Page 1

TC300

Protection valve for deep well pumping

Product specification sheet

Application

Protection valves of this type for deep well pumping is used to

permit pressure shock free starting and stopping of deep well

pumps.

Special Features

• High flow capacity

• Light weight

• High control accuracy

• Powder coated inside and outside - Powder used is physiologically and toxicologically safe

• Integral control circuit and ball valves

Range of Application

Medium Water

Operating pressure Max. 16 bar

Magnetic solenoid

pilot valve

24 V AC, IP 65

Construction

The surge anticipating valve comprises:

• Housing with PN16 flanges per ISO7005-2, EN1092-2

• 2 magnetic solenoid valves

• 2 needle valves

• End switch

• Control circuit with ball valves on inlet and outlet

• Control circuit with integral rinsable filter insert

Materials

• Ductile iron housing, cover plate and diaphragm plate

(ISO 1083), powder coated

• Red bronze/stainless steel regulating cone

• Stainless steel pressure spring and control rod

• Fibre-reinforced NBR diaphragm

• NBR and EPDM seals

• Stainless steel valve seat

• High quality synthetic material control circuits

EN0H-1334GE23 R0807 • Subject to change

• Brass compression fittings

• Brass magnetic solenoid valve housing

• Stainless steel filter insert

Technical Data

Operating temperature

Nominal pressure PN 16

Minimum pressure 0.7 bar

Connection size DN 50 - 450

Max. 80 °C

PN 25 on request

www.honeywell.com 79

Page 2

TC300 Protection valve for deep well pumping

Method of Operation

Protection valves of this type for deep well pumping are

controlled by two adjustable magnetic solenoid valves. One

magnetic solenoid valve is normally open when there is no electrical supply and the other is normally closed. In both magnetic

solenoid valves the upper or lower diaphragm chambers are

subjected to the outlet pressure to the pumping system. The

operation of the pump is controlled by the end switch on the

main valve.

Options

TC300- ... A = Housing with flange, PN 16,

ISO 7005, EN 1092-2

TC300- ... Z = PN 25, on request

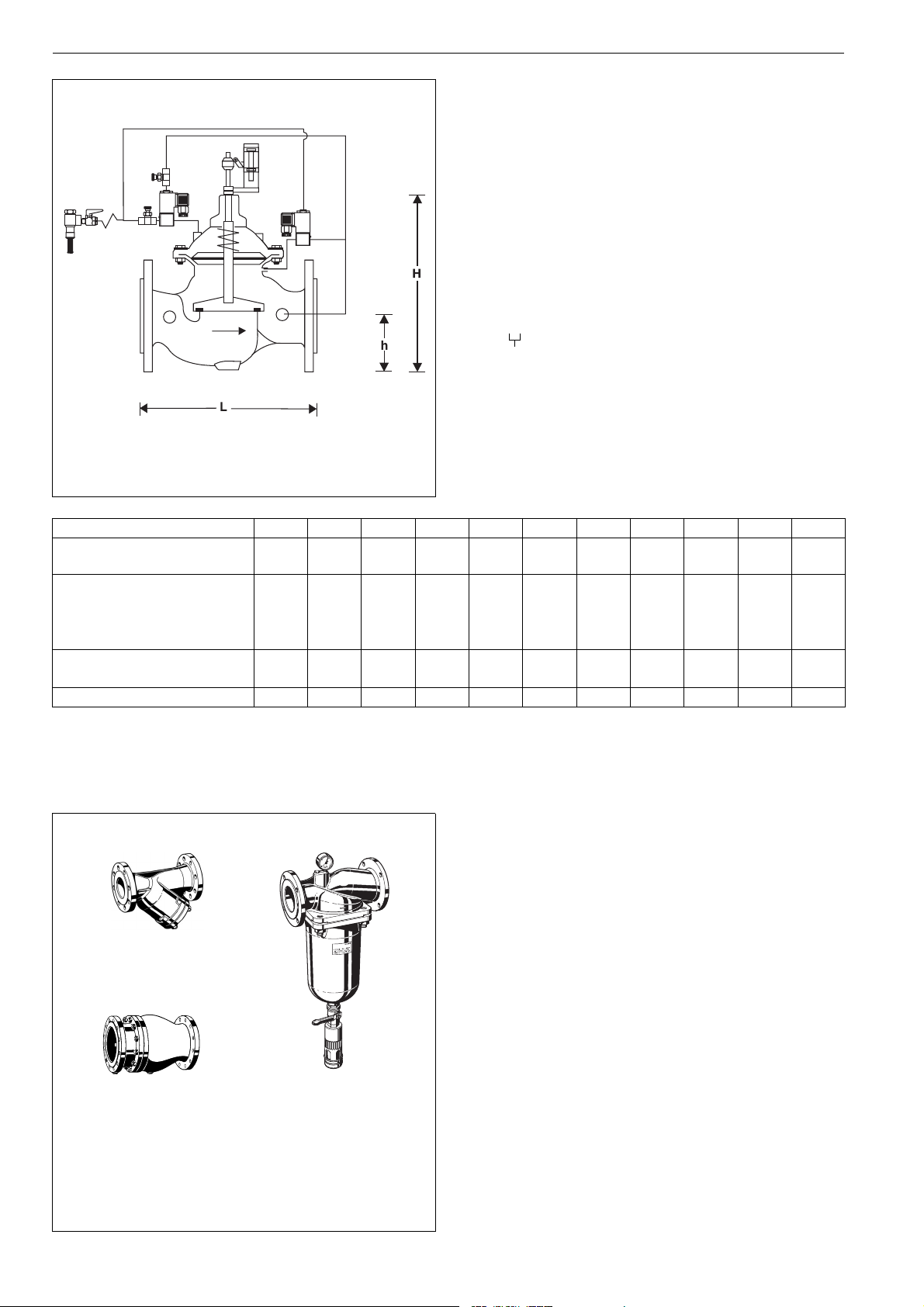

Connection size

Connection size DN 50 65 80 100 150 200 250 300 350 400 450

Weight approx.kg14 15 24 39 82 159 247 407 512 824 947

Dimensions (mm)

Flow rate (Q

) in m3/h

max

L

230

H

235

h

83

292

294

93

310

400

100

350

433

110

480

558

143

600

650

173

730

823

205

850

944

230

980

990

260

1100

1250

290

40 40 90 160 350 480 970 1400 1900 2500 3150

1200

1250

310

- V=5.5 m/s

kvs-value m3/h 43 43 103 167 407 676 1160 1600 1600 3300 3300

Accessories

FY69P Strainer

5

r

15

ba

0

16

With double mesh, grey cast iron housing, powder

coated inside and outside.

A = Mesh size approximately 0.5 mm

F76S-F Reverse-rinsing filter

FY69P

Red bronze housing and filter bowl. Available in sizes

DN 65 to DN 100, with filter mesh sizes 100 µm

or 200 µm

RV283P

80 www.honeywell.com

F76S-F

RV283P Check valve

Grey cast iron housing, powder coated inside and

outside. DIN/DVGW tested in compulsory test sizes

DN 65, DN 80 and DN 100

EN0H-1334GE23 R0807 • Subject to change

Page 3

Installation Example

0

0

0

0

0

0

0

0

TC300 Protection valve for deep well pumping

Installation Guidelines

• Install shutoff valves on both sides of the pressure sustaining

valves

• Install with flow in direction of arrow on housing

o Protects against damage from coarse dirt

• Note flow direction (indicated by arrow)

• Ensure good access

o Simplifies maintenance and inspection

• The opening period is dependent on the length of the supply

pipework and should be increased if this pipework is extremely long

• The valve of this type cannot prevent excess pressure such

as may be caused by a sudden electrical power failure

o For this purpose a PC 300 surge anticipating valve should

be fitted as well

• Install connectors for removal and refitting for maintenance

Flow Diagram

[

l/s

1000

500

100

50

10

5

EN0H-1334GE23 R0807 • Subject to change

1

3

]

[m

/h]

5000

1000

500

100

50

10

5

Typical Applications

Surge anticipating valves of this type, within the limits of their

specification, are suitable for installation in water supply systems

and also in commercial and industrial installations

The following are some typical applications:

• Water pressure shock load protection in pressure boosting

systems in mining

• Dedicated water supplies to industrial users

DN 45

DN 40

DN 35

DN 30

DN

25

DN 20

DN 15

DN 10

DN 80

DN 65

DN 50

1

0,01

0,05 0,1 0,5 1 105

[

]

bar

www.honeywell.com 81

Page 4

TC300 Protection valve for deep well pumping

Spare Parts

Protection valve TC300, from 2002 onwards

4

No. Description Dimension Part No.

1 Replacement

magnetic solenoid

DN 50 - 450 30-NC

0903765

valve

Normally closed when

electrical supply is off

3

1

3

2 Replacement

magnetic solenoid

valve

DN 50 - 450 30-NO

0903766

Normally open

3 Set of seals DN 50 0903750

DN 65 0903751

DN 80 0903752

DN 100 0903753

DN 150 0903754

DN 200 0903755

DN 250 0903756

DN 300 0903757

DN 350 0903758

3

3

DN 400 0903759

DN 450 0903760

4 End switch DN 50 - 450 0903764

3

3

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

2

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1334GE23 R0807

Subject to change without notice

© 2007 Honeywell GmbH

Loading...

Loading...