Page 1

V4295A,S; V8295A,S

Solenoid Gas Valves

APPLICATION

The electrically operated V4295A, S and V8295A, S Solenoid

Gas Valves control the flow of natural and LP (liquefied

petroleum) gases.

INSTALLATION INSTRUCTIONS

FEATURES

• V4295A,S are used with 120 Vac controllers;

V8295A,S are used with 24 Vac controllers.

• Models available in Normally Closed and Normally

Open configurations.

• Normally Closed models, for safety shut-off

applications, consist of a direct on/off operator for

opening and closing of the valve.

• Normally Open models, for vent (double block and

bleed) valve applications, consist of a direct electric

on/off operator for closing and opening of the valve.

• Models are suitable for the control of gaseous fluids in

gas consuming appliances according to international

standards.

• Models have 1/4 inch NPT inlet and outlet pressure

taps.

• Models have inlet screen to protect the valve from the

entry of dirt.

These valves are used on atmospheric boilers, commercial

water heaters, roof-top make-up air burners, power burners

and boilers.

SPECIFICATIONS

Models

V4295A Normally Closed (N.C.) Safety shut-off Valve, 120V

V4295S Normally Open (N.O.) Vent Valve, 120V

V8295A Normally Closed (N.C.) Safety shut-off Valve, 24V

V8295S Normally Open (N.O.) Vent Valve, 24V

Type of gas

Air, Natural, Manufactured, Mixed and LP gas.

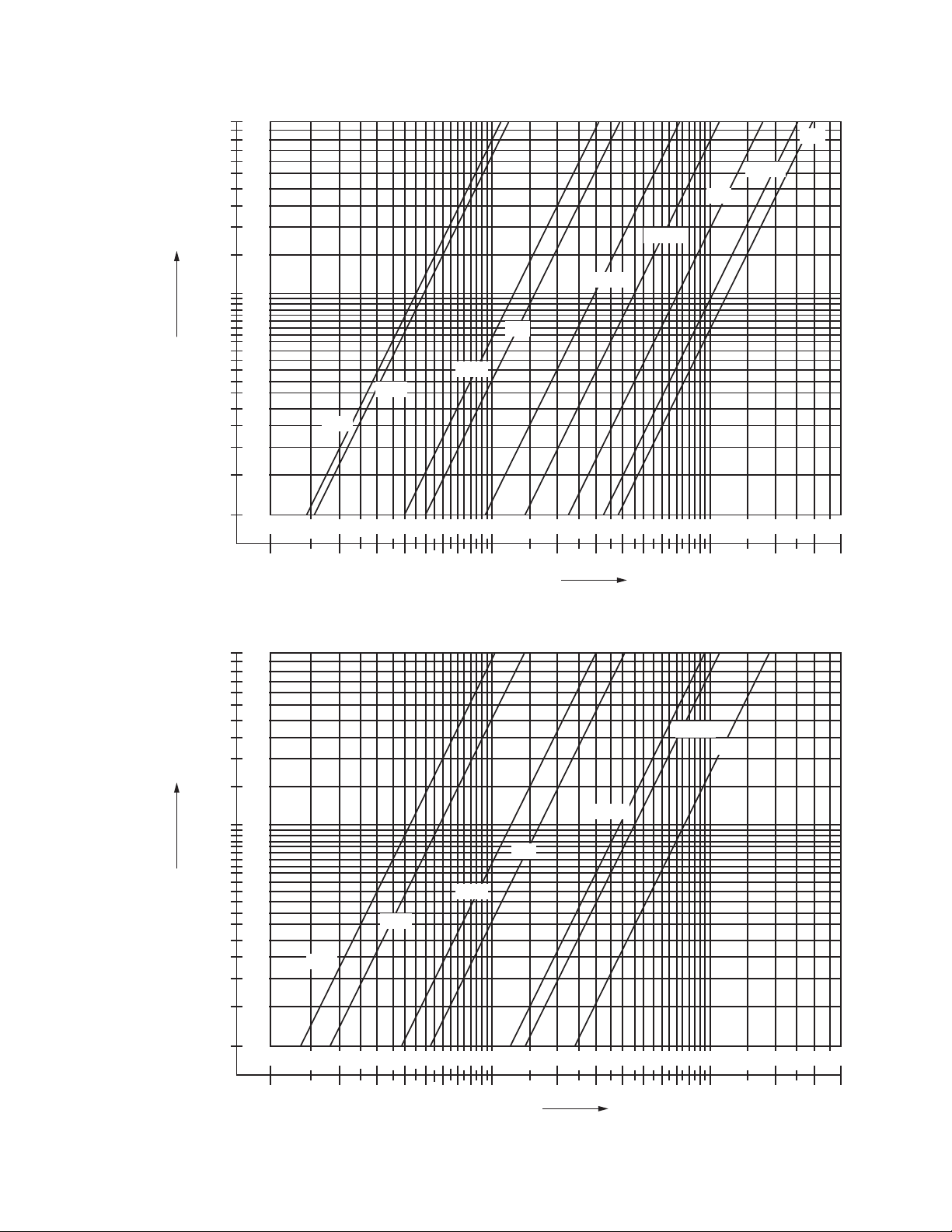

Valve capacities

Refer to Figures 1 and 2

Valve pattern

Straight through, non-offset

Body Material

Die cast aluminum

Electrical terminations

Screw terminal connections

Valve opening time

Less than 1 second

65-0194-04

Page 2

V4295A,S; V8295A,S SOLENOID GAS VALVES

Valve closing time

Current draw

Less than 1 second

Maximum operating pressure

3/8 in. through 3 in. pipe sizes: 2 psi

3/8 in. through 2 in. pipe sizes: 5 psi

Normally Closed (N.C.)

Pipe size (inch)

V4295A V8295A

120 Vac 24 Vac

2 psi 5 psi 2 psi

3/8 and 1/2 0.160 A 0.160 A 0.80 A

3/4 and 1 0.160 A 0.200 A 0.80 A

1-1/4 0.340 A 0.550 A 1.60 A

1-1/2 0.300 A 0.550 A 1.70 A

2 0.525 A 0.540 A 2.80 A

2-1/2 0.575 A n/a n/a

3 0.675 A n/a n/a

Normally Open (N.O.)

Pipe size (inch)

V4295A V8295A

120 Vac 24 Vac

2 psi

3/4 and 1 0.160 A 0.80 A

1-1/4 0.340 A 2.40 A

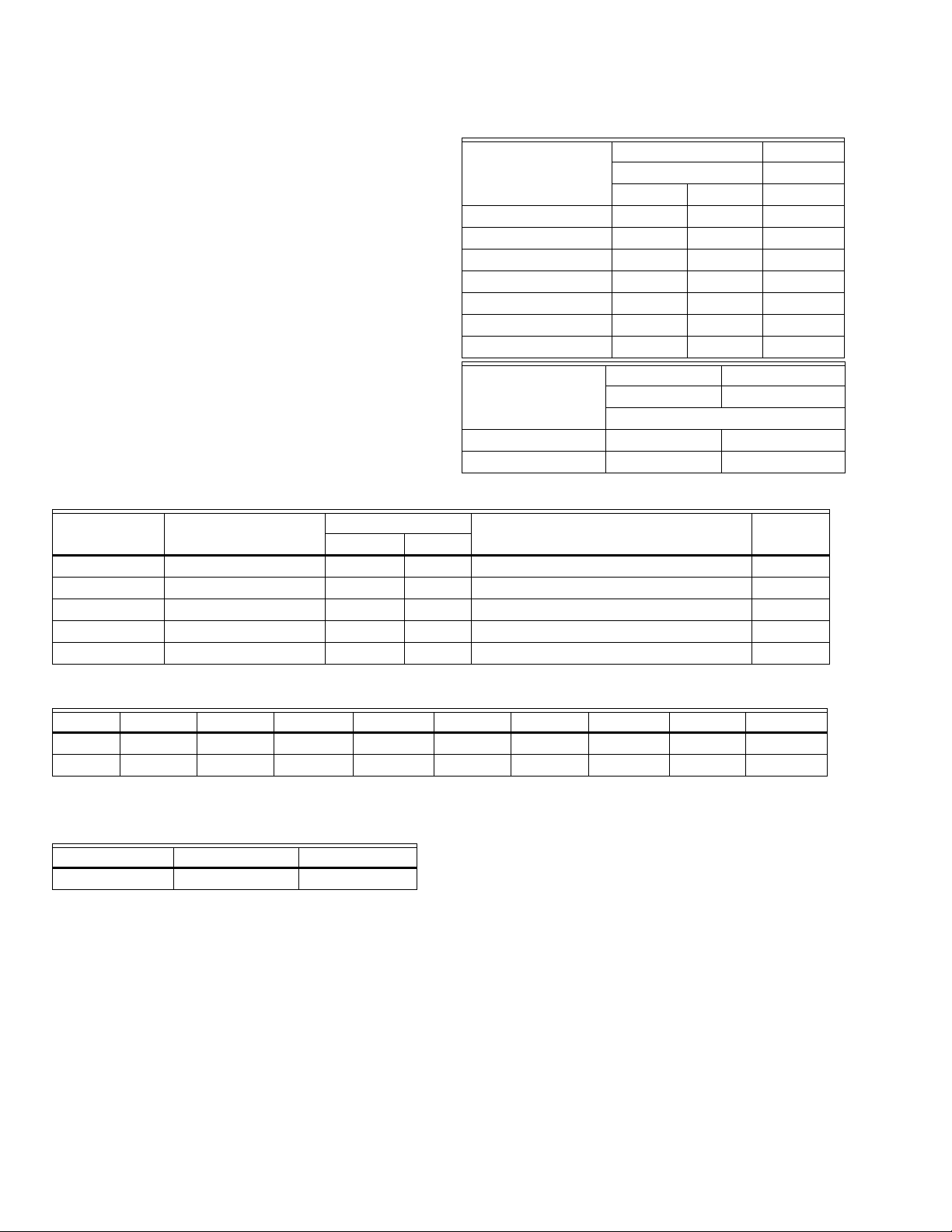

Table 1. Models Available.

Model Voltage/Frequency

Maximum Pressure

Pipe size (inch)

Thread

typepsi mbar

V4295A (N.C.) 110/120 Vac, 50/60 Hz 2.0 140 3/8, 1/2, 3/4, 1, 1-1/4, 1-1/2, 2, 2-1/2, 3 NPT

V4295A (N.C.) 110/120 Vac, 50/60 Hz 5.0 350 3/8, 1/2, 3/4, 1, 1-1/4, 1-1/2, 2 NPT

V4295S (N.O.) 110/120 Vac, 50/60 Hz 2.0 140 3/4, 1, 1-1/4 NPT

V8295A (N.C.) 24 Vac, 50/60 Hz 2.0 140 3/8, 1/2, 3/4, 1, 1-1/4, 1-1/2, 2 NPT

V8295S (N.O.) 24 Vac, 50/60 Hz 2.0 140 3/4, 1, 1-1/4 NPT

Table 2. Capacity in CFH at Pressure Drop of 1-Inch Water Column sp. gr. = 0.64 for V4295A, V8295A (N.C.).

3/8 in. 1/2 in. 3/4 in. 1 in. 1-1/4 in. 1-1/2 in. 2 in. 2-1/2 in.* 3 in.*

2 psi 230 250 645 790 1,450 2,190 3,465 5,070 6,100

5 psi 210 290 610 825 1,950 2,270 3,740 n.a. n.a.

* V4295A only

Table 3. Capacity in CFH at Pressure Drop of 1-Inch

Water Column sp. gr. = 0.64 for V4295S, V8295S (N.O.).

3/4 in. 1 in. 1-1/4 in.

350 420 1,100

65-0194—04 2

Page 3

6

24

520

4

16

3

12

V4295A,S; V8295A,S SOLENOID GAS VALVES

3 IN.

2-1/2 IN.

2 IN.

28

1

4

0.8

3.2

∆ P (KPA)

∆ P (IN. W.C.)

0.6

2.4

0.5

0.4

0.3

0.2

0.1

2.0

1.6

1.2

1.0

0.8

0.4

1 2 3 4 5 6 8 10 20 30 40 50 60 80 100 200 300 400

3/8 IN.

1/2 IN.

3/4 IN.

1 IN.

1-1/4 IN.

X 100Vg (NATURAL GAS SG 0.64) (CFH) =

1-1/2 IN.

M28666

Fig. 1. Capacity curves for V4295A and V8295A, 2 psi versions.

6

24

520

4

16

3

12

28

1

4

0.8

3.2

∆ P (KPA)

∆ P (IN. W.C.)

0.6

2.4

0.5

0.4

0.3

0.2

0.1

2.0

1.6

1.2

1.0

0.8

0.4

3/8 IN.

1 2 3 4 5 6 8 10 20 30 40 50 60 80 100 200 300 400

1/2 IN.

3/4 IN.

1 IN.

1-1/4 IN.

X 100Vg (NATURAL GAS SG 0.64) (CFH) =

1-1/2 IN.

2 IN.

M28667

Fig. 2. Capacity curves for V4295A, 5 psi versions.

3 65-0194—04

Page 4

V4295A,S; V8295A,S SOLENOID GAS VALVES

Ambient temperature rating

-40ºF to 145ºF (-40ºC to 63ºC)

Maximum fluid temperature rating

-40ºF to 145ºF (-40ºC to 63ºC)

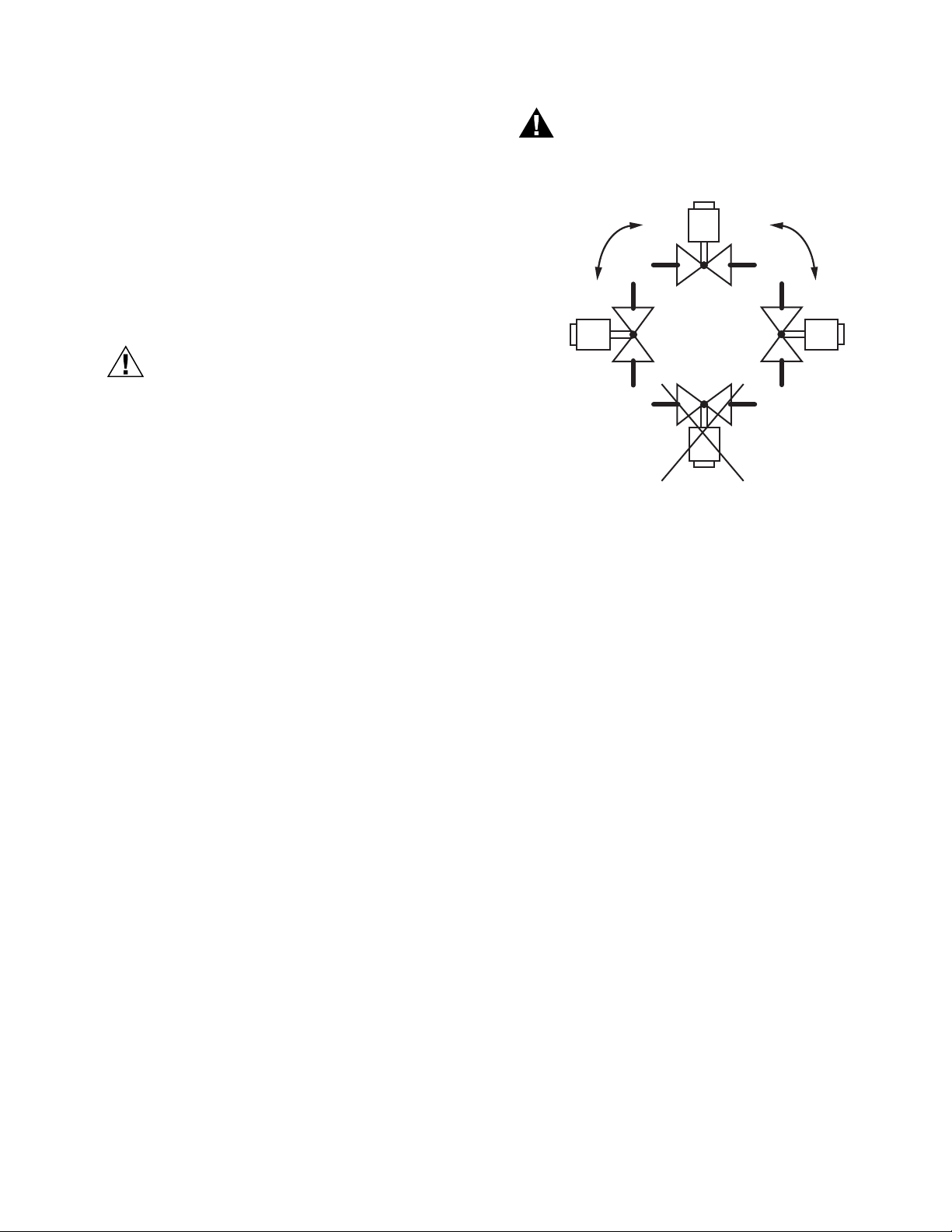

Mounting position

Vertical to 90 degrees from vertical, refer to Fig. 5.

Dimensions and weight

Refer to Figures 3 and 4.

D

C

E

Approvals

Underwriters Laboratories, Inc., File Number MH 18476,

Guide number YLOZ

AGA and CGA, File Number C2030014

Complies with standard ANSI Z21.21-CGA6.5

Automatic Valves for gas appliances and automatic safety

shut-off gas valves (revised edition of the former ANSI

Z21.21, CAN/CGA-6.5-M89, CAN/CGA-3.9-M87)

Factory Mutual:

V4/8295A: 2 psi rated, 3/8 in. to 3/4 in.

V4/8295A: 5 psi rated, 3/8 in. to 2 in.

V4/8295S: All

CSD-1 Acceptable.

D

C

B

B

E

A

M28661

Fig. 3. Dimensions (normally closed).

Fig. 4. Dimensions (normally open).

Table 4. Normally Closed (See Fig. 3).

Pipe size

3/8 in. NPT 2-7/8 4-7/16 4-7/16 2-3/16 2-3/16 3-3/4 3-3/4 2-3/16 2.5 2.2

1/2 in. NPT 2-7/8 4-7/16 4-7/16 2-3/16 2-3/16 3-3/4 3-3/4 2-3/16 2.5 2.2

3/4 in. NPT 3-7/16 5-1/4 5-13/16 2-3/16 2-1/2 3-3/4 4-1/16 2-3/4 4.0 4.4

1 in. NPT 3-15/16 5-1/4 6-5/16 2-3/16 2-1/2 3-3/4 4-1/16 3 4.5 4.4

1-1/4 in. NPT 5-15/16 8 8-9/16 2-1/2 3-5/16 4-1/16 4-15/16 4-3/8 12.8 10.6

1-1/2 in. NPT 5-15/16 8-3/8 8-9/16 3-3/8 3-5/16 4-15/16 4-15/16 4-3/8 12.8 10.6

2 in. NPT 6-11/16 8-3/8 9-3/16 3-3/8 3-3/4 4-15/16 5-5/16 5-3/8 14.0 13.4

2-1/2 in. NPT 9-1/2 12-3/4 — 4-9/16 — 6-1/8 — 7-7/8 28.5 —

3 in. NPT 9-1/2 12-3/4 — 4-9/16 — 6-1/8 — 7-7/8 31.0 —

Pipe size A (inch) B (inch) C (inch) D (inch) E (inch) (both sides) Weight (lbs)

3/4 in. NPT 3-7/16 5-1/2 2-3/16 3-3/4 2-3/4 4.0

1 in. NPT 3-15/16 5-1/2 2-3/16 3-3/4 3 4.5

1-1/4 in. NPT 5-15/16 8-3/4 2-1/2 4-1/16 4-3/8 12.8

A

(inch)

B (inch) C (inch) D (inch)

2 psi 5 psi 2 psi 5 psi 2 psi 5 psi 2 psi 5 psi

Table 5. Normally Open (See Fig. 4).

A

E (inch)

(both sides)

M28662

Weight (lbs)

65-0194—04 4

Page 5

INSTALLATION

CAUTION

WARNING

V4295A,S; V8295A,S SOLENOID GAS VALVES

When installing this product...

1. Read this instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

2. Check the rating given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced, flame safeguard control technician.

4. After installation is complete, check out product operation as provided in these instructions.

1. Turn off gas supply before starting installation.

2. Disconnect power supply before beginning

installation to prevent electrical shock and

equipment damage.

3. Do not remove seal over valve inlet or outlet

until ready to connect piping.

Prepare piping and install valve (Fig. 5)

1. Use new, properly reamed pipe which is free from chips.

2. Do not thread pipe too far.

3. Apply good quality pipe dope resistant to the action of

LP gas, putting a moderate amount on the male threads

only. If pipe dope lodges on the valve seat, it will prevent

proper closure.

4. Install valve in a horizontal pipe line, (refer to Fig. 5 for

mounting position) with the gas flow matching the direction indicated by the arrow on the casting.

5. Apply a parallel jaw wrench only to the wrench flats of

the valve body, next to the pipe being inserted. A

wrench applied to the valve body itself or to the end farthest from the pipe being inserted may distort the casting, resulting in malfunction on the gas valve.

6. The gas flow must be in the same direction as the arrow

on the body of the valve.

If the flow is not in the same direction of arrow,

valve may not shut off.

M28663

Fig. 5. Mounting position.

7. Make electrical connections as illustrated in the wiring

diagrams; see Fig. 6.

8. Turn on main gas and with a soap solution, check valve

installation for leaks.

WIRING

1. Disconnect power supply before making wiring connec-

tions to prevent electrical shock and equipment damage.

2. Installation and wiring must be in conformance with

National Electrical Code ANSI/NFPA 70, local codes

and regulations.

3. For normal installations, use moisture-resistance No. 14

wire suitable for at least 167ºF (75ºC) if using a Flame

Safeguard Primary Control, or 194ºF (90ºC) if using a

Flame Safeguard Programming Control.

4. For high temperature installations, use moisture resistant No. 14 wire selected for a temperature rating above

the maximum operating temperature.

5. Check the power supply circuit. The voltage and frequency must match those of the valve.

6. Refer to Fig. 6 for typical V4295A,S field wiring with

RM7800 (typical) Primary Safety Control. Refer to Fig. 7

for typical V8295A,S field wiring with Primary Safety

Control. Follow the burner manufacturer’s wiring diagram, when provided. Refer to burner controller (primary safety control) wiring diagram for specific wiring

terminal designations.

7. Make wiring connections at the electrical terminations

provided in the wiring compartment of the valve.

5 65-0194—04

Page 6

V4295A,S; V8295A,S SOLENOID GAS VALVES

WARNING

CAUTION

M28664

120 VAC

GROUND

G

4

N

L

9

NEUTRAL

LINE

VOLTAGE

MAIN VALVE

V4295A,S

RM7800

(TYPICAL)

L2

M28665

LIMIT(S)

TRANSFORMER

L1

(HOT)

L2

V8295A,S

G

NL

24 VOLT

THERMOSTAT

FLAME

SAFEGUARD

CONTROL

POWER SUPPLY. PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

CHECKOUT AND TROUBLESHOOTING

Do not allow fuel to accumulate in the combustion

chamber. If fuel is allowed to enter the chamber for

longer than a few seconds without igniting, an

explosive mixture could result.

1. Do not put the system into service until you

have satisfactorily completed all applicable tests

described in the Checkout section of the

instructions for the flame safeguard control and

any other test required by the burner

manufacturer.

2. Close all manual fuel shut off valves as soon as

trouble occurs.

CHECKOUT

Fig. 6. Wiring, V4295A,S.

Fig. 7. Wiring, V8295A,S.

OPERATION

The V4295A and V8295A Normally Closed series gas valves

are Class B fail safe shut off valves. The valve is opened by

energizing the direct ON/OFF operator. The direct ON/OFF

operator consists of a coil and stop sleeve assembly. Inside

the stop sleeve assembly is a plunger which is able to move

up and down, thus opening or closing the valve. The plunger

glides on two anti-friction bearings. A strainer, made of AISI

303 stainless steel, is incorporated into the valve.

65-0194—04 6

1. Check the performance of the valve by measuring the

pressures at the inlet and outlet pressure taps. The

pressure reading at the outlet tap may be slightly higher

than a downstream measurement due to dynamic gas

flow effects. The measurement at the outlet tap is for

reference only.

2. Shut off gas supply to valve and make sure valve is

closed when setting up pressure measuring equipment.

3. Set thermostat or controller to energize the valve and

check final outlet pressure.

4. Start the system and observe its operation through at

least one complete cycle to ensure the valve functions

as described in the section “Operation” on page 6.

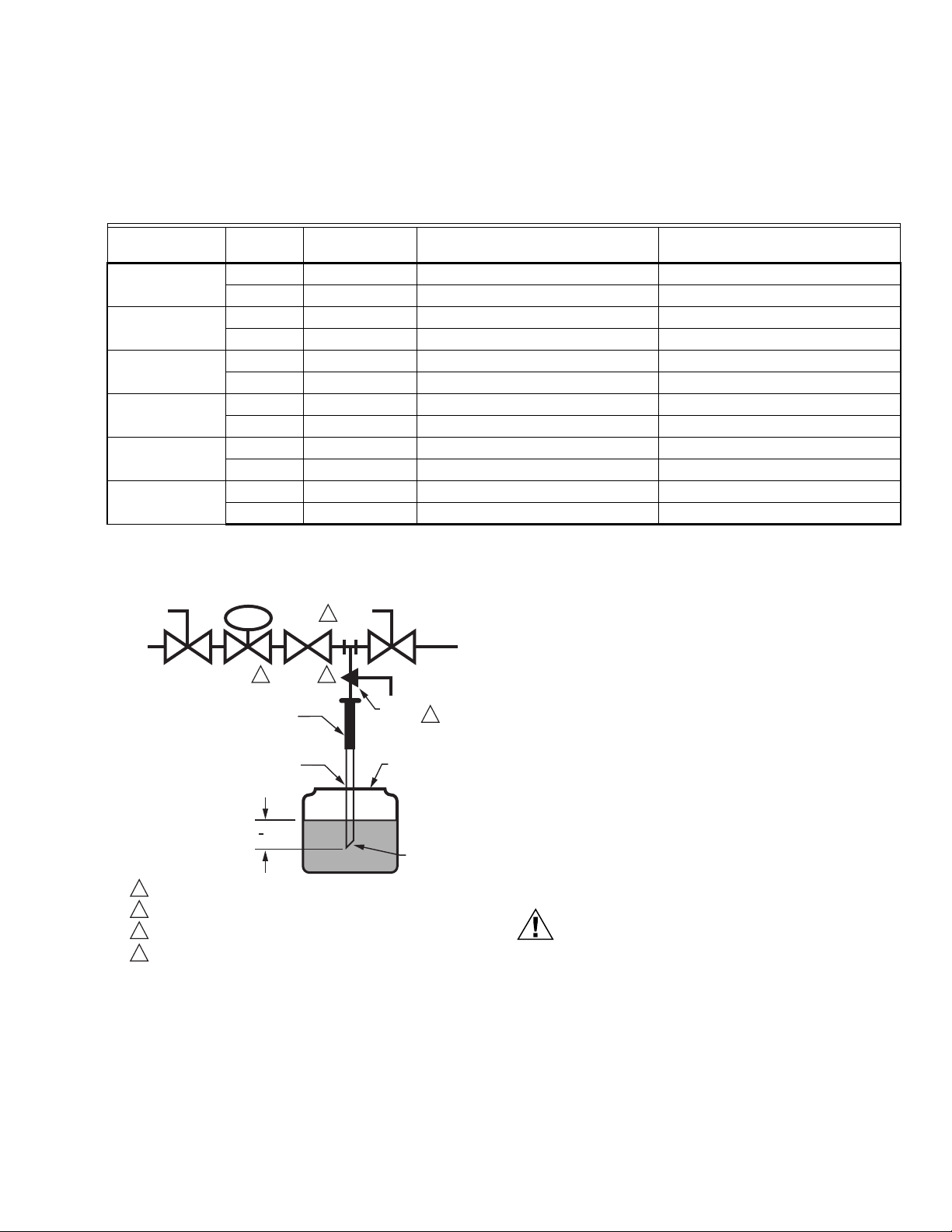

Valve Leak Test (Fig. 8)

This is a test for checking the closure tightness of the gas

safety shutoff valve. It should be performed only by trained,

experienced flame safeguard control technicians during the

initial startup of the burner system or whenever the valve is

replaced (see Service Information section). It is recommended

that this test also be included in the scheduled inspection and

maintenance procedures.

1. De-energize the control system to make sure no power

goes to the valve (C, Fig. 8).

2. Close the upstream manual gas cock (A).

3. Make sure the manual test petcock (F) is closed in the

leak test tap assembly (D).

4. Remove the leak test tap plug and connect the test

apparatus to the leak test tap (D).

5. Close the downstream manual gas cock (E).

6. Open the upstream manual gas cock (A).

7. Run the V4/8295A Valve to is open position (through the

safety system); then immediately de-energize the system to close the V4/8295A Valve.

8. Immerse a 1/4 in. (6 mm) tube vertically 1/2 in. (13 mm)

into a jar of water.

9. Slowly open the manual test petcock (F).

Page 7

V4295A,S; V8295A,S SOLENOID GAS VALVES

CAUTION

M9547F

GAS

SUPPLY

UPSTREAM

MANUAL

GAS COCK

DOWNSTREAM

MANUAL

GAS COCK

BURNER

DABC E

F

PRV

MANUAL

TEST

PETCOCK

SSOV

1/4 IN. (6 MM)

FLEXIBLE

TUBING

1/4 IN. (6 MM)

ALUMINUM OR

COPPER PILOT

TUBING

JAR OR GLASS

WITH WATER

CUT AT

45 DEGREE

ANGLE

CAN ALSO BE A PERMANENT PETCOCK.

PRV = PRESSURE REGULATING VALVE.

SSOV = SAFETY SHUTOFF VALVE.

USE ONLY ONE OF THE DOWNSTREAM TAPS ON THE SS0V.

1

2

3

4

4

2 3

1

1

2

(13 MM)

LEAK

TEST

TAP

10. When the rate of bubbles coming through the water stabilizes, count the number of bubbles appearing during a

ten-second period. Each bubble appearing represents a

IMPORTANT

To meet U.S. requirements, make sure leakage does

not exceed the rates in Table 6.

flow rate of 0.001 cfh.

Table 6. Valve Allowable Leakage Rate.

V4295A/V8295A

Pipe Size (in) Medium

Allowable

Leakage SCCH*

Maximum Number of Bubbles in 10

Seconds

3/8 & 1/2 0.64 gas 294 7 13

1.57 LP 188 4 20.4

3/4 & 1 0.64 gas 301 7 12.7

1.57 LP 192 5 19.9

1-1/4 & 1-1/2 0.64 gas 532 13 7.2

1.57 LP 341 8 11.2

2 0.64 gas 578 15 6.6

1.57 LP 370 9 10.3

1-1/2 0.64 gas 752 19 5.1

1.57 LP 481 12 8

3 0.64 gas 925 24 4.1

1.57 LP 592 15 6.5

* Based on air at standard conditions, test pressures provided by ANSI Z21.21.

Section 2.42 and a maximum of 235 cc/h per inch of seal-off diameter (not pipe size).

Minimum Number of Seconds for

10 Bubbles

NOTE: For international leak test requirements, contact the

Fig. 8. Valve leak test.

appropriate approval agency.

After the Test

1. Close the upstream manual gas cock (A).

2. Close the manual test petcock (F), remove the test

apparatus, and close the leak test tap (D).

3. Make sure the downstream manual gas cock (E) is

closed.

4. Open the upstream manual gas cock (A) and energize

the V4/8295A Valve through the safety system.

5. Test with rich soap and water solution to make sure

there is no leak at the leak test tap (D) or any pipe

adapter/valve mating surfaces.

6. De-energize the V4/8295A Valve (C).

7. Open the downstream manual gas cock (E).

8. Restore the system to normal operation. If two safety

shutoff valves are used, check each valve separately for

closure tightness.

TROUBLESHOOTING

Use utmost care during troubleshooting. Line

voltage is present at the actuator for V4295A,S and

present in controller circuits. Low voltage (24 Vac)

is present at the actuator for V8295A,S and

present in controller circuits.

IMPORTANT

Do not assume that the valve must be replaced until

all other sources of trouble have been eliminated.

7 65-0194—04

Page 8

V4295A,S; V8295A,S SOLENOID GAS VALVES

CAUTION

CAUTION

CAUTION

1. If the valve will not open when the thermostat or

controller is calling for heat:

a. Check that there is voltage at the valve actuator

lead wires or terminal block.

Line voltage (120 Vac) should be present when the

primary safety control energizes the V4295A,S

valve actuator. 24 Vac should be present when the

primary safety control energizes the V8295A,S

valve actuator.

b. If there is no voltage at the actuator, first ensure line

voltage power is connected to the master switch, the

master switch is closed and overload protection (circuit breaker, fuse or similar device) has not opened

the power line.

c. If there is still no voltage at the actuator, make sure

all appropriate contacts in the thermostat (or controller), limit(s) and flame safeguard control are closed.

If one or more are open, determine the cause(s) and

correct condition(s) before proceeding.

d. If there is proper voltage at the actuator but the

valve still does not open, first check that the gas

pressure is normal.

e. If the valve still does not open, replace valve.

2. If the valve will not close when one or more of the

appropriate contacts in the thermostat (or controller), limit(s) or flame safeguard control is open:

a. Make sure that the gas flow is in the direction of the

arrow on the valve body.

b. Make sure the valve actuator is wired in the correct

circuit. Open the master switch to remove power

from the actuator. If the valve closes now, the actuator may not be wired properly.

c. Look for a short in the electrical circuit.

SERVICE INFORMATION

1. Only qualified service technicians should

attempt to service or repair flame safeguard

control and burner.

2. Line voltage is present in the electrical circuits

to the valve. Open the master switch before

replacing the valve.

1. Label all wires prior to disconnection when

servicing valves. Wiring errors can cause

improper and dangerous operation.

2. Verify proper operation after servicing.

Scheduled inspection and maintenance

For periodic inspection and maintenance, set up a schedule

and follow it. Include the burner, valves and all other burner

controls. It is recommended that “Valve Leak Test (Fig. 8)” on

page 6 be included in the schedule. Refer to the flame

safeguard control instructions for more information.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2009 Honeywell International Inc.

65-0194—04 M.S. Rev. 02-09

Loading...

Loading...