Honeywell S4965 Product Handbook

PRODUCT HANDBOOK

1 EN2R-9053 0408R11-NE

Subject to change without notice. All rights reserved.

S4965 SERIES

COMBINED VALVE AND BOILER CONTROL SYSTEMS

APPLICATION

The S4965 boiler controls have been developed for application

in gas fired domestic appliances.

The S4965 boiler controls are used in conjuction with the

VK41.. series modulating or non modulating gas controls. (see

Product Handbook EN2R-9025 and EN2R-9004) They provide

both an optimised safety sub-system for programmed safe

light-up and flame supervision of the main burner of the

appliance and a boiler comfort control sub system for

temperature, pump, and 3-way valve control

Bi-directional communication with a MMI enables

comprehensive diagnostics and operation.

For glossary of terms, abbrevations and symbols see

document EN2R-9039

Contents

General

Description ......................................................................... 2

Features ............................................................................ 3

Dimensional drawing S4965 boiler control ........................ 4

Technical

Specifications .................................................................... 5

Connection diagram ..........................................................7

Timing diagram ................................................................8

Description of LOCON ......................................................9

Description of SQUARE...................................................10

General considerations ................................................... 11

Electrical connections and wiring ....................................12

Adjustments and final checkout ......................................13

Various

EMC guidelines ............................................................... 14

Quality assurance statement ........................................... 15

Standards and approvals ................................................ 15

Ordering information .......................................................16

EN2R-9053 0408R11-NE 2

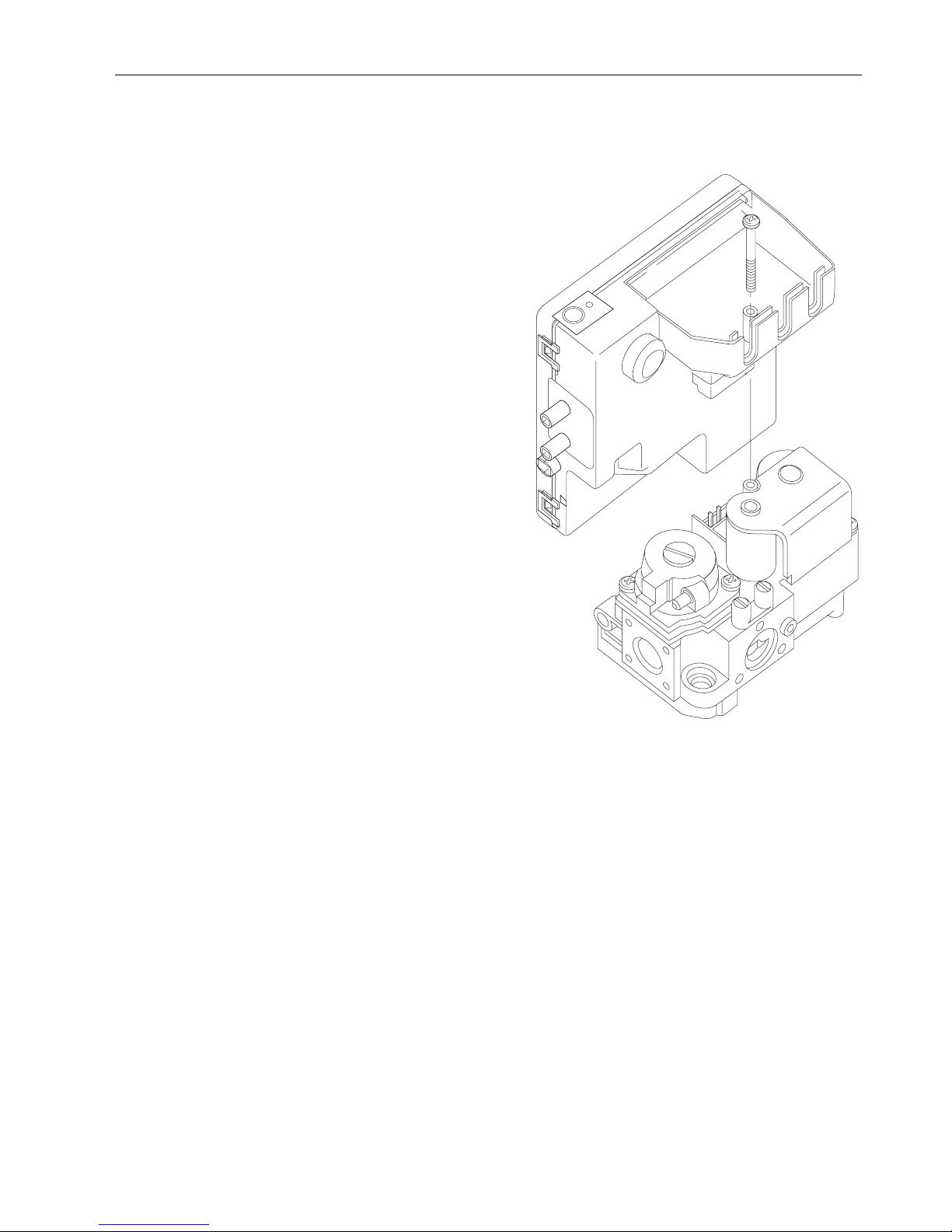

DESCRIPTION

The Combined Valve Boiler Control (CVBC) is the

combination of a VK41.. modulating or non-modulating gas

control with an electronic boiler control.

The boiler control consists of an automatic ignition control and

a comfort boiler control.

Most of the standard control functions of a gas fired boiler can

be performed within one single control box which can easily be

clicked on the gas control.

Possible applications are:

• Instantaneous water heaters.

• Floor standing boilers.

• Combi boilers.

• Low Nox boilers.

• Condensing boilers.

• See chapter Features for the standard features which can

be implemented in this control box.

ALARM

RESET

3 EN2R-9053 0408R11-NE

FEATURES

• Multi trial full sequence ignition control.

• Permanent operation in accordance with EN 298 (2003).

• Non volatile lock-out.

• Self learning ignition sequence; no minimum adjustment,

using LOCON.

• Direct Burner- or Intermittent Pilot operation.

• Integral ignition including emission filter.

• Combined ignition and flame sensing option.

• Phase insensitive flame detection.

• Lock-out at flame simulation.

• Restart after flame loss.

• AC or DC fan control (24 VDC fan needs external trafo).

• Dynamic airflow check.

• Lock-out on no air.

• Automatic fan assisted/atmospheric recognition.

• Integral gas pressure modulation circuitry.

• Pump control.

• 3-way valve control.

• Multi temperature CH and DHW control with DHW priority

setting.

•∆T control in CH mode

• Flow sensor input for DHW detection and control

• Sensor- or contact switch high limit at control.

• Communication to MMI enabling comprehensive

diagnostics and operation.

• Factory safety parameter settings.

• Installer and OEM comfort boiler control parameter

settings.

• On board transformer and wiring center.

• Integral and/or remote reset and alarm indicator.

• Electrical safety in accordance with EN 60730-1 (2000).

• Replacable fuse

• OpenTherm communication

EN2R-9053 0408R11-NE 4

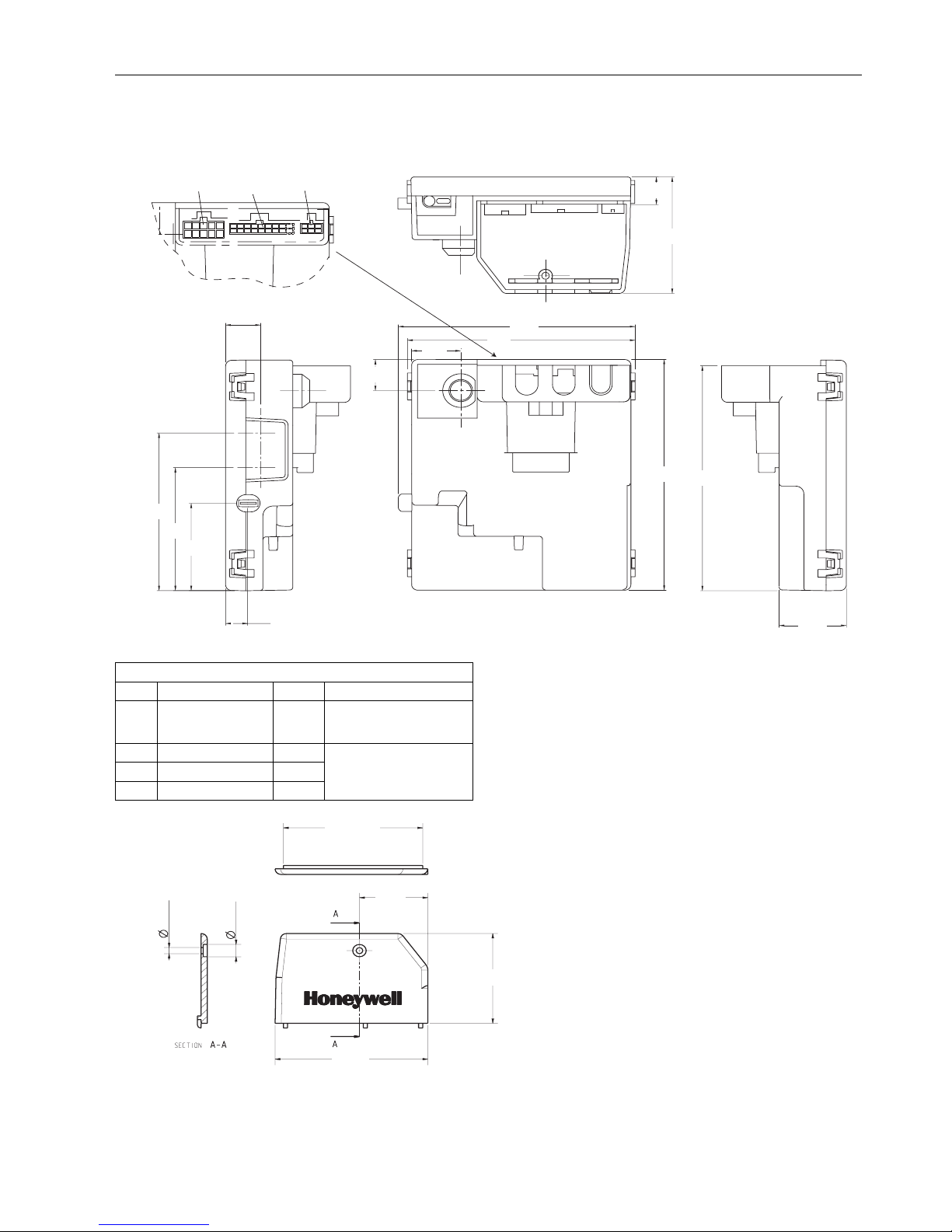

DIMENSIONAL DRAWING S4965 BOILER CONTROL

Molex Minifit (for X1) and Microfit (for X11 and X12) can be

used as alternatives

Dimension cover

110

115

120

117

82

64

46

17

12

61

14

33

24

16

1

6

3

1

1

8

9

16

18

15

10

X11X12X1

Material : ABS - V0

Tolerances ± 1 mm

unless noted

FOR CONNECTORS, USE FEMALE PARTS

Plastic part Pins Terminal

X1 TYCO 1-106527-0 10 TYCO 106528-2 (reel)

(for AWG 22-26, insulation

diameter 1,20 - 1,75 mm)

X11 TYCO 794617-6 6

TYCO 794607 (reel)

TYCO 794611

(for AWG 26-30)

X12 TYCO 1-794617-6 16

X12 TYCO 1-794617-8 18

6,6 ± 0,4

3,3 ± 0,3

68,1 ±0,3

33,4

74,65

48,2

Material : ABS - V0

Tolerances ± 1 mm

unless noted

5 EN2R-9053 0408R11-NE

SPECIFICATIONS

Models

Basically there is one PCB for a number of applications.

Depending on which components are mounted different

applications can be covered.

Supply voltage

230 Vac -15% +10%

50Hz ± 2%

Power consumption

5 VA

Humidity

90% RH max. at 40°C (non condensing)

Ambient temperature

-20 ... 60°C

Electrical rating

fusing: external: 2 A slow, sand filled

optional integral: 2A slow, sand filled

230V output 1 (ac fan or lpg valve):

230 Vac, 0.8 A max, cos ϕ ≤ 0.6

230V output 2 (pump or aux):

230 Vac, 0.8 A max, cos ϕ ≤ 0.6

230V output 3 (3 way or aux):

230 Vac, 0.8 A max, cos ϕ ≤ 0.6

230V output 4 (3 way or aux):

230 Vac, 0.8 A max, cos ϕ ≤ 0.6

Total output (1..4) : 2A

Room thermostat input:

230 Vac, 1 mA or by communication

Gas valve output: :

230Vrac, 50mA

Auxilary input:

12 Vdc, 100 kOhm

Air pressure switch input:

12 Vdc, 100 kOhm

DC fan control output:

5 V 10 mA

High limit switch input:

5 Vdc, 100 kOhm

Water pressure switch input:

12 Vdc, 100 kOhm

Flow sensor input and output:

12 ± 4Vdc, 10 mA max supply open collector input

Alarm output:

12 Vdc, 5 mA or by communication

OpenTherm output and communication:

In accordance with OpenTherm standard

Sensors inputs (total maximum 6):

Standard NTC T7335 10k-A material

(see survey S-T7335)

High limit dual sensor 10 kOhm NTC *

(Sensor type : T7336B 1001)

* this sensor needs special input

MicroCom Communication input and output:

input: logic “0” < 0.8 Vdc

logic “1” > 2 , < 24 Vdc (10 kOhm)

output: open collector 24 V and 10 mA max

DC output: depending on OS number:

9Vrac, 5mA max

or 24Vdc, 50mA and 7V, 250mA

Electrical PCB connectors

High voltage spark: 2.8 x 0.5 mm faston

or 4 mm round.

Flame sensing: 4.8 x 0.8 mm faston

Mains connector: 10 pole TYCO, AMP-duac

Low voltage connectors: 16 or 18 and 6 pole TYCO,

MATE-N-LOCK

Flame sensing

Factory parameter setting:

minimum flame current settable between 0.5 and 5 µA

Response time ON: < 0.2 s

Response time OFF: < 1 s

Ignition

Spark voltage: 15 or 20 kV @ 30pF

Spark frequency: 15 Hz

Spark pulse energy: 4 or 15 µAs

Timing

Pre purge time: 0 ... 51 s

Waiting time (T

w

): 0 ... 51 s

Pre ignition time: 0 ... 51 s

Safety time (T

s

): 0 ... 51 s

Number of retrials: 0 ... 255

Flame failure response time: 1 s

Stabilisation time: 0 ... 51 s

Post ignition/stabilisation time: 0 ... 51 s

Post purge time: 0 ... 51 s

Pump over run time: 0 ... 600 s

Anti cycling time: 0 ... 255 s

Timing tolerance ± 5%

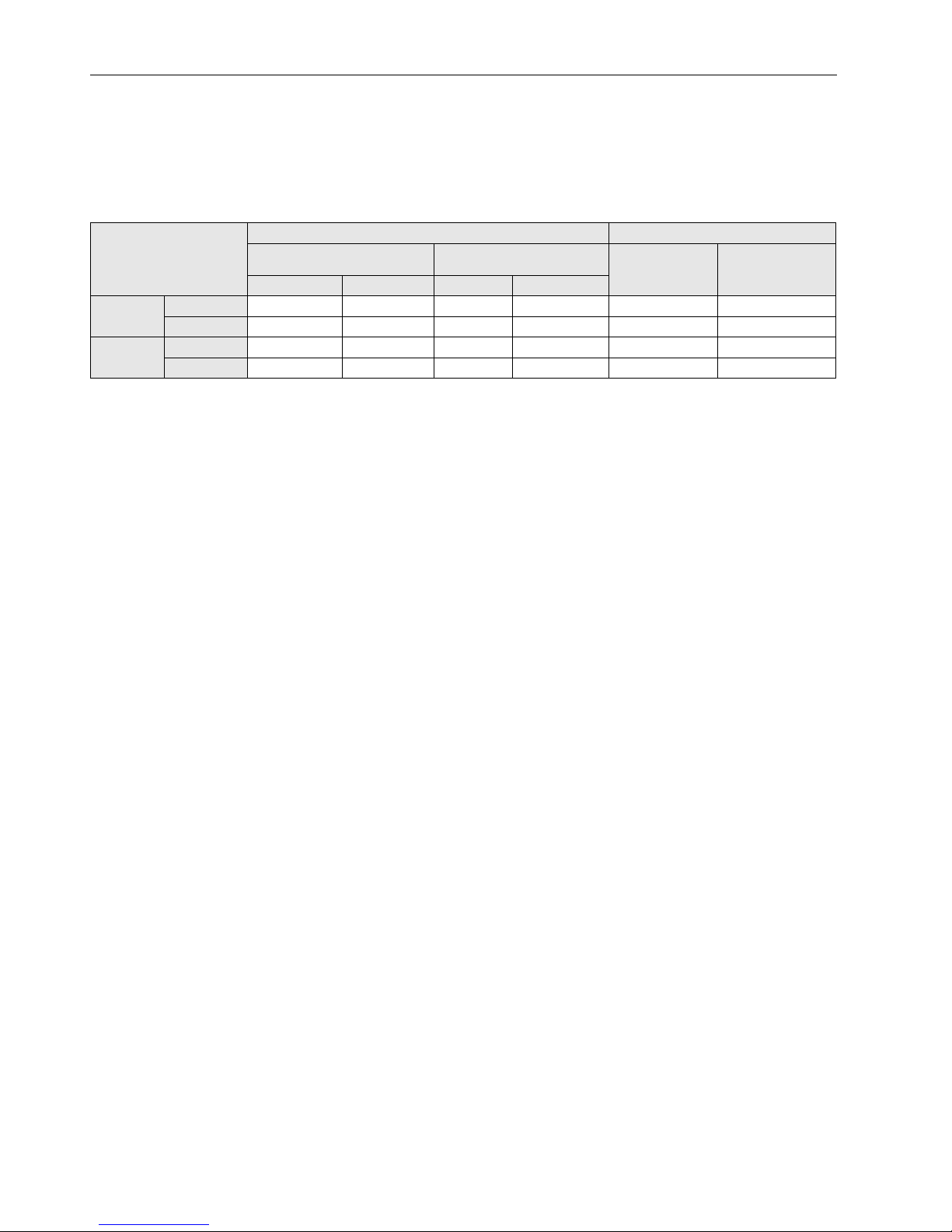

Application

Atmospheric combustion Premix combustion

Normal Combustion feedback

(LoCon)

Normal

(Pneumatic

gas/air)

SQUARE

(Electronic gas/air

or Gas addaptive)

Open flue Fan assistant Open flue Fan assistant

On /Off

Electronics S4965A S4965C ------------- ------------- S4965V -------------

Gasvalve VK4105A2/C2 VK4105A2/C2 ------------- ------------- VK4115V2 -------------

Modulation

Electronics S4965AM S4965CM S4965AL S4965CL S4965V S4965S

Gasvalve VK4105G1 VK4105G1 VK4105G2 VK4105G2 VK4115V2 VK4105G3

Loading...

Loading...