Page 1

Solenoid Safety Shut-Off Valve

APPLICATION

The V4297A controls gas flow to commercial and industrial

burners. The valve is part of the Honeywell Integrated Valve

Train System that allows gas train components to be directly

bolted together.

V4297A

PRODUCT DATA

FEATURES

• Used with natural or liquefied petroleum (LP) gases.

• V4297A normally closed valves are rated for final

shutoff service (safety shutoff).

• One valve body (small) applicable to five pipe sizes:

• 3/4 in. (19 mm), 1 in. (25 mm), 1-1/4 in. (32 mm),

1-1/2 in. (38 mm) and 2 in. (51 mm) pipes.

• Two valves with different capacities:

• V4297A1005: 1 in. (25 mm) internal opening

(small capacity).

• V4297A1013: 2 in. (51 mm) internal opening

(high capacity).

• Two 1/4 in. NPT upstream and one 1/4 in. NPT

downstream pressure taps and plugs.

• Accepts C6097 Pressure Switch mounted directly

to flange (upstream pressure tap only).

• NEMA 1 enclosure standard.

• Optional Visual Position Indicator available.

• Unpainted aluminum body.

® U.S. Registered Trademark

Copyright © 2001 Honeywell • All Rights Reserved

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 6

Wiring ............................................................................... 6

Operation And Checkout .................................................. 7

Troubleshooting ................................................................ 8

Service Information ............................................ ...... ...... .. 8

65-0246-1

Page 2

SOLENOID SAFETY SHUT-OFF VALVE

SPECIFICATIONS

IMPORTANT

The specifications in this publication do not include

normal manufacturing tolerances; therefore, an

individual unit may not exactly match the

specifications listed. Also, this product is tested and

calibrated under closely controlled conditions, and

some minor differences in performance can be

expected if those conditions are changed.

Models:

V4297A1005: small body, 1 in. (25 mm) internal opening

(small capacity).

V4297A1013: small body, 2 in. (51 mm) internal opening

(high capacity).

T yp es of Gas:

Gas Train Pipe Size:

1-1/4 in. (32 mm), 1-1/ 2 in. (38 mm), 2 in. (51 mm).

Operating Pressure Rating:

Valve Capacities:

Valve Type

Small Flange

Safety Shut-Off

(large flow)

V4297A1013

Safety Shut-Off

(small flow)

V4297A1005

a

Ratings at 1 in. (.025 kPa) pressure drop for gas with

0.64 sp gr.

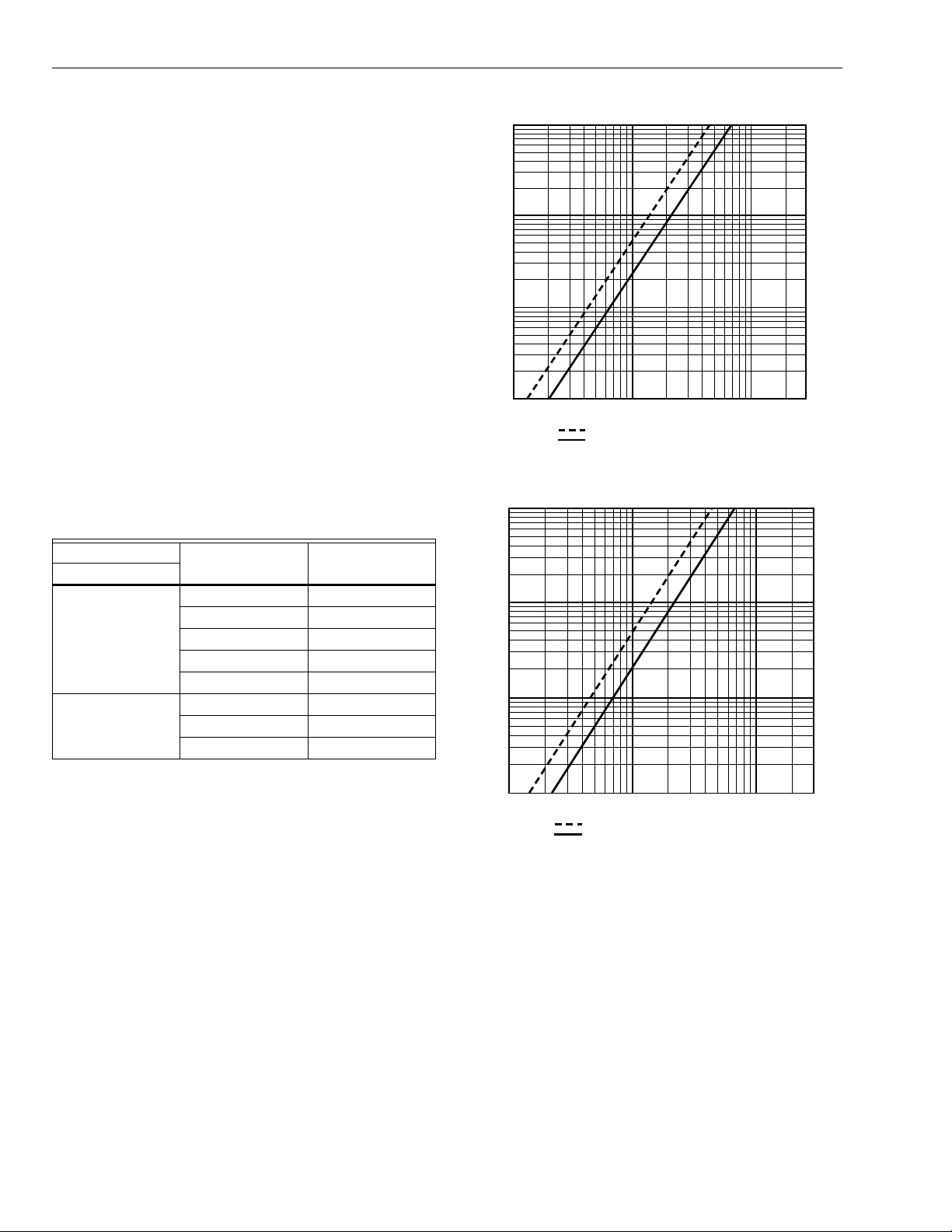

Flow Curves:

Natural, manufactured, mixed or LP only.

3/4 in. (19 mm), 1 in. (25 mm),

Maximum: 5 psi.

See Table 1.

Table 1. Valve Flow Capacities.

Pipe Diameter

(in.)

Flow Capacity

(cfh)

3/4 1190

1 1460

1-1/4 2260

1-1/2 2735

23060

3/4 650

1700

1-1/4 780

See Table 1 and Fig. 1 through 8.

a

100

10

1

PRESSURE DROP (IN. WC)

0.1

100 1,000 10,000 30,000

LEGEND:

FLOW CAPACITY (cfh)

Propane, sp. gr = 1.53.

Natural Gas, sp. gr = 0.64.

M16531

Fig. 1. Flow curves for V4297A1005 SSOV

with 3/4 in. (19 mm) pipe adapter.

100

10

1

PRESSURE DROP (IN. WC)

0.1

100 1,000 10,000 30,000

LEGEND:

FLOW CAPACITY (cfh)

Propane, sp. gr = 1.53.

Natural Gas, sp. gr = 0.64.

M16533

Fig. 2. Flow curves for V4297A1005 SSOV

with 1 in. (25 mm) pipe adapter.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1.

Your local Home and Building Control Sales Office (check white pages of your phone directory).

2.

Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (800) 328-5111

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

65-0246—1 2

Page 3

100

100

100 1,000 10,000 30,000

10

1

0.1

PRESSURE DROP (IN. WC)

FLOW CAPACITY (cfh)

M16536

Propane, sp. gr = 1.53.

Natural Gas, sp. gr = 0.64.

LEGEND:

100

100 1,000 10,000 30,000

10

1

0.1

PRESSURE DROP (IN. WC)

FLOW CAPACITY (cfh)

M16537

Propane, sp. gr = 1.53.

Natural Gas, sp. gr = 0.64.

LEGEND:

10

1

PRESSURE DROP (IN. WC)

0.1

100 1,000 10,000 30,000

LEGEND:

FLOW CAPACITY (cfh)

Propane, sp. gr = 1.53.

Natural Gas, sp. gr = 0.64.

M16534

SOLENOID SAFETY SHUT-OFF VALVE

Fig. 3. Flow curves for V4297A1005 SSOV

with 1-1/4 in. (32 mm) pipe adapter

100

10

1

PRESSURE DROP (IN. WC)

0.1

100 1,000 10,000 30,000

LEGEND:

FLOW CAPACITY (cfh)

Propane, sp. gr = 1.53.

Natural Gas, sp. gr = 0.64.

M16535

Fig. 4. Flow curves for V4297A1013 SSOV

with 3/4 in. (19mm) pipe adapter.

Fig. 5. Flow curves for V4297A1013 SSOV

with 1 in. (25 mm) pipe adapter.

Fig. 6. Flow curves for V4297A1013 SSOV

with 1-1/4 in. (32 mm) pipe adapter.

3 65-0246—1

Page 4

SOLENOID SAFETY SHUT-OFF VALVE

100

10

1

PRESSURE DROP (IN. WC)

0.1

100 1,000 10,000 30,000

LEGEND:

FLOW CAPACITY (cfh)

Propane, sp. gr = 1.53.

Natural Gas, sp. gr = 0.64.

M16538

Fig. 7. Flow curves for V4297A1013 SSOV

with 1-1/2 in. (38 mm) pipe adapter.

100

Valve Body Material:

Mounting:

Directly bolted to Integrated Valve Train

components.

Mounting Position:

See Fig. 9.

Aluminum.

Vertical to 90 degrees from vertical.

M16462

10

1

PRESSURE DROP (IN. WC)

0.1

100 1,000 10,000 30,000

LEGEND:

FLOW CAPACITY (cfh)

Propane, sp. gr = 1.53.

Natural Gas, sp. gr = 0.64.

Fig. 8. Flow curves for V4297A1013 SSOV

with 2 in. (51 mm) pipe adapter.

Bolt/Nut Fasteners:

Small Body:

3/8-16 by 1-3/8, Grade 5 bolt. Metric equivalent:

M8 by 1.25 by 35 mm, Class 9.8.

Tapping and Plug:

Taps: 1/4 in. NPT taps.Plugs: 1/4 inch hex head.

Ambient Operating Temperature Range:

-40°F (-40°C) to +130°F (54°C).

M16539

Fig. 9. Mounting positions for V4297A

Solenoid Shut-off Safety Valve.

Electrical Terminations:

Screw terminal connections.

Current Draw:

V4297A1005 small capacity, 120V: 0.2A.

V4297A1013 high capacity, 120V: 0.5A.

Valve Opening Time:

Valve Closing Time:

Dimensions:

See Fig. 10 and 11.

< 1 sec.

< 1 sec.

Weight:

V4297A1005: 8 lb (3.6 kg)

V4297A1013: 14 lb (6.3 kg)

Replacement Parts:

BBA51315 Coil for V4297A1005.

BBA51318 Coil for V4297A1013.

Accessories:

Pipe Adapters:

32000109-001 3/4 in. NPT.

32000109-002 1 in. NPT.

32000109-003 1-1/4 in. NPT.

32000109-004 1-1/2 in. NPT.

32000109-005 2 in. NPT.

KTCPI001 Visual Position Indicator.

4074EYF Bag Assembly (bolts, nuts and washers), supplied.

4074EYK Bag Assembly (O-rings and tube of lubricant),

supplied.

65-0246—14

Page 5

SOLENOID SAFETY SHUT-OFF VALVE

M16541

2 (51)

9

(229)

2-3/4

(70)

TOP VIEW

5-5/8

(143)

1/2 (13)

5-3/4 (147)

Fig. 10. Approximate dimensions of V4297A1005 SSOV in in. (mm).

TOP VIEW

2-3/4

1-1/2 (38)

(70)

5 (127)

1-1/2 (38)

2-1/2 (64)

2 (51)

5-1/2 (140)

5-5/8 (143)

3-3/4 (95)

6-1/4

(159)

M16532

5-3/4 (147)

Fig. 11. Approximate dimensions of V4297A1013 SSOV in in. (mm).

Approvals:

Underwriters Laboratories Inc. (UL): Listed.

Industrial Risk Insurers (IRI), formerly FIA: Acceptable.

International Approval Services (IAS): Design Certified.

Factory Mutual (FM): Approved. (KTCPI001 Visual Position

Indicator required if used with pipe size larger than 3/4 in.)

10-1/4

(260)

2 (51)

1/2 (13)

5 (127)

5-1/2 (140)

5-5/8 (143)

NOTE: NOTE: Some application codes, such as NFPA,

require visual indication of the valve position as

provided by the KTCPI001 Visual Position Indicator.

5 65-0246—1

Page 6

SOLENOID SAFETY SHUT-OFF VALVE

INSTALLATION

When Installing This Product...

1.

Read these instructions carefully. Be sure to follow

warning information carefully.

2.

Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3.

Installer must be a trained, experienced flame

safeguard co ntrol technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

WARNING

Explosion Hazard and Electrical Shock Hazard.

Can cause explosion, serious injury or death.

Turn off gas supply before beginning installation.

Disconnect power s upply before beg inning install ation.

More than one disconnection may be involved.

Mounting

Refer to the Integrated Valve Train Installation Instructions,

form 66-1099, for instructions on mounting a V 4297A in a

Honeywell Integrated Valve Train System. Refer to the

installation instructions packed with the Honeywell KTCPI001

Visual Position Indicator for mounting instructions of the

indicator.

WIRING

1.

Make sure all wiring agrees with all applicable local

codes, ordinances and regulations. An opening is

provided to accommodate rigid conduit or armored

cable for line voltage operation. See Fig. 12.

2.

Check the power supply circuit to verify the voltage

and frequency are correct for the valve.

3.

See Fig. 13 for typical V4297A wiring with the RM7800

Burner Controller. Follow the burner manufacturer

wiring diagram, when provided. Refer to the relay

module wiring diagram for specific wiring terminal

designations.

4.

Make wiring connections at the electrical terminations

provided in the valve wiring compar tm ent .

Fig. 12. Wiring compartment of V4297A SSOV.

V4297A

M16540

GROUND

NEUTRAL

LINE

VOLTAGE

N

L

MAIN VALVE

G

L2

4

9

120 Vac

RM7800

(TYPICAL)

Fig. 13. Typical wiring diagram for V4297A SSOV.

65-0246—16

Page 7

SOLENOID SAFETY SHUT-OFF VALVE

M9547D

GAS

SUPPLY

UPSTREAM

MANUAL

GAS COCK

DOWNSTREAM

MANUAL

GAS COCK

BURNER

D

LEAK

TEST

TAP

ABC E

F

PRV

MANUAL

TEST

PETCOCK

SSOV

1/4 IN. (6 MM)

FLEXIBLE

TUBING

1/4 IN. (6 MM)

ALUMINUM OR

COPPER PILOT

TUBING

JAR OR GLASS

WITH WATER

CUT AT

45 DEGREE

ANGLE

CAN ALSO BE A PERMANENT PETCOCK.

PRV = PRESSURE REGULATING VALVE.

SSOV = SAFETY SHUTOFF VALVE.

ONLY USE ONE OF THE DOWNSTREAM TAPS ON THE 550V.

1

2

3

4

4

2 3

1

1

2

(13 MM)

OPERATION AND CHECKOUT

Operation

The V4297A Safety Shutoff Valve is a normal ly closed valve.

The valve opens when it is energized and closes when the

power is removed.

WARNING

Explosion Hazard and Electrical Shock Hazard.

Can cause explosion, serious injury or death.

1.

Do not put the system into service until you have

satisfactorily completed the following Valve Leak

Test, all applicable tests described in the Checkout

section of the instructions for the flame safeguard

control and any other tests required by the burner

manufacturer.

2.

All tests must be performed by a trained,

experienced flame safeguard technician.

3.

Close all manual fuel shutoff valves immediately if

trouble occurs.

After the installation is comple te, cycle the va lve severa l times

with the manual fuel shutoff cock closed. Make sure the valve

functions properly. Also, perform the Valve Leak Test before

putting the valve into service.

Ta ble 2. Valve allowable leakage rate.

V4297A

Allowable leakage

a

(cc/hr)

Number of bubbles

(per 10 sec.)

Low Capacity 235 8

High Capacity 470 16

a

Based on air at standard conditions, test pressure provided

by ANSI Z21.21, Section 2.42 and a maximum of 235

cc/h/in of seal-off diameter (not pipe size).

Valve Leak Test (Fig. 14)

This is a test for checking the closure tightness of the gas

safety shutoff valve. It should be performed only by trained,

experienced flame safeguard control technicians during the

initial startup of the burner system or whenever the valve is

replaced (see Service Informatio n section). It is recommend ed

that this test also be included in the scheduled inspection and

maintenance procedu res. For a periodi c inspectio n test, follow

steps 1, 3, 4, 5, 8, 9, 10, 12, 13, 16 and 17.

1.

De-energize the control system to make sure no power

goes to the valve (C, Fig. 14).

2.

Close the upstream manual gas cock (A).

3.

Make sure the manual test petcock (F) is closed in the

leak test tap assembly (D).

4.

Remove the leak test tap plug and connect the test

apparatus to the leak test tap (D).

5.

Close the downstream manual gas cock (E).

6.

Open the upstream manual gas cock (A).

7.

Run the V4297A Valve to is open position (through the

safety system); then immediately de-energize the

system to close the V4297A Valve.

8.

Immerse a 1/4 in. (6 mm ) tu be ve rtic al ly 1/2 in . (1 3 m m)

into a jar of water.

9.

10.

IMPORTANT

Slowly open the manual test petcock (F).

When the rate of bubbles coming through the water

stabilizes, count the num be r of bubble s app eari ng

during a ten-second period. Each bubble appearing

represents a flow rate of 0.001 cfh.

T o me et U.S. requ irements, m ake sure l eakage do es

not exceed the rates in Table 2.

Fig. 14. Valve leak test.

NOTE: NOTE: For international leak test requirements,

contact the appropriate approval agency.

After the Test

1.

Close the upstream manual gas cock (A).

2.

Close the manual test petcock (F), remove the test

apparatus, and close the leak test tap (D).

3.

Make sure the downstream manual gas cock (E) is

closed.

4.

Open the upstream manual gas cock (A) and energize

the V4297A Valve through the safety system.

5.

Test with rich soap and water solution to make sure

there is no leak at the leak test tap (D) or any pip e

adapter/valve mating surfaces.

6.

De-energize the V4297A Valve (C).

7.

Open the downstream manual gas cock (E).

8.

Restore the system to normal operation. If two safety

shutoff valves are us ed, check ea ch valve sep arately for

closure tightness.

7 65-0246—1

Page 8

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

SOLENOID SAFETY SHUT-OFF VALVE

TROUBLESHOOTING

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

Use extreme caution while troubleshooting; line

voltage is present.

IMPORTANT

Troubleshooting Pr oced ure

If the valve does not open when the thermostat or controller

calls for heat:

If the valve does not close when one or more of the

appropriate contacts in the thermostat, controller, limits or

flame safeguard control is open:

Do not replace the valve until all other sources of

trouble are eliminat ed.

1.

Check for line vol tage at t he v al ve lea dw ire s o r terminal

block.

2.

If there is no voltage at the valve leadwires or terminal

block, make sure:

a. line voltage power is connected to the master

switch;

b. master switch is closed and overload protection

(circuit breaker, fuse or similar device) has not

3.

4.

5.

1.

2.

3.

4.

opened the power line.

If there is still no voltage at the valve leadwires or

terminal block, mak e sure all app ropriate contacts in the

thermostat or controller, limits and flame safeguard

controls are closed. If one or more are open, determine

the cause(s); correct the trouble, and proceed.

If there is proper voltage at the valve but the valve still

does not open, check for normal gas pressure.

If the valve still does not open, replace the valve.

Make sure the valve is wired in the correct circuit.

Open the master switch to remove power from the

valve.

If the valve closes now, check the wiring for the valve

and correct the wiring as necessary.

Check for a short in the electrical circuit and repair it as

necessary.

SERVICE INFORMATION

WARNING

Explosion Hazard and Electrical Shock Hazard.

Can cause explosion, serious injury or death.

Turn off gas s upply and di sconn ect al l elec trical po wer

to the valve before servicing.

IMPORTANT

Only trained, experienced flame safeguard control

technicians should att em pt to s erv ic e or rep ai r f lame

safeguard controls and burner assemblies.

Scheduled Inspecti on and Maintenance

Set up and follow a schedule for periodic inspection and

maintenance, including the burner, all other controls and the

valve(s). It is recommended that the valve leak test in the

Checkout section be included in this schedule. Refer to the

instructions for the primary safety control(s) for more

inspection and maintenance information.

Home and Building Control Home and Building Control Honeywell Asia Pacific Inc. Honeywell Europe S.A. Honeywell Latin American

Honeywell Honeywell Limited-Honeywell Limitée Room 3213-3225 3 Avenue du Bourget

1985 Douglas Drive North 35 Dynamic Drive Sun Hung Kai Centre 1140 Brussels 480 Sawgrass Corporate Parkway

Golden Valley, MN 55422 Scarborough, Ontario No. 30 Harbour Road Belgium Suite 200

65-0246—1 G.R. Rev. 2-01 www.honeywell.com

M1V 4Z9 Wanchai Sunrise FL 33325

Hong Kong

Region

Loading...

Loading...