Page 1

Put Bar Code Here

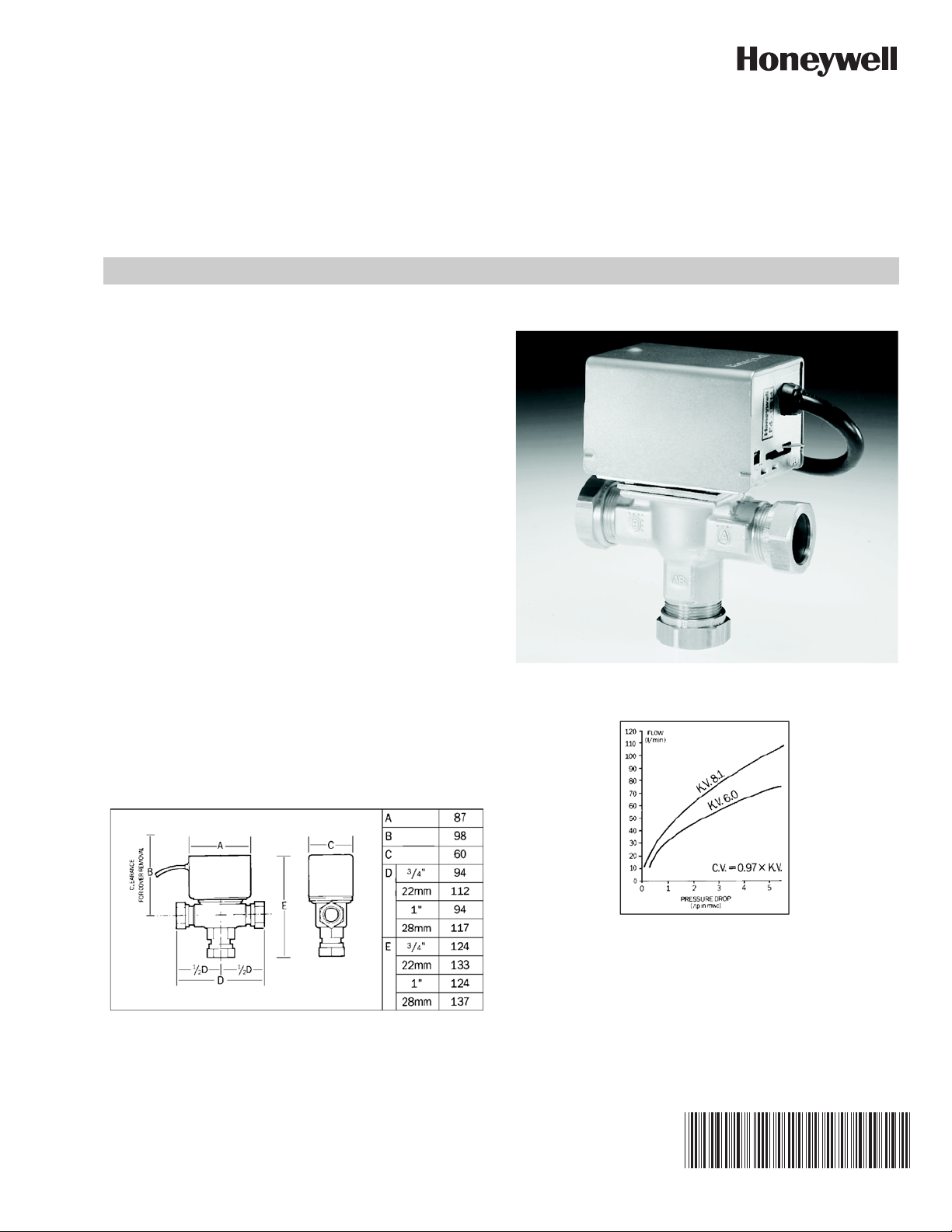

V4044C Diverter Valve

APPLICATION

The V4044C valve has been designed to control the flow of

water in a small bore domestic central heating system where

both radiator and hot water cylinder circulation are pumped. It

is typically suited for systems up to 90,000 Btu/h (26 KW).

SPECIFICATIONS

Voltage: 230-240V ~ 50 Hz

Power Consumption: 6W

Lead Supplied: 1 metre, 5 core

Operating Temperature Range: +5 to +88° C

INSTALLATION INSTRUCTIONS

Maximum Ambient Air Temperature: +52° C

Pipe Fitting Sizes: 22 mm & 28 mm compression fitting, 3/4”

& 1” BSP

Dimensions and KV values: See diagrams

SPARES AVAILABLE

Powerhead Part No. 40003916-002

Motor Part No. 40002737-003

Ball & O-ring Kit Part No. 272742A CARD

Fig. 1. Dimensions (mm)

Fig. 2. Flow Characteristics

95C-10818—04

Page 2

V4044C DIVERTER VALVE

INSTALLATION

V4044C incorporates a manual lever, the lever should

normally be in ‘AUTO’ position, but can be moved to ‘MAN.

OPEN’ position for system draindown and filling purposes

only.

Before fitting the valve, read through the plumbing and wiring

instructions.

This product MUST be installed by a competent person. The

installation MUST conform to I.E.E. Regulations and with The

Electricity at Work Regulations.

A Class ‘A’ switch (having contact separation of at least 3 mm

in all poles) must be incorporated in the fixed wiring as a

means of disconnecting the supply. The system must be

appropriately fused.

PLUMBING

The valve MUST NOT be fitted on the return pipework under

any circumstances. Flow from the boiler must be connected to

port AB, the radiator circuit to port A and the hot water cylinder

circuit port B.

The valve may be plumbed in at any angle, but must not be

mounted so that the valve head is below the horizontal level of

the pipework. In the unlikely event of a leak, a safety hazard

could result.

Do not grip the valve head while making and tightening up

plumbing connections. Attach a spanner (32 mm or 1 1/4” AF)

onto the valve body at each port, whilst tightening up the nuts.

Tighten compression nuts enough to make a watertight seal.

TAKE CARE NOT TO OVERTIGHTEN.

NO

MAN

OPEN

AUTO

MAN

OPEN

AUTO

NO

M32208

WIRING

The wiring diagram (Fig. 3) shows relevant connections to a

Honeywell junction box (Part No. 42002116-001). Ensure that

each numbered, lettered or coloured wire is connected to the

correct terminal in the junction box. Make sure all connections

are good and all terminal screws are firmly tightened.

Valve wiring configuration is:

Brown = Motor open

Blue = Neutral

Green/Yellow = Earth

NOTES:

a. Wiring diagram shows connections to a programmer

with separate control of heating and hot water.

b. If single channel time clock is used, connect

switched live from time clock to terminal 4 or 6 at

junction box, then link terminal 4 to terminal 6 with a

link wire.

c. If the programmer or time clock have no ‘Hot water

OFF’ terminal, then the time clock will need to be

replaced.

95C-10818—04 2

Page 3

V4044C DIVERTER VALVE

Fig. 3. ‘W’ Plan

3 95C-10818—04

Page 4

V4044C DIVERTER VALVE

CHECKOUT PROCEDURE

To ensure the valve is plumbed and wired correctly, carry out

the following checks after filling the system and switching on

the power:

1.

a. Check the manual lever is in ‘AUTO’ position.

b. Check programmer has power.

c. Check boiler is switched on and its thermostat set to

maximum.

2. Confirm correct hot water functions as follows:

a. Turn room thermostat to minimum setting or switch

off at programmer.

b. Set cylinder thermostat to maximum and program-

mer to ‘HOT WATER ON’.

c. Boiler should fire and pump should run. Feel pipe

approximately 12” from valve port B, it should get

hot.

3. Confirm correct heating functions as follows:

a. Turn cylinder thermostat to minimum.

b. Set room thermostat to maximum and programmer

to ‘HOT WATER AND CENTRAL HEATING ON’.

c. Boiler should fire and pump should run. Feel pipe

approximately 12” from port A, it should get hot.

COMPLETION

Reset both thermostats to temperature required, normally 60°

C for cylinder thermostat and 20° C for room thermostat.

Return programmer to ‘Auto’ or mode selected by

householder. Full installation, wiring and operating

instructions for SUNDIAL products are included in every

product pack. For special wiring diagrams or applications,

contact Honeywell.

Whilst Honeywell takes all practicable steps to design and manufacture its products to comply with the requirements of the Heath

and Safety at Work Act 1974, all products must be properly used and Purchasers are reminded that their obligations under the

Act are to ensure that the installation and operation of such products at a place of work should be safe and without risk to them.

Honeywell reserves the right at any time and without notice to change any product or information contained in this publication.

The wiring diagrams and installation instructions in this publication are provided for guidance purposes when installing recognised

standard systems only. Any application of this product not shown here, or any deviation from these instructions, is neither

recommended nor advised. Any such application or deviation should be referred to Honeywell for technical assistance.

Honeywell Control Systems Ltd.

Arlington Business Park

Bracknell, Berkshire RG12 1EB

Technical help desk: 08457 678999

www.honeywelluk.com

® U.S. Registered Trademark

© 2012 Honeywell International Inc.

95C-10818—04 K.K. Rev. 08-12

Printed in United States

Loading...

Loading...