Page 1

Sampling valve for chemical and microbiological parameters

Construction

The sampling valve consists of:

• Red bronze housing

• Red bronze body

• Dezincification resistant brass nut

• Dezincification resistant brass sleeve nut

• Stainless steel outlet pipe

•EPDM gaskets

• Red bronze piston

EN0H-1804GE23 R0307 • Subject to change

V4250

Alwa Sampling Valve

Product specification sheet

Application

Sampling valve for chemical and microbiological parameters in

drinking, bathing and swimming pool water.

Suppliers of drinking water for public use have to commission an

annual investigations of water to prevent Legionella occurrence

according German regulations TrinwV §§4, 14 (6) and 19 (7) and

Appendix 4.

There are defined sampling locations for the determination of

drinking water system contamination by Legionella.

Special Features

• May be retrofitted to any Alwa F/KFR/R fittings from DN15 to

DN80

• Valve body and outlet bend may be rotated through 360° and

hence may be aligned in any direction

• Outlet volume may be regulated and the valve may be shut off

by means of an allen key

• Certificate regarding suitability for sampling in accordance

with VDI 6023 and German water regulations

• Correct sampling procedure possible

• A sampling valve for all types of sampling

• All parameters to be determined may be taken at one point

• Horizontal and vertical mounting possible

• Sampling equipment is simple to operate and may be flame

sterilised

• Stable, long, stainless steel outlet bend generates a straight

water jet

• Valve body and parts in contact with the medium in red

bronze

• High quality, hygienic EPDM seat seal with German health

ministry plastics and water approval

Range of Application

Medium The sampling valve was developed for usage in cold

or hot drinking water systems, swimming pools and

bathing water systems.

The sampling valve should be used for investigation of Legionella

contamination at determined locations in potable water systems.

Technical Data

Operating temperature maximum 90 °C

Pressure rating (PN) 16 bar

www.honeywell.de/haustechnik 1

Page 2

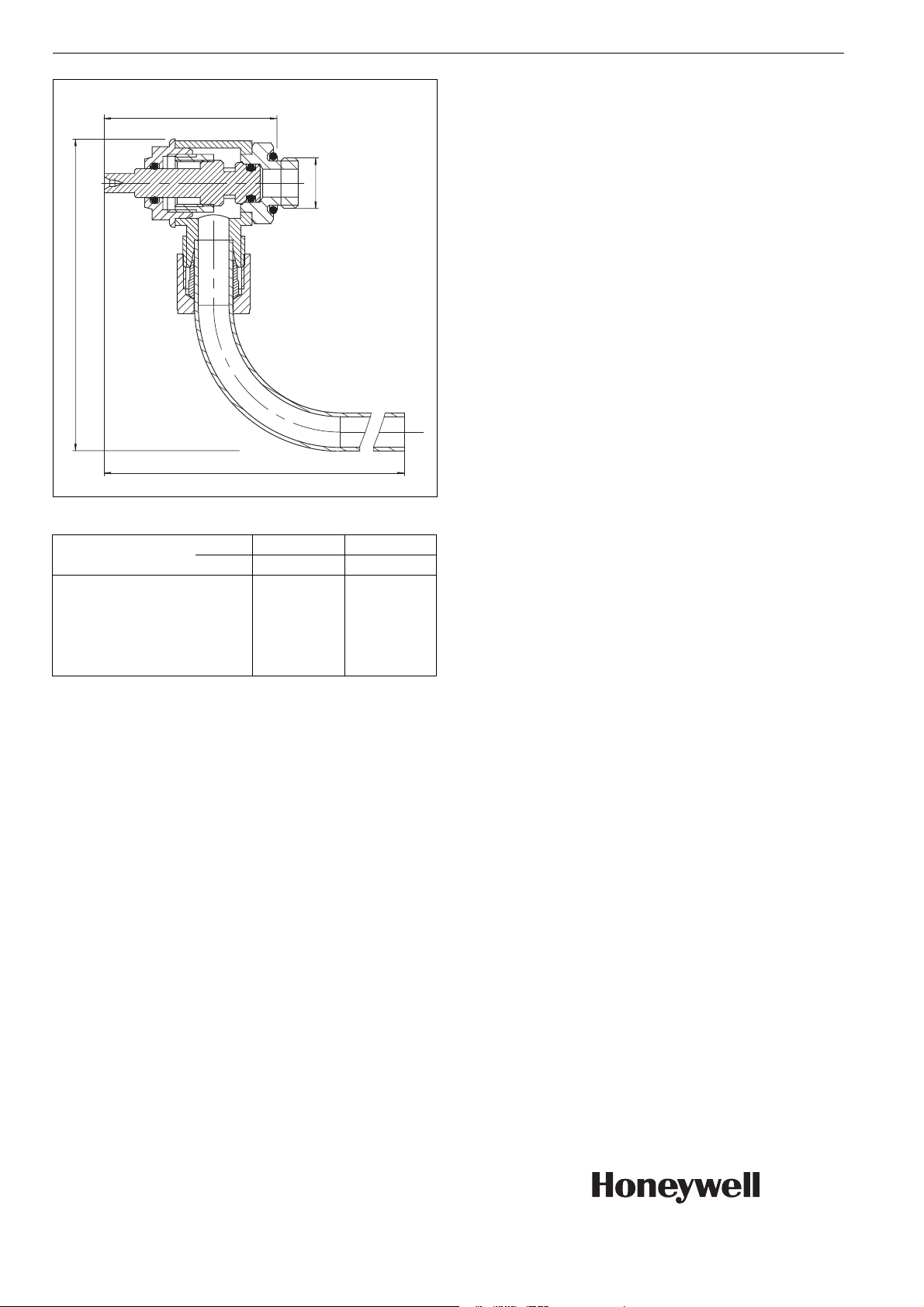

V4250 Alwa Sampling Valve

l

H

h

Method of Operation

Operators who supply drinking water to the public must commission tests for legionella once a year.

There are often no suitable sampling valves in the drinking water

system, so that sampling takes an unnecessarily long time and

G

cannot always be carried out correctly.

The sampling valve may be fitted horizontally or vertically on any

Alwa F/KFR/R fitting with a drain plug.

A flame is applied around the fitting to disinfect the stainless steel

outlet pipe. The sampling valve can be regulated and the flow

volume regulated with an allen spanner.

The sample is taken beneath the installation. Splashing is minimised by the form of the outlet pipe.

The stainless steel outlet tube can be swung out of the operating

area to either side.

Options

V4250A008 Sampling valve with connection size G1/4 for buil-

ding valves up to DN25

L

V4250A010 Sampling valve with connection size G3/8 for buil-

ding valves from DN32 to DN80

Connection size DN 6 DN 10

G

1

/

4

3

/

8

Dimensions mm

L 153.5 153.5

l44 44

H81.3 81.3

h69.8 69.8

Installation Guidelines

• Positioning of the sampling location must be determined by

the person carrying out sampling. The defined positions must

be identified in the plan for sampling locations in drinking

water systems.

• The sampling valve can be installed horizontally or vertically

to any valve with testing lobes.

• Insure the piping system is pressure-free before installing the

sampling valve

• The valve housing is only tightened at closed position due to

possibility to align valve to right position during installation.

• Please check for closed condition after installing.

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1804GE23 R0307

Subject to change

© 2007 Honeywell GmbH

Loading...

Loading...