Page 1

Place Bar Code Here

V4043, V4044 Valves;

CAUTION

V8043, V8044 Zone Valves

INSTALLATION INSTRUCTIONS

APPLICATION

These valves consist of an actuator motor and valve

assembly for controlling the flow of hot and/or cold water.

The V4043 and V8043 provide two-position, straightthrough control of supply water. The V4044 and V8044

provide two-position, diverting control of supply water.

The valves are designed for use with fan coil and other

units requiring quiet, compact water valves. The V8043E

and F also control supply water for baseboard radiators

and convectors. The V4043E and V8043J provide

straight-through control of steam only. Models are

available with 125 or 300 psi operating pressure.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions

1. Disconnect power supply before connecting

wiring to prevent electrical shock of equipment damage.

2. Normally it is not necessary to remove the

powerhead from the valve body during installation. If the valve must be disassembled, be

certain that it is reassembled with the water

IMPORTANT

LOCATION

Install the valve in an area with adequate clearance to:

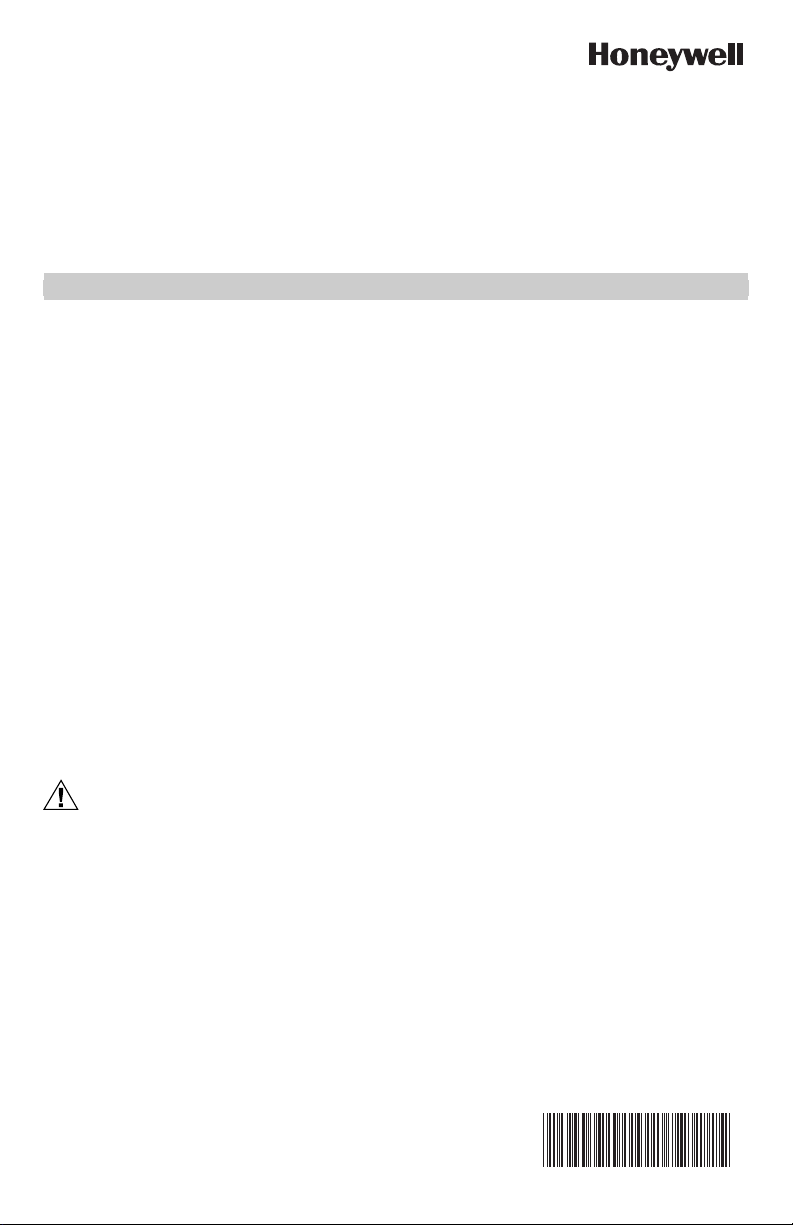

The valve location should be in an area where the

temperature does not exceed the maximum valve

operating temperature as shown in Fig. 1. The maximum

valve operating temperature depends on the maximum

ambient temperature at the valve location and the

maximum fluid temperature. Using the graph in Fig. 1,

the maximum valve operating temperature can be found

as follows:

1. Measure ambient temperature at valve and locate

2. Draw a line from this ambient temperature, parallel

3. Draw a line from this point down to the fluid temp-

flow in the direction of the arrow. Reversal of

the powerhead will result in damage to the

gear train.

3. On 24V systems, never jumper the valve coil

terminals even temporarily. This may burn

out the heat anticipator in the thermostat.

Use this valve in hydronic heating systems

which do not contain dissolved oxygen in the

system water. The dissolved oxygen, which is

found in systems that have a frequent source of

makeup water, causes the rubber plug inside

the valve to deteriorate and eventually fail.

— Move the manual opening lever on the side of the

powerhead.

— Remove the powerhead cover.

— Wire the powerhead.

— Replace the powerhead motor.

this temperature on the ambient temperature scale

on the graph.

with the fluid temperature scale, to the maximum

fluid temperature line.

erature scale to find maximum operating temperature. (Note the example, shown by the dashed line

in Fig. 1).

95-6983-11

Page 2

V4043, V4044 VALVES; V8043, V8044 ZONE VALVES

A

70

(21)

MAXIMUM AMBIENT

TEMPERATURE LINE

EXAMPLE: 150°F (66°C) IS THE AMBIENT TEMPERATURE AT THE VALVE,

235F (113C) IS MAXIMUM FLUID TEMPERATURE.

90

100

80

(32)

(38)

(27)

130

120

110

(54)

(49)

(43)

140

(60)

210

(99)

200

(93)

190

(88)

180

(82)

170

(77)

160

(71)

150

(66)

140

(60)

AMBIENT TEMPERATURE

130

(54)

120

(49)

110

(43)

100

(38)

90

(32)

80

(27)

DEGREES F

DEGREES C

Fig. 1. Maximum temperature characteristics of valves.

MOUNTING

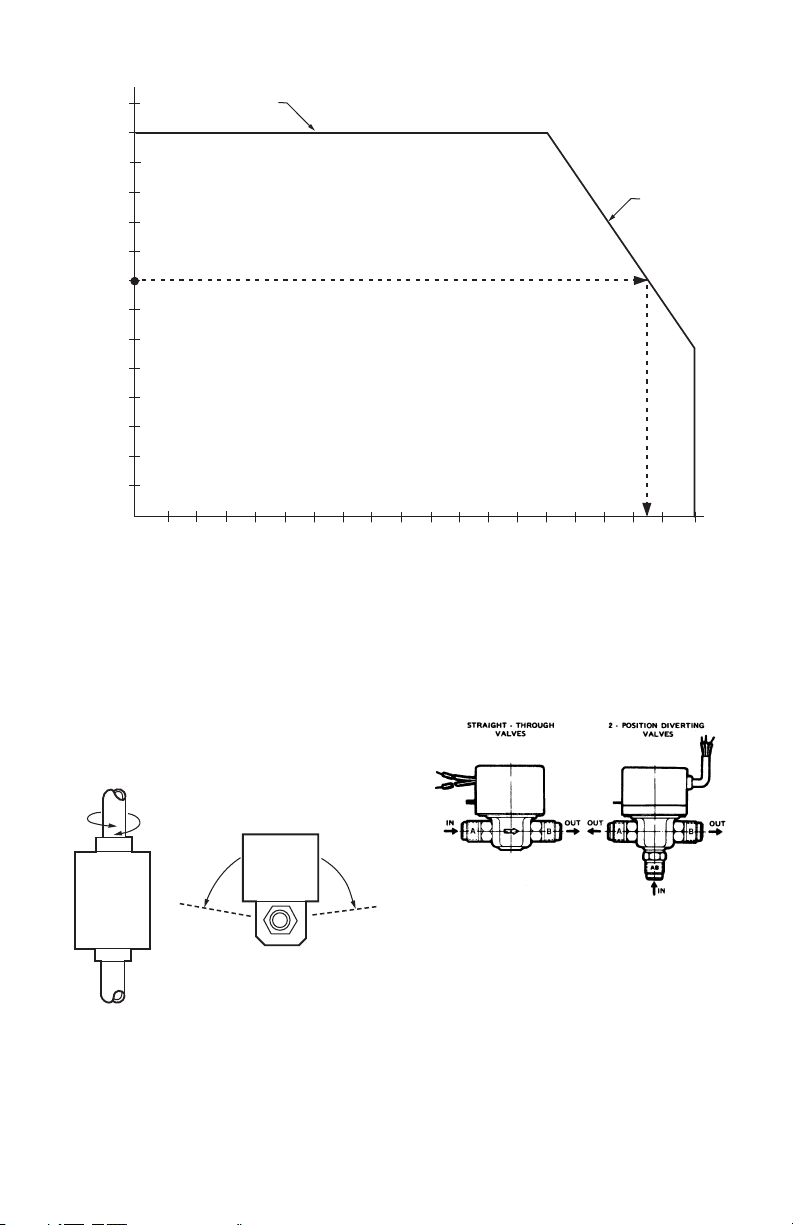

The valve can be mounted in any position on a vertical

line. If the valve is mounted horizontally; the powerhead

must be even with or above the center line of the piping.

Make sure that enough room is provided above the

powerhead to remove the cover for servicing.

MAXIMUM FLUID

TEMPERATURE

LINE

150

160

170

180

190

200

210

220

230

(66)

(71)

(77)

(82)

(88)

(93)

(99)

(104)

FLUID TEMPERATURE

when the valve is de-energized. Refer to the equipment

manufacturer’s instructions to determine which port (A or

B) should be connected to the coil bypass.

(110)

240

(116)

250

(121)

M8164

HORIZONTAL

PIPING

VERTICAL

PIPING

M10162

Fig. 2. Mounting positions.

Mount the valve directly in the tube or pipe. Make sure

that the flow through the valve is in the direction indicated

by the arrow stamped on the valve body.

On diverting valves, the three fittings or ports are labeled

on the bottom of the valve body casting. See Fig. 3. Port

AB is the inlet port and is open at all times. Port A is

closed when the valve is de-energized; port B is open

95-6983—11 2

Fig. 3. Inlet and outlet ports on straight-through and

diverting valves.

FLARE FITTING MODELS

Use new, properly reamed pipe, free from chips. The

valve body is threaded for standard 5/8 in. OD copper, 45

degree SAE flare fitting nuts. These nuts are not furnished

with the valve and must be obtained separately.

SWEAT COPPER MODELS

1. Use new, properly reamed pipe, free from dents or

corrosion.

2. Place the valve onto the pipe. Set the manual opening lever to MAN. OPEN position before applying

heat. This protects the plug inside the valve by

removing it from the seat.

Page 3

V4043, V4044 VALVES; V8043, V8044 ZONE VALVES

3. IMPORTANT: Take care not to burn the plastic portion of the composite adapter plate when soldering.

4. Sweat the joints, keeping the outer surface free

from solder. DO NOT use silver solder because of

the high melting temperature required.

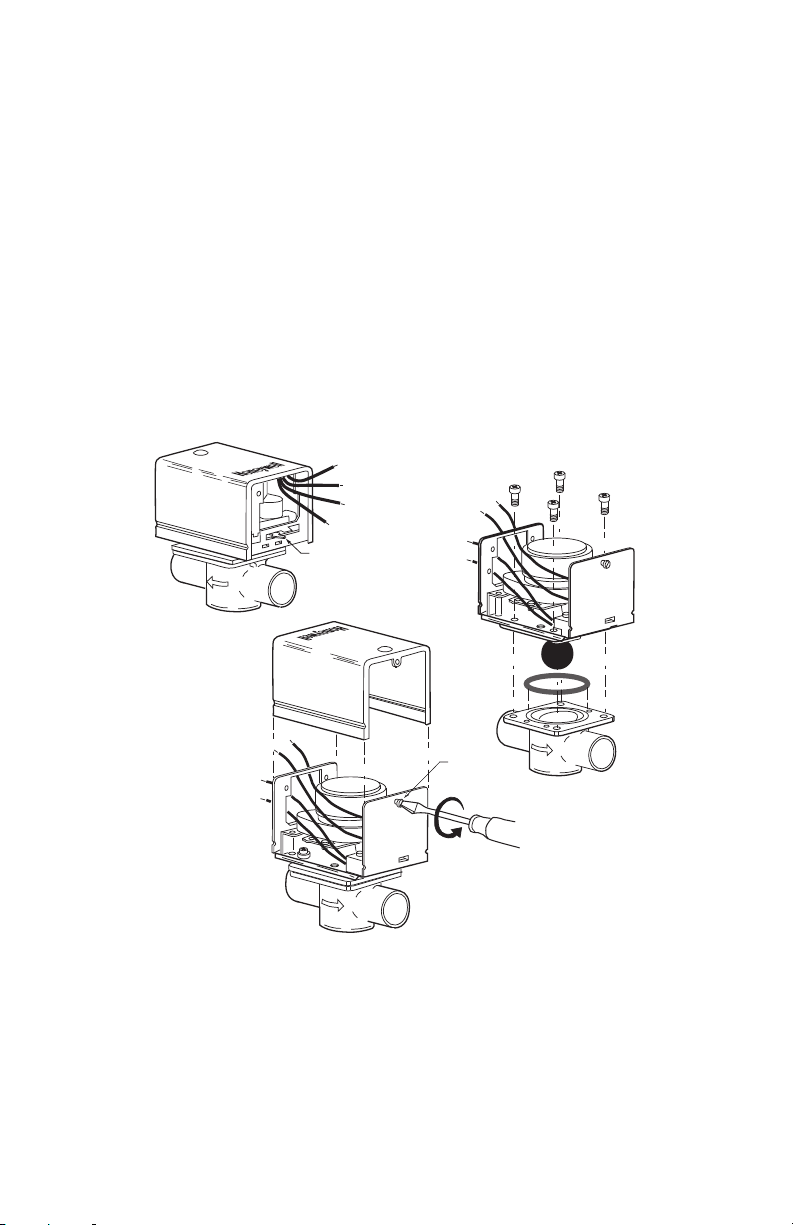

To Install Replacement Powerhead

SYSTEMS WITH OLD STYLE VALVE BODIES (SERIES

1-5)

To install a replacement powerhead in a system with an

old style body (series 1-5), the valve body must be

converted to accept the new powerhead using Part No.

40003918 Conversion Kit. The kit includes a metal plate

with a driveshaft and rubber plug, O-ring, and four screws.

IMPORTANT

Converting the valve body for use with the new

powerhead does not require removal of the valve

body from the pipeline. However, it is necessary

to drain the water from the system before beginning the conversion.

A

MAN

OPEN

AUTO

MANUAL

OPENING

A

LEVER

1. Disconnect the power supply before connecting the

wiring to prevent electrical shock or equipment

damage.

2. Disconnect the leadwires to the powerhead at the

terminal block or conduit connection. Remove the

conduit or cable connector if fitted. Label each wire

for rewiring later.

3. Drain the water from the system.

4. Remove the old powerhead from the valve body

(Fig. 4)

a. Place the manual opening lever (normally

closed models only) on the old powerhead in

the MAN. OPEN position (see Fig. 4A).

b. Remove the cover (Fig. 4B).

c. With the cover off, remove the four screws

securing the powerhead to the valve body.

d. Lift the powerhead off the valve body (Fig. 4C).

e. Remove the O-ring from the top of the valve

body.

C

6

V8043F 1051

24V 50/60 CY

.32 AMP @ 60 CY

B

MADE IN CANADA

A

Fig. 4. Remove old powerhead from systems using old style valve bodies

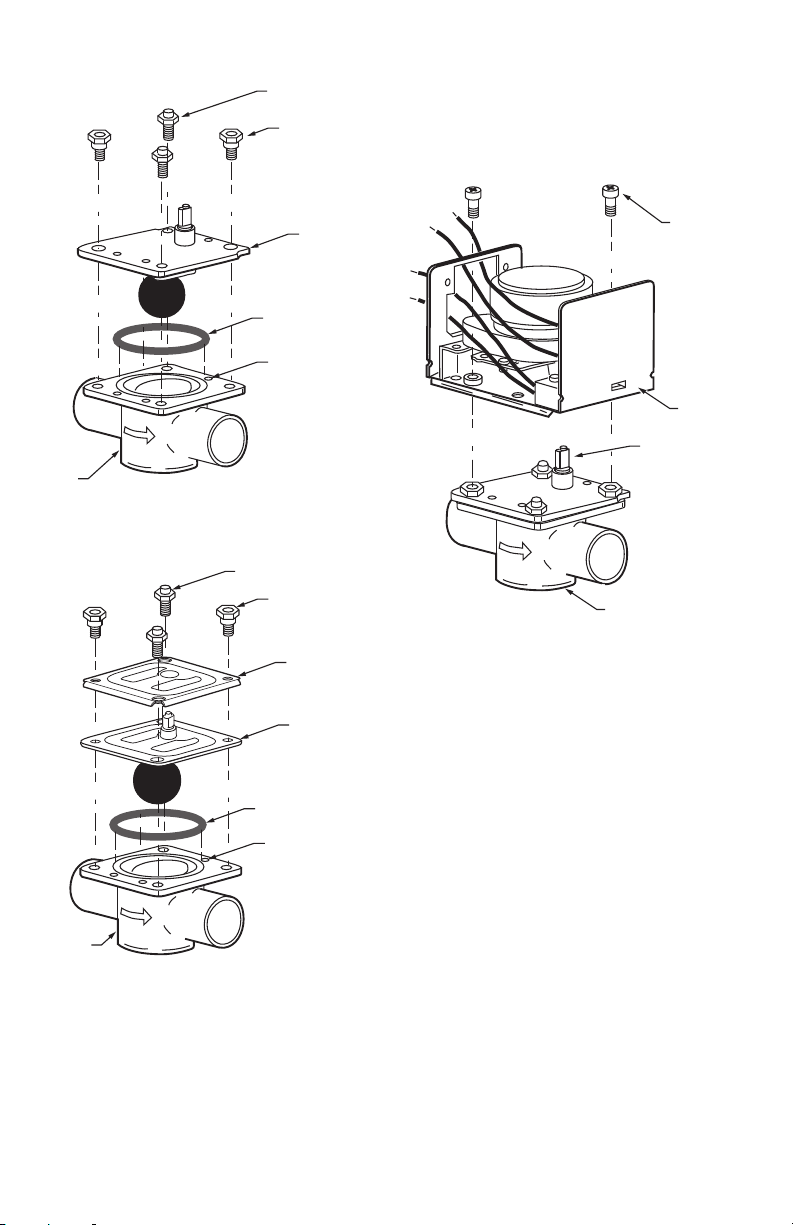

5. Install 40003918 Conversion Kit (Fig. 5)

a. Insert the new O-ring in the valve body.

b. Place metal plate with the rubber plug on top of

the valve body. Make sure the guide pins on the

underside of the metal plate fit into the recesses

on the valve body.

c. Secure the metal plate to the valve body with

the four screws (two sets) provided. One set of

screws has heads with recessed threads to

A

COVER

RETAINING

SCREW

6

V8043F 1051

24V 50/60 CY

.32 AMP @ 60 CY

MADE IN CANADA

B

insert screws for mounting the new powerhead;

insert this set into the larger screw openings.

The other set has domed heads; insert this set

into the smaller screw openings. Each set of

screws must be inserted in opposite corners of

the metal plate so the screws sit flat on the

plate. Make sure the guide pins on the plate fit

into the recesses on the valve body.

3 95-6983—11

B

M10174

Page 4

V4043, V4044 VALVES; V8043, V8044 ZONE VALVES

A

B

V8043F 1036

24V 50/60 CY

.32 AMP @ 60 CY

MADE IN CANADA

6

SECURING

SCREW (2)

REMOVABLE

HEAD

SHAFT

REMOVABLE HEAD

VALVE BODY ASSEMBLY

M10173

HEX-NUT SCREW

WITH DOMED HEADS (2)

HEX-NUT SCREWS

WITH RECESSED

THREADS AND

SHOULDER SHANK (2)

BRASS

ADAPTER

PLATE

O RING

LOCATING

RECESSES (3)

c. Secure the powerhead to the valve body with

the two screws provided.

d. If fitted, reconnect the conduit or cable. Recon-

nect the leadwires at the powerhead.

e. Replace the powerhead cover.

7. Turn on power.

A

VALVE

BODY

Fig. 5a. Install 40003918 conversion kit with brass

A

VALVE

BODY

Fig. 5b. Install conversion kit with composite (steel &

6. Install new powerhead (see Fig. 6)

a. Place the manual opening lever (normally

closed models only) on the new powerhead in

the MAN. OPEN position.

b. Fit the powerhead onto the valve body, ensuring

that the shaft seats correctly. The powerhead

should be aligned so that the manual opening

lever or slot for lever is at the port A end of the

valve body.

B

adapter plate.

HEX-NUT SCREW

WITH DOMED HEADS (2)

O RING

LOCATING

RECESSES (3)

B

plastic) adapter plate.

M32317

HEX-NUT SCREWS

WITH RECESSED

THREADS AND

SHOULDER SHANK (2)

STEEL

PLATE

PLASTIC

PLATE

M32316

Fig. 6. Install new powerhead.

SYSTEMS WITH NEW STYLE VALVE BODIES

(SERIES 6)

IMPORTANT

On a new style valve body that has been converted to accept the new powerhead, it is not

necessary to drain the system if the valve body

remains in the pipeline.

1. Disconnect the power supply before connecting the

wiring to prevent electrical shock or equipment

damage.

2. Disconnect the leadwires to the powerhead at the

terminal block or conduit connection. Remove the

conduit or cable connector, if fitted. Label each wire

for rewiring later.

3. Remove the old powerhead (see Fig. 7):

a. Place the manual opening lever (normally

closed models only) on the old powerhead in

the MAN. OPEN position (Fig. 7A).

b. Remove the screw securing the cover to the

powerhead (Fig. 7B).

c. Lift off the cover from the powerhead.

d. Remove the two screws securing the power-

head to the valve body (Fig. 6).

e. Lift the powerhead off the valve body.

95-6983—11 4

Page 5

Fig. 7. Remove old powerhead cover from systems using new style valve bodies.

A

AUTO

MAN

OPEN

MANUAL

OPENING

LEVER

COVER

RETAINING

SCREW

M10161

A

B

B

V8043F 1036

24V 50/60 CY

.32 AMP @ 60 CY

MADE IN CANADA

6

A

B

4. Install the new powerhead (see Fig. 6):

a. Place the manual opening lever (normally

closed models only) on the new powerhead in

the MAN. OPEN position.

b. Fit the powerhead onto the valve body, ensuring

that the shaft seats correctly. The powerhead

should be aligned so that the manual opening

lever or slot for lever is at the port A end of the

valve body.

c. Secure the powerhead to the valve body with

the two screws provided.

d. If fitted, reconnect the conduit or cable. Recon-

nect the leadwires to the powerhead.

e. Replace the powerhead cover.

5. Turn on the power.

V4043, V4044 VALVES; V8043, V8044 ZONE VALVES

TO

LINE

YELLOW

LEADS

MOTOR

AUXILIARY

SWITCH

THERMOSTAT

(TYPICALLY T87F)

TO CIRCULATOR

OR ANOTHER VALVE

RED LEADS

WIRING

Disconnect the power supply before connecting wiring to

prevent electrical shock or equipment damage.

All wiring must comply with local codes and ordinances.

Connections to the individual valves are shown in Fig. 8-

9. See Fig. 10 through 16 for typical hookups.

If replacing a Taco, Dole, Flair or White Rodgers 3-wire

valve with a 2-wire V8043E or F, see Fig. 17 through 29.

Check that the pressure rating of the new valve is

appropriate for the application.

M5953

Fig. 8. Typical wiring for V8043E, V8044E.

R

THERMOSTAT

(TYPICALLY T87F)

TO CIRCULATOR

OR ANOTHER

VALVE

END SWITCH

1

24V

TRANSFORMER

TH

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

TR

TH TR

Fig. 9. Typical wiring for V8043F.

5 95-6983—11

L1

(HOT)

L2

M5952

Page 6

V4043, V4044 VALVES; V8043, V8044 ZONE VALVES

T822 T822 T822

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

CONNECT V8043A BLACK LEADWIRE TO THERMOSTAT.

2

V8043A V8043A V8043A

2 2

M10168

Fig. 10. T822 thermostat, V8043A valve hookup.

T822 T822 T822

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

CONNECT V8043E YELLOW LEADWIRE TO THERMOSTAT.

3

CONNECT V8043E RED LEADWIRES TO L1 (HOT) LINE AND

PRIMARY CONTROL.

Fig. 11. T822, V8043E zone hookup for gas or oil. No

V4044, V8044

VALVE OPERATOR

AQUASTAT® CHANGEOVER CONTROL SWITCHES TO HEATING (RED)

1

AT FLUID TEMPERATURE OF 85F (29C) MAX TO COOLING (BLUE) AT

FLUID TEMPERATURE OF 60F (18C) MIN.

Fig. 12. Wiring diagram for V4044 and V8044 with

Aquastat changeover control.

2

V8043E V8043E V8043E

3 3 3

domestic hot water.

1

MOTOR

2 2

L4006A

CIRCULATOR

HEATING

COOLING

THERMOSTAT

RED

BLUE

YELLOW

HIGH

LIMIT

TO OIL PRIMARY

CONTROL OR TO

TRANSFORMER

AND LOW VOLTAGE

GAS VALVE

M10169

TO

POWER

M10171

T822 T822 T822

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

CONNECT V8043E YELLOW LEADWIRE TO THERMOSTAT.

3

CONNECT V8043E RED LEADWIRES TO AQUASTAT®.

Fig. 13. T822, V8043E zone hookup for gas or oil with

or without domestic hot water. Without domestic hot

water, use L8148J for gas, L8148A for oil. With

domestic hot water, use L8124E for gas, L8124A or C

ZONE 1

V8043F

END SWITCH

TH-TR

TH

TR

TZ

TV

C1

C2

TO

CIRCULATOR

Fig. 14. Typical 3-zone system. Use an AT87A

transformer to power up to 5 more zone valves.

2

V8043E V8043E V8043E

3 3 3

TT

1

2C1

C2

CIRCULATOR

for oil.

T87F

END SWITCH END SWITCH

TH-TR

L8124G

ZONE 2 ZONE 3

V8043F V8043F

TH

TR

L1

2

(HOT)

1

L2

B1

B2

TO BURNER

CIRCUIT

2 2

B1

TO BURNER

CONTROL

CIRCUIT

B2

M10170

T87F T87F

ADD

JUMPER

TO EACH

TH

120 V

POWER

SUPPLY

VALV E

TR

M5954

TH-TR

95-6983—11 6

Page 7

V4043, V4044 VALVES; V8043, V8044 ZONE VALVES

L1

(HOT)

L2

1

C

A

B

D

THERMOSTAT

V8043E

TO

AUXILIARY

CIRCUITS

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

M10163

YELLOW

YELLOW

RED

RED

E

CONNECTIONS FOR V8043E

TO

CIRCULATOR

CONTROL

CIRCUIT

(LEADWIRE MODEL)

TH-TR TH

ZONE 1

INTEGRAL

TRANSFORMER

W775A PANEL

ZONE 1

END SWITCH

V8043F

ZONE 2

END SWITCH

V8043F

TH-TR TH

TR

B

B

R

W

BR

T87F

TR

ZONE 2

T87F

ZONE 3

END SWITCH

V8043F

TH-TR TH

TR

ZONE 3

B

B

R

W

BR

W

BR

T87F

ZONE 4

END SWITCH

V8043F

TH-TR TH

TR

ZONE 4

B

B

R

B

B

R

W

BR

T87F

M5980

ZONE V8043E

RED

RED

YELLOW

YELLOW

W775A PANEL

RED

RED

YELLOW

POWER

SUPPLY

YELLOW

B

B

R

W

BR

L1

(HOT)

L2

Fig. 15. Typical 4-zone system. Use an additional W775A to power up to 4 more zone valves.

TO BURNER

AND / OR

ZONE 1

ZONE 2

T87F

T87F T87F T87F T87F

ZONE 3

ZONE 4

ZONE 5

CIRCULATOR

CIRCUIT

V8043F

END SWITCH

TH-TR

TH

TR

NOTE: IF CODE PERMITS, V8043E AND V8043F CAN BE USED INTERCHANGEABLY WHEN WIRED AS SHOWN.

V8043F

END SWITCH

TH-TR

Fig. 16. Typical 5-zone system. Use an AT87A transformer to power up to 5 more zone valves.

How to Replace a Taco 3-Wire Valve with

a Honeywell 2-Wire Valve

A

TO AUXILIARY

CIRCUITS

THERMOSTAT

19.)

B

C

D

E

1

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

Fig. 17. Existing Taco System. (Wires are identified by

letters for easy correspondence to wires on Figs. 18 &

TH

TR

AT87A

TRANSFORMER

TACO VALVE

1

2

3

M5958

V8043F

END SWITCH

TH-TR

TH

TR

L1

(HOT)

L2

1

Fig. 18. Wiring a Honeywell V8043E to a Taco System.

(Wires are identified by letters for easy

V8043E V8043E

YELLOW

YELLOW

RED

RED

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

YELLOW

YELLOW

RED

RED

M10164

correspondence to wires on Fig. 17.)

7 95-6983—11

Page 8

V4043, V4044 VALVES; V8043, V8044 ZONE VALVES

V8043F

END SWITCH

1

L1

(HOT)

L2

L1

(HOT)

L2

Fig. 19. Wiring a Honeywell V8043F to a Taco System

(2 options). (Wires are identified by letters for easy

correspondence to wires on Fig. 17.)

C

TH-TR

A

THERMOSTAT

V8043F

END SWITCH

1

C

TH-TR

A

THERMOSTAT

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

D

TO

AUXILIARY

E

CIRCUITS

TH

TR

B

D

TO

E

AUXILIARY

CIRCUITS

TH

TR

B

M5960

How to Replace a Dole 3-Wire Valve with

a Honeywell 2-Wire Valve

DOLE VALVE

C

B

THERMOSTAT

B

THERMOSTAT

A

D

22.)

A

C

E

F

1

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

Fig. 20. Existing Dole System. (Wires are identified by

letters for easy correspondence to wires on Figs. 21 &

1

L1

(HOT)

L2

TO TERMINALS

T, T ON

BURNER RELAY

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

Fig. 21. Wiring a Honeywell V8043E to a Dole System.

(Wires are identified by letters for easy

correspondence to wires on Fig. 20.)

D

3

1

F

TO TERMINALS

T, T ON

BURNER RELAY

V8043E

YELLOW

YELLOW

RED

RED

2

4

E

M5977

M5965

V8043F

A

B

TH-TR

C

THERMOSTAT

A

B

TH-TR

C

THERMOSTAT

END SWITCH

END SWITCH

1

L1

(HOT)

L2

1

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

Fig. 22. Wiring a Honeywell V8043F to a Dole system

(2 options). (Wires are identified by letters for easy

correspondence to wires on Fig. 20.)

V8043F

F

TO TERMINALS

E

T, T ON

BURNER RELAY

TH

TR

D

F

TO TERMINALS

E

T, T ON

BURNER RELAY

TH

TR

D

M5966

How to Replace a Flair 3-Wire Valve with

a Honeywell 2-Wire Valve

FLAIR VALVE

1

L1

(HOT)

L2

Fig. 23. Existing Flair System. (Wires are identified by

letters for easy correspondence to wires on Figs. 23 &

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

Fig. 24. Wiring a Honeywell V8043E to a Flair System.

(Wires are identified by letters for easy

correspondence to wires on Fig. 23.)

A

1

B

C

B

THERMOSTAT

TO TERMINALS

T, T ON

BURNER RELAY

THERMOSTAT

C

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

1

3

2

4

A

24.)

E

TO TERMINALS

T, T ON

F

BURNER RELAY

5

D

M5978

V8043E

YELLOW

D

YELLOW

E

F

RED

RED

M5965

95-6983—11 8

Page 9

V4043, V4044 VALVES; V8043, V8044 ZONE VALVES

V8043F

END SWITCH

1

L1

(HOT)

L2

L1

(HOT)

L2

1

Fig. 25. Wiring a Honeywell V8043F to a Flair System

(2 options). (Wires are identified by letters for easy

A

B

TH-TR

C

THERMOSTAT

V8043F

END SWITCH

1

A

B

TH-TR

C

THERMOSTAT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

correspondence to wires on Fig. 23.)

F

TO TERMINALS

E

T, T ON

BURNER RELAY

TH

TR

D

F

TO TERMINALS

E

T, T ON

BURNER RELAY

TH

TR

D

M5966

How to Replace a White-Rodgers 3-Wire

Valve with a Honeywell 2-Wire Valve

WHITE-RODGERS

WATE R VALVE

THERMOSTAT

56

4

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

1311 OR 1321

VALVE

6

4

5

Fig. 26. Existing White-Rodgers System.

1

L1

(HOT)

L2

5

3

THERMOSTAT

TO

AUXILIARY

1

CIRCUIT

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

IF TRANSFORMER SUPPLIES POWER TO AUXILIARY CIRCUIT,

2

WIRE AUXILIARY CIRCUIT AS SHOWN IN LOWER DIAGRAM.

TAPE UNUSED END AND TUCK INTO HOLE.

3

Fig. 27. Wiring a Honeywell V8043E to a White-

Rodgers System.

3

2

1

6

4

TO 6 ON

THERMOSTAT

TO AUXILIARY

CIRCUIT

TO AUXILIARY

CIRCUIT

YELLOW

RED

YELLOW

YELLOW

RED

RED

RED

1

L1

(HOT)

L2

M5711

2

M5712

V8043F

2

L1

(HOT)

1

L2

TO AUXILIARY

CIRCUITS

END SWITCH

TR

TH

TH-TR

6

5

4

3

THERMOSTAT

TO AUXILIARY

2

CIRCUITS

L1

(HOT)

1

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

IF TRANSFORMER SUPPLIES POWER TO AUXILIARY CIRCUIT,

WIRE AUXILIARY CIRCUIT AS SHOWN IN LOWER DIAGRAM.

3

TAPE UNUSED END AND TUCK INTO HOLE.

Fig. 28. Wiring a Honeywell V8043F to a White-

Rodgers System (one option).

END SWITCH

TH-TR

TR

TH

M5713

V8043F

TO

2

AUXILIARY

CIRCUIT

L1

(HOT)

1

L2

END SWITCH

TH TR

TH-TR

6

5

4

3

THERMOSTAT

TO

AUXILIARY

2

CIRCUIT

L1

(HOT)

1

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

IF TRANSFORMER SUPPLIES POWER TO AUXILIARY CIRCUIT,

2

WIRE AUXILIARY CIRCUIT AS SHOWN IN LOWER DIAGRAM.

TAPE UNUSED END AND TUCK INTO HOLE.

3

Fig. 29. Wiring a Honeywell V8043F to a White-

Rodgers System (alternate option).

END SWITCH

M5714

9 95-6983—11

Page 10

V4043, V4044 VALVES; V8043, V8044 ZONE VALVES

CAUTION

OPERATION AND CHECKOUT

On 24 V systems, never jumper the valve coil

terminals even temporarily. This may burn out

the heat anticipator in the thermostat.

NORMALLY CLOSED MODELS

With the manual opener set to AUTO and the powerhead

energized, the valve is opened as shown in Fig. 30A.

When the powerhead is de-energized, a spring-return

mechanism drives the valve to the closed position as

shown in Fig. 30B. The valve can also be opened with no

electrical power by moving the manual opening lever over

the stop and pushing slowly and firmly to the MAN. OPEN

position. The stop permits the valve to be locked in the

open position. The valve will return to the automatic

position when the valve is energized.

Auxiliary switch is not energized when the valve is

manually opened.

NORMALLY OPEN MODELS

When the powerhead is de-energized, a spring-return

mechanism drives the valve to the open position (Fig.

30A). When energized, the valve is closed as shown in

Fig. 30B. A reverse-acting thermostat is required to

control a normally open valve.

NOTE: Inlet Port is stamped “A”, Outlet Port is stamped

“B” on the valve body.

Checkout

1. Raise the setpoint on the zone thermostat above

the room temperature to initiate a call for heat.

2. Observe all control devices—the valve should open

and the auxiliary switch should make the circuit to

the circulator or other valve at the end of the opening stroke.

3. Lower the setpoint on the zone thermostat below

the room temperature.

4. Observe the control devices. The valve should

close and the auxiliary equipment should stop.

Service

This valve should be serviced by a trained, experienced

service technician.

1. If the valve is leaking, drain the system and check

to see if the O-ring needs replacing.

2. If the gear train is damaged, replace the entire powerhead assembly. See the Installation section. If the

motor is burned out, replace the motor. See

Replacement Parts list in the TRADELINE® Catalog.

NOTE: Honeywell zone valves are designed and tested

for silent operation in properly designed and

installed systems. However, water noises may

occur as a result of excessive water velocity or

piping noises may occur in high temperature

(over 212° F [100° C]) systems with insufficient

water pressure.

NOTE: These hydronic valves are not suitable for use in

open loop systems where there is air exposure.

B

OUT

A

IN

CLOSED POSITION

B

OUT

B

M5951

A

IN

OPEN POSITION

A

Fig. 30. V8043 operation for normally closed valve.

95-6983—11 10

Page 11

V4043, V4044 VALVES; V8043, V8044 ZONE VALVES

11 95-6983—11

Page 12

V4043, V4044 VALVES; V8043, V8044 ZONE VALVES

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2010 Honeywell International In c.

95-6983—11 T.D. Rev. 09-10

Printed in U.S.A.

Loading...

Loading...