Page 1

V48A,F,J; V88A,J

Diaphragm Gas Valves

The V48 and V88 are solenoid-operated diaphragm valves suitable for LP (Liquefied Petroleum), natural, and manufactured gases. They are

normally used on atmospheric boilers, commercial

water heaters, and rooftop heaters.

■ Line voltage, 2-wire thermostat or controller used

with a V48; V88 used with 24V thermostat.

■ Valves provide slow opening and fast closing.

■ Two second maximum closing time for 2 through

3 in. valves.

■ One second maximum closing time for 3/4 through

1-1/2 in. valves.

■ V48J, V88J rated for 150° F ambient temperature.

■ V48F rated for 5 psi (lb. per sq in.) [34.5 kPa].

V48A and V88A rated for either 1/2 or 1 psi [3.4 or

6.9 kPa], depending on model. V48J and V88J rated

for 1 psi [6.9 kPa].

■ One model for natural and LP gases.

■ Wide range of sizes and capacities.

■ Firm closing; diaphragm is both weight and spring

loaded.

■ Valve closes on power failure; recommended for

final shutoff service.

■ Adjustable or fixed bleed orifices available for in-

stallation by OEM.

■ Valve position indicator on 1-1/4 in. V48A2227 and

2 in. V48F1103 Valves.

CONTENTS

Specifications............................................... 2

Ordering Information ..................................2

Installation................................................... 5

Operation ..................................................... 8

Checkout and Troubleshooting ................... 9

Service Information ................................... 10

F.P. • Rev. 9-94 • ©Honeywell Inc. 1994 • Form Number 60-2080—8

1 60-2080—8

Page 2

V48A,F,J; V88A,J

SPECIFICATIONS • ORDERING INFORMATION

Specifications

MODELS:

V48A (120 Vac) or V88A (24 Vac) solenoid operated

diaphragm valves for 1/2 or 1 psi [3.4 or 6.9 kPa]

maximum operating pressure.

V48F (120 Vac) solenoid operated diaphragm valve for

5 psi [34.5 kPa] maximum operating pressure.

V48J (120 Vac) or V88J (24 Vac) solenoid operated

diaphragm valves for 1 psi [6.9 kPa] operating pressure and 150° F maximum ambient temperature.

TYPE OF GAS: Suitable for liquefied petroleum (LP), natu-

ral, manufactured, and sulfur-bearing gases.

VALVE CAPACITY: See table in Fig. 2.

VALVE PATTERN: Straight-through, nonoffset.

VALVE BODY MATERIAL: Die-cast aluminum.

PILOT TAPPING (see Table 1 for thread type): 3/4 through

1-1/2 inch valves: 1/8-27 NPT or 1/8-28 BSP.PI.

2 through 3 inch valves: 1/4-18 NPT or 1/4-19 BSP.PI.

BLEED TAPPING (see Table 1 for thread type): 1/8-

27 NPT or 1/8-28 BSP.PI.

VALVE OPENING TIME: Five seconds maximum at 2 oz/

in.2 [0.86 kPa] pressure. Adjustable bleed valve assem-

bly or fixed bleed orifices available for longer opening

time (NPT threads only; see Accessories).

VALVE CLOSING TIME (on power failure; measured at

2 oz/in.2 [0.86 kPa] pressure): 2 seconds maximum for 2

through 3 inch valves; 1 second maximum for 3/4 through

1-1/2 inch valves.

MAXIMUM OPERATING PRESSURE: See Table 1.

POWER CONSUMPTION (maximum): 9 watts or 15 VA.

AMBIENT TEMPERATURE RATING:

V48A,F and V88A: 32° F to 125° F [0° C to 52° C].

V48J and V88J: 32° F to 150° F [0° C to 65° C].

MAXIMUM FLUID TEMPERATURE:

V48A,F; V88A: 125° F.

V48J; V88J: 150° F.

THERMOSTAT HEAT ANTICIPATOR SETTING: For

60 Hz V88, set at 0.6A.

DIMENSIONS: See Fig. 1.

WEIGHT:

Pipe Size (in.) lb. kg

3/4 2-1/2 1.13

1 3 1.36

1-1/4 3-1/2 1.59

1-1/2 4 1.81

2 9 4.08

2-1/2 8-1/2 3.86

3 9-1/2 4.31

APPROVALS: (60 Hz models only):

Underwriters Laboratories Inc. Listed: File No. MH1639;

Guide No. YIOZ.

American Gas Association Design Certified: Report

No. 21-7B.

Canadian Gas Association Certified: For use with natu-

ral, manufactured, and mixed gases (60 Hz models

only).

NOTE: All models rated at 50 Hz and all models with

BSP.PI threads are not AGA Design Certified.

OPTIONAL FEATURE: Valve position indicator is avail-

able on 1-1/4 in. V48A2227 and 2 in. V48F1103.

REPLACEMENT COIL ASSEMBLIESa:

116930: 24V, 60 Hz V88A

116931: 120V, 60 Hz V48A.

116932: 220V, 50 Hz V48A

116932: 240V, 60 Hz V48A

118888: 24V, 60 Hz V88J

139937: 120V, 60 Hz V48J

a

These V48/V88 bonnet assemblies and solenoid operators

are not compatible with old style valve bodies.

Ordering Information

When purchasing replacement and modernization products from your TRADELINE® wholesaler or your distributor, refer to the

TRADELINE

1. Order number. 5. Optional valve position indicator (1-1/4 inch and larger valves only),

2. Pipe size. if desired.

3. Operating pressure rating. 6. Replacement coil assembly, if desired.

4. Transformer for V88. 7. Accessories, if desired.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Home and Building Control Sales Office (check white pages of phone directory).

2. Home and Building Control Customer Logistics

60-2080—8 2

®

catalog or price sheets for complete ordering number, or specify—

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 951-1000.

In Canada—Honeywell Limited/Honeywell Limitée, 740 Ellesmere Road, Scarborough, Ontario M1P 2V9. International Sales

Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan, Mexico,

Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

Page 3

V48A,F,J; V88A,J

SPECIFICATIONS

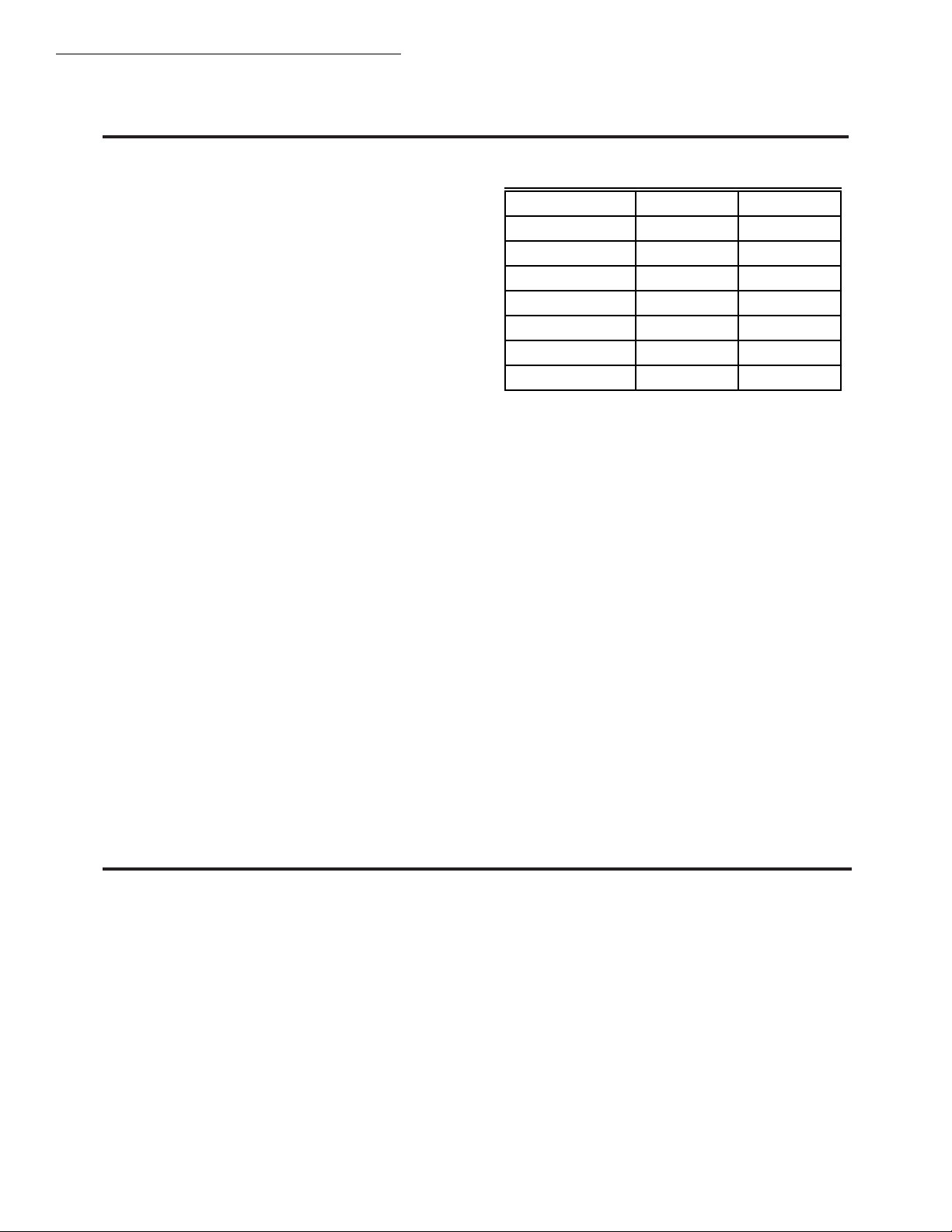

TABLE 1—MODELS AVAILABLE.

Model Voltage and Frequency (Psi) (Kpa) Pipe Size (in.)

Maximum Operating Pressure

Thread

Type

V48A 100V, 50 Hz 1/2 3.4 1, 1-1/4, 1-1/2 BSP.PI

1 6.9 2

120V, 60 Hz 1/2 3.4 3/4, 1, 1-1/4, 1-1/2 NPT

1 6.9 1, 1-1/4, 1-1/2, 2, 2-1/2, 3

220V, 50 Hz 1 6.9 1, 1-1/4, 1-1/2, 2, 3 BSP.PI

240V, 50 Hz 1 6.9 2 NPT

V48F 120V, 60 Hz 5 34.5 2 NPT

V48J 120V, 60 Hz

1 6.9 3/4, 1, 1-1/4, 1-1/2, 2 NPT

110V, 50 Hz

V88A 24V,60 Hz 1/2 3.4 3/4, 1, 1-1/4, 1-1/2 NPT

1 6.9 3/4, 1, 1-1/4, 1-1/2, 2, 2-1/2, 3

V88J 24V, 60 Hz 1 6.9 1, 1-1/4 NPT

a

A valve position indicator is on 1-1/4 in. V48A2227 and 2 in. V48F1103 Valves. BSP.PI—British Standard Parallel Internal

Threads; NPT—American Standard Taper Pipe Threads.

a

Fig. 1—Mounting dimensions of V48A,F,J and V88A,J Diaphragm Gas Valves.

APPROXIMATE DIMENSIONS

4-5/8

117.5

127.0

149.2

149.2

241.3

241.3

241.3

3-1/2

3-11/16

5-5/16

5-5/16

8-3/8

8-3/8

8-3/8

A

5

5-7/8

5-7/8

9-1/2

9-1/2

9-1/2

88.9

93.7

134.9

134.9

212.7

212.7

212.7

1-5/8

2-1/16

2-3/8

2-3/8

3-9/16

3-9/16

3-9/16

41.3

3-13/16

52.4

4-5/16

60.3

5-5/16

60.3

5-5/16

90.5

5-5/16

90.5

9-5/16

90.5

9-5/16

11

3

[93.7]

16

2

E

VALVE

SIZE

(IN.)

3/4

1-1/4

1-1/2

2-1/2

1

2

3

ABCDEF

IN. MM IN. MM IN. MM IN. MM IN. MM IN. MM

4-11/16

119.1

3/4

C

1-1/4

1-1/4

2-1/4

2-1/4

2-1/4

[46]

19.1

1

25.4

31.8

31.8

57.2

57.2

57.2

5-1/16

5-9/16

5-9/16

6-15/16

6-15/16

6-15/16

128.6

141.3

141.3

176.2

176.2

176.2

13

1

16

1

96.8

109.5

134.9

134.9

236.5

236.5

236.5

B

D

1

BLEED TAPPING: 1/8-27 NPT, OR 1/8-28 BSP. PL.

2

PILOT TAPING (2): 1/8-27 NPT FOR 3/4 THROUGH 1-1/2 IN. SIZES, 1/4-18 NPT FOR 2 THROUGH 3 IN. SIZES;

OR 1/8-28 BSP. PL FOR 1 THROUGH 1-1/2 IN. SIZES, 1/4-19 BSP.PL FOR 2 THROUGH 3 IN SIZES.

F

3 60-2080—8

M8487

Page 4

V48A,F,J; V88A,J

SPECIFICATIONS

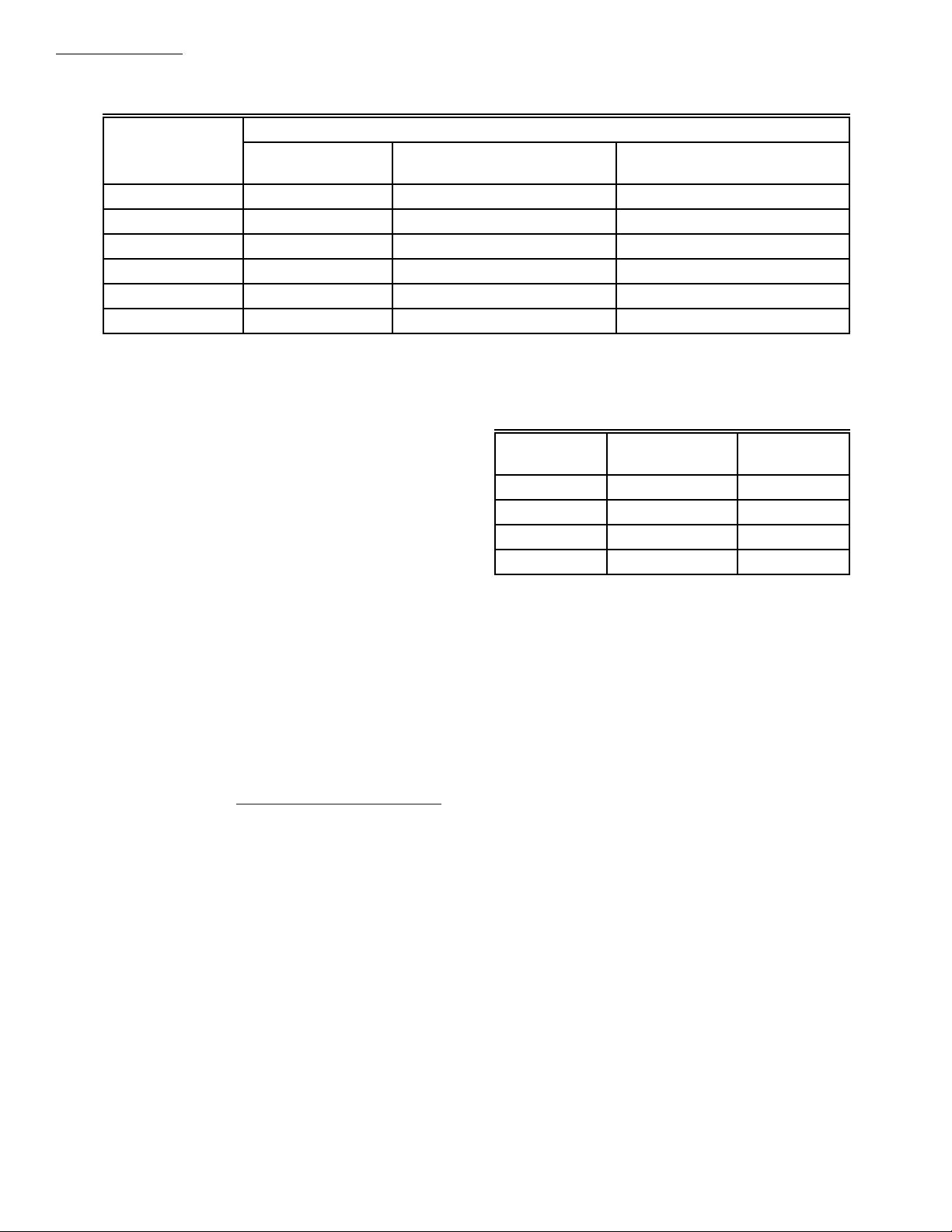

Valve Size (in.) No. Orifice

11 2 3

1-1/4 1 5 6

1-1/2 1 5 6

2 4 15 32

2-1/2 4 23 37

3 5 24 37

a

Time to reach 80% gas flow at fully open position. Inlet pressure; 4.2 in. wc [1.05 kPa] for 1 to 2 in. valves; 5 in. wc [1.25 kPa]

for 2-1/2 and 3 in. valves. Pressure drop across valves at fully open position. 0.2 in. wc [0.05 kPa] for 1 to 2 in. valves; 1 in. wc

[0.25 kPa] for 2-1/2 and 3 in. valves.

TABLE 2—EXTENDING VALVE OPENING TIME

Valve Opening Time (sec)

Orifice no. 122160,

0.018 in. [0.46 mm]

a

BY ADDING A BLEED ORIFICE.

Orifice no. 124674,

0.011 in. [0.28 mm]

ACCESSORIES:

Transformer AT72D: (40 VA) for all V88 models.

126590 Adjustable Bleed Valve Assembly: Consists of

adjustable bleed valve with sleeve and compression

nut for connecting to 1/4 in. tubing; see Fig. 8.

(Not available for valves with BSP.PI. threads.)

Bleed Orifice: Fixed (see Table 2 for appropriate size):

124674 Orifice: 0.011 in. [0.28 mm] diameter.

122160 Orifice: 0.018 in. [0.46 mm] diameter.

126070 Orifice Tool: Required for field mounting a

bleed orifice (in valves with NPT threads only).

GAS VALVE SIZING

1. Check the burner nameplate for (a) the type of gas

used, and (b) the gas flow capacity. The capacity will be

listed in Btu/h (Btu per hour) or in cf/h (cubic feet per

hour).

2. Call the gas utility for information on (a) the specific

gravity (sp gr) and (b) Btu per cubic feet (Btu/cu ft) for type

of gas used.

3. Find the capacity in cf/h. If the capacity is listed in

Btu/h, convert to cf/h by the following formula.

Capacity in cf/h = Btu/h (from burner nameplate)

Btu/cu ft (from gas utility)

4. For gases with specific gravities other than 0.64,

multiply the burner cf/h by the conversion factor in Table 3.

5. Use the corrected capacity in cf/h when determining

the gas valve size in Fig. 2.

6. Determine the maximum pressure drop across the

valve, and draw a horizontal line at this pressure in Fig. 2.

TABLE 3—CONVERSION FACTORS.

Type of

Gas

Average Specific

Gravity

Multiply

cf/h by

Manufactured 0.60 1.033

Mixed 0.70 0.956

LP—Propane 1.53 0.647

LP—Butane 1.98 0.569

7. Draw a vertical line in Fig. 2 at the capacity (cf/h)

previously determined. Use the corrected capacity for a

gas with a specific gravity other than 0.64.

8. Use the valve size at the intersection of the horizontal

and vertical lines. If the intersection is between valve sizes,

use the next higher valve size to the right.

TO SIZE TWO IDENTICAL VALVES PIPED

IN SERIES

1. Find the cf/h for the type of gas used.

2. Consider both valves as one unit. Determine the total

maximum pressure drop across the unit.

3. Find the pressure drop across the first valve by assuming it to be 45 percent of the total pressure drop.

4. Find the valve size from Fig. 2.

5. The second valve will be the same size as the first

valve.

60-2080—8 4

Page 5

Fig. 2—Pressure drop vs. capacity chart for sizing gas valves.

V48A,F,J; V88A,J

SPECIFICATIONS • INSTALLATION

[2.5] 10

9

[2.0] 8

7

[1.5] 6

5

[1.0] 4

[0.75] 3

2.5

[0.5] 2

1.5

[0.25] 1.0

0.9

[0.2] 0.8

0.7

[0.15] 0.6

0.5

PRESSURE DROP—INCHES W.C. [kPa]

[0.1] 0.4

A.G.A.RATING FOR

0.64 SP. GR. GAS AT

1 IN. PRESSURE DROP

VALVE SIZE CAPACITY

3/4 IN.

1 IN.

1-1/4 IN.

1-1/2 IN.

2 IN.

2-1/2 IN.

3 IN.

668 cf/h

1021 cf/h

2100 cf/h

2400 cf/h

4178 cf/h

5100 cf/h

5562 cf/h

PRESSURE DROP VS. CAPACITY

FOR 0.64 SP GR. GAS

1

3/4

3

2-1/2

2

1-1/2

1-1/4

[0.075] 0.3

0.25

[0.05] 0.2

0.15

[0.025] 0.1

1 1.5 2 2.5 3 4 5 6 7 8 9 10 1.5 2 2.5 3 4 5 6 7 8 9 10

MULTIPLY BY 100 MULTIPLY BY 1000

CAPACITY IN CUBIC FEET PER HOUR (cf/h)

FOR GAS WITH SPECIFIC GRAVITY OF 0.64

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application.

3

[1 cf/h = 0.0283 m

/hr]

3. Installer must be a trained, experienced, flame safe-

guard control technician.

4. After installation is complete, check out product

operation as provided in these instructions.

M8491

Installation

5 60-2080—8

Page 6

V48A,F,J; V88A,J

INSTALLATION

CAUTION

1. Turn off gas supply before starting installation.

2. Disconnect power supply before beginning installation to prevent electrical shock and equipment damage.

3. Do not remove seal over valve inlet or outlet

until ready to connect piping.

4. Do not bend tubing at the valve after the compression nut is tightened because this may

result in gas leakage at the connection.

5. Install valve in a horizontal pipe line in any

upright position with the gas flow in the direction indicated by the arrow on the casting.

3. Apply good quality pipe dope, putting a moderate

amount on the male threads only. If pipe dope lodges on the

valve seat, it will prevent proper closure. If using liquefied

petroleum (LP) gas, use pipe dope resistant to action of LP

gas.

4. Install valve in a horizontal pipe line in an upright

position with the gas flow in the direction indicated by the

arrow on the casting.

5. Apply a parallel jaw wrench only to the flat next to

the pipe being inserted. A wrench applied to the valve body

itself or to the end farthest from the pipe being inserted may

distort the casting, causing a malfunction.

6. The gas flow MUST be in the same direction as the

arrow on the bottom of the valve body.

PREPARE PIPING AND INSTALL VALVE (FIG. 3)

1. Use new, properly reamed pipe free from chips.

2. Do not thread pipe too far. Valve distortion or mal-

function may result from excess pipe in valve.

Fig. 3—Preparing piping and installing valve.

EXCESS DOPE

MAY BLOCK

DISC OFF

VALVE

SEAT

LOOSE CHIPS

REAM PIPE,

BLOW OUT

CHIPS (THEY MAY

LODGE ON SEAT)

WRONG

TOO LONG,

DISTORTS VALVE

SEAT

WRONG

TOO LONG,

DISTORTS VALVE

SEAT

RIGHT

NORMAL FULL

THREAD

RIGHT

NORMAL FULL

THREAD

RIGHT

VISE GRIPS

END NEXT

TO PIPE

BEING

INSERTED

BLEED

GAS

TAPPING

2 CLEAN

THREADS,

MODERATE

AMOUNT

OF DOPE

PILOT GAS

TAPPING

WARNING

If flow is not in direction of the arrow, the valve

may not shut off.

WRONG

NEVER USE VALVE

AS A HANDLE

WRONG

WRENCH HERE

RIGHT

WRENCH

CORRECTLY

APPLIED

NEXT TO

PIPE BEING

INSERTED

STRAINS VALVE BODY

60-2080—8 6

M7299

Page 7

V48A,F,J; V88A,J

INSTALLATION

CONNECT PILOT AND BLEED GAS TUBING

(FIG. 4)

1. Square off and remove burrs from end of the tubing.

Bend tubing to the desired form for routing to the pilot

burner. Do not bend tubing at the valve after the compres-

sion nut is tightened because this may result in gas leakage

at the connection.

2. Unscrew brass compression fitting from pilot gas

tapping (Fig. 3). Slip the fitting over the tubing and slide out

of the way.

IMPORTANT: When replacing a valve, cut off old com-

pression fitting and replace with a new compression

fitting. Never use the old compression fitting because

it may not provide a tight gas seal.

3. Push tubing into the pilot gas tapping on the outlet

end of the valve until it bottoms. While holding tubing all

the way in, slide fitting into place and engage threads—turn

until finger tight. Then use wrench and tighten one turn

beyond finger tight.

4. Connect other end of tubing to pilot burner according

to pilot burner manufacturer’s instructions.

5. If required, connect the tubing to bleed gas tapping

(Fig. 3 and 4) as described in step 3. Connect other end of

bleed tubing to main burner or to outside atmosphere.

b. If a conduit is required, run the conduit through the

opening in the actuator housing, and run the external

wires through the conduit.

c. Using solderless connectors, connect the external

wires to the two 6 in. [152.4 mm] black leadwires

(from the coil).

d. Locate the connections inside the actuator housing.

e. Replace the housing cover, and tighten the cover

screw holding it to the actuator housing.

8. Recheck the wiring circuits before putting the valve

into service.

Fig. 5—Typical wiring diagram for V48.

VALVE ACTUATOR

(BLACK LEAD WIRES)

LINE VOLTAGE

THERMOSTAT OR

CONTROLLER

JUNCTION

BOX

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

LIMIT(S)

1

FLAME

SAFEGUARD

CONTROL

M8490

L2

L1

(HOT)

Fig. 4—Connecting tubing to pilot for bleed

gas tapping.

GAS VALVE

TUBING

GAS FLOW

SLEEVE CLINCHES AROUND TUBING

AS NUT IS TIGHTENED

COMPRESSION FITTING

M7300

WIRING

1. Disconnect the power supply before making wiring

connections to prevent electrical shock and equipment

damage.

2. All wiring must comply with applicable electrical

codes, ordinances, and regulations. Use NEC Class 1 (line

voltage) wiring.

3. For normal installations, use moisture-resistant No.

14 wire suitable for at least 167° F [75° C] if using a flame

safeguard primary control, or for at least 194° F [90° C] if

using a flame safeguard programming control.

4. For high temperature installation, use moisture-re-

sistant No. 14 wire selected for a temperature rating above

the maximum operating temperature.

5. Check the power supply circuit. The voltage and

frequency must match those of the valve.

6. Refer to Fig. 5 or 6 for typical field wiring connections. Follow the burner manufacturer’s wiring diagram if

provided.

7. Make wiring connections inside the actuator housing

(Fig. 7):

a. Loosen the cover screw in the front of the actuator

housing, and remove the housing cover.

Fig. 6—Typical wiring diagram for V88.

VALVE ACTUATOR

(BLACK LEAD WIRES)

LIMIT(S)

1

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

TRANSFORMER

24 VOLT

THERMOSTAT

FLAME

SAFEGUARD

CONTROL

Fig. 7—Making wiring connections.

6 IN. [152.4 MM] INTERNAL

BLACK LEADWIRES

(FROM COIL)

SOLDERLESS

CONNECTORS

GROUNDING

SCREW

ACTUATOR

HOUSING

OPENING IN

ACTUATOR

HOUSING

CONDUIT

(IF REQUIRED)

M7302

COVER

SCREW

EXTERNAL

WIRES

M8488

7 60-2080—8

Page 8

V48A,F,J; V88A,J

INSTALLATION • OPERATION

INSTALLATION OF AN OPTIONAL ADJUSTABLE

BLEED VALVE (FIG. 8)

NOTE: This device is not available for valves with BSP.PI

threads.

Screw the 126590 Adjustable Bleed Valve into the

tapping marked BLEED. Be sure to screw the end with the

1/8-NPT threads into the BLEED tapping. Complete the

bleed line connection. Then alternately energize and deenergize the valve actuator, and adjust the screw on the

bleed valve for the desired valve opening time.

Fig. 8—Installing optional 126590 adjustable

bleed valve.

1

126590 ADJUSTABLE BLEED VALVE

COMPRESSION NUT

1/4 INCH

TUBING

7/16-24 UNS

SLEEVE

BLEED TAPPING

INSTALLATION OF AN OPTIONAL BLEED

ORIFICE (FIG. 9)

NOTE: The orifice tool cannot be used on valves with

BSP.PI threads.

Press the selected bleed orifice (see Table 2) over the

slotted end of the 126070 Orifice Tool. With the tool, insert

the orifice into the bleed port until the tool, threads mate

with the threads in the bleed port. Finger-thread the tool

into the bleed port (turn clockwise ) as far as possible; then use pliers to seat the orifice. Seating occurs

when the threading stops. Withdraw the tool and complete

the connection of the bleed tubing.

Fig. 9—Installing optional bleed orifice.

BLEED PORT

1/8-27 NPT

ADJUSTING SCREW

THIS DEVICE WILL NOT FIT VALVES

1

WITH BSP.PL THREADS.

1/8-27 NPT

7/16 INCH HEX

M7290

OPERATION OF THE V48 AND V88 (FIG. 10)

When the controller is not calling for heat, the coil is deenergized. The plunger in the 3-way actuator is in the

DOWN position so the bleed port is closed and the supply

port is open. Gas flows into the top part of the valve. The

gas pressure on top of the diaphragm, the weight, and the

spring hold the valve closed.

On a call for heat, the controller contacts close and the

coil is energized. This pulls the plunger to the UP position,

opening the bleed port and closing the supply port. The gas

in the top of the valve flows out through the bleed port. This

reduces the pressure on top of the diaphragm, allowing the

gas pressure below to lift the diaphragm and open the

valve.

BLEED ORIFICE

(SELECTED)

1

ORIFICE TOOL

THIS TOOL WILL NOT FIT VALVES

1

WITH BSP.PL THREADS.

M7298

Operation

When all the gas has bled off the top of the diaphragm,

the valve is fully open, permitting gas flow to the main

burner.

After the controller is satisfied, the procedure is reversed.

The controller contacts open so the coil is de-energized. The

plunger is released, moving to the DOWN position. This

closes the bleed port and opens the supply port so gas flows

again into the top port of the valve. As the gas pressure on

top of the diaphragm increases, the diaphragm begins to

close. When the pressures on both sides of the diaphragm

are balanced, the valve will be closed. The weight and

spring help to close the valve. If the gas supply fails and

there is no pressure below the diaphragm, the weight and

spring will close the valve.

60-2080—8 8

Page 9

Fig. 10—Operation of V48 and V88 diaphragm

gas valves.

PLUNGER

GAS

SUPPLY

WEIGHT

DIAPHRAGM

MAIN

GAS

SUPPLY

WEIGHT

DIAPHRAGM

SPRING

VALVE CLOSED

PLUNGER

SPRING

PASSAGE

BLEED

PORT

TO BURNER

GAS

SUPPLY

PASSAGE

BLEED

PORT

V48A,F,J; V88A,J

OPERATION • CHECKOUT AND TROUBLESHOOTING

In the event of a power failure during automatic operation, all V88 and V48 valves will close. Normal operation

will be resumed upon power restoration.

OPERATION OF THE VALVE POSITION

INDICATOR (FIG. 11)

An optional valve position indicator is available in the

1-1/4 in. V48A2227 and 2 in. V48F1103 Valves. When the

valve is open, a yellow disk shows in the window. When the

valve is closed, only the black top of the disk is visible.

Fig. 11—Valve position indicator (optional).

MAIN

GAS

SUPPLY

WEIGHT

DIAPHRAGM

MAIN

GAS

SUPPLY

VALVE OPENING

SPRING

VALVE OPEN

PLUNGER

TO BURNER

GAS

SUPPLY

PASSAGE

BLEED

PORT

TO BURNER

M8489

Checkout and Tr oubleshooting

WARNING

Do not allow fuel to accumulate in the combustion chamber. If fuel is allowed to enter the chamber for longer than a few seconds without igniting,

an explosive mixture could result.

CAUTION

1. Do not put the system into service until you

have satisfactorily completed all applicable

tests described in the Checkout section of the

instructions for the flame safeguard control,

and any other tests required by the burner

manufacturer.

2. Close all manual fuel shutoff valves as soon as

trouble occurs.

9 60-2080—8

Page 10

V48A,F,J; V88A,J

CHECKOUT AND TROUBLESHOOTING • SERVICE INFORMATION

CHECKOUT

Start the system and observe its operation through at

least one complete cycle to be sure the valve functions as

described in the Operation section.

TROUBLESHOOTING

CAUTION

Use utmost care during troubleshooting. Line voltage is present at the actuator for a V48 Valve, and

is present in all controller circuits for all V48 and

V88 Valves.

IMPORTANT: Do not assume that the valve must be

replaced until all other sources of trouble have been

eliminated.

If the valve will not open when the thermostat or

controller is calling for heat:

1. Check that there is voltage at the valve actuator

(black leadwires, Fig. 7). Be careful—there should be line

voltage at the actuator of a V48.

2. If there is no voltage at the actuator, first make sure

line voltage power is connected to the master switch, the

master switch is closed, and overload protection (circuit

breaker, fuse, or similar device) has not opened the power

line.

3. For a V88 only: If a line voltage power is okay, check

the transformer. Replace it if necessary.

4. If there is still no voltage at the actuator, make sure all

the appropriate contacts in the thermostat (or controller),

limit(s), and flame safeguard control are closed. If one or

more is open, determine the cause(s) and correct the condition(s) before proceeding.

5. If there is proper voltage at the valve actuator but the

valve still does not open, first check that the gas pressure at

the valve is normal. Then make sure that the bleed line is

unobstructed.

6. If the gas pressure and bleed line are okay but the

valve still does not open, replace the coil assembly. (Refer

to the Specifications section for the proper part number,

and to the Service Information section for the proper

procedure.)

7. If you replace the coil assembly and the valve still

does not open, replace the valve.

If the valve will not close when one or more of the

appropriate contacts in the thermostat (or controller),

limit(s), or flame safeguard control is open:

1. Make sure that the gas flow is in the direction of the

arrow on the valve body.

2. Make sure the valve actuator is wired in the correct

circuit. Open the master switch to remove power from the

valve actuator. If the valve closes now, the actuator may not

be wired properly.

3. Look for a short in the electrical circuit.

CAUTION

1. Only qualified service technicians should attempt to service or repair flame safeguard controls and burner systems.

2. Open the master switch before replacing the

coil assembly or the valve. Line voltage is

present in the electrical circuits to the valve.

SCHEDULED INSPECTION AND MAINTENANCE

A schedule should be set up and followed for periodic

inspection and maintenance for the burner and all other

controls and the valve(s). Refer to the instructions for the

flame safeguard control for more information.

REPLACING THE COIL ASSEMBLY (FIGS. 12

THROUGH 15)

1. Open the master switch to disconnect all power to the

valve actuator.

2. Loosen the cover screw in the front of the actuator

housing (Fig. 12) and remove the housing cover.

3. Disconnect the external wires from the two internal

black leadwires (Fig. 12).

4. Remove the two torx screws inside the actuator hous-

ing (Fig. 13) and lift off the housing.

Service Inf ormation

5. Remove the holding nut from the top of the coil

assembly (Fig. 13).

6. Lift the coil assembly straight up and off the plunger

tube assembly (Fig. 14).

7. Snap out the wraparound metal cover and remove the

metal base (Fig. 15). Save these parts for the replacement

coil.

8. Carefully unhook the cardboard insulator (Fig. 15)

and remove it. Save the insulator for the replacement coil.

9. Make sure the new coil assembly has the same part

number as the old one; then discard the old coil assembly.

10. Wrap the cardboard insulator around the new coil

assembly and carefully hook it together around the two

black leadwires (Fig. 15).

11. Insert the two black leadwires through the opening in

the metal base, and insert the new coil assembly into the

metal base (Fig. 15).

12. Snap the wraparound metal cover into place around

the new coil assembly (Fig. 15).

13. Slip the new coil assembly over the plunger tube

assembly (Fig. 14).

14. Replace the holding nut on top of the coil assembly

(Fig. 13) and tighten it securely.

15. Replace the actuator housing and tighten the two torx

screws holding it in place (Fig. 13).

16. Reconnect the external wires to the two internal

black leadwires (Fig. 12).

60-2080—8 10

Page 11

17. Replace the housing cover, and tighten the cover

WRAPAROUND

METAL COVER

M7304

BLACK LEADWIRES

METAL BASE

CARDBOARD

INSULATOR

COIL

ASSEMBLY

CARDBOARD

INSULATOR

HOOKED TOGETHER

screw holding it to the actuator housing (Fig. 12).

18. Close the master switch.

19. Test the valve to make sure it opens and closes as

described in the Operation section.

20. Verify proper operation after servicing.

Fig. 12—Wiring connections and actuator

housing

6 IN. [152.4 MM] INTERNAL

BLACK LEADWIRES

(FROM COIL)

SOLDERLESS

CONNECTORS

GROUNDING

SCREW

COVER

SCREW

EXTERNAL

WIRES

ACTUATOR

HOUSING

OPENING IN

ACTUATOR

HOUSING

CONDUIT

(IF REQUIRED)

M7302

V48A,F,J; V88A,J

SERVICE INFORMATION

Fig. 14—Coil assembly fits on plunger tube

assembly

COIL ASSEMBLY

PLUNGER TUBE

ASSEMBLY

M7303

Fig. 13—Internal view of actuator housing.

HOLDING NUT

COIL ASSEMBLY

GROUNDING

SCREW

ACTUATOR

HOUSING

2 TORX 20

SCREWS HOLDING

ACTUATOR HOUSING

M7301

Fig. 15—Coil assembly, insulator, and cover.

11 60-2080—8

Page 12

Home and Building Control Home and Building Control Helping You Control Your World

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, MN 55422 Scarborough, Ontario

M1P 2V9

60-2080—8 12

Printed in U.S.A.

QUALITY IS KEY

Loading...

Loading...