Honeywell T834B, T834C, T834J Installation Instructions Manual

T834B; T834C; T834J

Heating-Cooling Thermostats

INSTALLATION INSTRUCTIONS

APPLICATION

The T834B,C,J Heating-Cooling Thermostats provide 24

to 30 Vac control in heating-cooling systems. An spdt

mercury switch makes R to W on a temperature fall for

heating, and R to Y on a temperature rise for cooling.

Integral switches control HEAT-OFF-COOL or COOL-OFF

system operation and AUTO-ON or ON-AUTO fan

operation (fan switch on T834C,J only). In heat pump and

some electric heat systems, fan operation is controlled by

the thermostat during heating. Check the electric heat

manufacturer specifications for fan control requirements. If

fan control from the thermostat is necessary in an electric

heat application, use the T834C Thermostat model (dual

fuel) with optional fan control. Jumper terminals 1 and 2 to

control fan operation from the thermostat during heating.

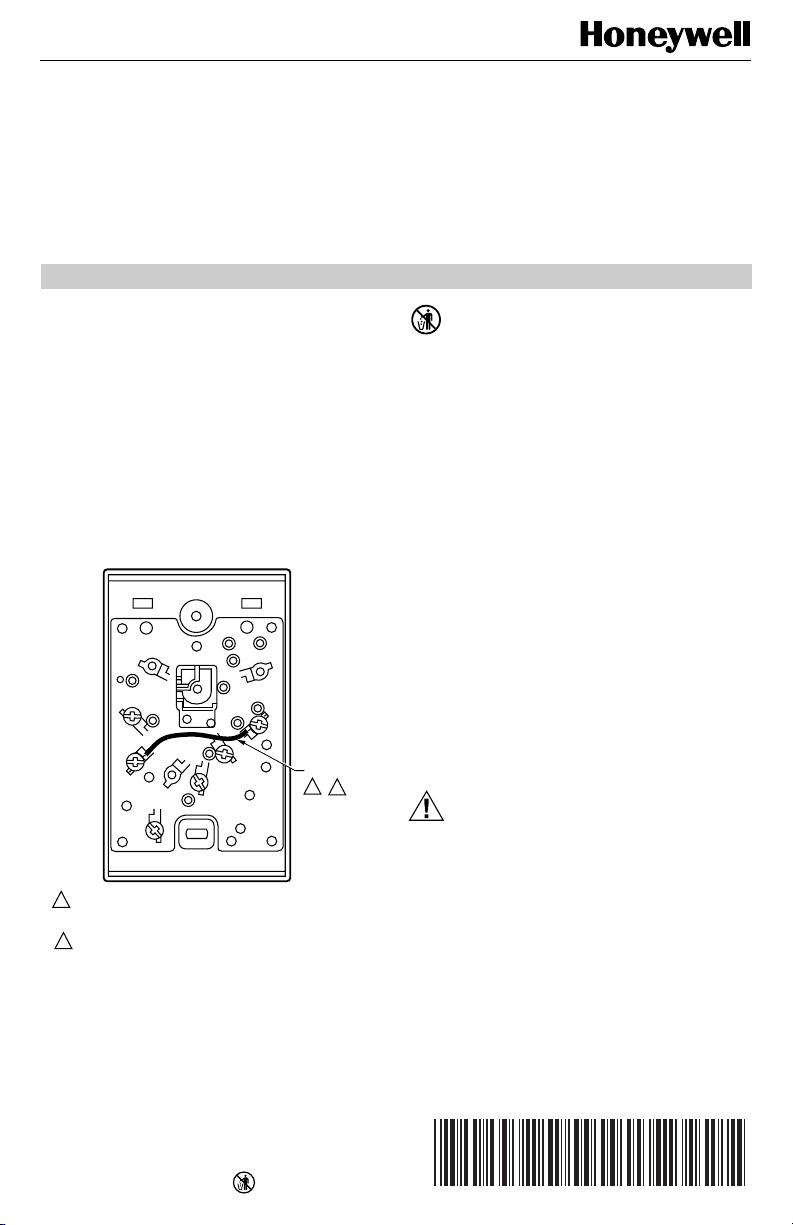

R

2

1

W

IN ELECTRIC HEAT AND HEAT PUMP APPLICATIONS, JUMPER

1

TERMINALS 1 AND 2 FOR AUTOMATIC FAN CONTROL IN HEATING

AND COOLING.

2

IN GAS-AND OIL-FIRED APPLICATIONS, JUMPER TERMINALS 1

AND Y FOR AUTOMATIC FAN CONTROL IN COOLING.

Fig. 1. Jumpering terminals for fan control.

G

Y

JUMPER

1

2

M8675

RECYCLING NOTICE

This control contains mercury in a sealed tube.

Do not place control in the trash at the end of

its useful life.

If this control is replacing a control that contains

mercury in a sealed tube, do not place your old

control in the trash.

Contact your local waste management authority

for instructions regarding recycling and the proper

disposal of this control, or of an old control

containing mercury in a sealed tube.

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Damage to Heating/Cooling System Possible.

Be careful when handling wires during

installation.

Disconnect power at furnace or at main breaker/

fuse before starting installation.

Location

Locate the thermostat about 5 ft (1.5m) above the floor on

an inside wall in an area with good air circulation at

average temperature.

Do not mount the thermostat where it may be affected by:

— drafts or dead spots behind doors or in corners.

— hot or cold air from ducts.

— radiant heat from the sun, fireplaces, or appliances.

®U.S. Registered Trademark

Copyright © 1999 Honeywell Inc. • • All Rights Reserved

X-XX UL

69-0444-10

T834B; T834C; T834J HEATING-COOLING THERMOSTATS

Wiring and Mounting

Disconnect power supply before beginning installation to

prevent electrical shock or equipment damage.

All wiring must comply with local codes and ordinances.

The T834 may be mounted directly on a wall or vertical

outlet box. Use Honeywell part no. 193121A Mounting

Plate Assembly (ordered separately) to mount on horizontal outlet box or cover marks left by old thermostat. If

mounting plate assembly is used, review instructions

provided with assembly before wiring and mounting

thermostat.

To wire and mount thermostat:

1. In replacement applications, check the existing

thermostat wires for cracked or frayed insulation.

Replace any wires in poor condition. If the wire is

plastered into the wall, make a hole next to the

wires and loosen the wires so they can be

pushed back into the wall later.

2. In new installations, run wiring (if necessary) to the

thermostat location.

3. Connect the wires to the terminals on the back of

the thermostat. See Fig. 3 through 12 for

internal schematic and typical hookup diagrams.

If control of fan operation from the thermostat is

required in a central electric heat application,

jumper terminals 1 and 2. See Fig. 1.

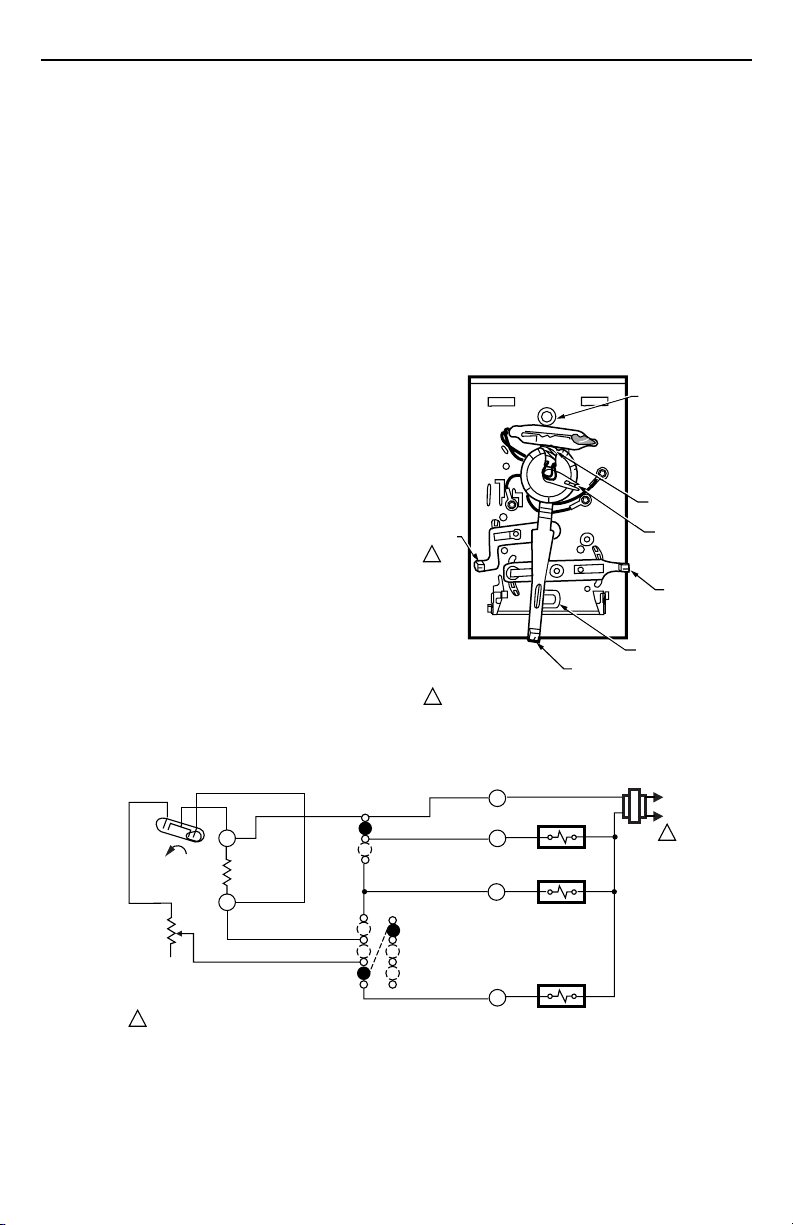

4. Remove thermostat cover by pulling outward on

bottom edge of the cover until it snaps free of the

thermostat base. See Fig. 2. Carefully remove

and discard the foam plastic shipping insert that

protects the switch and bimetal assembly during

shipping.

5. Set the adjustable heat anticipator indicator to

match the current draw of the primary heating

control (see Heat Anticipator Setting section).

6. Push excess wire back through the hole and plug

any opening with insulation to prevent drafts that

may affect thermostat performance.

7. Loosely fasten the thermostat to the wall or outlet

box with a screw through the top mounting hole.

Adjust the thermostat so that it is approximately

level and start the second screw through the

bottom mounting hole. Do not tighten.

8. Level the thermostat exactly using a spirit level or

plumb line. Tighten the mounting screws.

IMPORTANT

An incorrectly leveled thermostat will cause the

temperature control to deviate from setpoint.

9. Replace the thermostat cover.

MOUNTING HOLE

(THERMOSTAT

TO WALL OR

OUTLET BOX)

.18

.9

.7

.2

.5

3

.25

FAN

SWITCH

1

TEMPERATURE

1 FAN SWITCH AVAILABLE ON T834C ONLY.

SETTING LEVER

BIMETAL ELEMENT

BEHIND SCALE

ADJUSTABLE HEAT

ANTICIPATOR

INDICATOR

SYSTEM

SWITCH

MOUNTING HOLE

Fig. 2. Internal view of T834.

M8676

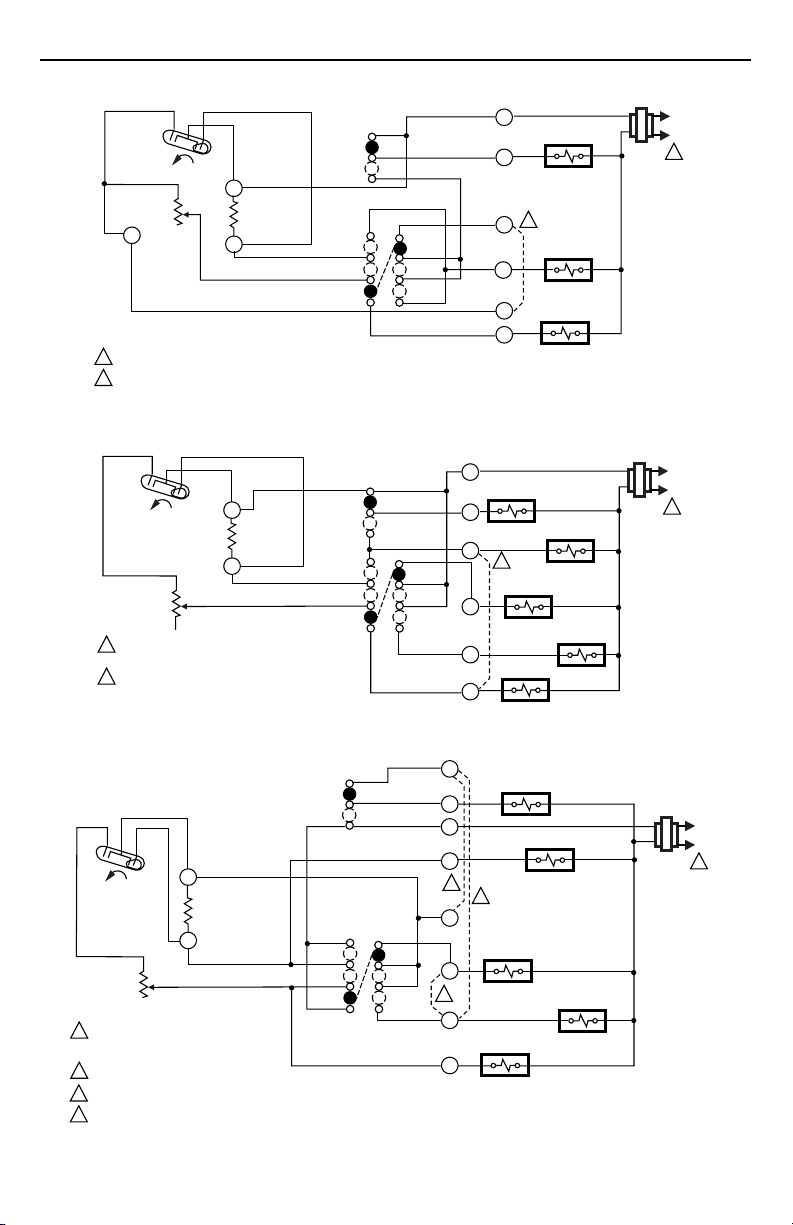

FAN SWITCH

H1

H1

ANTICIPATOR

1

C1

TEMP. FALL

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

C1

ANTICIPATOR

AUTO

SYSTEM

SWITCH

COOL

OFF

HEAT

ON

HEAT

OFF

COOL

R

G

Y

W

FAN RELAY

COMPRESSOR

CONTACTOR

HEAT RELAY

Fig. 3. Internal schematic and typical hookup diagram for T834C in standard heating-cooling system.

69-0444—10 2

M1119A

L1

(HOT)

L2

1

T834B; T834C; T834J HEATING-COOLING THERMOSTATS

FAN SWITCH

H1

H1

ANTICIPATOR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

IN ELECTRIC HEAT APPLICATION, JUMPER 1 AND 2 FOR AUTO FAN IN HEATING.

H1

TEMP. FALL

H1

ANTICIPATOR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

INSTALL JUMPER BETWEEN W AND Y TERMINALS

WHEN HEAT RELAY IS NOT USED.

C1

TEMP. FALL

C1

ANTICIPATOR

Fig. 4. Internal schematic and typical hookup for T834C dual fuel model

in a gas- or oil-fired, or central electric heat system.

C1

C1

ANTICIPATOR

ON

AUTO

SYSTEM

SWITCH

COOL

OFF

HEAT

FAN SWITCH

ON

AUTO

SYSTEM

SWITCH

COOL

OFF

HEAT

HEAT

OFF

COOL

HEAT

OFF

COOL

R

G

Y

B

O

W

R

G

1

Y

2

W

FAN RELAY

2

CHANGEOVER

RELAY (HEAT)

HEAT RELAY

FAN RELAY

2

COMPRESSOR

CONTACTOR

HEAT RELAY

COMPRESSOR

CONTACTOR

CHANGEOVER

RELAY (COOL)

M1037C

L1

(HOT)

L2

1

M2035A

L1

(HOT)

L2

1

Fig. 5. Internal schematic and typical hookup for T834C in heat pump system with supplementary heat.

HEAT

OFF

COOL

1

G

R

O

3

2

W

4

Y

B

FAN RELAY

2

HEAT RELAY

CHANGEOVER

RELAY (HEAT)

CHANGEOVER

RELAY (COOL)

COMPRESSOR

RELAY

FAN SWITCH

AUTO

ON

H1

C1

TEMPERATURE

FALL

H1

ANTICIPATOR

1

POWER SUPPLY. PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

2

JUMPER 1-Y FOR AUTO FAN IN COOLING ONLY.

3

JUMPER 1-2 FOR AUTO FAN WITH WAND Y.

4

JUMPER W-Y FOR SINGLE-STAGE HEAT PUMP.

Fig. 6. Internal schematic and typical hookup for T834C gas or oil-fired systems and single-stage

C1

ANTICIPATOR

SYSTEM

SWITCH

COOL

OFF

HEAT

heat pump or central electric heat.

3

L1

(HOT)

L2

1

M11342A

69-0444—10

Loading...

Loading...