Page 1

ST9103A

Electronic Fan Timer

INSTALLATION INSTRUCTIONS

APPLICATION

The ST9103A Electronic Fan Timer integrates control of all

burner and circulator fan operations in an oil furnace. This

control is the central wiring point for most of the electrical

components in the furnace. The basic purposes of the

ST9103A are to monitor the thermostat for heat, cool, and fan

demands and run the oil burner primary control and up to a

two-speed circulating fan as required. The ST9103A also

monitors a limit switch string, which energizes the circulating

fan whenever the limit switch opens.

Electronic air cleaner and humidifier convenience terminal

connections may be provided as an option. A means for

operating continuous indoor air circulation is also available as

an option.

SPECIFICATIONS

Electrical Ratings:

Power Requirements:

Voltage: 18-30 Vac, 50/60 Hz.

Current: 4 VA at 24 Vac.

Contact Ratings:

Circulating Fan: 15A Full Load, 30A Locked Rotor at

115 Vac (includes optional EAC load).

On/Off Delay Settings:

Delay On: 30 seconds, fixed.

Delay Off: 60, 90, 120, 150 seconds, field-adjustable.

Timing Tolerance: larger of ±20% or 5 seconds.

2. Check the ratings and specifications given in the

Instructions and on the product to assure the product is

suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out the product

operation as provided in these instructions.

CAUTION

Disconnect power supply before wiring to prevent

electrical shock or equipment damage.

Location and Mounting

The ST9103A is mounted in the appliance wiring

compartment using four No. 6 screws (obtained locally)

through standoffs on the corners of the board.

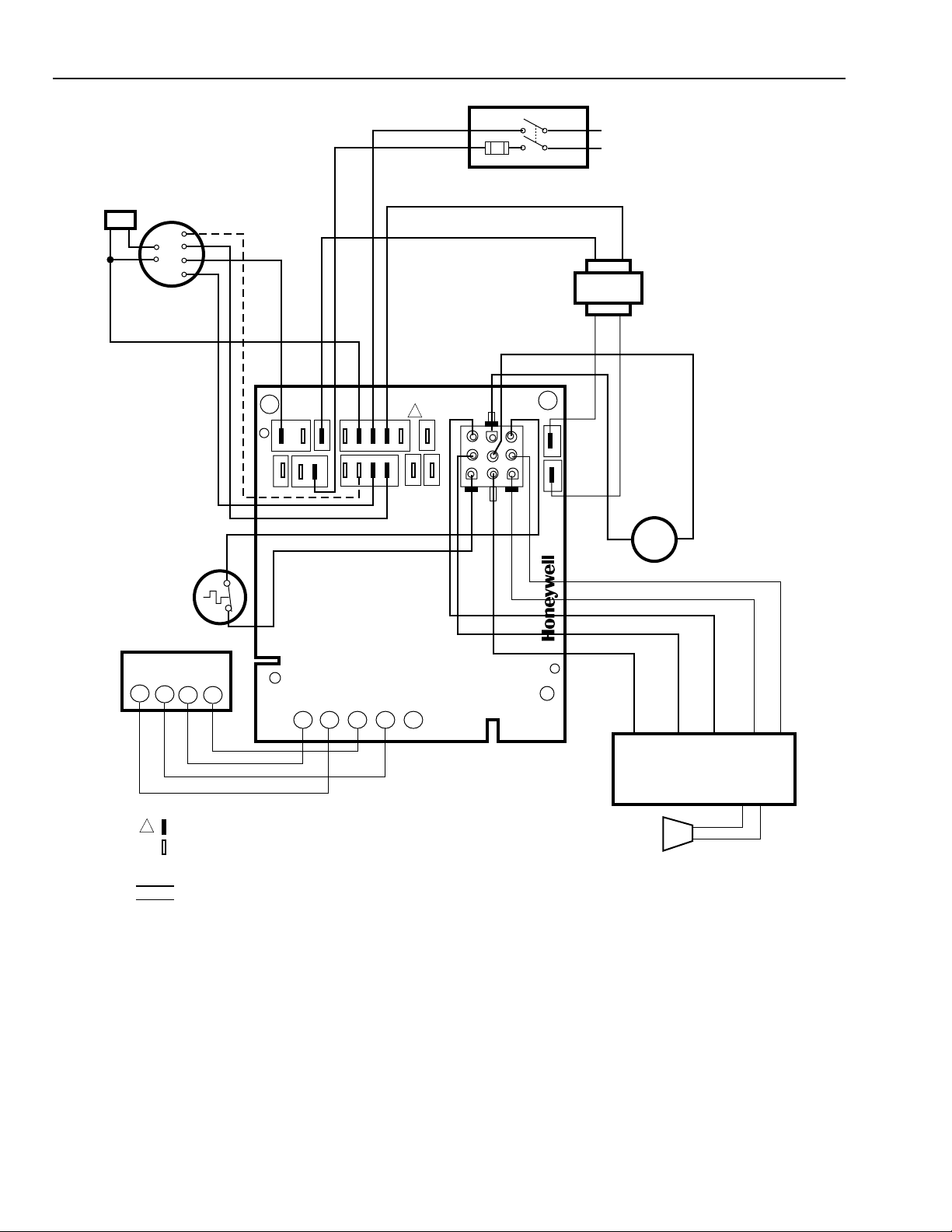

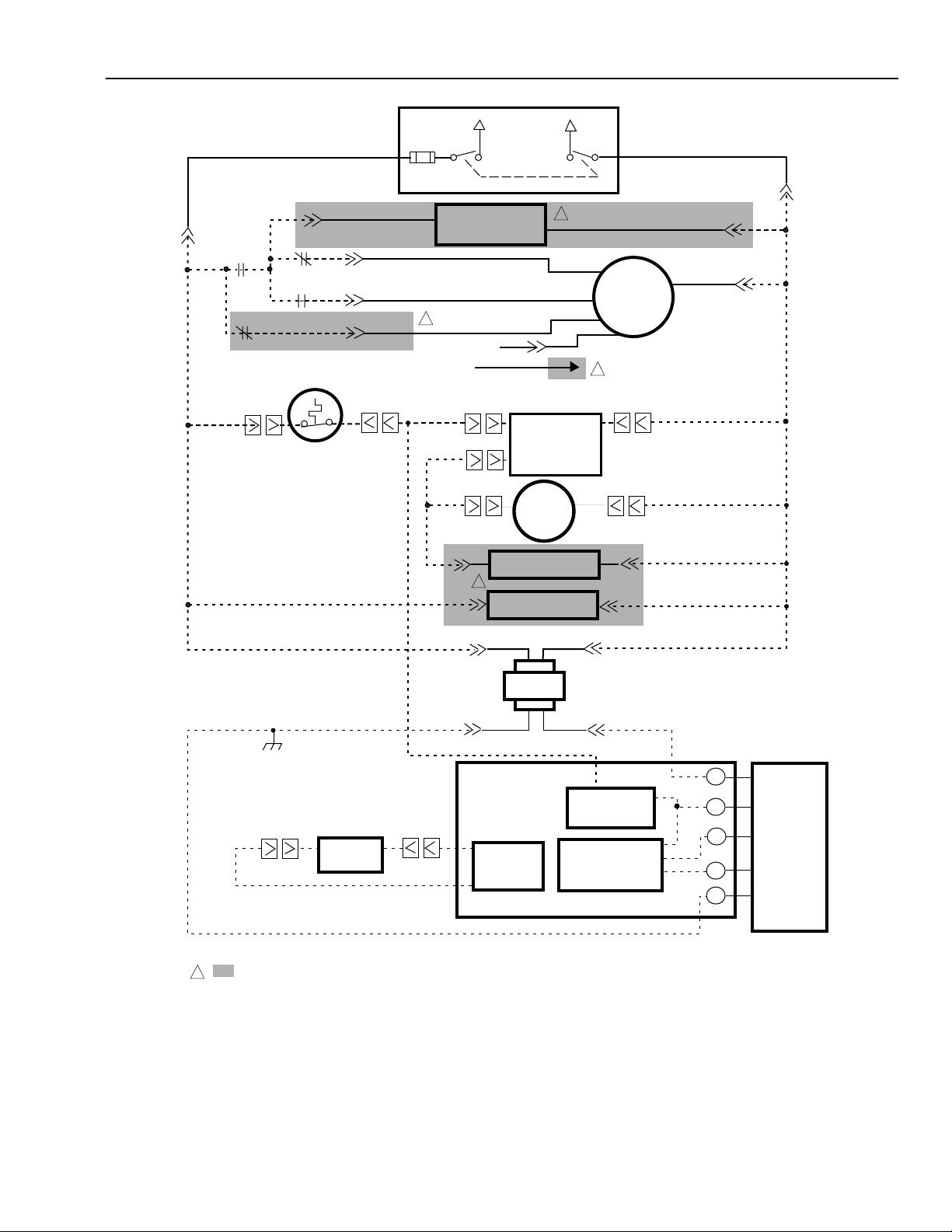

Wiring

All wiring must comply with local codes and ordinances.

Disconnect power before making wiring connections. Refer to

Fig. 1 for standard wiring connections. Refer to Fig. 2 for an

internal schematic.

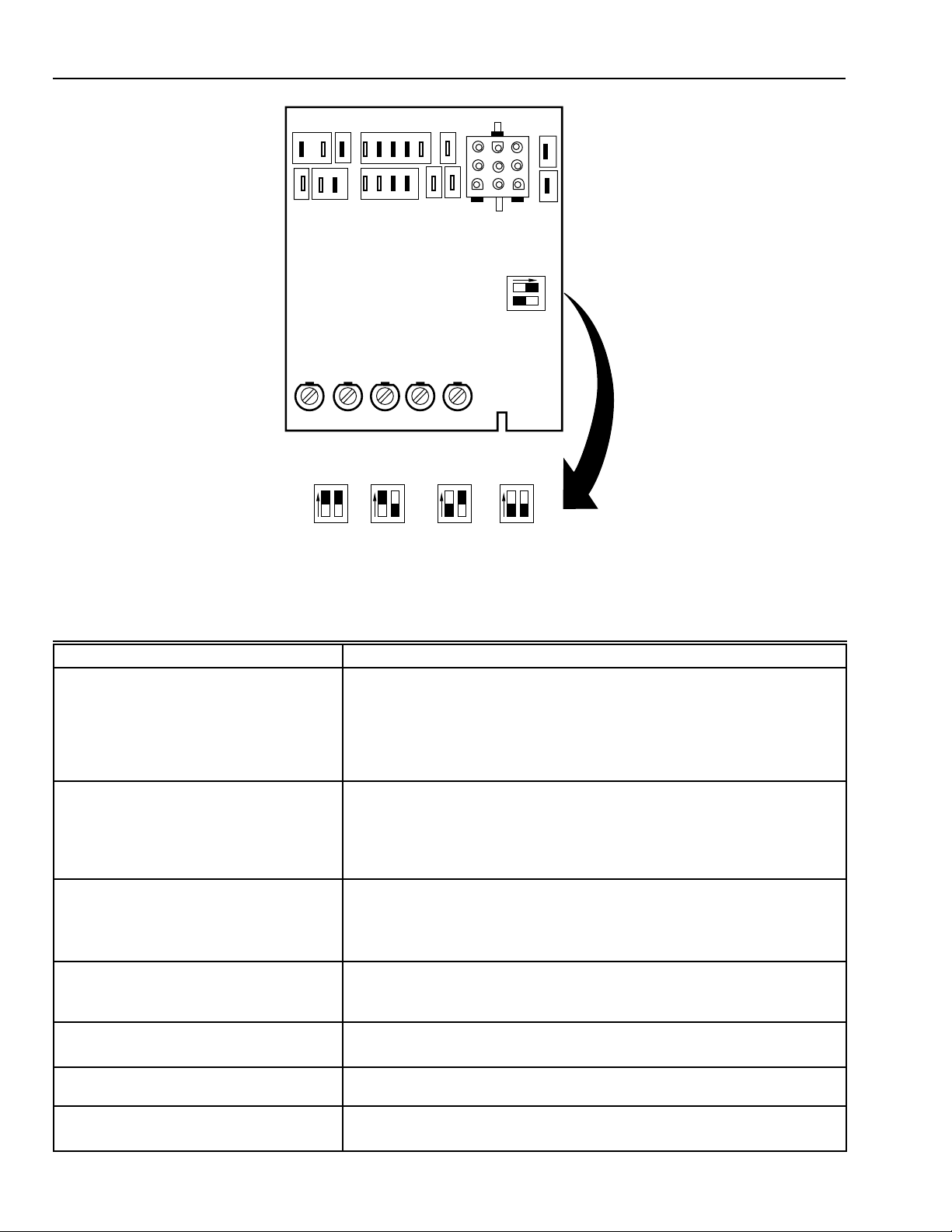

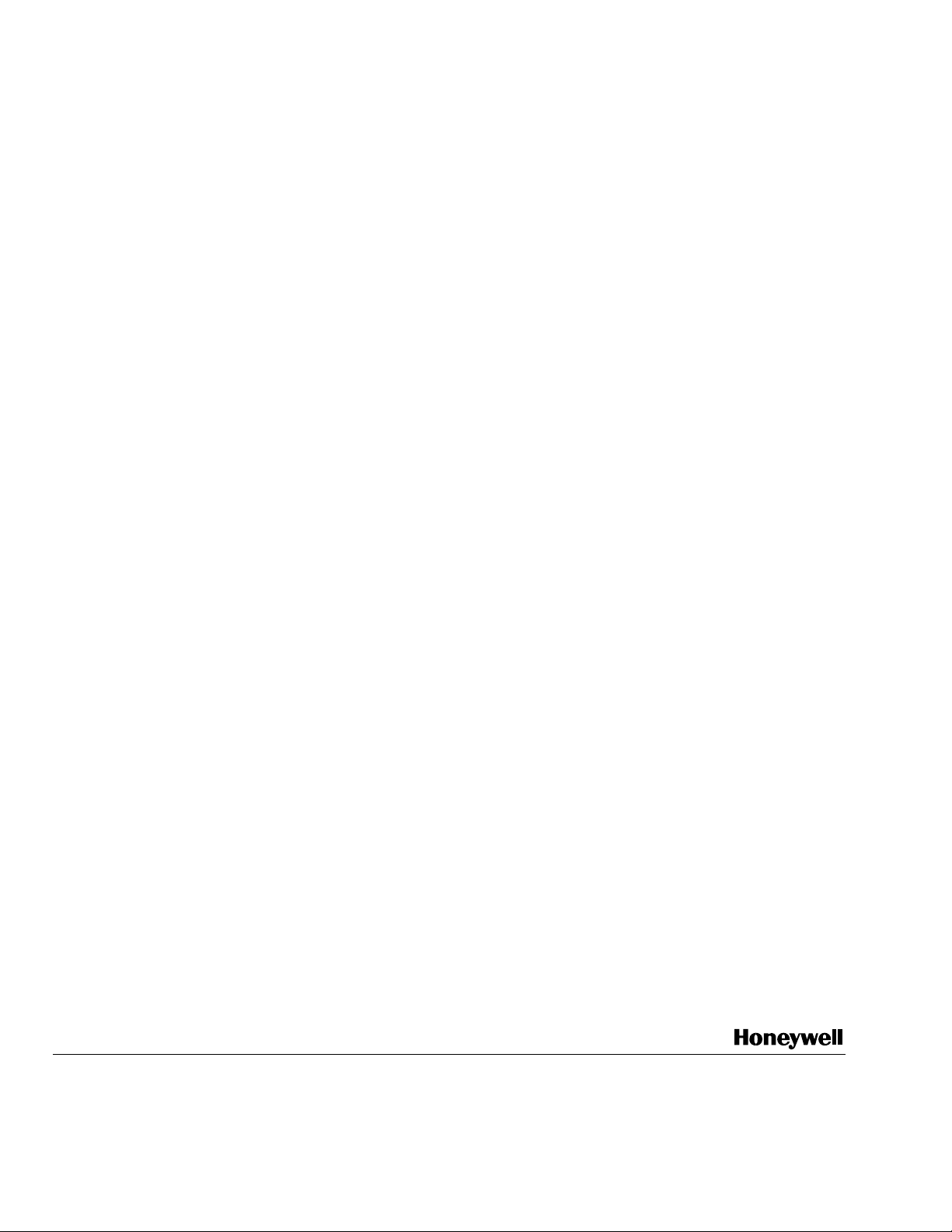

Setting the Heat Fan Off Delay Switches

Set the heat fan off delay switches to either 60, 90, 120, or

150 seconds, as shown in Fig. 3. The off delay time starts

when the burner motor is de-energized at the end of a

thermostat call for heat.

CHECKOUT

Envrionmental Ratings:

Temperature: -40 to +150° F [-40° to +66° C].

Humidity: 95% maximun, noncondensing.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

Copyright © 1997 Honeywell Inc. • All Rights Reserved

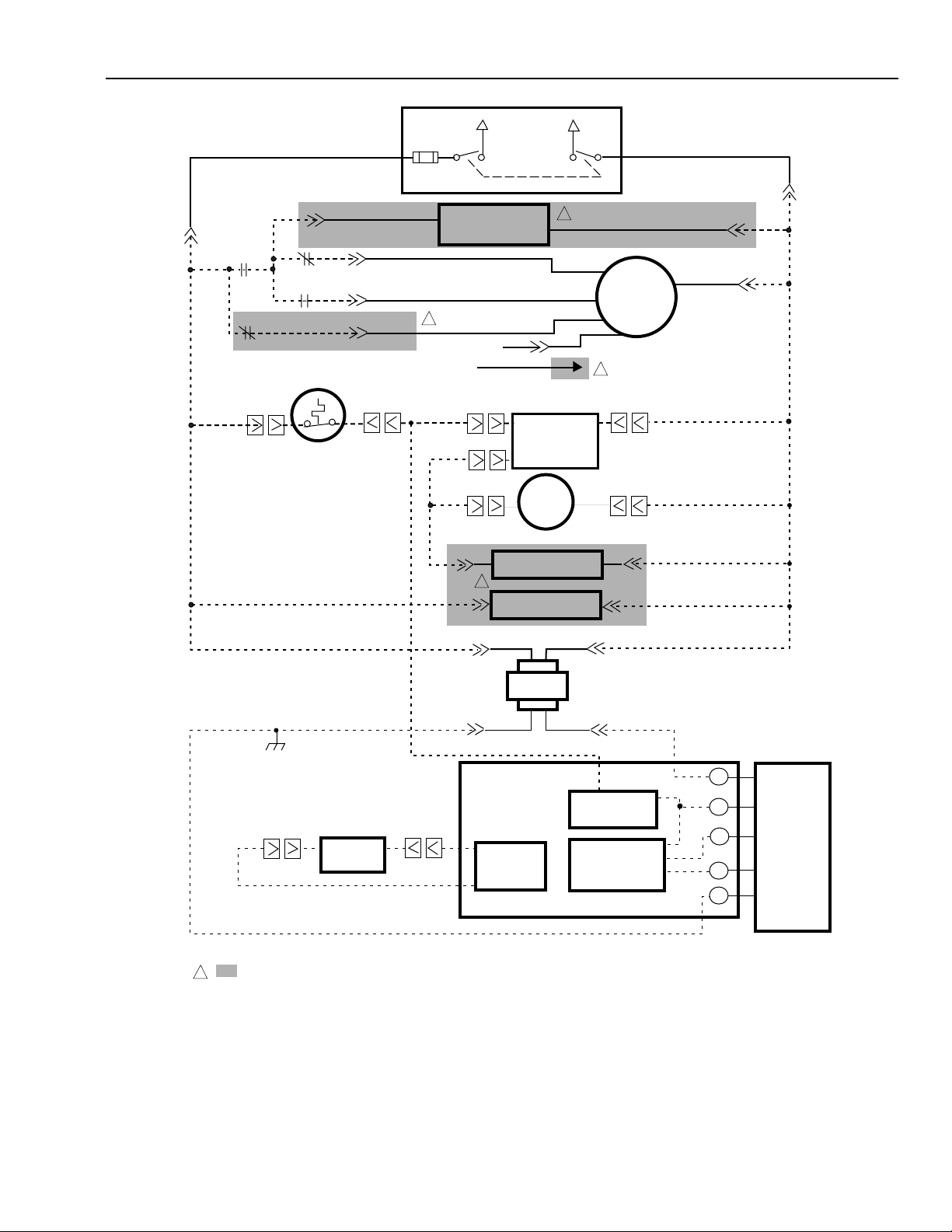

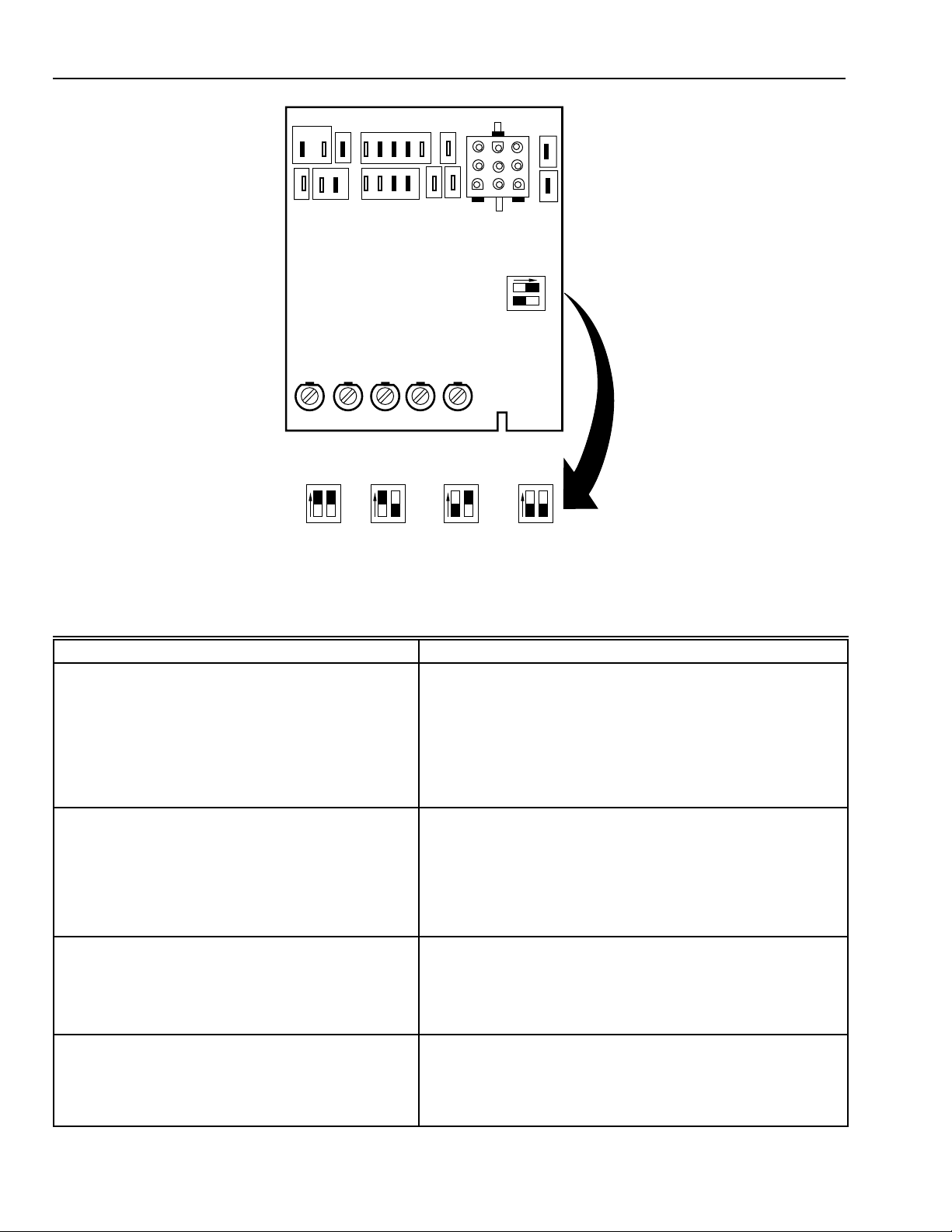

Assure the system operates properly by operating the system

through at least one complete heating cycle and cooling

cycle, if applicable. Troubleshoot by checking for appropriate

voltages at the ST9103A terminals controlling the burner

motor and heat and cool speed circulating fan. The ST9103A

schematic shows internal switching to clarify operation and

assist in troubleshooting. See Fig. 2.

X-XX UL

69-0771B

Page 2

S9103A ELECTRONIC FAN TIMER

STARTING

CAP

FUSE

INTERLOCK

L2 (N)

L1 (H)

TO 120 VAC

POWER SUPPLY

LO

ML

MH

HI

CIRCULATING

FAN

LIMIT

CONTROL

THERMOSTAT

120

VAC

24

VAC

ST9103

UNUSED

3

MOTOR

B

12

U

R

N

E

R

123

C

E

O

A

N

C

T

1

4

5

H

U

M

67

C

H

O

E

O

A

L

T

X

C

BURNER

MOTOR

GYW

R

DENOTES STANDARD TERMINAL.

1

DENOTES OPTIONAL TERMINAL.

NOTE:

DENOTES LINE VOLTAGE CONNECTIONS.

DENOTES LOW VOLTAGE CONNECTIONS.

W

R

G

Y

C

1

Fig. 1. Typical ST9103A wiring connections.

L1

(WHITE)

(BLACK)

OIL PRIMARY CONTROL

L2

ORANGE

R8991

FLAME DETECTOR

CAD CELL

T1 T2

M5551

69-0771B

2

Page 3

FUSE

TO 120 VAC

POWER SUPPLY

S9103A ELECTRONIC FAN TIMER

INTERLOCK

ELECTRONIC

AIR CLEANER

S2

K1

K1

CN6-9

K2 HEAT

COOL

K2

CONSTANT

LIMIT

CN6-1

(OPTIONAL)

1

CN6-2 CN6-4

L1

CN6-7

CN6-8

HUM

S1

S3

1

HUMIDIFIER

(OPTIONAL)

ACCESSORY

(OPTIONAL)

1

MED

HIGH

LOW

M1

M2

R8991

OIL PRIMARY

CONTROL

BURNER

MOTOR

120 VAC

MED-HIGH

1

L2

N4

CN6-5

N7

N6

CIRCULATION

BLOWER

N3

N1

N2

C

ST9103A OIL

ELECTRONIC

FAN TIMER

T1 T2

CN6-3

DENOTES OPTIONAL CONNECTIONS, COMPONENTS AND ACCESSORIES.

1

NOTE: DOTTED LINES REPRESENT PRINTED CIRCUIT BOARD WIRING.

R8891

CN6-6

R8991

CONTROL

K3

Fig. 2. ST9103A internal schematic.

24 VAC

X

R8991

LIMIT SENSOR

CIRCULATION

BLOWER

K1 K2

R

W

Y

G

C

THERMOSTAT

M5552

3

69-0771B

Page 4

S9103A ELECTRONIC FAN TIMER

UNUSED

3

123

4

5

H

E

A

T

H

U

M

67

X

C

ST9103A

ON

1

2

MOTOR

B

12

U

R

N

E

R

C

C

E

O

O

A

O

N

C

L

T

W

G

ON

1

60 SEC 90 SEC

ON

1

2

DELAY OFF SWITCH SETTINGS

Y

ON

1

120 SEC

C

ON

2

1

2

150 SEC

M5550

R

2

Fig. 3. Setting delay off switches.

ST9103 Operating Sequence.

Action System Response

Thermostat calls for heat.

(W terminal is energized.)

• ST9103A closes oil primary control T-T connections.

• Ignition system and oil primary control start the furnace. Oil flows as long as

oil primary control senses flame.

• Burner motor is energized and heat fan on delay timing begins. When timing

is complete, the circulating fan is energized at heat speed and warm air is

delivered to the controlled space.

Thermostat ends call for heat.

(W terminal is de-energized.)

• Oil primary control is de-energized, terminating the burner cycle.

• Heat fan off delay timing begins. When timing is complete, the circulating

fan is de-energized.

• ST9103A returns to standby mode (oil primary control and circulating

fan are off).

Burner fails to light. • Oil primary control locks out within lockout timing (timing depends on oil

primary control).

• Burner motor is de-energized.

• If heat fan has started, it continues through the selected delay off period.

Established flame fails. • Burner motor is de-energized and oil primary control goes into recycle mode.

• If selected heat fan off delay is longer than the recycle delay timing, the

heat fan continues to run through the next trial for ignition.

Thermostat begins call for cool.

(G and Y terminals are energized.)

Thermostat ends call for cool.

• Circulating fan is energized at cool speed.

• Cooling compressor turns on immediately.

• Circulating fan and cooling compressor turn off immediately.

(G and Y terminals are de-energized.)

Thermostat begins call for fan.

(G terminal is energized.)

• Circulating fan is energized immediately at cool speed.

• ST9103A maybe factory-configured to operate heat speed in this mode.

69-0771B

4

Page 5

S9103A ELECTRONIC FAN TIMER

ST9103 Operating Sequence (Continued).

Action System Response

Thermostat ends call for fan.

(G terminal is de-energized.)

Limit switch string opens. • Oil primary control shuts off burner.

Limit switch string closes. • ST9103A begins heat fan off delay sequence.

Continuous circulating fan is connected.

(Optional connectors are available for

separate circulating fan speed tap.)

Electronic air cleaner is connected.

(Optional connectors are available for 120

Vac electronic air cleaner.)

Humidity control is connected.

(Optional connectors are available for 120

Vac humidifier.)

• Circulating fan is de-energized.

• Circulating fan is energized immediately at heat speed.

• ST9103A opens oil primary control T-T connections.

• Circulating fan runs as long as limit string stays open.

• If there is a call for cooling or fan, the circulating fan switches from heat

speed to cool speed.

• Circulating fan turns off after the selected heat fan off delay timing.

• ST9103A recloses oil primary control T-T connections.

• Oil primary control is energized, initiating burner light off.

• Circulating fan is energized at low speed when there is no call for heat,

cool or fan.

• If fan operation is required by a call for heat, cool or fan, the ST9103A

switches off the continuous fan speed tap before energizing the other

fan speed.

• Electronic air cleaner (EAC) connections are energized when the heat or

cool speed of the circulating fan is energized. EAC connections are not

energized when the optional continuous fan terminal is energized.

• Humidifier connections are energized when burner motor is energized.

5

69-0771B

Page 6

S9103A ELECTRONIC FAN TIMER

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis MN 55408-0524

69-0771B69-0771B G.H. 3-97 Printed in U.S.A.

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 2C9

6

Helping You Control Your World

¤

Page 7

Temporisateur Électronique

pour ventilateur

ST9103A

INSTALLATION INSTRUCTIONS

APPLICATION

Le temporisateur électronique ST9103A pour ventilateur

assure la commande complète du brûleur et du ventilateur de

la pompe de circulation dans un appareil de chauffage au

mazout. Il constitue le point de connexion pour la plupart des

composants électriques de l’appareil de chauffage. Il doit

principalement surveiller les commandes de chauffage, de

refroidissement et de ventilation du thermostat et faire

fonctionner le régulateur primaire du brûleur à mazout et le

ventilateur de circulation d’air comportant deux régimes. Le

ST9103A surveille également le fonctionnement du câble de

l’interrupteur de fin de course qui met sous tension le

ventilateur de circulation dès que le contact de l’interrupteur

de fin de course s’ouvre.

Des bornes de raccordement à un filtre à air électronique et à

un humidificateur ainsi qu’un dispositif de circulation continue

de l’air ambiant à basse vitesse sont offerts en option.

FICHE TECHNIQUE

Caractéristiques électriques nominales:

Alimentation:

Tension: 18-30 V c.a., 50/60 Hz.

Intensité: 4 VA sous 24 V c.a.

Intensité nominale des contacts:

Ventilateur de circulation d’air: 15 A pleine charge, 30 A

rotor bloqué sous 115 V c.a. (y compris la charge en

option du filtre à air électronique).

Réglage de la temporisation (démarrage-arrêt):

Temporisation de démarrage: 30 secondes - fixe.

Temporisation d’arrêt: 60, 90, 120, 150 secondes -

réglable en clientèle.

Tolérance de temporisation: supérieure à ± 20 % ou ± 5

secondes.

Conditions ambiantes nominales:

Température: - 40 ° à 66 °C [-40 ° à 150 °F].

Humidité: 95 % maximum sans condensation.

INSTALLATION

Avant d’installer ce produit...

1. Bien lire les instructions. Ne pas les suivre pourrait

endommager le produit et constituer un danger.

2. Vérifier les caractéristiques spécifiées dans la fiche

technique et sur le produit afin de s’assurer que le

produit convient à l’application choisie.

3. L’installateur doit être un technicien d’expérience ayant

reçu la formation appropriée.

4. Une fois l’installation terminée, vérifier le

fonctionnement du produit en suivant les instructions

indiquées dans le présent document.

MISE EN GARDE

Couper l’alimentation avant de raccorder les fils afin

d’empêcher tout choc électrique ou tout dommage à

l’équipement.

Emplacement et installation

Monter le ST9103A dans l’enceinte où se trouve le câblage à

l’aide de quatre vis numéro 6 (non fournies).

Câblage

Tout le câblage doit être conforme aux codes et règlements

locaux en matière d’électricité. Couper l’alimentation avant

d’effectuer le raccordement. Consulter la fig. 1 pour le

raccordement type du temporisateur. Consulter la fig. 2 pour

le raccordement interne.

Réglage des commutateurs de temporisation

d’arrêt du ventilateur de chauffage

Régler les commutateurs de temporisation d’arrêt du

ventilateur de chauffage à 60, 90, 120 ou 150 secondes

comme le montre la figure 3. La temporisation d’arrêt

commence dès que le moteur du brûleur est mis hors tension

lorsque le thermostat met fin à l’appel de chaleur.

VÉRIFICATION

Faire fonctionner le système pendant un cycle complet de

chauffage et un cycle complet de refroidissement (s’il y a lieu)

pour vérifier s’il fonctionne normalement. Diagnostiquer les

anomalies en vérifiant la tension aux bornes du ST9103A qui

commandent le moteur du brûleur et le ventilateur de

circulation d’air en régime chauffage et en régime

refroidissement. Le schéma du câblage interne du ST9103A

permet de mieux comprendre le fonctionnement du système

et de détecter les causes d’anomalies. Voir fig. 2.

Copyright © 1997 Honeywell Inc. • All Rights Reserved

X-XX UL

69-0771B

Page 8

TEMPORISATEUR ÉLECTRONIQUE POUR VENTILATEUR ST9103A

CONDENSATEUR

DE DÉMARRAGE

MOYENNE-BASSE

MOYENNE-ÉLEVÉE

VENTILATEUR

DE CIRCULATION

D’AIR

BASSE

ÉLEVÉE

FUSIBLE

VERROUILLAGE

ST9103

1

4

5

H

U

M

67

R

C

E

H

F

A

R

U

O

F

I

F

D

A

I

G

S

E

S

E

M

E

N

T

B

U

R

N

E

R

INUTILISÉ

MOTEUR

12

3

123

C

F

O

A

N

É

T

L2 (N)

SOUS TENSION

NEUTRE

L1 (H)

VERS ALIMENTATION 120 V C.A.

120

V C.A

24

V C.A.

X

C

MOTEUR

DU BRÛLEUR

INTERRUPTEUR

DE FIN DE

COURSE

THERMOSTAT

GYW

1

NOTE:

R

W

G

BORNE STANDARD

BORNE FACULTATIVE

RACCORDEMENT TENSION SECTEUR

RACCORDEMENT BASSE TENSION

Fig. 1. Schéma de raccordement type du ST9103A.

R

Y

C

1

L2

L1

(NOIR)

ORANGE

(BLANC)

RÉGULATEUR PRIMAIRE

DE MAZOUT R8991

T1 T2

DÉTECTEUR DE FLAMME

CELLULE AU

CADMIUM

MF5551

69-0771B

2

Page 9

TEMPORISATEUR ÉLECTRONIQUE POUR VENTILATEUR ST9103A

VERS

FUSIBLE

ALIMENTATION

120 V C.A.

VERROUILLAGE

FILTRE À AIR

ÉLECTRONIQUE

S2

K1

K1

CN6-9

K2 CHAUFFAGE

REFROIDISSEMENT

K2

CONTINUE

INTERRUPTEUR

DE FIN DE COURSE

CN6-1

(FACULTATIF)

1

CN6-2 CN6-4

CN6-7

CN6-8

HUM

HUMIDIFICATEUR

( FACULTATIF)

1

S1

S3

ACCESSOIRE

(FACULTATIF)

1

MOYENNE

ÉLEVÉE

BASSE

M1

M2

L1

RÉGULATEUR

PRIMAIRE POUR

BRÛLEUR

À MAZOUT R8991

MOTEUR

DU

BRÛLEUR

120 V C.A.

MOYENNE

ÉLEVÉE

1

L2

CN6-5

N6

N4

VENTILATEUR DE

CIRCULATION D’AIR

N7

N3

N1

N2

24 V C.A.

C

TEMPORISATEUR

ÉLECTRONIQUE

POUR VENTILATEUR

ST9103A

T1 T2

CN6-3

CONNEXIONS, COMPOSANTS ET ACCESSOIRES FACULTATIFS.

1

N.B. LES LIGNES POINTILLÉES REPRÉSENTENT LE CÂBLAGE DE LA CARTE DE CIRCUITS IMPRIMÉS.

R8891

CN6-6

R8991

CONTROL

K3

X

CAPTEUR

DU LIMITEUR

R8991

VENTILATEUR DE

CIRCULATION D’AIR

K1 K2

Fig. 2. Schéma interne du ST9103A.

R

W

Y

G

C

THERMOSTAT

MF5552

3

69-0771B

Page 10

TEMPORISATEUR ÉLECTRONIQUE POUR VENTILATEUR ST9103A

INUTILISÉ

3

MOTEUR

B

U

R

N

E

R

12

123

C

F

O

A

N

É

T

4

5

H

U

M

67

C

R

H

E

A

F

U

R

F

O

F

I

A

D

G

I

E

S

S

E

M

E

N

T

1

2

X

C

ST9103A

ON

W

G

ON

1

60 SECONDES 90 SECONDES 120 SECONDES 150 SECONDES

ON

2

1

RÉGLAGE DES COMMUTATEURS

DE TEMPORISATION D’ARRÊT

Y

R

2

C

ON

1

2

ON

1

2

MF5550

Fig. 3. Réglage des commutateurs de temporisation d’arrêt.

Séquence de fonctionnement du ST9103A.

Action Réponse du système

Le thermostat commande un appel de chaleur.

(Borne W sous tension.)

• Le ST9103A ferme les contacts T-T du régulateur primaire.

• Le système d’allumage est sous tension et le régulateur

primaire met l’appareil de chauffage en marche. Le mazout

circule tant que le régulateur détecte une flamme.

• Le moteur du brûleur est sous tension et la temporisation de

démarrage ventilateur de chauffage commence. À la fin de la

temporisation, le ventilateur de circulation d’air est sous tension

et l’air chaud circule dans les pièces.

Fin de la commande de l'appel de chaleur du thermostat.

(Borne W hors tension.)

• Le régulateur primaire est hors tension et met fin au cycle de

chauffage.

• La temporisation d’arrêt du ventilateur de chauffage commence.

À la fin de la temporisation, le ventilateur de circulation d’air est

hors tension.

• Le ST9103A est ensuite en mode d’attente (régulateur primaire

et ventilateur de circulation sont hors tension).

Le brûleur ne fonctionne pas. • Le régulateur primaire s’arrête durant la temporisation de

sécurité (la temporisation dépend du régulateur primaire).

• Le moteur du brûleur est hors tension.

• Si le ventilateur de chauffage fonctionne, il s’arrêtera à la fin de

la temporisation d’arrêt choisie.

La flamme s’éteint. • Le moteur du brûleur est hors tension et le régulateur primaire

est en mode cycles de fonctionnement.

• Si la temporisation d’arrêt du ventilateur de chauffage est plus

longue que la temporisation de remise en marche, le ventilateur

fonctionnera jusqu’au prochain essai d’allumage.

69-0771B

4

Page 11

TEMPORISATEUR ÉLECTRONIQUE POUR VENTILATEUR ST9103A

Séquence de fonctionnement du ST9103A (Continué).

Action Réponse du système

Le thermostat commande le refroidissement.

(Bornes G et Y sous tension.)

Fin de la commande de refroidissement du thermostat.

(Bornes G et Y hors tension.)

Le thermostat commande le ventilateur.

(Borne G sous tension.)

Fin de la commande de ventilation du thermostat.

(Borne G hors tension.)

Le câble de l’interrupteur de fin de course s’ouvre. • Le ST9103A met le brûleur hors tension.

Le câble de l’interrupteur de fin de course se ferme. • Le ST9103A commande le début de la temporisation d’arrêt du

Le ventilateur de circulation d’air en continu est

raccordé. (Raccordement facultatif pour le

fonctionnement autonome du ventilateur de circulation

d’air.)

Un filtre à air électronique est raccordé

(Raccordement facultatif au filtre à air électronique

120 V c.a.)

Un hygrostat est branché.

(Raccordement facultatif à l’humidificateur 120 V c.a.)

• Le ventilateur de circulation d’air est actionné en régime

refroidissement.

• Le compresseur de refroidissement se met immédiatement en

marche.

• Le ventilateur de circulation d’air et le compresseur de

refroidissement s’arrêtent immédiatement.

• Le ventilateur de circulation d’air se met immédiatement en

marche en régime refroidissement.

• Le ST9103A peut être configuré en usine pour fonctionner en

régime chauffage lors d’une demande de ventilation.

• Le ventilateur de circulation d’air est hors tension.

• Le ventilateur de circulation d’air en régime chauffage est sous

tension.

• Le ST9103A ouvre les contacts T-T du régulateur primaire.

• Le ventilateur de circulation fonctionne tant que le câble de

l’interrupteur est ouvert.

• S’il y une commande de refroidissement ou de ventilation, le

ventilateur de circulation passe du régime de chauffage à celui

de refroidissement.

ventilateur de chauffage.

•À la fin de la temporisation choisie, le ventilateur de circulation

s’arrête.

• Le ST9103A referme les contacts T-T du régulateur primaire.

• Le régulateur primaire est mis sous tension et éteint le brûleur.

• Le ventilateur de circulation d’air est sous tension à basse

vitesse lorsqu’il n’y a pas de commande de chauffage, de

refroidissement ou de ventilation.

• S’il y a commande de chauffage, de refroidissement ou de

ventilation, le ST9103A coupe le contact de la ventilation

continue avant de faire fonctionner le ventilateur à une autre

vitesse.

• Dans les systèmes à deux régimes, le filtre à air électronique

est mis sous tension lorsque les régimes chauffage ou

refroidissement sont actionnés. Si l’option de fonctionnement

en continu du ventilateur est en fonction, les contacts du FAÉ

ne seront pas sous tension .

• L’humidificateur est actionné lorsque le moteur du brûleur est

sous tension.

5

69-0771B

Page 12

TEMPORISATEUR ÉLECTRONIQUE POUR VENTILATEUR ST9103A

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis MN 55408-0524

69-0771B69-0771B G.H. 3-97 Imprimé aux États-Unis

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 2C9

6

Pour la ma trise de votre univers

¤

Loading...

Loading...