Page 1

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J;

60-2133-9

V8044A,B,E Motorized Valves

PRODUCT DATA

FEATURES

• The V4043 and V8043 provide 2-position, straightthrough control of water.

• The V4044 and V8044 provide 2-position diverting

control of water.

V4043, V4044, V8043, V8044

Replacement Powerhead

V4043, V8043

V8043 Inverted Flare V4044, V8044

APPLICATION

These valves consist of an actuator motor and valve

assembly for controlling the flow of hot or cold water, or

steam.

IMPORTANT

These valves are not for use in systems containing

dissolved oxygen.

• Compact construction for easy installation.

• Manual opener for valve operation on power failure.

Valve returns to automatic position when power is

restored.

• Choice of sweat or flare fitting brass end connections

for standard copper tubing.

• Motor can be replaced by removing one screw,

without disturbing the valve body or draining the

system.

• Complete powerhead may be removed or replaced

without breaking the line connections or draining the

system.

• All models can be installed without disassembling

the valve.

• Fits under the cover of most baseboards.

•Available with integral auxiliary end switch (V4044B;

V8043E,F; V8044E) to permit sequencing of auxiliary

equipment.

• V4043E and V8043J provide straight-through control

of steam.

® U.S. Registered Trademark

Copyright © 1996 Honeywell Inc. • All Rights Reserved

Contents

Application........................................................................... 1

Features .............................................................................. 1

Specifications ...................................................................... 2

Ordering Information ........................................................... 2

Installation ........................................................................... 10

Operation and Checkout ..................................................... 20

Page 2

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

SPECIFICATIONS

TRADELINE® Models

TRADELINE® models are selected and packaged to provide

ease of stocking, ease of handling, and maximum

replacement value. TRADELINE® model specifications are

the same as those of standard models except as noted

below.

TRADELINE® Models Available:

V8043A,E, and V8043E,F (see Table 1).

Capacity Rating:

3.5 Cv (3.0 kV) nominal. (See Electrical Ratings table in

Standard Models section and Table 1.)

Additional Feature:

End switch enclosure included.

Standard Models

Models:

V4043: line voltage, straight-through valves.

V4044: line voltage, 2-position diverting valves.

V8043: low voltage, straight-through valves.

V8044: low voltage, 2-position diverting valves.

See Table 1.

Electrical Ratings

(See Table 1 for Voltage of Specific Models):

Voltage Amperes Voltage Amperes

24 0.320

100 0.087 240 0.040

120 0.080 277 0.037

208 0.044 — —

a

Maximum five V8043 Zone Valves per 40 VA transformer.

Changeover Aquastat® Control:

120V, 3.0A with 10.0A inrush.

End Switch:

120V, 4.4A running with 26.4A inrush (60 Hz). Pilot duty 50

VA at 24V.

Timing:

V4043 and V8043: Open or close in 15 seconds

maximum.

V4044 and V8044: Divert flow in 30 seconds maximum.

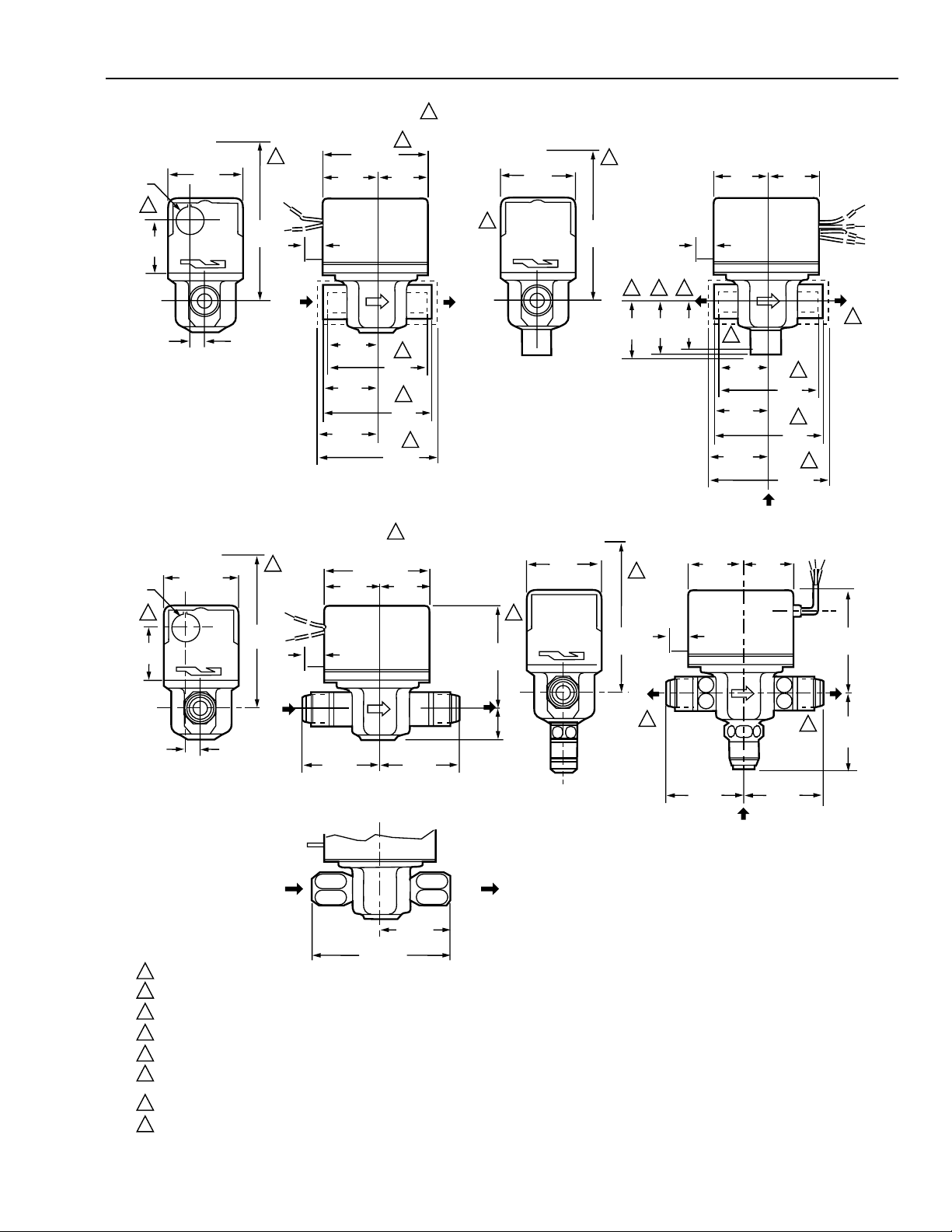

Dimensions:

See Fig. 1.

Manual Opener:

Manual opener (on all except the straight-through, normally

open valves) allows opening the valve in case of power

failure. Valve returns to automatic position when power is

restored.

a

220 0.042

ORDERING INFORMATION

For ordering information when purchasing replacement and modernization products from your TRADELINE® wholesaler or

your distributor, refer to the TRADELINE® Catalog or price sheets for complete ordering number, or specify:

1. Order number.

2. Voltage and frequency.

3. Size and type of end connections.

4. Cv (kV) rating.

5. Lead length if different from standard.

6. Replacement parts, if needed.

If you have additional questions, need further information, or want to comment on our products or services, please write or

phone:

1. Your local Honeywell Home and Building Control sales office (check white pages of phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitee, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9. International Sales

and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan,

Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

60-2133—9

2

Page 3

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

7/8 DIA.

(22)

8

1-1/2

(38)

15/32

(12)

7/8 DIA.

(22)

7

1-1/2

(38)

15/32

(12)

V043, V8043 SWEAT COPPER CONNECTION MODELS

3-1/2 (89)

1-3/4

(44)

AB

1-9/16

(40)

1-3/4

(44)

1-7/8

(47)

AUTO

2-3/8

(60)

MAN OPEN

5-1/4

(133)

1

3/8

(10)

IN

V4043, V8043 FLARE-FITTING MODELS

2-3/8 (60)

AUTO

MAN OPEN

5-1/4

(133)

1

IN

3/8

(10)

A

2-11/32

(59)

1-3/4

(44)

3-1/2 (89)

V8043 INVERTED FLARE MODELS

5

1-3/4

(44)

2

3-1/8

(79)

3

3-1/2

(89)

3-11/16

(94)

6

1-3/4

(44)

2-11/32

6

V4044, V8044 SWEAT COPPER CONNECTION MODELS

1

2-3/8

(60)

OUT

8

MAN OPEN

AUTO

5-1/4

(133)

4 3 2

1-11/16

1-7/8

(43)

(48)

3/8

(10)

1-1/2

(38)

4

1-3/4

(44)

AB

1-3/4

(44)

7

7

AB

1-9/16

(40)

1-3/4

(44)

1-7/8

(47)

3-1/8

(79)

3-1/2

(89)

3-11/16

(94)

2

3

4

INLET

V4044, V8044 FLARE-FITTING MODELS

2-3/8

(60)

1

1-3/4

(44)

1-3/4

(44)

8

5-1/4

3/8

MAN OPEN

AUTO

3-1/8

(79)

OUT

B

(133)

(10)

A

7

7/8

(22)

AB

3-1/8

(79)

B

2-1/4

7

(57)

(59)

2-11/32

(59)

2-11/32

(59)

INLET

IN

1-13/16

(46)

OUT

3-5/8 (92)

HEIGHT NEEDED TO REMOVE COVER.

1

2

DIMENSIONS FOR 1/2 IN. COPPER TUBING.

3

DIMENSIONS FOR 3/4 IN COPPER TUBING.

DIMENSIONS FOR 1 IN. COPPER TUBING.

4

4-7/8 IN. (124) MAX ON V8034F WITH TERMINAL BOARD ENCLOSURE.

5

V4034B AND V8043B VALVES THAT ARE NORMALLY OPEN IN THE DE-ENERGIZED POSITION HAVE NO MANUAL LEVER. THE VALVES ALSO HAVE A REVERSED

6

POWERHEAD WHERE THE LEADWIRES EXIT THE POWERHEAD ABOVE THE B (OUTLET) PORT RATHER THAN ABOVE THE A (INLET) PORT.

7

REFER TO MOUNTING INSTRUCTIONS.

8

OPENING FOR 1/2 IN. CONDUIT ON MANUAL LEVER SIDE FOR V4043, V8043; OPENING ON OPPOSITE SIDE FOR V4044, V8044.

Fig. 1. Mounting dimensions in in. (mm) of V4043/44, V8043/44 Motorized Valves.

3

M10175

60-2133—9

Page 4

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

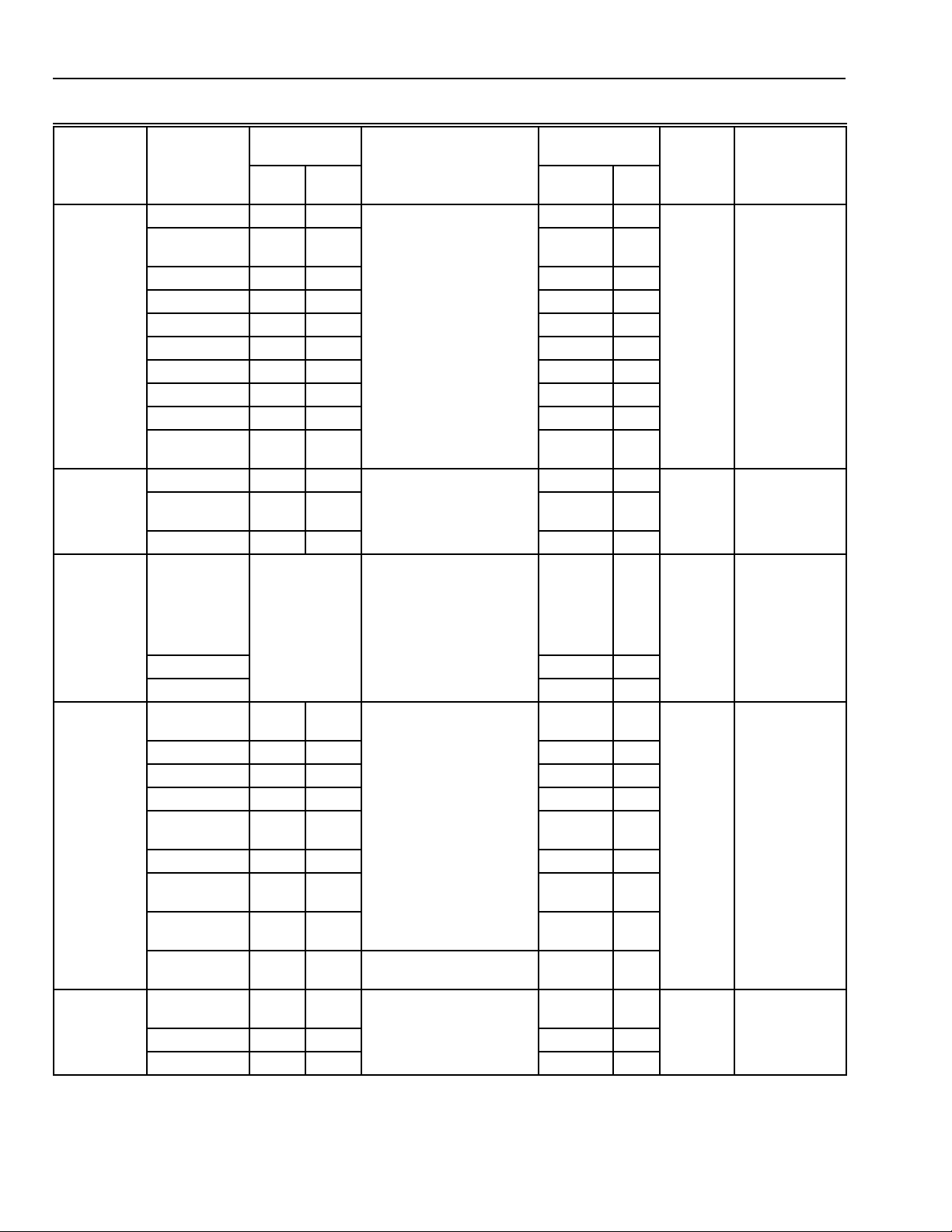

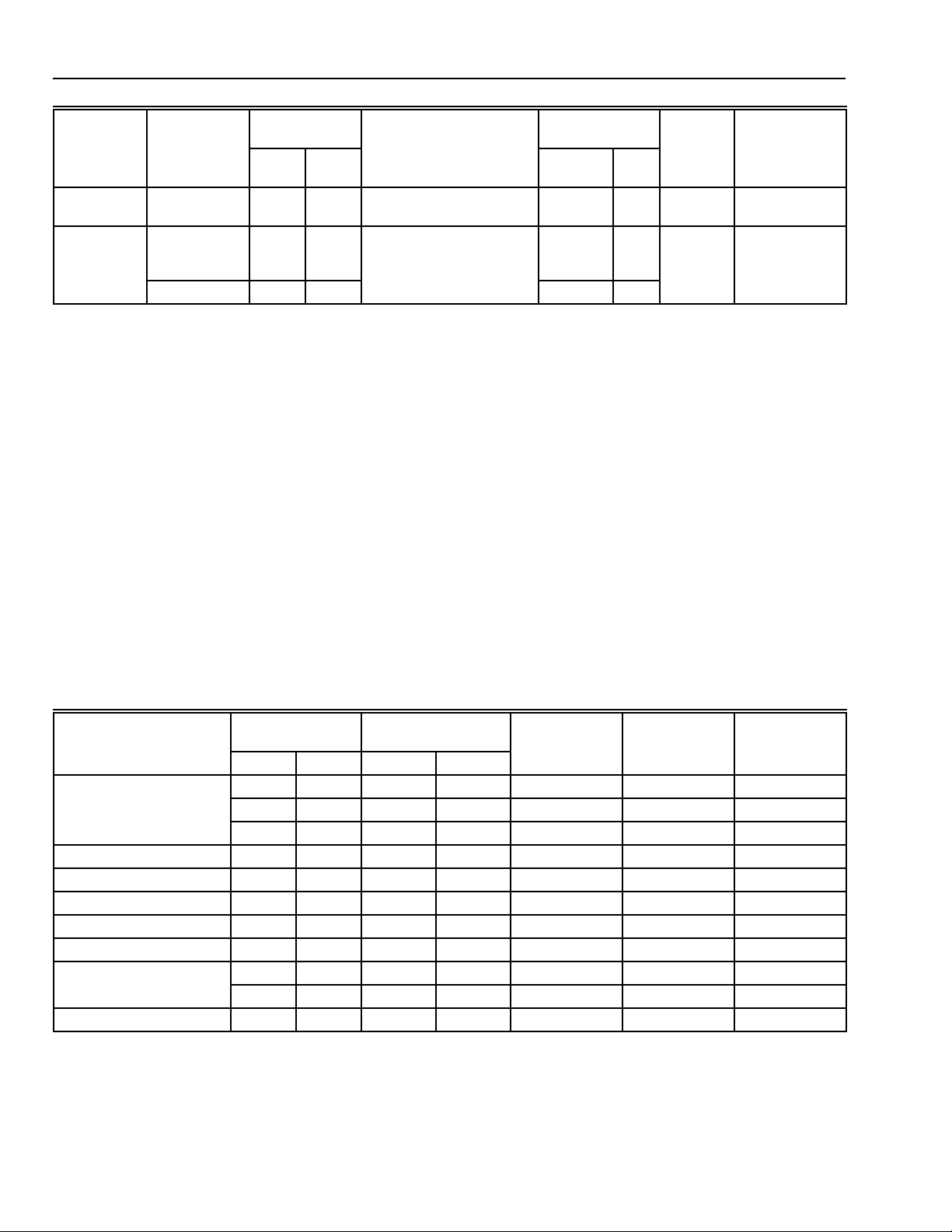

Table 1. Powerhead and Valve Body Specifications

Flow Capacity

Rating

Control

Model

V4043A 120V, 60 Hz 1.0 .86

Circuit Cv kV Wire Hookup Type

18 in. (457 mm) leadwires,

120V, 60 Hz 3.5 3.0

1/2 in. conduit opening.

120V, 60 Hz 8.0 7.0 Sweat 3/4

120V, 60 Hz 8.0 7.0 Sweat 1

120V, 60 Hz 3.5 3.0 NPT 1/2

120V, 60 Hz 3.5 3.0 NPT 3/4

120V, 60 Hz 10.0 8.6 NPT 1

208V, 60 Hz 3.5 3.0 Flare 1/2

220V, 50 Hz 3.5 3.0 Flare 1/2

240V, 50 or

3.5 3.0 Sweat or

60 Hz

V4043B 120V, 60 Hz 1.0 .86

120V, 60 Hz 3.5 3.0

18 in. (457 mm) leadwires,

1/2 in. conduit opening.

240V, 60 Hz 3.5 3.0 Sweat 1/2

V4043E

(steam only)

120V, 60 HzaCv not

applicable

18 in. (457 mm) leadwires,

1/2 in. conduit opening.

(15 psi

[103 kPA] low

pressure

steam rating).

208V, 60 Hz Sweat 1/2

240V, 60 Hz Sweat 1/2

V4044A 120V, 60 Hz 4.0 3.4 18 in. (457 mm) leadwires,

1/2 in. conduit opening.

120V, 60 Hz 7.0 6.0 Sweat

120V, 60 Hz 4.0 3.4 Sweat

208V, 60 Hz 4.0 3.4 Sweat 1/2

220V, 50 Hz 4.0 3.4 Sweat or

220V, 50 Hz 7.0 6.0 Sweat 3/4

240V, 50 Hz 4.0 3.4 Sweat or

240V, 60 Hz 4.0 3.4 Sweat or

277V, 60 Hz 4.0 3.4 24 in. (610 mm) leadwires,

1/2 in. conduit opening.

V4044B

(bottom inlet)

b,c

120V, 60 Hz 4.0 3.4 18 in. (457 mm) leadwires,

1/2 in. conduit opening.

120V, 60 Hz 7.0 6.0 Sweat 3/4

220V, 50 Hz 4.0 3.4 Flare 1/2

Pipe

Connections

Size

(in.)

Sweat 1/2

Sweat or

1/2

Flare

1/2

Flare

Sweat 1/2

Sweat or

1/2

Flare

d

Sweat

Sweat or

Flare

1/2 Straight-

1/2 2-position

c

c

3/4

e

1/2

1/2

Flare

1/2

Flare

1/2

Flare

Sweat 1/2

Sweat or

1/2 2-position

Flare

Valve

Body

De-energized

Position

Straight- Normally

through Closed

Straight-

Normally Open

through

Normally

through

Closed

Port A Normally

diverting

Closed

Port A Normally

diverting

Closed

60-2133—9

4

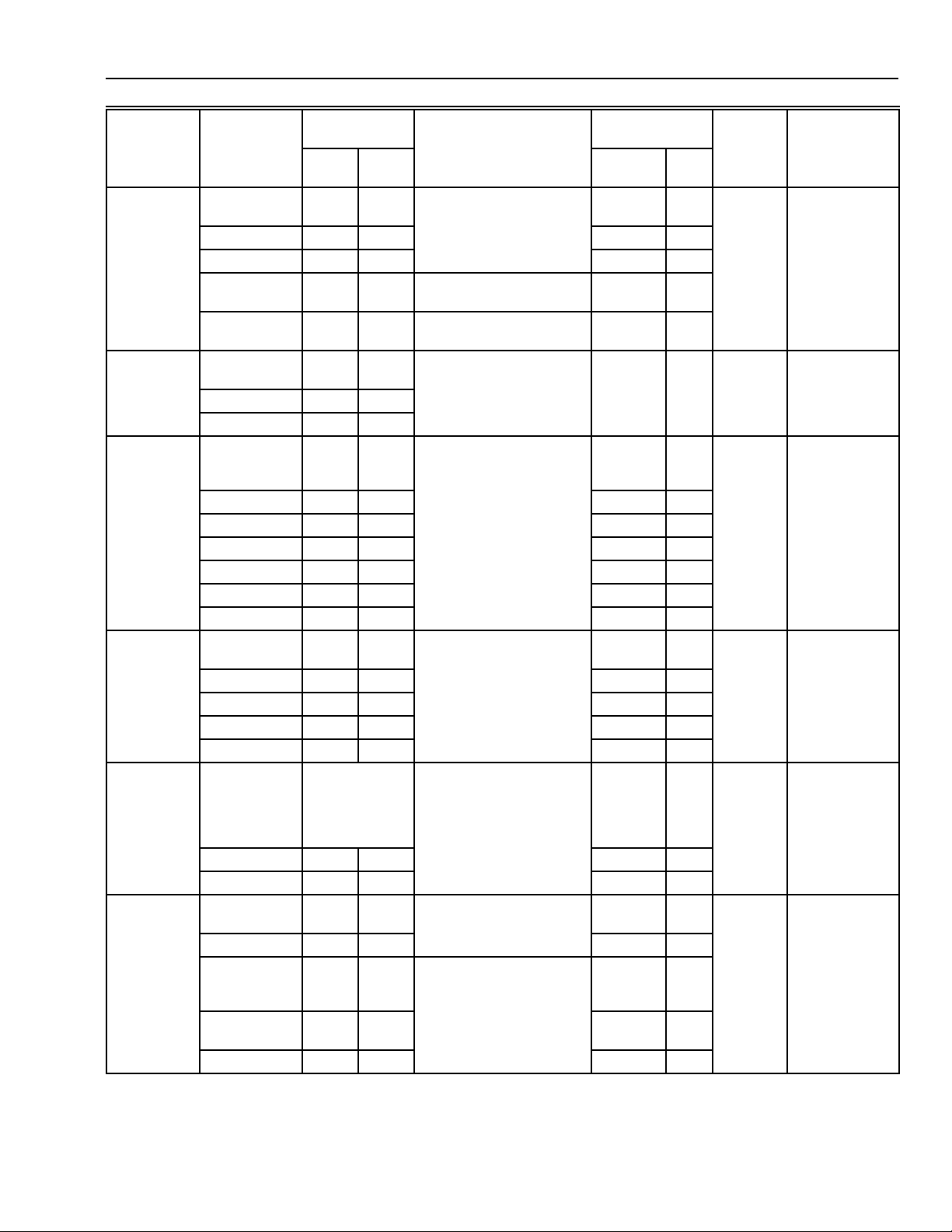

Page 5

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

Flow Capacity

Rating

Control

Model

Circuit Cv kV Wire Hookup Type

V8043A 24V, 60 Hz 3.5 3.0 18 in. (457 mm) leadwires,

1/2 in. conduit opening.

24V, 60 Hz 3.5 3.0 NPT 1/2

24V, 60 Hz 3.5 3.0 Sweat 3/4

24V, 60 Hz 8.0 7.0 36 in. (914 mm) leadwires,

1/2 in. conduit opening.

24V, 60 Hz 3.5 3.0 18 in. (457 mm) leadwires,

1/2 in. conduit opening.

V8043B 24V, 60 Hz 3.5 3.0 18 in. (457 mm) leadwires,

1/2 in. conduit opening.

24V, 60 Hz 3.5 3.0 Sweat 3/4

24V, 60 Hz 3.5 3.0 NPT 3/4

V8043E 24V, 60 Hz 3.5 3.0 18 in. (457 mm) leadwires

and end switch, 1/2 in.

conduit opening.

24V, 60 Hz 3.5 3.0 Sweat 3/4

24V, 60 Hz 3.5 3.0 Sweat 1

24V, 60 Hz 8.0 7.0 Sweat 3/4

24V, 60 Hz 8.0 7.0 Sweat 1

24V, 60 Hz 10.0 8.6 NPT 1

24V, 60 Hz 3.5 3.0 NPT 3/4

V8043F 24V, 60 Hz 3.5 3.0 Terminal Board and end

switch.

24V, 60 Hz 3.5 3.0 Sweat 3/4

24V, 60 Hz 3.5 3.0 Sweat 1

24V, 60 Hz 8.0 7.0 Sweat 3/4

24V, 60 Hz 8.0 7.0 Sweat 1

V8043J 24V, 60 Hz

d

Cv not

applicable. (15

18 in. (457 mm) leadwires,

1/2 in. conduit opening.

psi [103 kPa]

low pressure

steam rating).

24V, 60 Hz NPT 1/2

24V, 60 Hz NPT 3/4

V8044A 24V, 60 Hz 4.0 3.4 18 in. (457 mm) leadwires,

1/2 in. conduit opening.

24V, 60 Hz 7.0 6.0 Sweat 3/4

24V, 60 Hz 4.0 3.4 50 in. (1270 mm)

stranded leadwires, 1/2

conduit opening.

24V, 60 Hz 4.0 3.4 18 in. (457 mm) leadwires,

1/2 in. conduit opening.

24V, 60 Hz 4.0 3.4 NPT 3/4

Pipe

Connections

Sweat or

Flare

Size

(in.)

1/2 Straight-

Valve

Body

through

Sweat 3/4

Sweat 1

Sweat 1/2 Straight-

through

Sweat 1/2 Straight-

through

Sweat 1/2 Straight-

through

d

Sweat 1/2 Straight-

through

Sweat or

Flare

1/2 2-position

e

diverting

Sweat 1/2

NPT 1/2

De-energized

Position

Normally

Closed

Normally Open

Normally

Closed

Normally

Closed

Normally Open

Port A Normally

Closed

5

60-2133—9

Page 6

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

Flow Capacity

Rating

Control

Model

V8044B 24V, 60 Hz

Circuit Cv kV Wire Hookup Type

b

4.0 3.4 18 in. (457 mm) leadwires,

Sweat 1/2 2-position

1/2 in. conduit opening.

V8044E 24V, 60 Hz 4.0 3.4 18 in. (457 mm) leadwires

Sweat 1/2 2-position

and end switch, 1/2 in.

conduit opening.

24V, 60 Hz 7.0 6.0 Sweat 3/4

a

30 in. (762 mm) leads also available.

b

Includes integral changeover Aquastat® Control.

c

96 in. (2438 mm) leads also available.

d

30 in. (762 mm) leads also available.

e

Valve available with reduced (2.5 Cv [2.1 kV] ) rating on bypass port. Sweat fitting only.

Approvals:

Underwriters Laboratories Inc. Listed: V4043A,B,E;

V4044A,B; V8043A,B,E,J; V8044A,B,E: File MH11826, Vol.

1, dated 2-22-88.

Conversion Kits:

Conversion kits for converting old style (series 1-5) valve

bodies to accept 40003916 Powerhead (use with V4043,

V4044, V8043, V8044). Includes metal plate with driveshaft

and rubber ball, O-Ring and four screws.

Replacement Parts:

Motor Part Numbers (use with V4043, V4044, V8043,

V8044):

Tw o-way water valve body: 40003918-006.

Three-way water valve body: 40003918-007.

Tw o-way steam valve body: 40003918-008.

802360JA 24 Vac, 60 Hz, Class A, plated.

802360LA 120 Vac, 60 Hz, Class F, plated.

802360MA 208 Vac, 60 Hz, Class F, plated.

802360NA 220V 50 Hz, 240V 60 Hz, Class F, plated.

802360UA 24 Vac, 60 Hz, Class F, plated.

O-Ring Part Numbers:

272742A—Includes replacement ball plug, large O-Ring

and four screws.

272756A—Package of five large O-Rings.

Pipe

Connections

Size

(in.)

Valve

Body

diverting

diverting

De-energized

Position

Port A Normally

Closed

Port A Normally

Closed

Powerhead (see Table 2):

Includes motor, housing and two mounting screws.

Accessories:

803867A Conduit Cover: Includes 803858 Cover and

803859 Case (for V8043F).

Flow and Temperature Ratings:

Flow Capacity

Rating

Valve Family Cv kV psi kPa

Maximum

Closeoff Pressure

Max Fluid Min Fluid Max Ambient

Temperature Temperature Temperature

V4043A,B,E,J 1.0 .86 50 345 240°F (116°C) 40°F (5°C) 125°F (50°C)

3.5 3.0 20 138 240°F (116°C) 40°F (5°C) 125°F (50°C)

10.0 8.6 6.5 45 240°F (116°C) 40°F (5°C) 125°F (50°C)

V8043A,B,E,F 3.5 3.0 20 138 200°F (93°C) 40°F (5°C) 125°F (50°C)

8.0 7.0 8 55 200°F (93°C) 40°F (5°C) 125°F (50°C)

10.0 8.6 6.5 45 200°F (93°C) 40°F (5°C) 125°F (50°C)

V4044A,B 4.0 3.4 20 138 240°F (116°C) 40°F (5°C) 125°F (50°C)

7.0 6.0 10 69 240°F (116°C) 40°F (5°C) 125°F (50°C)

V8044A,B,E 4.0 3.4 20 138 200°F (93°C) 40°F (5°C) 125°F (50°C)

7.0 6.0 10 69 200°F (93°C) 40°F (5°C) 125°F (50°C)

V4043E, V8043J (steam) — — 15

a

103 240°F (116°C) 40°F (5°C) 125°F (50°C)

Static Pressure Rating of 125 psi (862 kPa) applies to all valves.

a

15 psi low pressure steam.

60-2133—9

6

Page 7

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

Table 2. Replacement Powerheads.

Valve

Model

Number Part Number

V4043A 40003916-022 Same 220/50, 240/60 0.04 18 in (457 mm) leads

40003916-023 Same 240, 50 0.04

40003916-024 Same 120, 60 0.08

V4043B 40003916-030 Same 240, 60 0.04

40003916-031 Same 120, 60 0.08

40003916-042 Same 208, 60 0.04

V8043A 40003916-021 Same 24, 50/60 0.32 Class A

V8043B 40003916-027 Same 24, 50/60 0.32

V8043E 40003916-026 Same 24, 50/60 0.32

V8043F 40003916-048 Same 24, 50/60 0.32 Terminal Board

V4044A 40003916-034 Opposite 240, 50 0.04 18 in. (457 mm) leads

40003916-035 Opposite 220/50, 240/60 0.04

40003916-036 Opposite 120, 60 0.08 96 in. (2438 mm) leads

40003916-047 Same 120, 60 0.08

V4044B 40003916-039 Opposite 220/50, 240/60 0.04 18 in. (457 mm) leads

40003916-040 Opposite 120, 60 0.08

40003916-045 Same 120, 60 0.08

V8044A 40003916-032 Opposite 24, 50/60 0.32 18 in. (457 mm) leads

40003916-046 Same 24, 50/60 0.32

V8044B 40003916-037 Opposite 24, 50/60 0.32 18 in. (457 mm) leads

40003916-044 Same 24, 50/60 0.32

Electrical Connection

on Which Side of

Manual Lever

Voltage (Vac)

and Frequency

(Hz)

Current

Draw (A)

Type of Electrical

Connection Motor

(conduit opening)

(conduit opening)

(conduit opening)

(conduit opening)

(conduit opening)

(conduit opening)

Class F;

plated

Class F;

plated

Class A;

plated

How to Find Maximum Valve Operating

Temperature

The maximum operating temperature for motorized valves

depends on the maximum ambient temperature at the valve

location, and on the maximum fluid temperature. Using the

graph in Fig. 2, find the maximum valve operating

temperature as follows:

쐃 Measure the ambient temperature at the valve and

locate that temperature on the ambient temperature

scale on the graph.

쐇 Draw a line from the ambient temperature, parallel with

the fluid temperature scale, to the maximum fluid

temperature line.

쐋 Draw a line from that point down to the fluid

temperature scale to find the maximum operating

temperature. (Note the example shown by the dashed

line in Fig. 2.)

To find the maximum ambient temperature for a valve when

the fluid temperature is known, reverse the procedure.

7

60-2133—9

Page 8

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

210

(99)

200

(93)

190

(88)

180

(82)

170

(77)

160

(71)

150

(66)

140

(60)

AMBIENT TEMPERATURE

130

(54)

120

(49)

110

(43)

100

(38)

90

(32)

80

(27)

MAXIMUM AMBIENT

TEMPERATURE LINE

EXAMPLE: 150°F (66°C) IS THE AMBIENT TEMPERATURE AT THE VALVE,

235°F (113°C) IS MAXIMUM FLUID TEMPERATURE.

MAXIMUM FLUID

TEMPERATURE

LINE

90

(32)

100

(38)

110

(43)

120

(49)

130

(54)

FLUID TEMPERATURE

DEGREES F

DEGREES C

70

(21)

80

(27)

Fig. 2. Maximum temperature characteristics of valves with Class F motors.

How to Find Valve Pressure Drop

The pressure drop in psi (kPa), equivalent ft (m) of pipe, or

feet of water (kPa) can be calculated from Fig. 3 through 8

as follows:

쐃 Calculate the flow rate to heat the zone.

쐇 Determine the Cv (kV) rating of the motorized valve.

쐋 Select the graph corresponding to the Cv (kV) rating

(Fig. 3 through 8).

쐏 Determine the pressure drop across the valve using

the following procedures for calculating pressure drop.

Pressure Drop in psi (kPa)

쐃 Locate the flow rate at the bottom of the graph.

쐇 Draw a line up from the flow rate to the intersection of

the curve.

쐋 Draw a line from the intersection to the left edge of the

graph to determine the pressure drop in psi (kPa).

140

(60)

150

160

170

180

190

200

210

220

230

240

(66)

(71)

(77)

(82)

(88)

(93)

(99)

(104)

(110)

(116)

Pressure Drop in Equivalent ft (m) of Pipe

NOTE: Both 1/2 and 3/4 in. pipe conversion scales are

available for this determination.

쐃 Locate the flow rate at the bottom of the graph.

쐇 Draw a line vertically to the top of the graph.

Determine the pressure drop for either the 1/2 or 3/4

in. pipe.

Pressure Drop in ft of Water (kPa)

쐃 Locate the flow rate at the bottom of the graph.

쐇 Draw a line up from the flow rate to the intersection of

the curve.

쐋 Draw a line from the intersection to the right edge of

the graph to determine pressure drop in ft of water

(kPa).

250

(121)

M8164

60-2133—9

8

Page 9

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

PRESSURE DROP, EQUIVALENT FEET OF PIPE (EQUIVALENT METERS OF PIPE)

120

100

90

(37)

(30)

(27)

30 (207)

20 (138)

10 (69)

9 (62)

8 (55)

7 (48)

6 (41)

5 (34)

4 (28)

3 (21)

PRESSURE DROP psi (kPa)

2 (14)

1 (7)

0

2

(0.13)

140

(43)

1CV

(0.86 KV)

6

4

(0.38)8(0.5)

(0.25)

GAL/MIN (l/s) FLOW RATE

500

600

(152)

(183)

10

(0.63)12(0.76)

(3/4 IN. PIPE)(1/2 IN. PIPE)

700

(213)

750

(229 )

-50 (149)

-40 (119)

-30 (89.5)

-20 (60)

-10 (30)

-5 (15)

Fig. 3. Flow characteristics of 1 Cv (0.86 kV) flow.

PRESSURE DROP, EQUIVALENT FEET OF PIPE (EQUIVALENT METERS OF PIPE)

(3/4 IN. PIPE)

9.0

(2.7)

10

8.0

(3)

(2.4)

50.0 (345)

10.0 (69)

5.0 (34)

1.0 (7)

0.50 (3.4)

PRESSURE DROP psi (kPa)

0.10 (0.69)

FT OF WATER psi (kPa) PRESSURE DROP

0.05 (0.34)

0

M9183A

0

(0.13)4(0.25)

Fig. 5. Flow characteristics of 3.5 Cv (3.0 kV) valve.

45

(13.7)

(18)

12

11

(3.6)

(3.4)

2

GAL/MIN (l/s) FLOW RATE

60

12.5

(3.8)

(0.38)

65

(20)

13

(4)

3.5CV

(3.0 KV)

8

6

(0.5)10(0.63)12(0.76)

70

(21.3)

(1/2 IN. PIPE)

14

(0.88)

(24.4)

-50 (149)

-40 (119)

-30 (89.5)

-20 (60)

-10 (30)

-5 (15)

-1 (3)

-0.5 (1.5)

-0.1 (0.3)

-0.05 (0.15)

M5979B

80

PRESSURE DROP FT OF WATER psi (kPa)

PRESSURE DROP, EQUIVALENT FEET OF PIPE (EQUIVALENT METERS OF PIPE)

45

8

(2.4)9(2.7)10(3)

0

(0.13)

(13.7)60(18)

2

(3/4 IN. PIPE)

50.0 (345)

10.0 (69)

5.0 (34)

1.0 (7)

.50 (3.4)

PRESSURE DROP psi (kPa)

.10 (0.69)

.05 (0.34)

11

(3.4)12(3.6)

12.5

(3.8)

2.5CV

4

6

(0.25)

(0.38)8(0.5)

GAL/MIN (l/s) FLOW RATE

65

(20)

(2.1 KV)

70

(21.3)

13

(4)

(1/2 IN. PIPE)

10

(0.63)12(0.76)14(0.88)

80

(24.4)

-50 (149)

-40 (119)

-30 (89.5)

-20 (60)

-10 (30)

-5 (15)

-1 (3)

-0.5 (1.5)

-0.1 (0.3)

-0.05 (0.15)

M9184A

Fig. 4. Flow characteristics of V4043A model with 2.5 C

(2.1 kv) rating and V4044A and V8044A bypass port (B)

with 2.5 Cv (2.1 kv) (reduced) rating.

PRESSURE DROP

EQUIVALENT FEET OF PIPE (EQUIVALENT METERS OF PIPE)

6.0

(1.8)

50

7.0

8.0

(1.5)

(2.1)

(2.4)

50.0 (345)

10.0 (69)

5.0 (34)

1.0 (7)

0.50 (3.4)

PRESSURE DROP psi (kPa)

0.10 (0.69)

0.05 (0.34)

FT OF WATER psi (kPa) PRESSURE DROP

02

(0.13)

v

Fig. 6. Flow characteristics of 4 Cv (3.4 kV) valve.

9.0

(2.7)

4

(0.25)

6

(0.38)

10

(3)

(0.5)

30

(9.1)40(12.2)

8

10

12

(0.63)

(0.76)

GAL/MIN (l/s)

45

(13.7)

4CV

(3.4 KV)

14

16

(0.88)

(1.1)

(1.0)

FLOW RATE

50

(15.2)

18

(3/4 IN. PIPE)(1/2 IN. PIPE)

(1.3)

55

(16.8)

20

22

(1.4)

24

(1.5)

60

(18)

26

(1.6)

28

(1.8)

-50 (149)

-40 (119)

-30 (89.5)

-20 (60)

-10 (30)

-5 (15)

-1 (3)

-0.5 (1.5)

-0.1 (0.3)

-0.05 (0.15)

30

(1.9)

PRESSURE DROP FT OF WATER psi (kPa)

M5717B

9

60-2133—9

Page 10

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

PRESSURE DROP, EQUIVALENT FEET OF PIPE (EQUIVALENT METERS OF PIPE)

13

(4)10(3)

50.0 (345)

10.0 (69)

5.0 (34)

1.0 (7)

0.50 (3.4)

PRESSURE DROP psi (kPa)

0.10 (0.69)

0.05 (0.34)

0

15

(4.6)

2.0

(0.6)

2

(0.13)

17

(5.2)

(0.25)

4

19

(5.8)

(0.38)

21

22

(6.4)

(6.7)23(7)

3.5

(1)

(1/2 IN. PIPE)

7CV

(6.0 KV)

14

10

12

(0.88)

(0.63)

(0.76)

GAL/MIN (l/s) FLOW RATE

3.0

(0.9)

6

20

(6)

8

(0.5)

16

(1.0)

(7.3)25(7.6)

18

20

(1.1)

(1.3)

24

22

(1.4)

24

(1.5)

26

(1.6)

(3/4 IN. PIPE)

28

(1.9)

(1.8)

Fig. 7. Flow characteristics of 7 Cv (6.0 kV) valve.

-50 (149)

-40 (119)

-30 (89.5)

-20 (60)

-10 (30)

-5 (15)

-1 (3)

-.5 (1.5)

-.1 (0.3)

-0.05 (0.15)

30

M9185A

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

FT OF WATER psi (kPa)

1. Disconnect power supply before connecting

wiring to prevent electrical shock or equipment

damage.

2. Normally it is not necessary to remove the

powerhead from the valve body during

installation. If the valve must be disassembled,

be certain that it is reassembled with the water

flow in the direction of the arrow. Reversal of the

powerhead results in damage to the gear train.

3. On 24V systems, never jumper the valve coil

terminals even temporarily. This can burn out the

heat anticipator in the thermostat.

PRESSURE DROP, EQUIVALENT FEET OF PIPE (EQUIVALENT METERS OF PIPE)

10

8

(3)12(3.7)

(2.4)

7

(2.1)

(2.7)

50.0 (345)

10.0 (69)

5.0 (34)

1.0 (7)

0.50 (3.4)

PRESSURE DROP psi (kPa)

0.10 (0.69)

0.05 (0.34)

0.01

0

9

(3.4)

1.5

(0.5)

2

(0.13)

1

(0.25)

4

2.0

(0.6)

13

(4)

(0.38)

15

14

(4.6)16(4.9)

(4.3)

2.5

(0.8)

(1/2 IN. PIPE)

8CV

(6.9 KV)

14

10

6

12

8

(0.88)

(0.63)

(0.76)

(0.5)

GAL/MIN (l/s) FLOW RATE

16

(1.0)

17

(5.2)18(5.5)

18

20

(1.1)

(1.3)

22

(1.4)

24

(1.5)

26

(1.6)

19

(5.8)

(1.8)

28

Fig. 8. Flow characteristics of 8 Cv (6.9 kV) valve.

(3/4 IN. PIPE)

-50 (149)

-40 (119)

-30 (89.5)

-20 (60)

-10 (30)

-5 (15)

-1 (3)

-0.5 (1.5)

-0.1 (0.3)

-0.05 (0.15)

30

(1.9)

M9186A

IMPORTANT

Use this valve in hydronic heating systems that do

not contain dissolved oxygen in the system water.

The dissolved oxygen, which is found in systems

that have a frequent source of makeup water,

causes the rubber plug inside the valve to

deteriorate and eventually fail.

Mounting

The valve can be mounted in any position on a vertical line.

See Fig. 9. If the valve is mounted horizontally; the

powerhead must be even with or above the center line of the

piping. Make sure to leave enough room above the

powerhead to remove the cover for servicing.

FT OF WATER psi (kPa) PRESSURE DROP

HORIZONTIAL

PIPING

VERTICAL

PIPING

M10162

60-2133—9

Fig. 9. Mounting positions.

10

Page 11

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

Mount the valve directly in the tube or pipe. Make sure that

the flow through the valve is in the direction indicated by the

arrow stamped on the valve body.

On diverting valves, the three fittings or ports are labeled on

the bottom of the valve body casting. See Fig. 1. Port AB is

the inlet port and is open at all times. Port A is closed when

the valve is de-energized; port B is open when the valve is

de-energized. Refer to the equipment manufacturer

instructions to determine which port (A or B) should be

connected to the coil bypass.

Flare Fitting Models

Use new, properly reamed pipe, free from chips. The valve

body is threaded for standard 5/8 in. OD copper, 45 degree

SAE flare fitting nuts. These nuts are not furnished with the

valve and must be obtained separately.

Sweat Copper Models

쐃 Use new, properly reamed pipe, free from dents or

corrosion.

쐇 Place the valve on the pipe. Set the manual opening

lever to MAN. OPEN position before applying heat.

This protects the plug inside the valve by removing it

from the seat.

쐋 Sweat the joints, keeping the outer surface free from

solder. DO NOT use silver solder because of the high

melting temperature required.

To Install Replacement Powerhead

System with Old Style Valve Bodies (Series 1-5)

To install a replacement powerhead in a system with an old

style body (series 1-5), the valve body must be converted to

accept the new powerhead using part no. 40003918

Conversion Kit. The kit includes a metal plate with a

driveshaft and rubber plug, O-ring, and four screws.

쐏 Remove the old powerhead from the valve body

(Fig. 10):

a. Place the manual opening lever (normally closed

models only) on the old powerhead in the MAN.

OPEN position (see Fig. 10A).

b. Remove the cover (Fig. 10B).

c. With the cover off, remove the four screws

securing the powerhead to the valve body.

d. Lift the powerhead off the valve body (Fig. 10C).

e. Remove the O-ring from the top of the valve body.

쐄 Install 40003918 Conversion Kit (Fig. 11):

a. Insert the new O-ring in the valve body.

b. Place metal plate with the rubber plug on top of

the valve body. Make sure the guide pins on the

underside of the metal plate fit into the recesses

on the valve body.

c. Secure the metal plate to the valve body with the

four screws (two sets) provided. One set of screws

has heads with recessed threads to insert screws

for mounting the new powerhead; insert this set

into the larger screw openings. The other set has

domed heads; insert this set into the smaller

screw openings. Each set of screws must be

inserted in opposite corners of the metal plate so

the screws sit flat on the plate. Make sure the

guide pins on the plate fit into the recesses on the

valve body.

쐂 Install new powerhead (see Fig. 12):

a. Place the manual opening lever (normally closed

models only) on the new powerhead in the MAN.

OPEN position.

b. Fit the powerhead onto the valve body, ensuring

that the shaft seats correctly. The powerhead

should be aligned with the manual opening lever

or slot for lever at the port A end of the valve body.

c. Secure the powerhead to the valve body with the

two screws provided.

d. If fitted, reconnect the conduit or cable. Reconnect

the leadwires at the powerhead.

e. Replace the powerhead cover.

쐆 Tu rn on the power.

IMPORTANT

Converting the valve body for use with the new

powerhead does not require removal of the valve

body from the pipeline. However, it is necessary to

drain the water from the system before beginning

the conversion.

쐃 Disconnect the power supply before connecting the

wiring to prevent electrical shock or equipment

damage.

쐇 Disconnect the leadwires to the powerhead at the

terminal block or conduit connection. Remove the

conduit or cable connector if fitted. Label each wire for

rewiring later.

쐋 Drain the water from the system.

11

60-2133—9

Page 12

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

A

AN

M

EN

AUTO

A

OP

MANUAL

OPENING

LEVER

B

C

6

1051

43F

80

V

Y

C

0/60

5

4V

2

Y

60 C

@

P

M

A

.32

A

M

A

D

A

N

A

C

IN

E

D

A

COVER

RETAINING

SCREW

6

1051

8043F

V

Y

50/60 C

24V

Y

60 C

@

P

M

.32 A

M

A

A

D

A

N

A

C

IN

E

D

A

B

Fig. 10. Remove old powerhead from systems using old style valve bodies.

B

M10174

60-2133—9

12

Page 13

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

A

B

VALV E

BODY

Fig. 11. Install 40003918 Conversion Kit.

HEX-NUT SCREW

WITH DOMED HEADS (2)

HEX-NUT SCREWS

WITH RECESSED

THREADS AND

SHOULDER SHANK (2)

ADAPTER

PLATE

O RING

LOCATING

RECESSES (3)

M10160

SECURING

SCREW (2)

Systems with New Style Valve Bodies (Series 6)

IMPORTANT

On a new style valve body or a valve body that was

converted to accept the new powerhead, it is not

necessary to drain the system if the valve body

remains in the pipeline.

쐃 Disconnect the power supply before connecting the

wiring to prevent electrical shock or equipment

damage.

쐇 Disconnect the leadwires to the powerhead at the

terminal block or conduit connection. Remove the

conduit or cable connector, if fitted. Label each wire for

rewiring.

쐋 Remove the old powerhead (see Fig. 13):

a. Place the manual opening lever (normally closed

models only) on the old powerhead in the MAN.

OPEN position (Fig. 13A).

b. Remove the screw securing the cover to the

powerhead (Fig. 13B).

c. Lift off the cover from the powerhead.

d. Remove the two screws securing the powerhead

to the valve body (Fig. 12).

e. Lift the powerhead off the valve body.

쐏 Install the new power head (see Fig. 12):

a. Place the manual opening lever (normally closed

models only) on the new powerhead in the MAN.

OPEN position.

b. Fit the powerhead onto the valve body, ensuring

that the shaft seats correctly. The powerhead

should be aligned with the manual opening lever

or slot for lever at the port A end of the valve body.

c. Secure the powerhead to the valve body with the

two screws provided.

d. If fitted, reconnect the conduit or cable. Reconnect

the leadwires to the powerhead.

e. Replace the powerhead cover.

쐄 Tu rn on the power.

6

6

3

0

1

F

3

4

0

8

V

Y

C

0

/6

0

5

V

4

2

Y

C

0

6

@

P

M

A

2

.3

A

M

A

B

A

D

A

N

A

C

IN

E

D

SHAFT

REMOVABLE HEAD

VALVE BODY ASSEMBLY

Fig. 12. Install new powerhead.

REMOVABLE

HEAD

M10173

Wiring

Disconnect the power supply before connecting wiring to

prevent electrical shock or equipment damage.

All wiring must comply with local codes and ordinances.

Connections to the individual valves are shown in Fig. 14

and 15. See Fig. 16 through 22 for typical hookups.

If replacing a Taco, Dole, Flair or White Rodgers 3-wire valve

with a 2-wire V8043E or F, see Fig. 23 through 35. Check

that the pressure rating of the new valve is appropriate for

the application.

13

60-2133—9

Page 14

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

A

LINE

YELLOW

LEADS

THERMOSTAT

(TYPICALLY T87F)TO

TO CIRCULATOR

OR ANOTHER VALVE

RED LEADS

MOTOR

N

A

M

N

E

P

O

T

U

A

B

O

MANUAL

OPENING

LEVER

AUXILIARY

SWITCH

A

M5953

B

Fig. 14. Typical wiring for V8043E, V8044E.

R

THERMOSTAT

(TYPICALLY T87F)

END SWITCH

TO CIRCULATOR

OR ANOTHER

VALVE

COVER

RETAINING

SCREW

6

V8043F 1036

24V 50/60 CY

.32 AMP @ 60 CY

MADE IN CANADA

A

B

M10161

Fig. 13. Remove old powerhead from systems using new

style valve bodies.

TH

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

TR

TH TR

Fig. 15. Typical wiring for V8043F.

1

L1

(HOT)

L2

24V

TRANSFORMER

M5952

60-2133—9

14

Page 15

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

RED

BLUE

YELLOW

MOTOR

HEATING

COOLING

THERMOSTAT

TO

POWER

V4044, V8044

VALVE OPERATOR

AQUASTAT® CHANGEOVER CONTROL SWITCHES TO HEATING (RED)

AT FLUID TEMPERATURE OF 85°F (29°C) MAX TO COOLING (BLUE) AT

FLUID TEMPERATURE OF 60°F (18°C) MIN.

1

1

M10171

L1

(HOT)

L2

1

1

2

2

3

2 2

3 3 3

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

CONNECT V8043E YELLOW LEADWIRE TO THERMOSTAT.

CONNECT V8043E RED LEADWIRES TO AQUASTAT®.

T822 T822 T822

V8043E V8043E V8043E

M10170

CIRCULATOR

TT

1

2C1

TO BURNER

CONTROL

CIRCUIT

B1

B2

C2

T822 T822 T822

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

CONNECT V8043A BLACK LEADWIRE TO THERMOSTAT.

Fig. 16. T822 Thermostat, V8043A valve hookup.

L1

(HOT)

L2

1

2

V8043A V8043A V8043A

T822 T822 T822

2

2 2

2 2

M10168

Fig. 18. Wiring diagram for V4044 and V8044 with

Aquastat® changeover control.

V8043E V8043E V8043E

3 3 3

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

CONNECT V8043E YELLOW LEADWIRE TO THERMOSTAT.

CONNECT V8043E RED LEADWIRES TO L1 (HOT) LINE AND

3

PRIMARY CONTROL.

Fig. 17. T822, V8043E zone hookup for gas or oil. No

domestic hot water.

L4006A

TO OIL PRIMARY

CONTROL OR TO

TRANSFORMER

AND LOW VOLTAGE

GAS VALVE

CIRCULATOR

HIGH

LIMIT

M10169

Fig. 19. T822, V8043E zone hookup for gas or oil with or

without domestic hot water. Without domestic hot water,

use L8148J for gas, and L8148A for oil. With domestic

hot water, use L8124E for gas, and L8124A or C for oil.

15

60-2133—9

Page 16

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

V8043F

END SWITCH

TH-TR

TH

TV

C1

TO

CIRCULATOR

TR

ZONE 1

T87F

V8043F V8043F

END SWITCH END SWITCH

TH-TR

TZ

C2

L8124G

2

B1

TO BURNER

CIRCUIT

ZONE 2 ZONE 3

T87F T87F

TH

TR

1

B2

L1

(HOT)

L2

TH-TR

TH

TR

120 V

POWER

SUPPLY

ADD

JUMPER

TO EACH

VALVE

M5954

Fig. 20. Typical 3-zone system. Use an AT87A Transformer to power up to five more zone valves.

CONNECTIONS FOR V8043E

(LEADWIRE MODEL)

ZONE V8043E

RED

RED

RED

RED

YELLOW

YELLOW

W775A PANEL

POWER

SUPPLY

YELLOW

YELLOW

B

B

R

W

BR

L1

(HOT)

L2

TO

CIRCULATOR

CONTROL

CIRCUIT

INTEGRAL

TRANSFORMER

ZONE 1

END SWITCH

V8043F

TH-TR TH

ZONE 1

W775A PANEL

ZONE 2

END SWITCH

V8043F

TR

B

B

R

W

BR

TH-TR TH

ZONE 2

TR

B

B

R

W

BR

ZONE 3

END SWITCH

V8043F

TH-TR TH

ZONE 3

TR

B

B

R

W

BR

ZONE 4

END SWITCH

V8043F

TH-TR TH

ZONE 4

TR

B

B

R

W

BR

60-2133—9

T87F

T87F

T87F

T87F

Fig. 21. Typical 4-zone system. Use an additional W775A to power up to four more zone valves.

16

M5980

Page 17

ZONE 1

T87F

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

ZONE 2

T87F T87F T87F T87F

ZONE 3

ZONE 4

ZONE 5

TO BURNER

AND / OR

CIRCULATOR

CIRCUIT

V8043F

END SWITCH

TH-TR

TH

TR

NOTE: IF CODE PERMITS, V8043E AND V8043F CAN BE USED INTERCHANGEABLY WHEN WIRED AS SHOWN.

V8043F

END SWITCH

TH-TR

TH

TR

AT87A

TRANSFORMER

V8043F

END SWITCH

TH-TR

L1

(HOT)

L2

1

V8043E V8043E

YELLOW

YELLOW

RED

TH

TR

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

RED

Fig. 22. Typical 5-zone system. Use an AT87A Transformer to power up to five more zone valves.

END SWITCH

C

TH-TR

A

THERMOSTAT

V8043F

TH

TR

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

THERMOSTAT

A

TO AUXILIARY

CIRCUITS

TACO VALVE

B

1

C

2

D

3

E

M5958

L1

(HOT)

L2

1

YELLOW

YELLOW

RED

RED

M10164

D

TO

AUXILIARY

E

CIRCUITS

B

Fig. 23. Existing Taco system. (Wires are identified with

letters to correspond with wires in Fig. 24 and 25.)

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

C

A

THERMOSTAT

TO

AUXILIARY

CIRCUITS

D

E

B

V8043E

YELLOW

YELLOW

RED

RED

M10163

Fig. 24. Wiring Honeywell V8043E to Taco System.

(Wires are identified with letters to correspond

with wires in Fig. 23.)

17

V8043F

END SWITCH

1

L1

(HOT)

L2

1

C

TH-TR

A

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

TH

THERMOSTAT

D

TO

AUXILIARY

E

CIRCUITS

TR

B

M5960

Fig. 25. Wiring Honeywell V8043F to Taco System

(two options). (Wires are identified with letters

to correspond with wires in Fig. 23.)

60-2133—9

Page 18

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

DOLE VALVE

L1

(HOT)

L2

1

B

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

A

C

THERMOSTAT

D

2

3

1

4

F

TO TERMINALS

T, T ON

BURNER RELAY

E

M5977

Fig. 26. Existing Dole System. (Wires are identified with

letters to correspond with wires in Fig. 27 and 28.)

L1

(HOT)

L2

1

THERMOSTAT

TO TERMINALS

T, T ON

BURNER RELAY

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

A

C

B

E

F

D

V8043E

YELLOW

YELLOW

RED

RED

M5965

Fig. 27. Wiring Honeywell V8043E to Dole System.

(Wires are identified with letters to correspond

with wires in Fig. 26.)

V8043F

L1

(HOT)

L2

END SWITCH

1

A

B

TH-TR

TH

C

F

TO TERMINALS

E

T, T ON

BURNER RELAY

TR

D

FLAIR VALVE

E

1

L1

(HOT)

L2

C

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

A

B

3

2

1

4

5

THERMOSTAT

F

D

TO TERMINALS

T, T ON

BURNER RELAY

M5978

Fig. 29. Existing Flair System. (Wires are identified with

letters to correspond with wires in Fig. 30 and 31.)

L1

(HOT)

L2

1

THERMOSTAT

TO TERMINALS

T, T ON

BURNER RELAY

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

A

C

B

E

F

D

V8043E

YELLOW

YELLOW

RED

RED

M5965

Fig. 30. Wiring Honeywell V8043F to Flair System.

(Wires are identified with letters to correspond

with wires in Fig. 29.)

V8043F

L1

(HOT)

L2

END SWITCH

1

A

B

TH-TR

TH

C

F

TO TERMINALS

E

T, T ON

BURNER RELAY

TR

D

THERMOSTAT

V8043F

END SWITCH

1

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

A

B

TH-TR

C

THERMOSTAT

TH

F

TO TERMINALS

E

T, T ON

BURNER RELAY

TR

D

Fig. 28. Wiring Honeywell V8043F to Dole System

(two options). (Wires are identified with letters to

correspond with wires in Fig. 26.)

60-2133—9

M5966

THERMOSTAT

V8043F

END SWITCH

1

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

A

B

TH-TR

C

THERMOSTAT

TH

F

E

TR

D

Fig. 31. Wiring Honeywell V8043F to Flair System

(two options). (Wires are identified with letters

to correspond with wires in Fig. 29.)

18

TO TERMINALS

T, T ON

BURNER RELAY

M5966

Page 19

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

TO AUXILIARY

CIRCUITS

V8043F

END SWITCH

TH-TR

TH

TR

5

4

6

1

2

3

THERMOSTAT

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

IF TRANSFORMER SUPPLIES POWER TO AUXILIARY CIRCUIT,

WIRE AUXILIARY CIRCUIT AS SHOWN IN LOWER DIAGRAM.

TAPE UNUSED END AND TUCK INTO HOLE.

1

2

3

TH

TR

TH-TR

END SWITCH

1

2

L1

(HOT)

L2

M5713

TO AUXILIARY

CIRCUITS

WHITE-RODGERS

WATER VALVE

THERMOSTAT

56

4

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

1311 OR 1321

VALVE

6

4

5

3

2

1

TO AUXILIARY

CIRCUIT

Fig. 32. Existing White-Rodgers System.

1

L1

(HOT)

L2

5

6

3

TO

AUXILIARY

CIRCUIT

1

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

IF TRANSFORMER SUPPLIES POWER TO AUXILIARY CIRCUIT,

2

WIRE AUXILIARY CIRCUIT AS SHOWN IN LOWER DIAGRAM.

TAPE UNUSED END AND TUCK INTO HOLE.

3

4

THERMOSTAT

TO 6 ON

THERMOSTAT

TO AUXILIARY

CIRCUIT

YELLOW

YELLOW

RED

RED

YELLOW

RED

RED

Fig. 33. Wiring Honeywell V8043E to

White-Rodgers System.

1

L1

(HOT)

L2

M5711

2

Fig. 34. Wiring Honeywell V8043F to White-Rodgers

System (one option).

V8043F

END SWITCH

TH TR

TH-TR

6

5

4

THERMOSTAT

END SWITCH

M5714

M5712

TO

2

AUXILIARY

CIRCUIT

L1

(HOT)

1

L2

3

TO

AUXILIARY

2

CIRCUIT

L1

(HOT)

1

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

IF TRANSFORMER SUPPLIES POWER TO AUXILIARY CIRCUIT,

2

WIRE AUXILIARY CIRCUIT AS SHOWN IN LOWER DIAGRAM.

TAPE UNUSED END AND TUCK INTO HOLE.

3

Fig. 35. Wiring Honeywell V8043F to White-Rodgers

System (alternate option).

19

60-2133—9

Page 20

V4043A,B,E,J; V4044A,B; V8043A,B,E,F,J; V8044A,B,E MOTORIZED VALVES

open valve.

OPERATION AND CHECKOUT

NOTE: Inlet Port is stamped A and Outlet Port is stamped

B on the valve body.

CAUTION

On 24V systems, never jumper the valve coil

terminals even temporarily. This can burn out the

heat anticipator in the thermostat.

Operation

Automatic Operation

On a call for heat by the zone thermostat, the valve opens

and its auxiliary switch contacts make, closing the circuit to

the system circulator. In a multizone system with all the valve

auxiliary switches wired in parallel, any zone calling for heat

can operate the circulator. When the call for heat ends, the

valve closes by integral spring return. The auxiliary switch

contacts break the circulator circuit.

Manual Operation

The motorized valve can be opened manually by lifting the

manual opening lever over the stop and pushing slowly and

firmly to the MAN. OPEN position. The stop permits the valve

to be locked in the open position. The valve returns to

automatic position when the valve is energized.

Normally Closed Models

With the manual opener set to AUTO and the powerhead

energized, the valve is opened as shown in Fig. 36A. When

the powerhead is de-energized, a spring-return mechanism

drives the valve to the closed position as shown in Fig. 36B.

The valve can also be opened with no electrical power by

moving the manual opening lever over the stop and pushing

slowly and firmly to the MAN. OPEN position. The stop

permits the valve to be locked in the open position. The valve

returns to the automatic position when the valve is

energized.

Auxiliary switch is not energized when the valve is manually

opened.

Normally Open Models

When the powerhead is de-energized, a spring-return

mechanism drives the valve to the open position (Fig. 36A).

When energized, the valve is closed as shown in Fig. 36B.

A reverse-acting thermostat is required to control a normally

Fig. 36. V8043 operation for normally closed valve.

A

IN

OPEN POSITION

A

B

OUT

A

IN

CLOSED POSITION

B

OUT

B

M5951

Checkout

쐃 Raise the setpoint on the zone thermostat above the

room temperature to initiate a call for heat.

쐇 Observe all control devices—the valve should open

and the auxiliary switch should make the circuit to the

circulator or other valve at the end of the opening

stroke.

쐋 Lower the setpoint on the zone thermostat below the

room temperature.

쐏 Observe the control devices. The valve should close

and the auxiliary equipment should stop.

Service

This valve should be serviced by a trained, experienced

service technician.

1. If the valve is leaking, drain the system and check to

see if the O-ring needs replacing.

2. If the gear train is damaged, replace the entire

powerhead assembly. See the Installation section. If

the motor is burned out, replace the motor. See

Replacement Parts list in the TRADELINE® Catalog.

NOTE: Honeywell zone valves are designed and tested for

silent operation in properly designed and installed

systems; however, water noises can occur as a result

of excessive water velocity or piping noises can

occur in high temperature (higher than 212°F

(100°C) systems with insufficient water pressure.

Valves are designed for normal cycling operations.

Product life will be shortened if energized

continuously.

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis MN 55408-0524

Honeywell Latin American Division

Miami Lakes Headquarters

14505 Commerce Way Suite 500

Miami Lakes FL 33016

60-2133—9 J.S. Rev. 11-96 Printed in U.S.A.

60-2133—9

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 2C9

Honeywell Europe S.A.

3 Avenue du Bourget

B-1140 Brussels Belgium

Printed on recycled paper containing at

least 10% post-consumer paper fibers.

20

Honeywell Asia Pacific Inc.

Room 3213-3225

Sun Hung Kai Centre

No. 30 Harbour Road

Wanchai

Hong Kong

Helping You Control Your World

www.honeywell.com/building/components

®

Loading...

Loading...