Defects Grade="4.0">11.5%</Defects>

<Decodability Grade="4.0">88.9%</Decodability>

<Decode Grade="4.0"/>

<QuietZone Grade="4.0"/>

<GlobalThreshold>49.4%</GlobalThreshold>

<PCS>77.3%</PCS>

<BarGain>-5.1%</BarGain>

</OverallParameter>

<LineProfileParameter>

VII Command Reference 37

Page 46

<Line ID="1">

<Grade>3.3</Grade>

<RMax>80.7%</RMax>

<RMin Grade="4.0">19.9%</RMin>

<ECMin Grade="4.0">44.6%</ECMin>

<SymbolContrast Grade="3.3">60.8%</SymbolContrast>

<Modulation Grade="4.0">73.4%</Modulation>

<Defects Grade="3.4">18.1%</Defects>

<Decodability Grade="4.0">90.5%</Decodability>

<Decode Grade="4.0"/>

<QuietZone Grade="4.0"/>

<GlobalThreshold>50.3%</GlobalThreshold>

<PCS>75.3%</PCS>

<BarGain>-5.4%</BarGain>

</Line>

<Line ID="2">

<Grade>3.4</Grade>

<RMax>80.7%</RMax>

<RMin Grade="4.0">19.6%</RMin>

<ECMin Grade="4.0">46.6%</ECMin>

<SymbolContrast Grade="3.4">61.1%</SymbolContrast>

<Modulation Grade="4.0">76.3%</Modulation>

<Defects Grade="4.0">4.7%</Defects>

<Decodability Grade="4.0">86.8%</Decodability>

<Decode Grade="4.0"/>

<QuietZone Grade="4.0"/>

<GlobalThreshold>50.1%</GlobalThreshold>

<PCS>75.7%</PCS>

<BarGain>-5.9%</BarGain>

</Line>

<Line ID="3">

<Grade>3.4</Grade>

<RMax>80.7%</RMax>

<RMin Grade="4.0">19.2%</RMin>

<ECMin Grade="4.0">47.0%</ECMin>

<SymbolContrast Grade="3.4">61.5%</SymbolContrast>

<Modulation Grade="4.0">76.5%</Modulation>

<Defects Grade="4.0">11.3%</Defects>

<Decodability Grade="4.0">90.1%</Decodability>

<Decode Grade="4.0"/>

<QuietZone Grade="4.0"/>

<GlobalThreshold>49.9%</GlobalThreshold>

<PCS>76.2%</PCS>

<BarGain>-5.4%</BarGain>

</Line>

<Line ID="4">

<Grade>3.2</Grade>

<RMax>80.3%</RMax>

<RMin Grade="4.0">19.6%</RMin>

<ECMin Grade="4.0">49.0%</ECMin>

<SymbolContrast Grade="3.3">60.7%</SymbolContrast>

<Modulation Grade="4.0">80.8%</Modulation>

<Defects Grade="3.2">19.3%</Defects>

<Decodability Grade="4.0">91.4%</Decodability>

<Decode Grade="4.0"/>

<QuietZone Grade="4.0"/>

<GlobalThreshold>49.9%</GlobalThreshold>

<PCS>75.5%</PCS>

38 VII Command Reference

Page 47

<BarGain>-5.2%</BarGain>

</Line>

<Line ID="5">

<Grade>3.5</Grade>

<RMax>80.7%</RMax>

<RMin Grade="4.0">17.6%</RMin>

<ECMin Grade="4.0">47.4%</ECMin>

<SymbolContrast Grade="3.5">63.1%</SymbolContrast>

<Modulation Grade="4.0">75.1%</Modulation>

<Defects Grade="4.0">7.3%</Defects>

<Decodability Grade="4.0">89.8%</Decodability>

<Decode Grade="4.0"/>

<QuietZone Grade="4.0"/>

<GlobalThreshold>49.2%</GlobalThreshold>

<PCS>78.1%</PCS>

<BarGain>-4.9%</BarGain>

</Line>

</LineProfileParameter>

</Barcode>

</Label>

Note: For more information about the contents in the sample code, refer to PX940 User

Guide.

VII Command Reference 39

Page 48

40 VII Command Reference

Page 49

Honeywell

9680 Old Bailes Road

Fort Mill, SC 29707

www.honeywellaidc.com

™

PX940-VII-EN-CR-1 Rev A

03/20

Loading...

Loading...