Page 1

TDC 2000 | TDC 3000

Universal Control Network| UCN

Distributed Control Systems

for Industrial Automation

Honeywell

Product PDF

Presented by – DCScenter.com

For Product Needs:

Email: sales@DCScenter.com

Call: 1-800-793-0630 Fax: 919-324-6602

http://www.DCScenter.com

Page 2

DCS Center

MasterLogic Programmable Logic Controller

The MasterLogic PLC is a small and compact controller that

installs conveniently into a confined space and delivers power

and performance for a control application.

Modular and Scalable

MasterLogic PLCs are modular, scalable and rack-based. The

PLC can be either stand-alone or distributed with peer-to-peer

connections. The CPUs, power supplies and rack sizes are

available in various models to best fit a particular application.

Compact Size

Key Features

• Powerful and versatile processors – high speed i.e.42

nanosec/step, 7MB program (including system

memory), 4MB system memory, 2MB data memory,

16MB built-in flash memory for program and data

backup

• Full redundancy (CPU, power and network) – same

CPU can operate in both redundant & non-redundant

mode.

• Compact pocket size modules – rack room and

cabinet space saver

• IEC61131-3 standard programming – LD/ SFC/ ST/

IL language option

• A vast library of standard function blocks and support

for creating new or user-defined function blocks

• Over 50 types of I/O modules – digital/ analog

(isolated), HSC, RTD, TC, position/ motion control

• Open network protocols with field devices –

Profibus™ DP, DeviceNet™, MODBUS (Ethernet &

Serial)

• Open communication with external systems –

Ethernet, fiber-optic (100MBPS), serial RS232/RS422

• Peer-to-peer communications between PLCs –

Dedicated Ethernet 100 MBPS or Fiber-optic option

The module size is as small as 27x98x90 mm (pocket size). This

contributes to cost and floor space efficiency in today’s world

where floor space is a premium resource. Transportation is also

made much easier.

Speed and Power

A reliable processor makes it intrinsically powerful. All program

instructions are executed at a high speed of 42 ns/step, unique to

Honeywell. Even complex instructions are processed at this fast

speed.

A dedicated I/O bus controller supplements the main processor in

I/O refresh to achieve high speed scanning (e.g. estimated 15ms

for large PLC applications, say, 2500 I/Os and program size of

400 Kbytes).

• Smart I/O modules (DIN rail) on open protocols –

Profibus-DP, DeviceNet, MODBUS expanding I/O

capacity, remote I/O applications or as RTUs for

other manufacturers’ PLC

• Hot swapping, Interrupt programs, user-defined

Events (for SOE data in ms)

• Integration with Experion PKS, Experion HS,

Experion LS architecture (including system

diagnostics and clock synchronization) and SCADA

systems

• Self-diagnostics – network diagnostics, system logs,

Auto scan, monitoring system

• Engineering software – ease of configuration and

trouble-shooting

• Program simulator to test programs offline without

PLC/CPU

Page 3

MasterLogic PLC 2

DCS Center

CPU Specification

Execution speed 42 nano sec/step

Program Memory (inc. System

Memory)

Built-in Flash Memory 16MB

Data Memory 2MB

Max rack I/O 23,808

Max I/O using Network 128,000

Max slots 372 slots

Max expansion 31 bases

Scan time (e.g. 2500 I/O, 400 Kbytes

of program)

Open Network Standards

Industrial communication standards have continuously evolved

and so has MasterLogic PLC’s interface capability with them. In

addition to MODBUS (Ethernet and serial), MasterLogic supports

other protocols such as Profibus™ DP, DeviceNet™, OPC DA

server etc. Open standards network DeviceNet and Profibus

devices, such as smart actuators, sensors, intelligent drives and

transducers can be easily connected to MasterLogic. Its plug &

play features and open standards support make them easily

interoperable. On a physical level, Fast Ethernet, Fiber-Optic,

RS232/ 422/ 485 communication links are directly supported.

Model : 2MLR-CPUH/T

2MLR-CPUH/F

7MB

15 milliseconds

Versatile CPU

• IEC61131-3 standard programming – LD/ SFC/ ST/ IL

language option

• MasterLogic allows for modularizing the entire program into

max. 256 easily managed sub-programs, executed once

every scan in the order. In addition, several interrupt driven

programs are supported:

Interrupt #program (max) Remarks

Timer 32

Internal Device 32 Memory variable

• Flash memory (16MB) for program and data retention

• Two built-in programming ports (USB@12MBPS and

RS232C)

• Built-in MODBUS slave RS232C communication port

• Real Time Clock (RTC)

• RUN/ STOP/ DEBUG mode of operation

• Configurable address range of two latch areas for data

retention (non-volatile memory)

• Self-diagnostics for system errors (memory, I/O, battery,

power, execution, delays)

• Direct I/O operation - IORF instruction for direct read/ write

of I/O modules for time-sensitive applications

Online Maintenance and Trouble-Shooting

• Hot-swapping of I/O modules through a software wizard or a

CPU dip switch

• Force I/O values (bit and word) for maintenance and trouble-

shooting

• Skip I/O of a selected I/O module or an entire I/O base

• User-defined Event Recording (SOE) – digital devices can

be configured for automatic event recording when falling,

rising or COS (change of state) with millisec, and timestamp

for SOE analysis

The PLC system alarm and event history is as follows:

Type Condition Size

Error Any error 2048 events

Mode RUN/STOP 1024 events

Power change Power ON/OFF 1024 events

System events Key system events 2048 events

Page 4

MasterLogic PLC 3

DCS Center

Digital I/O Modules

MasterLogic has a wide range of digital I/O modules:

• 24V DC input modules (Sink source or source only type)

• AC input modules (110V or 220V AC)

• Relay, Triac, transistor ouput modules (sink or source)

• 8, 16, 32, 64 points I/O module

• Photo-coupler isolation

• LED for module and input status

• Easy maintenance: Terminal block type, one-touch installation

of module

Analog I/O Modules

• High speed A/D or D/A (250µs/ channel) conversion and

processing

• Channel to channel isolation

Peer-to-Peer Communications

Peer-to-peer communication between PLCs is an important

requirement in large inter-related control applications. A high

speed Ethernet module at 100Mbps or optional fiber-optic

module ensures fast and reliable integration between

MasterLogic PLCs. Installation involves just a few simple

configuration steps i.e. basic parameter, HS link item settings,

etc.

Integrated PLC Engineering Environment

SoftMaster provides the engineer with an integrated PLC

engineering environment – all-in-one window such as ladder

programming, configuration/ setup of CPU or other

special/communication modules, debugging, monitoring,

troubleshooting, documentation and maintenance, etc.

• High resolution (16 bits)

• Digital value in 4 data formats

• Detection flags for input signal disconnect when analog input

range is 1 ~ 5V or 4 ~ 20 mA.

• LED status displays for RUN/ ERROR conditions

• Voltage/ Current switching option

• RTD (2-wire, 3-wire, 4-wire)

• Thermo-couple (K, J, B, T, E, R, S, N, C types)

Special Modules

• 2-channel high speed counter (voltage input or differential

voltage incremental encoder, preset function)

• Positioning modules

• Motion control module

If the field I/O signals are located too far away from the

MasterLogic CPU the same I/O modules can also be used as

remote I/O to reduce wiring costs and associated costs. In

addition, it also significantly increases the overall I/O capacity of

the MasterLogic PLC e.g. 23,808 to 128,000.

Project File

SoftMaster helps manage multiple PLCs through a single

window. One project file can include multiple PLCs from the site

as central storage of all PLC details.

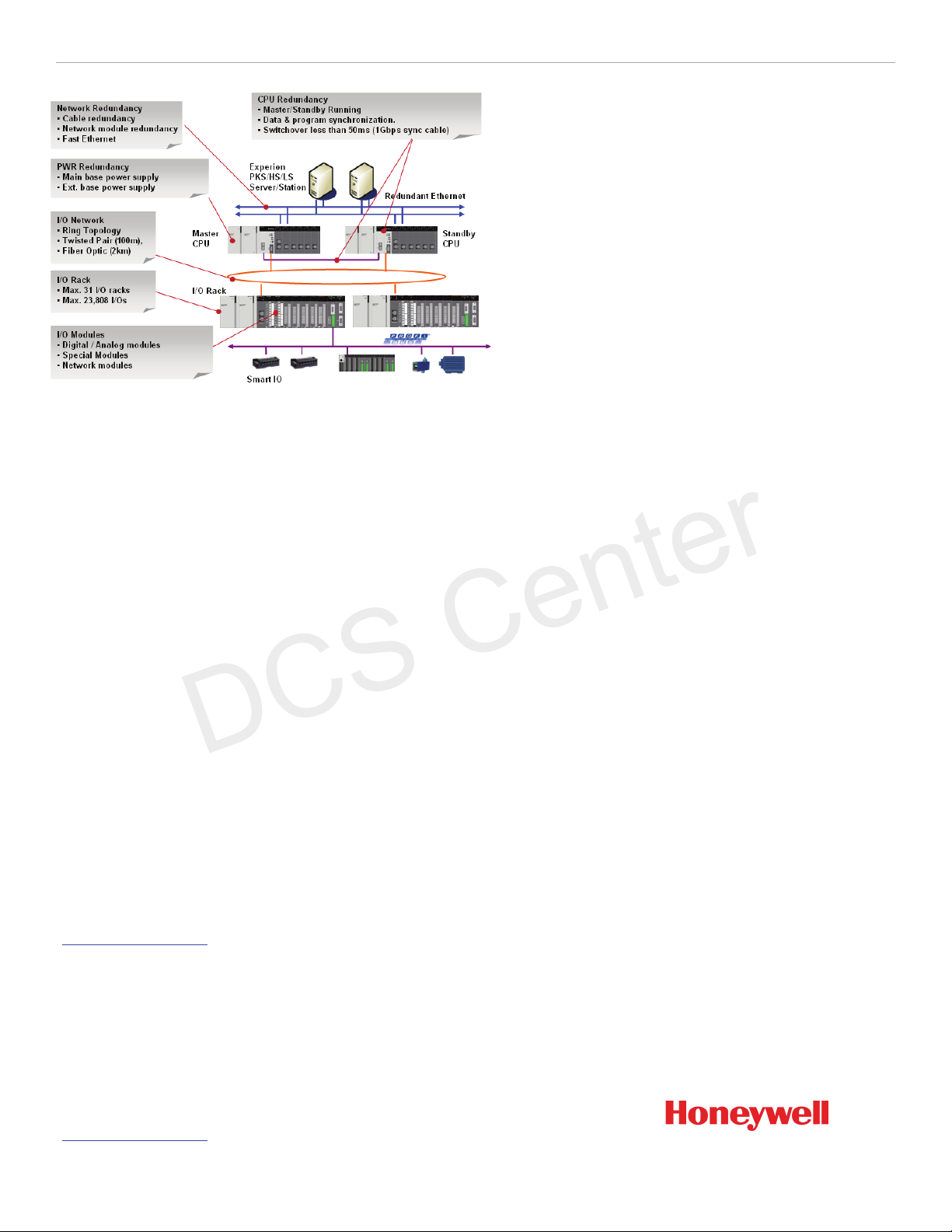

MasterLogic Redundancy

For critical applications, eliminating all single points of failure in

the system architecture ensures high availability. Redundancy

features include:

• CPU redundancy— Seamless switchover to standby CPU

within 50ms when master fails without interrupting operations

• Power supply redundancy for both CPU and I/O racks

• Network redundancy — ring topology providing dual

communication paths to I/O racks

• High speed synchronization of program and data between

primary and backup CPU via dedicated fiber optic line

• Built-in twisted pair or fiber-optic networks for local (100m)

and remote I/O (2km) racks on ring topology

• Base type remote I/O functionality

• Base I/O capacity enhanced to 23,808 (372 slots in 31 bases)

Page 5

MasterLogic PLC 4

A

DCS Center

Interface with Experion PKS, Experion HS, Experion LS

MasterLogic PLCs are tightly integrated with the Experion

architecture. They directly reside on the FTE or Ethernet network

of Experion PKS and the Ethernet network of Experion HS and

Experion LS, eliminating the need for any intermediate gateway

equipment.

• The interface supports configuring MasterLogic PLC

channels, controllers and points just like any other SCADA

interface

• For efficient communication optimization, the integration

supports both synchronous (timer based subscription of real

time data) and asynchronous (change of state, report by

Applications

• Process Industries: oil and gas, steel, cement, power

generation, chemicals, petrochemicals

• Automobile industries

• Food and Beverage

• Healthcare and Pharmaceuticals

• Textiles

• Material handling

• Water Treatment

exception) communication methods

• All PLC clocks are synchronized with the Experion PKS

server clock

• PLC system alarms and events (e.g. battery fail, CPU STOP,

RESET, ERROR) automatically cascade to Experion

summary page with acknowledgment, return to normal

function etc

• PLC system status (graphical display) monitoring from all

Experion Stations

• Semi-conductors

• Printers and Publishers

• Paints and Plastics

• OEM – partnerships with packaged equipment

manufacturers and machine builders

More Information

For more information on MasterLogic PLC, visit

www.honeywell.com/ps

Honeywell account manager.

Automation & Control Solutions

Process Solutions

Honeywell

2500 W. Union Hills Dr.

Phoenix, AZ 85027

Tel: +1-602-313-6665 or 877-466-3993

www.honeywell.com/ps

or contact your

PN-09-05-ENG

pril 2009

© 2009 Honeywell International Inc.

Loading...

Loading...