Page 1

ST7997

Oil Burner Mounted Electric Fan Timer

INSTALLATION INSTRUCTIONS

APPLICATION

The ST7997 Oil Burner Mounted Electric Fan Timer

integrates control of burner and circulator fan operations in

an oil furnace and is the central wiring point for most

electrical components in the furnace. The ST7997 mounts

on a standard four-inch by four-inch junction box typically

located on the oil burner. When used with the R7997

Integrated Oil Primary Controller and Ignitor, it provides

simplified wiring and field serviceability. The basic

purposes of the ST7997 are to monitor the thermostat for

heat, cool and fan demands, run the oil burner primary

control and run a two-speed circulating fan, as required.

The ST7997 also monitors a limit switch string that

energizes the circulating fan when the limit switch opens.

The ST7997 provides electronic air cleaner (EAC) and

humidifier (HUM) terminal connections for field installation

convenience.

SPECIFICATIONS

Electrical

Input Ratings

Supply Voltage:

102 to 132 Vac (120 Vac nominal), 60 Hz.

Supply Current:

100 mA maximum without loads connected to outputs.

20A maximum with loads connected to outputs.

Output Ratings:

Relay Contacts:

Circulator Heat or Cool Blower Speed Rating: 15A Full

Load Amperage (FLA) (0.75 pF)/30A Locked Rotor

Amperage (LRA) (0.5 pF).

NOTE: FLA rating is reduced by EAC load.

EAC:

1A maximum.

Circulator Continuous Blower Speed Rating:

8A FLA (0.75pF)/16A LRA (0.5pF).

Humidifier:

1A maximum.

Limit:

10A maximum.

L1/L2 (Burner):

20A maximum.

Thermostat Current:

Heat Mode: 100 mA (R7997 supplied).

Cool Mode: Cooling contactor load 500 mA maximum

(ST7997 supplied).

Cooling Contactor:

2 VA minimum, 12 VA maximum.

Molex® is a registered trademark of Molex Incorporated.

Fuse:

1A (automotive type ATO).

Delay Timings:

Heat On Delay: 45 or 60 seconds (fixed or field

selectable via DIP switch optional position 3).

Heat Off Delay: 60/100/120/150 seconds (four field

selections via DIP switch positions 1 and 2).

Cool On/Off Delay: 0/0 or 30/30 seconds (fixed).

Delay Timing Tolerances:

±5 seconds or ±20 percent, whichever is greater.

Environmental

Temperature Ranges:

Operating: -40°F (-40°C) to +150°F (66°C).

Storage: -20°F (-29°C) to +150°F (66°C).

Humidity:

90 percent relative humidity at 95°F (35°C),

noncondensing.

Approvals:

Underwriters Laboratories Inc. Component

Recognized: File 353.

Canadian Underwriters Laboratories inc. Component

Recognized: Pending approval.

Mechanical:

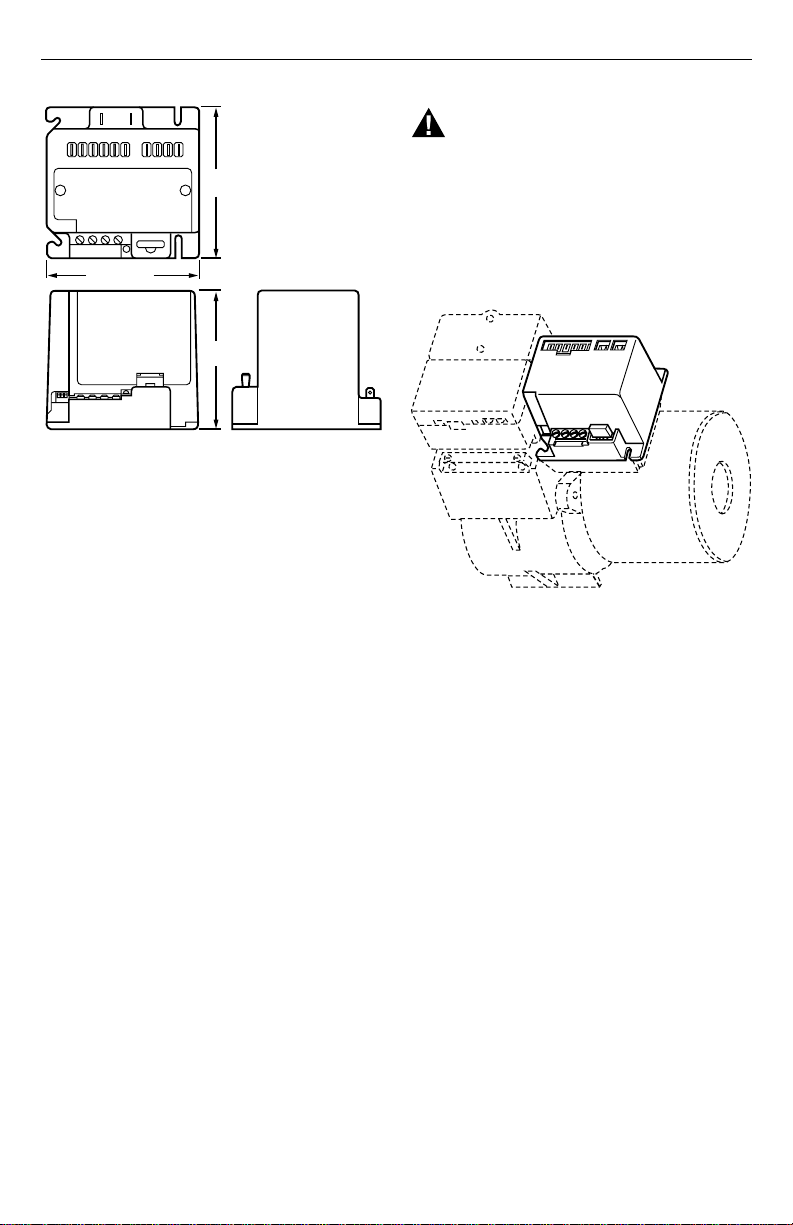

Dimensions (Fig. 1):

4-9/32 in. (109 mm) long by 4-1/4 in. (108 mm) wide by

3-27/32 (97 mm) high. See Fig. 1.

Molex® is a registered trademark of Molex Incorporated.

Copyright © 1998 Honeywell Inc. • All Rights Reserved

X-XX UL

69-1204

Page 2

ST7997 OIL BURNER MOUNTED ELECTRIC FAN TIMER

4-1/4

(108)

WARNING

Electrical Shock Hazard

Can cause serious injury or death.

Disconnect power supply before wiring to prevent

electrical shock or equipment damage.

C

YGRc

4-9/32 (109)

3-27/32

(97)

Fig. 1. ST7997A,B Oil Burner Mounted Electric Fan

Mounting:

Mounts directly on standard 4 in. (102 mm) by 4 in.

(102 mm) junction box.

Packaging:

Unit pack and bulk pack.

Connections:

R7997, Oil Burner Motor, Oil Valve and Power (L1, L2):

Circulator Blower (Neutral, Heat, Cool, Continuous),

Humidifier: Two 1/4 in. (6 mm) by 1/32 in. (0.8 mm)

Electronic Air Cleaner: Two 1/4 in. (6 mm) by 1/32 in.

Thermostat/Cooling Contactor: Four No. 4 screw

Timer dimensions in in. (mm).

Six (6) 1/4 in. (6 mm) by 1/32 in. (0.8 mm) quick

connects pass through recessed cover on bottom of

case.

Limit (Hot, Limit): One six-position Molex® in-line

connector flush with top of case or six 1/4 in. (6 mm)

by 1/32 in. (0.8 mm) quick connects individually

recessed in top of case.

quick connects individually recessed in top of case.

(0.8 mm) quick connects individually recessed in top

of case.

terminals marked Rc, Y, G and C on front side of

case.

INSTALLATION

Location and Mounting

Mount the ST7997 on the oil burner 4 in. (102 mm) by 4 in.

(102 mm) junction box compartment using four No. 6

screws (obtained locally). See Fig. 2.

ST7997R7997

M12920

BURNER

Fig. 2. ST7997A,B Oil Burner Mounted Electric Fan

IMPORTANT

Timer typical installation.

The ST7997 requires a mechanical or electronic

(power-stealing or battery-powered) five-wire

thermostat with independent heat/cool circuits

(R, W, Rc, Y, G).

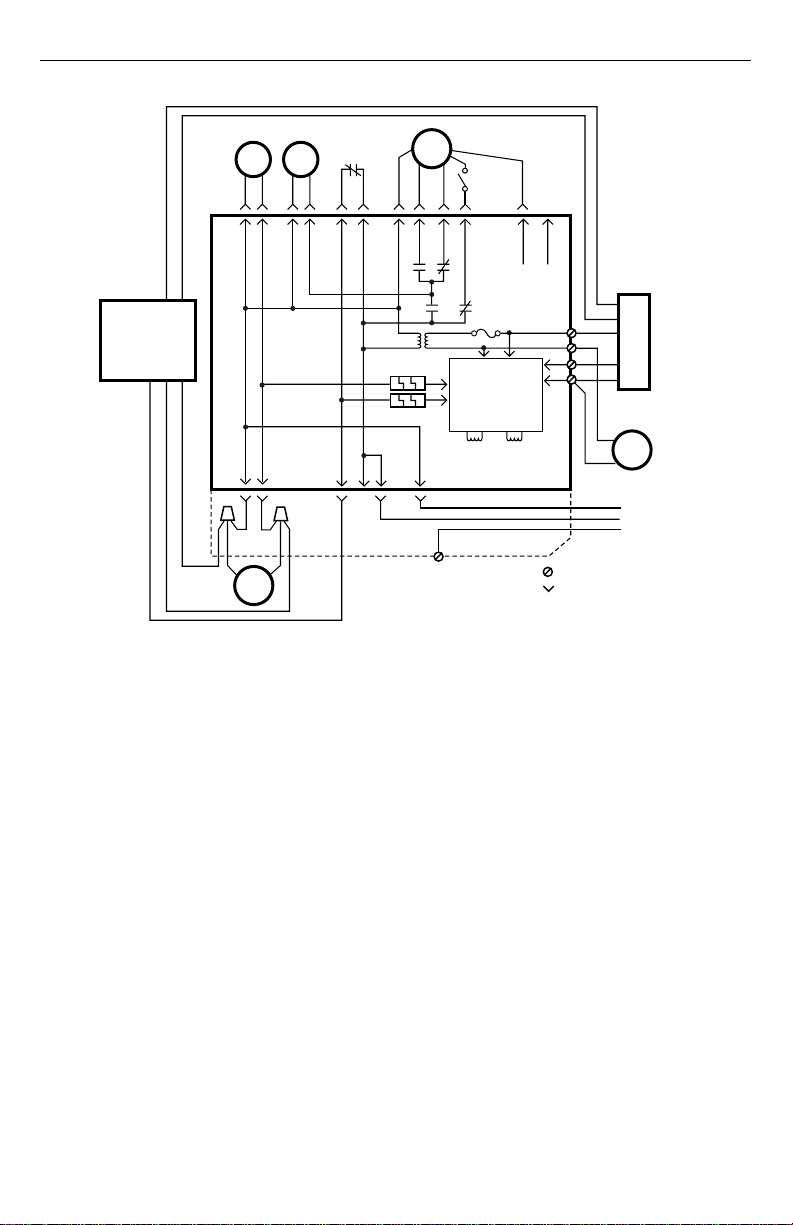

Wiring

All wire must comply with local codes and ordinances.

Refer to Fig. 3 for standard wiring connections and Fig. 4

for units with pre- and post purge.

Make wiring connections within the oil burner junction box

for applications requiring power-venting. Add a 4 in. by

4 in. (102 mm by 102 mm) junction box, at least 1/2 in.

(13 mm) deep between the ST7997 and the oil burner

junction box. See Fig. 5 for wiring diagram showing airflow

switch and power vent motor.

M12919

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them can damage the product or cause a hazardous

condition.

2. Check the ratings and specifications given in the

instructions and on the product to make sure the

product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out the product

operation as provided in these instructions.

69-1204

2

Page 3

ST7997 OIL BURNER MOUNTED ELECTRIC FAN TIMER

TT

R7997

INTEGRATED

OIL PRIMARY

WITHOUT

BLOWER DELAY

BLACK

ORANGE

WHITE

BURNER

MOTOR

HUMIDIFIER EAC

N

N

HUM

L2

BURNER/

VALVE

EAC

LIMIT

(LINE

VOLTAGE)

FURNACE

OIL

PRIMARY

LIMIT

L1

N

N

ISOLATION

L1

1K2

HI

1K1

L2

COOL

CIRCULATOR

BLOWER

MED LO

LO

HEAT

2K2

CONTINUOUS

2K1

F1

C

HEAT CALL

LIMIT

CONTROL

ELECTRONICS

K1 K2

RC

J-BOX

G

Y

OEFT

ST7997

MED HI

WIRES

UNUSED

RC

C

G

Y

SCREW TERMINAL

1/4 IN. QUICK CONNECT

R

W

RC

G

Y

THERMOSTAT

5-WIRE

COMPRESSOR

CONTACTOR

Fig. 3. ST7997 Oil Burner Mounted Electronic Fan Timer standard wiring connections.

L2

L1

GND

M12924

3

69-1204

Page 4

ST7997 OIL BURNER MOUNTED ELECTRIC FAN TIMER

CIRCULATOR

BLOWER

N

1K2

HI

L2

1K1

COOL

COOL

BURNER

MOTOR

MED LO

HEAT

HEAT

2K2

2K1

HEAT CALL

LIMIT

K1 K2

LO

CONTINUOUS

F1

RC

C

CONTROL

ELECTRONICS

ST7997

J-BOX

MED HI

WIRES

UNUSED

RC

C

G

G

Y

Y

OEFT

SCREW TERMINAL

1/4 IN. QUICK CONNECT

R

W

RC

G

Y

THERMOSTAT

5-WIRE

COMPRESSOR

CONTACTOR

L2

L1

GND

M12922

TT

R7997

INTEGRATED

OIL PRIMARY

WITH BLOWER

DELAY

RED

BLACK

ORANGE

WHITE

VIOLET

VALVE

HUMIDIFIER EAC

N

HUM

L2

BURNER/

OIL

N

VALVE

EAC

LIMIT

(LINE

VOLTAGE)

FURNACE

OIL

PRIMARY

LIMIT

L1

N

N

ISOLATION

L1

Fig. 4. ST7997 Oil Burner Mounted Electronic Fan Timer wiring for units with pre- and post purge.

NOTE: Two dummy quick connect terminals, labeled

“unused wires”, not connected to the ST7997

circuitry, are provided on the back of the case to

hold unused wires from the circulation blower

motor speed taps.

IMPORTANT

Field changes to the speeds (low, medium low,

medium high, high) of the ST7997 blower modes

(heat, cool, or continuous fan) can be made to

models using Molex® connectors by cutting

speed wires and splicing in an unused lead in

accordance with local and national codes.

69-1204

Wiring Options

Wiring options are listed in Table 1.

Setting the Heat Fan-Off and Heat Fan-On

Delay Switches

Set the Heat Fan-Off delay switches to 60, 90, 120 or

150 seconds. See Fig. 6. The off delay time starts when

the burner motor is de-energized at the end of a thermostat call for heat.

4

Page 5

ST7997 OIL BURNER MOUNTED ELECTRIC FAN TIMER

HUMIDIFIER EAC

N

HUM

TT

R7997

INTEGRATED

OIL PRIMARY

WITH BLOWER

DELAY

RED

WHITE

BLACK

ORANGE

VIOLET

AIR FLOW

SWITCH

VALVE

L2

BURNER/

OIL

Fig. 5. ST7997 Oil Burner Mounted Electronic Fan Timer airflow switch and power vent motor for

LIMIT

(LINE

VOLTAGE)

N

EAC

LIMIT

FURNACE

L1

OIL

PRIMARY

L1

POWER

VENT

MOTOR

VALVE

power venting wiring.

ISOLATION

CIRCULATOR

BLOWER

N

HI

MED LO

N

N

HEAT

COOL

1K2

2K2

1K1

2K1

HEAT CALL

LIMIT

K1 K2

L2

BURNER

MOTOR

LO

CONTINUOUS

F1

RC

C

CONTROL

ELECTRONICS

J-BOX

MED HI

WIRES

UNUSED

RC

C

G

G

Y

Y

OEFT

ST7997

SCREW TERMINAL

1/4 IN. QUICK CONNECT

R

W

RC

G

Y

THERMOSTAT

5-WIRE

COMPRESSOR

CONTACTOR

L2

L1

GND

M12923

Table 1. ST7997 Wiring Options.

Mode Action System Response

OPTIONS

Constant circulating fan is

connected. (Optional connectors are

available for separate circulating fan

speed tap.)

Electronic air cleaner is connected.

(Optional connectors are available

for 120 Vac electronic air cleaner.)

Humidity control is connected.

(Optional connectors are available

for 120 Vac humidifier.)

a. Circulating fan is energized at low speed when there is

no call for heat, cool or fan.

b. If fan operation is required by a call for heat, cool or

fan, the ST7997 switches off the continuous fan speed

tap before energizing the other fan speed.

Electronic air cleaner (EAC) connections are energized when

the heat or cool speed of the circulating fan is energized.

EAC connections are not energized when the optional

continuous fan terminal is energized.

NOTE: If continuous fan option is selected, connect EAC

to line voltage input (L1).

Humidifier connections are energized when burner motor is

energized on standard models and when oil valve is

energized on purging models.

5

69-1204

Page 6

ST7997 OIL BURNER MOUNTED ELECTRIC FAN TIMER

CHECKOUT

Verify system operation by running the system through

one complete heating and cooling cycle, if applicable.

Troubleshoot by checking for appropriate voltages at the

ST7997 terminals controlling the burner motor and heat

and cool circulating fan. The ST7997 schematic (Fig. 3)

shows internal switching to clarify operation and assist in

troubleshooting. Table 2 provides the ST7997 operating

sequence.

Use the green diagnostic LED to assist in troubleshooting:

a. Off when system is on and thermostat is satisfied.

b. On continuously when ST7997 recognizes a valid call

HEAT OFF DELAY TIME HEAT ON DELAY TIME

1

2

ON

120

1

2

ON

150

1

1

2

ON

(SHADED AREA IS SWITCH HANDLE POSITION.)

1

FOR SELECTED MODELS ONLY.

Fig. 6. ST7997 Fan Timer location and settings for

Heat Fan-Off and Heat Fan-On delay switches.

2

ON

60 90

1

c. Blinks rapidly on and off when limits are opened.

33

60 45

M12918

for cool or fan from the thermostat and/or a valid call

for heat from the R7997.

69-1204

6

Page 7

ST7997 OIL BURNER MOUNTED ELECTRIC FAN TIMER

Table 2. ST7997 Operating Sequence.

Mode Action System Response

HEAT Thermostat calls for

heat. (W terminal is

energized.)

Thermostat ends call for

heat.(W terminal is

de-energized.)

Burner fails to light. a. Oil primary control locks out within lockout timing (timing depends on

Established flame fails. a. Burner motor is de-energized, LED turns off, and oil primary control

COOL Thermostat begins call

FAN Thermostat begins call

for cool. (G and Y

terminals are energized.)

Thermostat ends call for

cool. (G and Y terminals

are de-energized.)

for fan. (G terminal is

energized.)

Thermostat ends call for

fan.(G terminal is

de-energized.)

LIMIT Limit switch string opens. a. LED flashes at 2 Hz rate (1/4 second on/off).

Limit switch string closes

(with existing call

for heat).

Limit switch string closes

(without existing call

for heat).

a. Thermostat calls for heat (closes oil primary control T-T connections.

b. Ignition system and oil primary control start the furnace. Oil flows as

long as oil primary senses flame.

c. Burner motor is energized, LED turns on, and heat fan on delay

timing begins. When timing is complete the circulating fan is

energized at heat speed and warm air is delivered to the controlled

space.

a. Oil primary control is de-energized, terminating the burner cycle, and

LED turns off.

b. Heat fan-off delay timing begins. When timing is completed, the

circulating fan is de-energized.

c. ST7997 returns to standby mode (oil primary control and circulating

fan are off, unless continuous fan operation is selected at the

thermostat).

oil primary control).

b. Burner motor is de-energized and LED turns off (even though the

thermostat is still calling for heat).

c. If heat fan has started, it continues through the selected heat-fan-off

delay period.

goes into recycle mode.

b. If selected heat fan-off delay timing is longer than the recycle delay

timing, the heat fan continues to run through the next trial for

ignition.

a. Cooling contactor is energized and LED turns on immediately.

b. Circulating fan is energized at cool speed when cool on-delay time is

complete.

a. Cooling contactor is de-energized and LED turns off immediately.

b. Circulating fan turns off when cool fan off-delay time is complete.

a. Circulating fan is energized immediately at heat speed and LED

turns on immediately.

a. Circulating fan is de-energized and LED turns off immediately.

b. Oil primary control shuts off burner.

c. Circulating fan is energized immediately at heat speed.

a. Oil primary control is energized, initiating burner lightoff and LED

changes to continuously on.

b. Circulating fan continues to operate at heat speed.

a. LED turns off.

b. Circulating fan turns off when heat fan-off delay time is complete.

c. Normal operation resumes; device is in standby awaiting next

thermostat command.

7

69-1204

Page 8

ST7997 OIL BURNER MOUNTED ELECTRIC FAN TIMER

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis, MN 55408-0524

69-1204

69-1204 G.R. 8-98

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 3N7

8

www.honeywell.com

Loading...

Loading...