Page 1

Honeywell

VE4000 & VE5000 SERIES

CLASS "A" GAS VALVES

INSTRUCTION SHEET

APPLICATION

These series class A gas valves are used for control and

regulation of gaseous fluids in gas power burners, atmospheric

gas boilers, melting furnaces, incinerators and other gas

consuming appliances

GENERAL

DESCRIPTION

VE4000 Series Gas Valve

The VE series gas valves offer a series of functionalities:

Gas valves, Normally Closed.

CPI switch optional

Gas valves for use with Honeywell V4055, V4062 and

V9055 fluid power actuators.

Relief valves Normally Open.

Adjustable opening characteristics optional

FEATURES

The VExxxxX1xxx series gas valves have a wrench boss

as well on inlet side as on outlet side for pipe fitting

incorporated in the valve housing.

The VExxxxX3xxx and VE5xxxX3xxx series gas valves

are equipped at both sides with mounting holes to adapt a

pilot solenoid valve combination, to allow either internal or

external pilot gas. Furthermore these valves are equipped

with two M6 mounting holes to adapt an A4020A

electronic leak test The VExxxxB series gas valves have

an adjustable flow rate regulator on top of the coil.

For the VE series gas valves a series of field replaceable

connection boxes (including circuits) are available

The VExxxxC series gas valves have adjustments for step

pressure flow rate and opening speed in hydraulic damper

unit on top of the coil.

The VExxxxS series gas valves normally open relief

valves have no option for mounting a CPI switch

The VE5xxxX3xxx series gas valves can be equipped with

a wide range of Honeywell fluid power actuators. These

fluid power actuators are field replaceable.

Subject to change without notice. All rights reserved.

ISTR0018 1602RA-NE

1

Page 2

/

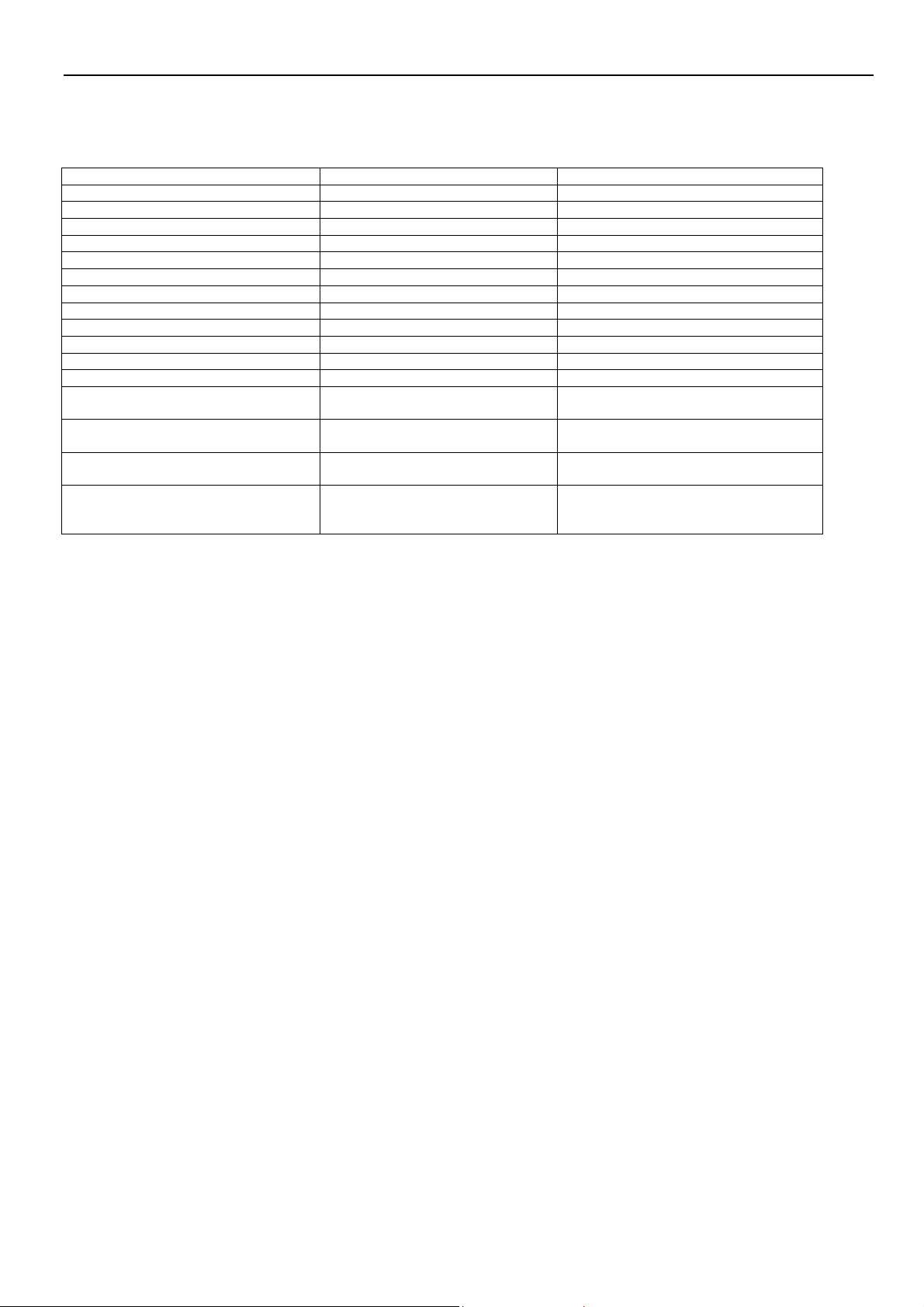

MODEL CHART

Options 1000/2000 series internal thread 3000

DN10 / 3/8” VExx10

DN15 / 1/2” VExx15

DN20 / 3/4” VExx20

DN25 / 1” VExx25

DN32 / 1 1/4” VExx32

DN40 / 1 1/2” VExx40

DN50 / 2” VExx50

DN65 / 2 1/2” VExx65 VExx65

DN80 / 3” VExx80 VExx80

DN100 / 4” VEx100

Non regulated ON/OFF (VExxxxAxxxx) Standard Standard

Flow regulator (VExxxxBxxxx) Optional Optional 2)

Adjustable opening and flow regulator

(VExxxxCxxxx)

Motorized opening: ON/OFF

(VE5xxxAxxxx)

Motorized opening: characterized

(VE5xxxCxxxx)

Safety relief valve, ON/OFF, Normally

Open, with or without position

indication switch (VExxxxSxxxx)

1) Except VExx65/VExx80

2) Except VE4100

Optional 1) Not available

Not available VE5065A3xxx

Not available VE5065C3xxx

Optional for:

VE..20

VE..25

4000 series flange connection

VE5085A3xxx

VE5085C3xxx

Not available

Honeywell

2

ISTR0018 1602RA-NE

Page 3

TECHNICAL

SPECIFICATIONS

VE series solenoid gas valves

VExx10 (DN 10)

VExx15 (DN 15)

VExx20 (DN 20)

VExx25 (DN 25)

VExx32 (DN 32)

VExx40 (DN 40)

VExx50 (DN 50)

VExx65 (DN 65)

VExx80 (DN 80)

VEx100 (DN 100)

VE series suitable for fluid power actuators

VE5065 (DN 65)

VE5080 (DN 80)

VE5100 (DN 100)

Pipe sizes 1000/2000 series

Inlet and outlet G3/8" up to G21/2" internal parallel pipe

thread according ISO 7-1

Pipe sizes 3000/4000 series

Flanged connection DN 65, DN 80 and DN100 according to

DN 16 UNI 2223.

Torsion and bending stress

Pipe connections meet Group 2 according EN 161

requirements.

Ambient temperature

-15 °C ... 60 °C

Supply voltage

24 V, 50/60 Hz 1)*

100-120 V, 50/60 Hz

200-240 V, 50/60 Hz

The applicable voltage is led to the solenoid coil via a

rectified circuit.

1): only for DN10 up to DN50

Operational voltage range

The gas valve will function between 85% and 110% of the

rated voltage

Electrical connection VE4xxx/VE6xxx/VE8xxx

Option 1: Wiring on terminal block on circuit cables entering

box via PG Cable Gland

Option 2: Connection by means of DIN plug on DIN faced

connection located on front cover according to

ISO4400 / DIN EN 175301-803

Electrical connection VE5xxx series

See product literature fluid power actuators

Enclosure VE4xxx/VE6xxx/ VE8xxx

IP 65 when using supplied PG gland and cable

diameter 7 – 13 mm for PG version or using suitable DIN

plug with gasket.

Honeywell

Capacity

See page 7 and 8

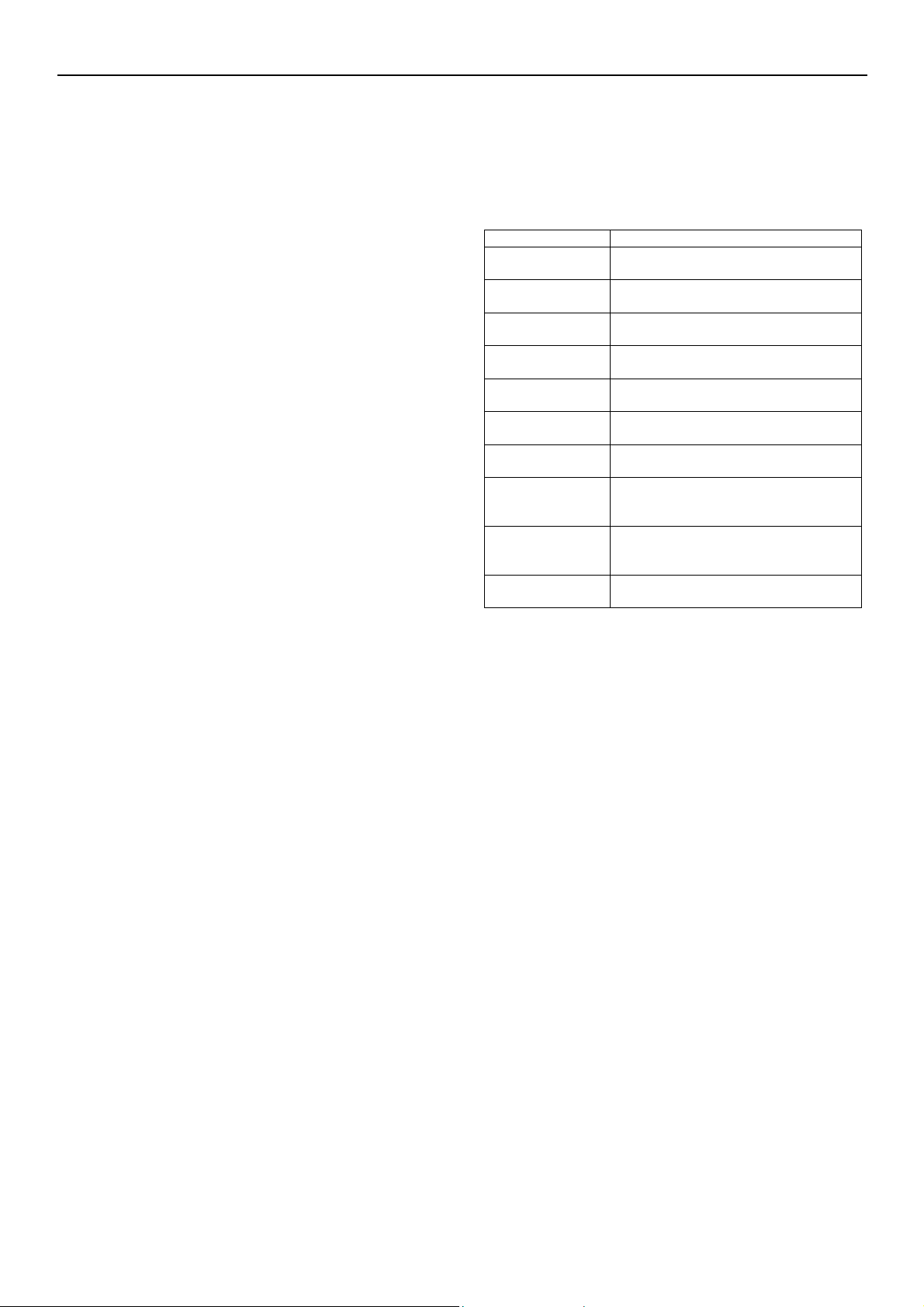

Maximum operating pressure

Inlet Maximum operating pressure (mbar)

VE4010/VE6010

VE8010

VE4015/VE6015

VE8015

VE4020/VE6020

VE8020

VE4025/VE6025

VE8025

VE4032/VE6032

VE8032

VE4040/VE6040

VE8040

VE4050/VE6050

VE8050

VE4065/VE6065

VE8065

VE5065

VE4080/VE6080

VE8080

VE5080

VE4100/VE6100

VE5100

200 or 500

200

200 or 500

200

200 or 500

200

200 or 500

200

200 or 500

200

200 or 500

200

200 or 500

200

200 or 500

200

200 or 360

200 or 500

200

200 or 360

200 or 500

200 or 500

3

ISTR0018 1602RA-NE

Page 4

Honeywell

POWER CONSUMPTION (VA)

Model

number

VExx10, C 15 17 13 -19 14-21 11-16 12-18

VExx15 15 17 13 -19 14-21 11-16 12-18

VExx20 21 23 17 -24 19-26 17-24 19-26

VExx25 21 23 17 -24 19-26 17-24 19-26

VExx32 start

VExx32 work

VExx40 start

VExx40 work

VExx50 start

VExx50 work

VExx65 start

VExx65 work

VExx80B start

VExx80 work

VEx100 start

VEx100 work

POWER CONSUMPTION Version S – 200 mbar

Model

number

VExx20S 16 19 17 21 14 17 16 19

POWER CONSUMPTION Version S – 360 mbar

Model

number

VExx20S 16 19 17 21 14 17 16 19

12 Volt,

50/60Hz

nominal

12 Volt,

50/60Hz

nominal

24Volt,

50/60Hz

nominal

N.A.

50

N.A.

50

N.A

49

N.A.

72

N.A.

72

N.A.

N.A.

12 Volt,

50/60Hz

110% of

nominal

12 Volt,

50/60Hz

110% of

nominal

24 Volt,

50/60Hz

110% of

nominal

N.A

55

N.A

55

N.A.

54

N.A.

54

N.A.

79

N.A.

N.A.

24Volt,

50/60Hz

nominal

24Volt,

50/60Hz

nominal

24 Volt,

50/60Hz

110% of

nominal

24 Volt,

50/60Hz

110% of

nominal

100-120 Volt,

50/60Hz

nominal

125-179

32-45

125-179

32-45

131-188

33-47

205-295

51-74

205-295

51-74

180-259

45-65

24 Volt

(dc),

nominal

(b)

24 Volt

(dc),

nominal

(b)

a)

a)

110 Volt,

50/60Hz

110% of

nominal

138-197

35-50

138-197

35-50

144-207

36-52

226-325

56-81

226-325

56-81

198-285

50-72

24 Volt

(dc),

110% of

nominal

24 Volt

(dc),

110% of

nominal

110

Volt,

50/60Hz

nominal

110

Volt,

50/60Hz

nominal

200-240 Volt,

50/60Hz

nominal

129-186

32-46

129-186

32-46

127-183

32-45

190-274

48-69

190-274

48-69

465-657

114-164

110

Volt,

50/60Hz

110% of

nominal

110

Volt,

50/60Hz

110% of

nominal

200-24-Volt,

50/60Hz

110% of

nominal

142-205

35-51

142-205

35-51

140-201

35-50

209-301

53-76

209-301

53-76

512-723

125-180

220

Volt,

50/60Hz

nominal

220

Volt,

50/60Hz

nominal

220 Volt,

50/60Hz

110% of

nominal

220 Volt,

50/60Hz

110% of

nominal

PERFORMANCE CHARACTERISTICS

Opening time (except VE5xxx series)

VExxxxA,B,S version: less than 1 second

VExxxxC version: adjustable from 1 up to 30 seconds at rated capacity

Closing time

VExxxxA, B, C and S series (except VE5xxx series)

Less than 1 second

Maximum working cycles/minute

S versions: 20

DN10–DN 25 A & B versions: 20

DN10-DN25 C versions: 1

DN32-DN100: 1

VE5... series: 1 cycle per 2 minutes

Duty cycle

Coil suitable for permanent energization

4

ISTR0018 1602RA-NE

Page 5

INSTALLATION

WARNING

Take care that installer is a trained experienced

service man.

Turn off gas supply before starting installation.

Disconnect power supply to prevent electrical shock

and/or equipment damage.

Mounting position

The gas valve can be mounted plus or minus 90 degrees from

the vertical.

Mounting location

The distance between the gas valve and the wall/ground, must

be at least 30 cm.

WARNING

The outlet of a pressure relief valve (VE4000S series)

must always be connected to open atmosphere.

Main gas connection threaded valves

Take care that dirt cannot enter the gas valve during

handling.

Ensure the gas flows in the same direction as the arrow

on the housing of the gas valve.

Use a sound taper fitting with thread according to ISO 7-1

(BS 21, DIN2999) or a piece of new, properly reamed

pipe, free from swarf

Do not thread or tighten the pipe or pipe fitting too far.

Otherwise valve distortion and malfunction could result.

Apply a moderate amount of good quality thread

compound to the pipe or fitting only, leaving the two end

threads bare. PTFE tape may be used as an alternative.

In order to tighten the pipe in the valve, do not use the

actuator as a lever but use a suitable wrench operating on

the wrench bosses.

Honeywell

Main gas connection flanged valves

Take care that dirt cannot enter the gas valve during

handling.

Ensure the gas flows in the same direction as the arrow

on the housing of the gas valve.

Ensure that inlet and outlet flanges are in line and

separated from each other enough to allow the valve to be

mounted between them without damaging the gasket.

Place gasket. If necessary grease it slightly to keep it in

place.

Mount gas valve between flanges using the bolts for each

flange.

WARNING

Tightness test after installation

Paint all pipe connections and gaskets with a strong

soap and water solution..

Start the appliance and check for bubbles. If a leak is

found in a pipe connection, remake the joint. A gasket

leak can usually be stopped by tightening the

mounting screws. Otherwise, replace the gas valve.

Electrical connection

CAUTION

Switch off power supply before making electrical

connections.

Take care that wiring is in accordance with local

regulations.

Use lead wire which can withstand 105 °C ambient.

The electric on/off operator is provided with a terminal block

for electrical connections.

Wiring

Follow the instructions supplied by the appliance

manufacturer.

5

ISTR0018 1602RA-NE

Page 6

Instructions Electrical connections

Connection instructions with PG gland

On each side of the connection box there are break out

area’s. See Fig 1. After removing the central part of one of

these break outs, the PG gland (supplied with the valve) can

be fitted.

Honeywell

After connecting wires ( L, N & PE) to dedicated connectors

on connector block, the connection needs to closed by

mounting the front cover. Before placing the cover, please

check the correct position of seal as shown in Fig 4. The

cover can only be mounted in one orientation. This is shown

in Fig 5.

Specified torque for cover screw: 0.5 Nm.

Specified cable diameter for gland: 7 – 13 mm.

Fig 1

After removing the nut from the gland, the gland can be

placed in the break out. The nut needs to turned onto the

gland inside the box and tightened as shown in Fig 2.

Specified torque for the nut: 4 Nm. Mounted PG gland

shown in Fig 3. Specified torque PG gland: 3 Nm.

Fig 2

Fig 4

Fig 5

Connection instructions DIN plug

Specified torque for DIN connector screw: 0.2 Nm.

Fig 3

Fig 6

6 ISTR0018 1602RA-NE

Page 7

ADJUSTMENT AND FINAL CHECKOUT

WARNING

Adjustments must be made by qualified persons only

CAUTION

To ensure a safe closing of the valves, it is essential

that voltage over the terminals of operators is

reduced to 0 Volt.

IMPORTANT

To ensure a satisfactory setting of the valve the

pressure drop over the valve should be at least 10%

of the supply pressure or 2.5 mbar which ever is the

greatest.

VExxxxB SERIES

(see fig 7.)

Flow rate adjustment

Remove the cap screw from top of the coil.

Place a socket head wrench into the adjustment nut.

Turn wrench counter--clockwise to increase or clockwise

to decrease flow rate.

Replace cap screw.

Honeywell

Step pressure adjustment. Fig 8

Opening speed adjustment

Remove the cap from top of the coil by loosening both

screws.

Place screw driver in the slot of adjustment screw which is

of center line.

Turn screw driver counter--clockwise to increase the

opening speed and therefore the time till full opening will

decrease.

Turn screw driver clockwise to decrease the opening

speed and therefore the time till full opening will increase.

Replace cap on top of the coil.

Flow adjustment fig 7

VExxxxC SERIES

(see fig. 8, 9 and 10)

The following characteristics can be adjusted:

flow rate

step pressure

opening speed

Step pressure adjustment

Remove the cap from top of the coil by loosening both

screws.

Place a screw driver in the slot of adjustment screw which

is situated in center of the valve.

Turn screw driver counter--clockwise to increase or

clockwise to decrease step pressure.

Replace cap on top of the coil.

Opening speed adjustment. Fig 9

)

Flow rate adjustment

Remove the cap screw from top of the coil by loosening

both screws

Place a wrench onto the adjustment nut.

Turn wrench counter--clockwise to increase or clockwise

to decrease flow rate.

Replace cap screw.

Flow rate adjustment. Fig 10

Final checkout of the installation

Set appliance in operation after any adjustment and observe

several complete cycles to ensure that all burner components

function correctly.

7

ISTR0018 1602RA-NE

Page 8

REPLACEMENT PARTS AND ACCESSORIES

WARNING

Take care that only qualified persons carry out the installation of parts, accessories, and add on comp onents.

Follow the installation instructions included in the package.

Check that the selected part, accessory or add on component is the correct one for the application in question.

Specification of data is given in the instruction leaflet in the package .Replace the old gaskets with the new ones

supplied in the package and check for leakage when the supply is switched on again. After installatio n an d/or

replacement has been completed, a gas leak test must be carried out. Also check the gas valve for satisfactory operation

after fitting accessories.

SPARE CONNECTION BOXES

Ordering

Valve type Voltage Connection

VExx10/VExx15 24 PG BB0xxxxx

100-120 PG BB0xxxxx

200-240 PG BB0xxxxx

VExx10/VExx15 24 DIN BB0xxxxx

100-120 DIN BB0xxxxx

200-240 DIN BB0xxxxx

VExx20/VExx25 24 PG BB0xxxxx

100-120 PG BB0xxxxx

200-240 PG BB0xxxxx

VExx20/VExx25 24 DIN BB0xxxxx

100-120 DIN BB0xxxxx

200-240 DIN BB0xxxxx

VExx32/VExx40 24 PG BB0xxxxx

100-120 PG BB0xxxxx

200-240 PG BB0xxxxx

VExx32/VExx40 24 DIN BB0xxxxx

100-120 DIN BB0xxxxx

200-240 DIN BB0xxxxx

number

Valve type Voltage Connection

VExx50 24 PG BB0xxxxx

100-120 PG BB0xxxxx

200-240 PG BB0xxxxx

VExx50 24 DIN BB0xxxxx

100-120 DIN BB0xxxxx

200-240 DIN BB0xxxxx

VExx65/VExx80 24 PG BB0xxxxx

100-120 PG BB0xxxxx

200-240 PG BB0xxxxx

VExx65/VExx80 24 DIN BB0xxxxx

100-120 DIN BB0xxxxx

200-240 DIN BB0xxxxx

VEx100 100-120 PG BB0xxxxx

200-240 PG BB0xxxxx

VEx100 100-120 DIN BB0xxxxx

200-240 DIN BB0xxxxx

Honeywell

Ordering

number

Honeywell

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Z.A. La Pièce 16, 1180 Rolle, Switzerland or its Authorized

Representative:

Automation and Control Solutions

Combustion Controls EMEA

Honeywell BV

Phileas Foggstraat 7

7821 AJ Emmen

The Netherlands

Tel.: +31 (-) 591 695 911

Fax: +31 (-) 591 695 200

http://ecc.emea.honeywell.com/default.htm

8 ISTR0018 1602RA-NE

Loading...

Loading...