Page 1

TRADELINE

T834C

Heating-Cooling Thermostat

Application

T834C Thermostats control 24 to 30 Vac single-stage heating-cooling systems. See Table 1 for specific models and

applications. An spdt mercury switch makes R to W on a temperature fall for heating, and R to Y on a temperature rise for cooling.

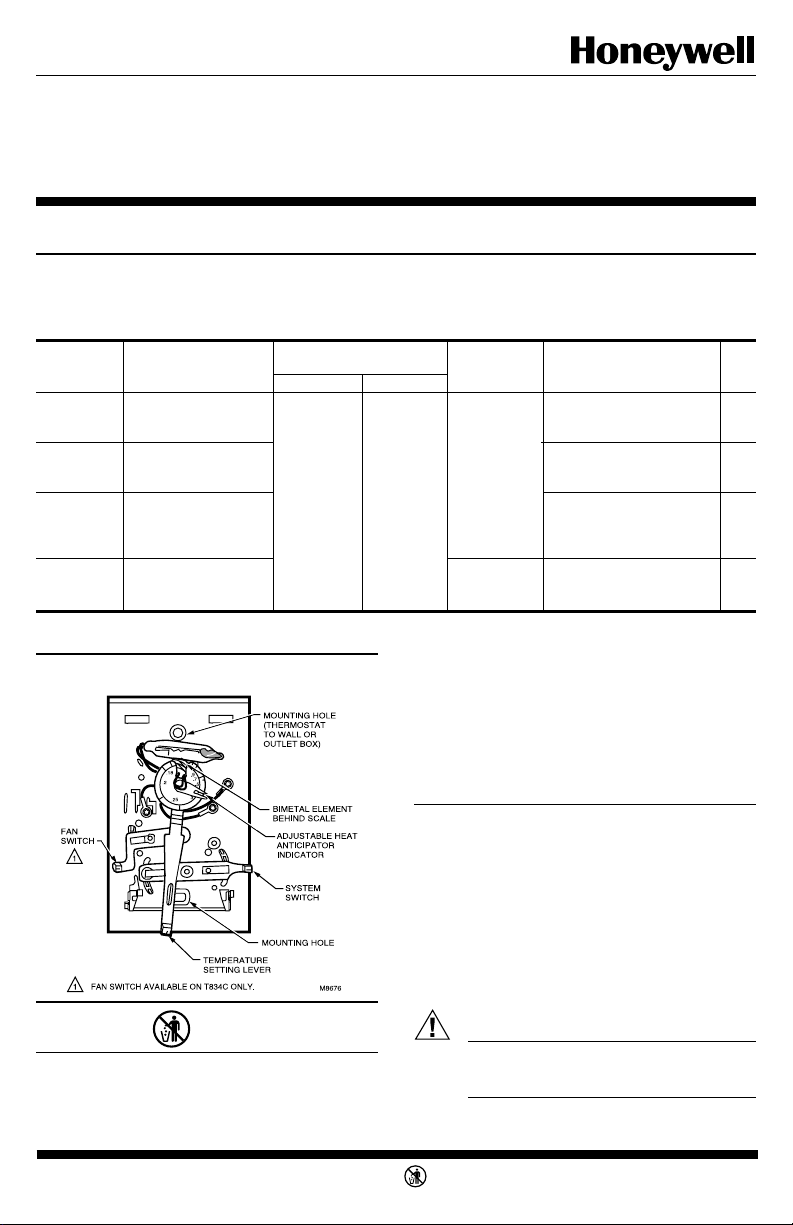

See Fig. 1.

TABLE 1—THERMOSTAT MODELS AND APPLICATIONS.

Model Switching Anticipator See

Number Application System Fan Range Comments Fig.

T834C1137 For use in standard HEAT-OFF- ON-AUTO 0.18 to 1.0A TRADELINE; Beige. 3

T834C1541 For use in gas- or SUPER TRADELINE; 4

T834C2267 For use in gas- or SUPER TRADELINE; 5

T834C2309 For use in standard 0.3 to 1.2A TRADELINE; Beige. 3

a

In electric heat applications without fan sequencers, jumper terminals 1 and 2 to control the fan from the thermostat during

heating.

Fig. 1—Internal view of T834C.

heating-cooling COOL

systems.

oil-fired, or central Beige.

electric heata systems.

oil-fired, single-stage Premier White.

heat pump or central (Jumper included.)

electric heata systems.

heating-cooling

systems.

structions regarding recycling and the proper disposal of this

control, or of an old control containing mercury in a sealed

tube.

1502.

Heat

Contact your local waste management authority for in-

If you have questions, call Honeywell Inc. at 1-800-468-

Recycling Notice

M3375

This control contains mercury in a sealed tube. Do not

place control in the trash at the end of its useful life.

If this control is replacing a control that contains mercury

in a sealed tube, do not place your old control in

the trash.

J. H. • Rev. 2-93 • • ©Honeywell Inc. 1993 • Form Number 69-0434—5

Installation

WHEN INSTALLING THIS PRODUCT...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the Instructions and on the

product to make sure the product is suitable for your applica-

tion.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided in these Instructions.

CAUTION

Disconnect power supply before beginning installation to prevent electrical shock or equipment

damage.

M3375

Page 2

LOCATION

Locate the thermostat about 5 ft. [1.5 m] above the floor

on an inside wall in an area with good air circulation at

average temperature.

Do not mount the thermostat where it can be affected by:

— drafts or dead spots behind doors or in corners.

— hot or cold air from ducts.

— radiant heat from the sun, fireplaces, or appliances.

— unheated (uncooled) areas behind the thermostat, such

as outside walls.

This thermostat is a precision instrument and was carefully adjusted at the factory. Handle it carefully.

MOUNTING AND WIRING

Disconnect power supply before beginning installation to

prevent electrical shock or equipment damage.

All wiring must comply with local codes and ordinances.

The T834C can be mounted directly to a wall or vertical

outlet box. Use Honeywell part no. 193121A (beige) or

202689A (gray) Mounting Plate Assembly (order separately) to mount on horizontal outlet box or cover marks left

by old thermostat. If mounting plate assembly is used, review

instructions provided with assembly before wiring and mounting thermostat. To wire and mount thermostat:

1. In replacement applications, check the existing thermostat wires for cracked or frayed insulation. Replace any

wires in poor condition. If the wire is plastered into the wall,

make a hole next to the wires and loosen the wires so that they

can be pushed back into the wall later.

2. In new installations, run wiring (if necessary) to the

thermostat location.

3. Set the adjustable heat anticipator indicator to match

the current draw of the primary heating control or as recommended by the equipment manufacturer (see Heat Anticipator Setting).

4. Connect the wires to the terminals on the back of the

thermostat. See Figs. 3-5 for internal schematic and typical

hookup diagrams. If using electric heat-compatible thermostat in central electric heat applications, jumper terminals 1

and 2 to control fan operation from the thermostat during

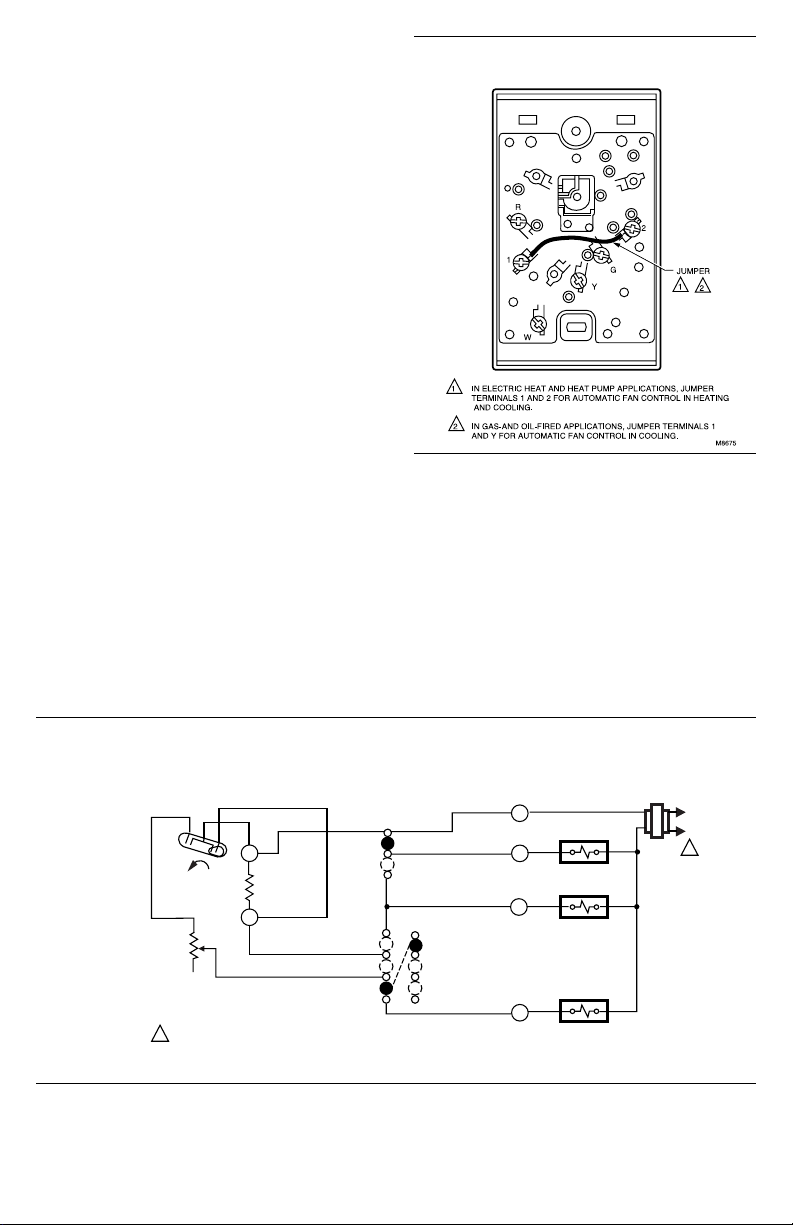

heating. See Fig. 2.

Fig. 2—Jumpering thermostat terminals to control

fan operation.

5. Remove thermostat cover by pulling outward on bottom edge until it snaps free of the thermostat base. Carefully

remove and discard the foam plastic shipping insert. This

insert protects the switch and bimetal assembly during shipping.

6. Push excess wire back through the hole and plug any

opening with insulation to prevent drafts that may affect

thermostat performance.

7. Fasten the thermostat to the wall or outlet box with a

screw through the top mounting hole. Adjust the thermostat

so that it is approximately level and fasten the second screw

through the bottom mounting hole. Do not tighten.

8. Exactly level the thermostat using a spirit level or

plumb line. Tighten the mounting screws.

Fig. 3—Internal schematic and typical hookup for T834C1137 and T834C2308 in a standard heating-cooling

system.

M1119A

L1

(HOT)

L2

1

FAN SWITCH

H1

H1

ANTICIPATOR

1

C1

TEMP. FALL

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

C1

ANTICIPATOR

AUTO

SYSTEM

SWITCH

COOL

OFF

HEAT

ON

HEAT

OFF

COOL

R

G

Y

W

FAN RELAY

COMPRESSOR

CONTACTOR

HEAT RELAY

2

Page 3

Fig. 4—Internal schematic and typical hookup for T834C1541 in gas- or oil-fired, or central electric heat system.

1

M2690

L1

(HOT)

L2

R

FAN

SWITCH

H1

H1

ANTICIPATOR

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

2

IN ELECTRIC HEAT OR SINGLE-STAGE HEAT PUMP APPLICATION, JUMPER 1 AND 2 FOR AUTO FAN IN HEATING AND COOLING.

Fig. 5—Internal schematic and typical hookup for T834C2267 in gas- or oil-fired, single-stage heat pump or

central electric heat system.

TEMP. FALL

C1

C1

ANTICIPATOR

ON

AUTO

SYSTEM

SWITCH

COOL

OFF

HEAT

2

HEAT

OFF

COOL

G

1

Y

2

W

FAN RELAY

COMPRESSOR

CONTACTOR

HEAT RELAY

1

FAN

SWITCH

AUTO

ON

H1

H1

ANTICIPATOR

1

2

3

4

C1

TEMP. FALL

C1

ANTICIPATOR

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

JUMPER 1-2 FOR AUTO FAN IN HEATING AND COOLING (ELECTRIC HEAT AND SINGLE STAGE HEAT PUMP SYSTEMS).

JUMPER 1-Y FOR AUTO FAN IN COOLING ONLY.

JUMPER W-Y FOR SINGLE-STAGE HEAT PUMP APPLICATIONS.

SYSTEM

SWITCH

COOL

OFF

HEAT

HEAT

OFF

COOL

4

G

R

O

2

2

W

Y

B

3

FAN RELAY

CHANGEOVER

RELAY (COOL)

HEAT RELAY

COMPRESSOR

RELAY

CHANGEOVER

RELAY (HEAT)

369-0434—5

M2323B

1

L1

(HOT)

L2

Page 4

9. Adjust temperature setting lever so mercury bulb is in

horizontal position. See Fig. 1.

10. Carefully replace thermostat cover.

IMPORTANT: An incorrectly leveled thermostat will cause

the temperature control to deviate from setpoint.

Setting and Adjustment

TEMPERATURE SETTING

Push the temperature setting lever to the desired control

point on the temperature scale. The same lever controls both

heating and cooling.

SYSTEM AND FAN SWITCHING

The T834C features SYSTEM and FAN switches for

control of the heating-cooling and fan systems.

The SYSTEM switch controls system operation as follows:

HEAT: Heating system only operates.

OFF: Both heating and cooling control systems are dis-

connected.

COOL: Cooling system only operates.

The FAN switch controls fan operation as follows:

AUTO: For gas- or oil-fired systems, the fan operates in

response to the thermostat in cooling; fan operates in

response to the plenum fan control in heating. For

single-stage heat pump and electric heat systems, the

fan operates in response to the thermostat in both

heating and cooling.

ON: The fan runs continuously.

To switch positions, use thumb and index finger to slide

lever to desired position. Switch lever must stop directly over

desired function indicator mark for proper circuit operation.

HEAT ANTICIPATOR SETTING

IMPORTANT: The T834C Thermostat has an adjustable

heat anticipator and equipment will cycle properly

ONLY IF THE ANTICIPATOR IS ADJUSTED TO

MATCH THE CURRENT DRAW OF THE ENTIRE

SYSTEM or as recommended by the equipment

manufacturer. Use this thermostat only on systems

with current draws that fall within the range of the

heat anticipator. Do not use this device on Powerpile

(millivolt) Systems.

A current rating is usually stamped in the nameplate of the

primary control. Set the adjustable heat anticipator indicator

to match the value given on the nameplate, except on thermostats used in systems as shown in Figs. 2-4. See Heat

Anticipator Settings (Figs. 2-4).

If current rating is not available, proceed as follows to

determine the rating:

1. Turn off power.

2. Wire thermostat, but do not mount it on the wall.

3. Connect ammeter between W wire and W terminal on

the thermostat.

4. Prepare the system for operation.

5. Turn on power.

6. Turn system switch to heat.

7. Increase thermostat setpoint as necessary to get system

operating.

8. With the system operating through the ammeter, wait

one minute, then read the ammeter.

9. Turn the system switch to OFF, and turn off power.

10. Adjust the heat anticipator to match the reading on the

ammeter.

11. Disconnect the ammeter, reconnect the W wire, and

mount the thermostat. Continue with system checkout.

NOTE: The heat anticipator may require further adjustment

for best performance. To lengthen burner-on time, move

the indicator in the direction of the longer arrows—not

more than a half scale marking at a time. To shorten

burner-on time, move indicator in opposite direction.

HEAT ANTICIPATOR SETTINGS (Fig. 4 only)

Heat Pump Systems (for about 3 cycles per hour)

Using ‘B’ Terminal

Set adjustable anticipator to 140 percent of combined

current draw of compressor and fan relays.

Using ‘O’ Terminal

Set adjustable anticipator to maximum scale setting. Limit

combined load current of compressor and fan relays to 0.8

amp, because cooling anticipator provides anticipation during heat cycle in this hookup.

Electric Systems (with auto fan in heating and cooling)

Set adjustable anticipator to combined current draw of

heating and fan relays.

Gas- and Oil- Fired Systems

(without auto fan in heating)

Set adjustable anticipator to current draw of heat relay or

valve.

Checkout

CAUTION

Do not check operation by shorting across terminals of system controls. This will damage the heat

anticipator.

IMPORTANT: To assure accurate temperature control, do

not touch or breathe on bimetal of thermometer.

HEATING

With system switch set at HEAT and fan switch at AUTO,

move the temperature setting lever about 10° F

[6° C] above room temperature.

Gas- or oil-fired systems—heating should start; fan

should start after a short delay.

Single-stage heat pump or central electric heat systems—both heating and fan should start immediately.

Move temperature setting lever 10° F [6° C] below room

temperature.

Gas- or oil-fired systems—heating should shut off and

fan should shut off after a short delay.

Single-stage heat pump or central electric heat systems—heating and fan should shut off immediately.

4

Page 5

COOLING

CAUTION

Do not operate cooling if outdoor temperature is

below 50° F [10° C]. Refer to manufacturer’s

recommendations.

NOTE: To prevent compressor short cycling, some manufac-

turers’ equipment includes a minimum off-timer to provide a five-minute time delay before activating the compressor when the thermostat last turned the compressor

off, or from when the system first received power. This

delay protects the compressor.

With the system switch set at COOL and the fan switch set

at AUTO, move the temperature setting lever about

10° F [6° C] below room temperature. Cooling and fan should

start (see NOTE above). Move the temperature setting lever

about 10° F [6° C] above room temperature. Cooling and fan

should shut off.

FAN

With the system switch set at OFF, and the fan switch at

ON, the fan should run continuously. Move the fan switch to

AUTO. In gas- or oil-fired systems, fan operation is controlled by the thermostat in cooling and by the plenum fan

control in heating. In single-stage heat pump and central

electric heat systems, fan operation is controlled by the

thermostat in both heating and cooling.

RECALIBRATION

These thermostats are calibrated at the factory and should

not need recalibration. If the thermostat seems out of adjustment, first check for accurate leveling. To check calibration,

proceed as follows.

1. Move the temperature setting lever to the left end (low

end) of the temperature scale. System switch must be placed

at OFF. Wait at least five minutes.

2. Remove the thermostat cover. Move the setting lever

until the switch just makes contact. The mercury in the switch

will drop to the left end of the tube.

3. Replace cover and wait five minutes for the cover

and the thermostat to lose the heat it has gained from your

hands. If the thermometer pointer and the setting lever

indicator read approximately the same, no recalibration

is needed.

If recalibration appears necessary, proceed as

follows:

1. Place the temperature setting lever at the same setting

as the thermometer. Remove cover.

2. Insert 104994A Calibration Wrench (order separately)

onto the hex nut under the coil. See Fig. 6. Holding the setting

lever so it does not move, turn the wrench clockwise until

the mercury drops to the right end of the tube. Remove

wrench and replace cover.

To ensure accurate temperature control, do not touch or

breathe on bimetal or thermometer.

3. Move the setting lever to a low setting. Wait at least

five minutes for temperature to stabilize.

4. Slowly move the setting lever until it reads the same as

the thermometer.

5. Remove cover. Holding the setting lever so it does not

move, reinsert wrench and carefully turn

counterclockwise until the mercury drops to the left

of the tube, but no farther.

6. Recheck calibration. Set the thermostat system switch

for desired operation and replace cover.

7. Adjust temperature setting lever so mercury bulb is in

position. See Fig. 1

8. Carefully replace thermostat cover.

Fig. 6—Recalibration procedure.

COIL SHOWN WITHOUT

HEAT ANTICIPATOR

CALIBRATION

WRENCH

M2044

569-0434—5

Page 6

Automation and Control Solutions

Honeywell Internationals Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, Minnesota 55422 Scarborough, Ontario M1V 4Z9

Loading...

Loading...