Page 1

Modular Pneumatic Controllers

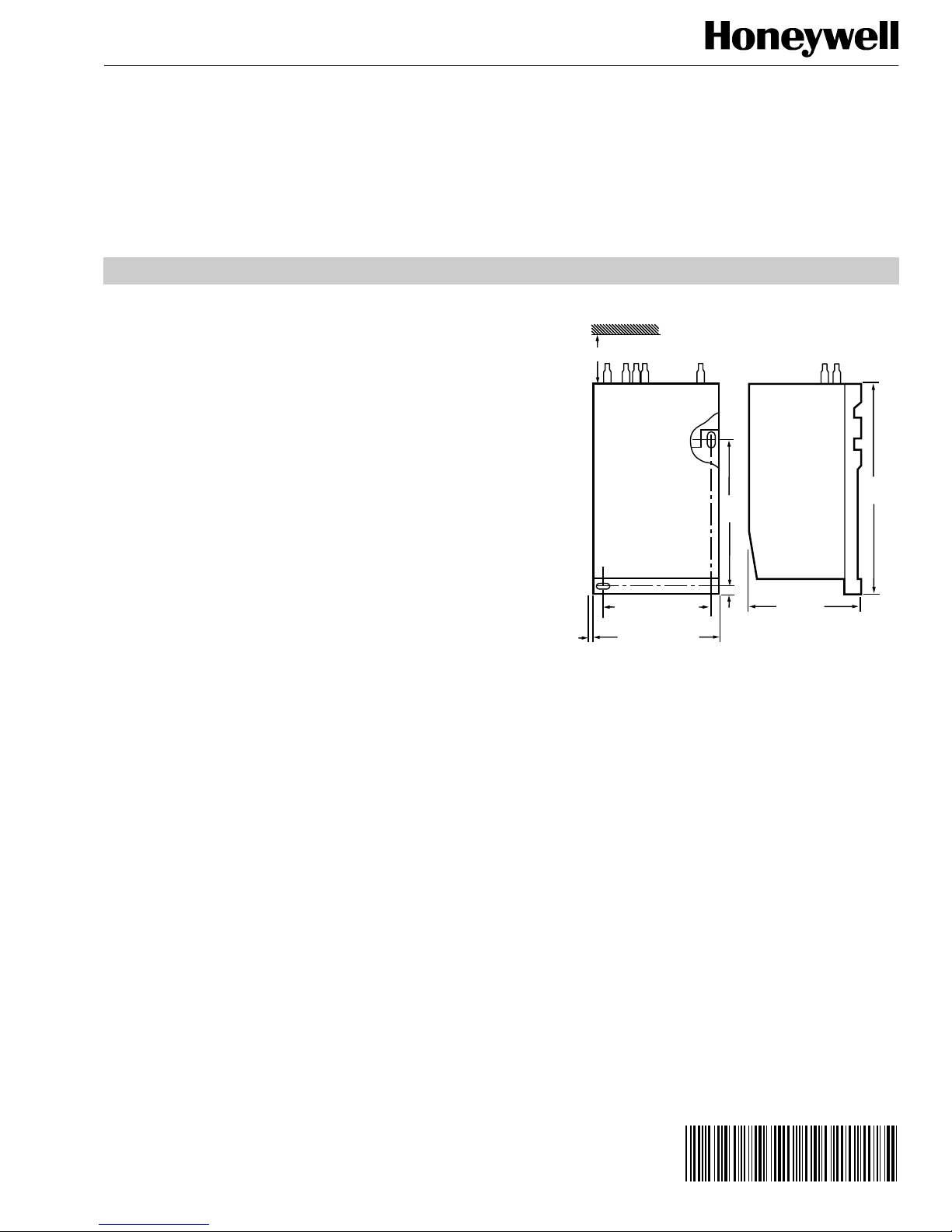

3 (75) MINIMUM CLEARANCE

4

(102)

3-3/8 (86)

9/32

(7)

RP920A: 1-1/2 (36)

RP920B-D: 3-1/4 (83)

5-7/8

(148)

1/8 (3)

MINIMUM

SPACING

BETWEEN

MODULES

RP920A: 1-7/8 (48)

RP920B-D: 3-13/16 (96)

M17581

INSTALLATION

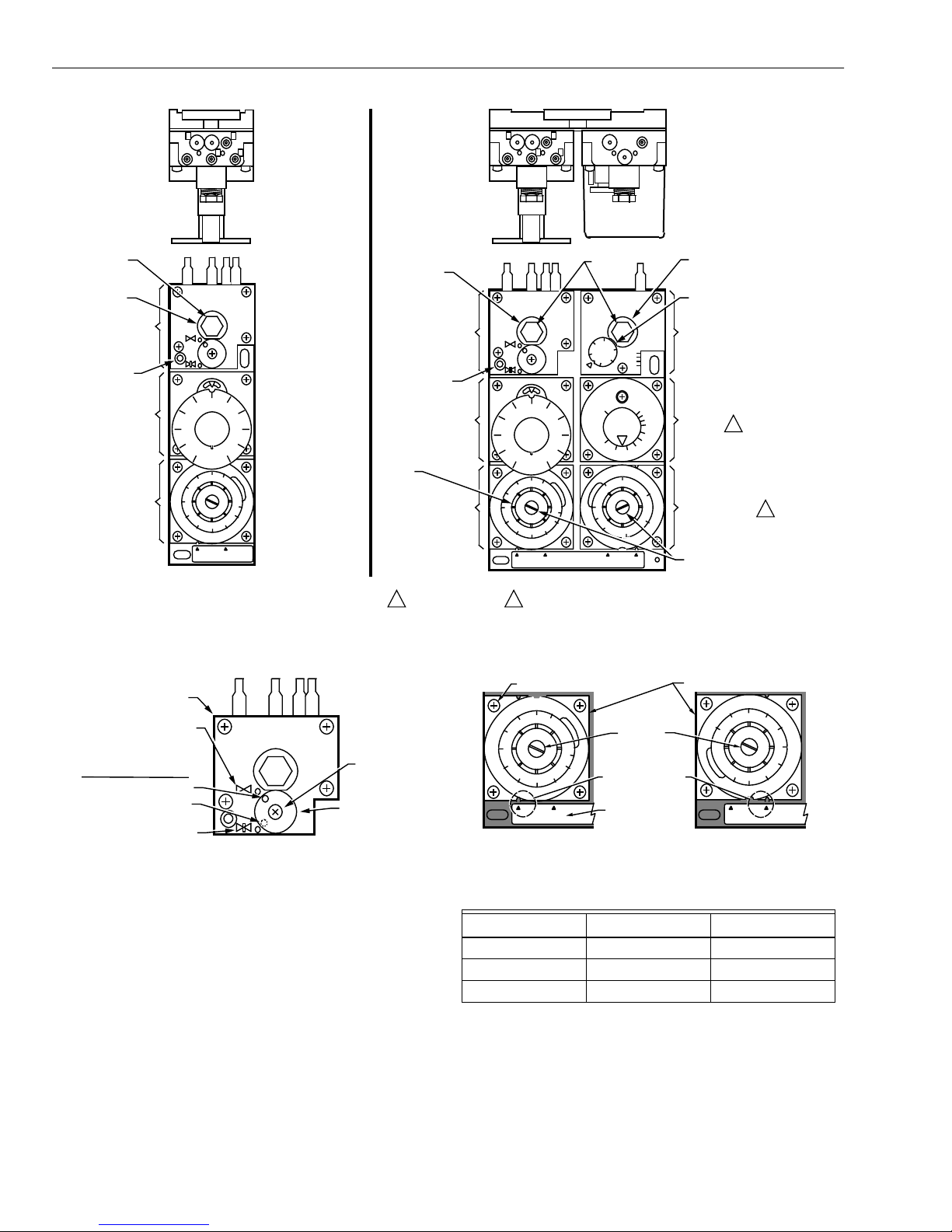

Adjustments Before Mounting

1.

If a connection to port 4, 6, 7, or 8 (Fig. 2) is required,

remove the self-tapping screw from port 8 and use the

screw to tap the appropriate port.

2.

Install 14003755-001 Barb Fit ting and O-ring fing er-tight

in the appropriate port.

3.

Reinstall the screw in port 8 if not used.

4.

If a remote restriction is used for the primary sensor,

block the internal air supply (adjustable after gage

installation, but easier to adjust before installation):

a. Loosen the screw one turn (Fig. 3) and rotate the

switchplate (light grey) 90 degrees co unterclockwise

to the sensor supply blocked position.

b. Retighten the screw and check for leaks. If a leak is

found, reposition the switchplate.

RP920A,B,C,D

INSTALLATION INSTRUCTIONS

Device Mounting

1.

2.

Connections

1.

2.

NOTES:

— The switchplate screw mu st be tightene d securely

to prevent a false inoperative senso r condi tio n.

— The compensation sensor on port 5 requires an

external restricted main air supply.

Mark and drill two No. 8 fastener mounting holes using

the controller or Fig. 1 dimensions as a template.

Mount the controller with two No. 8 fasteners (not

supplied).

Push the tubing on the port barb fittings according to

the job drawings. See Fig. 2 for port locations.

Install the gage or plug:

a. If no gage is used, tighten gage plugs finger-tight.

If a gage is used, remove the plug and, by hand,

screw the gage into the gage port three turns.

b. If the gage is not oriented for correct viewing, rotate

the gage counterclockwise unti l corre ct.

NOTE: A soft-rubber, factory-installed seal allows

plug or gage rotation (for alignment) without

leakage.

Fig. 1. RP920 Dimensions in in. (mm).

After Mounting Adjustments and Changes

Controller Action Change

1.

Loosen the four Proportional Module screws (Fig. 4).

2.

Remove the module.

3.

Rotate the module and its gasket 180 degrees, and

reinstall. Ensure that the notch on the module lines up

with the proper indication on the controller label (base).

4.

Retighten the four screws.

5.

Recalibrate if required.

Negative (Winter) to Positive (Summer)

Compensation Change (RP920 B and D only)

1.

Loosen the four compensation module screws (Fig. 5).

2.

Remove the module.

3.

Rotate the module and its gasket 180 degrees, and

reinstall. Ensure that the notch on the module lines up

with the proper indication on the controller label (base).

4.

Retighten the four screws.

5.

Recalibrate, if required.

® U.S. Registered Trademark

Copyright © 2000 Honeywell • All Rights Reserved

95- 7392EF

Page 2

RP920A,B,C,D MODULAR PNEUMATIC CONTROLLERS

GAGE PLUG

PRIMARY SENSOR

GAGE PORT

Connector

Block Module

BLP TEST TAP

Setpoint

Module

Proportional

Module

RP920A

4 8 9

2 3 1

60

40

20

W

1

0

%

5

10

20

40

30

DIR.

REV.

RP920A

1 – MAIN

2 – BRANCH

3 – PRIMARY

SENSOR

132

4 – VENT

8 – CLOSED/REMOTE

SETPOINT

9 – CPA

80

100

Xp (%)

45

PRIMARY SENSOR

GAGE PORT

Connector

Block Module

BLP TEST TAP

Setpoint

Module

PROPORTIONAL

BAND ADJUSTMENT

KNOB

Proportional

Module

RP920B,C,D

4 8 9

32

2 3 1

60

40

20

W

1

0

%

5

10

20

40

30

DIR. REV.

100

Xp (%)

45

1

80

RP920D

7

GAGE

PLUGS

7 6 5

100

80

60

20

40

TR

0.5

1

300

Ac (%)

5

50

1 – MAIN

2 – BRANCH

5

6

Wc

%

0

B

+

C

+

B

C

Min

20

15

10

4

3

1.5

2

250

200

150

100

NEG.

POS.

3 – PRIMARY

SENSOR

4 – VENT

5 – COMPENSATION

SENSOR

6 – VENT

7 – VENT

8 – CLOSED/REMOTE

SETPOINT

9 – CPA

COMPENSATION SENSOR

OR BRANCH GAGE PORT

COMPENSATION STARTPOINT

ADJUSTMENT KNOB

Switch

Block

Module

Integral

7

Module

5

Compensation

Module

MODULE KNOB SCREWS

(DO NOT LOOSEN)

1

2

RP920C,D ONLY.

1

Fig. 2. Module and port Locations.

Connector

Block Module

SENSOR

SUPPLY OPEN

SWITCHPLATE

POSITION INDICATOR

2 3 1

SCREW

OPEN POSITION

BLOCKED POSITION

SENSOR SUPPLY BLOCKED

(EXTERNAL RESTRICTOR)

SWITCHPLATE

C5102

Fig. 3. Primary sensor air supply.

Gage Function and Integral Action Cut-off

Adjustment (RP920C and D)

The position of the gasket located under the switch block

module (Fig. 2) determines the function of the field-installed

Switch Block Module gage and enables/disables the integral

action cut-off function. See Table 1 for factory and field

settings.

RP920B,D ONLY.

2

CAPTIVE SCREW (4)

5

10

Xp (%)

20

45

40

30

DIR. REV. DIR. REV.

DO NOT

ADJUST

SCREW

NOTE LOCATION

OF NOTCH

CONTROLLER

LABEL

DIRECT ACTING

PROPORTIONAL MODULE

40

45

Xp (%)

5

REVERSE ACTING

Fig. 4. Changing controller action.

Table 1. Switch Block Gasket Position.

Model Field Setting

a

Options

RP920B B C

RP920C B B+

RP920D B C, C+, B+

a

Shipped from the factory in this position.

B = Branch line gage.

C = Compensation sensor gage.

+ = Integral action cut-off enabled.

M17584

30

20

10

C5103

95-7392EF 2

Page 3

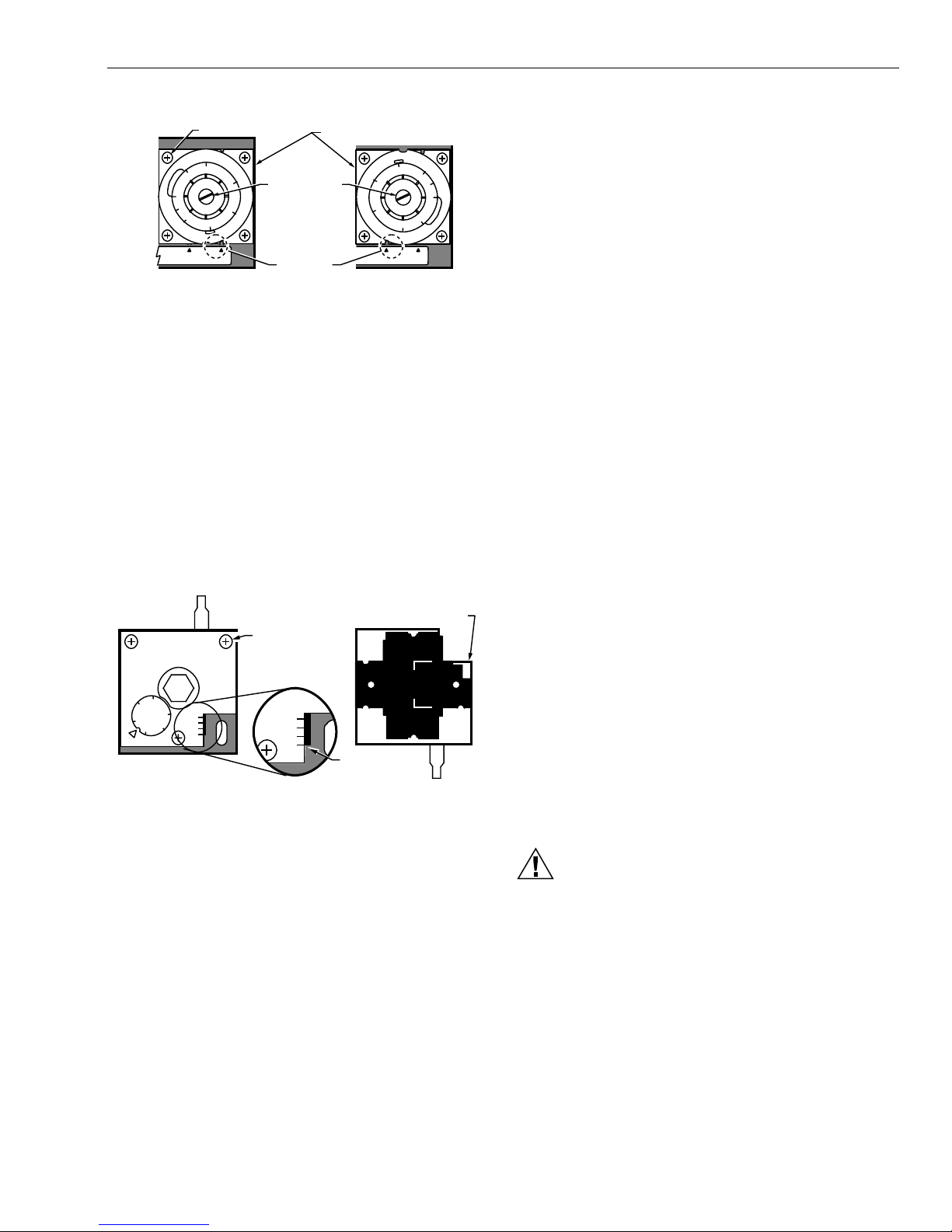

CAPTIVE SCREW (4)

CAUTION

250

300

Ac (%)

5

50

100

POS.

NEG.

NEGATIVE COMP. (FACTORY SET)

200

150

DO NOT

ADJUST SCREW

COMPENSATION MODULE

NOTE

LOCATION

OF NOTCH

100

150

200

250

POS.NEG.

POSITIVE COMP.

50

5

Ac (%)

300

C5104

Fig. 5. Changing from negative to positive compensation.

1.

Check the gasket tab position (Fig. 6, front view).

2.

Loosen the three switch block module screws and

remove the module.

3.

Remove the gasket and note the letters (B, B+, C, C+)

embossed on the module back.

4.

Rotate and/or flip the gasket until the gasket position

matches the functions desired (Fig. 6, back view).

RP920A,B,C,D MODULAR PNEUMATIC CONTROLLERS

Adjustments:

1.

If using a scaleplate o ve r lay, insert the overlay betw ee n

the setpoint knob and the transparent overlay retainer.

Note positions of the key and non-coded scaleplate

overlay notch (Fig. 7).

2.

Adjust the setpoint (W

using the setpoint knob.

3.

If the control point deviates excessively from the

setpoint (W

consideration.

), calibrate, taking the throttling range into

1

), according to the job drawings,

1

REMOTE SETPOINT

Setpoint (W

primary sensor span from a remote 3 to 15 ps i (21 to 103 k Pa)

) is controlled from 0 to 100 percent of the

1

bleed-type signal.

Adjustments:

1.

Adjust the setpoint knob to 100 percent (Fig. 7) or to

the maximum remote setpoint limit to be applied.

2.

Install the 14003755-001 Barb Fitting and O-ring to

port 8 and connect to a bleed-type remote setpoint

device (e.g., SP970) and a remote setpoint gage.

NOTE: With the correct gasket position, only the

desired let ter shows.

5.

Install the gasket on the switch block module back.

6.

Reinstall the module, and tighten the three screws.

7.

If used, connect the integral action cut-off switching

components to ports 6 and 7.

GASKET SHOWN IN C POSTION. B, B+, AND C+ LEGENDS

CANNOT BE SEEN WITH GASKET IN THE C POSTION,

BUT ARE ILLUSTRATED HERE TO DISLPLAY LOCATION.

CAPTIVE SCREW (3)

Switch Block

+

B

+

C

B

C

B

B

+

GASKET TAB

IN C POSITION

C

C

+

BACK

C5105

60

FRONT

7 6 5

W

100

80

%

0

40

20

c

+

B

+

C

B

C

Fig. 6. Integral action cut-off and gage

function gasket position.

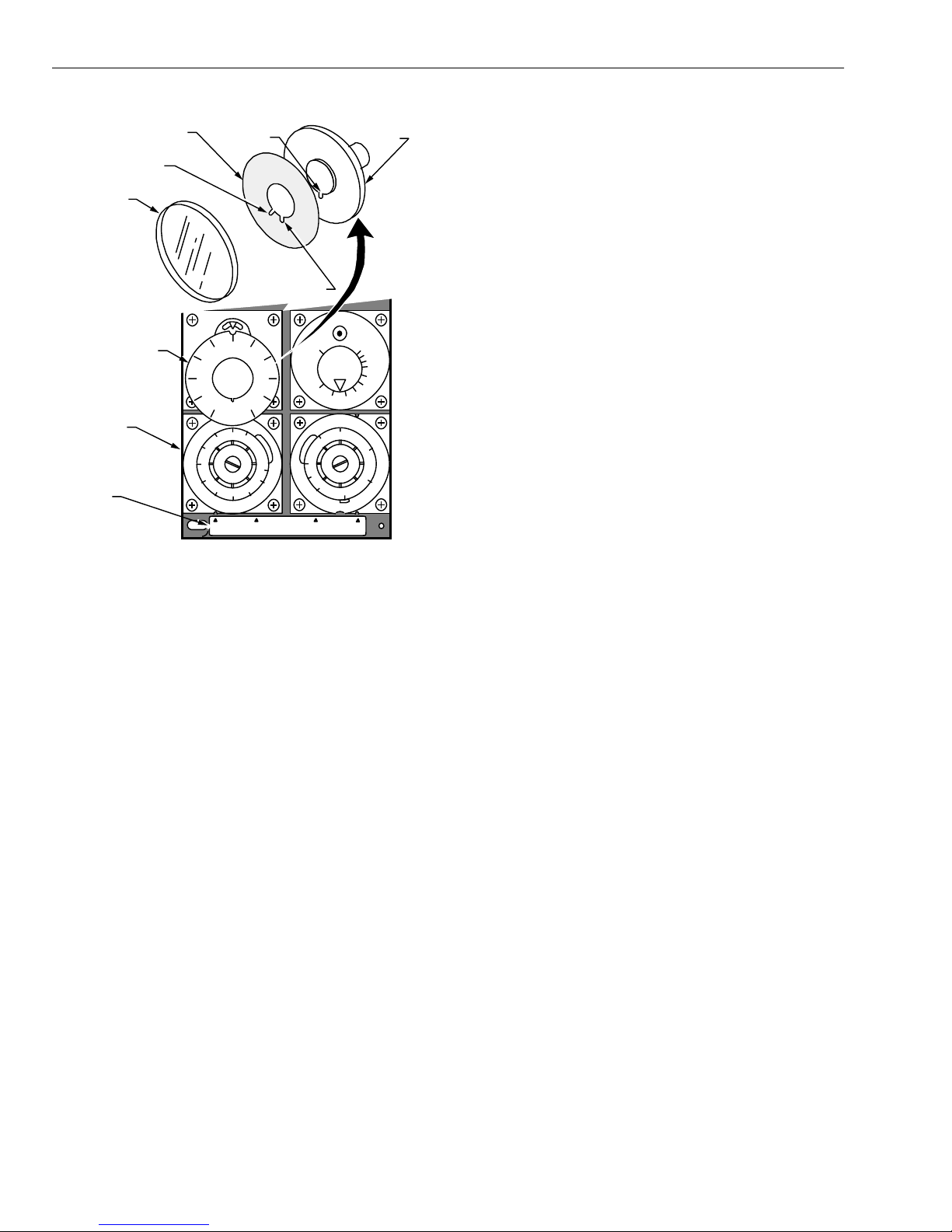

Setpoint (W1) Adjustment

The setpoint knob is embossed with a 0 to 100 percent scale

which correlates with the values in Table 3 (see Appendix).

Scaleplate overlays are included to directly match various

sensor ranges.

Three methods of controlling setpoint (W

LOCAL SETPOINT

Adjust setpoint (W

) directly on the controller.

1

) are available:

1

CONTROL POINT ADJUSTMENT (CPA)—AVAILABLE ON SPECIFIC

MODELS

Local (baseline) setpoint (W

and can be varied ±15 percent of the primary sensor span

) is adjusted on the controller

1

from a remote 3 to 15 psi (21 to 103 kPa) signal.

Adjustments:

1.

Pipe CPA to port 9.

2.

If used, select the proper scaleplate overlay.

3.

Note the position of key on the setpoint knob and the

non-coded scaleplate overlay notch (Fig. 7) for

controllers with U.S. A. labels. Controlle rs (RP920B,C,D)

with German labels must use “R” coded scaleplate

overlay notch when using a CPA device.

4.

Insert the scaleplate overlay between the setpoint knob

and the transparent overlay retainer.

5.

Adjust the setpoint (W

using the setpoint knob.

) according to the job drawings

1

Proportional Band (Xp) Adjustment

Adjust the proportional band (Xp), according to the job

drawings, using the proportional module proportional band

adjustment knob (see Fig. 2).

Control Loss Hazard.

Loosening knob screws can induce controller

leaks.

Use CCT819 and Authority S etting Ad justment Tool or

a narrow, stiff-blade putty knife to rotate adjustment

knobs (Xp and Ac).

Authority (Ac) Adjustment (RP920B and D only)

Adjust the authority (Ac), according to the job drawings, with the

compensation module authority adjustment knob (see Fig. 2).

3 95-7392EF

Page 4

RP920A,B,C,D MODULAR PNEUMATIC CONTROLLERS

SCALEPLATE OVERLAY

"R" CODED SCALEPLATE

OVERLAY NOTCH

OVERLAY

RETAINER

SETPOINT KNOB

Setpoint

Module

LABEL

C5106

SETPOINT

KNOB KEY

R

NON-CODED

SCALEPLATE

OVERLAY NOTCH

60

40

20

20

80

W

1

100

0

%

5

10

Xp (%)

45

40

30

DIR. REV. POS. NEG.

HONEYWELL

RP920

SETPOINT

KNOB

TR

0.5

1

Ac (%)

5

Min

20

15

10

7

5

4

3

1.5

2

250

300

200

150

50

100

Fig. 7. Setpoint (W1) Adjustment.

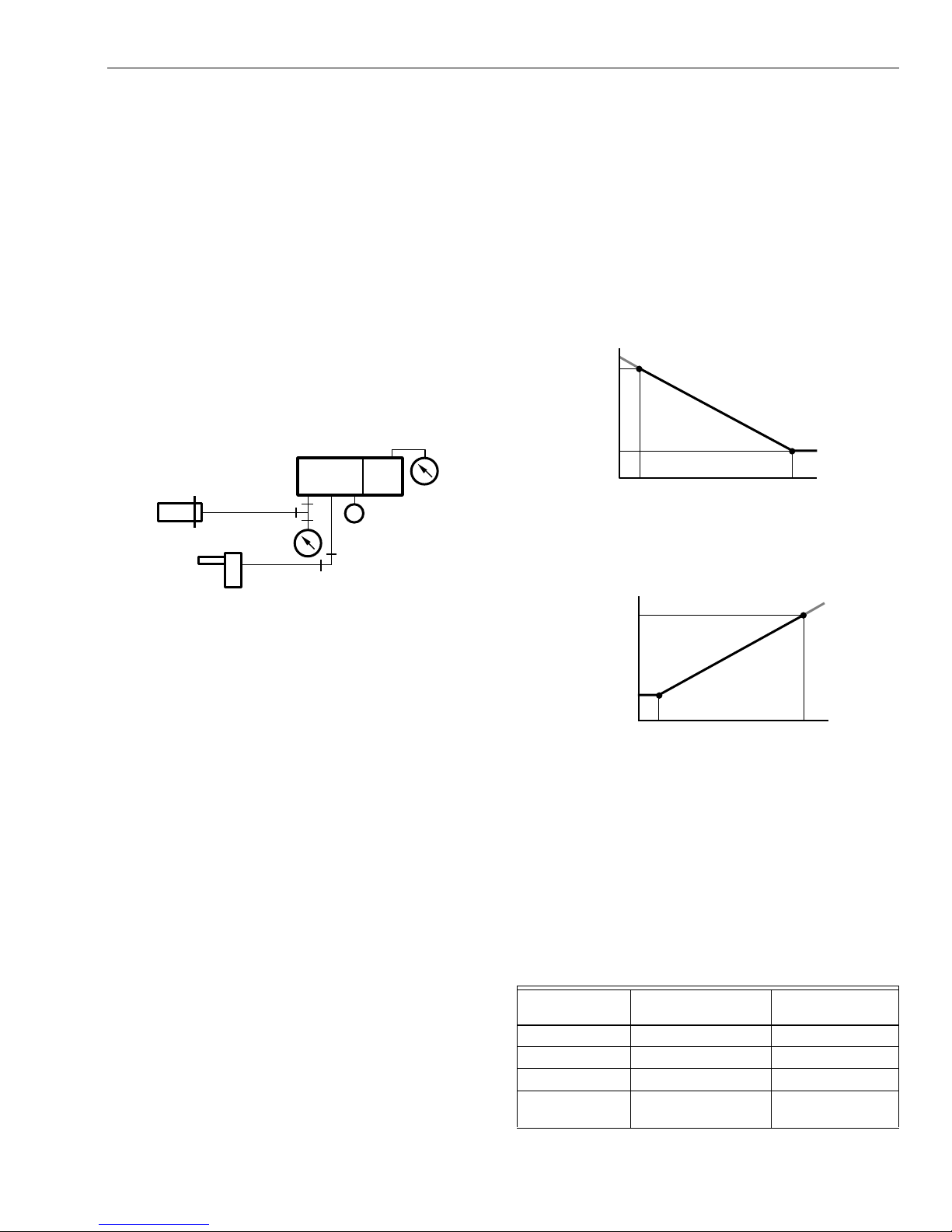

Compensation Startpoint (Wc) Adjustment

(RP920B and D only)

Adjust the compensation startpoint (Wc), according to the job

drawings (reset schedule), using the compensation startpoint

adjustment knob (see Fig. 2). For direct-acting sensors, the

knob setting is equal to the compensation value

corresponding to th e lowest value given for the pr imary senso r

(from the reset schedule). See Fig. 9 and 10. If the value

given is not a percentage, convert it to a percentage of the

compensation sensor range using Table 3 (see Appendix):

1.

Find the correct sensor range column.

2.

Find the desired temperature in the column.

3.

Read the equivalent pressure in the second column.

4.

Read the equivalent pe rcentage in the first co lumn.

Reset Time (Tr) Adjustment (RP920C and D only)

Adjust the reset time (Tr), according to the job drawing s, using

the reset time adjustment knob (see Fig. 2):

1.

Decrease setting until the system becomes unstable.

2.

Increase the setting slightly until the system becomes

stable.

Replacing Cover

1.

If a cover is used, snap the cover straight on the front.

2.

The cover can be secured further by tightening the selftapping screw in the cover lower right corner.

CALIBRATION

Sensors

Sensors are calibrated to the sy st em a nd req uire n o separate

calibration.

Systems

All RP920 Controllers a re f actory calibrat ed. It i s int end ed tha t

the controller be adjusted to the field-calculated values listed

on the job drawing. This controller startup approach will be

adequate for most systems. If it is determined that closer

calibration is required, use the following procedures:

NOTES:

— The controller allows all adjustments to be made

independently. For example, changing the

proportional band (X

calibration of the: setpoint (W

startpoi nt (W

— If a CPA device is used, apply 9 psi (62 kPa) to

), or authority (Ac) adjustment.

c

port 9.

— If a remote setpoint is used, block port 8.

RP920A System

1.

Install either:

a. a temporary receiver gage (matching the primary

sensor) or a 0 to 30 psi (0 to 207 kPa) gage in the

primary sensor gage port if one is not permanently

installed, or

b. a “tee” gage into the sensor line (port 3).

2.

Apply mainline pressure (MLP) to the system.

3.

Install a 0 to 3 0 psi (0 to 207 kPa) gag e in the branchli ne

pressure (BLP) test tap (moisten the needle before

inserting).

4.

If the sensor reading is greater than ±10 percent of the

expected setpoint, remove the se nsor tubing from por t 3

and apply a pressure equivalent (expected setpoint)

using a CCT816B Calibration Unit.

NOTE: For the most accurate calibration, the actual

measured variable at the sensor must be

±10 percent of the expec ted se tpo int.

5.

With the sensor at or near the desired control point,

adjust the setpoint knob until the BLP equals the

controlled device throttling range midpoint, e.g., 8 psi

(55 kPa) for a 3 to 13 psi (21 to 90 kPa) range device.

6.

If the setpoint (W

match, remove the setpoint knob and replace it so the

) and primary sensor gage do not

1

setpoint matches the primary sensor gage reading.

7.

Ensure W

8.

Calibration is complete.

is at the desired setpoint.

1

RP920B Systems

1.

Install in port 5 either a receiver gage that matches the

compensation sensor, or a 0 to 30 psi (0 to 207 kPa)

gage (see Fig. 8).

) setting does not affect the

p

), compensation

1

95-7392EF 4

NOTE: If the controller is setup for a compensation

gage in the right gage p ort, plug port 5 and use

the existing gage.

Page 5

RP920A,B,C,D MODULAR PNEUMATIC CONTROLLERS

PRIMARY SENSOR

FULL

COMP

SETPOINT

(W1 )

COMPENSATION

STARTPOINT (Wc )

COMPENSATION SENSOR

C5111

2.

Install a 0 to 30 psi (0 to 207 kPa) gage in BLP test tap

or in BLP gage port if one is not permanently installed.

3.

Apply MLP to the system.

4.

Adjust the authority knob to minimum.

5.

Adjust the compensation startpoint knob until the

receiver gage (port 5) reads the pressure equivalent of

the compensation startpoint (W

6.

If the compensation startpoint (W

startpoint do not match, rem ov e the k no b and re pla ce it

) (Fig. 9 or 10).

c

) and desired

c

so they do match.

7.

The compensation startpoint (W

) is now calibrated.

c

NOTE: The response of the receiver gage may be

slow (up to one minute). The controller is not

defective under these conditions.

8.

Set up the CCT816B Calibration Unit (Fig. 11) to

connect to port 3 (primary sensor).

NOTE: Sensors are not connected.

THE GAGE RANGE MUST

MATCH THE RANGE OF THE

SENSOR FEEDING PORT 5

PRIMARY

SENSOR

4 8 9 7 5

2 3 1 6

M

C5109

17.

Remove the CCT816B Calibration Unit and pipe

sensors.

RP920C and D Systems

1.

Remove the integral module screw (Fig. 13) and install

the 14003755-001 Barb Fitting and O-ring in its place.

2.

Apply 8 psi (55 kPa) to the integral module.

3.

Calibrate the RP920:

a. RP920C: follow the procedure for the RP920A.

b. RP920D: follow the procedure for the RP920B

except that the calibration value of the BLP for

4.

Fig. 9. Negative compensation calibration reset sc hedule.

Steps 10 and 15 should both be 8 psi (55 kPa).

When calibration is complete, remove the barb fitting

from the integral module and replace the screw.

FULL

COMP

PRIMARY SENSOR

SETPOINT

(W 1)

COMPENSATION

STARTPOINT (Wc )

C5110

COMPENSATION SENSOR

Fig. 8. Piping for RP920B compensation

startpoint (W

9.

Apply a pressu re equ ivale nt of the p rimary sen sor valu e

c

corresponding to the compensation start (

the reset schedule (Fig. 9 or 10).

10.

Adjust the setpoint knob until the BLP equals the

expected pressur e of the cont rolled device at

conditions.

11.

If needed, remove the setpoint knob and replace it

so the setpoint matches the primary sensor value at

comp start

12.

The setpoint (W

13.

Set up the CCT816B Calibration Unit (Fig. 12) to

.

) is now calibrated.

1

connect to port 3 (primary sensor) and port 5

(compensation sensor).

14.

Apply sensor input pressures equivalent to the full

compensation on the building schedule.

15.

Adjust the authority (A

expected pressure of the controlled device at full

) knob until the BLP equals the

c

compensation conditions.

16.

Calibration is complete.

IMPORTANT

Changing compensation startpoi nt (W

(W1) affects only the one corresponding value of the

reset schedule, while changing authority (A

only the slope of the reset schedule.

NOTE: See the Compensation Startpoint (W

Adjustment section for more information.

) setting.

comp start

comp start

) or setpoint

c

) affects

c

)

c

) on

Fig. 10. Positive co m pen sa ti on c al ibr a ti on r e se t sc he du le .

RP920B Calibration Example

Assume the following conditions:

— A 10°F (5.6K) throttling range.

— Using a 2.5 to 6.5 psi (17 to 45 kPa) operator with a

normally open (N.O.) valve where conditions are: 6.5 psi

(45 kPa) with no load and 2.5 psi (17 kPa) with full load.

— See Fig. 14 for the schedule graph.

— See Table 2 for the reset schedule.

Table 2. Reset Schedule.

Compensation

Range

Start 120°F (49°C) (40%) 60°F (16°C) (50%)

Full 160°F (71°C) (60%) 0°F (-18°C) (20%)

Operating Span 40°F (22K) 60°F (33K)

Sensor Range 40 to 240°F

5 95-7392EF

Primary Sensor

(Discharge)

(4 to 11 6°C)

Compensation

Sensor (OA)

-40 to 160°F

(-40 to 71°C)

Page 6

RP920A,B,C,D MODULAR PNEUMATIC CONTROLLERS

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

CCT816B

CALIBRATION UNIT

3

NO

CONNECTION

PRIMARY

SENSOR

C5112

4 8 9 7 5

2 3 1 6

M

NO

CONNECTION

PRIMARY SENSOR

RESTRICTION

SWITCH

BLOCKED

M

(BLOCKED RESTRICTION

ALTERNATE OK)

Fig. 11. RP920B setpoint (W1) CCT816B

Calibration Unit piping.

Initial Settings:

(W

Setpoint

)

= 120°F (49°C) = 40% = 7.8 psi (53.8 kPa).

1

For Calibration Step 5:

Compensation sensor at start = Compensation startpoint

W

= 60°F (15°C) = 50% = 9 psi (62 kPa)

c

For Calibration Step 9:

Primary sensor at start = 120° F (49°C) or 7.8 psi (53 .8 kPa)

For Calibration Step 10:

Desired BLP = 6.5 psi (45 kPa)

For Calibration Step 15:

Primary sensor at full compensation =

160°F (71°C) = 10.2 psi (70 kPa)

Compensation sensor at full compensation =

0°F (-18°C) = 5.4 psi (37.2 kPa)

Expected BLP = 2.5 psi (17 kPa)

(W )

COMPENSATION

SENSOR

M

489 7 5

231 6

M

NO

CONNECTION

PRIMARY

SENSOR

C5113

PRIMARY SENSOR

RESTRICTION

SWITCH

BLOCKED

M

Fig. 12. RP920B authority (A

c

Calibration Unit piping.

TR

0.5

1

1.5

Min

20

15

10

7

5

4

3

2

INSTALL 14003755-001

BARB FITTING AND APPLY

8.0 PSI (55 kPa)

INTEGRAL

MODULE

CCT816B

CALIBRATION UNIT

3

NO

CONNECTION

(BLOCKED RESTRICTION

ALTERNATE OK)

) CCT816B

c

C5114

M

Fig. 13. Integral module piping.

Home and Building Control Home and Building Control Honeywell Asia Pacific Inc. Honeywell Europe S.A. Honeywell Latin American

Honeywell Honeywell Limited-Honeywell Limitée Room 3213-3225 3 Avenue du Bourget Region

1985 Douglas Drive North 35 Dynamic Drive Sun Hung Kai Centre 1140 Brussels 480 Sawgrass Corporate Parkway

Golden Valley, MN 55422 Scarborough, Ontario No. 30 Harbour Road Belgium Suite 200

M1V 4Z9 Wanchai Sunrise FL 33325

95-7392EF B.B. 8-00

Hong Kong

160F

FULL

(71C)

COMP

120F

SETPOINT

PRIMARY SENSOR

(48C)

(W )

1

0F

(–18C)

COMPENSATION

STARTPOINT (W )

COMPENSATION SENSOR

2.5 PSI

(17.5 kPa)

EXPECTED

BLP

6.5 PSI

(45.5 kPa)

c

C5115

Fig. 14. Calibration example reset schedule.

www.honeywell.com

Page 7

Régulateurs pneumatiques modulaires

75 (3) DÉGAGEMENT MINIMAL

102

(4)

86 (3-3/8)

7

(9/32)

RP920A: 36 (1-1/2)

RP920B-D: 83 (3-1/4)

148

(5-7/8)

3 (1/8)

ESPACEMENT

MINIMAL

ENTRE LES

MODULES

RP920A: 48 (1-7/8)

RP920B-D: 96 (3-13/16)

MF17581

INSTALLATION

Réglage à effectuer avant l’installation

1.

S’il faut une connexion aux orifices 4,6, 7 ou 8 (Fig. 2),

retirer la vis autota raudeuse d e l’orific e 8 et util iser la vi s

pour tarauder l’orifice adéquat.

2.

Installer le raccord à crans 14003755-001 et le joint

torique sur l’orifice adéquat et serrer à la main.

3.

Replacer la vis dans l’orifice 8 s’il n’est pas utilisé.

4.

Si on emploie un restricteur à distance avec le capteur

primaire, bloquer l’orifice interne d’alimentation en air

(il peut être réglé après l’installation du manomètre,

mais il est plus facile de le régler avant) :

a. Dévisser la vis d’un tour (Fig. 3) et faire tourner la

plaque de commutation de 90 degrés dans le sens

antihoraire pour mettre l’alim en tati on du cap teu r en

position bloquée.

b. Resserrer la vis et vérifier s’il y a des fuites. En cas

de fuite, replacer la plaque de commutation.

RP920A,B,C,D

NOTICE D’INSTALLATION

REMARQUES :

— La vis de la plaque de commutation doit être bien

— Le capteur de compensation de l’orifice 5 exige

Installation de l’appareil

1.

À l’aide du régulateur comme gabarit ou après avoir

consulté l’encombrement à la Fig. 1, marquer et percer

deux ouvertures de montage pouvant recevoir des

attaches n

2.

Installer le régulateur au moyen de deux attaches n

(non fournies).

serrée pour éviter une fausse défaillance du

capteur.

l’emploi d’un restricte ur extern e de la c analisati on

principale d’alimentati on en air.

o

8.

o

8

Fig. 1. Encombrement du RP920 en mm (po).

Raccordements

1.

Pousser la canalisation sur le raccord à crans

conformément aux plans de l’installation. Voir la Fig. 2

pour connaître l’emplac em en t de s orifi ce s.

2.

Installer le manomètre ou le bouchon :

a. Si le manomètre n’est pas utilisé, resserrer à la

main le bouchon de la prise de manomètre. Si un

manomètre est utilisé, retirer le bouchon et, à la

main, insérer le manomèt re dans l’ orifice rése rvé au

manomètre en lui faisant faire trois tours.

b. Si le manomètre est mal orienté, le faire tourner

dans le sens antihoraire jusqu’à ce que le cadran

soit correct.

REMARQUE : Un joint de caoutchouc souple installé

en usine permet de faire tourner le

manomètre (pour le mettre dans la

bonne position) sans provoquer de

fuites.

® Marque déposée aux É.-U.

Copyright © 2000 Honeywell Tous droits réservés

95- 7392EF

Page 8

RÉGULATEURS PNEUMATIQUES MODULAIRES RP920A,B,C,D

PRISE DE

MANOMÈTRE

ORIFICE DU

MANOMÈTRE

DU CAPTEUR

PRIMAIRE

Bloc de

raccordement

PRISE D'ESSAI

PRESSION

SECONDAIRE

Module du

point de

consigne

Module de

régulation

proportionnelle

RP920A

4 8 9

2 3 1

60

40

20

W

1

0

%

5

10

20

40

30

DIR.

REV.

RP920A

1 - CANALISATION

PRINCIPALE

2 - CANALISATION

SECONDAIRE

132

3 - CAPTEUR

PRIMAIRE

4 - ÉVENT

8 - POINT DE

CONSIGNE

FERMÉ/À DISTANCE

9 - RÉGLAGE DU

POINT DE

CONTRÔLE (RPC)

80

100

Xp (%)

45

ORIFICE DU MANOMÈTRE

DU CAPTEUR

PRIMAIRE

Bloc de

raccordement

PRISE D'ESSAI

PRESSION

SECONDAIRE

Module du

point de

consigne

BOUTON DE RÉGLAGE

DE LA

BANDE

PROPORTIONELLE

Module de

régulation

proportionnelle

RP920B,C,D

4 8 9

32

2 3 1

60

40

20

W

1

100

0

%

5

10

20

40

30

DIR. REV.

1

80

Xp (%)

45

RP920D

7

6

PRISES DE

MANOMÈTRE

7 6 5

100

80

Wc

%

0

60

B

+

C

+

20

40

B

C

TR

Min

0.5

20

4

1

3

1.5

2

250

300

200

Ac (%)

5

150

50

100

NEG.

POS.

5

15

10

7

5

1 - CANALISATION PRINCIPALE

2 - CANALISATION SECONDAIRE

3 - CAPTEUR PRIMAIRE

4 - ÉVENT

5 - CAPTEUR DE

COMPENSATION

6 - ÉVENT

7 - ÉVENT

8 - POINT DE CONSIGNE

FERMÉ/À DISTANCE

9 - RPC

CAPTEUR DE COMPENSATION OU

ORIFICE DU MANOMÈTRE DE

PRESSION SECONDAIRE

BOUTON DE RÉGLAGE DU POINT

DE DÉPART DE LA COMPENSATION

Bloc de

commutation

Module de

régulation

intégrale

Module de

compensation

VIS DU BOUTON DU MODULE

(NE PAS DESSERRER)

1

2

Fig. 2. Emplacement des modules et des orifices.

Bloc de

connexion

2 3 1

ALIMENTATION

DU CAPTEUR

OUVERTE

PLAQUE DE COMMUTATION

INDICATEUR DE POSITION

POSITION OUVERTE

POSITION BLOQUÉE

ALIMENTATION

DU CAPTEUR BLOQUÉE

(RESTRICTEUR EXTERNE)

VIS

PLAQUE

DE COMMUTATION

Fig. 3. Alimentation en air du capteur primaire.

RP920C, D SEULEMENT.

1

Ajustements et modifications après montage

CF5102

Modification de l’action du régulateur

RP920B, D SEULEMENT.

2

VIS IMPERDABLES (4)

5

10

Xp (%)

20

45

40

30

DIR. REV. DIR. REV.

NE PAS

RÉGLER

LA VIS

NOTER

L’EMPLACEMENT

DE L’ENCOCHE

ÉTIQUETTE

DU RÉGULATEUR

ACTION DIRECTE

Module de régulation

proportionnelle

40

45

30

Xp (%)

10

5

ACTION INVERSE

Fig. 4. Modification de l’action du contrôleur.

1.

Dévisser les quatre vis (Fi g. 4 ) du mo dul e de r égulation

proportionnelle.

2.

Retirer le module.

3.

Faire tourner le module et son joint d’étanchéité de

180 degrés, puis le réinstaller. S’assurer que l’encoche

du module est vis-à-vis l’indication adéquate de

l’étiquette du régulateur (base).

4.

Resserrer les quatre vis.

5.

Étalonner de nouveau, au besoin.

MF17584

20

CF5103

95-7392EF 2

Page 9

Passage de la compensation négative (hiver) à la

JOINT D’ÉTANCHÉITÉ EN POSITION C. NORMALEMENT,

LES LETTRES B, B+ ET C+ N’APPARAISSENT PAS

LORSQUE LE JOINT EST EN POSITION C ; ELLES SONT

ILLUSTRÉES POUR INDIQUER LEUR EMPLACEMENT.

CF5105

LANGUETTE

DU JOINT

D’ÉTANCHÉITÉ

DEVANT

ARRIÈRE

VIS IMPERDABLES (3)

Bloc de

commutation

7 6 5

40

20

0

60

80

100

%

W

c

C

B

C

+

+

B

B

C

B

C

+

+

B

B

+

C

+

C

EN POSITION C

compensation positive (été) (RP920B et D seulement)

1.

Desserrer les quatre vis (Fig. 5) du module de

compensation.

2.

Retirer le module.

3.

Faire tourner le module et son joint d’étanchéité de

180 degrés, puis le réinstaller. S’assurer que l’encoche

du module est vis-à-vis l’indication adéquate de

l’étiquette du régulateur (base).

4.

Resserrer les quatre vis.

5.

Étalonner de nouveau, au besoin

.

Ajustement de la fonction manomètre et blocage de

l’action intégrale (RP920C et D)

La position du joint d’étanchéité situé sous le module du bloc

de commutation (Fig. 2) détermine la fonction du manomètre

installé sur place sur le bloc de commutation. Elle détermine

également si l’action intégrale est bloquée ou non. Voir le

Tableau 1 pour connaître les réglages de l’usine et ceux qu’il

est possible de faire sur place.

RÉGULATEURS PNEUMATIQUES MODULAIRES RP920A,B,C,D

7.

Raccorder les composants de commutation du blocage

de l’action intégrale aux orifices 6 et 7, selon le cas.

Réglage du point de consigne (W1)

Le bouton de réglage du point de consigne (W1) est marqué

en relief d’une échelle allant de 0 à 100 %; cette échelle

correspond aux valeurs énumérées au Tableau 3 (voir

Annexe). Plusieurs caches acco mpagnent le r égulateur pour

que le bouton de réglage puisse correspondre à diverses

plages de service du capteur.

Il existe trois méthode s de r églage du po int de co nsig ne (W

1

):

Tableau 1. Position du joint d’étanchéité

du bloc de commutation

Modèle Réglage de l’usine

a

Options

RP920B B C

RP920C B B+

RP920D B C, C+, B+

a

Expédié de l’usine dans cette position.

B = Manomètre dans la canalisation secondaire.

C = Manomètre du capteur de compensation.

+ = Action intégrale bloquée.

VIS IMPERDABLES (4)

250

300

Ac (%)

COMP. NÉGATIVE

(RÉGLAGE DE L’USINE)

200

5

50

POS.

150

100

NEG.

L’EMPLACEMENT DE

L’ENCOCHE

Module de compensation

NE PAS

AJUSTER

LES VIS

NOTER

100

150

200

250

POS.NEG.

COMP. POSITIVE

Fig. 5. Passage de la compensation négative

à la compensation positive.

50

300

CF5104

5

Ac (%)

Fig. 6. Position du joint d’étanchéité selon la fonction du

manomètre et le blocage de l’action intégrale.

POINT DE CONSIGNE LOCAL

Le bouton de réglage du point de consigne (W

directement au régulateur.

) est réglé

1

Ajustements :

1.

Si on utilise un cache, insérer ce cache entre le bouton

de réglage du point de consigne et la rondelle de

retenue transparente. Noter la position de la clé et de

l’encoche non codée du cache (Fig. 7).

2.

Ajuster le point de consigne (W

utilisant le bouton de réglage du point de consigne.

3.

Étalonner seulement si le poi nt de contr ôle s’écart e trop

du point de consigne (W

bande proportionnelle.

1

) selon les plans en

1

) en tenant compte de la

POINT DE CONSIGNE À DISTANCE

Point de consigne (W1) commandé de 0 à 100 % de la

gamme du capteur primaire à partir d’un signal de type purge

de 3 à 15 psi (21 à 103 kPa).

1.

Vérifier la position de la languette du joint d’étanchéité

(Fig. 6, vue du devant).

2.

Dévisser les trois vis du bloc de commutation et retirer

le module.

3.

Retirer le joint d’étanchéité et remarquer les lettres (B,

B+, C, C+) en relief sur le revers du module.

4.

Faire tourner ou basculer le joint d ’étanchéité jusqu’à ce

que sa position corresponde à la fonction souhaitée

(Fig. 6, arrière).

REMARQUE : Lorsque la position est la bonne , seule la

5.

Installer le joint d’étanchéité au dos du module du bloc

de commutation.

6.

Réinstaller le module, puis resserrer les trois vis.

lettre voulue est visible.

Ajustements :

1.

Ajuster le bouton du point de consigne (W

(Fig. 7) ou à la valeur de consigne maximale souhaitée.

2.

Installer le raccord à crans 14003755-001 et le joint

) à 100 %

1

torique sur l’orifice 8 et raccorder à un appareil à point

de consigne de ty pe purge (par exem ple à un SP970) et

à un manomètre de point de consigne à distance.

RÉGLAGE DU POINT DE CONTRÔLE – OFFERT AVEC CERTAINS

MODÈLES SEULEMENT

Le point de consigne (W

régulateur et peut varier de ± 15 % par ra pport à l’intervalle du

) local (de référence) est ajusté au

1

capteur primaire à partir d’un signal à distance de 3 à 15 psi

(21 à 103 kPa).

3 95-7392EF

Page 10

RÉGULATEURS PNEUMATIQUES MODULAIRES RP920A,B,C,D

Ajustements :

1.

Installer une canalisation entre le dispositif de réglage

du point de contrôle et l’orifice 9.

2.

Sélectionner le cache adéquat, selon le cas.

3.

Dans le cas de régulateurs port ant une étiquette

américaine, noter la position de la clé et de l’encoche

non codée du cache (Fig. 7). D ans le cas de régulateurs

portant une étiquette allemande (RP920B,C,D), utiliser

le cache portant une encoche identifiée par la lettre R

lorsqu’un appareil avec réglage du point de co ntrôle es t

employé.

4.

Insérer le cache entre le bouton de réglage du point de

consigne et la rondelle de retenue transparente.

5.

Ajuster le point de consigne (W

utilisant le bouton de réglage du point de consigne.

CLÉ DU BOUTON

DE RÉGLAGE

CACHE

CACHE AVEC ENCOCHE

CODÉE "R"

RONDELLE

DE RETENUE

TRANSPARENTE

BOUTON DE

RÉGLAGE DU POINT

DE CONSIGNE

Module du

point de

consigne

ÉTIQUETTE

CF5106

DU POINT DE

CONSIGNE

60

40

20

W

1

0

%

5

10

20

30

DIR. REV. POS. NEG.

HONEYWELL

) selon les plans en

1

BOUTON DE RÉGLAGE

R

CACHE

AVEC ENCOCHE

NON CODÉE

TR

0.5

80

RP920

1

Ac (%)

5

40

100

Xp (%)

45

DU POINT DE

CONSIGNE

1.5

2

250

300

50

100

Fig. 7. Ajustement du point de consigne (W

Réglage de l’autorité (Ac) (RP920B et D seulement)

Régler l’autorité (Ac) selon les plans en utilisant le bouton de

réglage de l’autorité (A

.

(Fig. 2)

) situé sur le module de compen sation

c

Réglage du point de départ de la compensation (Wc)

(RP920B et D seulement)

Régler le point de départ de la compensation (Wc) selon les

plans (tableau de compensation) à l’aide du bouton de réglage

du point de départ de la compensation (W

cas de capteurs à action directe, le réglage du bouton est égal

) (Fig. 2). Dans le

c

à la valeur de compensation correspondant à la valeur la plus

basse indiquée pour le capteur primaire (en fonction du tableau

de compensation). Voir les Fig. 9 et 10. Si la valeur indiquée

n’est pas exprimée en pourcentage, convertir cette valeur en

pourcentage de la gamme du capteur de compensation ou

consulter le T ableau 2. V oici comment utiliser le Tableau 3 (voir

Annexe) :

1.

Trouver d’abord la colonne correspondant à la gamme

du capteur.

2.

Trouver ensuite la température souhaitée dans le

tableau.

3.

Relever la pression équivalente dans la deuxième

colonne.

4.

Relever le pourcentage équivalent dans la première

colonne.

Ajustement du délai de compensation (Tr)

(RP920C et D seulement)

Min

20

15

10

7

5

4

3

200

150

).

1

Régler le délai de comp ens ation (Tr) en fonction des p lan s e n

utilisant le bouton de réglage du délai de compensation (T

(Fig. 2) :

1.

Abaisser le réglage jusq u’à ce que le syst ème d ev ienne

)

r

instable.

2.

Augmenter le réglage légèrement jusqu’à ce que le

système redevienne stable.

Couvercle

1.

Si l’on se sert du couvercle, rabaisser le couvercle en

droite ligne à partir du devant.

2.

Le couvercle peut être fixé plus solidement : il suffit de

resserrer la vis autotaraudeuse située dans le coin

inférieur droit du couvercle.

Réglage de la bande proportionnelle (Xp)

Ajuster la bande proportio nnell e (Xp) en fonction des plan s en

utilisant le bouton de rég lag e d e la bande proportio nne lle (X

situé sur le module de régulation propor tionnelle (Fig. 2).

MISE EN GARDE

Risque de perte du signal.

Le fait de serrer la vis du bouton peut provoquer

une fuite du régulateur.

Utiliser l’outil CCT819 servant à régler l’autorité, ou

encore un co uteau à mastic mince et rigide pour faire

tourner le bouton (X

95-7392EF 4

et Ac).

p

ÉTALONNAGE

)

p

Capteurs

Les capteurs n’ont pas be soin d’être étalonnés puisqu’ils sont

étalonnés en fonction du système.

Systèmes

Tous les régulateurs RP920 sont étalonnés en usine. Il est

prévu que le régulateur soit ajusté selon les valeurs de

l’installation indiqu ée s sur l es pla ns . Cette façon de mettre en

service le régulateur convi ent en prin cipe à la plupart des

systèmes. S’il est déterminé qu’un étalonnage plus précis est

nécessaire, s uivre les étapes ci-dessous :

Page 11

RÉGULATEURS PNEUMATIQUES MODULAIRES RP920A,B,C,D

M

CAPTEUR

PRIMAIRE

4 8 9 7 5

2 3 1 6

LA GAMME DU MANOMÈTRE DOIT CORRESPONDRE

À CELLE DU CAPTEUR QUI ALIMENTE L’ORIFICE 5.

CF5109

REMARQUE :

— Le régulate ur est conçu de façon que tous les

réglages puiss ent être effectués indépendamment

les uns des autres . Par exemple, la modification

de la bande proportionnelle ( Xp) n’a pas d’effet

sur l’étalonnage du point de consigne (W1), le

point de départ de la compensation (W c) ou le

réglage de l’autorité (Ac).

— Si un dispositif de réglage du po int de contrôle est

employé, appliquer une pression de 9 psi

(62 kPa) à l’orifice 9.

— Si un point de consigne à distance est utilisé,

bloquer l’orifice 8.

Système RP920A

1.

Installer :

a. soit un manomètre récepteur temporaire

(correspondant au capteur primaire) ou un

manomètre de 0 à 30 psi (0 à 207 kPa) da ns l’orifice

du manomètre du capteur primaire si un tel

manomètre n’est pas déjà installé en permanence,

ou encore.

b. installer un manomètre en T dans la canalisation du

2.

3.

4.

capteur (orifice 3).

Appliquer la pression de la canalisation principale au

système.

Installer un manomètre de 0 à 30 psi (0 à 207 kP a) dans

la prise d’essai de la pression de la canalisation

secondaire (hum idifier la pointe du manom ètre ava nt de

l’insérer).

Si le relevé du capteur est sup érieur de ± 10 % au point

de consigne prévu, retirer la canalisation du capteur de

l’orifice 3 et appliquer une pression équivalente (point

de consigne prévu) au moyen de l’instrument

d’étalonnage CCT816B.

2.

Installer un manomètre de 0 à 30 psi (0 à 207 kPa) dans

la prise d’essai de la canalisation secondaire ou dans

l’orifice de m anomètre de la canalisation second aire s’il

n’y a pas déjà un manomètre inst allé en permanence.

3.

Appliquer la pression de la canalisation principale au

système.

4.

Ajuster le bouton de réglage de l’autorité (A

minimum.

5.

Ajuster le bouton de réglage du point de départ de la

) au

c

compensation jusqu ’à ce que le manomètre récepteur

(orifice 5) indique une pression équivalente au point de

départ de la co mpensation (W

6.

Si le bouton du point de départ (W

départ ne correspondent pas, retirer le bouton et le

), (Fig. 9 ou 10).

c

) et le point de

c

replacer de façon qu’il corresponde au point de départ.

7.

Le point de départ de la compensation (W

maintenant étalonné.

) est

c

REMARQUE : Il se peut que le manom ètre récepteur

soit lent à réagir (jusqu’à une minute).

Le régulateur n’es t pas po ur au tan t

défectueux.

8.

Fixer l’unité d’étalonnage CCT816B (Fig. 11) à l’orifice 3

(capteur primaire).

REMARQUE : Les capteurs ne sont pas raccordés.

REMARQUE : Pour un étalonnage plus précis, la

5.

Si le capteur est au point de contrôle prévu ou à une

valeur satisfaisante, ajuster le bouton de réglage du

point de consigne (W

canalisation secondaire soit égale au centre de la

bande proportionnelle de l’appareil à régler, par

exemple, 8 psi (55 kPa) pour un appareil d ont la gamme

est de 3 à 13 psi (21 à 90 kPa).

6.

Si le point de c onsigne (W

primaire ne correspondent pas, retirer le bouton de

réglage du point de consigne (W

façon que le point de consigne corresponde au relevé

du manomètre du capteur primaire.

7.

S’assurer que le point de consigne (W

souhaitée.

8.

L’ét alo nna ge es t ter miné.

Système RP920B

1.

Installer un manomètre récepteur correspondant au

capteur de compensation ou un manomètre de 0 à 30

psi (0 à 207 kPa) dans l’orifice 5, comme l’illustre la

Fig. 8.

REMARQUE : Si le régulateur comporte un manomètre

variable réelle mesurée au capteur doit

être à ± 10 % du point de consigne

prévu.

) jusqu’à ce que la pression de la

1

) et le manomètre du capteur

1

) et le replacer de

1

) à la valeur

1

de compensation dans l’orifice de

manomètre adéquat, bloquer l’orifice 5

et utiliser le manomètre existant.

Fig. 8. Raccordement des canalisations pour le réglage

du point de départ de la compensation (W

9.

Appliquer une pression équivalente à la valeur du

) du RP920B.

c

capteur primaire qui corr espond au poi nt de départ de l a

compensation (

comp start

) figurant dans le tableau de

compensation (Fig. 9 ou 10).

10.

Ajuster le bouton du poi nt de cons igne jusq u’à ce q ue la

pression de la canalisation secondaire soit égale à la

pression prévue de l’appareil à régler lorsque les

conditions de point de départ de la compensation sont

atteintes.

11.

Au besoin, retirer le bouton du point de consigne et le

replacer de façon qu’il correspon de à la valeur du

capteur primaire au po in t de départ de la compensa tion.

12.

Le point de consigne (W

13.

Fixer l’unité d’étalonnage CCT816 B (Fig. 12) à l’orifice 3

) est maintenant étalonné.

1

(capteur primaire) et à l’orifice 5 (capteur de

compensation).

14.

Appliquer des pressions d’entrée au capteur

équivalentes à la pleine compensation selon le tableau

de compensation du bâtiment.

5 95-7392EF

Page 12

RÉGULATEURS PNEUMATIQUES MODULAIRES RP920A,B,C,D

15.

Ajuster le bouton de réglag e de l’autorité (A

que la pression de la canalisation secondaire

) jusqu’à ce

c

corresponde à la pression prévue de l’appareil à régler

aux conditions de pleine compensation.

16.

L’ét alo nna ge es t main ten ant term in é.

PLEINE

COMPENSATION

IMPORTANT

La modification du point de départ de la compensati on

) ou du point de consi gne (W1) n’a d’effet que sur

(W

c

la valeur correspondan te du tableau de compensation,

tandis que la modifi ca tion de l’autorité (A

que sur la pente du tab lea u de com pe nsa tion .

REMARQUE : Voir la section sur l’ajustement du point

de départ de la compensation (W

obtenir pl us de détails.

17.

Retirer l’unité d’étalonnage CCT816B et raccorder les

capteurs aux canalisations.

Systèmes RP920C et D

1.

Retirer la vis du mo dule d e r égulat ion in tégrale (Fig. 13)

et installer le raccord à crans 14003755-001 et le joint

torique à la place.

2.

Appliquer une pression de 8 psi (55 kPa) au module de

régulation intégrale.

3.

Étalonner le RP920 comme suit :

a. RP920C : suivre les mêmes directives que pour le

RP920A.

b. RP920D : suivre les mêmes directives que pour le

RP920B; les valeur s d’étalonn age de la pres sion de

la canalisation secondaire aux étapes 10 et 15

devraient toutefois être de 8 psi dans (55 kPa) dans

4.

les deux cas.

Une fois l’étalonnage terminé, retirer le raccord à crans

du module de régulation intégrale et remettre la vis en

place.

PLEINE

COMPENSATION

) n’a d’effet

c

) pour

c

CAPTEUR

PRIMAIRE

POINT DE

CONSIGNE

(W1 )

POINT DE DÉPART DE

LA COMPENSATION (Wc )

DÉPART

COMPENSATION

CAPTEUR

DE COMPENSATION

C5111

Fig. 10. Tableau de compensation pour l’étalonnage

de la compensation positive.

4 8 9 7 5

2 3 1 6

UNITÉ D’ÉTALONNAGE CCT816B

M

PAS DE RACCORDEMENT

CAPTEUR

PRIMAIRE

INTERRUPTEUR DE

LA RESTRICTION DU

CAPTEUR

PRIMAIRE

BLOQUÉ

M

3

CAPTEUR

PRIMAIRE

POINT DE

CONSIGNE

(W1)

CAPTEUR DE

COMPENSATION

POINT DE DÉPART

DE LA COMPENSATION

(Wc )

Fig. 9. Tableau de compensation pour l’étalonnage

de la compensation négative.

95-7392EF 6

DÉPART

COMPENSATION

CF5110

PAS DE RACCORDEMENT

(AUTRE MÉTHODE DE BLOCAGE

DE LA RESTRICTION ACCEPTABLE)

Fig. 11. Raccordement des canalisations pour

l’unité CCT816B servant à l’étalonnage

du point de consigne (W

) du RP920B.

1

Exemple d’étalonnage du RP920B

Supposons les condition s sui va nte s :

1.

Bande proportionnelle de 10 °F (5,6 K).

2.

Supposons également un opérateur de 2,5 à 6,5 psi

(17 à 45 kPa) avec vanne n.o. où 6,5 psi (45 kPa)

équivaut à une charge nulle et 2,5 psi (17 kPa) à une

pleine charge.

3.

Voir la Fig. 14 pour obtenir le graphique du tableau de

compensation.

4.

Voir le Tableau 2 pour obtenir le tableau de

compensation.

CF5112

Page 13

RÉGULATEURS PNEUMATIQUES MODULAIRES RP920A,B,C,D

Capteur primaire au départ = 120 °F (49 °C) ou 7,8 psi (53,8 kPa)

Pression désirée à la canalisation secondaire = 6,5 psi (45 k Pa)

Capteur de compensation à la pleine compensation =

0 °F (-18 °C) = 5,4 psi (37,2 kPa)

Pression désirée à la canalisation secondaire = 2,5 psi (17 k Pa)

1

1.5

2

3

4

5

7

10

15

20

Min

0.5

TR

INSTALLER UN RACCORD À CRANS

14003755-001 ET APPLIQUER UNE

PRESSION DE 8 PSI (55 kPa)

MODULE DE

RÉGULATION

INTÉGRALE

CF5114

CAPTEUR PRIMAIRE

2.5 PSI

(71 °C)

160 °F

(18 kPa)

PLEINE

COMPENSATION

POINT DE

CONSIGNE

(W )

1

PRESSION PRÉVUE

À LA CANALISATION

SECONDAIRE

6.5 PSI

(49 °C)

120 °F

(45 kPa)

0°F

CAPTEUR DE

(–18 °C)

COMPENSATION (Wc)

POINT DE DÉPART DE LA COMPENSATION (W )

CF5115

c

Tableau 2. Tableau de compensation

Capteur de

GAMME DE

COMPENSATION

Capteur primaire

(air de soufflage)

compensation

(air extérieur)

DÉPART 120 °F (49 °C) (40 %) 60 °F (15 °C) (50 %)

PLEINE 160 °F (71 °C) (60 %) 0 °F (-18 °C) (20 %)

PLAGE DE SERVICE 40 °F (22 K) 60 °F (33 K)

GAMME DU CAPTEUR 40 à 240 °F

-40 à 160 °F (4 à 71 °C)

(4 à 116 °C)

CAPTEUR DE

COMPENSATION

M

489 7 5

231 6

M

UNITÉ D’ÉTALONNAGE CCT816B

M

PAS DE RACCORDEMENT

Réglages d’origine :

Point de consigne (W

) = 120°F (49°C)

1

= 40% = 7 ,8 psi (53,8 kPa)

Pour la cinquième étape d’étalonnage :

Capteur de compensation au d épart = point de départ de la

compensation (W

W = 60 °F (15 °C) = 50 % = 9 psi (62 kPa)

c

).

c

Pour la neuvième étape d’étalonnage :

Pour la dixième étape d’étalonnage :

Pour la quinzième étape d’étalonnage :

Capteur primaire à la pleine compensation =

160 °F (71 °C) = 10,2 psi (70 kPa)

CAPTEUR

PRIMAIRE

INTERRUPTEUR

DE LA RESTRICTION

DU CAPTEUR

PRIMAIRE

BLOQUÉ

PAS DE RACCORDEMENT

M

3

(AUTRE MÉTHODE DE BLOCAGE DE

LA RESTRICTION ACCEPTABLE)

Fig. 12. Raccordement des canalisations

pour l’unité CCT816B servant à l’étalonnage

de l’autorité (A

) du RP920B.

c

Fig. 13. Raccord de la canalisation au module

de régulation intégrale.

CF5113

Fig. 14. Tableau de compensation pour

exemple d’étalonnage.

7 95-7392EF

Page 14

RÉGULATEURS PNEUMATIQUES MODULAIRES RP920A,B,C,D

APPENDIX / ANNEXE

Tableau 3. Tableau de conversion des valeurs du capteur en pourcentage équivalent ou en pression équivalente.

% Span

% gamme

0 3 (20.7) 65 15 15 -40 (-40) 40 (4) -20 (-29) — — 30 (-1) 50 (10)

1 3.1 (21.5) 65.4 15.8 15.8 -38 (-39) 42 (6) -19 (-28) — — 31 (-1) 50.5 (10)

2 3.2 (22.3) 65.8 16.5 16.5 -36 (-38) 44 (7) -18 (-28) — — 32 (0) 51 (11)

3 3.4 (23.2) 66.2 17.3 17.3 -34 (-37) 46 (8) -17 (-27) — 25 (-4) 33 (0) 51.5 (11)

4 3.5 (24.0) 66.6 18.1 18 -32 (-36) 48 (9) -16 (-27) 0 (-18) 26 (-3) 34 (1) 52 (11)

5 3.6 (24.8) 67 18.8 18.8 -30 (-34) 50 (10) -15 (-26) 3 (-16) 28 (-2) 35 (1) 52.5 (11)

6 3.7 (25.6) 67.4 19.6 19.5 -28 (-33) 52 (11) -14 (-26) 5 (-15) 29 (-2) 35.5 (2) 53 (12)

7 3.8 (26.5) 67.8 20.4 20.3 -26 (-32) 54 (12) -13 (-25) 8 (-14) 30 (-1) 36 (2) 53.5 (12)

8 4.0 (27.3) 68.2 21.2 21 -24 (-31) 56 (13) -12 (-24) 10 (-12) 31 (0) 37 (3) 54 (12)

9 4.1 (28.1)

10 4.2 (29.0) 68.9 22.7 22.5 -20 (-29) 60 (16) -10 (-23) 15 (-9) 33 (1) 40 (4) 55 (13)

11 4.3 (29.8) 69.3 23.5 23.3 -18 (-28) 62 (17) -9 (-23) 18 (-8) 34 (1) 40 (4) 55.5 (13)

12 4.4 (30.6) 69.7 24.2 24 -16 (-27) 64 (18) -8 (-22) 20 (-7) 36 (2) 41 (5) 56 (13)

13 4.6 (31.4) 70.1 25 24.8 -14 (-26) 66 (19) -7 (-22) 23 (-5) 37 (3) 42 (5) 56.5 (14)

14 4.7 (32.3) 70.5 25.8 25.5 -12 (-24) 68 (20) -6 (-21) 25 (-4) 38 (3) 43 (6) 57 (14)

15 4.8 (33.1) 70.9 26.5 26.3 -10 (-23) 70 (21) -5 (-21) 27 (-3) 39 (4) 43 (6) 57.5 (14)

16 4.9 (33.9) 71.3 27.3 27 -8 (-22) 72 (22) -4 (-20) 29 (-1) 40 (4) 44 (7) 58 (14)

17 5.0 (34.7) 71.7 28.1 27.8 -6 (-21) 74 (23) -3 (-19) 31 (0) 41 (5) 45 (7) 58.5 (15)

18 5.2 (35.6) 72.1 28.8 28.5 -4 (-20) 76 (24) -2 (-19) 34 (1) 42 (6) 46 (8) 59 (15)

19 5.3 (36.4) 72.5 29.6 29.3 -2 (-19) 78 (26) -1 (-18) 36 (2) 43 (6) 47 (8) 59.5 (15)

20 5.4 (37.2) 72.9 30.4

21 5.5 (38.1) 73.8 31.2 30.8 2 (-17) 82 (28) 1 (-17) 40 (4) 45 (7) 48 (9) 60.5 (16)

22 5 .6 (38.9) 73.7 31.9 31.5 4 (-16) 84 (29) 2 (-17) 42 (6) 46 (8) 49 (10) 61 (16)

23 5 .8 (39.7) 74.1 32.7 32.3 6 (-14) 86 (30) 3 (-16) 44 (7) 47 (8) 50 (10) 61.5 (16)

24 5 .9 (40.5) 74.5 33.5 33 8 (-13) 88 (31) 4 (-16) 47 (8) 48 (9) 51 (10) 62 (17)

25 6.0 (41.4) 74.9 34.2 33.8 10 (-12) 90 (32) 5 (-15) 49 (9) 49 (9) 52 (11) 62.5 (17)

26 6 .1 (42.2) 75.3 35 34.5 12 (-11) 92 (33) 6 (-14) 51 (11) 50 (10) 53 (11) 63 (17)

27 6.2 (43.0) 75.7 35.8 35.3 14 (-10) 94 (34) 7 (-14) 53 (12) 51 (11) 54 (12) 63.5 (17)

28 6 .4 (43.8) 76.1 36.5 36 16 (-9) 96 (36) 8 (-13) 56 (13) 52 (11) 54.5 (12) 64 ( 18)

29 6.5 (44.7) 76.4 37.3 36.8 18 (-8) 98 (37) 9 (-13) 58 (14) 53 (12) 55.5 (13) 64.5 (18)

30 6.6 (45.5) 76.8 38.1 37.5 20 (-7) 100 (38) 10 (-12) 60 (16) 54 (12) 56 (14) 65 (18)

31 6.7 (46.3) 77.2 38.8 38.3 22 (-6)

32 6 .8 (47.2) 77.6 39.6 39 24 (-4) 104 (40) 12 (-11) 64 (18) 57 (14) 58 (15) 66 (1 9)

33 7.0 (48.0) 78 40.4 39.8 26 (-3) 106 (41) 13 (-11) 66 (19) 58 (14) 59 (15) 66.5 (19)

34 7.1 (48.8) 78.4 41.2 40.5 28 (-2) 108 (42) 14 (-10) 69 (20) 59 (15) 60 (16) 67 (19)

35 7.2 (49.6) 78.8 41.9 41.3 30 (-1) 110 (43) 15 (-9) 71 (21) 60 (16) 61 (16) 67.5 (20)

36 7 .3 (50.5) 79.2 42.7 42 32 (0) 112 (44) 16 (-9) 73 (23) 61 (16) 62 (17) 68 (20)

37 7.4 (51.3) 79.6 43.5 42.8 34 (1) 114 (46) 17 (-8) 75 (24) 62 (17) 63 (17) 68.8 (20)

38 7 .6 (52.1) 80 44.2 43.5 36 (2) 116 (47) 18 (-8) 77 (25) 63 (17) 64 (18) 69 (21)

Table 3. Sensor Value to Equivalent Percentage or Equivalent Pressure Conversion Chart.

LP915A

25 - 125

(-4 - 52)

psi (kPa)

Humidity Sens ors

Capteurs d’humidité LP914

%RH °F (°C)

65 -

15 -

15 -

-40 - 160

95

85

75

(-40 - 71)

68.6 21.9 21.8 -22 (-30) 58 (14) -11 (-24) 13 (-11) 32 (0) 38 (3) 54.5 (12)

30 0 (-18) 80 (27) 0 (-18) 38 (3) 44 (7) 47.5 (9) 60 (16)

40 - 240

(4 - 116)

102 (39) 11 (-12) 62 (17) 56 (13) 57 (14) 65.5 (19)

-20 - 80

(-29 - 27)

0 - 200

(-18 - 93)

25 - 125

(-4 - 52)

TP925,

TP974 1044,1051 1077 1085

50 - 100

(10 - 38)

95-7392EF 8

Page 15

RÉGULATEURS PNEUMATIQUES MODULAIRES RP920A,B,C,D

Table 3. Sensor Value to Equivalent Percentage or Equivalent Pressure Conversion Chart. (Continued)

Tableau 3. Tableau de conversion des valeurs du capteur en pourcentage équivalent ou en pression équivalente.

Humidity Sens ors

Capteurs d’humidité LP914

LP915A

TP925,

TP974 1044,1051 1077 1085

%RH °F (°C)

% Span

% gamme

psi (kPa)

65 -

95

15 -

85

15 -

75

-40 - 160

(-40 - 71)

40 - 240

(4 - 116)

-20 - 80

(-29 - 27)

0 - 200

(-18 - 93)

25 - 125

(-4 - 52)

25 - 125

(-4 - 52)

50 - 100

(10 - 38)

39 7.7 (52.9) 80.2 45 44.3 38 (3) 118 (48) 19 (-7) 78 (26) 64 (18) 65 (18) 69.5 (21)

40 7.8 (53.8) 80.5 45.7 45 40 (4) 120 (49) 20 (-7) 80 (27) 66 (19) 65.5 (19) 70 (21)

41 7.9 (54.6) 80.7 46.3 45.5 42 (6) 122 (50) 21 (-6) 82 (28) 67 (19) 66 (19) 70.5 (21)

42 8 .0 (55.4) 81 47 46 44 (7) 124 (51) 22 (-6) 84 (29) 68 (20) 67 (20) 71 (22)

43 8.2 (56.3) 81.2 47.6 46.5 46 (8) 126 (52) 23 (-5) 87 (30) 69 (20) 68 (20) 71.5 (22)

44 8 .3 (57.1) 81.3 48.3 47 48 (9) 128 (53) 24 (-4) 89 (32) 70 (21) 69 (21) 72 (2 2)

45 8.4 (57.9) 81.7 48.9 47.5 50 (10) 130 (54) 25 (-4) 91 (33) 71 (22) 70 (21) 72.5 (22)

46 8 .5 (58.7) 81.9 49.6 48 52 (11) 132 (56) 26 (-3) 93 (34) 72 (22) 71 (22) 73 (23)

47 8.6 (59.6) 82.2 50.2 48.5 54 (12) 134 (57) 27 (-3) 96 (35) 73 (23) 72 (22) 73.5 (23)

48 8 .8 (60.4) 82.4

50.9 49 56 (13) 136 (58) 28 (-2) 98 (37) 74 (23) 73 (23) 74 (23)

49 8.9 (61.2) 82.7 51.6 49.5 58 (14) 138 (59) 29 (-2) 100 (38) 75 (24) 74 (23) 74.5 (24)

50 9.0 (62.1) 82.9 52.2 50 60 (16) 140 (60) 30 (-1) 102 (39) 76 (24) 75 (24) 75 (24)

51 9.1 (62.9) 83.1 52.9 50.5 62 (17) 142 (61) 31 (-1) 104 (40) 77 (25) 76 (24) 75.5 (24)

52 9.2 (63.7) 83.4 53.5 51 64 (18) 144 (62) 32 (0) 106 (41) 78 (26) 77 (25) 76 (24)

53 9.4 (64.5) 83.6 54.2 51.5 66 (19) 146 (63) 33 (1) 108 (42) 79 (26) 77.5 (25) 76.5 (25)

54 9 .9 (65.4) 83.9 54.8 52 68 (20) 148 (64) 34 (1) 110 (43) 80 (27) 78 (26) 77 (25)

55 9.6 (66.2) 84.1 55.5 52.5 70 (21) 150 (66) 35 (2) 112 (44) 81 (27) 79 (26) 77.5 (25)

56 9 .7 (67.0) 84.4 56.1 53 72 (22) 152 (67) 36 (2) 114 (46) 82 (28) 80 (27) 78 (26)

57 9.8 (67.8) 84.6 56.8 53.5 74 (23) 154 (68) 37 (3) 116 (47) 83 (28) 81 (27) 78.8 (26)

58 1 0.0 (68.7) 84.8 57.5 54 76 (24) 156 (69) 38 (3) 118 (48) 84 (29) 82 (28) 79 (26)

59 10.1 (69.5) 85.1 58.1 54.5

78 (26) 158 (70) 39 (4) 120 (49) 85 (29) 83 (28) 79.5 (26)

60 10.2 (70.0) 85.3 58.8 55 80 (27) 160 (71) 40 (4) 122 (50) 86 (30) 84 (29) 80 (27)

61 10.3 (71.1) 85.6 59.4 55.5 82 (28) 162 (72) 41 (5) 124 (51) 87 (31) 85 (29) 80.5 (27)

62 10.4 (72.0) 85.8 60.1 56 84 (29) 164 (73) 42 (6) 126 (52) 88 (31) 86 (30) 81 (27)

63 10.6 (72.8) 86 60.7 56.5 86 (30) 166 (74) 43 (6) 127 (53) 89 (32) 87 (31) 81.5 (27)

64 10.7 (73.6) 86.3 61.4 57 88 (31) 168 (76) 44 (7) 129 (54) 90 (32) 88 (31) 82 (28)

65 10.8 (74.5) 86.5 62 57.5 90 (32) 170 (77) 45 (7) 131 (55) 91 (33) 89 (32) 82.5 (28)

66 10.9 (75.3) 86.8 62.7 58 92 (33) 172 (78) 46 (8) 133 (56) 92 (33) 90 (32) 83 (28)

67 11.0 (76.1) 87 63.4 58.5 94 (34) 174 (79) 47 (8) 135 (57) 93 (34) 91 (33) 83.5 (29)

68 11.2 (76.9) 87.3 64 59 96 (36) 176 (80) 48 (9) 136 (58) 94 (34) 92 (33) 84 (29)

69 11.3 (77.8) 87.5 64.7 59.5 98 (37) 178 (81) 49 (9) 138 (59) 95 (35) 93 (34) 84.5 (29)

70 11.4 (78.6) 87.7 65.3 60 100 (38) 180 (82)

50 (10) 140 (60) 96 (36) 93 (34) 85 (29)

71 11.5 (79.4) 88 66 60.5 102 (39) 182 (83) 51 (11) 142 (61) 97 (36) 94 (35) 85.5 (30)

72 11.6 (80.3) 88.2 66.6 61 104 (40) 184 (84) 52 (11) 144 (62) 98 (37) 95 (35) 86 (30)

73 11.8 (81.1) 88.5 67.3 61.5 106 (41) 186 (86) 53 (12) 146 (63) 99 (37) 96 (36) 86.5 (30)

74 11.9 (81.9) 88.7 68 62 108 (42) 188 (87) 54 (12 147 (64) 100 (38) 97 (36) 87 (31)

75 12.0 (82.7) 89 68.6 62.5 110 (43) 190 (88) 55 (13) 149 (65) 101 (38) 98 (37) 87.5 (31)

76 12.1 (83.6) 89.2 69.3 63 112 (44) 192 (89) 56 (13) 151 (66) 102 (39) 99 (37) 88 (31)

77 12.2 (84.4) 89.4 69.9 63.5 114 (46) 194 (90) 57 (14) 153 (67) 103 (39) 100 (38) 88.5 (31)

78 12.4 (85.2) 89.7 70.6 64 116 (47) 196 (91) 58 (14) 155 (68) 104 (40) 101 (38) 89 (32)

79 12.5 (86.0) 90 71.2 64.5 118 (48) 198 (92) 59 (15) 156 (69) 105 (41) 102 (39) 89.5 (32)

9 95-7392EF

Page 16

RÉGULATEURS PNEUMATIQUES MODULAIRES RP920A,B,C,D

Table 3. Sensor Value to Equivalent Percentage or Equivalent Pressure Conversion Chart. (Continued)

Tableau 3. Tableau de conversion des valeurs du capteur en pourcentage équivalent ou en pression équivalente.

Humidity Sens ors

Capteurs d’humidité LP914

LP915A

TP925,

TP974 1044,1051 1077 1085

%RH °F (°C)

% Span

% gamme

psi (kPa)

65 -

95

15 -

85

15 -

75

-40 - 160

(-40 - 71)

40 - 240

(4 - 116)

-20 - 80

(-29 - 27)

0 - 200

(-18 - 93)

25 - 125

(-4 - 52)

25 - 125

(-4 - 52)

50 - 100

(10 - 38)

80 12.6 (86.9) 90.2 71.9 65 120 (49) 200 (93) 60 (16) 158 (70) 106 (41) 103 (39) 90 (32)

81 12.7 (87.7) 90.4 72.5 65.5 122 (50) 202 (94) 61 (16) 160 (71) 107 (42) 104 (40) 90.5 (32)

82 12.8 (88.5) 90.6 73.2 66 124 (51) 204 (96) 62 (17) 162 (72) 108 (42) 105 (41) 91 (33)

83 13.0 (89.4) 90.9 73.9 66.5 126 (52) 206 (97) 63 (17) 164 (73) 109 (43) 106 (41) 91.5 (33)

84 13.1 (90.2) 91.1 74.5 67 128 (53) 208 (98) 64 (18) 166 (74) 110 (43) 107 (42) 92 (33)

85 13.2 (91.0) 91.4 75.2 67.5 130 (54) 210 (99) 65 (18) 167 (75) 111 (44) 108 (42) 92.5 (34)

86 13.3 (91.8) 91.6 75.8 68 132 (56) 212 (100) 66 (19) 169 (76) 112 (44) 109 (43) 93 (34)

87 13.4 (92.7) 91.9 76.5 68.5 134 (57) 214 (101) 67 (19) 171 (77) 113 (45) 110 (43) 93.5 (34)

88 13.6 (93.5) 92.1 77.1 69 136 (58) 216 (102) 68 (20) 173 (78) 114 (46) 111 (44) 94 (34)

89 13.7 (94.3) 92.3

77.8 69.5 138 (59) 218 (103) 69 (21) 175 (79) 115 (46) 112 (44) 94.5 (35)

90 13.8 (95.1) 92.6 78.4 70 140 (60) 220 (104) 70 (21) 176 (80) 116 (47) 113 (45) 95 (35)

91 13.9 (96.0) 92.8 79.1 70.5 142 (61) 222 (106) 71 (22) 178 (81) 117 (47) 114 (45) 95.5 (35)

92 14.0 (96.8) 93.1 79.8 71 144 (62) 224 (107) 72 (22) 180 (82) 118 (48) 114.5 (46) 96 (36)

93 14.2 (97.6) 93.3 80.4 71.5 146 (63) 226 (108) 73 (23) 182 (83) 119 (48) 115 (46) 96.5 (36)

94 14.3 (98.5) 93.5 81.1 72 148 (64) 228 (109) 74 (23) 183 (84) 120 (49) 116 (47) 97 (36)

95 14.4 (99.3) 93.8 81.7 72.5 150 (66) 230 (110) 75 (24) 185 (85) 121 (49) 117 (47) 97.5 (36)

96 14.5 (100.1) 94 82.4 73 152 (67) 232 (111) 76 (24) 187 (86) 122 (50) 118 (48) 98 (37)

97 14.6 (100.9) 94.3 83 73.5 154 (68) 234 (112) 77 (25) 188 (87) 123 (51) 119 (48) 98.5 (37)

98 14.8 (101.8) 94.5 83.7 74 156 (69) 236 (113) 78 (26) 190 (88) 124 (51) 120 (49) 99 (37)

99 14.9 (102.6) 94.8 84.3 74.5 158 (70) 238 (114) 79 (26) 192 (89) 125 (52) 121 (49) 99.5 (38)

100 15.0 (103.4) 95 85 75

160 (71) 240 (116) 80 (27) 193 (90) — 122 (50) 100 (38)

101 15.1 (104.2) — — — — — — 195 (91) — 123 (51) —

102 15.2 (105.1) — — — — — — 197 (91) — 124 (51) —

103 15.4 (105.9) — — — — — — 198 (92) — 125 (52) —

104 15.5 (106.7) — — — — — — 200 (93) — — —

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your

use or modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and

against any liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the

literature by you.

Régulation résidentielle Régulati on rés identielle Honeywell Asie du Pacifique Honeywell - Amérique latineHoneywell Eu ro p e S .A .

et commercial e et commerciale

Honeywell Honeywell limited-Honeywell Limitée Sun Hung Kai Centre Suite 200 1140 Bruxelles

1985 Douglas Drive 35, Dynamic Drive No. 30 Harbour Road Sunrise FL 33325 Belgique

Golden Valley, MN 55422 Scarborough (Ontario) Wanchai

M1V 4Z9 Hong Kong

95-7392EF B.B. 8-00

Room 3213-3225 480 Sawgrass Corporate Parkway 3, avenue du Bourget

Imprimé aux États-Unis sur du papier

recyclé contenant au moins 10 %

de fibres post-consommation.

www.honeywell.com

Loading...

Loading...