62-2016-07

TB7600 Series Communicating

TB7600 Series

Thermostat

TB7600 Series

Thermostat with

Occupancy Sensor

RTU/Heat Pump Thermostats

FOR COMMERCIAL HVAC APPLICATIONS

INSTALLATION INSTRUCTIONS

APPLICATION

The TB7600 Series PI thermostat family is specifically

designed for single stage and multi-stage control of heating/

cooling equipment such as rooftop and self-contained units.

The TB7600 Series are communicating thermostats with

models available in BACnet

mesh protocols and can be easily integrated into a WEBs-AX

building automation system based on the NiagaraAX

platform. The product features an intuitive, menu-driven,

back-lit LCD display, which walks users through the

programming steps, making the process extremely simple.

Accurate temperature control is achieved due to the product’s

PI time proportional control algorithm, which virtually

eliminates temperature offset associated with traditional,

differential-based thermostats.

Depending on the model, up to three remote sensor inputs

are available. All models contain a SPST auxiliary switch,

economizer function and a discharge air sensor input. For more advanced applications, an economizer control logic has

been integrated onto the thermostat for use with proportional damper economizer actuators.

Thermostats equipped with an occupancy sensor cover provide advanced active occupancy logic, which will

automatically switch occupancy levels from Occupied to Unoccupied as required by local activity being present or not.

This advanced occupancy functionality provides advantageous energy savings during occupied hours without

sacrificing occupant comfort. All thermostats are PIR ready and can be ordered with or without Honeywell occupancy

sensor. The occupancy sensor cover is available to order separately if a PIR is needed at a later time.

which can be used to control lighting or disable the

® MS/TP and ZigBee® wireless

®

FEATURES

• Available in BACnet MS/TP and ZigBee wireless protocols

• Backlit LCD display with dedicated function menu keys for simple operation

• Built in default profile set-up for easier start up and commissioning

• Fully integrated advanced occupancy functionality with a PIR accessory cover on some models

• Non-volatile EEPROM memory prevents loss of parameters during power outage

• Programmable smart fan operation can provide energy savings during night mode

• Password protection to minimize parameter tampering

• Three levels of keypad lockout to limit access to change user parameters such as setpoints, system mode,

etc.

• Gas/oil or electric system compatibility for all type of applications

• SPST auxiliary output can be used for lighting and/or economizer override

• 0 to 10 Vdc economizer output for more retrofit oppor tunities

— Built in dry bulb economizer logic using outdoor temperature sensor

— Input for supply/mixed air temperature sensor

• Support single and two stages heat pump with one auxiliary heat stage

TB7600 SERIES COMMUNICATING RTU/HEAT PUMP THERMOSTATS

• Remote indoor averaging sensing with 2, 3, 4, 9 or 16 sensors

• Remote discharge air sensor input

• Automatic frost protection to prevents costly freeze damage

• Anti short cycle and minimum on/off run time protection to reduce wear and maximizes life span of

mechanical equipment

• Two programmable digital inputs for added flexibility can be use to monitor filter status, activate a remote

temporary occupancy switch, and/or used as a general purpose service indicator

• 7 day programmable models, 2 or 4 events for use in non-networked applications*

• Six hour reserve prevents the need to reprogram day/time on programmable models after a power outage

Heat Pump Model Specific Features

• Selectable single or dual stage compressor stages

• High balance point locks out auxiliary heating when outside air temperature is above set value, low balance

point locks out heat pump compressor operation when outside air temperature is below the set value

• Comfort/economy mode maximizes heat pump use before turning on auxiliary heating

• Compressor/auxiliary interlock adds flexibility by locking out heat pump operation during auxiliary heating

to prevent high pressure trip when the coil is downstream of the auxiliary heat source

* Use programmable models only when installing as standalone thermostats that may eventually be added to a WEBs-

AX network. When a programmable thermostat is added to a network, schedules should be applied through the WEBStation-AX.

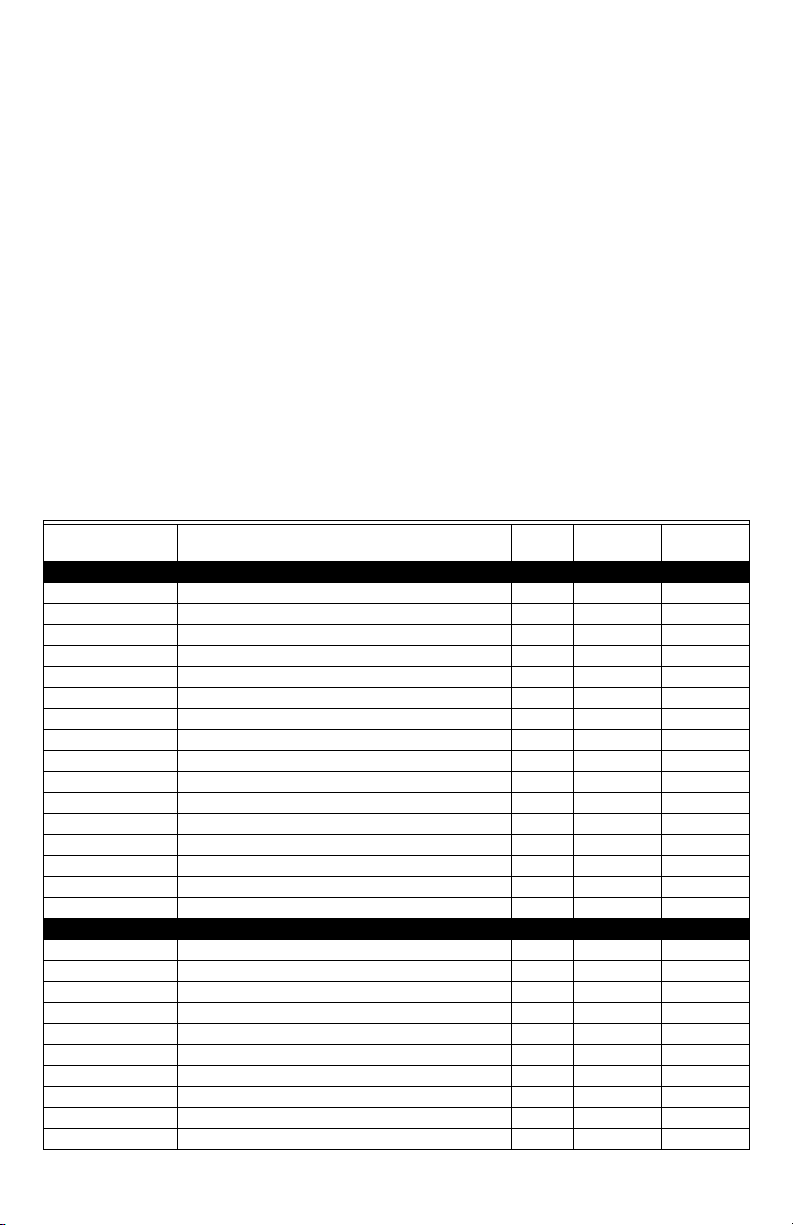

TB7600 Series Model Selection

Occupancy

Product Number Description Outputs Scheduling

BACnet Models

TB7600A5014B Single Stage RTU 1H/1C No

TB7600A5514B Single Stage RTU 1H/1C No X

TB7600B5014B Multi-stage RTU 2H/2C No

TB7600B5514B Multi-stage RTU 2H/2C No X

TB7600H5014B Heat Pump 3H/2C No

TB7600H5514B Heat Pump 3H/2C No X

TB7605B5014B Economizer RTU 2H/2C No

TB7605B5514B Economizer RTU 2H/2C No X

TB7652A5014B Single Stage RTU 1H/1C Yes

TB7652A5514B Single Stage RTU 1H/1C Yes X

TB7652B5014B Multi-stage RTU 2H/2C Yes

TB7652B5514B Multi-stage RTU 2H/2C Yes X

TB7652H5014B Heat Pump 3H/2C Yes

TB7652H5514B Heat Pump 3H/2C Yes X

TB7656B5014B Economizer RTU 2H/2C Yes

TB7656B5514B Economizer RTU 2H/2C Yes X

Wireless Models

TB7600A5014W Single Stage RTU 1H/1C No

TB7600A5514W Single Stage RTU 1H/1C No X

TB7600B5014W Multi-stage RTU 2H/2C No

TB7600B5514W Multi-stage RTU 2H/2C No X

TB7600H5014W Heat Pump 3H/2C No

TB7600H5514W Heat Pump 3H/2C No X

TB7605B5014W Economizer RTU 2H/2C No

TB7605B5514W Economizer RTU 2H/2C No X

TB7652A5014W Single Stage RTU 1H/1C Yes

TB7652A5514W Single Stage RTU 1H/1C Yes X

1

Sensor

2

62-2016—07 2

TB7600 SERIES COMMUNICATING RTU/HEAT PUMP THERMOSTATS

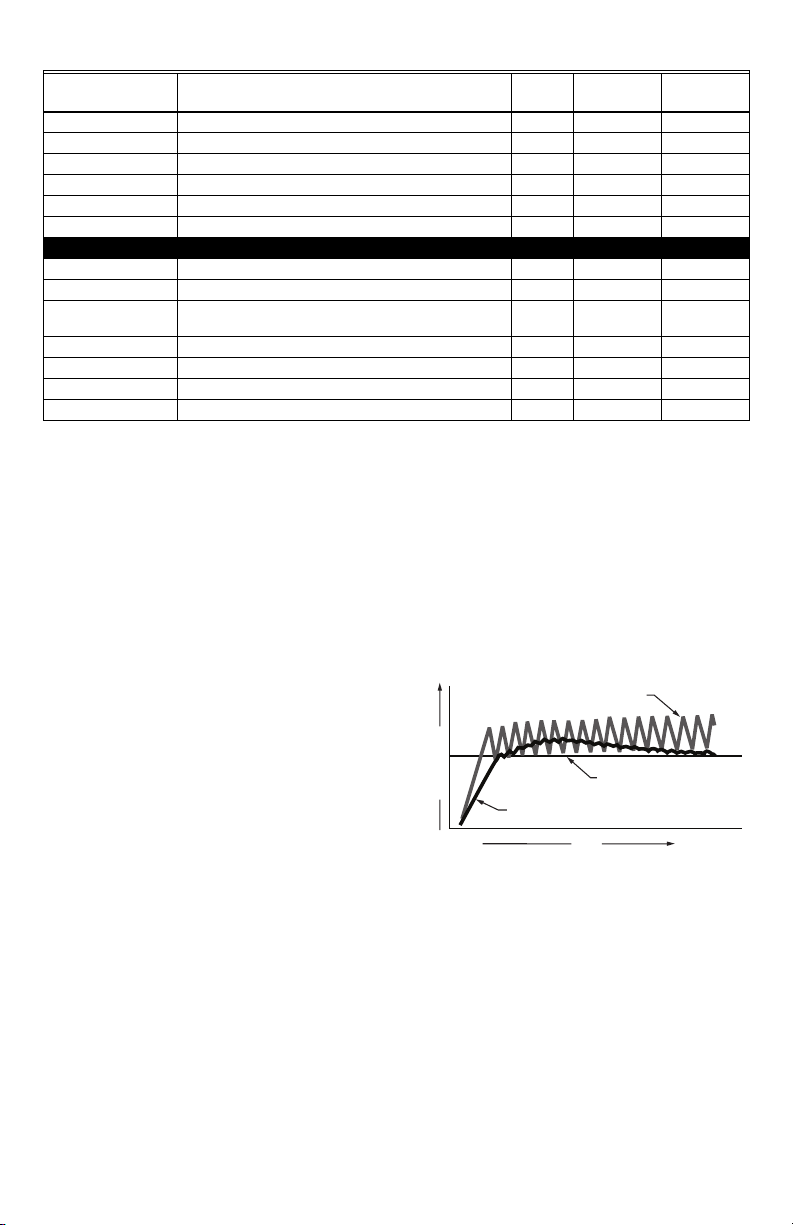

ON/OFF THERMOSTATS WASTE ENERGY

SETPOINT

(COMFORT TEMPERATURE)

TIME

PI ELECTRONIC CONTROLS DO NOT WASTE ENERGY

TEMPERATURE

M16927

Fig. 1. On/Off mechanical control vs.

PI electronic control.

Product Number Description Outputs Scheduling

1

Sensor

2

Occupancy

TB7652B5014W Multi-stage RTU 2H/2C Yes

TB7652B5514W Multi-stage RTU 2H/2C Yes X

TB7652H5014W Heat Pump 3H/2C Yes

TB7652H5514W Heat Pump 3H/2C Yes X

TB7656B5014W Economizer RTU 2H/2C Yes

TB7656B5514W Economizer RTU 2H/2C Yes X

Accessories

TB-PIR-RTU RTU Occupancy Sensor Cover

TB-RA-1014 Wireless Remote Antenna Base

TB-RP5000W Wireless Repeater for TB7XXX Series Wireless

Thermostats

TBST-5014W ZigBee Wireless Survey Toolkit

TB-VWG-APP-1014 TB7XXX Series Wireless Communication Card

TB-WALL-1014 Room Sensor 10K NTC Type 2

TB-WALLOVR-1014 Room Sensor with Override 10K NTC Type 2

1Use programmable models only when installing as standalone thermostats that may eventually be added to a WEBs-

AX network. When a programmable thermostat is added to a network, schedules should be applied through the WEBStation-AX.

2Thermostats ordered without an occupancy sensor cover can be retrofitted with an occupancy sensor cover later if

needed.

More Information

We recommend downloading the appropriate integration reference document (wireless or BACnet) and if installing

thermostats with occupancy sensor covers, then also downloading the PIR Application Guide before you begin

installation. All documentation is available on http://customer.honeywell.com.

— BACnet Integration Manual for TB7600 Series Thermostats (Form No. 63-4523)

— Wireless Installation & Integration Reference Guide for TB7200, TB7300, and TB7600 Thermostats

(Form No. 63-4522)

— PIR Application Guide for TB7600 Series Thermostats (Form No. 63-4525)

— Sensors Product Overview Brochure (Form No. 63-9285) for a complete listing of compatible sensors.

Theory of Operation

The TB7600 uses a proprietary adaptive logic algorithm to

control the space temperature. This algorithm controls the

heating/air conditioning system to minimize overshoot while still

providing comfort. It provides exceptional accuracy due to its

unique PI time proportioning control algorithm, which virtually

eliminates temperature offset associated with traditional,

differential-based on/off thermostats.

INSTALLATION AND WIRING

Mounting Locations

• Do not install on an outside wall.

• Must be installed away from any heat source.

• Should not be installed near an air discharge grill.

• Should not be mounted in direct sun radiation.

• Nothing must restrain vertical air circulation to the thermostat.

• Wall surface must be flat and clean.

IMPORTANT

• If replacing an old thermostat, label the wires before removal of the old thermostat.

3 62-2016—07

TB7600 SERIES COMMUNICATING RTU/HEAT PUMP THERMOSTATS

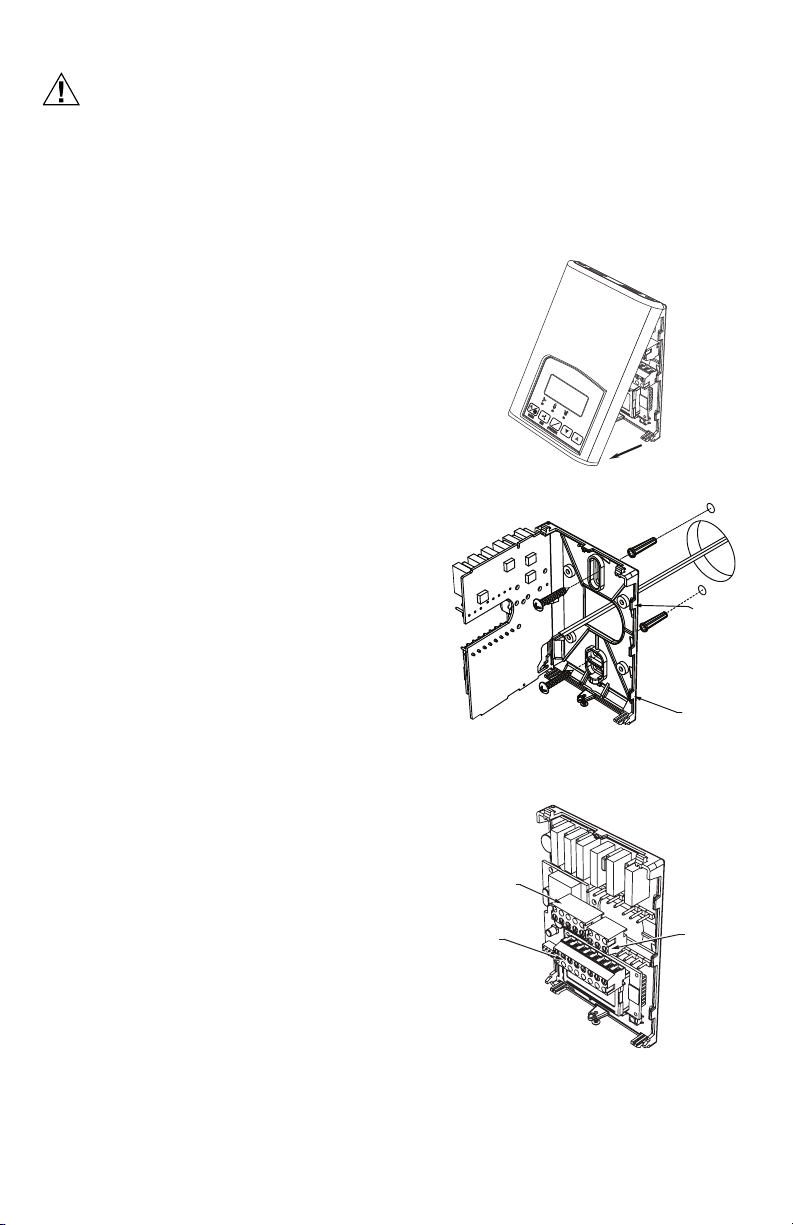

CAUTION

°C

°F

M21300

Fig. 2. Remove cover of thermostat

PCB

RETAINING

TABS

PCB

RETAINING

TABS

M21301

Fig. 3. Location of PCB retaining tabs and

mounting screws

Fig. 4. Terminal blocks

Electronic controls are static sensitive devices. Discharge yourself properly before manipulation and installing

the thermostat.

Short circuit or wrong wiring may permanently damage the thermostat or the equipment.

Anti-short cycling can be set to 0 minutes for equipment that has an anti-cycling timer. Do not set to 0 unless the

equipment has an internal anti-cycling timer or damage to equipment can occur.

All TB7600 Series thermostats are to be used only as operating controls. Whenever a control failure could lead

to personal injury and/or loss of property, it becomes the responsibility of the user to add safety devices and/

or alarm system to protect against such catastrophic failures.

Thermostat Installation

1. Open up by pulling on the bottom side of thermostat.

(Fig. 2)

2. Remove wiring terminals.

3. Open the thermostat PCB to the left by pressing the PCB

retaining tabs. (Fig. 3).

4. Pull cables 6 inches out of the wall.

5. Thread cable through the central hole of the base.

6. Align the base and mark the location of the two mounting

holes on the wall. Install proper side of base up.

7. Install anchors in the wall.

8. Insert screws through the mounting holes on each side of

the base and mount base on wall. (Fig. 3).

9. Gently swing back the circuit board back to the base and

push on it until the tabs lock it in place.

10. Strip each wire 1/4 inch.

11. Wire the terminals. See Table 1 for terminal descriptions

and wiring diagram.

12. Gently push back excess cable into hole.

13. Install wiring terminals in correct location (Fig. 4).

14. Reinstall the cover (top first).

15. Install security screw on the bottom, center of the thermo-

stat cover.

62-2016—07 4

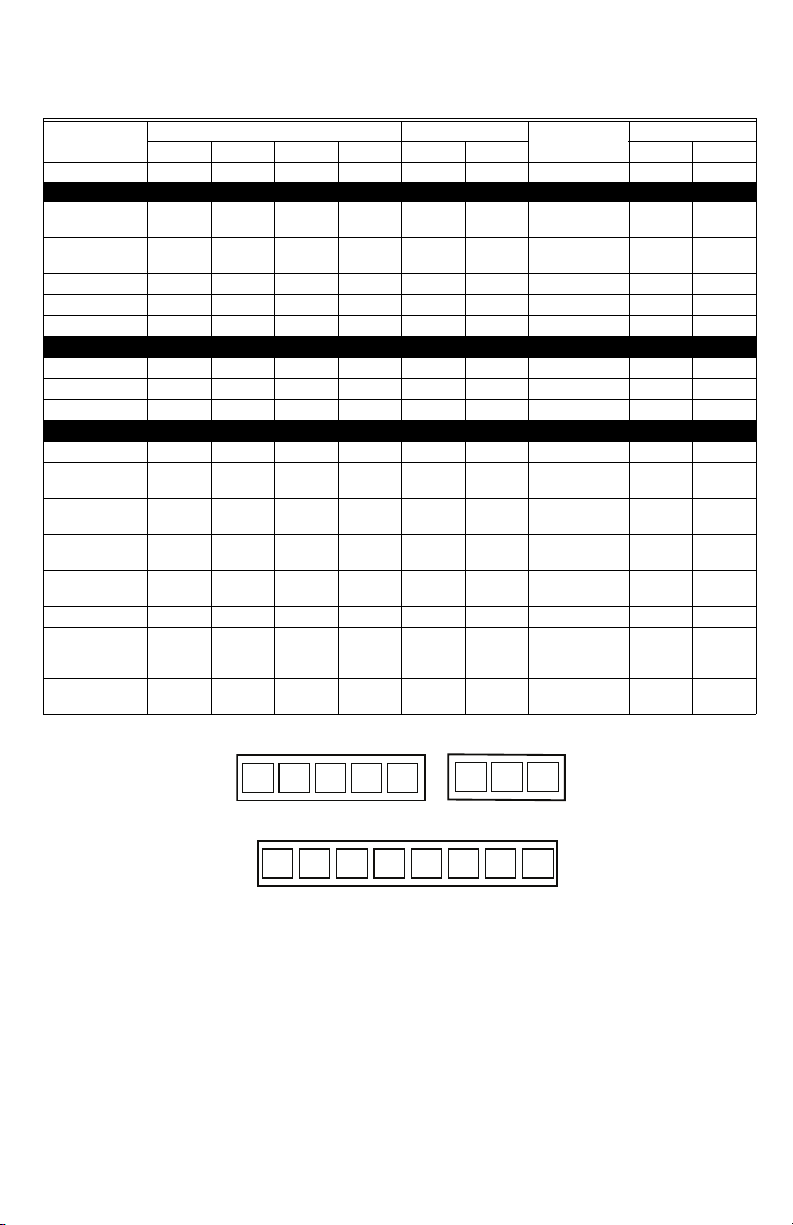

TOP LEFT

5 POLE

CONNECTOR

BOTTOM

8 POLE

CONNECTOR

TOP RIGHT

3 POLE

CONNECTOR

M21302

TB7600 SERIES COMMUNICATING RTU/HEAT PUMP THERMOSTATS

Wiring Identification and Screw Terminal Arrangement

Tab l e 1. Terminal identification

Multistage 1H/1C

Model Number

TB7656B TB7605B TB7652B TB7600B TB7652A TB7600A TB7652H TB7600H

Model Number

Programmable Yes No Yes No Yes No Programmable Yes No

Top left terminal block

1- Cool Stage 2 Y2 Y2 Y2 Y2 Blank Blank 1- Compressor

2- Cool Stage 1Y1Y1Y1Y1Y1Y12- Compressor

Stage 2

Stage 1

3- Fan GGGGGG3- Fan GG

4- 24 V - HotRCRCRCRCRCRC4- 24 V - HotRCRC

5- 24 V - ComCCCCCC5- 24 V - ComCC

Top right terminal block

6- RH RH RH RH RH RH RH 6- RH RH RH

7- Heat Stage 1 W1 W1 W1 W1 W1 W1 7- AUX Heat W1 W1

8- Heat Stage 2 W2 W2 W2 W2 Blank Blank 8- O/B O/B O/B

Bottom terminal block

9- Econo EC EC Blank Blank Blank Blank 9- Not Used Blank Blank

10- Auxiliary

Output

AuxAuxAuxAuxAuxAux10- Auxiliary

Output

11- Digital Input 1DI1 DI1 D I1 DI1 DI1 DI1 11 - Digital Input 1DI1 DI1

12- Digital Input 2DI2 DI2 D I2 DI2 DI2 DI2 12 - Digital Input 2DI2 DI2

Heat Pump

Y2 Y2

Y1 Y1

Aux Aux

13- Remote

Sensor

RS RS RS RS RS RS 13- Remote

Sensor

RS RS

14- Scom S COM S COM S COM S COM S COM S COM 14- Scom S COM S COM

15- Remote

Outdoor

Sensor

16- Mixed Air

Sensor

OS OS OS OS OS OS 15- Remote

MS MS MS MS MS MS 16- Mixed Air

5 POLE LEFT TOP CONNECTOR

Y1

Y2

EC

G

AU

RC

8 POLE BOTOM CONNECTOR

D1 D2

3 POLE LEFT TOP CONNECTOR

C

RS

Scom

RH W1

OS

Outdoor

Sensor

Sensor

W2

O/B

MS

M16928

OS OS

MS MS

Fig. 5. Screw terminal arrangement

NOTES:

— If auxiliary output is used to toggle occupancy of the electronic control card inside the equipment, configure

the relay parameter (Aux cont) to the N.O. setting. A second relay can be added for additional functionality

of the occupancy output.

— If the same power source is used for the heating stages, install jumper across RC and RH. Maximum cur-

rent is 2.0 amps.

— Economizer output uses a half bridge rectifier. Reference of the control signal is the common of the power

supply of the thermostat (terminal C).

— Electromechanical contacts are to be used with the digital inputs. Electronic triacs cannot be used as mean

of switching for the input. The switched leg to the input for the input to activate is terminal C (common).

— The transformer of the unit provides power to the thermostat and the additional loads that will be wired to

the thermostat.

5 62-2016—07

TB7600 SERIES COMMUNICATING RTU/HEAT PUMP THERMOSTATS

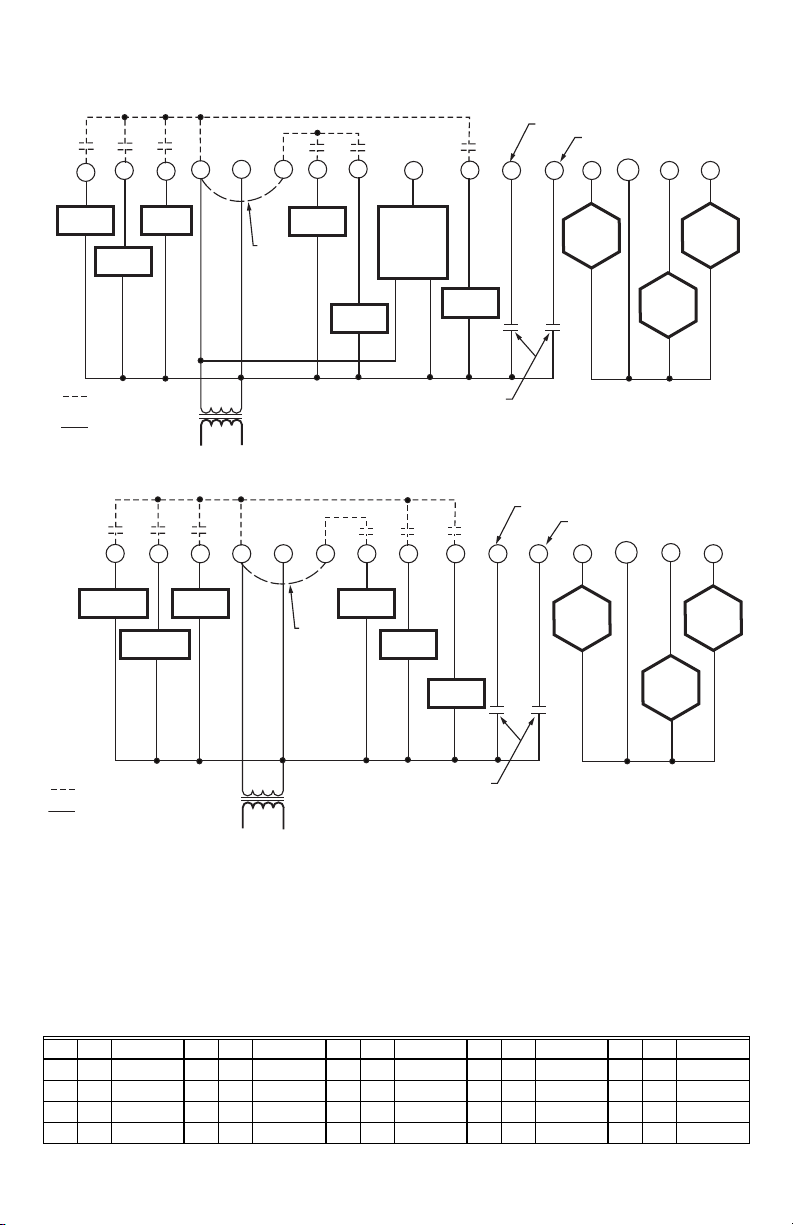

Y2

Y1

G

RC

C

RH

W1

JUMPER

J1

COOL

STAGE 2

COOL

STAGE 1

FAN

HEAT

STAGE 1

HEAT

STAGE 2

0-10 VDC

24V

COM

AUXILIARY

OUTPUT

W2

EC

AU

DI1

DI2

DIGITAL INPUT #1

DIGITAL INPUT #2

RS

Scom

OS

MS

REMOTE

MIXED AIR

SENSOR

REMOTE

OUTDOOR

SENSOR

REMOTE

ROOM

SENSOR

FIELD CONTACTS

THERMOSTAT

INTERNAL WIRING

SYSTEM WIRING

M16929

24 VAC

T1

ECONOMIZER

ACTUATOR

Y2

Y1

G

RC

C

RH

W1

JUMPER

J1

COMPRESSOR

STAGE 2

COMPRESSOR

STAGE 1

FAN

AUXILIARY

HEAT

REVERSING

VALV E

AUXILIARY

OUTPUT

O/B

AU

DI1

DI2

DIGITAL INPUT #1

DIGITAL INPUT #2

RS

Scom

OS

MS

REMOTE

MIXED AIR

SENSOR

REMOTE

OUTDOOR

SENSOR

REMOTE

ROOM

SENSOR

THERMOSTAT INTERNAL WIRING

SYSTEM WIRING

24 VAC

T1

FIELD CONTACTS

M16930

Detailed Wiring Diagrams for Selected Models

Fig. 6. TB7656B5x00(x) 2 Heat/2 Cool/Economizer/Programmable

Fig. 7. TB7652H5x00(x) Heat pump/Programmable

Sensor Wiring for all Thermostat Models

Remote mount outdoor temperature sensors must be10 Kohm NTC @ 77 F.

Remote sensors can be used for:

• Various averaging combinations (3 thermistors with 2 dip switches are provided with each sensor)

• Optional occupancy led

• Optional override key

Table 2. Temperature vs. Resistance for 10 Kohm NTC thermistor (R

ºF ºC Kohm ºF ºC Kohm ºF ºC Kohm ºF ºC Kohm ºF ºC Kohm

-40 -40 324.3197 -4 -20 94.5149 32 0 32.1910 68 20 12.4601 104 40 5.3467

-31 -35 234.4009 5 -15 71.2430 41 5 25.1119 77 25 10.0000 113 45 4.3881

-22 -30 171.3474 14 -10 54.1988 50 10 19.7390 86 30 8.0694 122 50 3.6202

= 10KW±3%, B

25°C

25/85°C

-13 -25 126.6109 23 -5 41.5956 59 15 15.6286 95 35 6.5499 131 55 3.0016

62-2016—07 6

= 3975K±1.5%)

TB7600 SERIES COMMUNICATING RTU/HEAT PUMP THERMOSTATS

Scom

RS

AU

C

D1

Scom

RS

AUX

C

DI

Scom

RS

TB7600 SERIES

THERMOSTAT

TB7600 SERIES

THERMOSTAT

TB-WALLOVR-1014 TB-WALL-1014

DIP SWITCHES

S1 = ON S2 = ON

DIP SWITCHES

S2-1 = ON S2-2 = ON

ON

12

S2

DIP SWITCHES

S2-1 = ON S2-2 = ON

ON

12

S2

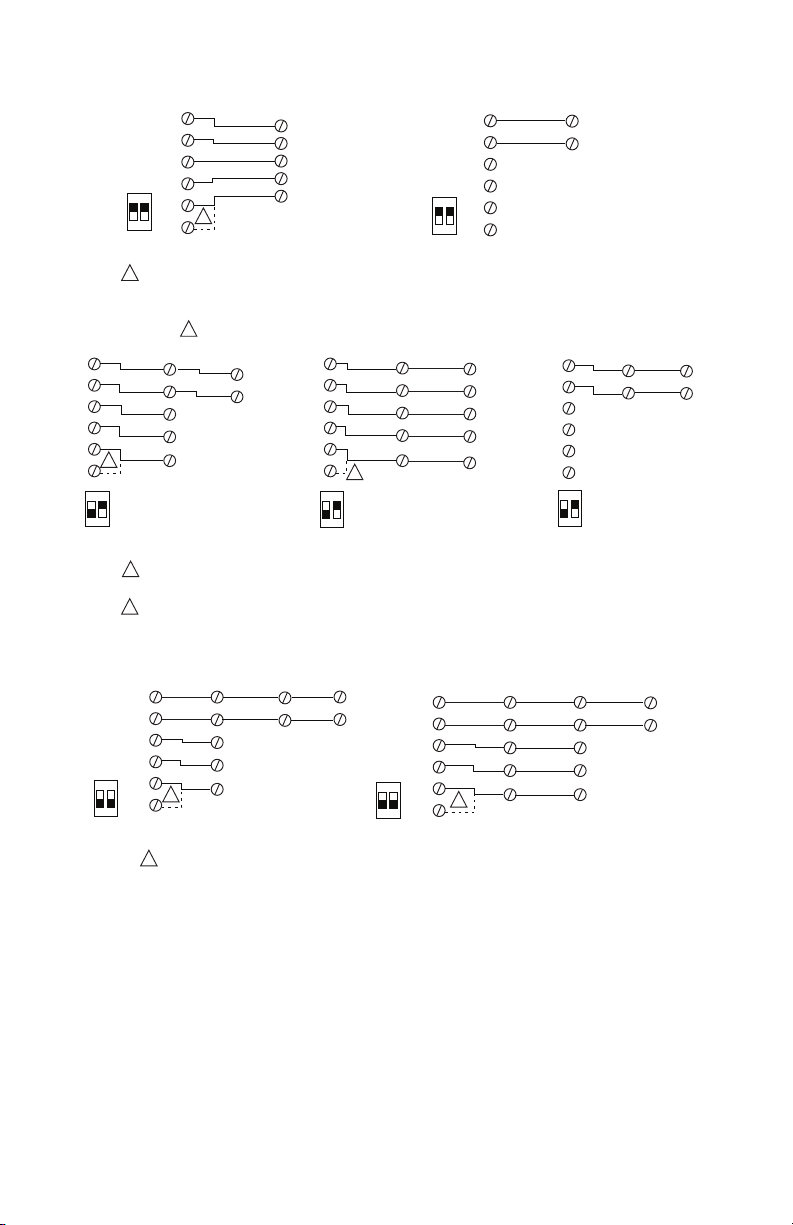

REMOTE WIRING 1 SENSOR

M16996

DIP SWITCHES

S1 = ON S2 = ON

D2

Scom

RS

AU

C

D1

D2

EITHER D1 OR D2 CAN BE USED ON THE TB7600 FOR CONNECTION FROM THE DI ON THE WALL MODULE WITH OVERRIDE.

1

1

Fig. 8. Wiring example of single remote wall mounted room sensor

REMOTE WIRING 2 SENSORS

TB7600 SERIES

THERMOSTAT

Scom

RS

AU

C

D1

2

D2

S2

ON

12

DIP SWITCHES

S2-1 = OFF

S2-2 = ON

1

Scom

AUX

TB-WALL-1014

RS

DIP SWITCHES

S1 = OFF

S2 = ON

C

DI

TB-WALLOVR-1014 TB-WALL-1014

DIP SWITCHES

S1 = OFF

S2 = ON

TB-WALL-1014 AND TB-WALLOVR-1014 CAN BE MIXED AND MATCHED

1

TB-WALL-1014 AND TB-WALLOVR-1014 ARE TO BE WIRED IN PARALLELL

ENSURE THE DIP SWITCH SETTING IS CORRECT IN EACH REMOTE SENSOR

EITHER D1 OR D2 CAN BE USED ON THE TB7600 FOR CONNECTION FROM THE DI ON THE WALL MODULE WITH OVERRIDE.

2

Scom

RS

TB7600 SERIES

THERMOSTAT

Scom

RS

AU

C

D1

D2

S2

ON

12

DIP SWITCHES

S2-1 = OFF

S2-2 = ON

TB-WALLOVR-1014

Scom

RS

AUX

C

DI

2

DIP SWITCHES

S1 = OFF

S2 = ON

TB-WALLOVR-1014

Scom

RS

AUX

C

DI

DIP SWITCHES

S1 = OFF

S2 = ON

TB7600 SERIES

THERMOSTAT

Scom

RS

AU

C

D1

D2

S2

ON

12

DIP SWITCHES

S2-1 = OFF

S2-2 = ON

Scom

RS

DIP SWITCHES

S1 = OFF

S2 = ON

M16997A

Fig. 9. Wiring examples of two remote wall mounted room sensors for averaging applications

REMOTE WIRING 3 SENSORS

TB7600 SERIES

THERMOSTAT

Scom

RS

AU

C

S2

D1

ON

12

DIP SWITCHES

S2-1 = OFF

S2-2 = OFF

1

D2

EITHER D1 OR D2 CAN BE USED ON THE TB7600 FOR CONNECTION FROM THE DI ON THE WALL MODULE WITH OVERRIDE.

1

TB-WALLOVR-1014

Scom

RS

AUX

C

DI

DIP SWITCHES

S1 = OFF

S2 = OFF

TB-WALL-1014

Scom

RS

DIP SWITCHES

S1 = OFF

S2 = OFF

TB-WALL-1014

Scom

RS

S2

DIP SWITCHES

S2-1 = OFF

S2-2 = OFF

TB7600 SERIES

THERMOSTAT

ON

12

Scom

RS

AU

C

D1

D2

TB-WALLOVR-1014

Scom

1

RS

AUX

C

DI

DIP SWITCHES

S1 = OFF

S2 = OFF

TB-WALLOVR-1014

Scom

RS

AUX

C

DI

TB-WALL-1014

DIP SWITCHES

S1 = OFF

S2 = OFF

Fig. 10. Wiring examples of three remote wall mounted room sensors for averaging applications

TB-WALL-1014

DIP SWITCHES

S1 = OFF

S2 = ON

Scom

RS

M16998

Scom

RS

7 62-2016—07

TB7600 SERIES COMMUNICATING RTU/HEAT PUMP THERMOSTATS

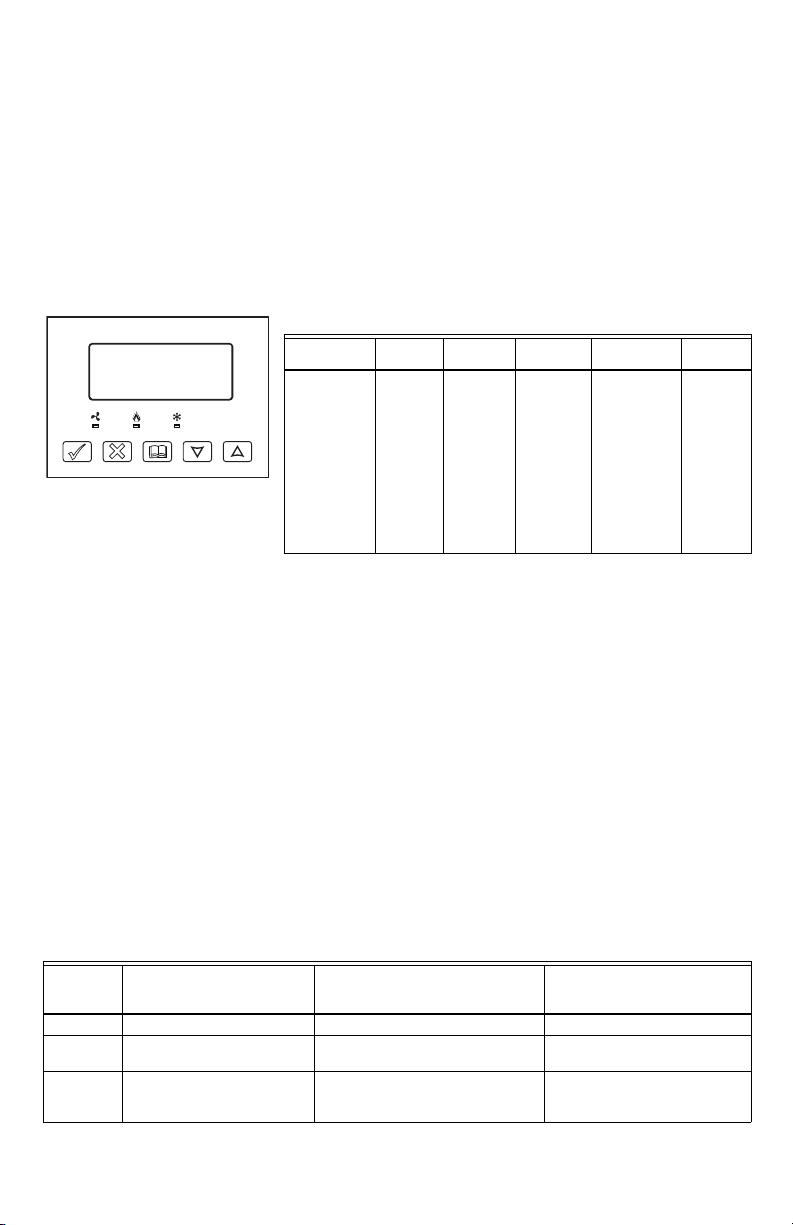

Fig. 11. Heat pump, multistage

and single stage models buttons

and display

THERMOSTAT USER INTERFACE

The thermostat features a two-line, eight-character display. There is a low-level backlit level that is always active and

can only be seen at night. To turn on the back light to high level, press any key on the front panel. The back lit display

will return to low level when the thermostat is left unattended for 45 seconds.

When left unattended, the thermostat has an auto scrolling display that shows the actual status of the system. Use the

MenuScro in the configuration menu to lockout the scrolling display and to only present the room temperature and

conditional outdoor temperature to the user. With this option enabled, no local status is given on the system mode or

occupancy.

Each item is scrolled one by one with the back lighting in low level mode. Pressing any key will cause the back light to

come on to high level. When left unattended for 10 seconds after changes are made, the display will resume automatic

status display scrolling.

Table 3. Sequence and possible display options

Room Temp

RoomTemp

x.x °C or°F

YES NO MENU

Manual scroll of each menu item is achieved by pressing the Ye s (scroll) key repetitively. The last item viewed will be

shown on the display for 30 seconds before returning to automatic scrolling. Temperature is automatically updated

when scrolling is held.

Outdoor air temperature display is only enabled when outdoor air temperature sensor is connected.

• A maximum range status display of 122 F (50 C) indicates a shorted sensor. Associated functions, such as mode

lockouts and economizer function are automatically disabled.

• A minimum range status -40 F (-40 C) is not displayed and indicates a opened sensor or a sensor not connected.

Associated functions, such as mode lockouts and economizer function are automatically disabled.

If alarms are detected, they will automatically be displayed at the end of the status display scroll. During an alar m

message display, the back lit screen will light up at the same time as the message and shut off during the rest of the

status display. Two alarms maximum can appear at any given time. The priority for the alarms is as follows:

• Frost ON: Indicates that the heating is energized by the low limit frost protection room temperature setpoint 42 F

(5.6 C)

• SetClock: Indicates that the clock needs to be reset. There has been a power failure which has lasted longer than 6

hours

• Service: Indicates that there is a service alarm as per one of the programmable digital input (DI1 or DI2)

• Filter: Indicates that the filters are dir ty as per one of the programmable digital input (DI1 or DI2)

• Fan lock: Indicates that the heating and cooling action are locked out due to a defective fan operation

Three status LEDs on the thermostat cover are used to indicate the status of the fan, a call for heat, or a call for cooling.

See Table 4 for more details.

LED

operation

Fan LED on When G Fan terminal operates When G Fan terminal operates When G Fan terminal operates

Heating

LED on

Cooling

LED on

Heat pump models

When Y1 and/or W1 terminal(s)

operate in heating mode

When Y1 terminal operate in

cooling mode

M16916

*Network value only

TB76xxH

>

Table 4. LED Status

Multistage and single stage models

TB7600A, TB7652A, TB7600B and

When W1 terminal operate in heating

mode

When Y1 terminal operate in cooling

mode

for the auto-scroll display

Clock

status

Monday

12.00 AM

>

Sys mode

auto

Sys mode

off

Sys mode

heat

Sys mode

cool

Sys mode

emergenc

TB7652B

System

mode

Schedule

>

status

Occupied Outdoor

Occupied

hold

Unoccup SetClock

Unoccup

hold

Override Fan lock

Outdoor

>

x.x °C or°F

Multistage economizer models

TB7605B and TB7656B

When W1 terminal operate in

heating mode

When Y1 terminal operate in

cooling mode and or economizer

output is in function

Tem p*

>

Service

Frost ON

Filter

Alarms

62-2016—07 8

TB7600 SERIES COMMUNICATING RTU/HEAT PUMP THERMOSTATS

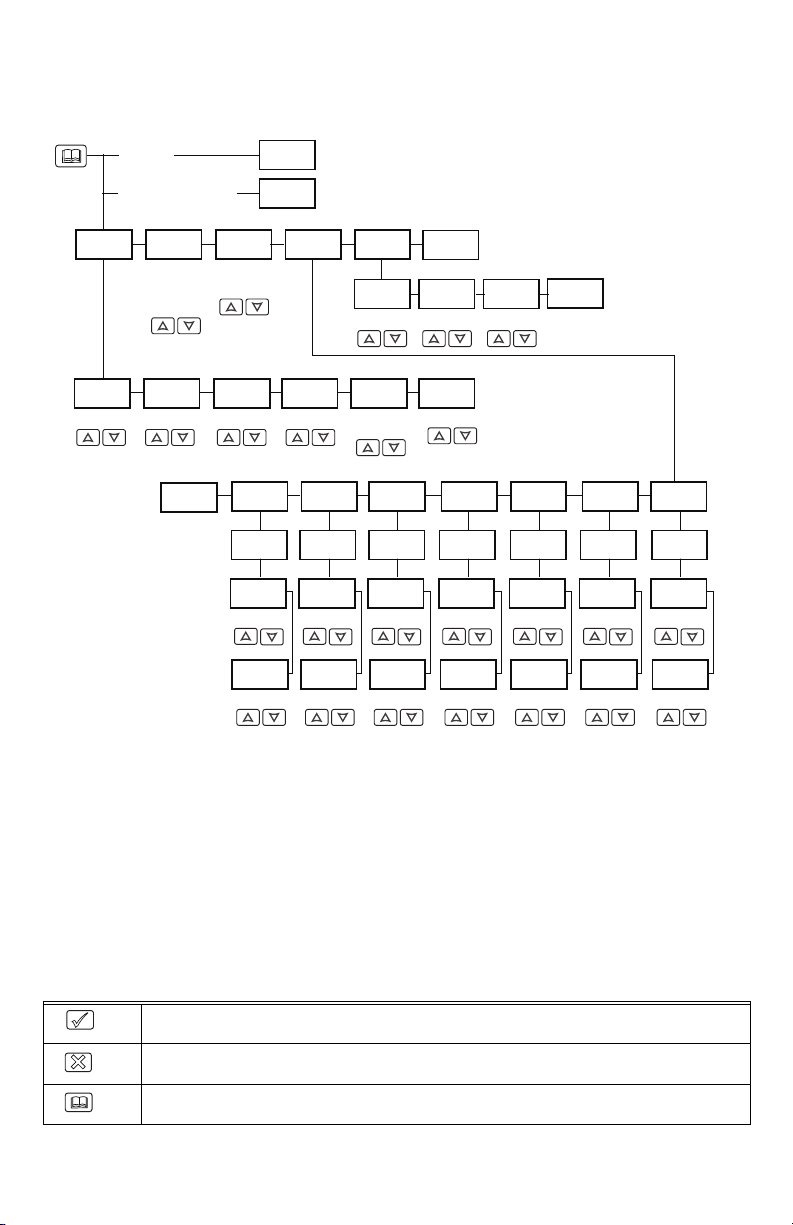

User menu flow chart

NOTE: Prompts may not all be present depending on model selected

FAN MODE

SET? Y/N

ON

SMART

AUTO

UNOCC CL

SET? Y/N

SUNDAY

SET? Y/N

OCCUPIED

DAY? Y/N

OCCUPIED

12:00 PM

UNOCCUP

12:00 PM

TIME

TIME

OVERRIDE

SCHD Y/N

CANCEL

OVRD Y/N

UNOCC HT

SET? Y/N

SCHEDULE

SET? Y/N

SATURDAY

SET? Y/N

OCCUPIED

DAY? Y/N

OCCUPIED

12:00 PM

TIME

UNOCCUP

12:00 PM

TIME

IF STATUS IS:

UNOCCUPIED

IF STATUS IS:

TEMPORARY OCCUPIED TIME

TEMPERAT

SET? Y/N

COOLING

SET? Y/N

TEMPERATURE TEMPERATURE TEMPERATURE TEMPERATURE

SYS MODE

SET? Y/N

OFF

EMERGENC

HEAT

COOL

AUTO

HEATING

SET? Y/N

EXIT

Y/N

CLOCK

SET? Y/N

TIME

SET? Y/N

°F/°C

SET? Y/N

EXIT

MENU Y/N

DAY

SET? Y/N

TIME DAY 12/24

EXIT

Y/N

°C

°F

FRIDAY

SET? Y/N

OCCUPIED

DAY? Y/N

OCCUPIED

12:00 PM

TIME

UNOCCUP

12:00 PM

TIME

THURSDAY

SET? Y/N

OCCUPIED

DAY? Y/N

OCCUPIED

12:00 PM

TIME

UNOCCUP

12:00 PM

TIME

12/24 HRS

SET? Y/N

WEDNESDA

SET? Y/N

OCCUPIED

DAY? Y/N

OCCUPIED

12:00 PM

TIME

UNOCCUP

12:00 PM

TIME

EXIT

Y/N

TUESDAY

SET? Y/N

OCCUPIED

DAY? Y/N

OCCUPIED

12:00 PM

TIME

UNOCCUP

12:00 PM

TIME

MONDAY

SET? Y/N

OCCUPIED

DAY? Y/N

OCCUPIED

12:00 PM

TIME

UNOCCUP

12:00 PM

TIME

M16931

User Control Options

The TB7600 Series thermostat features an intuitive, menu-driven, back-lit LCD display that walks users through the

programming steps, making the programming process extremely simple. This menu is typically accessed by the user to

modify system setting such as temperature or system mode, fan mode, etc.

It is possible to bring up the user menu at any time by pressing the MENU key. The status display automatically

resumes after exiting the user-programming menu.

If the user pauses at any given time during programming, Auto Help text is displayed to help and guide the user

through the usage and programming of the thermostat. When left unattended for 45 seconds, the display will resume

automatic status display scrolling.

User options are accessed and programmed using 5 keys on the thermostat cover and are described in Table 5.

Table 5. User Control with Thermostat Keys

The YES key is used to confirm a selection, to move onto the next menu item and to manually scroll

M16911

M16912

M16913

through the displayed information.

The NO key is used when you do not desire a parameter change, and to advance to the next menu

item. Can also be used to toggle between heating and cooling setpoints.

The MENU key is used to access the Main User Menu or exit the menu.

9 62-2016—07

Loading...

Loading...