Page 1

V4943/V8943B,C,N;

V4944/V8944B,C,L,N

Regulating Diaphragm Gas Valves

PRODUCT DATA

FEATURES

• Models are available for natural or liquid petroleum

(LP) gases.

• Valve models L, N are rapid opening (less than six

seconds) and fast closing, and are available for LP and

natural gases, respectively.

• Line voltage with two-wire thermostat or controller is

used with V4943; V8943 is used with 24V thermostat or

controller.

• V4944 is used with line voltage dual-stage thermostat

or controller; V8944 is used with 24V dual-stage

thermostat or controller.

• Slow opening B,C valve models are available for

natural and LP gases respectively.

• Valve closes on power failure; recommended for final

shutoff service.

APPLICATION

The V4943/V8943B and N (single stage) and V4944/V8944B

and N (two stage) are solenoid-operated diaphragm valves

suitable for natural gas only. The V4943/V8943C and

V4944/V8944C and L are solenoid-operated diaphragm

valves suitable for Liquefied Petroleum (LP) gas only. These

valves are used on boilers, unit heaters, duct furnaces,

makeup air and rooftop heaters.

• Valve closing time: 2 seconds maximum at 7 inches wc

inlet pressure.

• Valves rated for 0.5 pound per square inch (psi) (3.4

kPa).

• Leadwires and cover for electrical conduit connections

are provided.

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 6

Operation .......................................................................... 9

Checkout and Troubleshooting ......................................... 10

Service Information .......................................................... 12

65-0214-08

Page 2

V4943/V8943B,C,N; V4944/V8944B,C,L,N REGULATING DIAPHRAGM GAS VALVES

SPECIFICATIONS

Models:

All models are solenoid-operated regulating diaphragm gas

valves. Details are shown in Table 1.

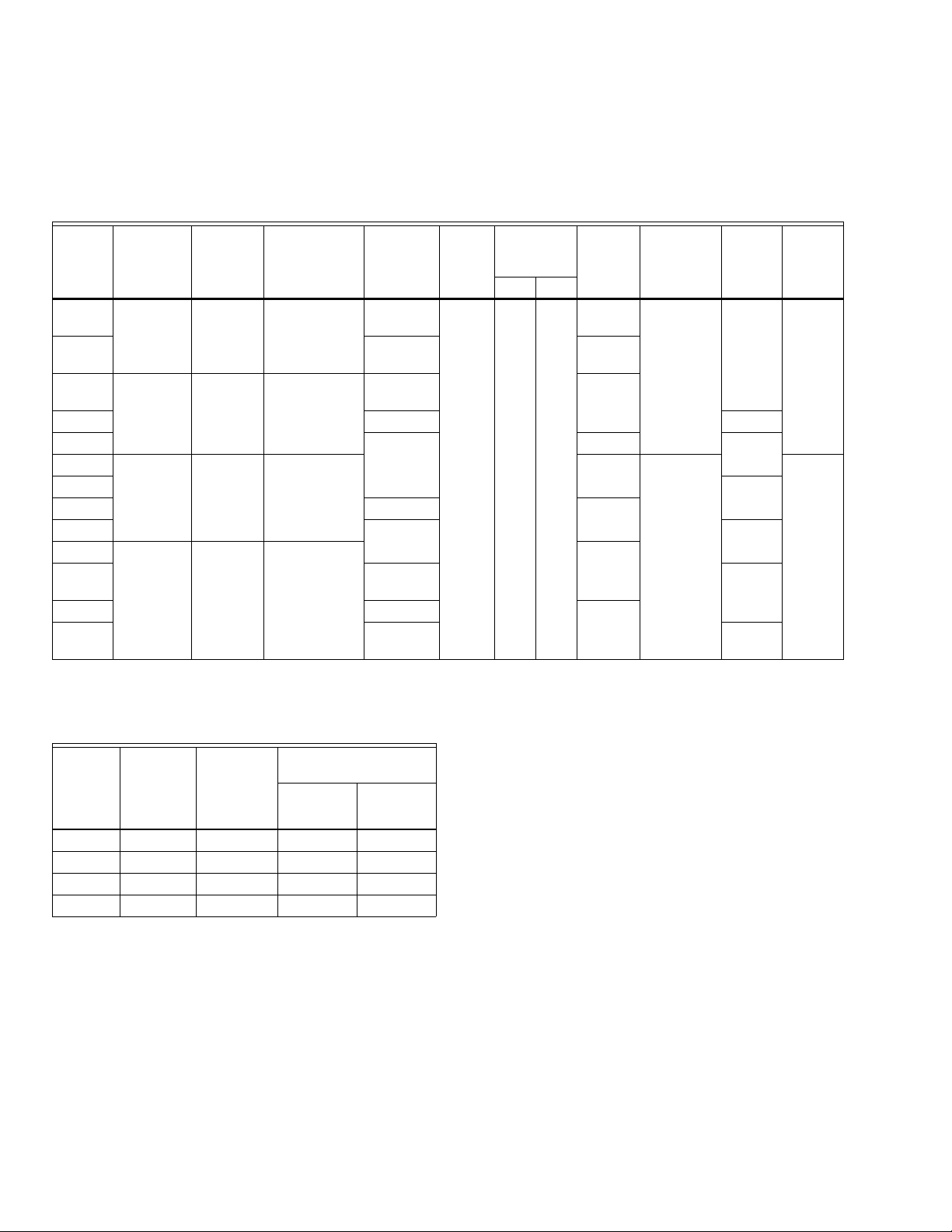

Table 1. Model Availability.

Power

Volt ag e

and

Model

V4943B 120V

V4943N 1, 1-1/4,

V8943B 24V,(+10%,

V8943C 1, 1-1/4 LP

V8943N 1, 1-1/4,

V4944B 120V

V4944C LP

V4944L 1-1/4 <6

V4944N 1, 1-1/4,

V8944B 24V

V8944C 1, 1-1/4,

V8944L 1, 1-1/4 <6

V8944N 1, 1-1/4,

a

Includes natural gas, mixed air-natural gas, LP gas-air.

Frequency

(+10%,

-15%),

60 Hz

-15%)

50/60 Hz

(+10%,

-15%)

60 Hz

(+10%,

-15%)

50/60 hz

Maximum

Current

0.055A 6.6 1, 1-1/4,

0.363A 9.0 1, 1-1/4,

0.077A 9.0 3 to 25 Two stage 3

0.470A 11.3 3 to 25

Consumption

(VA

Maximum)

Pipe Size

(in.)

1-1/2, 2

1-1/2

1-1/2, 2

1-1/2

1-1/2, 2

1-1/2

1-1/2, 2

Thread

Typ e

NPT 0.5 3.4 3 to 25 Single

Maximum

Operating

Pressure

Opening

Time

(sec.)

<6

3 to 25

<6

Pressure

Regulation

stage

Type of

Gas

Natural

Natural

Natural

LP

Natural

Number

of Lead-

wirespsi kPa

a

2

a

a

a

Flow Capacity: See Table 2.

Table 2. V4/8943 and V4/8944 Flow Capacity.

CSA

Certified

1.0 in. pd

Pipe Size

(in.)

1 1,000 1,000,000 1,000 300

1-1/4 1,600 1,600,000 1,600 480

1-1/2 2,300 2,300,000 2,300 780

2 3,000 3,000,000 3,000 870

Natural

Gas cfh

Btuh per

1000 cfh

Natural

gas

Regulation Capacities

0.64 sp gr Natural Gas

Maximum

cfh

Minimum

cfh

Valve Pattern:Straight-through, non offset.

Valve Body Material:Die-cast aluminum.

Electrical Terminations:1/4 in. (6 mm) spade terminals

(quick connects). Leadwires and cover for electrical conduit

connections are provided.

Valve Closing Time: On power failure, a maximum of

2 seconds at 7 in. wc inlet pressure.

Ambient Temperature Ratings: -40°F to +150°F (-40°C to

+66°C).

Maximum Fluid Temperatures: 150°F (66°C).

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number. If you have additional questions, need further information,

or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Environmental and Combustion Controls Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

3. http://customer.honeywell.com or http://customer.honeywell.ca

International Sales and Service Offices in all principal cities of the world. Manufacturing in Belgium, Canada, China, Czech

Republic, Germany, Hungary, Italy, Mexico, Netherlands, United Kingdom, and United States.

65-0214—08 2

Page 3

V4943/V8943B,C,N; V4944/V8944B,C,L,N REGULATING DIAPHRAGM GAS VALVES

CAUTION

Pressure Reference Port Vent: 5/16–24 UNF internal

tapping.

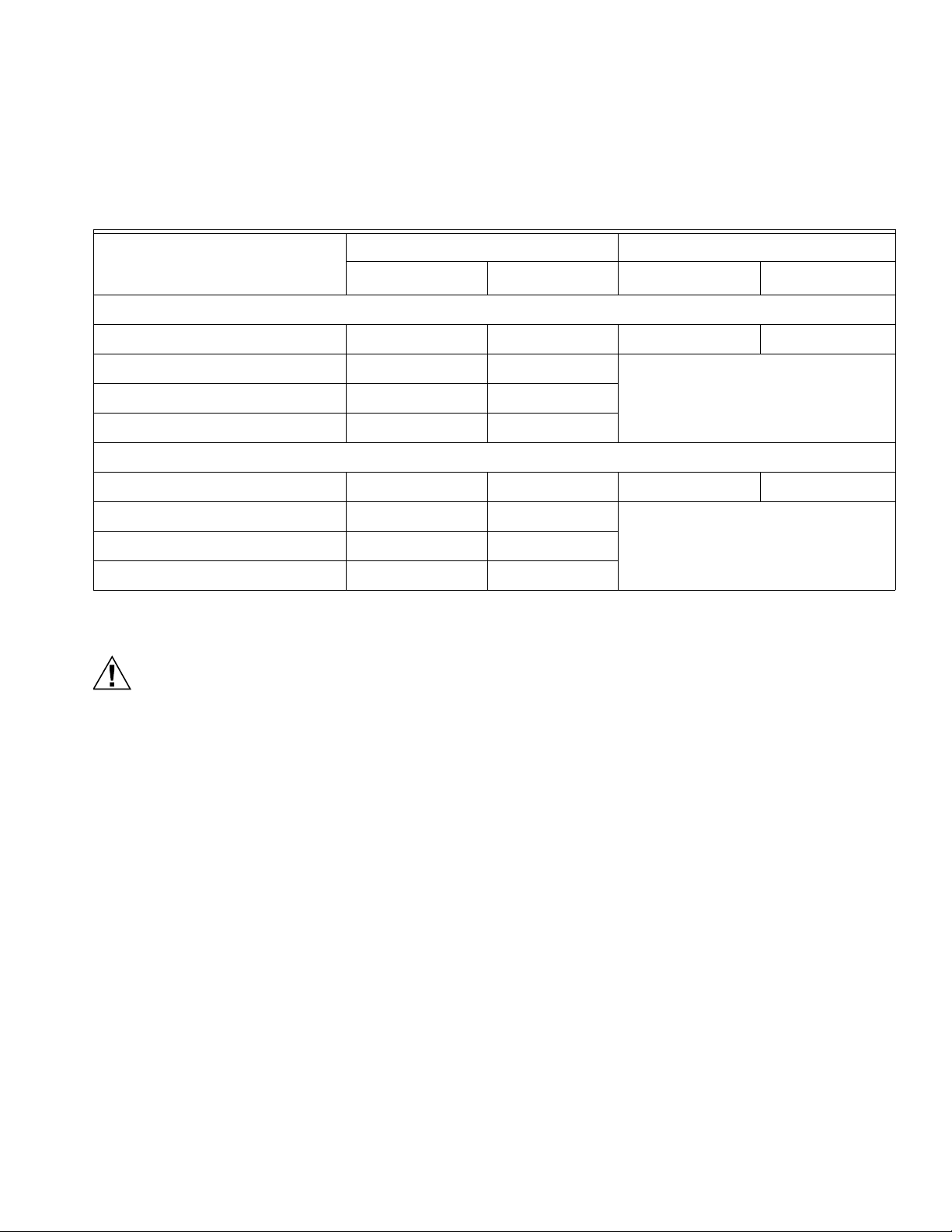

Standard Factory Settings: See Table 3.

Weight:

1 in., 1-1/4 in. valves: 4 lb (1.8 kg).

1-1/2 in., 2 in. valves: 5 lb (2.3 kg).

Dimensions: See Fig. 1.

Table 3. Factory Settings and Regulation Ranges.

Natural Gas (i.e. B, N models) LP Gas (i.e. C, L models)

Firing stages

a

Factory Setting Adj. Range

b

Factory Setting Adj. Range

Low Fire:

Standard Models 0.8” wc 0.8” to 2” wc 1.4” wc 1.4” to 4.2” wc

Special Models (Group 1) 1.6” wc 1.6” to 4.2” wc

Special Models (Group 2) 0.8” wc 0.8” to 2” wc

Special Models (Group 3) 0.8” wc 0.8” to 2” wc

High Fire:

Standard Models 3.5” wc 3” to 4.5” wc 10” wc 8.8” to 11.5” wc

Special Models (Group 1) 3.5” wc 3” to 4.5” wc

Special Models (Group 2) 3.5” wc 1.4” to 4.2” wc

b

Special Models (Group 3) 5” wc 4.0” to 7” wc

a

V4943 is a single-stage valve, please refer to “High Fire” for spring specifications.

b

Do not adjust or operate valve outside of the specified ranges.

DO NOT adjust or operate valve outside of the

specified ranges. Valve will not regulate or work

properly.

Special Models (Group 1): V4944B1075, V4944B1083, V4944B1091, V8944B1092, V8944B1100, V8944B1118

Special Models (Group 2): V4944B1109, V4944B1125, V4944B1141, V4944B1166; V4943B1050, V4943B1068, V4943B1076,

V4943B1084

Special Models (Group 3): V4944B1117, V4944B1133, V4944B1158; V4943B1092, V4943B1100, V4943B1118

Approvals:

Underwriters Laboratories Listed: File Number MH1639

CSA Certified: Report Number C2030020 (except those listed as Special Models Group 2 and Special Models Group 3)

Commonwealth of Massachusetts Product Certification Number: G1-12-05-22

Mounting Position:

Standard Position: Upright (horizontal).

NOTE: V4944B1059, V4944N1052 and V4944N1060 can

Accessories:

AT72D Transformer (40 VA) for all 24 Vac models.

204480 Vent Pipe Adapter

be mounted upright to 90 degrees from the

upright on the horizontal axis with respect to the

inlet connection.

3 65-0214—08

Page 4

V4943/V8943B,C,N; V4944/V8944B,C,L,N REGULATING DIAPHRAGM GAS VALVES

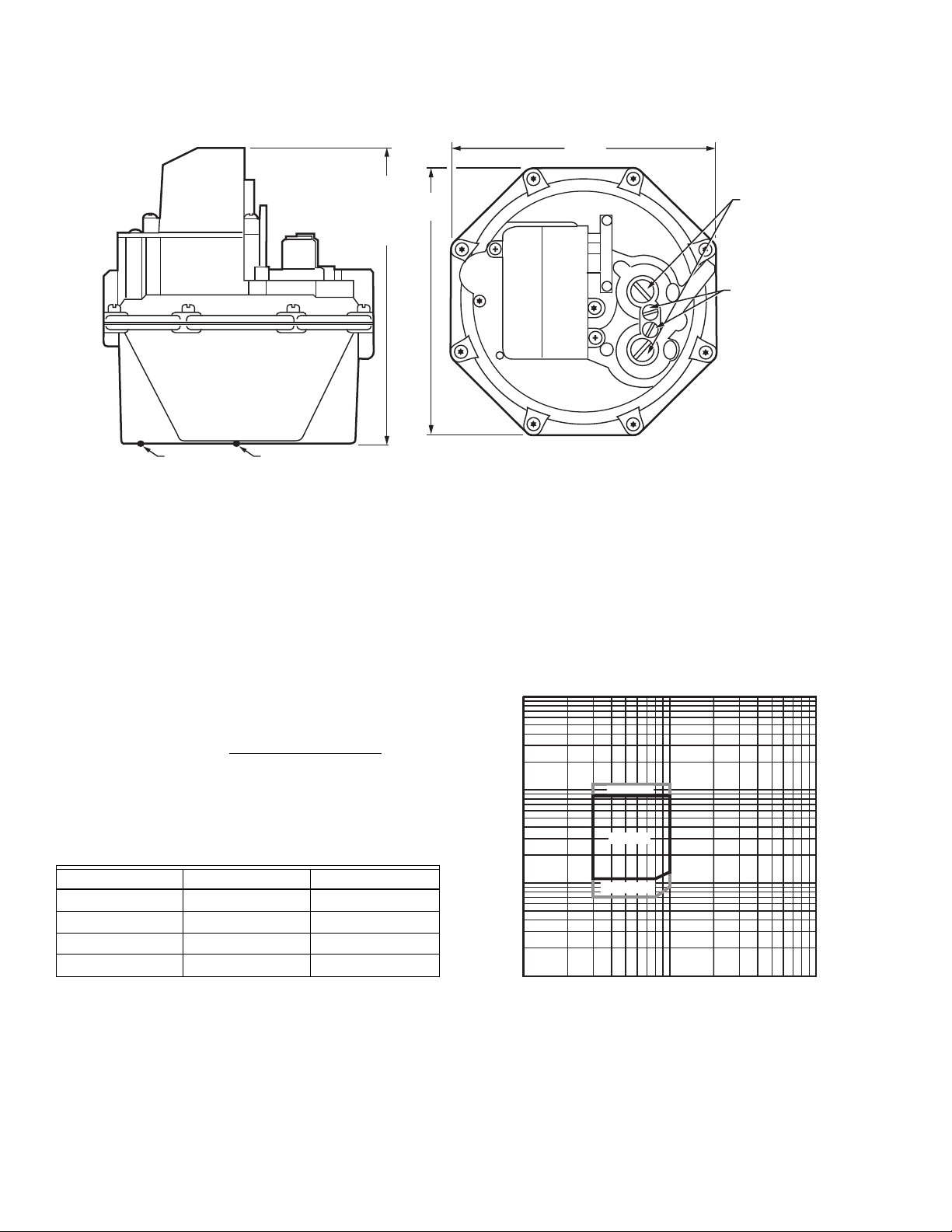

6-9/16 (167)

FOR 1, 1-1/4

OR

7-3/8 (187)

FOR 1-1/2, 2

SIDE VIEW

6 (152)

6

(152)

TOP VIEW

M23375

ATMOSPHERIC

PRESSURE

REFERENCE

PORT WITH

INTERNAL

VENT LIMITER

OUTLET

PRESSURE

TAP

INLET

PRESSURE

TAP

PRESSURE

REGULATOR

ADJUSTMENT

CAPS

M23376

1 INCH V4/8944B/N REGULATION AREA

0.1

1

10

100

FLOW NATURAL GAS (CFH)

PRESSURE DROP (IN. WC)

100

1000

10000

PO < 2.5 IN.

ANY PO

PO > 2 IN.

Fig. 1. V4943/44 and V8943/44 dimensions in in. (mm).

Gas Valve Sizing

1. Check the burner nameplate for:

a. the type of gas used, and

b. the gas flow capacity. The capacity will be listed in

2. Contact the local gas utility for information regarding:

a. the specific gravity (sp gr) and

b. the Btu per cubic foot (Btucf) for the type of gas used.

3. Find the capacity in cf/h. If the capacity is listed in Btu,

convert to cf/h using the following formula:

4. For gases with specific gravities other than 0.64, multiply

the burner cf/h using the proper conversion factor in

Table 4.

Type of Gas sp gr (average) Multiply cfh by

Manufactured 0.60 0.968

Mixed 0.70 1.046

LP-Propane 1.53 1.546

LP-Butane 1.98 1.759

5. Use the corrected burner capacity in cfh when determining the gas valve size in Figs. 2–9.

6. Determine the maximum pressure drop across the valve

and draw a vertical line at this pressure in Figs. 2–9.

British thermal units per hour (Btuh) or in cubic feet

per hour (cfh).

Capacity in cfh = Btuh (burner nameplate)

Btu/cf (gas utility)

Table 4. Gas Conversion Factors.

7. At the point of intersection of the vertical line and the

curve, draw a horizontal line to intersect the flow

(capacity) scale. The point of intersection indicates the

capacity that can be obtained with the maximum

pressure drop.

8. If the capacity at the maximum pressure drop is

insufficient, use the capacity vs. pressure drop curve for

the next larger valve size and repeat steps 6 and 7.

Fig. 2. Capacity vs. pressure drop of Natural Gas

curves for 1 in. valve.

65-0214—08 4

Page 5

V4943/V8943B,C,N; V4944/V8944B,C,L,N REGULATING DIAPHRAGM GAS VALVES

M23377

1.25 INCH V4/8944B/N REGULATION AREA

0.1

1

10

100

FLOW NATURAL GAS (CFH)

PRESSURE DROP (IN. WC)

100

1000

10000

PO < 2.5 IN.

ANY PO

PO > 2 IN.

M23378

1.5 INCH V4/8944B/N REGULATION AREA

0.1

1

10

100

100 1000 10000

FLOW NATURAL GAS (CFH)

PRESSURE DROP (IN. WC)

PO < 2.5 IN.

ANY PO

PO > 2 IN.

M23379

2 INCH V4/8944B/N REGULATION AREA

0.1

1

10

100

100 1000 10000

FLOW NATURAL GAS (CFH)

PRESSURE DROP (IN. WC)

ANY PO

PO > 2 IN.

Fig. 3. Capacity vs. pressure drop of Natural Gas

curves for 1-1/4 in. valve.

Fig. 4. Capacity vs. pressure drop of Natural Gas

curves for 1-1/2 in. valve.

Fig. 5. Capacity vs. pressure drop of Natural Gas

curves for 2 in. valve.

100

10

PRESSURE DROP (IN. WC)

0.1

1 INCH V4/8944C/L REGULATION AREA

ANY PO

1

100 1000 10000

PO < 7 IN.

FLOW LP GAS (CFH)

M23380

Fig. 6. Capacity vs. pressure drop of LP Gas

curves for 1 in. valve.

5 65-0214—08

Page 6

V4943/V8943B,C,N; V4944/V8944B,C,L,N REGULATING DIAPHRAGM GAS VALVES

WARNING

100

10

PRESSURE DROP (IN. WC)

0.1

1.25 INCH V4/8944C/L REGULATION AREA

ANY PO

1

100 1000 10000

PO < 5.5 IN.

FLOW LP GAS (CFH)

Fig. 7. Capacity vs. pressure drop of LP Gas

curves for 1-1/4 in. valve.

100

10

1.5 INCH V4/8944C/L REGULATION AREA

M23381

100

10

PRESSURE DROP (IN. WC)

0.1

2 INCH V4/8944C/L REGULATION AREA

ANY PO

1

100 1000 10000

PO < 8 IN.

FLOW LP GAS (CFH)

M23383

Fig. 9. Capacity vs. pressure drop of LP Gas

curves for 2 in. valve.

To size two identical valves piped in series:

1. Find the cf/h for the type of gas used.

2. Consider both valves as one unit. Determine the

maximum pressure drop across the one unit.

3. Find the pressure drop across the first valve by assuming

it to be 45 percent of the total pressure drop.

4. Find the valve size from Figs. 2–9.

5. The second valve will be the same size as the first valve.

ANY PO

1

PRESSURE DROP (IN. WC)

0.1

100 1000 10000

PO < 8 IN.

FLOW LP GAS (CFH)

Fig. 8. Capacity vs. pressure drop of LP Gas

curves for 1-1/2 in. valve.

M23382

INSTALLATION

Explosion hazard.

Can cause serious injury, death or equipment

damage.

Installation and service by trained professionals only.

Exceeding the pressure rating or use of unspecified

fuel can lead to improper operation of the valve and can

create an explosion hazard. Property damage, severe

bodily injury or death can result.

When installed in the Commonwealth of

Massachusetts, the installation and servicing of this

product must be done by a licensed gas fitter or

plumber.

Consult specifications before installing valve.

65-0214—08 6

Page 7

V4943/V8943B,C,N; V4944/V8944B,C,L,N REGULATING DIAPHRAGM GAS VALVES

WARNING

WARNING

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained experienced flame safeguard

control technician.

4. After installation is completed, check out product operation as provided in these instructions.

Explosion hazard and electrical shock hazard.

Can cause serious injury or death.

1. Turn off gas supply before starting installation.

2. Disconnect power supply before beginning

installation to prevent electrical shock and equipment

damage.

3. Do not remove seal over valve inlet or outlet until

ready to connect piping.

Prepare Piping and Install Valve (Fig.

10).

1. Use new, properly reamed pipe free from chips.

2. Do not thread pipe too far. Valve distortion or malfunction

can result from excess pipe in valve.

3. Apply good quality pipe dope resistant to the action of LP

gas; put a moderate amount only on the pipe threads. If

pipe dope lodges on the valve seat, it will prevent proper

closure.

4. Install the valve in a horizontal pipe line in an upright

position with the gas flow in the direction indicated by the

arrow on the casing. The valve must be upright

(electrical connection tower in the up position) on a

horizontal axis with respect to the inlet connection

(see Fig. 10). Certain models may be mounted in the

limited horizontal position (any position from upright to

90 degrees to upright on an horizontal axis with respect

to the inlet connection. See Specifications section.)

5. Apply a parallel jaw wrench only to the flat next to the

pipe being inserted. A wrench applied to the valve body

itself or to the end farthest from the pipe being inserted

can distort the casting and cause a malfunction.

6. The gas flow must be in the same direction as the arrow

on the bottom of the valve body.

Explosion and Fire Hazard.

Can cause serious injury or death.

If flow is not in direction of arrow, valve may not

shut off; which can cause excess gas and harm to

equipment or personnel.

7. Make electrical connections as illustrated in the wiring

diagrams (see Figs. 11–14).

8. Turn on the main gas and, with a soap solution, check

the valve installation for leaks.

9. The V4943/V8943, V4944/V8944 combination valve

pressure regulating sections are provided with integral

vent limiters.

7 65-0214—08

Page 8

V4943/V8943B,C,N; V4944/V8944B,C,L,N REGULATING DIAPHRAGM GAS VALVES

WARNING

CAUTION

CORRECT

WRENCH

CORRECTLY

APPLIED NEXT

TO PIPE BEING

INSERTED

INCORRECT

CORRECT

TWO CLEAN

THREADS,

MODERATE

AMOUNT

OF DOPE

EXCESS DOPE CAN PUSH DISK

OFF THE

VALVE

SEAT

LOOSE

CHIPS

NORMAL

FULL

THREAD

CORRECT

CORRECT

NORMAL

FULL THREAD

REAM PIPE,

BLOW OUT CHIPS (THAT

CAN LODGE ON SEAT)

TOO LONG;

DISTORTS

VALVE SEAT

INCORRECT

TOO LONG,

DISTORTS

VALVE SEAT

AVOID

USING

VALVE AS

HANDLE

VISE GRIPS

END NEXT

TO PIPE

BEING

INSERTED

INCORRECT

WRENCH

HERE STRAINS

VALVE BODY

M6877

Fig. 10. Preparing the piping and installing the valve.

Wiring

Electrical Shock Hazard.

Can cause serious injury, death or equipment

damage.

Disconnect the power supply before making

connections to prevent electrical shock and equipment

damage.

1. All wiring must comply with applicable electrical codes,

ordinances and regulations. Use NEC Class 1 (line

voltage) wiring.

2. For normal installations, use moisture-resistant No. 14

wire suitable for at least 167°F (75°C) when using a

flame safeguard primary control, or for at least 194°F

(90°C) when using a flame safeguard programming

control.

3. For high temperature installations, use

moisture-resistant No. 14 wire selected for a temperature

rating above the maximum operating temperature.

4. Check the power supply circuit. The voltage and

frequency must match those of the valve.

5. See Fig. 11 through 14 for typical field wiring

connections. Follow the burner manufacturer wiring

diagram, if provided.

6. Make wiring connections at the electrical wires provided

at the top of the valve.

Equipment Damage Hazard.

Miswiring can cause equipment damage.

1. Label all wires prior to disconnection when servicing

valves. Wiring errors can cause damage to the

equipment through improper and dangerous

operation.

2. Verify proper operation after servicing.

3. After the installation is complete, cycle the valve

several times with the manual fuel shutoff cock

closed. Make sure the valve and actuator function

properly.

4. If the installation is gas tight and functioning properly,

proceed to the Checkout section.

65-0214—08 8

Page 9

V4943/V8943B,C,N; V4944/V8944B,C,L,N REGULATING DIAPHRAGM GAS VALVES

L1

(HOT)

L2

1

LIMIT(S)

TRANSFORMER

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

M6888B

24-VOLT

THERMOSTAT

FLAME SAFEGUARD

CONTROL

V8943B,C,N

SINGLE-STAGE

VALV E

PV

PV

MV

ORANGE

BLACK

L1

(HOT)

L2

1

LIMIT(S)

FLAME

SAFEGUARD

CONTROL

SECOND

STAGE

CONTROLLER

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

M6886B

COM

STG 1

STG 2

ORANGE

BLACK

BLUE

V4944B,C,L,N

TWO-STAGE VALVE

PV

PV

MV

MV

CONTROLLER

V4943B,C,N

LINE VOLTAGE

THERMOSTAT

OR CONTROLLER

BLACK ORANGE

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

LIMIT(S)

PV

JUNCTION

BOX

PV

MV

SINGLE-STAGE

VALVE

FLAME

SAFEGUARD

CONTROL

1

Fig. 11. Typical wiring diagram for V4943B,N.

Fig. 12. Typical wiring diagram for V8943B,C,N.

L2

L1

(HOT)

M6887

TWO-STAGE

CONTROLLER

FLAME

LIMIT(S)

L1

1

HOT

L2

TRANSFORMER

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

V8944B1050, V8944B1068, V8944B1076,V8944B1084

V8944C1041, V8944C1058, AND V8944C1066 HAVE A

MOLEX® CONNECTOR WITH 72 IN. (1829 MM) LEAD

WIRES: ORANGE (MV), PINK (PV), GRAY (COM).

SAFEGUARD

CONTROL

ORANGE

BLACK

BLUE

PV MV

PV

MV

V8944B,C, L, N

TWO-STAGE VALVE

M6889A

Fig. 14. Typical wiring diagram for V8944B,C,L,N with three

leadwire electrical termination.

OPERATION

General

The V4943/V8943B,C, N and V4944/V8944B,C,L, N Valves are

solenoid-operated diaphragm gas valves with one or two

stages of regulation. They can operate as a shut-off valve and

a pressure regulating valve. The V4943/V8943B,C,N have a

single stage of regulation (high fire) and the V4944/

V8944B,C,L,N have two stages of regulation (high fire and low

fire). The models with L and N suffixes are rapid opening

devices while the B- and C-suffixed models are slow opening

devices.

Fig. 13. Typical wiring diagram for V4944B,C,L,N with three

leadwire electrical termination.

In a redundant valve (two valves in series) system, it is

recommended that the V4943/V8943B,C, N and

V4944/V8944B,C,L, N Valves be positioned downstream from

the redundant valve for proper operation of the pressure

regulator(s). The V4943/V8943N and V4944/V8944L,N models

have a 0.022 in. bleed orifice in the bleed line (the valves bleed

internally to the outlet side) and are rapid opening valves

(maximum opening time is six seconds). The V4943/V8943B,C

and V4944/V8944B,C models have bleed orifices varying in

diameter from 0.014 to 0.018 in. to control the opening time.

The range of outlet pressure is adjusted by turning a screw

which changes the compression in the regulator spring. The

valves are suitable for natural gas (B and N models) or LP

(C and L models) applications. Do not adjust or operate valve

outside of the specified ranges (see Table 3).

Leadwires and a cover for electrical conduit connections are

provided with each valve.

The valves are available in 1 in., 1-1/4 in., 1-1/2 in. and 2 in.

sizes. The 1 in. and 1-1/4 in. valves share a common body

casting and the 1-1/2 in. and 2 in. valves share a larger body

casting. The valves are intended to replace the

V4843/V8843B,C,N and V4844/V8844B,C,N lines of valves.

The valves are used as combination controls, providing both

pressure regulation and shutoff functions for burners. Typical

burner applications include boilers, process equipment, ovens,

incinerators, water heaters, rooftop units, and commercial/

industrial atmospheric/power burners. The burner firing rates

range from 400 kbtu/hour to 5,000 kbtu/hour.

9 65-0214—08

Page 10

V4943/V8943B,C,N; V4944/V8944B,C,L,N REGULATING DIAPHRAGM GAS VALVES

WARNING

CAUTION

Operation of the V4943B,C,N/ V8943B,N

The V4943/V8943B,C,N Valves are combination gas controls

that include a single stage of pressure regulation in addition to

the shut-off function. They have a single solenoid and a single

regulating diaphragm.

When the controller is not calling for heat, the valve solenoid

coil is not energized. Static gas inlet pressure and a spring act

together to close the valve. In this condition, a three-way servo

valve directs inlet pressure directly above the main diaphragm,

creating static pressure on both sides of the main diaphragm.

On a call for heat, the controller contacts close and the valve

solenoid coil is energized, opening the servo valve and

allowing the gas that is above the main diaphragm to bleed

downstream, and diverting inlet (supply) gas through a supply

orifice. This reduces the pressure above the diaphragm, and

the gas that is bled off flows through a regulating valve to the

outlet of the gas valve. The pressure differential across the

main diaphragm is greater than the spring force, so the valve

opens. The valve opening rate is controlled by a timing orifice

through which the bleed gas passes.

Once the valve is open, outlet pressure is sensed through the

bleed passage. The outlet pressure acts on the regulating

(servo) diaphragm and tends to open or close the integral

regulating valve until a force balance is established between

the outlet pressure acting on the servo diaphragm and the

regulator spring that acts on the atmospheric side of the servo

diaphragm.

The system is balanced when the flow of supply gas through

the supply orifice is equal to the outflow of gas through the

regulating valve. The regulated output pressure required to

achieve equilibrium is varied by increasing or decreasing the

spring force acting on the atmospheric side of the regulating

diaphragm. Pressure adjustment is done through the use of a

threaded nylon screw acting on the regulating spring.

Regulator springs with different spring rates provide the

various ranges of pressure regulation needed for natural and

LP gases.

After the controller is satisfied, the procedure is reversed. The

controller contacts open and the solenoid coil is de-energized.

The plunger is released, moving to the down position. The

servo valve closes, diverting supply gas away from the orifice

and allowing the gas inlet pressure to act directly above the

main diaphragm. The resulting increase in upper chamber

pressure, along with the main spring, forces the main

diaphragm against the valve seat, stopping the gas flow.

In the event of a power failure during automatic operation of the

valve, the V4943/V8943B,C,L,N Valve servo valve closes,

diverting supply gas away from the orifice and allowing the gas

inlet pressure to act directly on the main diaphragm. The

change in upper chamber pressure, along with the main

spring, forces the main diaphragm against the valve seat,

stopping the gas flow. Normal operation will resume upon the

restoration of power.

Operation of the V4944/V8944B,C,L,N Valves

These models use two pressure regulators (low fire and high

fire) and two solenoids to provide two distinct stages of

pressure regulation. The first stage pressure regulator solenoid

activates the same quick-close orifice valve and servo valve as

in the V4943/V8943 models, but the bleed gas now flows

through a first stage (low fire) regulator valve to the outlet. This

maintains the outlet at a pressure controlled by the low fire

regulator. The second stage regulator (high fire) is set to a

higher outlet pressure. When the second stage solenoid is

energized, gas is shunted past the low fire regulator through a

timing orifice. The increased flow of supply gas (due to the

second servo valve opening) further reduces the pressure

above the main diaphragm, causing it to open more. The

corresponding increase in outlet pressure forces the low fire

regulator closed, and the valve regulates off the high fire

regulator.

The V4944/V8944L and N models use a timing orifice that

gives an opening time to low fire of less than six seconds. The

slower opening V4944/V8944B and C use timing orifices that

give an opening time of three to 25 seconds.

Both regulators can be adjusted separately and the springs are

sized so that the highest achievable pressure of the low

pressure regulator range is less than the lowest achievable

pressure of the high fire pressure regulator. The high fire

setpoint cannot be achieved without the first stage solenoid

being energized.

Valve closing operation is identical to that described for V4943/

V8943B,C,N valves.

CHECKOUT AND TROUBLESHOOTING

Explosion or Fire Hazard.

Can cause serious injury or death.

Do not let fuel accumulate in the combustion chamber.

If fuel is allowed to enter the chamber for longer than a

few seconds without igniting, an explosive mixture

could result.

Equipment Damage Hazard.

Failure to complete tests can cause equipment

damage.

1. Do not put the system into service until you have

satisfactorily completed all applicable tests

described in the Checkout section of the instructions

for the flame safeguard control, and any other tests

required by the burner manufacturer.

2. Close all manual fuel shutoff valves as soon as

trouble occurs.

65-0214—08 10

Page 11

V4943/V8943B,C,N; V4944/V8944B,C,L,N REGULATING DIAPHRAGM GAS VALVES

M9547F

GAS

SUPPLY

UPSTREAM

MANUAL

GAS COCK

DOWNSTREAM

MANUAL

GAS COCK

BURNER

DABC E

F

PRV

MANUAL

TEST

PETCOCK

SSOV

1/4 IN. (6 MM)

FLEXIBLE

TUBING

1/4 IN. (6 MM)

ALUMINUM OR

COPPER PILOT

TUBING

JAR OR GLASS

WITH WATER

CUT AT

45 DEGREE

ANGLE

CAN ALSO BE A PERMANENT PETCOCK.

PRV = PRESSURE REGULATING VALVE.

SSOV = SAFETY SHUTOFF VALVE.

USE ONLY ONE OF THE DOWNSTREAM TAPS ON THE SS0V.

1

2

3

4

4

2 3

1

1

2

(13 MM)

LEAK

TEST

TAP

Checkout

1. Valve outlet pressure measurements are made at a point

approximately five pipe diameters downstream from the

valve outlet. Consider pressure measurements made at

the outlet pressure tap as reference measurements only,

because turbulence and dynamic gas flow effects may

result in erratic pressure readings.

2. Shut off gas supply to valve and make sure valve is

closed when setting up pressure measuring equipment.

3. Set up pressure measuring equipment.

4. Make sure the valve is closed. Turn on the supply gas to

the valve.

5. Set the thermostat or controller to energize the valve and

check the final outlet pressure. See step 1. Allow enough

time for the system pressure to stabilize.

6. For regulator setpoint and spring range, please refer to

Table 3.

7. The low pressure regulator (V4944/V8944B,C,L,N) and

high pressure regulator V4943V8943B,C,N and

V4944/V8944B,C,L,N) adjustment screws (use a T-40

six-lobe [TORX®] driver or 5/16-in. standard driver) are

located under the slotted aluminum screw cap(s) of the

adjustment screw housings (see Fig. 1). To adjust the

pressure setting:

a. Temporarily remove the slotted aluminum screw cap

and gasket from the housing that contains the

regulator adjustment setscrew.

b. Turn the adjustment setscrew (use a T-40 six-lobe

[TORX®] driver or 5/16-in. standard driver) clockwise

to increase the pressure setting or counterclockwise

to decrease the pressure setting. Allow adequate time

(30 to 60 seconds) for the pressure to reach

equilibrium between pressure adjustments.

c. After the regulators have been properly adjusted,

replace the gasket and slotted aluminum screw cap

on the adjustment screw housing.

8. Start the system and observe its operation through at

least one complete cycle to make sure the valve

functions properly.

8. Immerse a 1/4 in. tube vertically 1/2 in. (13 mm) into a jar

of water.

9. Slowly open the test petcock (F).

10. When the rate of bubbles coming through the water

stabilizes, count the number of bubbles appearing during

a ten-second period. Each bubble appearing during a

ten-second period represents a flow rate of

approximately 0.001 cfh.

To meet code requirements, leakage must not exceed the

values in Table 5.

Table 5. Allowable Leakage Rates.

Pipe Size

(in.)

Allowable

Leakage

a

Number of Bubbles

per 10 sec.

1, 1-1/4 353 11 (Nat. gas), 7 (LP)

1-1/2, 2 453 14 (Nat. gas), 9 (LP)

a

Based on air standard conditions, test pressures in

accordance with ANSI Z21.21, Section 2.4.2 and a maximum

of 235 cc/h per inch of seal-off-diameter. Seal-off diameter is

not the same as pipe size.

11. Close the upstream manual gas cock (A).

12. Close the test petcock (F), remove the test apparatus,

and replace the leak test tap plug (D).

13. Open the upstream manual gas cock (A) and energize

the safety shutoff valve (C).

14. Test with soap bubbles to make sure there is no leak at

the test tap (D).

15. De-energize the safety shutoff valve (C).

16. Open the downstream manual gas cock (E).

17. Restore the system to normal operation.

Valve Leak Test (See Fig. 15).

This test checks the tightness closure of a gas safety shutoff

valve. It should be performed by a qualified technician during

the initial startup of a burner system, or whenever the valve is

replaced (see Service Information section). It is recommended

that this test also be included in scheduled inspection and

maintenance procedures.

1. De-energize the control system to make sure there is no

power to the safety shutoff valve (C) shown in Fig. 15.

2. Close the upstream manual gas cock (A).

3. Make sure the manual test petcock (F) is closed in the

leak test tap assembly (D).

4. Remove the leak test tap plug (valve outlet pressure tap

can be used as a test tap) and connect the test

apparatus to the leak test tap (D).

5. Close the downstream manual gas cock (E).

6. Open the upstream manual gas cock (A).

7. Run the safety shutoff valve (C) to its fully open position

(through the safety system); then immediately

de-energize the system to close the valve.

Fig. 15. Valve leak test.

11 65-0214—08

Page 12

V4943/V8943B,C,N; V4944/V8944B,C,L,N REGULATING DIAPHRAGM GAS VALVES

WARNING

WARNING

CAUTION

Troubleshooting

Electrical Shock Hazard.

Can cause electrical shock or equipment damage.

Use utmost care during troubleshooting. Line voltage

is present right at the electrical terminations for the

V4943B,C,N and V4944B,C,L,N valves, and present in

all controller circuits for all V4943/V8943 and V4944/

V8944 valves.

IMPORTANT

Do not assume that the valve must be replaced until

all other sources of trouble have been eliminated.

1. If the valve will not open when the thermostat or

controller calls for heat:

a. Check that there is voltage at the proper electrical

terminations. Be careful—there should be line

voltage at the actuator of V4943 and V4944 valves.

b. If there is no voltage at the actuator, first make sure

line voltage power is connected to the master

switch, the master switch is closed and overload

protection (circuit breaker, fuse or similar device)

has not opened the power line.

c. For V8943A only: If line voltage power is correct,

check transformer output. Replace the transformer if

necessary.

d. If there is still no voltage at the actuator, make sure

all appropriate contacts in the thermostat or

controller, limits and flame safeguard control are

closed. If one or more is open, determine the

cause(s) and correct the condition(s) before

proceeding.

e. If there is proper voltage at the valve actuator but

the valve still does not open, first check that the gas

pressure at the valve is normal.

f. If the valve still does not open, replace the valve.

2. If the valve will not close when one or more of the

appropriate contacts in the thermostat or controller,

limit(s) or flame safeguard control is open:

a. Make sure that the gas flow is in the direction of the

arrow on the valve body.

b. Make sure the valve actuator is wired in the correct

circuit. Open the master switch to remove power

from the valve actuator. If the valve closes now, the

actuator may not be wired properly. Check and

correct the wiring, if necessary.

c. Look for a short in the electrical circuit.

SERVICE INFORMATION

Electrical Shock Hazard

Can cause serious injury, death or equipment

damage.

1. Only qualified service technicians should attempt to

service or repair flame safeguard controls and

burner systems.

2. Line voltage is present in the electrical circuits to the

valve. Open the master switch before replacing the

valve.

Scheduled Inspection and Maintenance

For periodic inspection and maintenance, set up a schedule

and follow it. Include the burner valves (check for external

leakage around all seals and joints with leak detector; also

check for internal valve seat leakage—see Valve Leak Test

section) and all other controls. Refer to the flame safeguard

control instructions for more information.

Equipment Damage Hazard.

Can cause equipment damage or improper

operation.

Label all wires prior to disconnecting when servicing

valves. Wiring errors can cause improper and

dangerous operation.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

Verify proper operation after servicing.

® U.S. Registered Trademark

© 2011 Honeywell International Inc.

65-0214—08 M.S. Rev. 09-11

Printed in United States

Loading...

Loading...