Put Bar Code Here

Honeywell Model 700/800 Signal

Contents

Application ....................................................................... 1

Features ........................................................................... 1

Specifications ................................................................... 3

Approvals ......................................................................... 3

Installation ........................................................................ 3

Operation ......................................................................... 11

Modbus Communication .................................................. 16

Troubleshooting ................................................................ 19

Maintenance .................................................................... 19

Safety Manual: 700 Signal Processor .............................. 35

Safety Manual: 70X & 80X Viewing Head ........................ 38

Processor and Viewing Head

USER MANUAL

The two Model 700 signal processors are similar, with 12

push-buttons, a two-digit numeric display, and four LED status

indicators for operator interface. The only difference between

the two is that one accepts AC power and the other accepts

DC power. Both models also accept 24VDC backup power.

Most of the signal processor connections are made through

Phoenix plug-in connectors. Communication connections are

made through modular phone jacks located at the top of the

signal processors (Fig. 7).

Both signal processor models mount on a standard 35 mm

DIN rail. They snap into place and may be released from the

rail using a flat screwdriver.

There are two types of viewing heads—IR/flicker-sensitive and

UV-sensitive—with various features offered resulting in ten

different models. See Table 1 on page 2 for details.

The S702 and S706 viewing head housings are larger in

diameter than the S80X series, are made of aluminum, and

are secured with over-center latches to their mounting blocks

(Fig. 8). In contrast, the S802 and S806 viewing head

housings are smaller in diameter and are made of stainless

steel (Fig. 9). An 800 series viewing head is secured in its

mounting block by a friction twist-lock.

APPLICATION

The Honeywell Model 700ACSP and Model 700DCSP signal

processors are single-channel, fail safe, flame monitoring

systems when used In conjunction with the S70X/S80X

viewing heads. They offer easy setup, excellent discrimination,

and high reliability.

FEATURES

Viewing heads are interchangeable between the two signal

processor models. Any viewing head in the two families will

work with any of the signal processors.

Two signal processor models are available:

• Model 700ACSP Universal 85-265 VAC powered

• Model 700DCSP 22-26VDC powered

The IR/flicker sensitive viewing heads have a high-pass filter

that passes flicker frequencies above 33 Hz. Some models

have a built-in high pass filter that only passes frequencies

above 155 Hz. The high frequency filter models are identified

by adding “HF” to the model number. The UV models respond

to the absolute level of UV radiation—not UV flicker—so there

is no filter option.

66-2069-01

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

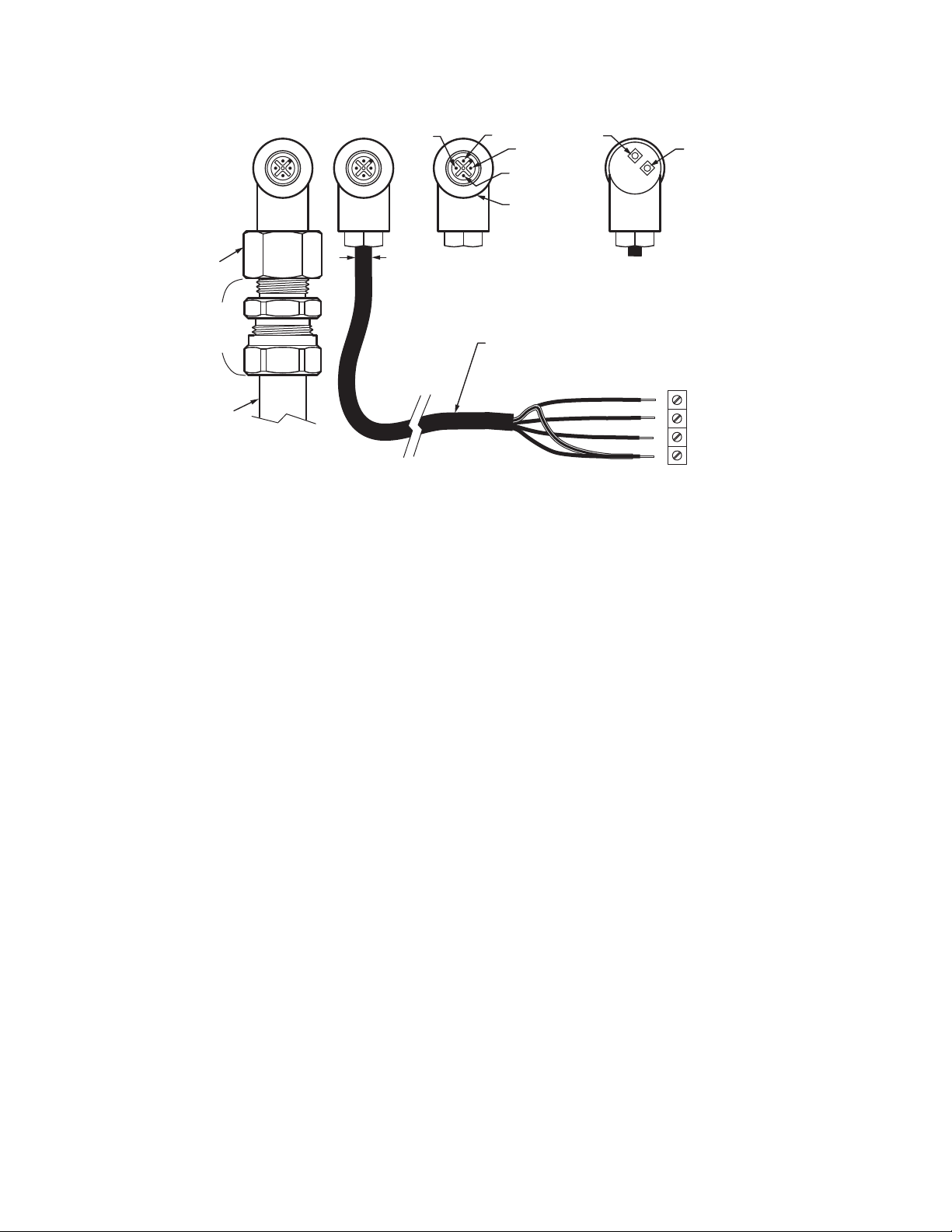

The standard electrical connector supplied with both the 700

and 800 viewing head models has two indicator LEDs inside

it: the green LED indicates signal pulses (helpful in

alignment), and the orange LED indicates self-check activity

between the signal processor and the viewing head (Fig. 4).

The green LED also flashes once per second when the

orange LED is pulsed as the viewing head sends an ID code

back to the signal processor.

Model 700 viewing heads are also available with a 1/2 in. pipe

fitting for connecting to electrical conduits. The four

connecting wires exit through an epoxy seal in the 1/2 in. pipe

fitting. The LED indicators are not present in the pipe-fitting

option. The pipe fitting models are identified by adding "PF" to

the model number.

The available models are shown in Table 1.

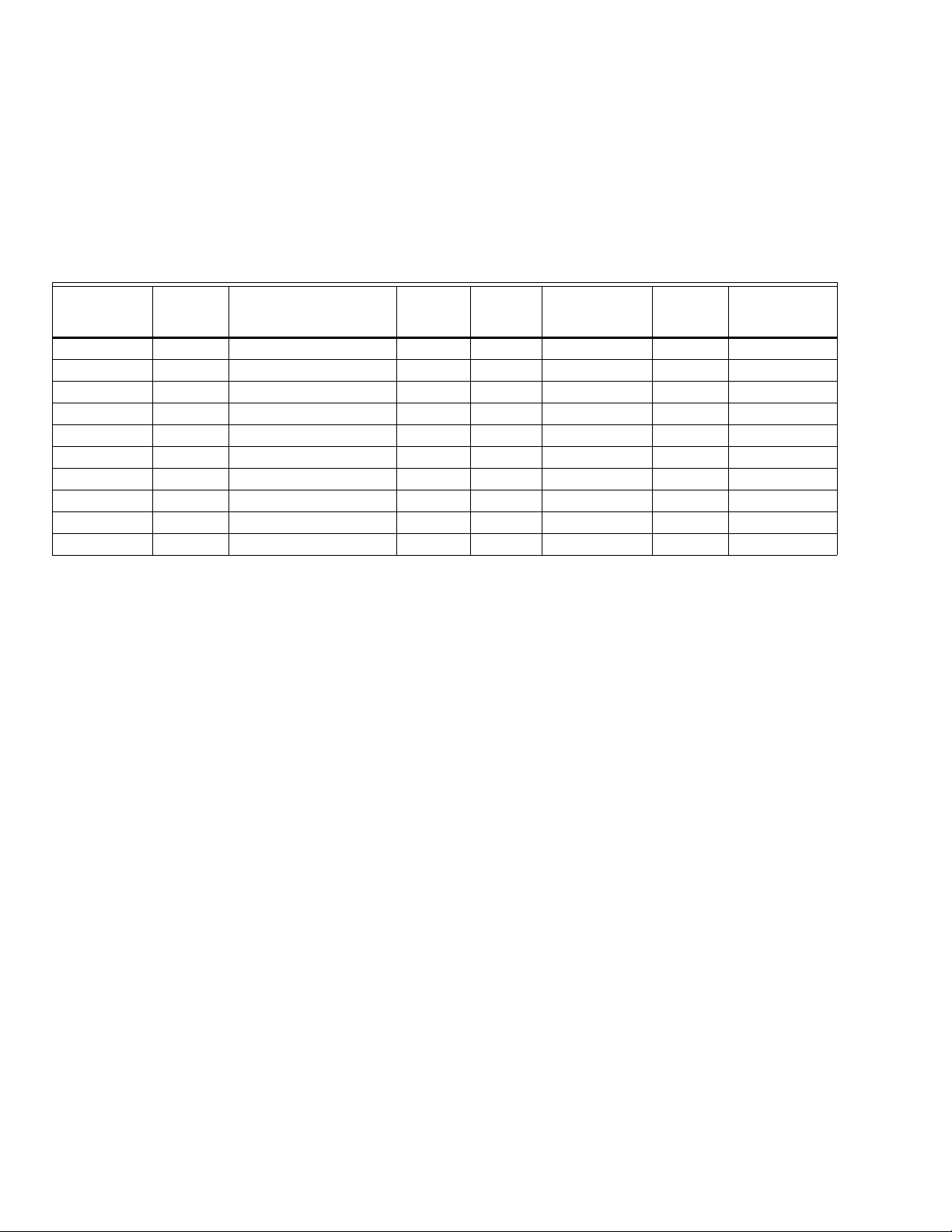

Table 1. Available viewing head models and associated features.

High

Frequency

Filter 155Hz

Aluminum

Housing

Stainless Steel

Housing

Model Connector

Pipe Fit Connection ½ in

NPTM with 10-ft (3.0m)

pigtail

UVTron

Sensor IR Sensor

S702 X X X

S702HF X X X X

S702PF X X X

S702HFPF X X X X

S706 X X X

S706PF X X X

S706PF-050* X X X

S802 X X X

S802HF X X X X

S806 X X X

*S706PF-050 has a 50-ft (15 m) pigtail

All models include the following:

1. Electronic check (no mechanical shutter) for self-check of the system.

2. All IR viewing heads respond to flicker frequencies above 33Hz, with exception of the HF versions, which only respond to

flicker frequencies above 155 Hz.

The viewing heads, the viewing head connector, and the cable

provided are watertight, and have NEMA 4 and 4X ratings

when the connector is properly tightened with pliers and the

cable is protected from UV exposure.

The availability of both UV-sensing and IR/flicker-sensing

viewing heads ensures that the flame monitoring systems can

provide good discrimination in virtually any application. UV

sensing is appropriate for monitoring natural gas, some mixed

gases and light oil flames. IR/ flicker sensing is appropriate for

monitoring heavy oil and coal flames.

66-2069—01 2

SPECIFICATIONS

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

Series 700 and 800 Viewing Heads

MODELS S702, S702PF, S702HF, S702HFPF, S706,

S706PF, AND MODELS S802, S802HF, AND S806

Electrical

Input Power: 22VDC to 26VDC, 150 mA MAX from Model

700ACSP or 700DCSP Signal Processor

Environmental

Viewing Head Sealing: NEMA TYPE 4/4X rated when the

molded connector ring is tightened with pliers and a UV

protection is provided for the cable by installing in conduit.

Ambient Temperature: -40°F to 185°F (-40°C to 85°C)

IR Detector Spec

S702, S702PF, S702HF, S702HFPF, S802, S802HF:

Germanium photodiode with spectral response 950nm to

1710nm (1/2 intensity points) and peak spectral response

at 1400nm

High Pass Filter Pickup: 33 Hz standard, 155 Hz high

frequency option (-HF)

IR Optical

Angle of View: 1 degree (1.45” dia. at 6 ft. or 3.7cm dia. at

1.8m)

UV Detector Spec

S706 & S706PF, S806: UVtron with spectral response 185nm

to 260nm and a peak response at 210nm

UV Optical

Angle of View: 5 degrees (1 inch per foot)

Cable & Connector

Signal Proc. to V.H.:

(Standard) Honeywell C330, 4 Conductor, 18 ga., shielded,

90C, Sunlight Resistant, 15 ft. long, with ITC rating for US

and CIC rating for Canada. (This rating permits use in

hazardous locations without a conduit.)

With PF option Honeywell C330 cable or 4 conductor, 22

ga. or larger with overall braided shield, 95% coverage, or

with shield over the signal line may be used for extension

purposes. Tie shield to ground at viewhead end and signal

processor end of cable. (Cable must be protected by a

conduit in hazardous locations.)

Dimensions

Refer to Fig. 8 and Fig. 9.

Model 700ACSP & Model 700DCSP Signal

Processer

Electrical: Model 700ACSP

Primary Input Power: 85-265VAC, 50-60 HZ, 0.07A Max.

fused (with either V.H. connected)

Battery Backup Voltage: 22VDC to 26VDC, 0.2A DC Max.

fused (with either V.H. connected)

Electrical: Model 700DCSP

Primary Input Power: 22VDC to 26VDC, 250 mA Max. fused

(with either V.H. connected)

Battery Backup Voltage: 22VDC to 26VDC, 0.5A DC Max.,

fused (with either V.H. connected)

Outputs

Flame Relay: 2 form C contacts

Self-Checking Relay: 1 form C contact

Relay Contact Ratings: 5A at 125 VAC, 277 VAC, & 30 VDC;

1/8 HP 125 & 250 VAC

Analog Flame Signal: Isolated 0 to 20 mA or 4 to 20 mA

output for remote meters or DCS, 360 ohms maximum

resistance

Environmental

Ambient Temperature: 32°F to 140°F (0°C to 60°C)

Dimensions

Refer to Fig. 10 and Fig. 11.

APPROVALS

S70X/S80X Viewing Heads (Connector series and Pipe fit

series [PF])

CSA for CLASS I, DIV 2, GROUPS A, B, C, D & T4A

FM 7610/NEMA 4X and CLASS 1, DIV 2, GROUPS A, B, C, D

& T4A*

SIL 3 “Fit for Use”

IECEx CSA 10.0003 Ex nA IIC T4 Gc

-40<Ta<85ºC, -40<TA<185ºF

*IP67/NEMA 4/4X rating applies when connector ring is

properly tightened and cable is UV shielded

700ACSP and 700DCSP Signal Processors

CSA (C, US)

FM

INSTALLATION

When Installing These Products...

1. Read these instructions carefully. Failure to follow them

could damage the products or cause a hazardous

condition.

2. Check the ratings given in the instructions and one the

products to make sure the products are suitable for your

application.

3. Installer must be a trained, experienced, flame

safeguard control technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Signal Processor Mounting

The 700ACSP and 700DCSP signal processors mount on a

standard 35mm DIN rail. They snap into place and may be

released from the rail using a flat screwdriver.

3 66-2069—01

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

Grounding and Shielding

NOTE: Installer must be a trained, experienced flame

safeguard service technician and should be

familiar with the equipment operation and

limitations and be aware of any applicable local

codes and regulations.

1. Connect a safety ground to the viewing head housing (if

applicable).

2. The viewing head and all associated cable/conduit must

be at least 12 inches (31 cm) from any source of high

energy or voltage (for example, igniter equipment).

3. Install a ground wire from the ignition transformer case

to the igniter assembly.

4. Ensure all igniter wires and cables show no signs of

wear. Replace any igniter cables or wires that are frayed

or cracked.

5. The viewing head must be electrically isolated from the

burner front.

a. Electrical isolation can be accomplished by

installing an Ultem nipple (R-518-13) or an Ultem

locking coupler adapter (R-518-PT13 or R-518PT13L) in conjunction with a locking coupler (R-518CL13-HTG) between the viewing head flange and

the burner mount.

b. The purge air line should also be isolated from the

viewing head. This can be accomplished by

installing any insulating material, for example a

rubber hose, in between the purge air line and the

viewing head.

Signal Processor Power Connections

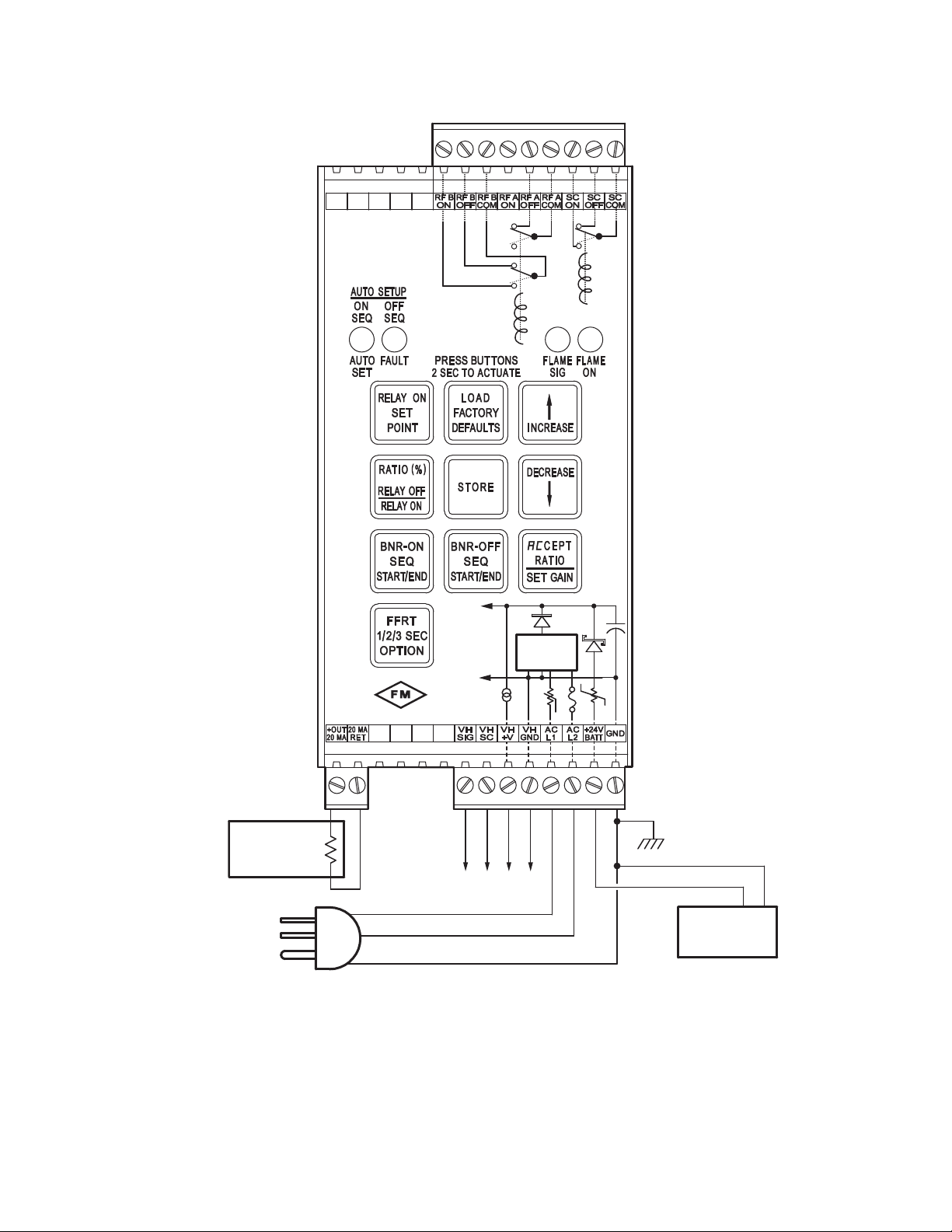

The Model 700ACSP power and relay connections are shown

in Fig. 1. The AC power supply to the 700ACSP Signal

Processor passes through a 2A fuse and an inrush current

limiter.

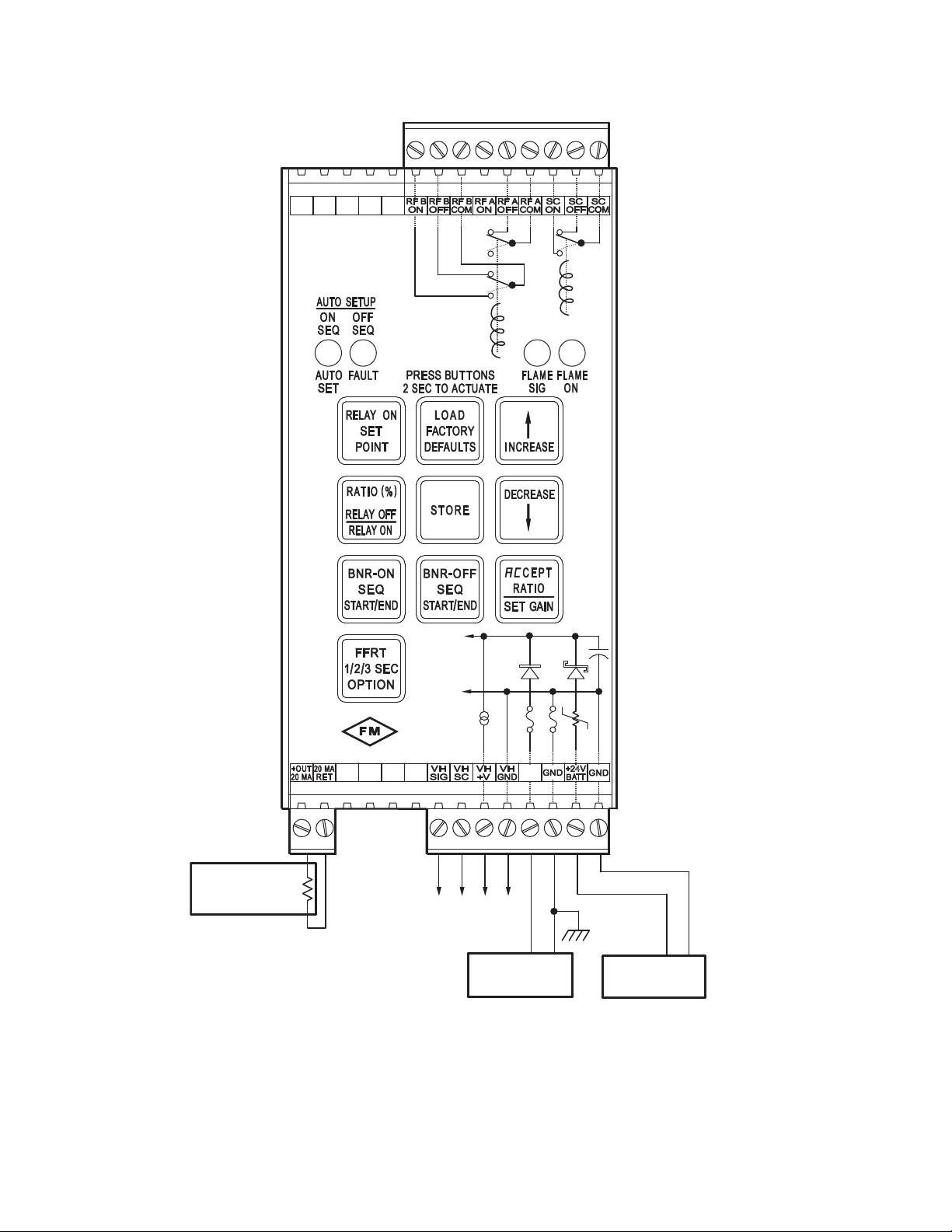

The Model 700DCSP power and relay connections are shown

in Fig. 2. The maximum current rating for each 700DCSP is

250mA.

In the Model 700 signal processors the flame relay (RF A/B

ON, OFF, COM) has two sets of FORM C (SPDT) contacts

and the self-check relay (SC ON, OFF, COM) has one set (Fig.

1 and Fig. 2). The self-check relay is energized whenever the

signal processor is powered and is operating normally,

whether the flame relay is energized or not. Internally, the

flame relay is wired in series with the self-check relay (not

shown), which prevents the flame relay from energizing if the

self-check relay is not energized.

Unique fail-safe circuitry for the self-check and flame relays

ensure that in the event of any critical component failure

occurrence, system response will be to de-energize the selfcheck relay, which in turn de-energizes the flame relay.

Some of the internal power wiring of the Model 700ACSP and

Model 700DCSP signal processors is shown in Fig. 1 and

Fig. 2. Rectifier diodes separate the battery backup input from

the main power bus until the battery voltage exceeds the

internal DC voltage plus a diode voltage drop. Resettable

fuses (shown as resistors with slashes) and conventional

fuses prevent internal failures from loading the power sources.

With the Model 700DCSP, if a backup battery is to be used

with a main power supply, the two power sources would be

wired as shown in Fig. 2. If no backup battery is to be

installed, the main power supply can be connected at +26V

PWR and GND as shown in Fig. 2 or it can be connected to

the +24V BATT input and GND. It is preferable to use the

battery connections because it takes advantage of the

resettable fuse at the battery input; resettable fuses recover

automatically from a fault within a few seconds after power is

removed. At the +26V PWR input and its associated GND,

conventional1A fuses are used because they are able to

protect against 240VAC being applied by accident (this could

happen if a Model 700DCSP is installed in a cabinet wired for

a Model 700ACSP).

66-2069—01 4

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

APPROVED

AC IN

GROUND

TO VIEWING

HEAD

24 V

BACKUP BATTERY

(OPTIONAL)

0-20 OR 4-20 MA

FOR INDICATOR OR

INSTRUMENTATION

360 OHMS MAX

+

-

+

-

CHASSIS,

EARTH, OR

SYSTEM GND

M34280

+

+26VDC

GND

.125 A

.4A

2

A

AC POWER

SUPPLY

-t°

Fig. 1. Model 700ACSP Signal Processor Wiring.

5 66-2069—01

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

+

+26VDC

GND

.4A1A 1A

.125 A

LIM

M34282

APPROVED

24 V

BACKUP BATTERY

(OPTIONAL)

+

-

0-20 OR 4-20 MA

FOR INDICATOR OR

INSTRUMENTATION

360 OHMS MAX

+

-

CHASSIS,

EARTH, OR

SYSTEM GND

DC POWER SUPPLY

250 MA

+

-

+26

PWR

TO VIEWING

HEAD

Fig. 2. Model 700DCSP Signal Processor Wiring.

66-2069—01 6

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

RED

BLACK

WHITE

GREEN

TERMINAL

VH SIG

VH SC

VH +V

VH GND

CONDUIT

ENCLOSURE

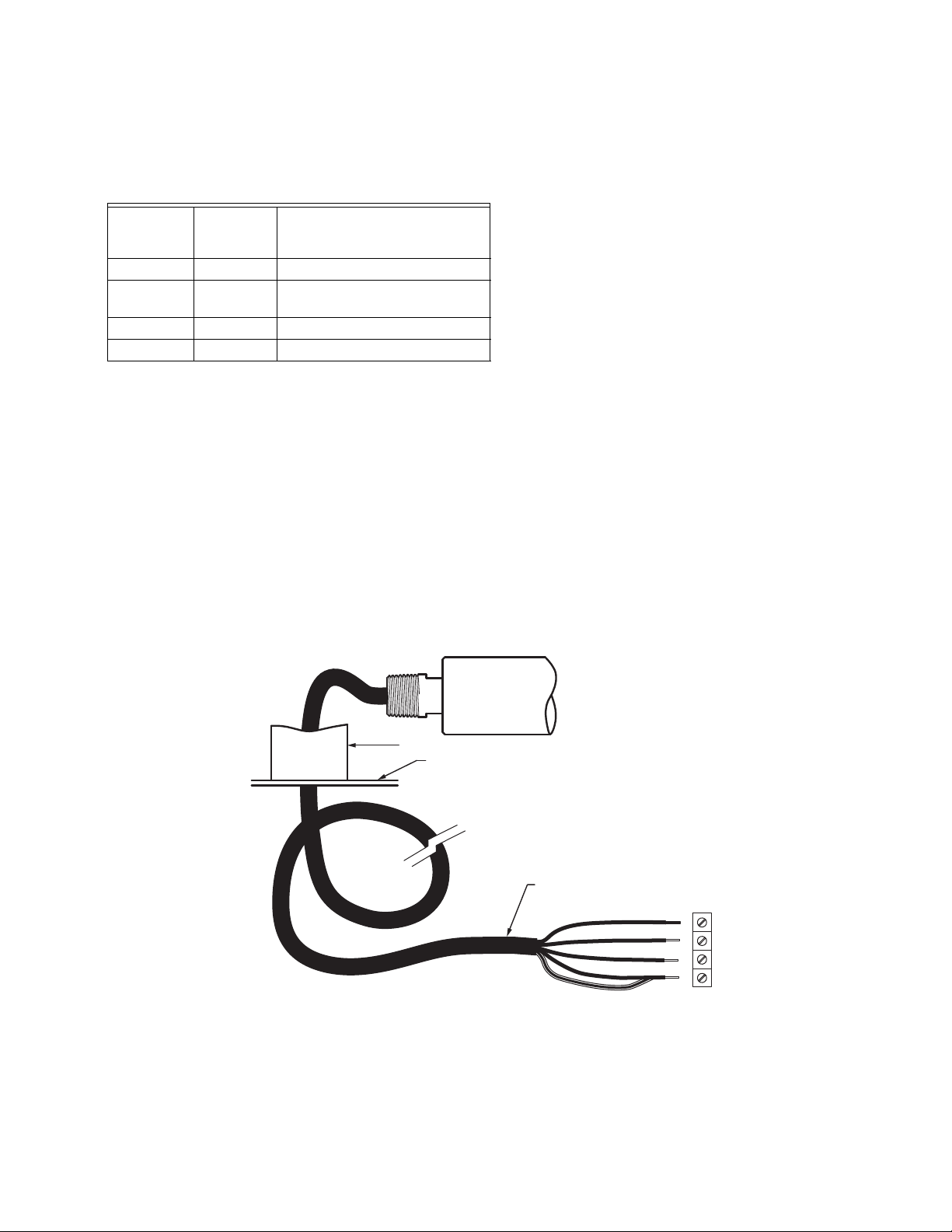

S702PF, S702HFPF OR S706PF

SHIELD

GRAY CABLE

WITH OVERALL SHIELD

STANDARD "PIGTAIL" LENGTH = 10 FEET (3 METERS)

M34285A

Viewing Head Connector and Wiring

Viewing heads are wired to the appropriate terminals located

on bottom of the 700ACSP, 700DCSP, P531 or P532 signal

processors. The terminals are listed functionally in Table 2.

Table 2. Terminal Descriptions.

700ACSP or

700DCSP

Ter minal

P531 or

P532

Terminal

VH SIG VH3 SIG Flame Signal from Viewing Head

VH SC VH3 SC Shutter Drive Signal to Viewing

Head

VH +V VH3 +V +24VDC Power to Viewing Head

VH GND VH3 GND GND Signal Ground

Connectors and cables are shown in Fig. 3, Fig. 4, and Fig. 5.

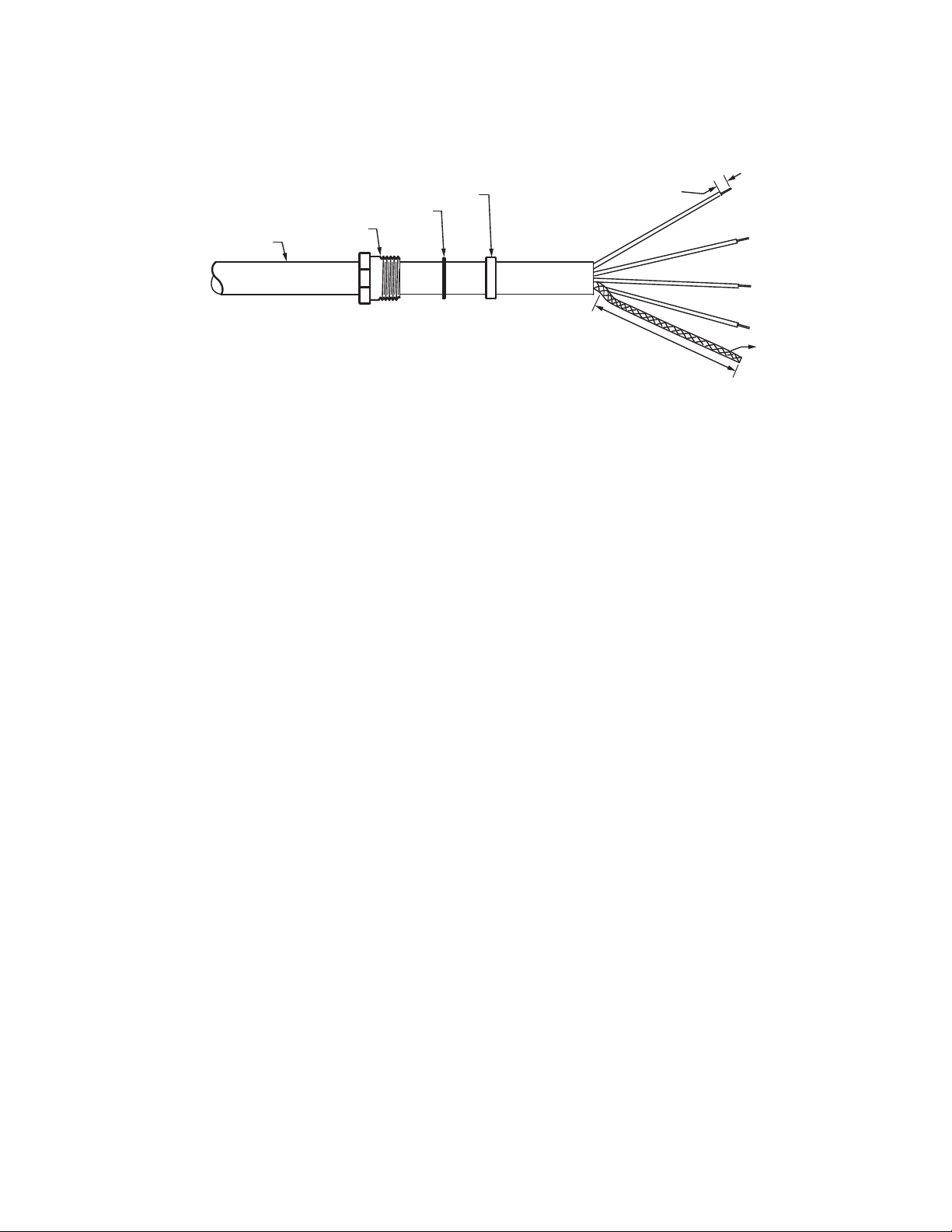

Fig. 3 shows the viewing head cable with the 1/2 in. NPT pipe

fitting and pigtail for use in a conduit. The gray cable is

labeled: LAPP USA UNITRONIC 190CY B (UL) TYPE CMG

105C 22AWG/4C SHIELDED E130334 – CSA CMG 105C or

AWM II A/B 300V LL74246. The standard pigtail length is 10

feet (3.0m). The S706PF-050 has a 50-ft (15 m) pigtail length.

This cable must be used with a conduit in hazardous

locations. It can also be ordered commercially as Olflex

602204S.

The recommended cable for hazardous locations, C330, is

shown in Fig. 4 with the right-angle connector and Fig. 5. It is

supplied as standard in a 15 ft. (4.6m) length with other

available lengths. This cable does not have to be used in a

conduit. It is labeled: C-330E193849 (UL) TYPE ITC 4/C 18

Description

AWG 90C 300V OR c(U L) CIC 90C 600 V FT4 SU NLIG HT

RESISTANT. C330 cable with or without the connector wired

at the factory can be purchased from Honeywell. Refer to

“Accessories” on page 10 for part numbers.

The customer may also supply his own cable; a replacement

mating viewing head connector should be ordered. Refer to

“Accessories” on page 10 for part numbers. The use of

shielded cable is recommended, either an overall shield or a

cable with a shield for the signal line. The shield should be

connected to GND at the processor end and to the ground

wire at the viewing head end. The cable diameter should not

exceed 0.307" in order for it to go through the hex bushing in

the connector. But note that wiring the cable to the connector

is not easy because of the limited space. Also, the LED

indicator assembly must be mounted inside the connector

and, preferably, soldered in place. Thus, it is recommended to

purchase a pre-wired cable and connector assembly from

Honeywell.

NOTE: FOR CLASS I, DIV 2 RATING, CABLING IN

HAZARDOUS LOCATIONS MUST COMPLY WITH

NEC ARTICLE 500 REQUIREMENTS AND

APPLICABLE GOVERNING CODES.

In the U.S., cables should have UL’s ITC rating; in Canada,

cables should have CSA’s CIC rating. The recommended

C330 cable has both ratings.

NOTE: To obtain a NEMA 4X seal between the connector

and the viewing head, tighten the metal

connector ring securely.

Fig. 3. Model 700 Viewing Head Cable With 1/2 in. NPT Fitting.

7 66-2069—01

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

VH SC

700 LTA

T&B #5330

LIQUID

TIGHT

FITTING

FLEXIBLE LIQUID

TIGHT CONDUIT,

SUCH AS

ElectriFlex LT-516

5-16 (8)

MAX

Fig. 4. Model 700/800 Viewing Head Cable Connections.

Cable Preparation

NOTE: This section will typically be used for reference

Honeywell C330 cable is recommended for use with the

S70X/S80X viewing heads and signal processors. C330 cable

has a UL ITC rating and can be used in the US in hazardous

locations. Note the flame signal wire is shielded, and that the

shield must be terminated at both ends.

NOTES:

Connection of the Honeywell type C330 cable to the viewing

head plug is shown in Fig. 5. Cable preparation should be

done as follows:

• Remove the cable entry nut from the plug housing.

• Remove the retainer and rubber grommet.

• Unscrew the plug end from the connector body.

only. The S70X/S80X connector parts are very

small and delicate and difficult to assemble. It is

advisable to purchase pre-made cables from

Honeywell.

— The shield is used as the signal ground wire

which goes to terminal SIG GND on the signal

processor. The shield must be braided type for

this application in order to maintain an electrical

path. For this reason, a foil type shield should not

be used. The signal ground shield is also the selfchecking or shutter drive circuit return path. It is

recommended that the Honeywell C330 cable be

used for all S70X/S80X applications.

— Shield shrink tubing is required on the SIG GND

wire at both ends.

VH SIG

VIEWING HEAD

CONNECTOR

LOOKING AT PINS

C330 LIGHT BLUE CABLE

WITH SHIELDED WHITE CONDUCTOR

(RATED ITC BY UL & CIC BY CSA)

VH +V

VH GND/SHIELD

METAL

CONNECTOR

RING

GREEN

LED

SHIELD

WHITE

BLACK

RED

GREEN

VIEWING HEAD

CONNECTOR

LOOK ING AT BACK

TERMINAL

ORANGE

LED

VH SIG

VH SC

VH +V

VH GND

M34286

2. Slide the shield back until a bulge develops close to

where the wire exits the cable outer covering.

3. Carefully spread a few strands of the shield at the bulge

(making sure not to break any strands) to create an

opening and pull the wire out of shield through opening.

4. Carefully return shield to original shape and length by

pulling gently, then cover the shield with heat shrink

tubing to insulate it.

5. Slide the nut (with threads toward the cable end), the

retainer and the grommet onto the cable.

6. Slip the cable through the bottom opening of the

connector through the 90-degree bend and out the plug

end of the connector body.

7. Strip each wire 3/8” as shown in the assembly drawing.

8. Proceed to wire the connector as follows:

a. Connect the viewing head signal wire (the shielded

wire) WHT into the designated terminal by inserting

into opening and then tightening the retaining screw.

b. Connect the self-checking signal wire BLK to its

designated terminal.

c. Connect the signal ground shield from WHT wire

with shrink tubing to its designated terminal.

d. Connect the +24VDC power wire RED to its

designated terminal.

e. Connect the power ground wire GRN to the proper

terminal.

9. Carefully slide the wired plug end into the connector

body. Screw the plug onto the connector body until tight.

10. Reassemble the grommet, retainer and cable entry nut

and tighten to the connector body.

1. Strip 2 inches of the C330 cable outer cover from the

cable removing any cellophane wrap or filler material.

Strip the insulation from the shielded wire (if insulated

over shield) a full 2 inches to expose the shield.

66-2069—01 8

Cable at the signal processor end should be prepared in a

similar way to the plug end, particularly the shield from the

WHT wire. Follow the wiring connections as shown in Fig. 5,

making sure that the shield does not touch the other adjacent

terminals.

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

3 CONDUCTORS PLUS 1 COAX

3 CONDUCTORS: 18 AWG

COLOR WHITE: 38 AWG BRAIDED SHIELD 90% COVERAGE

JACKET: TPE (TPAF) LIGHT BLUE

GROMMET

FLAT WASHER OR RETAINER

CABLE ENTRY NUT

CABLE

CABLE PREPARATION

STRIP 3/8" TYPICAL

1-19/64 (33)

NOTE: IMPORTANT INSULATE SHIELD WITH SHRINK TUBING LEAVING 3/8" STICKING OUT.

TYPICAL

Fig. 5. C330 Cable Preparation.

Protecting the Viewing Head Cable (Connector Series)

It is usually desirable to mechanically protect the cable going

to the viewing head. For the connector model viewing heads,

flexible conduit and adapters can be used for this purpose.

See Fig. 4. The 700LTA (liquid tight viewing head cable

adapter) is a custom part available from Honeywell; it screws

into the right-angle connector in place of the standard hex

bushing. The 700LTA is used with a Thomas and Betts #5330

liquid tight fitting which is designed to give a watertight seal for

flexible Liquatite

®

conduit, such as part number LT-516 by

Electri-Flex. The components have internal dimensions to

clear a 5/16 in. diameter cable. For each viewing head a

700LTA, a flexible conduit, and two T&B fittings will be needed.

Honeywell sells the 700LTA while the other parts can be

purchased commercially. The installer can fit the liquid tight

flexible conduit over the cable supplied with the viewing head

by first unscrewing the hex bushing from the connector and

removing it from the cable and then sliding the 700LTA, T&B

and flexible conduit assembly over the cable and screwing the

assembly into the right-angle connector. The flexible conduit is

terminated with the second T&B fitting which ends with a 3/8

in. NPT thread.

Note that when the wiring needs to meet Class I, Division 2

requirements for use in hazardous locations and when conduit

is used, the conduit must be sealed where the cable passes

from the hazardous location to the non-hazardous location in

order to keep potentially hazardous gases from being

conducted into the non-hazardous area.

Viewing Head Connector LED Indicators

The viewing head connector has orange and green LEDs

which can be viewed from the rear of the connector.

The green LED displays the pulses out of the viewing head

and the orange LED shows that the self-checking signal from

the signal processor is reaching the viewing head. If power is

on at the signal processor, the orange LED should flash at one

pulse per second, even if the viewing head is not plugged in.

This is helpful in troubleshooting.

With no flame signal present, the green LED will flash one

pulse per second in step with the self-checking signal. The

viewing head is sending back an ID pulse; this is part of the

self-checking system. When a flame is present, the green

LED will flash at a rate proportional to the flame signal, except

when the pulses are interrupted once per second for the selfcheck pulse arrival at the viewing head. The pulse rate of the

green LED flashes can be used for aiming the viewing head.

Viewing Head Mounting and Sighting

Mounting is 1/2-in. NPT (F) for all viewing head models with a

1/4-in. NPT (F) purge air connection. Before beginning the

actual installation, determine the best location for mounting

the viewing head based upon the following factors:

Viewing Head Mounting Block

The S70X viewing heads are held firmly in place in their

mounting blocks by two galvanized steel latches. The S80X

viewing head is secured in its mounting block by a friction

twist-lock. The mounting blocks are made from a hard Delrin

rated for continuous service to 180°F (82°C). An alternative

mounting block made from Ultem

and S80X viewing heads, rated for continuous service up to

320°F (160°C). Refer to the ACCESSORIES section for part

numbers.

Pressure

The S70X viewing head lens will withstand 50 psi (3.4 bar)

while the S80X lens will withstand 90 psi (6.2 bar), provided

the compression ring on the purge air adapter is tightened

properly. If the lens assembly is exposed to greater pressures

through the sight pipe, then an isolation unit must be used.

Honeywell isolation units with purge air entrance are available

SHIELD

M33282

®

1000 is available for S70X

9 66-2069—01

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

as accessories; ISO-UNIT, ISO-UNITSS, ISO-UNITHPGT.

Each has a quartz window, two 1-in. NPTF connections and a

1/2-in. NPTF purge port.

Temperature

The case temperature of the viewing head housing must not

exceed 185°F (85°C) while the standard Delrin mounting

block must not exceed 180°F (82°C) continuous service. Care

should be taken to ensure the case housing and mounting

block temperatures do not exceed these values.

Purge air will help reduce conducted heat through the sight

pipe and flange. A heat insulating Ultem replacement viewing

head mounting block is available for both the S70X/S80X

models (part numbers 700UA and 800UA) with a continuous

service rating of 320°F (160°C) as well a 1/2-in. NPTM Ultem

nipple (part number R-518-13) or an Ultem locking coupler

adapter (R-518-PT13 or R-518-PT13L) to reduce the

conducted heat, but direct radiation can cause the housing

case temperature to exceed limits. If the ambient heat (direct

radiation) is excessive, then an air cooling canister with vortex

cooler should be considered or alternately a fiber optic

extension. The extension uses a fiber optic cable assembly

between the sight pipe and the viewing head, allowing the

viewing head to be placed further away from the heat source.

Refer to the Fiber Optic Manual 69-2683 or contact your

distributor or the factory for assistance with fiber optic

selection and pricing.

as possible so as to sight along the flame rather than across

the flame. Doing so will ensure continuous flame detection

under changing load conditions. See Fig. 14, 15 and 16.

Utilizing a sighting or the sight pipe aimed at the root of the

flame (where the turbulent combustion air mixes with the

flame) is a good starting point for optimizing the sighting.

Where practical, using a swivel mount to "zero-in" on the

highest signal will assure maximum performance. The

optimum scanner location is parallel to the burner center line.

The use of a swivel mount allows for line of sight adjustment,

where practical to use.

Examples of viewing head installation with and without a

swivel mount are shown in Fig. 12 and Fig. 13. If using a sight

pipe, its diameter should be large enough to allow a

reasonable field of view, and to allow for adjustment of the

swivel mount angle.

In some instances, it may be beneficial to use two sets of

setpoints for Flame On, Flame Off and gain. The two-channel

capability (primary and alternate viewing head settings) is

ONLY possible when using the P531 or P532 signal

processors; it is not possible when using the 700ACSP or

700DCSP signal processors. The switch-over from Channel A

to Channel B can be implemented from the burner control

system. Refer to the P531/P532 user manual, 66-2068, for

further information regarding switch-over and the use of

Channels A and B with independent settings.

Purge Air

Use a flexible air supply line, to allow for repositioning of the

viewing head and sight pipe until a final and permanent

position has been decided. A continuous flow of air must be

maintained in order to reduce the conducted heat and to keep

the sight pipe and viewing head lens free of dirt and debris. Air

required is about 5 SCFM (0.13 Nm3 /min) delivered at 1 in.

(25mm) above the maximum pressure as measured at the "Y"

or "T" section of the purge air connection for each viewing

head. The air supply must be clean, free of oils and water, and

preferably cool. In order to electrically isolate the viewing

head, the purge air line should be installed using an insulating

material, such as a rubber hose, in between the purge air line

and the viewing head.

Vibration

Do not install the viewing head where it could be subject to

high vibration. Provide an anti-vibration mount if excessive

vibrations are present.

Clearance

Make sure there will be sufficient room to remove the viewing

head housing for servicing.

Viewing Head Mounting

Honeywell offers a range of swivel mounts, both pipe thread or

flange mounting for use with sight pipes or direct windbox

mounting. See “Accessories” on page 10 or the Honeywell

website for further details.

Viewing Head Sighting

The sighting of the viewing head should be parallel to the

center line of the burner in the direction of the flame. If used,

the sight pipe should be mounted as close to the center line

ACCESSORIES

Orifice disks (kit M-702-6) - Used to reduce the signal

brightness in cases where the signal brightness is too strong.

Located immediately in front of the lens, it will reduce the

amount of signal to the sensor. Bag assembly contains orifice

disks and retaining rings. Orifice disks come with 3/8, 1/4,

3/16 and 1/8 inch diameter holes. Contact the factory for

guidance in using orifice disks.

Insulating nipple (R-518-13) - 1/2-in. NPTM Ultem heat and

electrical insulating nipple typically used in conjunction with a

swivel mount and union.

VH insulating mounting block (700UA, 800UA) - 1/2 in.

NPTF Ultem heat and electrical insulating mounting block,

used in place of the supplied Delrin mounting block. 1/4 in.

NPTF purge air connection. Typically used in conjunction with

a swivel mount. Rated for continuous service up to 320°F

(160°C).

Swivel mounts, small (700-1, 700-2, 700-3) - All have 1/2 in.

NPTM viewing head connections on one end with varying

process connections including 1 in. NPTF, 1/2 in. NPTF and

1/2 in. flanged.

Swivel mounts, large (M-701-1, M-701-2, M-701-2-FLG, M701-2-SS, M-701-3, M-701-3P, M-701-4) - All have 1 in NPTF

viewing head connections, one end with varying process

connections including 2 in. pipe slip on, 2 in. NPTF, 2 in.

flanged, 2 in. NPTF in stainless steel construction, 4.5 in.

flanged with 3 bolts, 3 in. NPTF and 2-bolt flanged.

Appropriate fittings must be used to adapt the 1/2 in. NPTF

viewing head process connections.

66-2069—01 10

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

Insulating locking coupler adapters (R-518-PT13, R-518PT13L) - 1/2 in. NPTM Ultem adapters insulate the viewing

head electrically and thermally and are used with the R-518CL13-HTG locking couplers. The R-518-PT13L has a quartz

lens.

Locking coupler (R-518-CL13-HTG) - Used with the R-518PT13 and R-518-PT13L insulating locking coupler adapters.

Process connection end is 1/2 in. NPTF.

Connector (ASY784) - Replacement quick disconnect

connector for all S70X/S80X models.

Connector + Cable (ASY782) - Replacement pre-assembled

15-foot (4.7m), 4-conductor cable (C330) with quick

disconnect (ASY784) for all S70X/S80X non-pipe fitting

models. There are also five more pre-assembled cable and

connector assemblies available; ASY782-030 (30ft/9m),

ASY782-050 (50ft/15m), ASY782-100 (100ft/30m), ASY782200 (200ft/61m) and ASY782-250 (250ft/76m).

Cable (C330) - 4 conductor cable with braided shield. Sold

per foot.

Isolation Units (ISO-UNIT, ISO-UNITSS, ISO-UNITHPGT) -

All have 1 in. NPTF connections with 1/2 in. NPTF purge ports

and quartz window. Painted aluminum or stainless steel

construction. The HPGT version has a 1/2 in. thick quartz

window for higher pressures. Appropriate fittings must be

used to adapt the 1/2 in. NPTF viewing head process

connections.

Liquid tight cable adapter (700LTA) - S70X/S80X viewing

head cable adapter with 3/8 in. NPTF conduit connection.

Air cooling canister (700ACC, 800ACC) - Has an air inlet

port on side. Used with vortex coolers. S80X models can be

used with the 700ACC if the 800ACC-RING adapter is used.

Vortex coolers (M3204, M3208, M3210, M4025) - Used with

air cooling canister. Contact your distributor or the factory for

selection assistance.

Cable restraints (800CR, 700CRLT) - Liquid tight S80X and

S70X cable restraint versions. The 800CR includes the

700CRLT and the 800ACC-RING adapter.

S80X adapter ring (800ACC-RING) - Adapter ring to fit S80X

viewing heads to 700ACC cooling jacket and 700CRLT liquid

tight cable restraint.

Right angle adapter (700RAA) - S70X/S80X viewing head

right angle adapter. 1/2 in. NPTF to 1/2 in. NPTM connections.

Mounting blocks (700DA, 700DA-1, 800DA) - Delrin

replacement adapter/mounting blocks for S70X and S80X

viewing heads. All have 1/4 in. NPTF purge air connections.

Rated for continuous service up to 180F (82C). The 700DA

and 800DA have 1/2 in. NPTF process connections while the

700DA-1 has a 1 in. NPTF process connection. For more 1 in.

NPT accessories that can be used with the 700DA-1, refer to

the S55XB/BE manual, 66-2064.

USB to RS422/RS485 Converter (COMMOD) - Protocol

converter for use with external communication with a remote

computer.

Fiber Optic System Compatibility - The S70X and S80X

viewing heads are compatible with the Honeywell FASA fiber

optic extension products. The S700FOAD and S800FOAD

adapters are applicable, depending on the application.

Contact your distributor or the factory for assistance with fiber

optic selection and pricing.

OPERATION

IR Detector

The S702 and S802 viewing head models use a Germanium

photodiode, which responds to IR radiation/flicker in the flame.

Flame flicker is caused by the combustion, or forced air

injected in to the flame. Combustion air can be mixed with the

fuel (pulverized coal) or can be introduced separately. In either

case, forced air is introduced in such a way as to aid the

combustion process. This air is usually made turbulent by

causing it to swirl with spin vanes located in the burner throat.

Flame flicker is created when turbulent air mixes with the

flame. It is composed of random frequencies and the amount

of high frequency flicker is dependent on the fuel and the

burner.

The S702, S702PF and S802 viewing head models respond

to flicker frequencies above 33Hz while the S702HF,

S702HFPF and S802HF viewing heads respond to flicker

frequencies above 155Hz. All flicker frequencies below the

filters are ignored, so it is important to sight the viewing head

on the highly turbulent portion of the flame that contains the

higher frequencies. The location of the higher frequencies can

be predicted by examining the burner with regard to where the

turbulent air enters the flame. The optimum scanner location

is parallel to the burner center line (Fig. 14). The use of a

swivel mount is encouraged to allow for line of sight.

Filter Selection for IR Viewing Head

If a good count ratio between BNR-ON and BNR-OFF cannot

be obtained when using an IR viewing head—particularly

when monitoring oil flames—an IR viewing head with the High

Frequency (HF) filter option is recommended. The standard IR

viewing head responds to flicker frequencies above 33 Hz;

with the HF option, the IR viewing head responds to flicker

frequencies above155 Hz.

UV Detector

The S706, S706PF and S806 viewing head models use the

UVTron tube, with a spectral response of 185-260nm and

peak response of 210nm to ultraviolet radiation. The output of

the detector is a pulse stream of randomly spaced pulses

whose average rate is proportional to the UV radiation present

in the flame. The UV radiation is a direct result of the

combustion process as oxygen combines with hydrocarbons

in the fuel in the blue part of the flame. The yellow part of

flames, and the background radiation from hot refractory, do

not emit UV radiation.

The spectral range of the UV tube makes it ideal for

discriminating between flame and glowing refractory. As with

any UV radiation, it can be absorbed or masked by unburned

fuel, smoke, oil mist, dirt dust and other impurities in the fuel.

Care should be taken to select the proper viewing head for the

fuel used. Additionally, the contaminants that mask UV can be

diluted by providing a strong flow of air through the sight pipe

to clear a viewing path through the attenuating material. See

“Purge Air” on page 10.

11 66-2069—01

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

It may also be desirable to sight the detector at an area

containing fewer masking agents such as near the burner

nozzle or near the entrance of the combustion air. Increasing

the viewing area of the detector by shortening the sight pipe or

by increasing the diameter of the sight pipe can also reduce

the attenuating effects of the masking agents.

In general, the UV viewing heads will work well on natural gas

and light oil flames. The sighting for both oil and gas flames

should be parallel to the axis of the burner and aimed at the

root of the flame, as with the IR detector. (See previous

section, "IR Detector.") The highest UV intensity occurs near

the root of the flame (Fig. 15). In addition, the zone of higher

UV intensity does not overlap the same zones of adjacent or

opposing burner so that, with proper sighting, discrimination

can be achieved.

With low NOx gas burners, the UV radiation is usually much

less in intensity and spread out. Relatively high readings can

be obtained from all over the furnace when many burners are

in service. This is particularly true when flue gas recirculation

is used. There will however, be a relatively stronger signal

near the "root" of the flame and the more intense spot should

be located during the aiming or sighting process. This "root" or

intense spot may be further out than with the standard gas

burner so it is imperative that a swivel mount be used when

making sighting adjustments.

Another factor that needs to be considered when aiming the

viewing head is the load condition of the boiler. The flames

from a burner can be radically different at different loads. This

is one of the reasons for choosing an optimum sighting initially

that will minimize signal swing due to changing loads.

Self-Checking

There is a small processor in both the IR and UV viewing

heads, so it is possible that this processor could fail and

produce erroneous viewing-head pulses. The self-check

circuitry guards against this. There are several tasks that

require intelligent interaction between the viewing heads and

the signal processor. If all of these interactions do not occur

properly, the viewing head will not send pulses back to the

signal processor and the flame relay will open.

Verifying the validity of the gain code received is one of the

tasks performed by the processor in the IR and in the UV

viewing heads. The self-check pulse from the signal

processors is a 100ms-wide, 20V to 24V pulse with two

“notches” or breaks in it. The position of each of the two

notches communicates a gain code of one to nine plus parity

to the viewing head. The viewing head sends back an ID

pulse in the first half of the 100ms self- check time. A viewing

head expects to receive data with a certain parity. If a viewing

head does not receive its correct parity plus the gain code

once per second, it produces no output pulses.

There is also intelligent interaction between the older S706

viewing heads, which did not have the gain-change feature

from the signal processor. The processor in the S706 viewing

head monitors the 100ms width of the self-check pulse

coming from the signal processor. If the pulse is not the

correct width the viewing head produces no output pulses.

Also, if the signal processor receives any pulses back from the

viewing head during the last half of the100ms self-check time,

it assumes that a processor failure has occurred in the viewing

head, opens both relays, and displays “LO” (lockout).

Adjustment of VH Sighting and Gain

NOTE: Adjustment to the viewing head parameters

cannot be made unless the viewing head is

connected and communicating with the signal

processor.

The viewing head should be properly sighted before the

setpoints are adjusted. Adjustment can be made easier by a

1/2 in. swivel joint, which Honeywell can supply if one is not

available (refer to “Accessories” on page 10).

While the burner is firing, vary the viewing angle while

observing the green LED on the connector at the rear of the

viewing head. Adjust the viewing angle for the maximum pulse

rate, then lock the swivel joint to preserve this mechanical

setting. If the green LED pulse rate is very high or very low,

see the two paragraphs below. The locked mechanical setting

should still be correct when Model 700 viewing heads are

interchanged, because inside each Model 700 viewing head

the optical axis is aligned with the mechanical axis within ±1/4

degree. Also, the reading shouldn’t change when a viewing

head is rotated in the mount.

For the above sighting adjustments to work properly, the

flashing rate of the green LED in the connector at the rear of

the viewing head must be reasonable. On the -PF (pipe fitting)

version, there are no LEDs. The installer must observe the

flame signal on the signal processor instead.

A count rate of 16 to 20 is recommended for proper operation.

If the displayed count is above 25, the pulses begin to blur

together, making changes in the pulse rate difficult to observe.

If the count is higher (29 or 30), then the viewing head is

saturated. Saturation indicates that the count could be even

higher, possibly 50 or more, but it is internally clamped. With

count rates at or close to saturation, the installer will not be

able to adjust the viewing head in the swivel mount to

maximize the count rate properly. It should be possible to

sufficiently decrease the count rate to a usable level by

decreasing the gain. See “Manual Setup of Setpoints” on

page 13 of this manual. If the gain is set to 1 and the count is

still 25 or higher, orificing is likely required. See the section on

orificing below.

If the displayed count is less than 8 or 10, it will be difficult to

maximize the count by adjusting the viewing head aim, since

the pulses occur too infrequently. In such a case the gain

should be increased. If the gain is set to a maximum and the

count rate persists below 8 or 10, the system can still be made

to work reliably as long as the count rate drops significantly

when the flame is removed. However, the setup should be

reviewed for proper viewing head aim and sight path to ensure

it is optimized.

Orificing

Orifice disks have been used in applications with older viewing

heads that did not have adjustable gain in order to reduce the

extreme brightness of certain burner flames. The orifice disk

kit is part number M-702-6. Orifice disks come with 3/8, 1/4, 3/

16 and 1/8 inch diameter holes. Contact the factory for

guidance is using orifice disks. The disks are installed with

retaining rings in the flange at the edge of the 1/2 inch NPT

female pipe thread for the process connection. An internal

type retaining ring is first installed by positioning a ring in the

machined groove inside the flange opening from the housing

66-2069—01 12

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

side. The orifice disk is then inserted. Use a second retaining

ring to hold it in place so that it is sandwiched tightly between

the two retaining rings.

If the displayed flame count is 25 or higher when the gain is

set to 1, an orificing disc inserted in the back end of the

mounting block can be used. Choose a disc that gives a

reading of 12 to 24 at a low fire firing rate. The discs have a

range of orifice sizes; each size step results in about a 2:1

change in the counts displayed.

Signal Processor User Interface

The 700ACSP and 700DCSP signal processors have a user

interface that includes four lights, a two-digit display and

twelve push buttons for operation and programming. Each

button has at least one specific purpose.

To enter a menu, press and hold the applicable button for 2

seconds. Adjustments to the applicable setpoint can be made

via the INCREASE or DECREASE arrow buttons. To store the

new setting, press the STORE button until “--“ is shown,

indicating the value has been accepted.

If no activity occurs for a period of four seconds while the

menu value is displayed, it will revert back to the operating

display.

To exit a menu at any time without saving changes, simply

press the RESET/rE button.

The following describes the functions of the LED indicators,

display and push buttons:

Front Panel LED Indicators and Display

• ON SEQ/AUTO SET LED (green):

— Used in conjunction with the BNR-ON SEQ START/

END and BNR-OFF SEQ START/END buttons during

the automatic setup process

• OFF SEQ/FAULT LED (green):

— Used in conjunction with the BNR-ON SEQ START/

END and BNR-OFF SEQ START/END buttons during

the automatic setup process

— Indicates a fault condition

• Two digit display

— When in operating mode, the display indicates the

current flame signal, which ranges between 00 and 29

— Upon power up, indicates whether an IR or UV viewing

head is attached and the selected gain setting; such

as r7 (IR with gain of 7) or u5 (UV with gain of 5).

— Indicates various characters during the automatic

setup process as well as whether the panel is locked

• FLAME SIG LED (yellow):

— When a flame is present, LED flashes at a rate

proportional to flame signal, except when the pulses

are interrupted once per second for viewing head selfchecks.

• FLAME ON LED (red):

— When the flame signal is above the selected value, the

LED will be illuminated and the flame relay will be

energized.

Push Button Functions

• RELAY ON SETPOINT button:

— Allows user to select flame on threshold value. When

the flame signal is above the selected value, the flame

relay will be energized. Used in conjunction with the

INCREASE, DECREASE and STORE buttons (range

of 00 to 29).

• LOAD FACTORY DEFAULTS button:

— Used to restore all settings to the factory default

values

•

↑ INCREASE button:

— Used to increase parameter value when in

programming mode

• RATIO (%) RELAY OFF/RELAY ON button:

— Used along with the INCREASE, DECREASE and

STORE buttons to set the RELAY OFF setpoint at a

percentage of the RELAY ON setpoint. Adjustable

from 20% to 80%.

• STORE button:

— Stores new parameter values during programming

— After making changes “--” will be displayed indicating

the new values are accepted and stored

•

↓ DECREASE button:

— Used to decrease parameter value when in

programming mode

• BNR-ON SEQ START/END button:

— Used to initiate and proceed through the automatic

parameter setup sequence, which includes the RELAY

ON, RATIO (%) and GAIN settings (the FFRT, mA

output and communication address must be set

manually)

• BNR-OFF SEQ START/END button:

— Used during the automatic parameter setup sequence

• ACCEPT RATIO/SET GAIN button:

— Allows user to set the viewing head gain in conjunction

with the INCREASE, DECREASE and STORE buttons

— Used in conjunction with the BNR-ON SEQ START/

END and BNR-OFF SEQ START/END buttons during

the automatic setup process

• FFRT 1/2/3 SEC OPTION button:

— Used to set the FFRT timing along with the

INCREASE, DECREASE and STORE buttons

• 0-20MA 4-20MA OPTION button:

— Used in conjunction with the INCREASE, DECREASE

and STORE buttons to select the proportional mA

output for the flame signal

• RESET rE button:

— Resets a lockout condition

— Also used to exit a menu while programming

— Used to set the Modbus address along with the

INCREASE, DECREASE and STORE buttons

Manual Setup of Setpoints

The keypad of the signal processor is used to set the IR/UV

GAIN, RELAY ON, RATIO % (Relay Off), FFRT and mA output

option setpoints. The following section describes this process.

Also refer to Fig. 21, 22, 23, 24 and 25.

Setting the Viewing Head Gain

The gain of the IR and UV viewing heads can be adjusted. In

addition to the information in this section, refer to Fig. 25. At

power-up, the 700 signal processors display codes to tell the

operator what type of viewing head and what gain is being

used. Default values are “r5” for the IR viewing head and “u5”

13 66-2069—01

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

for the UV viewing head. The “r” or “u” denote IR or UV

viewing heads, respectively, while the numeric digit indicates

the current gain setting. The gain can be adjusted from 1 to 9

with a gain of 5 being the factory default gain.

To change the gain, press and hold the SET GAIN button for

two seconds until the current value is displayed. Use the

INCREASE and DECREASE buttons to change the setting as

appropriate while the value is displayed. To store the new

setting, press the STORE button until "--" is shown, indicating

the value has been accepted.

If no activity occurs for a period of four seconds while the

value is displayed, the display will return to the operation

mode without saving the new setpoint.

To exit the menu at any time without saving changes, simply

press the RESET/rE button.

The gain is live; changes are effective immediately, but if the

displayed gain value is not stored (by pressing STORE), and

no other buttons are pressed, the processor returns to the

previous setting after four seconds.

The gain steps have a ratio of 1:1.19, meaning they increase

19% with every step (multiply by 1.19). Going from a gain of 1

to 5 or 5 to 9 doubles the gain whereas going from a gain of 9

to 5 or 5 to 1 halves the gain.

Relay On Setpoint

The two numeric digits on the Model 700 signal processor

normally display the incoming count during operation; that is,

the number of pulses that arrive between self-check pulses.

This count ranges from 00 to 29.

Refer to Fig. 21 for a flowchart of setting the Relay On

setpoint. Press and hold the RELAY ON SETPOINT key for

two seconds to access this setpoint. The RELAY ON SET

POINT value will be displayed. If no further keys are pressed,

this display will disappear in four seconds and the incoming

count will again be displayed. If the RESET key is pressed,

the display will return immediately to displaying the incoming

count.

While the RELAY ON SET POINT is displayed, you may

increase or decrease the setting by using the INCREASE and

DECREASE arrow keys. To store the new setting, press the

STORE button until "--" is shown, indicating the value has

been accepted.

To exit the menu at any time without saving changes, simply

press the RESET/rE button or wait 4 seconds until the display

reverts to the incoming count value. To extend the display

time, press the RELAY ON SETPOINT button again; the

display will time out for four seconds after the key is released if

no other buttons are pressed.

The displayed value of the RELAY ON SET POINT is live; that

is, if the relay is off and the adjusted value falls below the

current flame signal count, the relay will turn on immediately

(FFRT settings are ignored). This immediate response can be

seen if the count is low and the RELAY ON SET POINT is set

above it; if the RELAY ON SET POINT is then adjusted down

to the count level, the FLAME ON relay will be energized.

Ratio (%) Relay Off/Relay On Setpoint

For a flowchart of this setpoint process, refer to Fig. 22. The

key labeled RATIO (%) RELAY OFF/RELAY ON is used to set

the RELAY OFF SET POINT at a percentage of the RELAY

ON SET POINT. This percentage is adjustable from 20% to

80%. For example, if the RELAY ON SET POINT is set to 16

and the RATIO (%) is set to 50% (the factory default values)

the relay will energize if the displayed count goes to 16 or

higher and de-energize when the count drops to 08 or less for

one to three seconds, depending on the FFRT (Flame Failure

Response Time) setting. The adjustment of the RATIO setting

is live. Adjustments will cause the Flame Relay to de-energize

immediately, ignoring FFRT settings.

To access this setpoint, press and hold the ACCEPT RATIO/

SET GAIN button for 2 seconds until the current value is

displayed. While the value is displayed, adjustments may be

made via the INCREASE or DECREASE arrow buttons. To

store the new setting, press the STORE button until "--" is

shown, indicating the value has been accepted.

If no activity occurs for a period of four seconds while the

value is displayed, the RATIO display will disappear and the

old ratio setpoint will take effect.

To exit the menu at any time without saving changes, simply

press the RESET/rE button.

Setting FFRT (Flame Failure Response

Time)

To access the FFRT setpoint, press and hold the FFRT 1/2/3

SEC OPTION button for 2 seconds until the current value is

displayed. Refer to Fig. 23 for the setup flowchart. The FFRT

can be set at 1, 2 or 3 seconds. While the value is displayed,

adjustments may be made via the INCREASE or DECREASE

arrow buttons. To store the new setting, press the STORE

button until "--" is shown, indicating the value has been

accepted.

The FFRT changes are not live; they take effect only if the

STORE button is pressed. FFRT values do not relate to the

RELAY ON SETPOINT and RATIO (%)/RELAY OFF values.

Therefore, during automatic setup, if the AUTO SET LED is

on, confirmation is not needed to change the FFRT setting.

If no activity occurs for a period of four seconds while the

value is displayed, the FFRT display will disappear and the old

setpoint will take effect.

To exit the menu at any time without saving changes, simply

press the RESET/rE button.

0/4-20mA Output Option

An analog output current is provided for operating a remote

meter or other instrumentation. The load resistance should

not exceed 360 Ohms for the Model 700 signal processors.

The resistance can be chosen to give the desired voltage

swing. For example, if 2V is desired for a 20 mA output, a 100

Ohm resistor would be used. Fig. 24 contains a flowchart for

the mA output setup.

The analog current output selections are 0 to 20 milliamps, or

from 4 to 20 milliamps. Selection of the applicable range is

made by pressing and holding the 0-20 MA/4-20 MA OPTION

button until the current value is shown. 02 denotes the 020mA selection while 42 denotes the 4-20mA selection (the

66-2069—01 14

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

default value). While the value is displayed, it may be changed

via the INCREASE or DECREASE arrow buttons. To store the

new setting, press the STORE button until "--" is shown,

indicating the value has been accepted.

Confirmation is not requested if the 0-20/4-20 setting is

changed when AUTOSET LED is on

The 0/4-20mA output option is live; the operative range

changes as soon as the displayed selection is changed.

However, the value must still be saved via the STORE button

in order to be saved in the signal processor's EEPROM.

To exit the menu at any time without saving changes, simply

press the RESET/rE button or wait four seconds.

The analog current output is scaled according to the RELAY

ON setting. It is scaled so that, if the counts coming in are at a

count rate equal to the RELAY ON setting, the current output

is approximately 13 MA when the range selected is 0-20 MA,

and about 14.6 MA when the range selected is 4-20 MA.

Note that the actual maximum level for the current output is

19.8 MA.

Automatic Setup of Setpoints

With this feature, the Model 700 signal processors set the

RELAY ON SET POINT, the RATIO % (Relay Off), and the UV/

IR GAIN automatically. Calculations for these settings are

carried out in the signal processor as the operator takes the

system through BURNER ON and BURNER OFF sequences.

Fig. 18, 19 and 20 flowchart the automatic setup sequence.

The FFRT (flame failure response time) and the 0/4-20mA

output option must be manually setup after the automatic

setup process is complete. Refer to the Manual Setup of

Setpoints section and Fig. 23 and 24. for details on setting

these 2 parameters.

Before starting the automatic setup sequence, adjust the

RELAY ON SET POINT to get the FLAME ON relay to

energize.

Press BNR-ON SEQ START/END key for two seconds. If the

FLAME ON relay is de-energized, the display will show “bo”

(burner off); press RESET to clear this. If the FLAME ON relay

is energized, the ON SEQ LED will start flashing slowly and

the numeric display will start counting down from 59 while the

processor takes data at one reading per second. The FLAME

ON relay will remain energized if the flame is present,

according to the current settings, until valid new values are

obtained. To end the data sampling, press the same button,

BNR-ON SEQ START/END, again, but ensure that an

adequate number of data samples has been taken. At least 30

seconds of BNR-ON data sampling is recommended; ten

seconds is a minimum. The software will not respond to a

second press of the button for 10 seconds. RESET may also

be pressed while the data sampling is occurring; the data

sampling process will be aborted and the old values will

remain in effect.

After BNR-ON data sampling is complete, the OFF SEQ LED

flashes. Turn off the burner and immediately press the BNROFF SEQ START/END key (a two-second press is not

required). The displayed timer then counts down from 29. This

process may be interrupted, but at least 15 seconds of BNROFF data sampling is recommended. The data sampling

process can be aborted by pressing RESET, in which case the

data for both BNR-ON and BNR-OFF will be discarded and the

previous values will remain in effect.

If the data is good, that is, the computed ratio is 71% or less

when BNR-OFF data sampling is complete, the display shows

the ratio in percentage for one second, followed by “- -” to indicate

a successful setup. The signal processor then turns on the

AUTO SET LED to verify that the values stored internally were

derived from the BNR-ON/BNR- OFF data sampling sequence.

If the data received is marginal, with the computed ratio ranging

from 72% to 80%, the display alternates be- tween “AC” and

the computed ratio, for example, “AC” and “75.” Press either the

ACCEPT RATIO or RESET keys. If ACCEPT RATIO is

pressed, the display responds with “- -”, the ratio is stored,

and the AUTO SET LED is turned on. If RESET is pressed, the

display returns to the counts, both of the AUTO SETUP LEDs

are turned off, and the old setpoints are used.

If the ratio computed as a result of BNR-ON and BNR- OFF

data sampling is higher than 80%, the display will show “UA”

(unacceptable), alternating with the unacceptable ratio. For

example, if the computed ratio is 93%, the display would

alternate between “UA” and “93.” RESET must be pressed to

clear this; the old values for RELAY ON and RATIO will remain

in effect.

The values can be worse than just unacceptable. If the flame

relay de-energizes while reading BNR-ON values, the display

will show “bo,” and data-taking will be aborted. Other faults,

such as a BNR-ON flame signal that is too low to use, or BNROFF readings that are too close to the BNR-ON readings, can

result in “rE” being displayed. RESET should then be pressed.

The signal processor also adjusts the viewing head gain during

the BNR-ON and BNR-OFF data sampling sequence.

Normally, after the sequence, the display should read about

20, because the gain has been adjusted to give this reading. If

it is less than about 18, you should find that the gain has been

set to 9; if it is more than about 22, you should find that the

gain has been set to 1.

Once the values have been stored through this sequence, you

can check the RELAY ON SET POINT, the RATIO, or the

GAIN by pressing the appropriate key for two seconds.

However, if you attempt to change these values by pressing

the INCREASE or DECREASE keys, the display will show

“CF” (confirm), and the AUTO SET LED will flash rapidly. To

confirm the desired change, press the RELAY ON SET-POINT

key, the RATIO key, or the SET GAIN key a second time. To

discontinue any changes, press the RESET key or simply wait

four seconds for a time out to occur.

The user confirms they wish to make changes, the values will

change when you use the INCREASE or DECREASE keys.

Meanwhile, the AUTO SET LED will be flashing. The AUTO

SET LED will de-energize only if the changed values are

stored; if the changed values were not stored, the AUTO SET

LED will light and the old values will remain in effect.

If values were obtained automatically, that is, if the AUTO SET

LED is on and the BNR-ON SEQ START/END key is pressed,

the display will also show “CF.” If the BNR-ON SEQ START/

END key is pressed again, the signal processor will begin the

BNR-ON data sampling sequence.

15 66-2069—01

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

Loading Factory Defaults

Fig. 17 shows the flowchart for restoring default values.

Pressing and holding the LOAD FACTORY DEFAULTS button

will result in the values shown in Table 3 being loaded and

stored in EEPROM. During the automatic setup sequence, if

the AUTO SET LED is on when the LOAD FACTORY

DEFAULTS key is pressed, “CF” will be displayed. Press the

LOAD FACTORY DEFAULTS key again to confirm the change,

or press RESET to abort the change. If the factory defaults

are loaded, the AUTO SET LED will be turned off.

Table 3. S70X/S80X Default Settings

Relay on setpoint 16

Ratio (%) relay off/relay on 50%

FFRT (Flame Fail Response Time) 1 sec

0-20mA/4-20mA OPTION 4-20mA

UV/IR Gain 5

Communication address 0

Panel Lock

A pattern of key presses will result in the panel being locked

so as to block any changes to the values stored in the signal

processor. With the panel locked, values may be examined,

but the signal processor will not respond to the STORE key.

The panel should be locked after the setpoints are set.

Contact the factory to obtain the procedure to lock or unlock

the panel.

Refer to Fig. 6 and Fig. 7 for a typical communication wiring

and addressing scheme as well as the required wiring of the

COMMOD communication converter.

The 700ACSP and 700DCSP signal processors have two

modular phone jacks for RS-422 communications. The jacks

are wired in parallel so that point-to-point cables can be

jumped from unit to unit to interconnect multiple Model 700

signal processors. The RS-422 interface IC is a MAX489. The

ICs can drive up to quantity 32, Model 700 signal processors

on the same bus.

For communication with external controls or computers, refer

to Table 4 for the Modbus registers map.

Communication Setting

700ACSP and 700DCSP can only communicate via Modbus

RTU protocol, with the following configuration:

• 9600 baud

• 8 data bits

•no parity

• 1 stop bit

NOTE: Default protocol must be changed in order to use

Modbus communication. It may be set for Modbus by

using key sequence below at the front panel of the

700 as follows:

1. Press and hold BNR-OFF SEQ START/END

button for 2 seconds.

2. Press up arrow to change setting from P0 to P1.

3. Press STORE.

Working with Older UV Viewing Heads

When the signal processor has been set up with an older UV

viewing head without communications, the settings may be

viewed and changed whether or not the viewing head is

connected. But, if the viewing head is changed from a new

intelligent type to an older UV type without communications,

the display panel will remain inoperative until pulses start

coming in from the old UV viewing head. Then the signal

processor will recognize the older UV viewing head, make the

appropriate changes, and begin responding to the keys

pressed on the front panel.

MODBUS COMMUNICATION

The 700ACSP and 700DCSP signal processors are capable

of communication with Flametools software running on a

Microsoft® Windows® PC, S7999D touch screen or other

device that supports Modbus RTU protocol. Both Flametools

and the S7999D include graphic user interfaces. Other

devices will require the user to generate an interface. The data

transmitted to and from the 700ACSP/700DCSP is over two

twisted pairs that are differentially driven and received

according to the RS-422 standard. Honeywell offers a RS485/

422 to USB converter to use in conjunction with the 700ACSP/

700DCSP signal processors. The Honeywell part number is

COMMOD.

The factory default Modbus address of the 700ACSP and

700DCSP is 0 and must be changed to a number between 1

and 32 to establish communication between the signal

processor and the host control. When more than one signal

processor is in the network, ensure that each signal processor

has a unique Modbus address within the range of 1 to 32.

Modbus RTU Function Supported

Four Modbus functions are supported:

• 01 Output coil read

• 03 Holding register read

• 06 Preset single holding register

• 16 Preset multiple holding register

NOTES:

— Before Model 700 signal processors are

connected to the RS-422 bus, their individual

Modbus addresses must be set to differing values

between 1 and 32.

— The RESET button on front of the 700ACSP or

700DCSP signal processors is used to set the

Modbus address.

— Press and hold the RESET button for two

seconds and the current address will appear. It

may be changed with the up or down arrow keys.

— Pressing the STORE button will store the new

address.

66-2069—01 16

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

Table 4. MODBUS registers map.

Register Name Description Minimum Maximum

40001 FLAMECOUNT Flame count of active viewing head (read only) 0 3425

40002 PROCSTATUS Processor status bitmask (read only)

0255

bit 1: flame on relay status (1=relay energized, 0=off)

bit 2: Processor Lockout status (0 =lockout, 1=not lockout)

bit 3: Panel access disabled (1=disabled, 0=enabled)

bit 4: 4 - 20 ma output (0=0 to 20, 1=4 to 20)

40003 FLAMEON Flame On setpoint (read/write) 3 (S70X) 29

40007 OUTPUTGAIN Gain of the 0/4-20mA output (read/write) 20 80

40010 IRGAIN IR sensor gain setting (read/write) 1 9

40012 UVTGAIN UV tube gain setting (read/write) 1 9

40017 TYPE Viewing head type bitmask (read only)

-bit 0: UV viewing head

bit 1: IR viewing head

40021 TIMEDELAY Time Delay (read only)

12

=1 for 700XXSP

40022 FFRT Flame failure response time setting in seconds (read/write) 1 3

40023 VERSION Firmware version (read only) - -

40024 MODEL Model number (read only) - -

40084 ERRORCODE Error code (read/write)

-NOTE: writing a non zero number to this register is not allowed

40085 BAUD Baud rate setting (bits/second). Only affects RS-485

96 192

communication, not IRDA. (read, write)

96=9600 (default), 192=19200.

The SP and the master device must have the same baud

settings.

40086 PARITY Parity setting. Only affects RS-485 communication, not IRDA.

01

(read/write)

0= none (default), 1=odd

40087 ADDRESS Modbus address used by RS-485 and IRDA (read/write).

0247

Each device must have a unique address.

40089 PROTOCOL Protocol (read/write)

01

0=Honeywell protocol, 1=Modbus protocol

17 66-2069—01

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

USB TO RS422/485 CONVERTER

M33831

SIDE VIEW

BOTTOM VIEW

NC

WIRE

SIDE

PRODUCT

SIDE

A TDA(–)

B TDB(+)

C RDA(–)

D RDB(+)

E GND

TDA(–)

TDB(+)

RDA(–)

RDB(+)

GND

NOTES:

SELECT THE APPROPRIATE DIP SWITCH SETTINGS FOR RS-422 COMMUNICATION PER THE VENDOR’S INSTRUCTION SHEET.

RJ11 CONNECTOR IS CUSTOMER SUPPLIED AND WIRED.

SOFTWARE DRIVERS MAY BE DOWNLOADED FROM B&B ELECTRONICS’ WEBSITE.

RJ11

MODULAR

CONNECTOR

1

2

3

4

5

6

COLOR TYPE A

WHI

BLK

RED

GRN

YEL

BLU

COLOR TYPE B

BLU

YEL

GRN

RED

BLK

WHI

CONVERTER

CONNECTOR

NC

RDA (-)

RDB (+)

TDA (-)

TDB (+)

GND

DESCRIPTION

NC

FROM PROCESSOR

FROM PROCESSOR

TO PROCESSOR

TO PROCESSOR

GROUND

CAUTION: THE ORDER OF THE COLORS IN THE CABLE CAN BE TYPE A OR TYPE B. CHECK

COLORS AT THE CONNECTOR.

1

BOILER

ADDRESS

BNR 1

11

BNR 2

12

BNR 3

13

BNR 4

14

BNR 5

15

BNR 6

16

BNR 1

ADDRESS

NOTES: A CONVERTER MAY BE NECESSARY FOR COMMUNICATION WITH THE MODBUS MASTER CONTROL.

31

BOILER 3

USE SHIELDED CABLE FOR COMMUNICATION WIRING.

DRAWING IS FOR GENERAL REFERENCE ONLY.

FOR RS422 COMMUNICATION WITH THE 700ACSP OR 700DCSP, AN RJ11 CONNECTOR WITH 5 WIRES

FROM EACH SIGNAL PROCESSOR WILL BE REQUIRED (RDA-, RDB+, TDA-, TDB+, GND), FOLLOWING

POLARITY FROM EACH SIGNAL PROCESSOR.

BNR 2

32

MODBUS

MASTER CONTROL

Fig. 6. Typical Communication Wiring and Recommended Addressing.

NOTE: Refer to Fig. 7 for converter to RJ11 wiring details.

BNR 3

33

BNR 4

34

M34457

66-2069—01 18

Fig. 7. COMMOD Communication Converter Wiring.

TROUBLESHOOTING

HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

Lockout or Faulty VH Indication

If the viewing head produces any pulses during the last one

third of the self-check time, the relay will immediately deenergize, the display will show “LO” (lockout), and the FAULT

LED will flash on and off rapidly. Exit lockout by pressing

RESET.

If a pulse or pulses come in during the last one third of the

self-check time while the automatic data sampling is taking

place, the automatic process will be aborted, the relay will be

de-energized if it was energized, the display will show “LO”

(lockout), and the FAULT LED will flash on and off rapidly.

Press RESET to exit this.

If a viewing head is disconnected, the display will show “L1.”

Reconnect the viewing head and press RESET.

If the signal processor displays "EE" upon power up, it is an

indication that the EEPROM stored data for the viewing head

does not match for the currently connected viewing head. For

further information on this condition, refer to the Parameter

Match Error Section below.

Parameter Match Error

If the signal processor displays "EE" upon power up, it is an

indication that the EEPROM stored data for the viewing head

does not match for the currently connected viewing head. This

error can occur when a different model viewing head is

connected to the signal processor than was previously

connected. As a result, the signal processor discards the

previous stored parameters and loads factory defaults, except

the RELAY ON SETPOINT is set to 31.

Setpoint values and other parameters plus error-checking

codes are stored in EEPROM (Electrically Erasable

Programmable Read Only Memory) in the signal processors.

This data is then error-checked when it is read at power up. If

the data does not match exactly what was previously stored,

the signal processor discards all data, displays “EE”, and

loads factory defaults. The RELAY ON SETPOINT is set to 31.

Since the flame count cannot go this high, the flame relay

cannot be energized. The signal processor can be reset by

changing the RELAY ON SETPOINT to a reasonable value or

by pressing LOAD FACTORY DEFAULTS.

Panel Lock with No VH Connected

The signal processor requires continuous communication with

the connected viewing head. If the viewing head is

disconnected, communication will be lost and the display is

made inoperative where no settings can be examined or