Page 1

T8195B/Q682B,C, Y8224A

M3375

Heating or Cooling and Heating/Cooling

New Construction Thermostat,

Wallplate and Subbase

Installation Instructions for the Trained Service Technician.

Preparation

Recycling Notice

Check thermostat and subbase (if used) suitability for the

heating, cooling, or heating/cooling system. Refer to Table 1.

Assemble tools required: flat bladed screwdriver, hand or

power drill with 3/16-in. drill bit, wire cutter/stripper or

sharp knife, bubble level or plumb bob and line.

Assure power is off to the heating, cooling, or heating/

cooling system at the main fuse panel. Most buildings have

a separate switch box or circuit breaker for disconnecting

power to the heating and cooling (if applicable) equipment.

This thermostat is compatible with most heating, cooling,

or heating/cooling systems. Refer to Table 1 for thermostat

and system compatibility information.

TABLE 1—THERMOSTAT AND SYSTEM COMPATIBILITY.

Type of Heating System

to be Controlled Conditions/Compatibility

Electric (Line Voltage)—typical

baseboard and radiant

Fan Coil Unit • Compatible. Assure correct subbase identity is selected for fan control.

Gas—Direct Spark Ignition

(DSI), Intermittent Pilot (IP), and

Standing Pilot (SP)

Heat Pump • Compatible. Assure correct subbase identity is selected for fan control and

Hot Water Zone • Honeywell 2-wire valves are compatible.

Oil • Assure that the 24V control transformer common is accessible for connection

Vent Damper • Honeywell damper motors are compatible.

Warm Air Zone • Most are compatible.

a

If thermostat is not compatible with the system being controlled, the system will not operate. No hazard exists. The thermostat will not be damaged unless it is used to directly control a line voltage system. For proper system operation, a Honeywell

R841 or R8239D1015 Isolating Relay must be added to the thermostat control circuit.

b

Consult manufacturer for installation requirements.

• The R8239D1015 Isolating Relay or R841 Silent Switching Center must be

installed in the thermostat control circuit.

• Compatible. Assure that 24V control transformer common is accessible for

connection to thermostat cable conductor and power to the transformer is not

regularly interrupted by high temperature or limit operation.

changeover control (O terminal for cool and B terminal for heat). Jumper Y

to W for heat pump compressor control.

• Some non-Honeywell 2-wire valves require an R8239D1015 Isolating Relay

in the thermostat control circuit.

• Some 3-wire valves require an R8239A1052 Isolating Relay in the

thermostat control circuit.

to thermostat cable conductor and power to the transformer is not regularly

interrupted by high temperature, purge cycle, or limit operation.

• Some non-Honeywell damper motors require an R8239D1015 Isolating

Relay in the thermostat control circuit.a Check control amperage

requirement.

This control contains mercury in a sealed tube. Do not

place control in the trash at the end of its useful life.

If this control is replacing a control that contains mercury

in a sealed tube, do not place your old control in the trash.

Contact your local waste management authority for instructions regarding recycling and the proper disposal of this

control, or of an old control containing mercury in a sealed

tube.

If you have questions, call Honeywell Inc. at 1-800468-1502.

a

a

a, b

D.F. • Rev. 11-94 • • ©Honeywell Inc. 1994 • Form Number 69-0564—3

1 69-0564—3

M3375

Page 2

Installation

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could cause a hazardous condition.

2. Installer must be a trained experienced service technician.

3. After installation is complete, check out product op-

eration as provided in these instructions.

IMPORTANT: An incorrectly leveled subbase will cause

the temperature control to deviate from setpoint. It is

not a calibration problem.

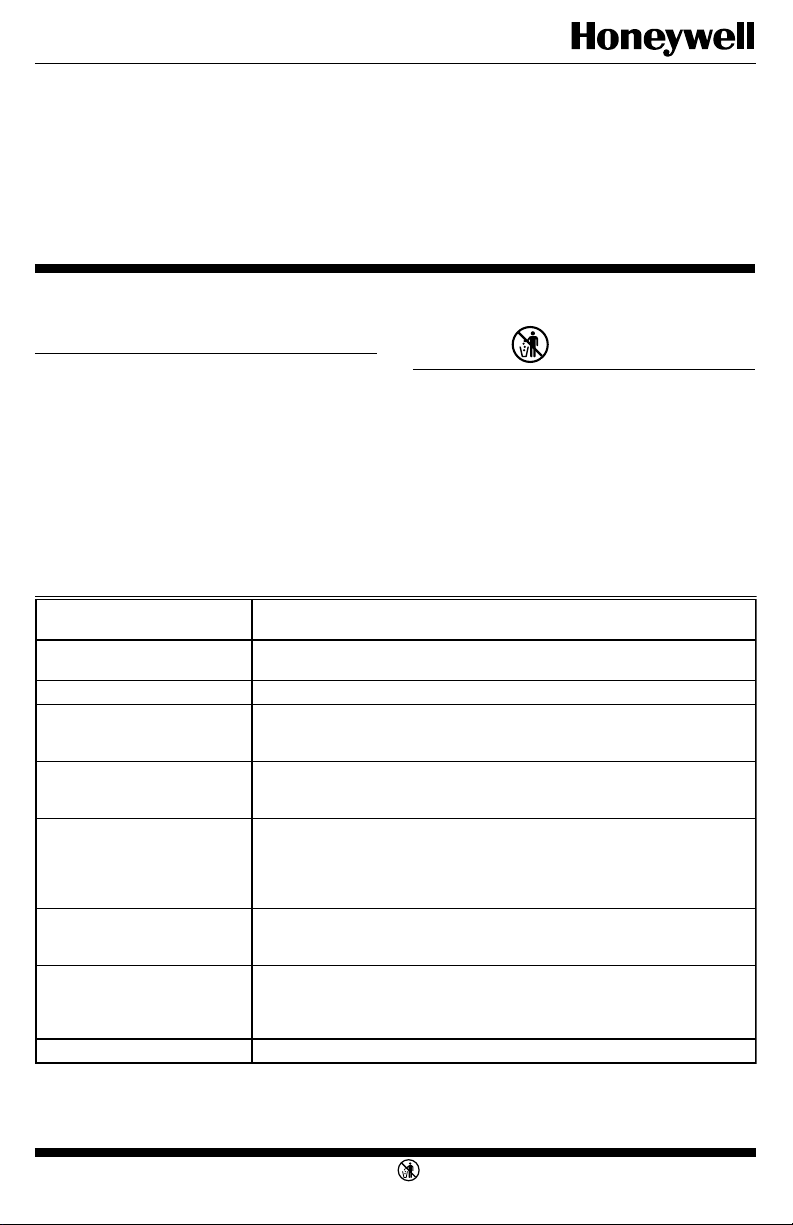

Fig. 1—Unpack thermostat.

CAPTIVE MOUNTING

SCREWS

1

12

2

3

11

4

1

0

5

9

6

8

7

7

8

6

9

10

1

1

12

LIFT

COVER

THERMOSTAT

COVER

CAUTION

1. Disconnect power supply to prevent electrical

shock or equipment damage.

2. To prevent interference with the thermostat linkage, keep wire length to a minimum and run

wires as close as possible to the subbase.

3. Do not overtighten thermostat captive mounting screws because damage to subbase threads

can result.

4. Do not short across coil terminals on relay. This

can burn out the thermostat heat anticipator.

LOCATION

Locate thermostat about 5 ft [1.5m] above the floor in an

area with good air circulation at average temperature.

Do not mount the thermostat where it may be affected by:

— drafts, or dead spots behind doors and in corners.

— hot or cold air from ducts.

— radiant heat from the sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

behind the thermostat.

Run wires from the heating, cooling, or heating/cooling

equipment to the new thermostat location.

IMPORTANT: This control requires an additional con-

ductor to the control transformer common (e.g., a

typical 2-wire heating system requires three wires be

pulled, a 4-wire heating/cooling requires five wires).

UNPACK THERMOSTAT

Handle your new thermostat carefully; rough handling

may interfere with its accuracy. Before unpacking, refer to

Fig. 1.

Remove and discard the shipping wrap.

IMPORTANT: Save package of screws and instructions

for the homeowner.

Remove the thermostat cover by lifting from the bottom.

Set aside cover until needed later.

Carefully remove the material protecting the mercury

switch bulb.

Loosen two captive mounting screws, and separate wallplate (if provided) from back of thermostat base.

MOUNT WALLPLATE OR SUBBASE

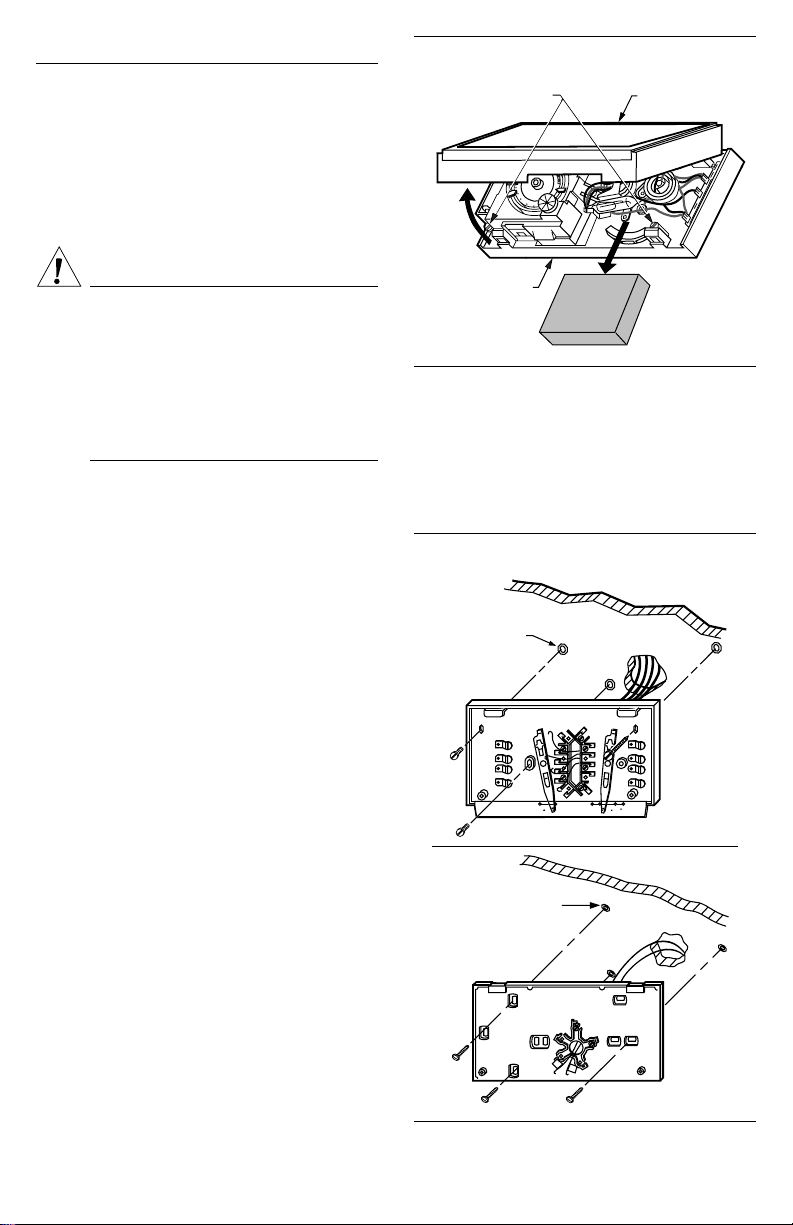

Wall Mounting (Fig. 2)

Hold the wallplate or subbase in position on wall (Fig. 2).

Mark holes on the wall for anchors. Use spirit level to

make sure the wallplate or subbase is level.

THERMOSTAT BASE

REMOVE

PACKING

MATERIAL

M8605

Drill 3/16-in. holes, and gently tap anchors into holes

until flush with the wall.

Pull wires through the large wiring hole in the wallplate or

subbase.

Loosely fasten the wallplate or subbase to the wall with

the three screws. Do not completely tighten the screws.

Carefully level the wallplate or subbase (Fig. 3), and

firmly tighten the screws.

Fig. 2—Mounting wallplate or subbase to wall.

3 SCREW HOLES

WITH PLASTIC

ANCHORS

O

B

R

W

G

FAN

HEATING/COOLING SUBBASE

3 SCREW HOLES

WITH PLASTIC

ANCHORS

HEATING-ONLY

WALLPLATE

Y

AUTO OFF

HEATON

COOL

M1552A

M857

69-0564—3 2

Page 3

Fig. 3—Leveling methods for wallplate or

subbase.

or heating/cooling equipment manufacturer. If not available,

refer to the Typical Wiring Diagrams section at the end of

this publication.

WIRE WALLPLATE OR SUBBASE

PLUMB

LINE

PLUMB

BOB OR

WEIGHT

FAN

SPIRIT LEVEL

O

B

R

W

G

Y

AUTO OFF

HEATON

COOL

M1555

nections to prevent electrical shock or equipment damage.

NOTE: All wiring must comply with local electrical codes

Wallplate (Heating or Cooling Systems)

necessary.

terminals. For cooling-only systems, connect wires R, Y,

and C terminals. Firmly tighten the screws. The system lowvoltage transformer powers the timer (Fig. 11).

or nonflammable insulation to prevent drafts from affecting

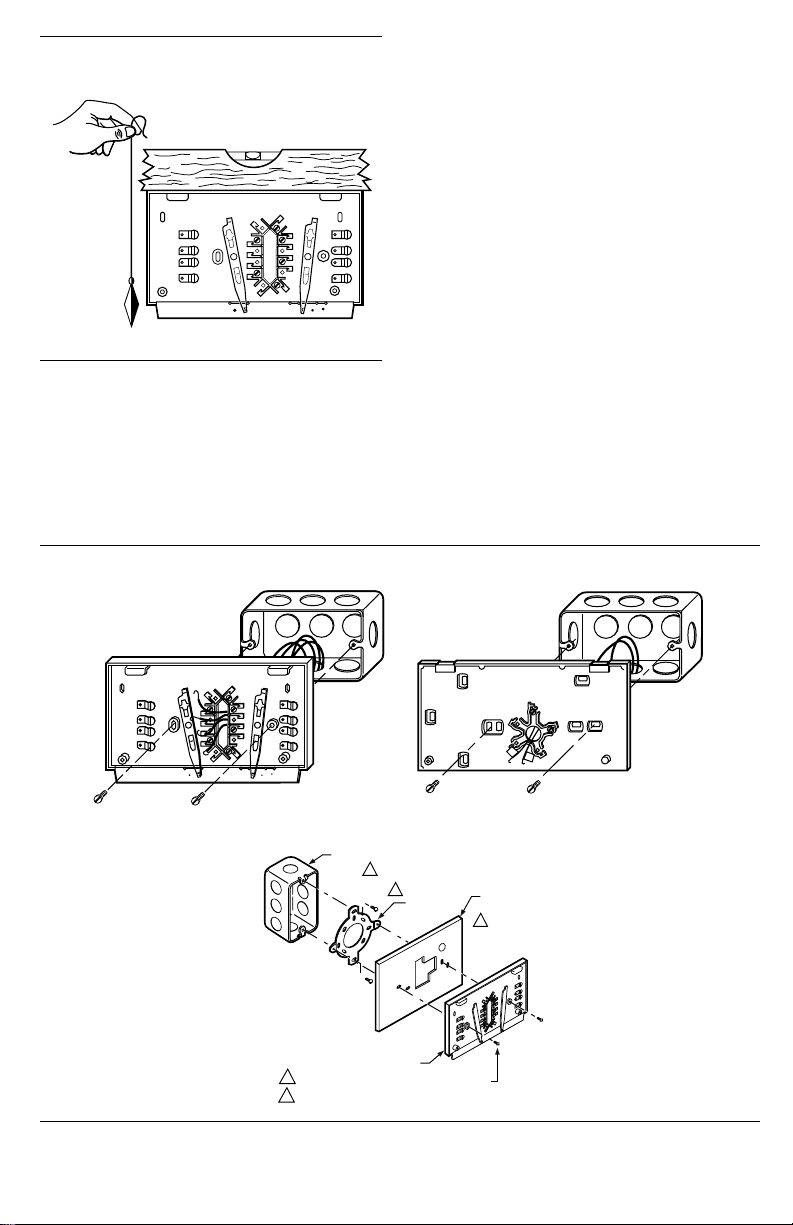

Outlet Box Mounting (Fig. 4)

thermostat operation.

Use a horizontally mounted outlet box if possible. If a

vertical outlet box is used, mount the wallplate or subbase on

Subbase (Heating/Cooling Systems)

a 202689A Cover Plate Assembly (ordered separately). Follow the instructions provided with the cover plate assembly.

necessary.

Align the wallplate or subbase mounting holes on the

outlet box and loosely fasten with two screws.

Carefully level the wallplate or subbase (Fig. 3), and

firmly tighten the screws.

Fig. 4—Mounting wallplate or subbase on horizontal outlet box.

subbase. If labels do not agree with your new subbase, refer

to Table 2 and the installation instructions furnished with

the subbase.

Follow the instructions provided by the heating, cooling

Disconnect the power supply before making wiring con-

and ordinances.

Refer to Fig. 5 and strip the thermostat wire insulation as

For heating-only systems, connect wires to R, W, and C

Push excess wire back into the wall.

Plug the hole in the wall with nonhardening caulk, putty,

Refer to Fig. 5, and strip the thermostat wire insulation as

Connect the wires to the corresponding terminals on the

EXISTING

HORIZONTAL

OUTLET BOX

FAN

O

B

R

W

G

Y

AUTO OFF

HEATON

HEATING/

COOLING

SUBBASE

COOL

M1553A

VERTICAL

OUTLET

BOX

NOT INCLUDED WITH UNIT.

1

ACCESSORY PARTS AVAILABLE.

2

EXISTING

HORIZONTAL

OUTLET BOX

R

W

WALLPLATE

M856

1

2

SUBBASE OR

WALLPLATE

ADAPTER

RING

MOUNTING

SCREWS (2)

COVER

PLATE

2

R

G

O

B

W

Y

M1554A

3 69-0564—3

Page 4

Fig. 5—Methods of connecting terminals.

FOR STRAIGHT

CONNECTION—

STRIP 5/16 in. [8 mm]

Fig. 6—Thermostat mounting.

FOR WRAPAROUND

CONNECTION—

STRIP 7/16 in. [11 mm]

BARRIER

M1556B

TABLE 2—TERMINAL DESIGNATIONS.

Subbase

Terminal

Control

Function

R Control transformer power.

W Heating control circuit.

Y Cooling control circuit; jumper to W

for heat pump compressor control if

no P terminal on subbase.

G Fan control circuit.

C Clock control (transformer common).

O Cooling damper or changeover/

reversing valve, makes continuously

in cool.

B Heating damper or changeover/

reversing valve, makes continuously

in heat.

The timer is powered by the system low-voltage trans-

former. 24 Vac must be maintained across terminals R and C.

Push excess wire back into the wall.

Plug the hole in wall with nonhardening caulk, putty, or

nonflammable insulation to prevent drafts from affecting

thermostat operation.

MOUNT THE THERMOSTAT

Note the tabs on the top inside edge of the thermostat base.

These tabs fit the slots molded into the top of the wallplate or

subbase.

Hang the thermostat base on the wallplate or subbase.

Insert the two captive mounting screws located in the

bottom corners of the base (Fig. 6).

Firmly tighten the screws.

INSERT TIMER BATTERIES (OPTIONAL)

Power is supplied to the clock by the 24-Vac transformer.

Two AAA alkaline backup batteries (not included) may be

installed to supply power to the timer if power is interrupted

due to power failure.

Install the batteries in the thermostat (Fig. 7).

Once a year or when batteries are dead, replace with two

new AAA alkaline batteries. We recommend Energizer

batteries.

TAB (2)

MOUNTING SLOT (2)

1

12

2

3

1

1

4

10

5

9

6

8

7

7

8

6

9

10

11

12

THERMOSTAT

BASE

WALLPLATE

OR SUBBASE

Fig. 7—Insert timer backup batteries.

BATTERY LOCATION FOR

(2) AAA BATTERIES;

INSTALL WITH POSITIVE

ENDS UP

SET TIMER

Adjust the clock by moving the knob clockwise . Do

not reverse the knob.

When time is correctly set, the time indicator arrow

(triangle shape) points to the corresponding daytime (light)

or nighttime (dark) portion of the program dial.

ATTACH THERMOSTAT COVER

Make sure the packing inserts in the thermostat base are

removed.

Place the two tabs on the upper edge of the cover into the

mounting slots in the thermostat base (Fig. 9).

Swing the cover downward until it catches at the bottom of the base.

®

CAPTIVE

MOUNTING SCREWS

M8603

M8585

69-0564—3 4

Page 5

Fig. 8—Set timer.

50

60

70

80

M8604

PROGRAM

PINS (4)

SEE OWNER'S

MANUAL FOR

DETAILS

TIMER

SETTING

KNOB

TIME

INDICATOR

ARROW

M5161

Fig. 9—Attach cover.

Fig. 10—Temperature control levers.

LOW TEMPERATURE

(BLUE MARK)

SET LEVER

HIGH TEMPERATURE

(RED MARK)

SET LEVER

SET TEMPERATURE CONTROL LEVERS

The two levers on the top of the thermostat control the

low and high temperatures for energy savings and comfort

control (Fig. 10). The lever on the left (blue mark) controls

the lower temperature. The lever on the right (red mark)

controls the higher temperature.

We recommend pushing the levers together at an appropriate temperature for either heat or cool until the occupant

programs the thermostat and makes the final temperature

selections.

SET SUBBASE SWITCHES (IF APPLICABLE)

The subbase system switch controls system operation as

follows:

HEAT: Heating system is controlled by the thermostat.

Cooling system is off.

COOL: Cooling system is controlled by the thermostat.

Heating system is off.

OFF: Both the heating and cooling systems are off. If the

fan switch is in the AUTO position, the fan is also off.

The subbase fan switch controls fan operation as follows:

ON: Fan operates continuously.

AUTO: Fan operates with the cooling equipment as con-

trolled by the thermostat or with the heating equipment

as controlled by the plenum switch. In electric heat,

heat pump, and fan coil systems, the fan is controlled

by the thermostat in heating and cooling.

To switch positions, use thumb or index finger to slide

lever to the desired position. For proper circuit operation,

switch lever must stop in detent over the desired function

indicator mark.

70

60

50

80

M859

Checkout

CAUTION

Do not check operation by shorting across terminals of system controls. This will damage the heat

anticipator.

HEATING-ONLY SYSTEM

Turn on power to the furnace.

Push both temperature setting levers together at least 5° F

[3° C] above the room temperature. The main burner should

come on. The fan will start when the furnace heats up.

Move both levers 5° F [3° C] below the room temperature. The burner should shut off.

Operate the entire heating system at least one complete

cycle.

If thermostat fails any test, refer to the Troubleshooting

Guide in the Owner’s Manual.

Reset both the temperature setting levers to the desired

temperatures.

5 69-0564—3

Page 6

COOLING-ONLY SYSTEM

Turn on power to the cooling equipment.

Push both temperature setting levers together at least 5° F

[3° C] below the room temperature. The cooling equipment

will operate, and the fan will start. Allow for any time delay

that may be built into the compressor control circuit.

NOTE: To avoid compressor damage, do not operate the

system when outdoor temperature is below 50° F [10° C].

Refer to manufacturer recommendations.

Move both levers 5° F [3° C] above room temperature.

The cooling equipment and the fan should shut off.

Operate the entire cooling system at least one complete

cycle.

If thermostat fails any test, refer to the Troubleshooting

Guide in the Owner’s Manual.

Reset both the temperature setting levers to the desired

temperatures.

HEATING/COOLING SYSTEM

Turn on power to the furnace and cooling system.

Place the system switch lever to HEAT and fan switch

lever to AUTO.

Push both temperature setting levers together at least 5° F

[3° C] above room temperature. The main burner should

come on. The fan will start when the furnace heats up. (If

central electric heat, fan coil or heat pump system, fan starts

immediately.)

Move both levers 5° F [3° C] below room temperature.

The burner should shut off.

Place the system switch lever to COOL and the fan switch

lever to AUTO. The cooling equipment will operate, and the

fan will start. Allow for any time delay that may be built into

the compressor control circuit.

NOTE: To avoid compressor damage, do not operate the

system when outdoor temperature is below 50° F [10° C].

Refer to manufacturer recommendations.

Move both temperature setting levers together at least

5° F [3° C] above the room temperature. The cooling equipment should shut off.

Place the fan switch to ON. The fan should run continuously with the system switch in any position.

Place the system switch to OFF. Move both temperature

setting levers to various positions. The heating and cooling

systems should not operate.

Operate the entire system for at least one complete cycle

with the system switch at COOL and one complete cycle

with the switch at HEAT.

If thermostat fails any test, refer to the Troubleshooting

Guide in the Owner’s Manual.

Reset both the temperature setting levers to the desired

temperatures.

Leave Owner’s Manual and Assistance Information in a

convenient place for the building occupant or provide with

other appliance manuals.

Typical Wiring Diagrams

Follow the hookup diagram supplied with your heating,

cooling, or heating/cooling equipment. If not available, use

Figs. 11 through 13 as a guide.

REMEMBER: Your wiring must follow local electrical codes

and ordinances.

Fig. 11—Typical hookup for T8195B Thermo-

stat and Q682C Wallplate in gas heating

control system.

H

FALL

HEAT

ANTICIPATOR

W

THERMOSTAT

C

Y

WALLPLATE

M503A

TIMER

H

C

FALL

HEAT

ANTICIPATOR

COOL

ANTICIPATOR

R

C

GAS

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

CONTROL

69-0564—3 6

Page 7

Fig. 12—Typical hookup for T8195B Thermostat and Q682B Subbase in conventional heating/

cooling system.

TIMER

THERMOSTAT

SUBBASE

L1

(HOT)

L2

THERMOSTAT

HEAT/COOL

ANTICIPATOR

SYSTEM

SWITCH

OFF

HEAT

COOL

C

R

B

HEATING

1

DAMPER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

REMOTE INDICATION FOR FILTER OPTIONAL.

2

TIMER

O

COOLING

DAMPER

HEAT

ANTICIPATORS

FAN

RELAY

H

FALL

FAN

SWITCH

ON

AUTO

G

H

FALL

C

HEAT

RELAY

C

H

FALL

2

FILTER

LED

OFF

HEAT

COOL

W

Y

COOLING

RELAY

C

X

SWITCH

M8606

H

C

FALL

SUBBASE

L2

1

L1

(HOT)

COOL

ANTICIPATORS

SYSTEM

SWITCH

OFF

HEAT

COOL

C

W

HEAT

RELAY

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.1

Y

COMPRESSOR

CONTACTOR

AUTO

G

FAN

RELAY

ON

FAN

SWITCH

HEAT

OFF

COOL

R

M573B

7 69-0564—3

Page 8

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario M1V 4Z9

Loading...

Loading...