Honeywell TC, TC 1, TC 1V, TC 1C, TC 2 Technical Information

...

AGA

Tightness controls TC

Technical Information · GB

3 Edition 08. 17

• Adjustable test period which can be adapted to different systems

• Adjustable test instant allows quick system start

• Maximum safety thanks to self-monitoring electronics

Safety manual for products complying with EN 615082

Contents

Tightness controls TC ...............................1

Contents ............................................2

1 Application ........................................4

1.1 Application examples ..............................7

1.1.1 TC 1V with valVario controls ...........................7

1.1.2 TC 1C with combination control CG..D or CG..V . . . . . . .8

1.1.3 TC 2 with two gas solenoid valves .....................9

1.1.4 TC 2 with two gas solenoid valves and one

auxiliary valve for discharge...............................10

1.1.5 TC 2 with two gas solenoid valves and one

auxiliary valve for discharge................................11

1.1.6 TC 2 in a multiple burner system with several

valves installed in series................................... 12

1.1.7 TC 3 in a multiple burner system with several

valves installed in series...................................13

1.1.8 TC 4 with two gas solenoid valves ...................14

1.1.9 TC 4 with two gas solenoid valves and one

auxiliary valve for discharge...............................15

1.1.10 TC 4 in a multiple burner system with two

auxiliary valves for supply and discharge ................. 16

1.1.11 TC 4 in a multiple burner system with several

valves installed in series....................................17

2 Certification ......................................18

2.1 TC 1, TC 2, TC 3 ...................................18

2.2 TC 4 ...............................................19

3 Function ......................................... 20

3.1 TC 1, TC 2, TC 3 .................................. 20

3.1.1 Connection diagrams for TC 1, TC 2 ................20

3.1.2 Connection diagrams for TC 3 .......................21

3.1.3 Test procedure for TC 1, TC 2, TC 3 ..................22

3.1.4 Test instant TC 1, TC 2, TC 3.........................24

3.1.5 Test instant for Mode 1: testing before burner run..24

3.1.6 Test instant for Mode 2: testing after burner run ...25

3.1.7 Test instant for Mode 3: testing before and after

burner run .................................................26

3.1.8 Measurement time t

for TC 1, TC 2, TC 3 ...........27

M

3.1.9 Calculation example for t

..........................27

M

3.2 TC 4 ...............................................28

3.2.1 Connection diagram ................................ 28

3.2.2 Test procedure TC 4 .................................29

3.2.3 TC 4 test instant ......................................31

3.2.4 Test instant for Mode 1: testing before burner run ..31

3.2.5 Test instant for Mode 2: testing after burner run ...32

3.2.6 Test period t

3.2.7 Calculation example for t

for TC 4 ...............................33

P

..........................33

P

3.3 Test volume VP for TC 1, TC 2, TC 3, TC 4 .........34

3.4 Leakage rate Q

..................................35

L

3.5 Animation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4 Selection .........................................37

4.1 TC 1, TC 2, TC 3 ...................................37

4.1.1 Selection table........................................37

4.1.2 Type code ............................................37

4.2 TC 4 ...............................................37

4.2.1 Selection table........................................37

4.2.2 Type code ............................................37

5 Project planning information . . . . . . . . . . . . . . . . . . . . 38

5.1 Selecting the auxiliary valves . . . . . . . . . . . . . . . . . . . . .38

5.2 Start rate ..........................................39

5.3 Installation........................................39

5.3.1 TC 1V for solenoid valves for gas VAS, VCx..........39

5.3.2 TC 1C for combination controls CG .................39

5.3.3 TC 2..................................................40

5.3.4 TC 3..................................................40

5.3.5 TC 4..................................................40

5.4 Electrical connection of TC 1, TC 2 ...............41

5.5 Determining the relief line size....................41

6 Accessories.......................................42

6.1 Socket.............................................42

6.2 Valve connection cable ...........................42

6.3 External pressure switch for TC 4 ................42

TC · Edition 08.17 2

= To be continued

▼

7 Technical data ................................... 43

7.1 TC 1, TC 2, TC 3 ....................................43

7.2 TC 4............................................... 44

7.3 Indicators and operating controls................ 46

7.4 Dimensions........................................47

7.5 Converting units...................................47

7.6 Safety-specific characteristic values ............ 48

8 Safety information in accordance with

EN 615082 for TC 1, TC 2, TC 3 ................... 49

8.1 General............................................49

8.1.1 Type of action........................................49

8.1.2 Other classifications ................................ 49

8.1.3 Electrical data .......................................49

8.2 Interfaces ........................................ 50

8.2.1 Electrical wiring .....................................50

8.2.2 Connection terminals ...............................50

8.2.3 Inputs................................................50

8.2.4 Outputs...............................................51

8.3 SIL and PL for TC 1, TC 2, TC 3 ...................51

9 Maintenance cycles ..............................52

10 Glossary ........................................ 53

10.1 Tightness control ................................53

10.2 Valve proving system VPS .......................53

10.3 Safety interlocks .................................53

10.4 Diagnostic coverage DC .........................53

10.5 Operating mode .................................53

10.6 Hardware fault tolerance HFT ...................53

10.7 Probability of dangerous failure PFH

10.8 Mean time to dangerous failure MTTF

Feedback ...........................................55

Contact.............................................55

..........54

D

........54

d

TC · Edition 08.17 3

Application

▼

1 Application

TC 1, TC 2 TC 3 TC 4

The tightness control TC checks the fail-safe function

of both valves before each start-up or after each shutdown of a system with two safety valves.

The aim is to identify an inadmissible leak on one of the

gas valves and to prevent burner start. The other gas

valve continues working properly and takes over the

safe shut-off of the gas supply.

It is used in industrial thermoprocessing equipment, on

boilers and on forced draught burners.

Standards ISO 135772, EN 7462 and EN 676 stipulate tightness controls for capacities over 1200 kW

(NFPA 86: from 117 kW or 400,000 Btu/h in conjunction with a visual indicator). Pre-purge of the combustion chamber can be dispensed with under certain

conditions in accordance with EN 7462, if a tightness

TC · Edition 08.17 4

control is used. In this case, the system must be vented

into a safe area.

TC 1V, TC 1C

Tightness control TC 1V can be directly flange-mount-

ed to all valVario controls. There is only one version for

all sizes.

TC 1C can be used for combination controls CG 1 to 3.

An adapter plate is supplied for installation.

Application

TC 2 and TC 4

Tightness controls TC 2 and TC 4 can be used with gas

solenoid valves of any nominal size, which are quick

opening or slow opening with start rate. It is possible to

conduct a tightness test on pneumatically operated or

slow opening valves without start rate by using additional auxiliary valves.

Slow opening motorized valves VK up to DN 65 which

are directly flanged together can also be checked by

TC 2 and TC 4 within a temperature range of 0 to 60°C

(32 to 140°F).

An adapter plate is provided for installation of the TC 2.

TC 3

Tightness control TC 3 is a universal device for quick

and slow opening gas solenoid valves of any nominal

size as well as for motorized valves. The tightness test is

carried out with the valves installed in TC 3.

TC 4

Tightness control TC 4 consists of detection circuitry

and can be installed in the control cabinet, separately

from the system. An external pressure switch takes

over the mechanical pressure test between the valves.

Tightness control TC 4 is independent of gas type and

inlet pressure p

and can be used for a test period of up

u

to 10 minutes with a large test volume.

TC · Edition 08.17 5

Application

TC 1V on a valVario double solenoid valve TC 4 installed separately from the system in a control

cabinet

TC · Edition 08.17 6

Application

1.1 Application examples

PZ = Internal pressure sensor of the TC for the compari-

son of inlet pressure pu and interspace pressure p

pd = Outlet pressure

V

= Test volume

P

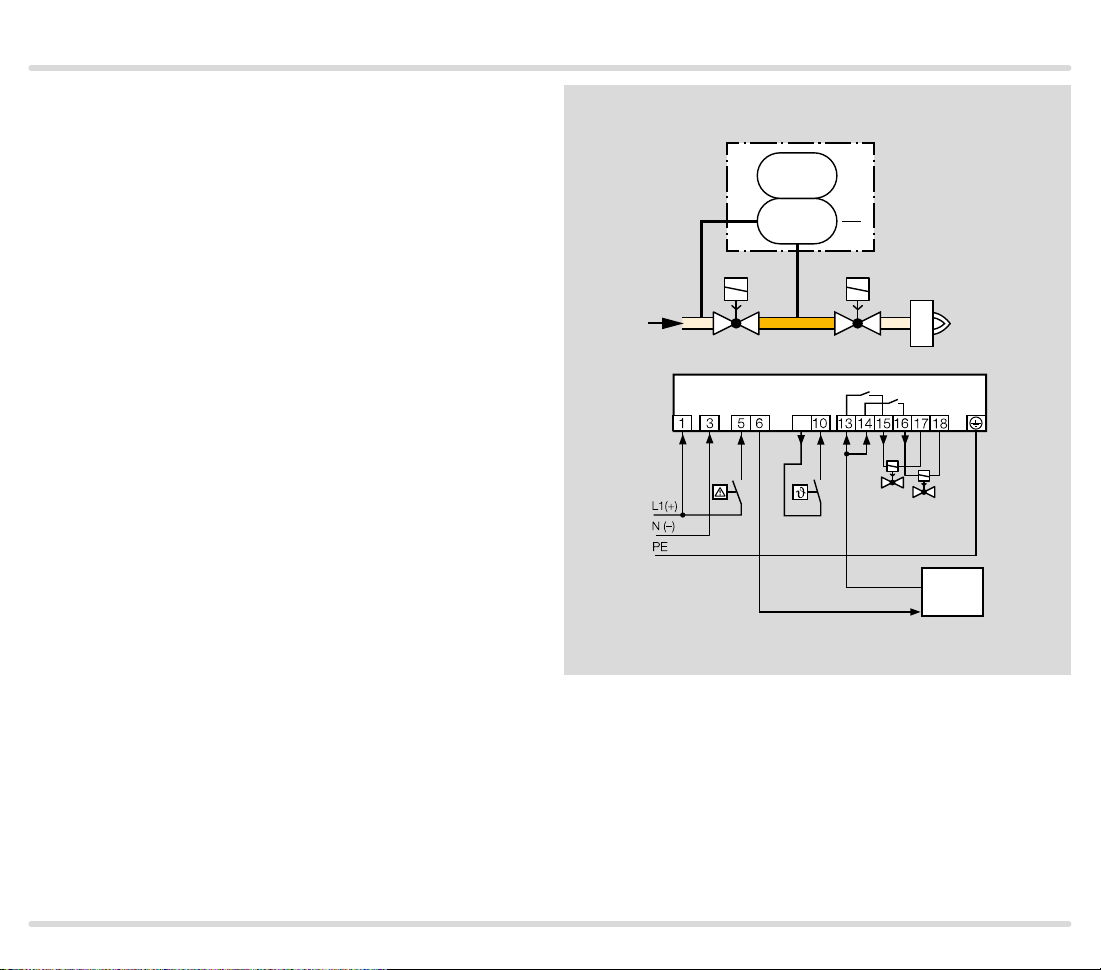

1.1.1 TC 1V with valVario controls

Mains voltage = control voltage

V1: quick or slow opening valve with start rate.

V2: pressure regulator with solenoid valve.

Tightness control TC 1V checks gas solenoid valves V1

and V2 and the pipe between the valves for tightness.

If both valves are tight, the TC forwards the OK enable

signal to the automatic burner control unit GFA. This

opens valves V1 and V2 simultaneously. The burner

starts.

z

p

u

TC 1V

p

PZ

VAS

V1 V2

u

2

VAD

p

z

V

P

TC 1V

9

V1

V2

GFA

OK

TC · Edition 08.17 7

Application

1.1.2 TC 1C with combination control CG..D or CG..V

Mains voltage = control voltage

V1 and V2: quick opening valves.

TC 1C is directly flange-mounted to combination con-

trol CG..D or CG..V and checks gas solenoid valves V1

and V2 in the combination control for tightness.

Once the tightness test has been carried out successfully, the tightness control forwards the OK enable

signal to the automatic burner control unit GFA. This

opens valves V1 and V2 in the combination control CG

simultaneously. The burner starts.

TC 1C

p

PZ

CG

p

PZ

u

V1 V2

u

2

p

z

V

P

TC 1C

9

V1

GFA

OK

TC · Edition 08.17 8

Application

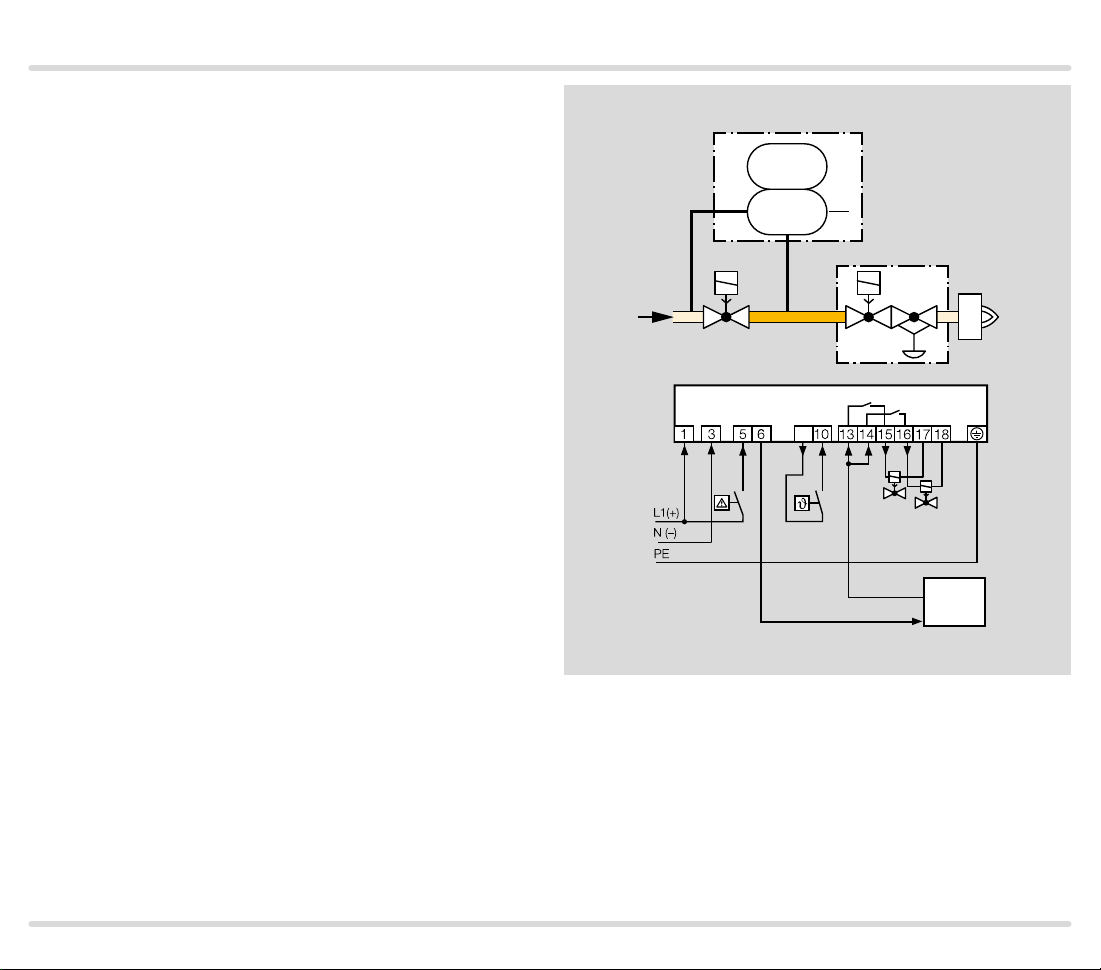

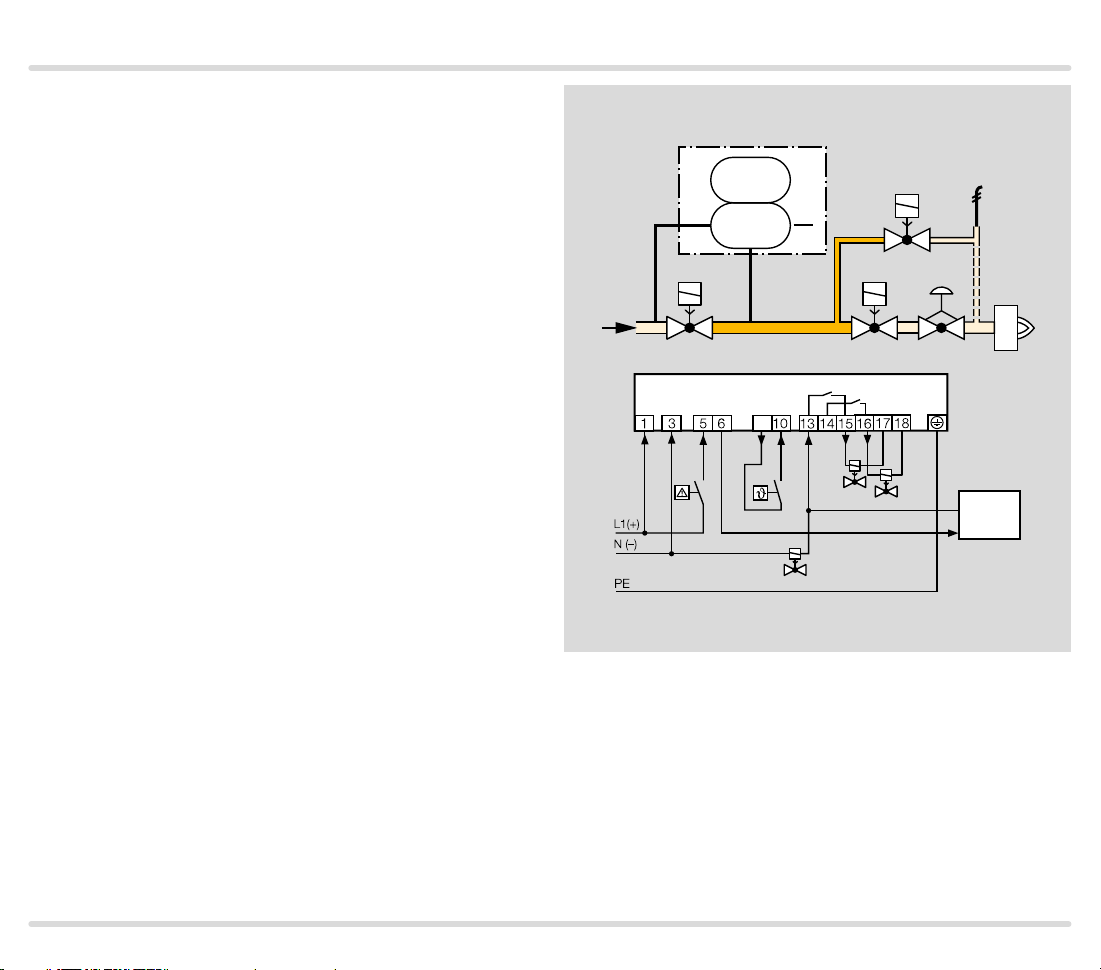

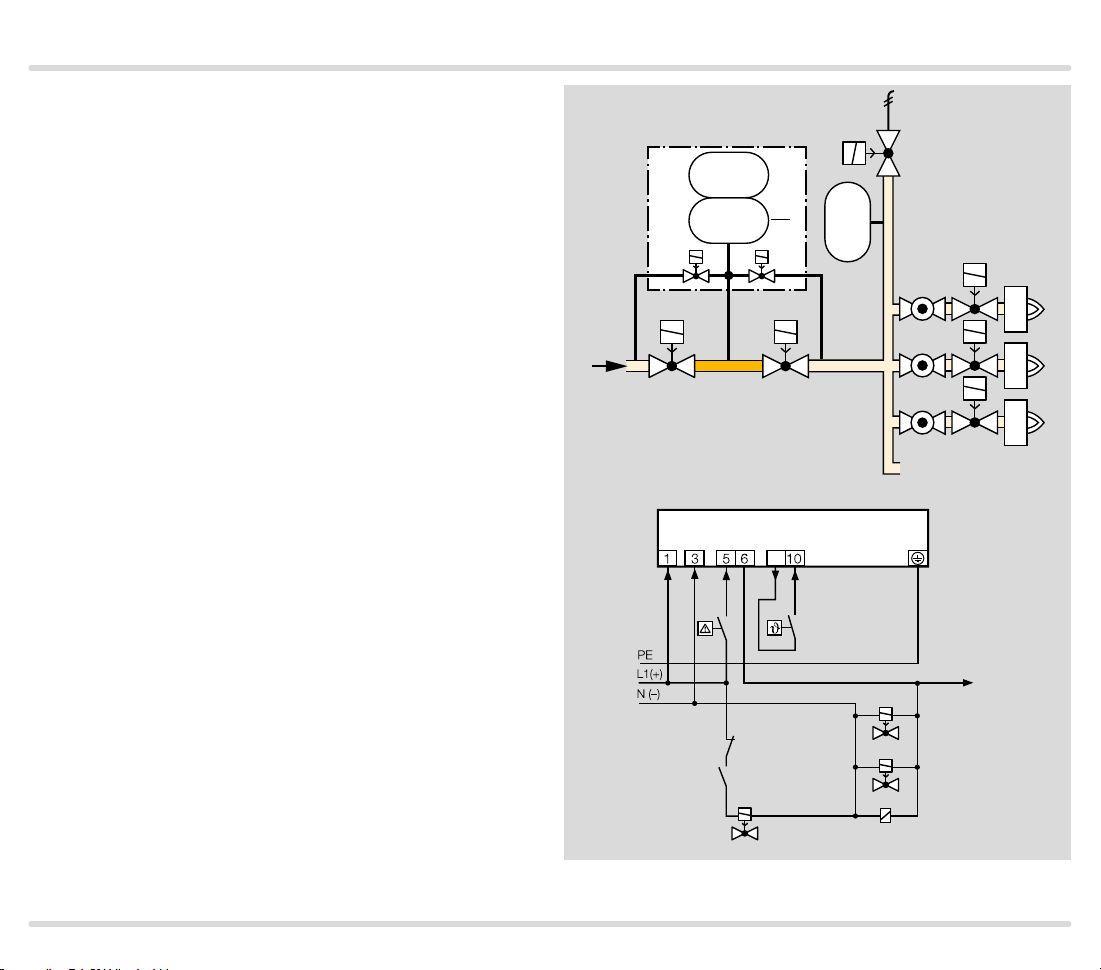

1.1.3 TC 2 with two gas solenoid valves

Mains voltage = control voltage

V1 and V2: quick or slow opening valves with start rate.

TC 2 checks gas solenoid valves V1 and V2 and the pipe

between the valves for tightness.

If both valves are tight, the TC forwards the OK enable

signal to the automatic burner control unit GFA. This

opens valves V1 and V2 simultaneously. The burner

starts.

TC 2

p

PZ

V1 V2

p

u

V

u

2

p

z

P

TC 2

9

V1

V2

GFA

OK

TC · Edition 08.17 9

Application

1.1.4

TC 2 with t wo gas solenoid valves and one auxiliar y

valve for discharge

Mains voltage = control voltage

V1 and V2: quick or slow opening valves with start rate.

V3: quick or slow opening valve with start rate, nominal

size is dependent on test volume VP and inlet pressure pu, see page 38 (Project planning information),

but is at least DN 15.

TC 2 checks gas solenoid valves V1, V2, the auxiliary

valve V3 and the pipe between the valves for tightness.

It must be ensured that the interspace p

ing the 3-second opening time. This is not guaranteed

by the gas pressure regulator downstream of V2. A relief

line is thus used to discharge the test volume VP safely

into the combustion chamber or into a safe area. Auxiliary valve V3 can also be used as a pilot gas valve. Since

valve V2 remains closed during the test, it can also be a

slow opening motorized valve VK.

Once the tightness test has been carried out successfully, the tightness control forwards the OK enable signal to the automatic burner control unit GFA. The GFA

opens the gas solenoid valves V1 and V2 simultaneously. The burner starts.

is vented dur-

z

TC 2

p

PZ

V1 V2

p

u

u

2

p

z

V

P

V3

TC 2

9

OK

V1

V3

V2

GFA

TC · Edition 08.17 10

Application

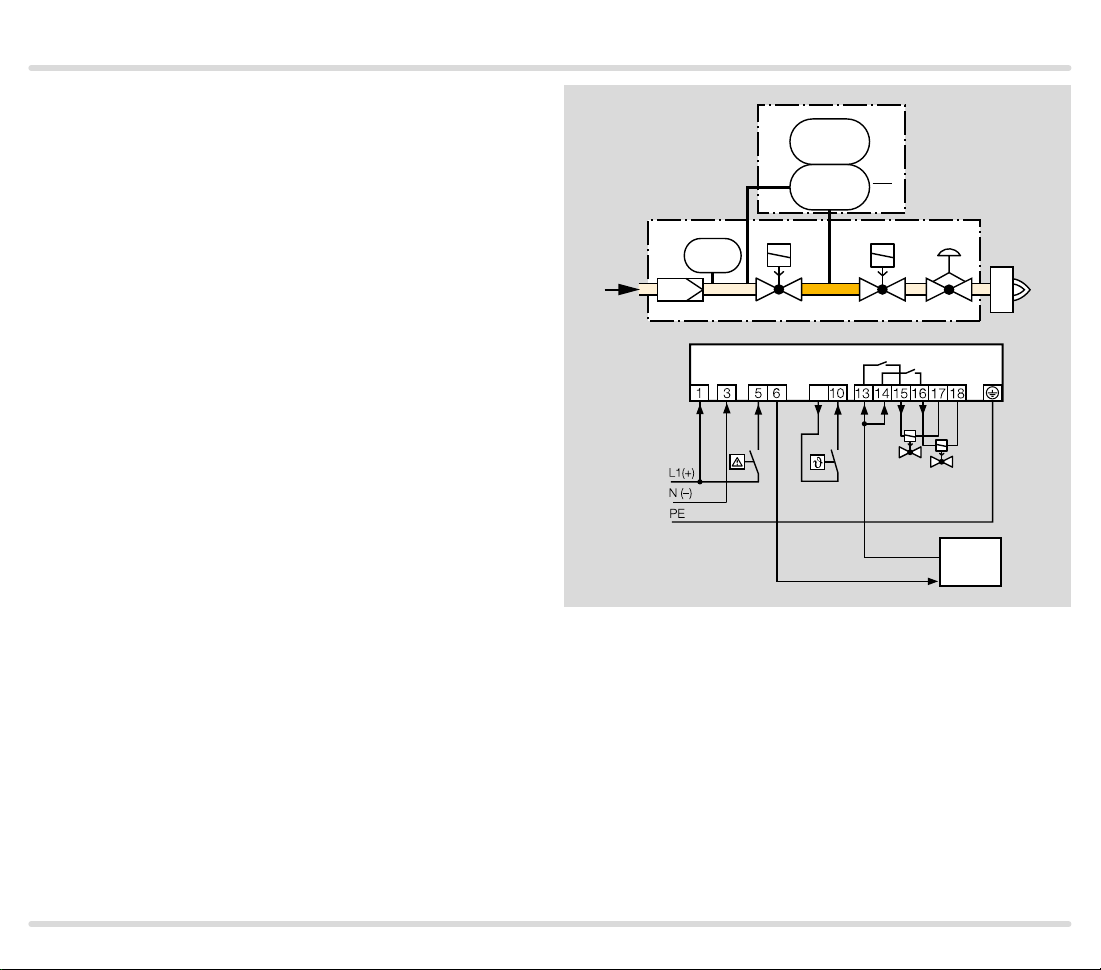

1.1.5

TC 2 with t wo gas solenoid valves and one auxiliar y

valve for discharge

Mains voltage = control voltage

V1: quick or slow opening valve with start rate.

V2: any.

V3: quick opening, nominal size is dependent on test

volume VP and inlet pressure pu, see page 38 (Project planning information), but is at least DN 15.

TC 2 checks gas solenoid valves V1, V2, the auxiliary

valve V3 and the pipe between the valves for tightness.

If all the gas solenoid valves are tight, the tightness

control forwards the OK enable signal to the automatic

burner control unit GFA. The GFA opens the gas solenoid valves V1 and V2 simultaneously. The burner

starts.

A relief line is used to discharge the test volume V

a safe area. Thanks to the installed auxiliary valve V3,

valve V2 can also be a slow opening motorized valve VK.

into

P

TC 2

p

PZ

V1

p

u

u

2

V3

p

z

V

P

V2

TC 2

9

OK

V1

V3

V2

GFA

TC · Edition 08.17 11

Application

1.1.6

TC 2 in a multiple burner sys tem with several valves

installed in series

Mains voltage = control voltage

V3 and V4: quick opening, nominal size is dependent

on test volume V

(Project planning information), but is at least DN 15.

When using slow opening main valves ( V1 and V2), auxiliary valves (V3 and V4) must be used for the supply

and discharge of the test volume V

TC 2 checks the central shut-off valve V1, the gas so-

lenoid valve V2, the auxiliary valves V3 and V4 and the

pipe between these valves for tightness.

Valve V2 can only be checked for tightness when the

pressure downstream of V2 approximately corresponds

to the atmospheric pressure and the volume downstream of valve V2 is 5 x VP. The gas solenoid valve VAS

and the pressure switch DG

pressure. The pressure switch must be adjusted in such

a way so that enough pressure is relieved and no air can

get into the pipework.

Once the tightness test has been carried out successfully, TC 2 opens the main valves V1 and V2 with the

OK enable signal and enables the downstream burner

control units.

and inlet pressure pu, see page 38

P

.

P

are used to relieve the

VAS

TC 2

p

PZ

V1 V2

p

u

V3

p

z

u

VAS

2

PZ

V4

V

P

VAS

DG

TC 2

9

V3

V4

OK

V2

V1

DG

K1

VAS

VAS

TC · Edition 08.17 12

K1

Application

1.1.7

TC 3 in a multiple burner sy stem with several valves

installed in series

V1 and V2: any.

TC 3 checks slow opening main valves V1 and V2 and

the pipe between these valves for tightness.

The test volume V

TC 3 auxiliary valves.

Valve V2 can only be checked for tightness when the

pressure downstream of V2 approximately corresponds

to the atmospheric pressure and the volume down-

stream of valve V2 is 5 x VP. The gas solenoid valve VAS

and the pressure switch DG

pressure. The pressure switch must be adjusted in such

a way so that enough pressure is relieved and no air can

get into the pipework.

Once the tightness test has been carried out success-

fully, TC 3 opens the main valves V1 and V2 with the

OK enable signal and enables the downstream burner

control units.

is supplied and discharged via the

P

are used to relieve the

VAS

TC 3

p

PZ

2

p

u

V1 V2

p

u

p

z

V

P

VAS

u

PZ

p

d

VAS

DG

TC 3

9

OK

K1

DG

VAS

VAS

TC · Edition 08.17 13

V2

V1

K1

Application

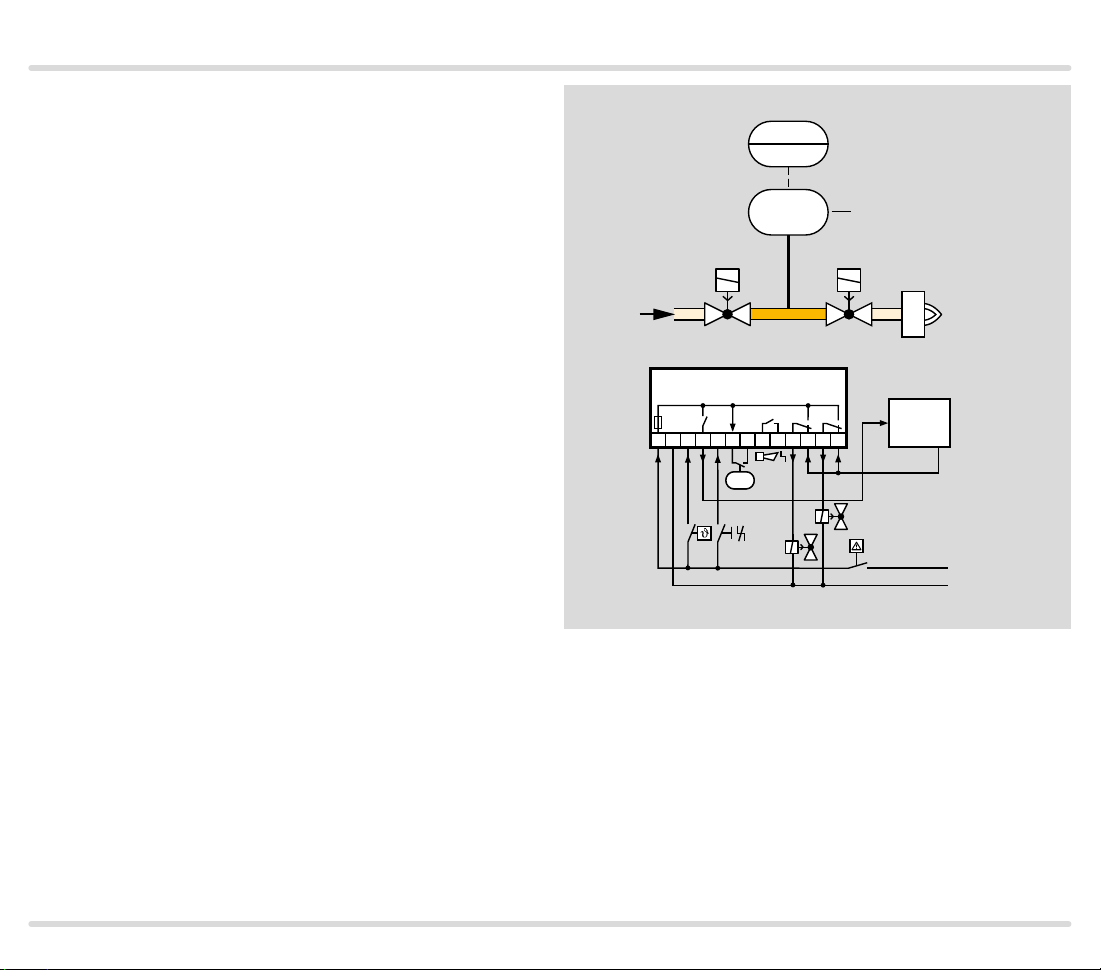

1.1.8 TC 4 with two gas solenoid valves

V1 and V2: quick or slow opening valves with start rate.

TC 4 checks gas solenoid valves V1 and V2 and the pipe

between the valves for tightness.

The external pressure switch DG monitors the pressure

between the two valves.

Once the tightness test has been carried out success-

fully, TC 4 forwards the OK enable signal to the auto-

matic burner control unit GFA. The GFA opens the gas

solenoid valves V1 and V2 simultaneously. The burner

starts.

TC 4

DG

PZ

V1

p

u

p

z

V

P

TC 4

1 2 345 6 7 8 9 10 1112 13

PZ

V2

V1

p

u

2

V2

GFA

OK

L1(+)

N(-)

TC · Edition 08.17 14

Application

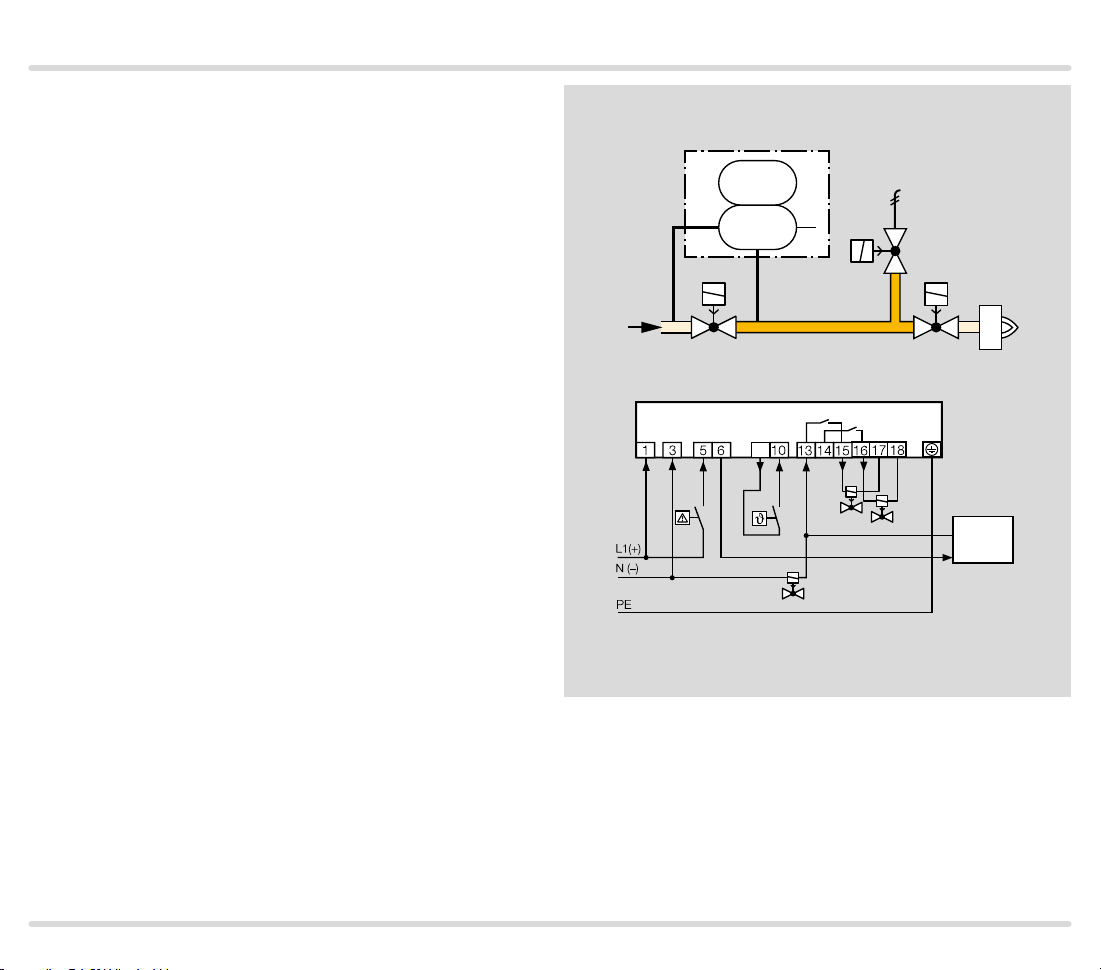

1.1.9

TC 4 with t wo gas solenoid valves and one auxiliar y

valve for discharge

V1: quick or slow opening valve with start rate.

V2: any.

V3: quick opening, nominal size is dependent on test

volume VP and inlet pressure pu, see page 38

(Project planning information), but is at least DN 15.

TC 4 checks gas solenoid valves V1, V2, the auxiliary

valve V3 and the pipe between the valves for tightness.

It must be ensured that the interspace p

ing the 2-second opening time. This is not guaranteed

by the gas pressure regulator downstream of V2. A relief

line is thus used to discharge the test volume VP safely

into the combustion chamber or into a safe area. Since

valve V2 remains closed during the test, it can also be a

slow opening motorized valve VK.

If all the gas solenoid valves are tight, TC 4 forwards

the OK enable signal to the automatic burner control

unit GFA. The GFA opens the gas solenoid valves V1

and V2 simultaneously. The burner starts.

is vented dur-

z

TC 4

DG

PZ

V1 V2

p

u

p

z

V

P

TC 4

1 2 345 6 7 8 9 10 1112 13

PZ

V3

ϑ

V1

p

2

V3

u

GFA

OK

V2

L1(+)

N(-)

TC · Edition 08.17 15

Application

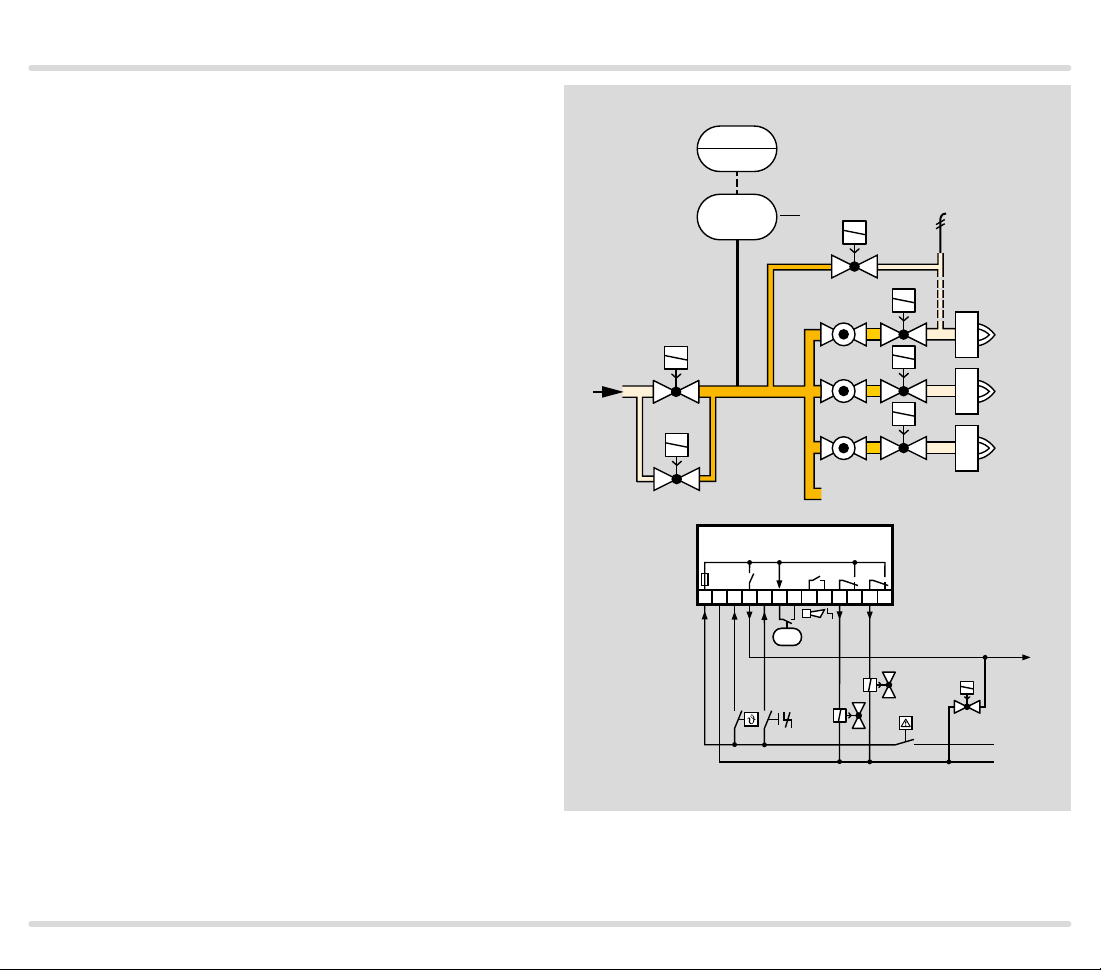

1.1.10

TC 4 in a multiple burner sys tem with two auxil iary

valves for supply and discharge

V1: any.

V2 and V3: quick opening, nominal size is dependent

on test volume VP and inlet pressure pu, see page 38

(Project planning information), but is at least DN 15.

TC 4 checks the central shut-off valve V1, the auxiliary

valves V2 and V3, the burner valves and the pipe be-

tween these valves for tightness.

The test volume V

is supplied via the auxiliary valve V3.

P

The external pressure switch DG monitors the pressure

between the gas solenoid valves V1, V2 and the burner

valves.

Once the tightness test has been carried out success-

fully, TC 4 opens gas solenoid valve V1. The TC forwards

the OK enable signal simultaneously to the automatic

burner control units for the burner valves. The burner

valves open and the burners start.

Thanks to the relief line and auxiliary valve V2, the test

volume VP is discharged into a safe area or into the

combustion chamber.

TC 4

PZ

z

p

u

2

V2

V

P

DG

V1

p

u

p

V3

TC 4

1 2 3 4 5 6 7 8 9 10 1112 13

PZ

V2

V3

OK

V1

L1(+)

N(-)

TC · Edition 08.17 16

Application

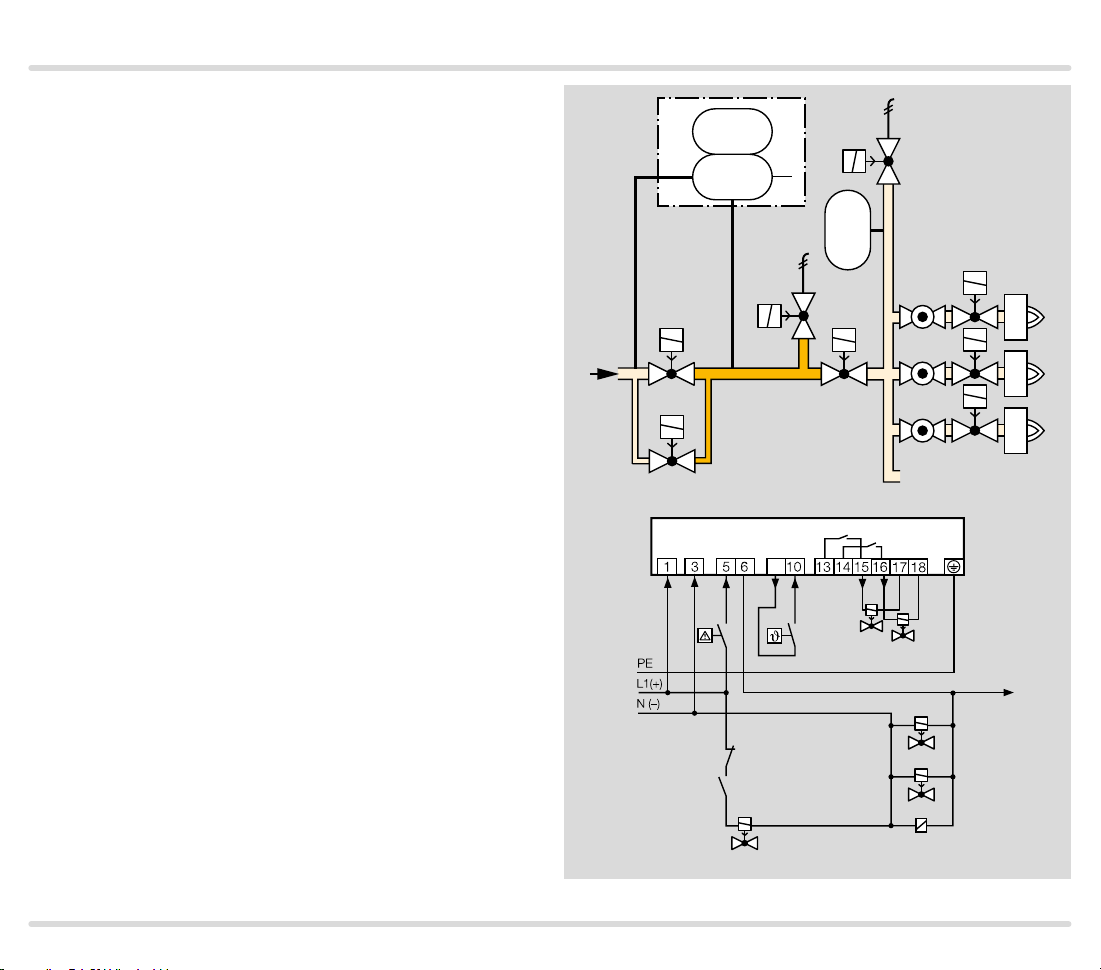

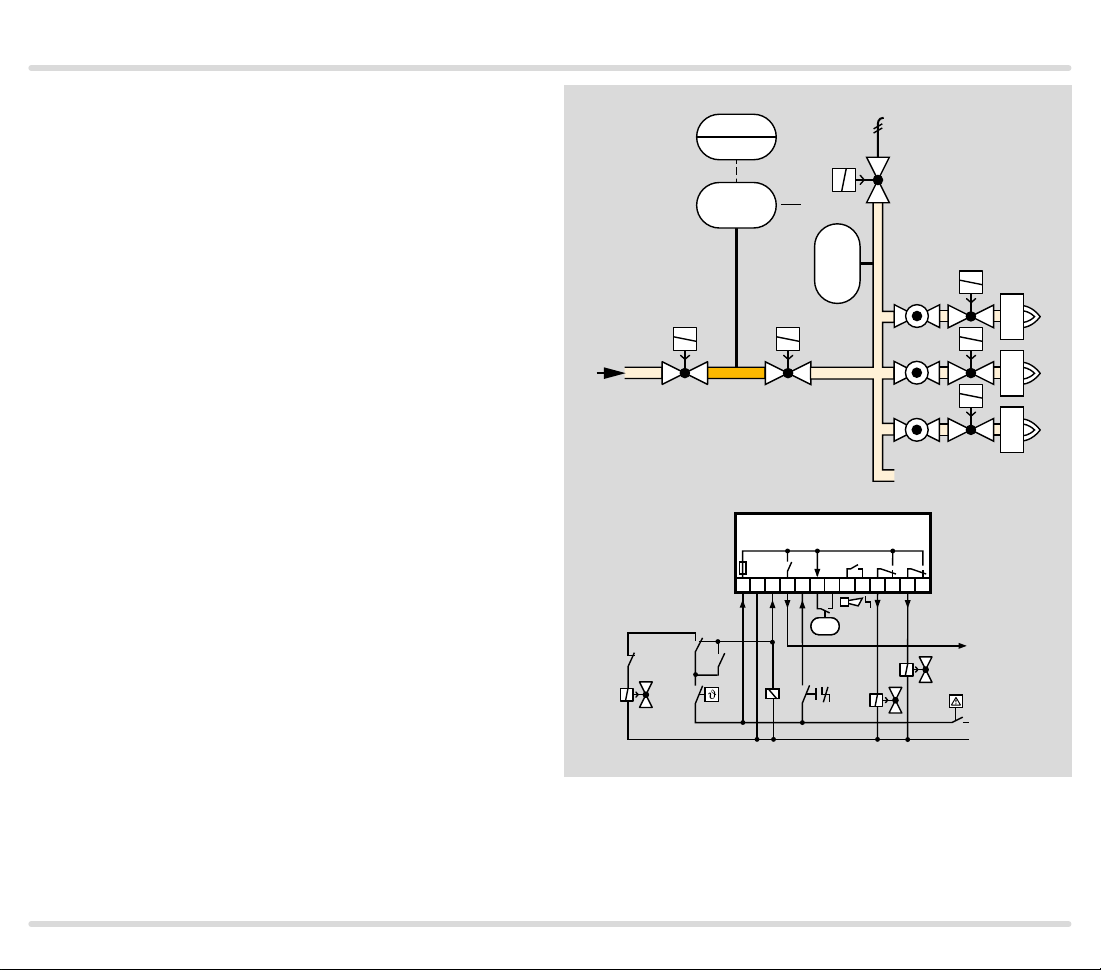

1.1.11

TC 4 in a multiple burner sy stem with sever al valves

installed in series

V1 and V2: quick or slow opening valves with start rate.

Tightness control TC 4 checks the central shut-off valve

V1, the gas solenoid valve V2 and the pipe between

these valves for tightness.

Valve V2 can only be checked for tightness when the

pressure downstream of V2 approximately corresponds

to the atmospheric pressure. The gas solenoid valve

VAS and the pressure switch DG

are used to relieve

VAS

the pressure. The pressure switch must be adjusted in

such a way so that enough pressure is relieved and no

air can get into the pipework.

After the thermostat /start-up signal ϑ has been applied,

first DG

is checked. If the pressure downstream of

VAS

V2 is correct, the VAS closes and the tightness test is

started.

Once the tightness test has been carried out success-

fully, TC 4 opens the main valves V1 and V2 with the

OK enable signal and enables the downstream burner

control units.

TC 4

DG

PZ

p

u

2

PZ

V1 V2

p

p

u

z

V

P

VAS

VAS

DG

TC 4

1 2 3 4 5 6 7 8 9 10 1112 13

k1

DG

VAS

VAS

k1

K1

PZ

V2

V1

OK

L1(+)

N(-)

TC · Edition 08.17 17

Loading...

Loading...