Page 1

T812, TS812 Thermostats

INSTALLATION INSTRUCTIONS

APPLICATION

The T812 and TS812 Thermostats are low voltage,

controls for heat only, cool only or heating and cooling

systems. See Table 1.

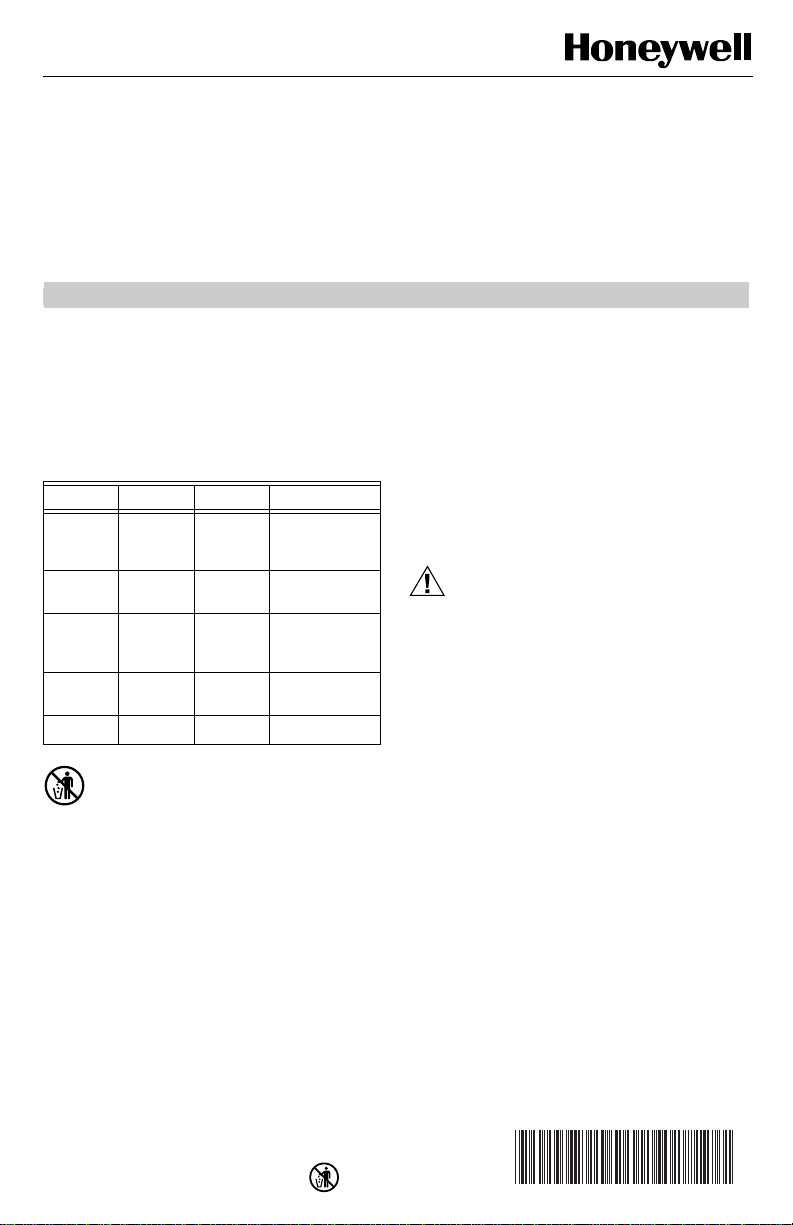

Table 1. Model Descriptions.

Model Voltage System Anticipator

T812A 24 Vac Heat only Adjustable

T812B 12 Vdc Heat only .18A to 1.2A @

T812C 24 Vac Heat and

T812D 24 Vac Cool only Fixed 24 Vac to

TS812A 750 mV Heat only .1A @ .75 Vdc

MERCURY NOTICE

If this control is replacing a control that contains

mercury in a sealed tube, do not place your old

control in the trash.

Contact your local waste management authority

for instructions regarding recycling and the

proper disposal of the old thermostat.

Cool

.18A to 1.2A @

30 Vac

12 Vdc

Adjustable

.18A to 1.2A @

30 Vac

30 Vac

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these Instructions .

CAUTION

Electrical Shock Hazard.

Can cause personal injury or equipment

damage.

Disconnect power supply before beginning

installation.

Location

Locate the thermostat about 5 ft (1.5m) above the floor in

an area with good air circulation at average temperature.

Do not mount the thermostat where it can be affected by:

— drafts, or dead spots behind doors and in corners.

— hot or cold air from ducts.

— radiant heat from the sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) area such as outside wall behind

the thermostat.

® U.S. Registered Trademark

Copyright © 2004 Honeywell International Inc. • • All Rights Reserved

69-1606ESF-3

Page 2

T812, TS812 THERMOSTATS

A

MOUNTING HOLES (2) USED TO

9

MOUNTING HOLES (2) USED TO

MOUNTING HOLE

(THERMOSTAT

TO WALL)

MOUNTING

TABS (3)

SNAP SWITCH CONTACTS

TEMPERATURE

SETTING LEVER

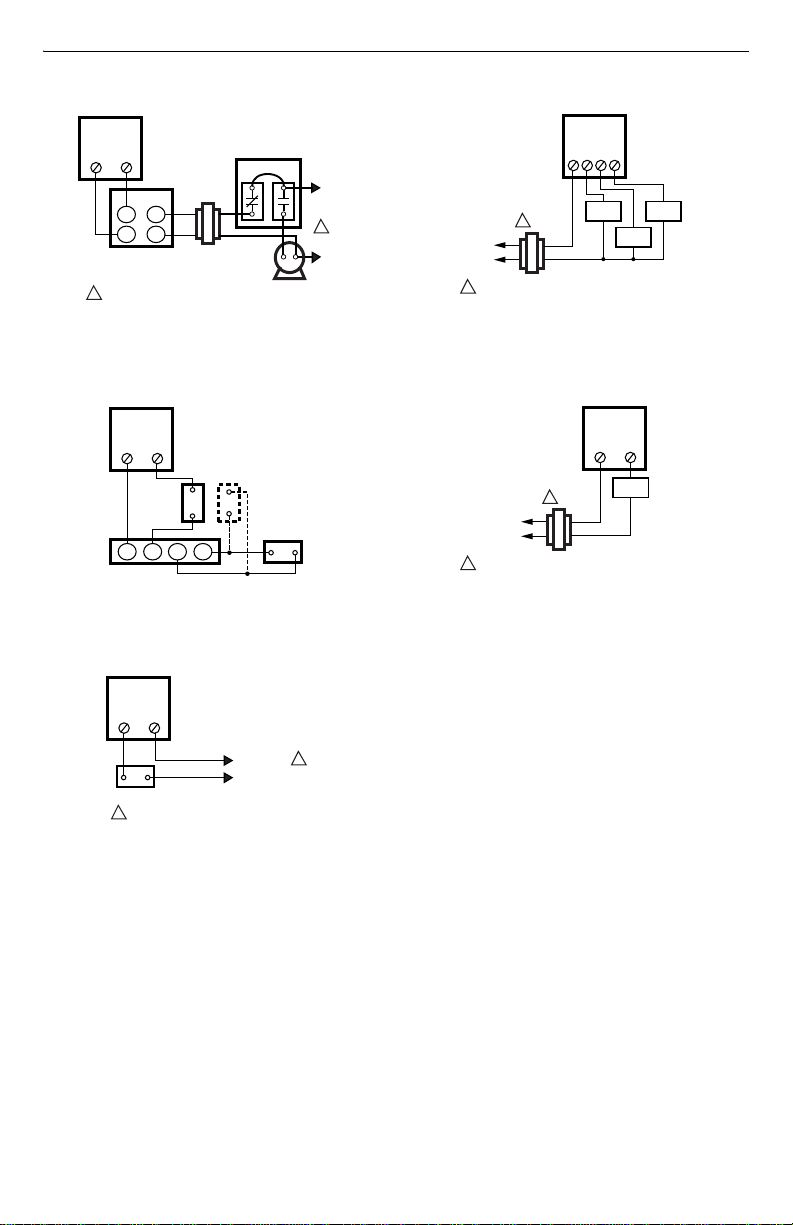

3. Connect the thermostat wires to the appropriate

terminals on the thermostat back. See Fig. 4-8 for

typical hookup diagrams.

4. Push any excess wire back through the hole and

plug any opening to prevent drafts that could affect

thermostat performance.

5. Adjust the heat anticipator (select models) to

match the current draw of the system primary control. See Heat Anticipator Setting section.

6. Fasten the thermosta t to the wa ll with scr ew s

through the mounting holes on the upper left and

right sides of the device. See Fig. 2.

7. Replace the thermostat cover.

MOUNT THERMOSTAT TO WALL

(FOR MODELS WITH SUBBASE).

SCREWS (3)

USED

TO MOUNT

THERMOSTAT

ONTO

SUBBASE

Fig. 1. Internal view of T812 with adju stable heat

BIMETAL

ELEMENT

ADJUSTABLE

HEAT ANTICIPATOR

INDICATOR LEVER

anticipator.

ADJUSTABLE HEAT

ANTICIPATOR

SCALE

MOUNTING HOLE

(THERMOSTAT TO WALL)

M20496

Wiring and Mounting

All wiring must comply with local codes and ordinances.

MOUNT THERMOSTAT TO WALL

(FOR MODELS WITHOUT SUBBASE).

M20883

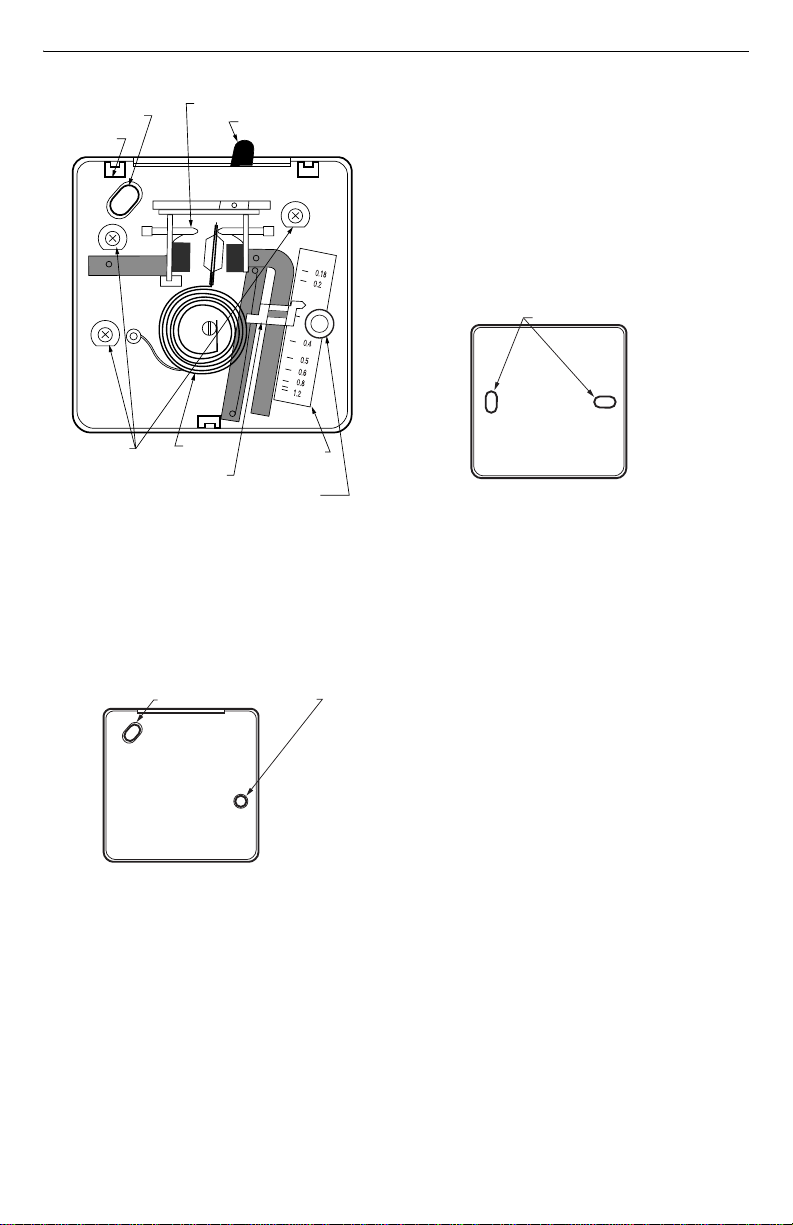

Fig. 2. Mounting hole locations for models without

T812 and TS812 Models Without Subbase

1. In replacement applications, inspect the old wi re s

for frayed or cracked insulation and replace any

wires in poor condition; in new installations, run two

wires to the location.

2. Grasping the thermostat cover on the top and the

bottom with one hand, push in on the bottom center and pull outward until the cover snaps free from

the thermostat base.

subbase.

M2088

Fig. 3. Mounting hole locations for models with

subbase.

T812 Models With Subbase

1. In replacement applications, inspect the old wires

for frayed or cracked insulation and replace any

wires in poor condition; in new installations, run the

appropriate number of wires to the location.

2. Grasping thermostat cover on top and bottom with

one hand, push in on bottom center and pull outward until cover snaps free from thermostat base.

3. Disconnect thermostat from subbase by unscrewing the three screws under the thermostat cover.

See Fig. 1.

4. Connect the wires to the terminals on the front of

the subbase. See Fig. 4-8.

5. Push any excess wire back through the hole and

plug any opening to prevent drafts that could affect

thermostat performance.

6. Loosely fasten thermostat subbase to the wall with

a screw through the right mounting hole. Adjust the

subbase so it is approximately level and start the

second screw through the left mounting slot.

7. Level the thermostat subbase for appearance only;

it is not required for accurate operation.

8. Tighten the mounting screws. See Fig. 3.

9. Mount the thermostat to the thermostat subbase by

tightening the three screws. See Fig. 1.

10. Adjust the heat anticipator (select models) to

match the current draw of the system primary control. See Heat Anticipator Setting section.

11. Replace the thermostat cover.

69-1606ESF-3 2

Page 3

7

T812A

THERMOSTAT

A

9

0

S

1

S

COMBINATION FAN

RW

TH

THTRTR

GAS VALVE

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

AND LIMIT CONTROL

TRANSFORMER

LIMIT FAN

FAN

MOTOR

(HOT)

1

M2043

L1

L2

Fig. 4. T812A in typical gas heating system.

T812, TS812 THERMOSTATS

T812C

THERMOSTAT

R

W Y G

1

L1

L2

POWER SUPPLY. PROVIDE DISCONNECT MEAN

1

AND OVERLOAD PROTECTION AS REQUIRED.

HEAT

FAN

COOL

M2044

Fig. 7. T812C in heating and cooling syst em .

TS812

THERMOSTAT

RW

PILOT CONTROL

(IF USED)

LIMIT

CONTROL

TH1 TH2 PP PP

MILLIVOLT

GENERATOR

M20438

Fig. 5. Typical hookup to TS812A in millivolt system.

T812B

THERMOSTAT

WR

1

TO 12 Vdc

POWER SUPPLY

GAS VALVE

POWER SUPPLY. PROVIDE DISCONNECT

1

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

M2043

Fig. 6. T812B in 12 Vdc application.

T812D

THERMOSTAT

RY

1

L1

L2

POWER SUPPLY. PROVIDE DISCONNECT MEAN

1

AND OVERLOAD PROTECTION AS REQUIRED.

COOL

M2044

Fig. 8. T812D in cooling only ap plication.

3 69-1606ESF-3

Page 4

SETTING AND CHECKOUT

Temperature Setting

Move the temperature setting lever to the desired

setpoint on the thermostat scaleplate, see Fig. 1, to

control the temperature to desired point. (On posi tive off

models, the control circuit is broken when the lever is

moved to the extreme lowest setting of the temperatu re

scale.)

Heat Anticipator Setting (Select Models)

IMPORTANT

1. Use this thermostat only with controls that have

current rating equal to (or within) the rating of

the heat anticipator.

2. Setting the heat anticipator allow s the therm ostat to maintain accurate temperature control.

Models with an adjustable heat anticipator should be

adjusted to match the current draw of the primary control

for optimum thermostat performance. To adjust, move

the anticipator indicator lever to correspond to the control

rating. See Fig. 1.

If the setting and current rating are not available, wire the

thermostat into the system, but do not attach it to the

wall. If the thermostat is already mounted, remove it from

the wall, leaving it connected to the system wiring.

Connect an ammeter of the appropriate range (about

0.0A to 2.0A) between the terminals on the back of the

thermostat. Move the temperature setting lever to a low

setting so the contacts are broken. In cold weather, it

may be necessary to hold the switch so the controls

remain open. Allow the system to operate through the

ammeter for one minute. Adjust the anticipator to match

the meter reading.

NOTE: For best performance, the heat anticipator can

require further adjustment. To lengthen burneron time, move the indicator to a higher number,

but not more than one-half scale marking at a

time. To shorten burner-on time, move the indicator in the opposite direction.

Cool Anticipator (Select Models)

Models with a cooling anticipator have a 24 Vac to 30 V ac

fixed anticipator.

Checkout

CAUTION

Shorting Hazard.

Can damag e he at anticipator.

Do not check operation by shorting across

system control terminals.

Observe the system through at least one complete

automatic cycle. Make certain that the system operates

as intended. Check for correct operation of positive off

switch, if used.

Calibration

This thermostat is carefully calibrated at the factory and

cannot be field-adjusted.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

69-1606ESF-3 G.H. Rev. 5-04 Printed in China www.honeywell.com/yourhome

M1V 4Z9

Page 5

Termostatos T812 y TS812

NOTIFICACIÓN SOBRE

INSTRUCCIONES DE INSTALACIÓN

APLICACIÓN

Los termostatos T812 y TS812 son controles de bajo voltaje

para sistemas de calefacción solamente, de enfriamiento solamente, o de calefacción y enfriamiento. Consulte la T abla 1.

Tabla 1. Descripciones de los Modelos.

Modelo Voltaje Sistema Anticipador

T812A 24 V ca Calefacción

T812B 12 V cd Calefacción

T812C 24 V ca Calefacción

T812D 24 V ca Enfr iami e nto

TS812A 750 mV Calefacción

únicamente

únicamente

y

enfriamiento

únicamente

únicamente

Ajustable

0.18 A a 1.2A

@ 30 V ca

0.18 A a 1.2 A

@ 12 V cd

Ajustable

0.18 A a 1.2 A

@ 30 V ca

Fijo 24 V ca

a30 V ca

0.1 A @

0.75 V cd

EL MERCURIO

Si este control re emplaz ará un co ntro l que cont enga

mercurio en un tubo sellado, no tire el control

viejo a la basura.

Comuníquese con la autoridad local enc arg ada

de la administración de desperdicios para recibir

instrucciones respecto al reciclaje y el modo

adecuado de deshacerse del termostato viejo.

INSTALACIÓN

Cuando instale este producto…

1.

Lea cuidadosamente estas instrucciones. El no seguirlas

podría resultar en daños al producto o ser causa de una

condición riesgosa.

2.

Verifique las calificaciones que se incluyen en las

instrucciones y en el producto para asegurarse de que el

producto sea el adecuado para el uso que se le quiere dar.

3.

El instalador debe ser un técnico de servicio capacitado

y experimentado.

4.

Después de terminar la instalación, verifique el

funcionamiento del producto como se indica en estas

instrucciones.

PRECAUCIÓN

Riesgo de descarga eléctrica.

Puede ser causa de lesiones a la persona

o da ño al equipo.

Antes de iniciar la instalación, desconecte el

suministro de energía.

Ubicación

Coloque el termostato aproximadamente a 5 pies (1.5 m)

de altura en un área con buena circulación de aire cuya

temperatura sea promedio.

No monte el termostato en donde éste pueda verse

afectado por:

— corrientes de aire o puntos muertos detrás de las

puertas y en las esquinas.

— aire caliente o frío proveniente de conductos.

— radiación de calor del sol o de otros aparatos.

— tuberías y chimeneas ocultas.

— área sin calefacción (enfriamiento) tal como una

pared exterior detrás del termostato.

® Marca registrada en los E.U.A.

Copyright © 2004 Honeywell International Inc.

Todos los derechos reservados

69-1606ESF-3

Page 6

TERMOSTATOS T812 Y TS812

)

O

E

).

ORIFICIO DE MONTAJE

(TERMOSTATO A LA PARED)

LENGÜETAS DE

MONTAJE (3)

CONTACTOS DEL INTERRUPTOR RÁPID

PALANCA DE AJUSTE

DE TEMPERATURA

3.

Conecte los cables del termostato a las terminales

apropiadas en el dorso del termostato. Consulte la

Figura 4-8 respecto a diagramas típicos de conexiones.

4.

Meta el cable excedente de nuevo a través del orificio y

tape cualquier abertura para evitar corrientes de aire que

pudieran afectar el funcionamiento del termostato.

5.

Ajuste el anticipador de calor (modelos selectos) para

que concuerde con el consumo de corriente del control

primario del sistema. Consulte la sección sobre

Configuración del anticipador de calor.

6.

Fije el termostato a la pared con tornillos utilizando los

orificios de instalación que se encuentran en los lados

superior izquierdo y superior derecho del aparato.

Consulte la Figura 2.

7.

Reinstale la cubierta del termostato.

ORIFICIOS PARA INSTALACIÓN (2)

UTILIZADOS PARA INSTALAR

EL TERMOSTATO EN LA PARED

(PARA MODELOS CON BASE INFERIOR

TORNILLOS (3)

UTILIZADOS

PARA INSTALAR

L TERMOSTATO

EN LA BASE

INFERIOR

Fig. 1. Vista interna del T812 con anticipador

ELEMENTO

BIMETÁLICO

PALANCA

INDICADORA

DEL ANTICIPADOR

DE CALOR AJUSTABLE

de calor ajustable.

ESCALA DEL

ANTICIPADOR

DE CALOR

AJUSTABLE

ORIFICIO DE

INSTALACIÓN

(TERMOSTATO A LA PARED

MS20496A

Cableado e instalación

Todo el cableado debe cumplir con los códigos y leyes locales.

ORIFICIOS PARA INSTALACIÓN (2)

UTILIZADOS PARA INSTALAR

EL TERMOSTATO EN LA PARED

(PARA MODELOS SIN BASE INFERIOR).

MS20883

Fig. 2. Ubicaciones de los orificios de instalación

para los modelos sin base inferior.

Modelos T812 y TS812 sin base inferior

1.

En aplicaciones de reemplazo, inspeccione los alambres

viejos para asegurarse de que su aislamiento no esté

desgastado ni agrietado y reemplace cualquier cable

que se encuentre en malas condiciones; en instalaciones nuevas, extienda dos cables hacia la ubicación.

2.

Sujetando la cubierta del termostato por la parte superior

e inferior con una mano, empuje hacia adentro el centro

de la parte inferior y estire hacia afuera hasta que la

cubierta se desprenda de la base del termostato.

MS20889

Fig. 3. Ubicación de los orificios de in stalación

para los modelos con base inferior.

Modelos T812 con base inferior

1.

En aplicaciones de reemplazo, inspeccione los alambres

viejos para asegurarse de que su aislamiento no esté

desgastado ni agrietado y reemplace cualquier cable

que se encuentre en malas condiciones; en instalaciones nuevas, extienda dos cables hacia la ubicación.

2.

Sujetando la cubierta del termostato por la parte superior

e inferior con una mano, empuje hacia adentro el centro

de la parte inferior y estire hacia afuera hasta que la

cubierta se desprenda de la base del termostato.

3.

Desconecte el termostato de la base inferior, desatornillando los tres tornillos que s e e ncuen tran bajo la cub ierta

del termostato. Consulte la Figura 1.

4.

Conecte los cables a las terminales que están en la

parte delantera de la base inferior. Consulte la Fig. 4-8

5.

Meta el cable excedente de nuevo a través del agujero y

tape cualquier abertura para evitar corrientes de aire que

pudieran afectar el funcionamiento del termostato.

6.

Fije holgadamente la base inferior del termostato a la

pared con un tornillo a través d el orific io de in st a lació n

izquierdo. Ajuste la base inferior de tal manera que esté

casi nivelada e inserte el segundo tornillo a través del

orificio de instalación izquierdo.

7.

Nivele la base inferior del termostato sólo por cuestiones

de apariencia; esto no es necesario para que opere con

precisión.

8.

Apriete los tornillos de instalación. Consulte la Figura 3.

9.

Instale el termostato en la base inferior apretando los

tres tornillos. Consulte la Figura 1.

10.

Ajuste el anticipador de calor (modelos selectos) para

que concuerde con el consumo de corriente del control

primario del sistema. Consulte la sección sobre Configuración del anticipador de calor.

11.

Reinstale la cubierta del termostato.

69-1606ESF-3 2

Page 7

TERMOSTATOS T812 Y TS812

)

S

.

.

TERMOSTATO

T812A

COMBINACIÓN DE VENTILADOR

RB

TM

TMTRTR

VÁLVULA DE GAS

SUMINISTRO DE ENERGÍA. PROPORCIONE UN MEDIO

1

DE DESCONEXIÓN Y DE PROTECCIÓN CONTRA

UNA SOBRECARGA, SEGÚN SE REQUIERA.

Fig. 4. T812A en un sistema típico de calefacción

TERMOSTATO

TS812

RB

CONTROL

DE LÍMITE

TM1 TM2

Fig. 5. Conexión típica al TS812A en siste m a

TERMOSTATO

T812B

Y CONTROL DE LÍMITE

LÍMITE VENTILADOR

TRANSFORMADOR

MOTOR DEL

VENTILADOR

por gas.

CONTROL DE PILOTO

(SI SE USA)

PP PP

de milivoltios.

(CALIENTE

MS20437

GENERADOR

DE MILIVOLTIO

MS20438A

L1

1

L2

TERMOSTATO

T812C

R

B A G

1

L1

L2

SUMINISTRO DE ENERGÍA. PROPORCIONE UN MEDIO

1

DE DESCONEXIÓN Y DE PROTECCIÓN CONTRA

UNA SOBRECARGA, SEGÚN SE REQUIERA.

Fig. 7. T812C en sistema de calefacción

L1

L2

SUMINISTRO DE ENERGÍA. PROPORCIONE

1

UN MEDIO DE DESCONEXIÓN Y DE PROTECCIÓN

CONTRA UNA SOBRECARGA, SEGÚN SE REQUIERA

Fig. 8. T812D en aplicación de enfri am ie nt o

CALOR

y enfriamiento.

TERMOSTATO

T812D

RA

1

únicamente.

FRÍO

VENTILADOR

MS20440

FRÍO

MS20441

BR

A SUMINISTRO

DE ENERGÍA

1

VÁLVULA DE GAS

SUMINISTRO DE ENERGÍA. PROPORCIONE

1

UN MEDIO DE DESCONEXIÓN Y DE PROTECCIÓN

CONTRA UNA SOBRECARGA, SEGÚN SE REQUIERA

DE 12 V CD

MS20439

Fig. 6. T812B en aplicación de 12 V cd.

3 69-1606ESF-3

Page 8

TERMOSTATOS T812 Y TS812

AJUSTE Y REVISIÓN

Ajuste de temperatura

Mueva el indicador de ajuste de temperatura al punto de

referencia deseado en la placa de escala del termostato,

consulte la Figura 1, para controlar la temperatura al punto

deseado. (En los modelos con apagado positivo, el circuito

de control se interrumpe cuando se mueve la palanca hacia

la posición más baja de la escala de temperatura.)

Ajuste del anticipador de calor (Modelos selectos)

IMPORTANTE

1. Utilic e este termostato únicamente c on controles que tengan un valor nominal de corriente

igual al (o que se encuentre dentro del rango

del) valor nominal del anticipador de calor.

2. El ajuste del anticipador de calor permite al

termostato mantener un control preciso de

la temperatura.

Los modelos con un anticipador de calor ajustable deben

ajustarse para que coincidan con el consumo de corriente del

control primario para un desempeño óptimo del termostato.

Para ajustarla, mueva la palanca indicadora del anticipador

para que coincida con el valor nominal del control. Consulte

la Figura 1.

Si el ajuste y el valor nominal de corriente no están disponibles,

conecte el termostato en el sistema, pero no lo coloque en la

pared. Si el termos ta to y a e stá in st a la d o, qu íte lo de la pared,

dejándolo conectado al cableado del sistema.

Conecte un amperímetro del rango apropiado (aproximadamente de 0.0 A a 2.0 A) entre las terminales que se encuentran

en la parte posterior del termostato. Mueva la palanca de ajuste

de temperatura a un valor más bajo, de tal manera que los

contactos se interrumpan. En clima frío tal vez sea necesario

sostener el interruptor de tal manera que los controles permanezcan abiertos. Permita que el sistema opere a través del

amperímetro durante un minuto. Ajuste el anticipador para que

coincida con la lectura del amperímetro.

NOTA: Para obtener el mejor desempeño, el anticipa-

dor puede requerir más ajuste. Para alar gar

el tiempo en que el quemador permanece

encendido, coloque el indicador en un número

mayor, pero no más de medi a marca de esca la

a la vez. Para reducir el tiempo en que el quemador permanece encendido, mueva el indicador en la dirección opuesta.

Anticipador de frío (Modelos selectos)

Los modelos con un anticipador de enfriamiento cuentan con

un anticipador fijo de 24 Vca a 30 Vca.

Verificación

PRECAUCIÓN

Riesgo de corto circuito.

Puede dañar el anticipador de calor.

No compruebe la operación mediante un corto

entre las terminales de control del sistema.

Observe el sistema cuando menos durante un ciclo automático

completo. Asegúrese de que el sistema opere según lo esperado.

Compruebe la correcta operación del interruptor de apagado

positivo, si se está utilizando.

Calibración

Este termostato se ha calibrado cuidadosamente en la fábrica

por lo que no puede ajustarse en el campo.

Soluciones de automatización y control

Honeywell Internation al Inc. Honeywell Limited- Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

69-1606ESF-3 G.H. Rev. 5-04 Impreso en China www.honeywell.com/yourhome

M1V 4Z9

Page 9

Thermostats T812 et TS812

NOTICE D'INSTALLATION

APPLICATION

Les thermostats T812 et TS812 sont des régulateurs

basse tension pour systèmes de chauffage seulement,

systèmes de refroidissement seulement ou systèmes de

chauffage et refroidissement. Voir le Tableau 1.

Tableau 1. Description des modèles.

Modèle Tension Système

T812A 24 V c.a. Chauffage

T812B 12 V c.c. Chauffage

T812C 24 V c.a. Chauffage

T812D 24 V c.a. Refroidisse-

TS812A 750 mV Chauffage

seulement

seulement

et

refroidissement

ment

seulement

seulement

Résistance

anticipatrice

Réglable 0,18

A à 1,2 A sous

30 V c.a.

0,18 A à 1,2 A

sous 12 V c.c.

Réglable 0,18

A à 1,2 A sous

30 V c.a.

Fixe, 24 V c.a.

à 30 V c.a.

0,1 A sous

0,75 V c.c.

AVIS DE RECYCLAGE

Si le présent thermostat remplace un thermostat

contenant du mercure dans une ampoule scellée,

ne pas jeter l'ancien thermostat à la poubelle.

Communiquer avec le service d'enlèvement des

déchets de la municipalité pour savoir comment

recycler ce type de thermostat et comment en

disposer.

INSTALLATION

Avant d'inst aller ce produi t…

1. Lire attentivement les présentes instructions. Le

fait de ne pas les suivre pourrait constituer un danger ou endommager le produit.

2. Vérifier les caractéristiques nominales spéci fiées

dans les instructions et celles indiquées sur le produit pour s'assurer que celui-ci convient à l'usage

prévu.

3. L'installateur doit être un technicien d'expérience

ayant reçu une formation pertinente.

4. Une fois l'installation terminée, vérifier le fonc tionnement du produit en suivant les présentes instructions.

MISE EN GARDE

Risque de choc électrique.

Peut causer des blessures ou des

dommages matériels.

Couper l'alimentation avant d'installer ce produit.

Choix de l'emplacement

Installer le thermostat à environ 1,5 m (5 pi) au-dessus

du plancher dans un endroit où la circulation de l 'air est

bonne et la température est moyenne.

Ne pas installer le thermostat dans un endroit où les

conditions suivantes peuvent nuire à son bon

fonctionnement :

— courants d'air ou zones sans circulation d'air der-

rière les portes et dans les coins.

— air chaud ou froid provenant des gaines.

— chaleur radiante du soleil ou des appareils

ménagers.

— tuyaux et cheminées dissimulés

— endroits non chauffés (ou non refroidis), p. ex.

mur extérieur derrière le thermostat

® Marque de commerce déposée aux É.-U.

Copyright © 2004 Honeywell International Inc. • Tous droits réservés •

69-1606ESF-3

Page 10

THERMOSTATS T812 ET TS812

MF20496A

(

INTERRUPTEURS À RUPTURE BRUSQUE

3

TROUS DE MONTAGE (2) DU

MF20889

TROU DE MONTAGE

THERMOSTAT MURAL)

LANGUETTES

DE MONTAGE (3)

LEVIER DE RÉGLAGE

DE LA TEMPÉRATURE

3. Raccorder les fils du thermostat aux bornes correspondantes à l'arrière du thermostat. Se report er

aux schémas de raccordement des Fig. 4 à 8.

4. Rentrer le surplus de fils dans le mur et boucher

les trous pour éviter que les courants d'air ne

nuisent au bon fonctionnement du therm ostat.

5. Régler la résistance anticipatrice de chaleur (sur

certains modèles) en fonction de l'appel de courant

de l'appareil de commande du système. Voir la

section Réglage de la résistance anticipatrice de

chaleur.

6. Utiliser le trou de montage dans la partie

supérieure gauche et celui du côté droit pour fixer

le thermostat au mur à l'aide de vis. Voir la Fig. 2.

7. Remettre le couvercle sur le thermostat.

TROUS DE MONTAGE (2) DU

THERMOSTAT SUR UN MUR

(MODÈLES AVEC PLAQUES

DE COMMUTATION).

VIS (3) POUR LE

MONTAGE DU

THERMOSTAT

SUR LA

PLAQUE DE

COMMUTATION

Fig. 1. Vue de l'intérieur du T812 avec résistance

anticipatrice de chaleur réglable.

ÉLÉMENT

BIMÉTALLIQUE

LEVIER DE

L'INDICATEUR

DE RÉSISTANCE

ANTICIPATRICE

DE CHALEUR

RÉGLABLE

ÉCHELLE DE LA

RÉSISTANCE

ANTICIPATRICE DE

CHALEUR RÉGLABLE

TROU DE MONTAGE

(THERMOSTAT MURAL)

Raccordement et montage

Le câblage doit être conforme aux codes d'électr ici té et

aux règlements locaux.

THERMOSTAT SUR UN MUR

(MODÈLES SANS PLAQUE

DE COMMUTATION).

Fig. 2. Emplacement des trous de montage sur les

Modèles T812 et TS812 sans plaque de

commutation

1. Dans le cas de remplacement d'un thermostat,

2. Saisir d'une main la partie supérieure et la partie

modèles sans plaque de commu tation.

s'assurer que l'isolant des anciens fils n'est ni

craquelé ni effiloché; remplacer tous les fils

abîmés. Dans le cas d'une nouvelle installation,

amener les deux fils jusqu'à l'emplacement choisi.

inférieure du couvercle du thermostat, appuyer sur

la partie inférieure, au centre, et tirer pour dégager

le couvercle de la base du thermostat.

MF2088

Fig. 3. Emplacement des trous de m ontage sur le s

modèles avec plaque de commutation.

Modèles T812 avec plaque de commutation

1. Dans le cas de remplacement d'un thermostat,

s'assurer que l'isolant des anciens fils n'est ni

craquelé ni effiloché; remplacer tous les fils

abîmés. Dans le cas d'une nouvelle installation,

amener les fils appropriés jusqu'à l'emplacem ent

choisi.

2. Saisir d'une main la partie supérieure et la partie

inférieure du couvercle du thermostat, appuyer sur

la partie inférieure, au centre, et tirer pour dégager

le couvercle de la base du thermostat.

3. Dévisser les trois vis sous le couvercle du thermostat pour retirer le thermostat de la plaque de commutation. Voir la Fi g . 1 .

4. Raccorder les fils aux bornes sur le devant de la

plaque de commutation. Voir les Fig. 4 à 8.

5. Rentrer le surplus de fils dans le mur et boucher

les trous pour éviter que les courants d'air ne

nuisent au bon fonctionnement du therm ostat.

6. Fixer sans serrer la plaque de commutation au mur

en insérant une vis dans le trou de montage droit.

Placer la plaque de manière qu'elle soit presque

droite et insérer la deuxième vis dans la fente

gauche.

7. Mettre le thermostat de niveau, mais essentiellement à des fins d'esthétique. Le thermostat fonctionnera avec précision même s'il n'est pas de

niveau.

8. Serrer les vis de montage. Voir la Fig. 3.

9. Monter le thermostat sur la plaque de commutation

du thermostat à l'aide des trois vis. Voir la Fig. 1.

69-1606ESF-3 2

Page 11

10. Régler la résistance anticipatrice de chaleur (sur

1

S

N

2

7

THERMOSTAT

A

THERMOSTAT

N

THERMOSTAT

0

S.

THERMOSTAT

MF20441

S.

THERMOSTAT

certains modèles) en fonction de l'appel de courant

de l'appareil de commande du système. Voir la

section Réglage de la résistance anticipatrice de

chaleur.

11. Remettre le couvercle sur le thermostat.

T812A

R W

TH

THTRTR

VANNE À GAZ

ALIMENTATION. FOURNIR AU BESOIN UN DISPOSITIF DE

1

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES

TRANSFORMATEUR

Fig. 4. T812A dans un système de chauffage au gaz

TS812

RW

LIMITEUR

TH1 TH2 PP PP

Fig. 5. Schéma de raccordement typique d'un

TS812A à un système à tension mv.

RÉGULATEUR DE

VENTILATEUR ET

LIMITEUR COMBINÉS

LIMITEUR

MOTEUR DU

VENTILATEUR

typique.

RÉGULATEUR DE VEILLEUSE

(LE CAS ÉCHÉANT)

GÉNÉRATEUR

À TENSION MV

VENTILATEUR

MF20438

SOU

TENSIO

MF2043

L

1

L

THERMOSTATS T812 ET TS812

T812B

WR

1

VERS

ALIMENTATION

VANNE À GAZ

ALIMENTATION. FOURNIR AU BESOIN UN

1

DISPOSITIF DE COUPURE ET UNE PROTECTIO

CONTRE LES SURCHARGES.

12 V c.c.

MF20439

Fig. 6. T812B dans une applicati on 12 V c. c.

T812C

R W Y G

1

L1

L2

ALIMENTATION. FOURNIR AU BESOIN UN DISPOSITIF DE

1

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGE

Fig. 7. T812C dans un système de chau ffage et de

L1

L2

ALIMENTATION. FOURNIR AU BESOIN UN DISPOSITIF DE

1

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGE

CHAUFFAGE

REFROIDISSEMENT

refroidissement.

T812D

RY

1

REFROIDISSEMENT

VENTILATEUR

MF2044

Fig. 8. T812D dans une application de

refroidissement seulement.

3 69-1606ESF-3

Page 12

RÉGLAGE ET VÉRIFICATION

Réglage de la température

Placer le levier de réglage de la température au point de

consigne voulu (voir la Fig. 1) pour assurer la régulation

à la température désirée. (Sur les modèles avec position

de fermeture (OFF), le circuit de commande s'ouvre

lorsque le levier est déplacé à la valeur la plus basse de

l'échelle de température.)

Réglage de la résistance anticipatrice de chaleur (sur certains modèles)

IMPORTANT

1. Utiliser ce thermostat seulement avec des

appareils de commande dont l'intensité nominale est égale (ou dans les limites) à l'intensité

nominale de la résistance anticipatrice de

chaleur.

2. Le réglage de la résistance anticipatrice de

chaleur assure une régulation précise de la

température par le thermostat.

Pour un rendement optimal, le réglage des modèles

munis d'une résistance anticipatrice de chaleur réglable

doit correspondre à celui de l'appel de courant de

l'appareil de commande. Pour effectuer le réglage,

placer le levier de l'indicateur de la résistance

anticipatrice au point de l'échelle correspondant à

l'intensité nominale de l'appareil de commande. Voir la

Fig. 1.

Si le réglage et les caractéristiques nominales du courant

ne sont pas indiqués, raccorder le thermostat au

système, sans toutefois le fixer au mur. Si le thermostat

est déjà fixé au mur, le retirer, mais le laisser brancher au

système.

Raccorder un ampèremètre d'échelle appropriée (0,0A à

2,0 A environ) aux bornes à l'arrière du thermostat.

Déplacer le levier de réglage à une température plus

basse pour faire ouvrir le circuit. Lorsque la température

est basse, il faut parfois maintenir l'interrupteur enfoncé

pour que les appareils de commande restent ouverts.

Faire fonctionner le système avec l'ampèremètre

pendant une minute. Régler la résistance anticipatrice à

la valeur indiquée sur l'ampèremètre.

REMARQUE : D'autres réglages sont parfois néces-

saires pour un meilleur rendement. Pour

augmenter la durée du chauffage,

déplacer l'indicateur à une valeur plus

élevée, une demi-graduation à la fois .

Pour diminuer la durée de chauffage,

déplacer l'indicateur dans le sens opposé.

Résistance anticipatrice de froid (sur certains modèles)

Les modèles munis d'une résistance anticipatrice de froid

ont une résistance anticipatrice fixe de 24 V c.a. à

30 V c.a.

Vérification

MISE EN GARDE

Risque de court circuit.

Peut endommager la résistance anticipatrice.

Pour vérifier le fonctionnement de l'apparei l, ne

pas court-circuiter les bornes des appareils de

commande du système.

Faire fonctionner le système pendant au moins un cycle

automatique complet. S'assurer qu'il fonctionne

normalement. Le cas échéant, vérifier si l'interru pt eur

avec position de fermeture fonctionne correctement.

Étalonnage

Ce thermostat a été étalonné avec soin à l'usine; il ne

peut être réglé en clientèle.

Solutions de régulation et d'automatisation

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35, Dynamic Drive

Golden Valley, MN 55422 Scarborough (Ontario)

69-1606ESF-3 G.H. Rev. 5-04 Imprimé aux China www.honeywell.com/yourhome

M1V 4Z9

Loading...

Loading...