Page 1

T8112C,D Electronic

Programmable Thermostats

INSTALLATION INSTRUCTIONS

APPLICATION

The T8112C,D thermostats provide electronic

programmable control for 24 to 30 Vac heating and

cooling systems.

RECYCLING NOTICE

If this control is replacing a control that contains

mercury in a sealed tube, do

control in the trash.

Contact your local waste management authority

for instructions regarding recycling and the proper

disposal of the old thermostat.

not

place your old

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

1. Disconnect power supply to prevent electrical

shock or equipment damage.

2. After wiring is complete, push excess wire

back into the hole and plug hole with

nonhardening caulk, putty or insulation to

prevent drafts from affecting thermostat

operation.

Location

Install the thermostat about 5 ft. (1.5m) above the floor in

an area with good air circulation at average temperature.

Do not install the thermostat where it can be affected by:

— drafts, or dead spots behind doors and in corners.

— hot or cold air from ducts.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

behind the thermostat.

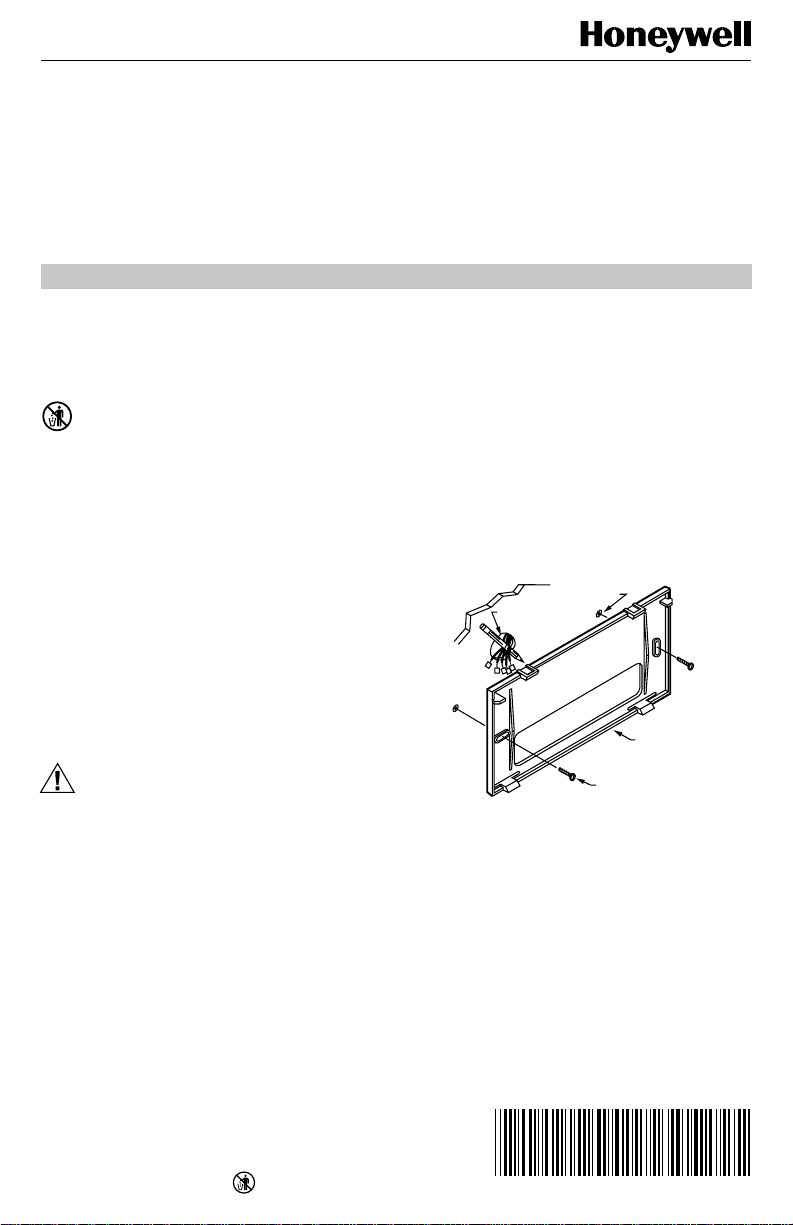

Mounting Plate Installation

Position mounting plate on the wall. Use a level to make

sure mounting plate is level. Use a pencil to mark the two

mounting holes. See Fig. 1.

WALL ANCHORS (2)

WIRES THROUGH

WALL OPENING

WALL

MOUNTING

PLATE

MOUNTING

SCREWS (2)

Fig. 1. Mounting plate installation.

M1718

®U.S. Registered Trademark

Copyright © 1998 Honeywell Inc. • • All Rights Reserved

X-XX UL

69-0917-2

Page 2

T8112C,D ELECTRONIC PROGRAMMABLE THERMOSTATS

1. Remove mounting plate from the wall, and drill

3/16 inch holes in wall (if drywall) as marked. For

firmer material such as plaster or wood, drill

7/32 inch holes. Gently tap anchors (provided) into

drilled holes until flush with the wall.

2. Reposition mounting plate over holes, pulling

wires through wiring opening. Loosely insert two

mounting screws into holes.

3. Level for appearance only; the thermostat will

function properly even when not level. Tighten

mounting screws. See Fig. 2.

LEVEL

M1714A

Fig. 2. Leveling mounting plate.

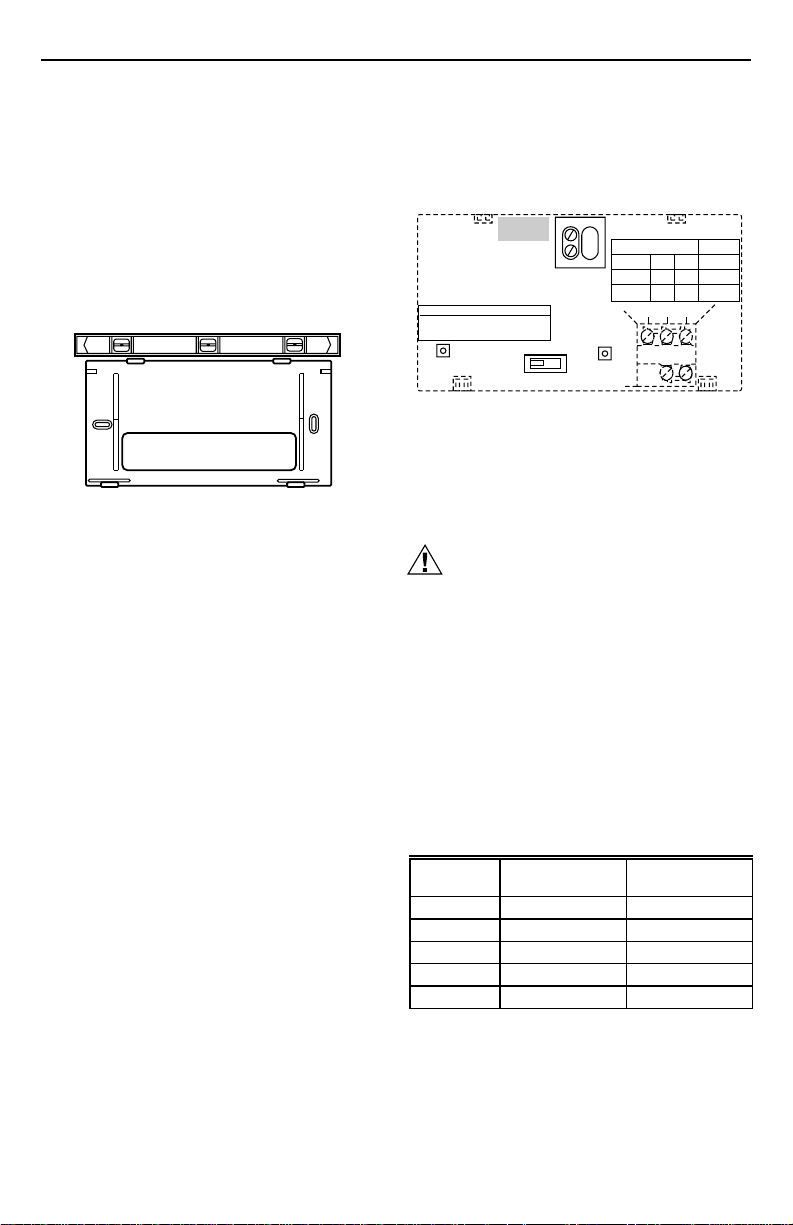

Adjust Fan Operation Switch,

as Required

The Thermostat fan operation switch, labeled FUEL

SWITCH is factory set in the F position. See Fig. 4. This

is the correct setting for most systems. If your system is

an electric heat system, set the switch to E. The E setting

allows the fan to turn on immediately with the heating or

cooling in a system where the G terminal is connected.

Adjust System On-time, as Required

The system on-time is factory-set for a warm air, gas or

oil heating system. If you are installing it on another type

of system, the system on-time must be adjusted

accordingly by setting screws A and B on the back of the

thermostat. Use the heating system table shown in Fig. 3

as a guide. The system on-time should be optimized

according to the type of system to minimize room

temperature swings. Setting the screw

means turning the screw approximately 360° or one

complete turn. Setting the screw in means tightening the

screw completely down.

In the event that you want longer furnace on-time,

readjust the screws A and B as follows:

• Warm Air Furnace—set at the Hot Water setting (A—

out one turn, B—in).

• Electric Furnace—Leave at the Warm Air Furnace

setting (A—in, B—in).

NOTE: This thermostat does not have a setting for

steam/gravity air. Cycles would not be long

enough for accurate temperature control.

out one turn

IMPORTANT

When using a high efficiency furnace such as a

90 percent or greater AFUE (Average Fuel

Utilization Efficiency) unit, adjust screw A out

one turn and screw B in.

THERMOSTAT BACK

FOR HIGH EFFICIENCY FURNACE (90%+ AFUE)

ADJUST:

SCREW A–OUT 1 TURN

SCREW B–IN

FUEL SWITCH – F POSITION

A C

B D

FUEL SWITCH

F

ADJUST SCREWS THROUGH HOLES

TO SELECT OPERATION DESIRED

WARM AIR

FURNACE

HOT WATER

BOILER

ELECTRIC

FURNACE

E

HEATING SYSTEM

A–IN

A–OUT

1 TURN

A–IN

W Y G

R

B–IN

B–IN

B–OUT

1 TURN

FUEL SWITCH

POSITION

F

F

E

Rc

M3669

Fig. 3. Back view of thermostat.

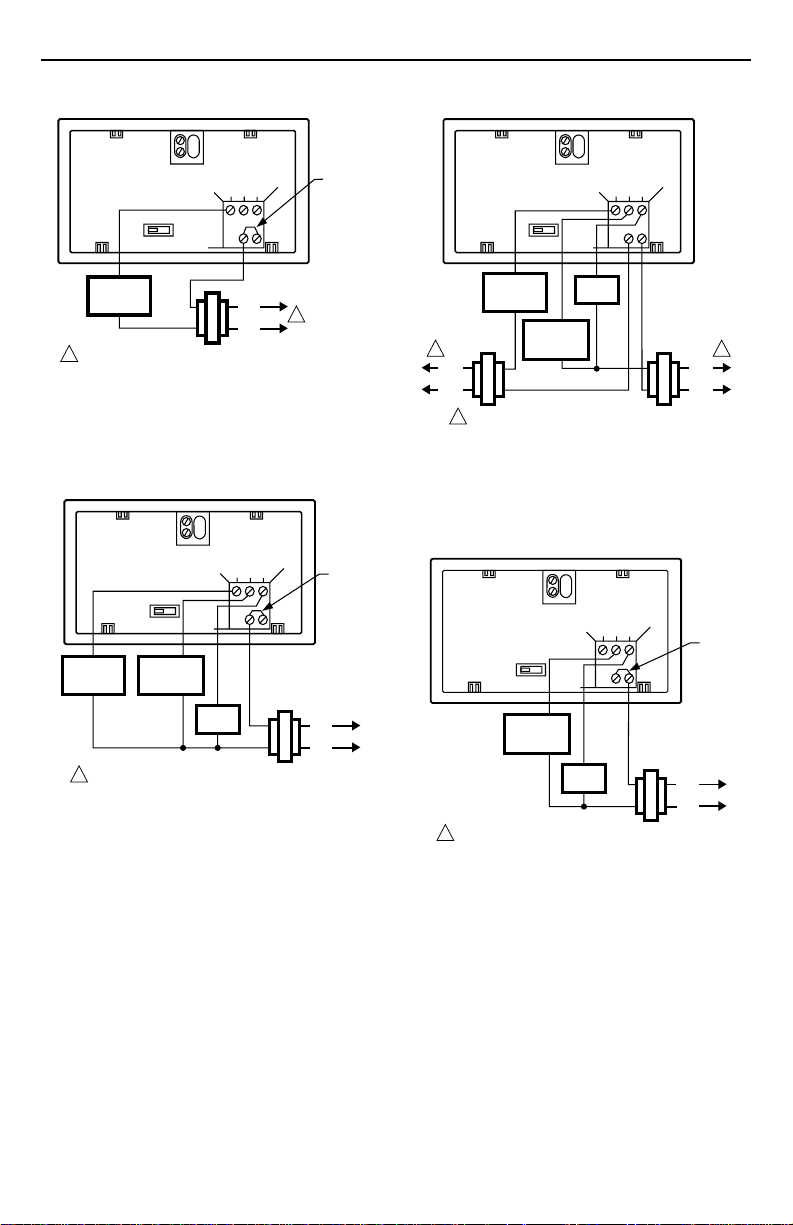

Wiring Thermostat

All wiring must comply with local electrical codes and

ordinances. Ref er to Fig. 4 through 7 for typical hookups. A

letter code is located near each terminal for identification.

See Table 1 f or terminal cross referencing inf ormation.

CAUTION

Disconnect power before wiring to prevent

electrical shock or equipment damage.

1. Connect the system wires to the thermostat. See

Fig. 8. A letter code is located near each terminal

for identification.

NOTE: Hold the thermostat as shown in Fig. 9 to

minimize need for wire extenders.

2. Securely tighten each terminal screw.

3. Push excess wire back into the hole.

4. Plug hole with nonflammable insulation to prevent

drafts from affecting the thermostat.

Table 1. Typical Wire Colors and Functions

Thermostat

Terminal

G Green Fan

Y Yellow Cooling

W White Heating

Rc Blue Air Cond. Power

R Red Furnace Power

a

Wire colors are typical; verify at heating/cooling

equipment connection.

Connect to

Wire Color

a

Function

69-0917—2

2

Page 3

T8112C,D ELECTRONIC PROGRAMMABLE THERMOSTATS

R

Rc

W Y G

B D

A C

3-WIRE COOL-ONLY (JUMPER INTACT)

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

1

JUMPER

M848A

COOLING

CONTACTOR

COIL

FAN

RELAY

2-WIRE HEAT-ONLY (JUMPER INTACT)

A C

B D

W Y G

R

HEATING

RELAY OR

VALVE COIL

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

Fig. 4. Typical hookup in two wire lead

only (jumper intact) application.

L1

(HOT)

L2

4-WIRE HEAT/COOL (JUMPER INTACT)

A C

B D

W Y G

R

HEATING

RELAY OR

VALVE COIL

1

COOLING

CONTACTOR

COIL

FAN

RELAY

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

Fig. 5. Typical hookup in four wire heat

and cool (jumper intact) application.

5-WIRE HEAT/COOL (JUMPER REMOVED)

A C

B D

JUMPER

Rc

HEATING

RELAY OR

1

M1709B

JUMPER

Rc

L1

(HOT)

L2

M1710B

VALVE COIL

COOLING

1 1

L1

(HOT)

L2

1

Fig. 6. Typical hookup in five wire heat

and cool (jumper removed) application.

CONTACTOR

COIL

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

FAN

RELAY

W Y G

R

Rc

L1

(HOT)

L2

M1711B

Fig. 7. Typical hookup in three wire cool

only (jumper intact) application.

3

69-0917—2

Page 4

T8112C,D ELECTRONIC PROGRAMMABLE THERMOSTATS

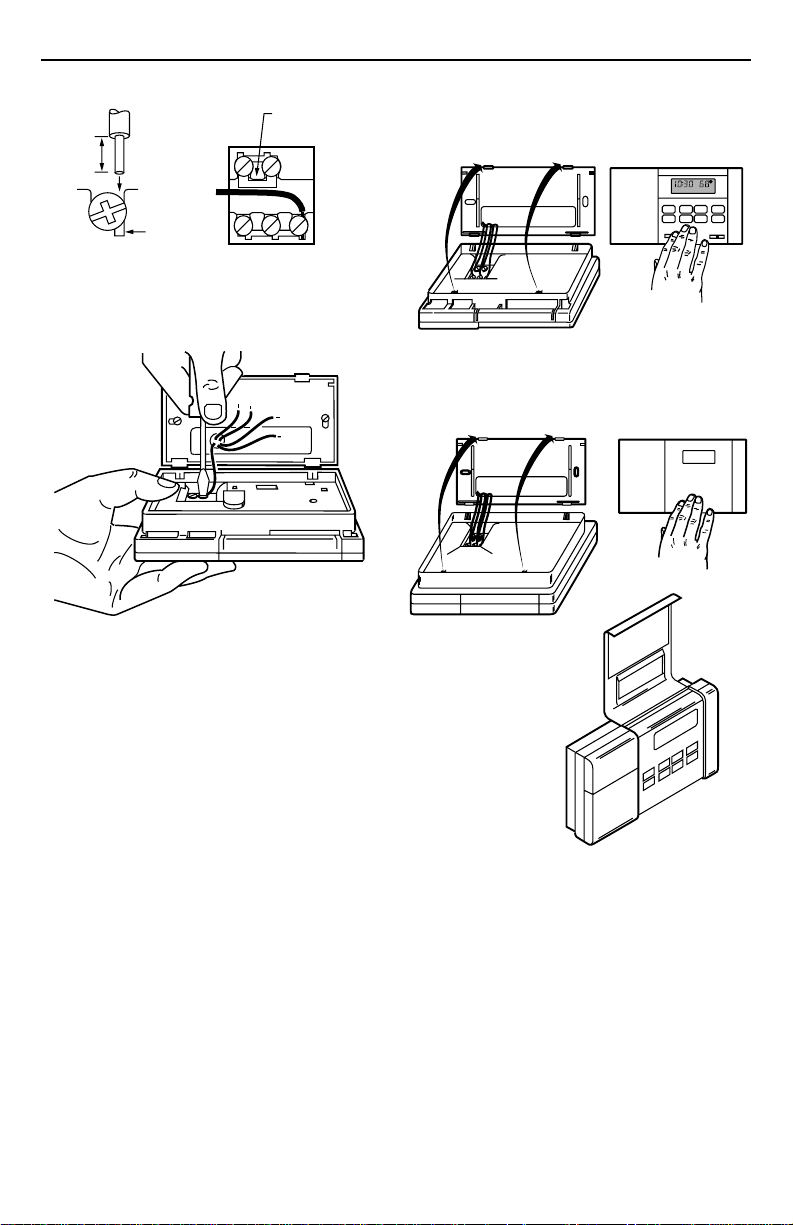

T8112C

A.

THERMOSTAT AND MOUNTING PLATE.

5/16 in.

(8 mm)

STRIP

INSERT

STRAIGHT

UNDER

SCREW HEAD

END OF WIRE

VISIBLE HERE

c

R

JUMPER (FACTORYINSTALLED) REMOVE

IF 5-WIRE SYSTEM

R

WY G

M1712A

Fig. 8. Proper wiring technique.

T8112D

A. ENGAGE TABS AT TOP OF

THERMOSTAT AND MOUNTING PLATE.

M3002A

Fig. 9. Holding thermostat while installing.

Mounting Thermostat on Mounting Plate

1. Engage tabs at the top of thermostat and mounting

plate. See Fig. 10.

2. Press lower edge of case to latch.

NOTE: To remove the thermostat from the wall, first

pull out at the bottom of the thermostat; remove

top last.

ENGAGE TABS AT TOP OF

C. SWING COVER OPEN TO

CHECK OPERATION.

B.

PRESS LOWER EDGE

OF CASE TO LATCH.

AM

TU

LEAVE

B. PRESS LOWER EDGE

OF CASE TO LATCH.

M13063

M5780

69-0917—2

Fig. 10. Mounting thermostat on mounting plate.

4

Page 5

T8112C,D ELECTRONIC PROGRAMMABLE THERMOSTATS

Installing Batteries

IMPORTANT

Batteries must be installed for programming and

operation of the thermostat and heating/cooling

system.

1. Use two AA alkaline batteries; nonalkaline

batteries will not last as long, and can leak,

causing damage to the thermostat or wall surface.

Energizer batteries are recommended.

2. Make sure the thermostat is set in the OFF position.

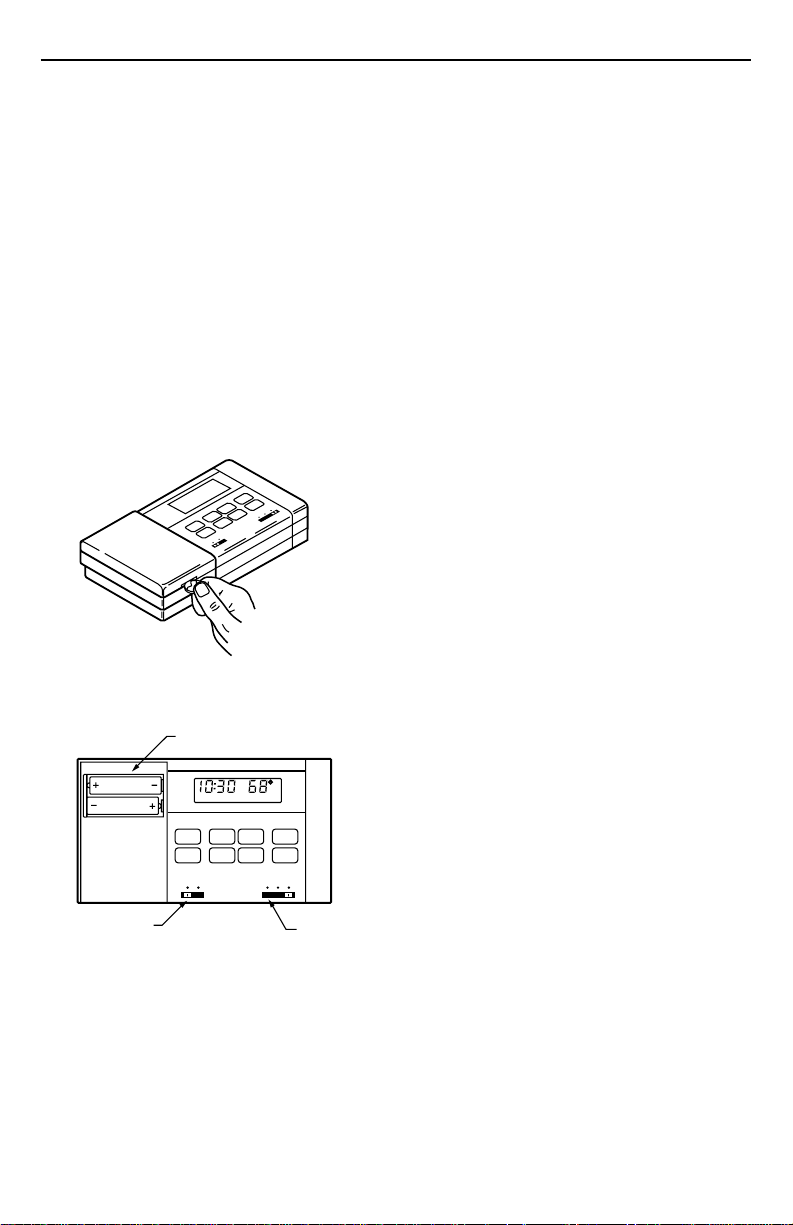

3. Use a coin to remove the battery door. See Fig. 11.

4. Install the new batteries making sure positive and

negative terminals are oriented correctly. See

Fig. 12.

5. Replace battery door.

M5781

Fig. 11. Remo ving battery door.

INSTALL TWO AA ALKALINE

BATTERIES AS SHOWN

AM

TU

LEAVE

As the batteries are running low, a “bAt Lo” indicator flash

for one to two months before batteries run out completely.

Replace the batteries as soon as possible after the

indicator starts flashing. If the batteries are not replaced

sometime during the flashing “bAt Lo,” the indicator

eventually stops flashing. “bAt Lo” will stay on without

flashing, indicating the thermostat and heating/cooling

system have stopped working and the batteries are almost

completely dead.

After the batteries are completely dead, the “bAt Lo”

indicator disappears, leaving a completely blank display.

To remove, press down on left ends of batteries. If the

new batteries are installed within 20 to 30 seconds of

removing the old ones, the thermostat does not have to

be reprogrammed. If the display is blank, the batteries

are dead or incorrectly installed and the thermostat has

to be reprogrammed. See Owner’s Manual for

programming instructions.

SETTINGS

Current Time/Day

To set time, press and release the Set Clock/Day key

once. Press the Time keys until the current time shows.

To set day, press and release the Set Clock/Day key

again. Press the Time ke ys until the current day shows.

Press Run Program key.

See Owner’s Manual for complete programming

instructions.

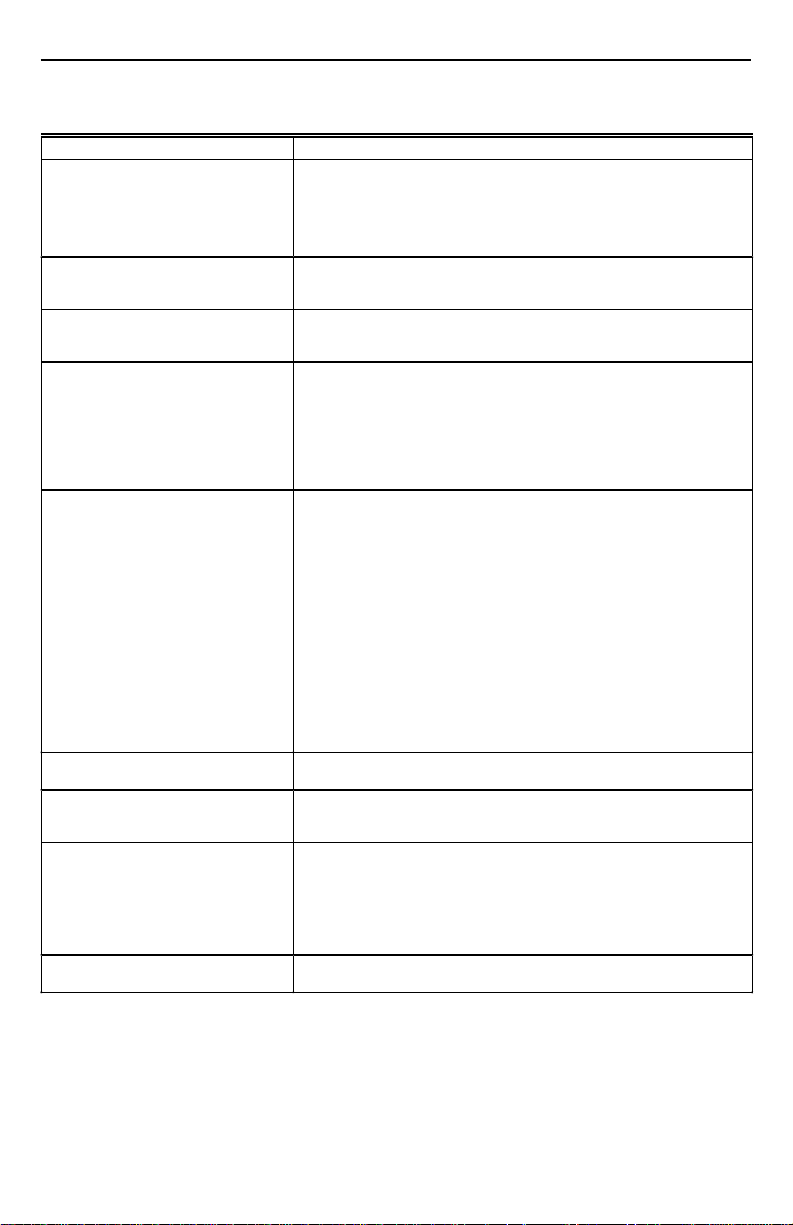

Fan Switch

FAN AUTO: Normal setting f or most homes. A single-

speed fan turns on automatically with the air conditioner

of furnace. A two-speed fan usually runs on high with

the air conditioner and on low with the furnace.

NOTE: When Fan Operation Switch on the back of the

thermostat is in E position, the fan operates with

the furnace only.

FAN ON: The fan runs continuously. Used for improved

air circulation during special occasions or for more

efficient electronic air cleaning.

Auto On

Fan

FAN SWITCH

Fig. 12. Installing batteries.

System

Cool Off Heat

SYSTEM

SWITCH

M5782

System Switch

System switching positions control thermostat operation

as follows:

COOL: The thermostat controls the air conditioning

system.

OFF: Both the heating and air conditioning systems

are off.

HEAT: The thermostat controls the heating system.

5

69-0917—2

Page 6

T8112C,D ELECTRONIC PROGRAMMABLE THERMOSTATS

CHECKOUT

Heating

Do

not

check heating system operation by jumpering

thermostat terminals at the primary control such as the

gas valve, zone valve, or oil burner control This will

damage the thermostat. Instead, you could jumper R

and R wires at the thermostat.

Cooling

To avoid possible compressor damage, do not operate

the cooling system when outside temperature is below

50°F (10°C). See compressor manufacturer instructions

for further information.

NOTE: When cooling setting is changed, thermostat

can delay up to five minutes before turning on

the air conditioner. This delay protects the

compressor.

Fan

Move the thermostat system switch to OFF and the fan

switch to ON. The fan should run continuously. With the

system switch still in the OFF position, move the fan

switch to AUTO; the fan should stop.

Move the system switch to HEAT and the fan switch

to AUTO.

Press key until the setting is about 10°F (6°C) abov e room

temperature. Heating should start and the fan should run

after a short delay (immediately if fan operation switch is

set in E position).

Press key until setting is about 10°F (6°C) below room

temperature. The heating equipment should shut off.

Move the system switch to COOL and the fan switch

to AUTO.

Press key until setting is about 10°F (6°C) below room

temperature. The cooling equipment and fan should start.

Press key until the setting is about 10°F (6°C) abov e room

temperature. The cooling equipment and fan should stop.

Move the system switch to OFF and the fan switch to

AUTO. The system and fan should be off.

69-0917—2

6

Page 7

T8112C,D ELECTRONIC PROGRAMMABLE THERMOSTATS

TROUBLESHOOTING GUIDE

If… Then…

Display will not come on. • Set the system switch to OFF. Remove batteries. Insert batteries

Temperature display will not go lower

than 45° F (7° C) or higher than 88° F

(31° C) during programming.

Temperature change occurs at the

wrong times.

Heating will not come on. • Check that switch on thermostat is set to HEAT. Allow a minimum of five

Cooling will not come on. • Check that switch on thermostat is set to COOL. Allow a minimum of five

Too warm or too cool. • Press Run Program key to check the current temperature setting.

SYSTEM ON indicator is lit, but no heat

is coming from the registers.

Thermostat current temperature setting

does not match the display temperature

to within ± 1°.

bAtLo remains on display after batteries

are installed.

backward for at least five seconds to reset thermostat. Correctly replace

batteries. Display should come on.

• Make sure batteries are fresh and installed correctly.

• Gently clean battery contacts using a soft pencil eraser. Do not use

anything abrasive on the clips.

• The temperature setting limit is reached. The setting range is 45° F to

88° F (7° C to 31°C).

• Check the program times for the period in question. Be sure that AM and

PM indications are correct. Make sure the current day and time are

correct. Reprogram if necessary.

minutes for time guard protection to expire.

• Check the system fuse or circuit breaker and replace or reset if

necessary.

• Check for correct wiring and good connections.

• Disconnect and jumper wires R and W. If heat does not come on, check

out the heating system.

• If display is blank or says “bAt Lo,” install fresh batteries.

minutes for time guard protection to expire.

• Check the system fuse or circuit breaker and replace or reset if

necessary.

• Check for correct wiring and good connections.

• Disconnect and jumper wires R and Y. If cooling does not come on,

check out the cooling system.

• If display is blank or says “bAt Lo,” install fresh batteries.

• The thermostat has a built-in time delay on cooling. Allow at least five

minutes after changing the setting before the air conditioner starts.

• Make sure outdoor disconnect is engaged (on).

• If temperature setting is lower than current temperature, and SYSTEM

ON indicator is lit, move system switch from COOL to OFF for ten

minutes. After ten minutes, return switch to COOL position. If air

conditioner comes on, compressor could have reached its high limit

temperature protection and shut down.

• If 2- or 4-wire installation, verify that R-Rc jumper is installed

• If desired, change the temperature setting. See the Owner’s Manual.

• Allow time for the furnace to heat up and the fan to come on before

checking for heat at the register. (Check to make sure the Cycle Rate in

the Installation section is correct.)

• Check that the wiring hole in the wall behind the wallplate has been

plugged with insulation to prevent drafts that might adversely affect

thermostat operation.

• Be aware that it is normal for the current setting and display temperature

to differ on occasion.

• During recovery from setback or setup, setting and display temperatures

can differ for up to 30 minutes after recovery period.

Remove batteries. Wait one hour. Install fresh Alkaline batteries.

NOTICE

This equipment is a Class B digital apparatus, which complies with Canadian Radio Interference Regulations, CRC

c.1374.

7

69-0917—2

Page 8

T8112C,D ELECTRONIC PROGRAMMABLE THERMOSTATS

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis, MN 55408-0524

69-0917—2

69-0917—2 G.H. Rev. 4-98 Printed in Mexico www.honeywell.com

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 3N7

8

Loading...

Loading...