Honeywell RP908A 1039, RP908B Series, RP908A 1047, RP908A 1013, RP908A 1054 Service Data

...Page 1

GENERAL

DESCRIPTION

The RP908A and B are force balance pneumatic

amplifiers, with adjustable proportional band, for use as

Controllers in HVAC systems,

The RP908 is no longer being manufactured. There is

an RP920 model available for all RP908A and B applications. Refer to Application Replacement Listing in the

REPAIR section.

APPLICATION

RP908A

RP908A &

B

PNEUMATIC CONTROLLERS

The RP908A, in conjunction with a remote sensor,

provides direct or limit control in air conditioning control systems, with or without remote control point

adjustment (CPA). It may be adjusted for either direct or

reverse acting operation. Refer to Figures 1 and 2 for

these applications.

5737-2

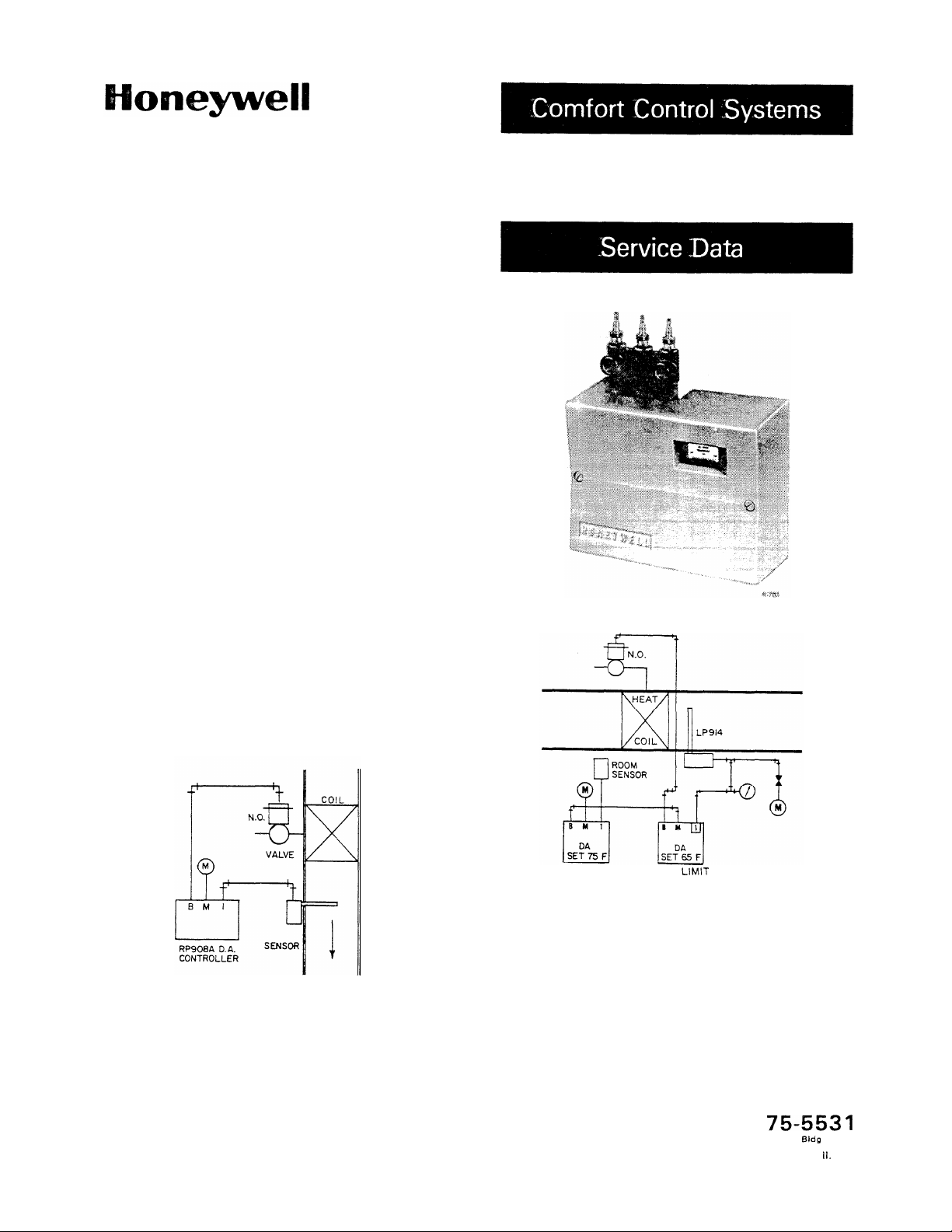

Fig. 1. Typical RP908A Primary Control of Normally

Open Valve.

PRIMARY

CONTROLLER

LIMIT

LOW

CONTROLLER

5759-2

Fig. 2. Typical RP908A Low Limit Control.

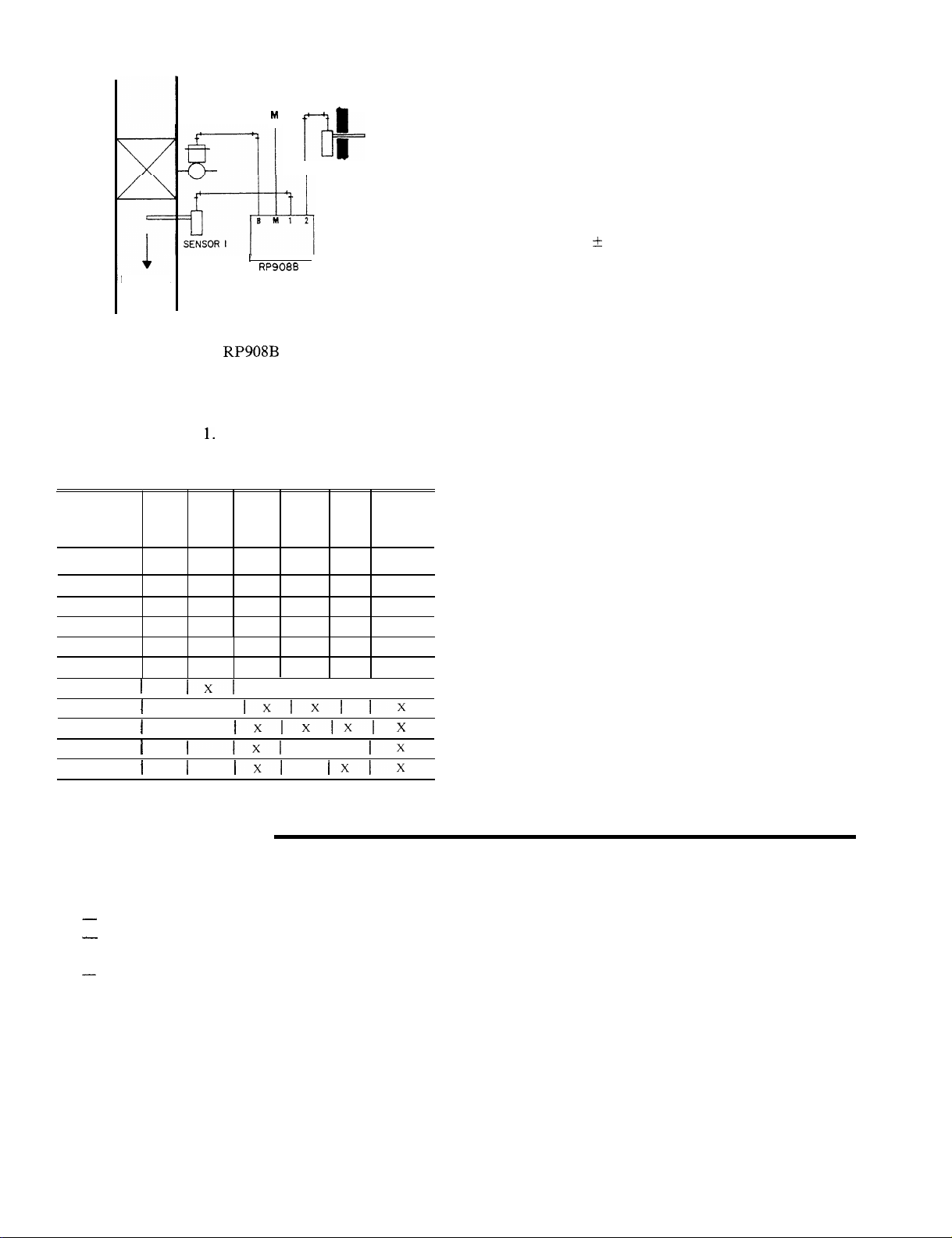

RP908B

The RP908B dual input Controller is applied to compensating systems by using an additional compensating

signal to change the control point of the Controller (Fig.

3). Temperature, humidity, pressure, or dewpoint may

be controlled by using the appropriate sensors,

Rev. 6-84

Form No

75-553 1

Commercial Bldp

MLFTAB:

Group

111

C. 6.

Page 2

1

DISCHARGE

hl

Q

I

RP908B

I

I

I+

SENSOR 2

D.A.

J

5760-2

SUPPLY AIR PRESSURE: 18 psi (124

MAXIMUM SAFE AIR PRESSURE: 25 psi (172

kPa)

nominal.

kPa).

AMBIENT TEMPERATURE LIMITS: 40 to 120F (4 to

9OC).

PROPORTIONAL BAND:

2-1/2

to 40 percent of pri-

mary sensor span, field adjustable.

AUTHORITY: 10 to 200 percent of primary sensor span,

field adjustable.

REMOTE CPA:

-t

10 percent of sensor span.

OPERATION

RP908A

Fig. 3. Typical RP908B Application.

SPECIFICATIONS

MODELS: See Table

Table 1. RP908A and B Model Listing.

Single

Model

RP908A

1005 X

RP908A

1013 X

RP908A

1021 X

RP908A

1039 X

RP908A

1047

RP908A

1054 X

RP908A

1042

RP908B

1003

RP908B

1011

RP908B

1029

RP908B

1037

Input Limit

1

I

I

I

I

1.

Single

Input

IXI

I

I

11x1

I

Dual With

Input Cover

X

I I I

lxlxl

Ixlxlxl

I

1x1

X

X

X

X

With

CPA

X

X

Ixlx

With

Calibration

Knob

X

X

X

X

X

X

Ix

x

Ix

When used in a heating system with the Controller set

for direct action, a drop in temperature at the sensor

lowers the branchline pressure, opening the valve to

increase the flow of heating medium to the coil (Fig. 1). If

the CPA model is used, an increase in air pressure on the

CPA port raises the setpoint of the Controller and a

decrease lowers it.

Used as a low limit Controller, the

RP908B

reduces

branchline pressure from the primary Controller, opening a heating valve to maintain discharge temperature at

setpoint (Fig. 2).

RP908B

Operation is similar to RP908A. However,

an

increase

in outdoor temperature causes the compensating (outdoor) sensor to reset the control point of the Controller

to raise the branch line pressure (Fig. 3). The resulting

change in branch line is dependent on the authority setting on the Controller.

MAINTENANCE

EQUIPMENT REQUIRED

-

Plastilube 311057 for O-rings, screw threads, etc.

-

Molycote or similar commercial powdered lubri-

cant for pivots and plungers in units with CPA.

-

0 to 30 psi test gage (if gages have not been installed

in system).

GENERAL

The only preventive maintenance necessary is an

annual visual check for leaks, loose fittings, etc, and an

operational and calibration check.

75-553 1

OPERATIONAL CHECK

Check main air pressure for 18 psi (124 kPa) at Controller. For models with manual CPA adjustment, move

CPA switch up and down and observe the action of the

Controller. If the system’ does not have CPA, the sen-

sor(s) may be disconnected and the port plugged so that

pressure may be slowly built up, causing the Controller to

operate from one extreme position to the other. Bleeding

this pressure slowly causes the Controller to operate in

the opposite direction. The main lever should move

smoothly, and the branchline pressure should change

gradually in the proper direction.

2

Page 3

CALIBRATION CHECK

RP908A

Change the

sensor temperature if the two do not already match. The

branchline pressure should be at its calibration pressure

of 8 + 1 psi (55

drawings. If recalibration is necessary, see CALIBRATION,

RP908B

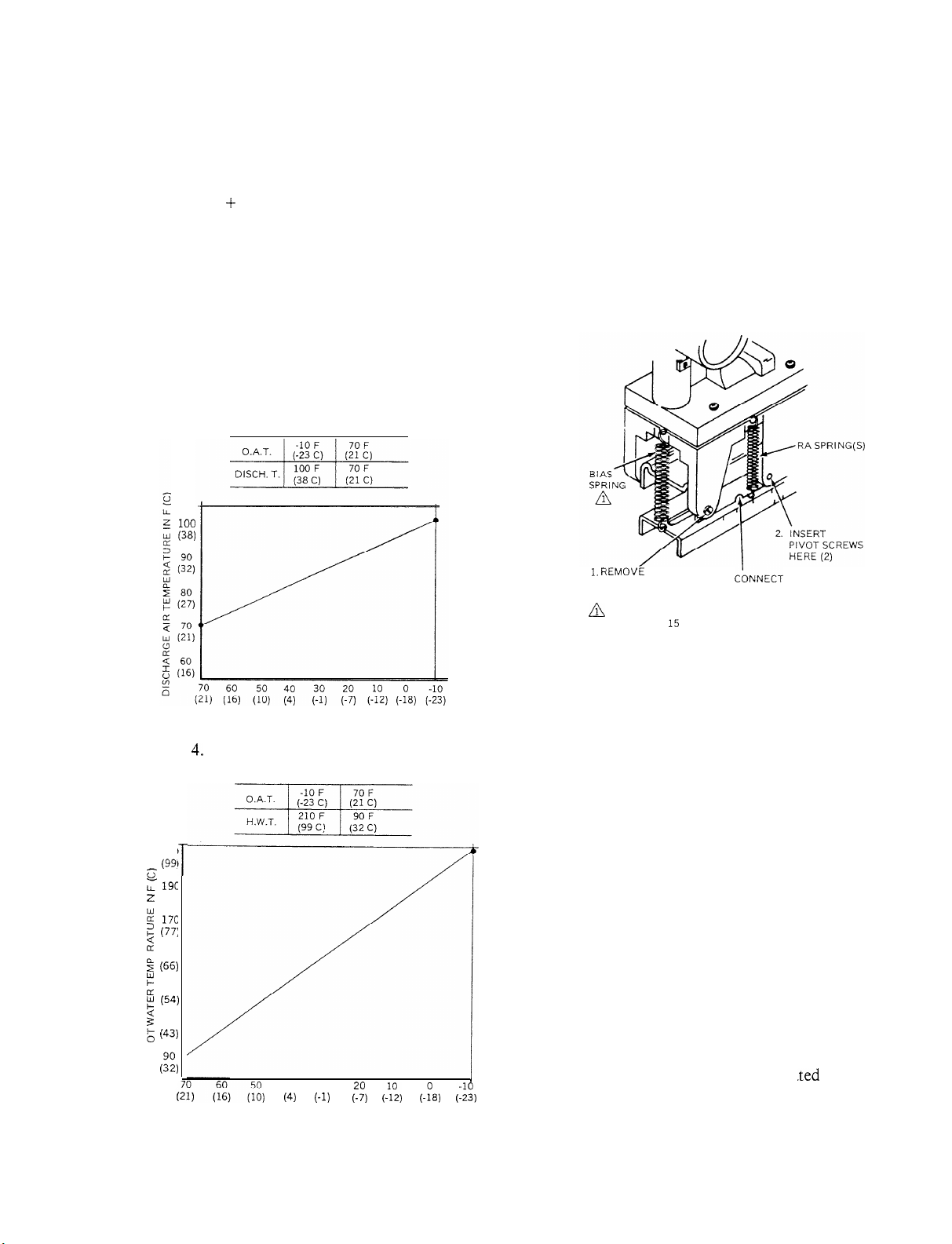

Determine the existing calibration temperature from

the reset schedule on the job drawings. Draw a straight

line on graph as shown in Figure 4. Measure the temperature at the Port 2

sor temperature (Fig. 5). Measure temperature at Port 1

sensor location. This temperature must agree within two

100

(38)

setpoint

-t-

7

kPa)

sensor.

of the Controller to the existing

unless otherwise noted on job

Find corresponding Port 1 sen-

percent of the sensor range span and the branchline pressure must be within the operating range of the controlled

device. If recalibration is necessary, see CALIBRATION.

CHANGE FROM DIRECT TO REVERSE

ACTING

The change from direct to reverse acting is made by

following the three steps listed in Figure 6.

OUTDOOR AIR TEMPERATURE IN F(C)

20884

Fig. 4, Typical Discharge Air Reset Schedule.

21c

(99:

T

??

:

19c

z

(88

2

17c

2

(77:

;:

w 150

ii

(66)

?

[L

130

p

(54)

s

110

g

(43)

I

(Zi,

40 30

OUTDOOR AIR TEMPERATURE IN F (C)

(4)

(-1)

(770)

(-:“z,

(-:8) (::i)

Fig. 5. Typical Hot Water Reset Schedule for

Radiation Systems.

20885

1.

RENlOVE PIVOT

SCREWS (2)

A

DISCONNECT WHEN PROPORTIONAL BAND (PB) IS

LESS THAN 15 PERCENT, REGARDLESS OF ACTION.

3.

CbNNECT

TO NOTCHES (2)

RA SPRINGS (2)

4707-l

Fig, 6. Set-Up for Reverse-Acting Operation.

ADJUSTMENTS

PROPORTIONAL BAND

If the original setting shown on the job drawings must

be changed:

1. Loosen the Proportional Band Adjustment Knob

(Fig. 7) and slide the Proportional Band Indicator

to the desired setting.

NOTE: When a proportional band of more than

I5 percent is used, fasten the Bias Spring

to the Lever Assembly (Fig. 6). This spring

is left unconnected if proportional band is

15 percent or less.

I

2. The Controller must be recalib

proportional band is changed.

ra

.ted

whenever the

75-553 1

Page 4

REMOTE CONTROL POINT

A pressure change from 3 to 13 psi (21 to 90

kPa)

in the

remote CPA port changes the control point proportionately by 20 percent of the sensor span.

1 (and Port 2 if RP908B is used). If the reset signal on an

RP908B is produced by the output of a room thermostat

or pressure control, a

Port 2. Otherwise, the scale range on the

30-psi

gage must be installed in

gage should

match the range of the sensor for Ports 1 and 2.

SETPOINT

The

setpoint

is raised by turning the

Setpoint

Knob

(Fig. 7) counterclockwise. This increases the force from

the

setpoint

spring on the lever assembly so that a greater

force from the sensor chamber is required to cause an

increase in branchline pressure.

The

setpoint

It has 10 marked divisions, each equaling

screw has a vernier for fine adjustment.

l/2

percent of

the sensor span (1 degree F per division for a 200-degree

sensor span, or 20 turns for the whole span).

SETPOINT

SCREW WITH 10 MARKED

DiVISIONS

CONTROLLER WITHOUT CPA

ADJUSTMENT

SETPOINT

KNOB

RP908A

There are two methods of calibrating the RP908A

when 18 psi (124

kPa)

main air is supplied to the Control-

ler and the internal restriction is not blocked.

CALIBRATION USING AN ADJUSTABLE

RESTRICTION

1,

Install the proper scaleplate on the Controller if not

already installed.

2.

Disconnect the Port 1 sensor and connect an adjustable restriction to Port 1.

Choose a

3.

setpoint

and adjust the restriction until the

gage in Port 1 shows this setpoint.

Turn the

4.

reads 8 psi (55

setpoint

knob until the branchline pressure

kPa).

This is standard calibration. On

some applications, the calibration branchline pressure

may be set at a different point that relates to the spring

range of the device being operated.

Move the scaleplate until the

5.

setpoint

indicator agrees

with the chosen setpoint, and tighten.

6.

Disconnect the adjustable restriction and reconnect

the sensor.

LPROPORTIONAL

CONTROLLER WITH CPA

BAND INDICATOR

.

20887

Fig. 7. RP908 Adjustment Locations.

CALIBRATION

GENERAL

Always calibrate with 18 psi (124

sure. On CPA models, set CPA to 8 psi (5.5

30-psi gage must be installed in the branchline port

during calibration and a temperature, humidity, or pressure gage matching the sensor should be installed in Port

kPa)

main air pres-

kPa).

A 0 to

CALIBRATION WITH GAGES

1. Install

30-psi

match Port

gages in Ports 1 and B. Port I gage must

B.

Install proper scaleplate on the Controller if not

already done.

Turn the

psi (55

setpoint

kPa)

knob until branchline pressure is 8

or other selected calibration pressure (see

Step 4 of CALIBRATION USING AN ADJUSTABLE RESTRICTION).

Move the scaleplate until the

setpoint

indicator is at

the reading shown on the Port 1 gage and tighten.

Adjust the

setpoint

to the desired control setting.

RP908B

The only method of calibrating the RP908B is to use

an adjustable restriction. If the settings are known, proceed to Step 1 of RP908B CALIBRATION PROCEDURE. If the settings ‘must be calculated, read the

following and calculate as shown. Authority Calculator

No. 813 may be used to simplify these calculations.

Although these examples are shown for a hot water reset

system, the formulae also apply to other systems-

75-553 I

4

Page 5

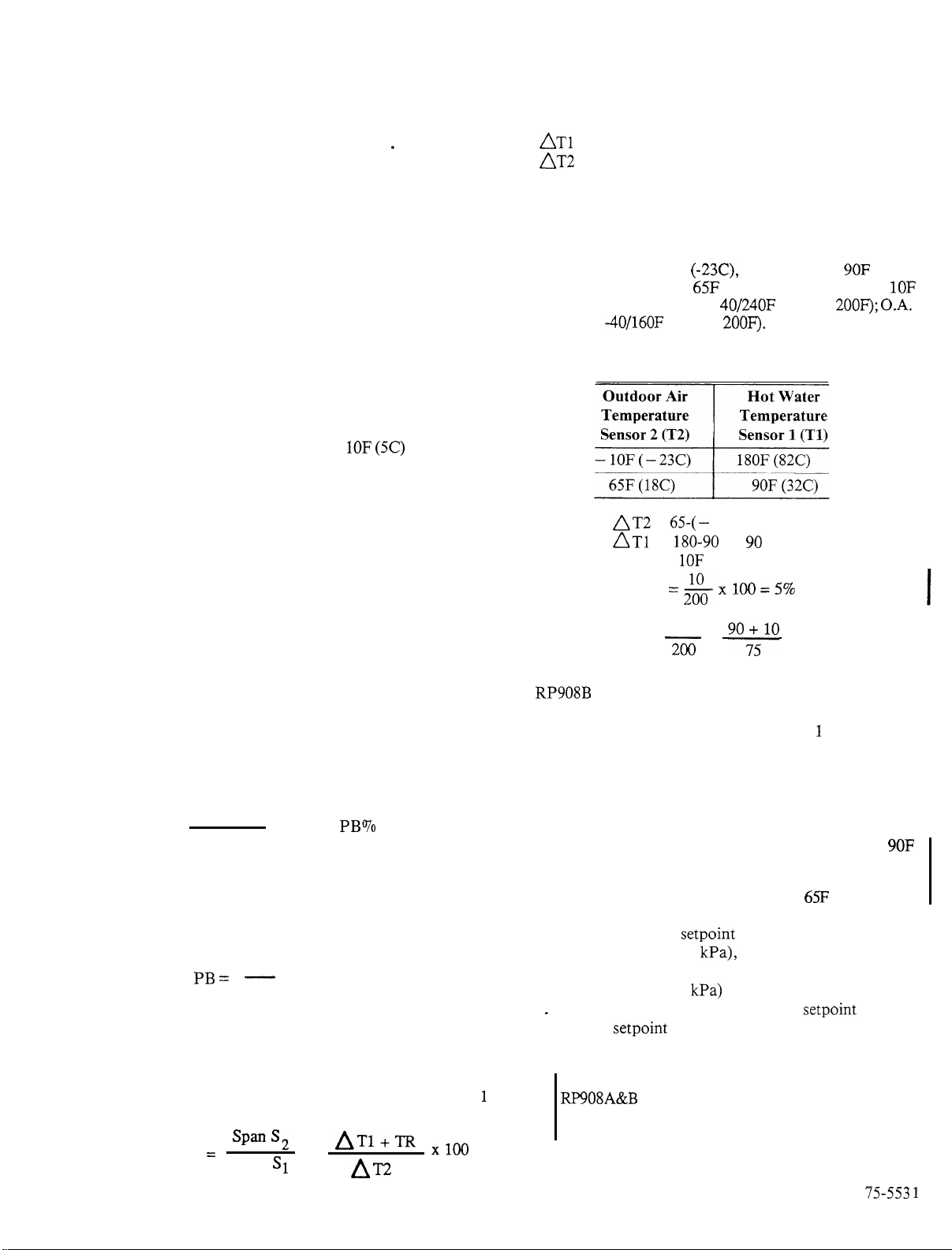

Two separate parameters must be known in order to

properly calibrate a reset system, Reset Schedule and

Throttling Range. Proportional Band and Authority

may be calculated from these parameters

RESET SCHEDULE

The reset schedule is plotted by determining the outdoor air temperature at which designed maximum heating water temperature is needed and the outdoor air

temperature at which no heating is required.

THROTTLING RANGE (TR)

Throttling Range indicates the change in water temperature at the sensor to cause the valve to move from

fully open to fully closed (full heat to no heat). It is desirable to have a throttling range as narrow as possible for

efficient control and yet wide enough to produce stable

operation. A throttling range of

mended trial setting. If the system will not stabilize after

being in operation for a short period of time, the throttling range should be increased (this requires recalculation of the proportional band, authority, and

recalibration). An unstable system can be recognized by

frequent, repetitive changes in branchline pressure,

known as hunting or cycling.

a

10F (5C)

is a recom-

Where:

TR = Throttling Range

AT1= Change in Hot Water Temperature

AT2

= Change in Outdoor Air Temperature

EXAMPLE:

Determine settings for a system where hot water should

be controlled at 180F (82C) when outdoor air

temperature is -lOF

when outdoor air is

(5C). Hot Water Sensor

Sensor

-40/160F

AT2

ATI

TR =

PB = &

(-23C),

65F

(18C). Assume a TR of

40/24OF

(Span =

Reset Schedule

=

65-(-

10) = 75

=

180-90

=

10F

x100=5%

and reduced to

(Span =

2OOF).

go

9OF

200F);

(32C)

0-A.

IOF

When the throttling range has been selected, it must be

converted to a proportional band value that can be set on

the Controller.

PROPORTIONAL BAND (PB)

Proportional Band is similar to throttling range except

it is expressed in terms of percent of temperature change

rather than degrees. Proportional band can be determined by using the following formula:

TR

Sensor Span

EXAMPLE:

When a sensor having a 200-degree span is used and a

IO-degree TR has been selected:

PB =

200

AUTHORITY

Authority indicates the amount of effect that the change

in outdoor air temperature will have on the control point.

The formula must take into account

and Sensor 2. The complete formula is:

Authority

=

Span S,

Span SI

x 100 = PB%

10

-

x 100 = 5%

the

spans of Sensor

A~l+m xloQ

X

Al-2

1

Authority =

RP908B

I. Install the scaleplate matching the Port I sensor on the

2.

3.

4

5

CALIBRATION PROCEDURE

Controller if not already done.

Disconnect the sensors to Ports 1 and 2 and connect an

adjustable restriction to each port. If an external main

has been connected to the sensor line, install the

adjustable restriction on the sensor side of the tee.

Select the low end of the Sensor 1 schedule or

(32C). Adjust the No. 1 restriction until the Sensor 1

gage reads that temperature. Also set Sensor 2 at “low

end” of reset schedule, in this example

Set the authority and proportional band into the Con-

troller. Adjust the

gage reads 12 psi (83

closed” pressure if the valve has other than a standard

4 to 11 psi (28 to 76

.

Move the scaleplate until the desired

with the

ler is now in calibration.

REPLACEMENT PAGE FOR:

RP908A&B

Service Data

75-5531 6-84 II. C. 6.

setpoint

200

2oo

indicator and tighten. The Control-

Pneumatic Controllers

90;5IO

x

setpoint

kPa),

kPa) spring range.

x 100 = 133%

knob until the branchline

or until it reads the “valve

65F

(18C).

setpoint

8-88

90F

lines up

75-553 1

Page 6

TROUtBLESHOOTlNG

Before troubleshooting the RP908, make a visual

check of the Controller to see that springs and pivots are

connected

properly

for the application. If the RP908 is

MEASURE CONTROLLED

VARIABLE. COMPARE

WITH SENSOR 1 GAGE

READING.

REMOTE

CPA ONLY

-

4

still not working properly, refer to Fig. 8, RP908

Troubleshooting Flowchart.

CONTROLLER

NOT CONTROLLING

ADJUST PRV OR

YES

CHECK VALVE OR DAMPER

FOR CLOSEOFF, LEAK, OR

MALFUNCTION. CHECK

FOR CLOGGED RESTRICTIONS,

FILTERS. SCREENS. SENSOR

LINE AIR LEAK, BAD SENSOR,

OR GAGE OUT OF CALIBRATION.

CORRECT AS NECESSARY.

RF’908

I

I

RECONNECT TO

l

I8

PSI MAIN.

RECALIBRATE

AND RECHECK

CHECK DEVICE

OPERATION.

REPLACE IF

NECESSARY

1

CHECK BRANCH

LINE PRESSURE

TEST BRANCH

LINE FOR

LEAKS. REPAIR

IF NECESSARY.

CHECKOPERATION.

Fig. 8. RP908 Troubleshooting Flowchart.

CHECK OPERATION

TEST TUBING

FOR LEAKS

REPAIR IF

NECESSARY

LUBRICATE CONTROLLER

PIVOT POINTS. REPLACE

CONTROLLER IF LIBRICATION

DOESN’T HELP

h

1

CONTROLLER

NOW MATCH

REPLACE SENSOR,

CHECK OPERATION.

I

x2593

I

75-553 1

Page 7

REPAIR

RP908 DISASSEMBLY PROCEDURES

1.

Disconnect system air. Loosen the two Screws and

remove Cover (Fig. 9, Part 1).

2,

Loosen the three Screws securing the Controller to

the Backplate, and move Controller to a bench,

If replacing the CPA Seal, it is necessary to do this

while the Bracket is attached to the Body

easy to rip the CPA Seal if the

Assembly is loose. See Step 15, CPA Models.

r---cAuT1oN------l

a.

Remove the four Screws securing the Bracket to the

Body (Fig. 9, Part 2).

4.

Remove the four Screws securing the Manifold (Fig.

9, Part 3).

5.

Lift the Manifold from the Body.

6.

Remove and discard the Gasket, if replacing.

7_

Note the location of the Filters and Restriction(s),

The RP908A may have two or three Filters (depending on model), and the

four Filters. Some Controllers may have a field-

installed Blank Orifice in place of a Restriction, Filter, Screen, and Washer. If this Blank Orifice is

required, the job drawing will show a box drawn

around the port of the

NOTE: Serviceline Repair Kit 14002696-001 is

available for order. This kit contains one

Gasket, four O-Rings, four Screens, two

Restrictions, four Filters, and four

Washers

8.

Remove the Washers, Filters, Screens, Restriction,

and O-Rings, if replacing, and discard.

9.

Remove Blank Orifice, if installed. Install replacement parts in reverse order,

IO.

For Body repair, first disconnect the Bias Spring and

the two Reverse Acting Springs at the lower attachment point.

111.

Remove the two Pivot Screws securing the Lever

Assembly to the Body. Set Lever Assembly and

Screws aside.

12.

Remove the two Screws securing Upper Lever

Assembly. Set Upper Lever Assembly and Screws

aside.

13.

Remove the two cross-head Screws from the Cover

Assembly to replace any parts in the Cover

Assembly,

RP908B

RP908

e

Setpoint

may have three or

to be blocked.

It is very

Screw

14.

For replacement of the Proportional Band Adjustment Knob, simply unscrew from the Indicator

Assembly.

15.

Non-CPA Models:

Remove the

point Spring,

then come right out.

CPA Models:

a. Loosen the two cross-head Screws and remove the

CPA Housing (Fig. 9, Part

the Seal while the bracket is still attached to the

Body. The Seal should be removed and then the

Bracket detached from the Body to remove the

Setpoint

point Screw Assembly.

b. Remove the two cross-head Screws from the end

of the Authority Adjustment Lever Assembly.

Remove the two Screws from the front and back

of the Bracket to remove the Body Assembly that

is situated over the Authority Adjustment Lever

Assembly.

16,

Assemble RP908 in reverse order and turn on system

air.

17.

Make all Settings and Adjustments applicable to

model according to job drawings. Perform Operational Check and Calibrate (see MAINTENANCE

section).

Setpoint

Knob,

Knob (Fig. 9, Part 4). The

Setpoint

Nut, and Setpoint Screw will

4),

Setpoint

Spring, and/or the

Set-

Carefully remove

Set-

REPLACEMENT OF RESTRICTION

WlTH BLANK ORIFICE

The Internal Restriction must be replaced with a

Blank

external source of restricted air, This occurs when the air

supply to the M Port of the Controller is varied by other

controls, or when a single sensor is connected to more

than one Controller. To replace the Restriction with a

Blank Orifice, proceed as follows, referring to Figure 9,

Part 3.

Restriction is not blocked, do not plug the unused port

but leave it open to avoid building up to mainline pres-

sure in the sensor chamber. Two limit models of the

RP908A

Orifice identified by a red Manifold. When field install-

ing a Blank Orifice, the Manifold and job drawings

should be marked, indicating that the Restriction is

blocked.

Grifice

1. Remove the Manifold and Gasket.

2. Remove the Port 1 O-Ring, Restriction, Screen,

Filter, and Washer. Install Blank Orifice 316125.

3. Reassemble the O-Ring, Gasket, and Manifold,

carefully noting orientation of the Gasket,

When using only one port of an

when the sensor is supplied with an

RP908B

were provided with a factory-installed Blank

and the

75-553 1

Page 8

REPLACEMENT OF RP908 WITH

RP920

Table 2 lists specific model numbers of the RP920 that

are direct replacements for the RP908.

PARTS AND ACCESSORIES

Table 2. Application Replacement Listing.

PARTS LIST

Refer to Figure 9, Parts 1 through 4, and Table 3 for

available replacement parts for the

trollers. Those items listed without a part number are no

longer available.

Fig. 9

Ref. No.

4

5

6

7

8

9

10

11

12

Part Number

3.5 1277-00767

3

15299-00767

-

315282

315255

315263

3 15293-00605

3

15740-00062

315284-00101

315204A

3

16205A

-

14002696-00 1

14004146-001

312826

315249

3 15245

315253

RP908A

Backplate

Backplate

Screw, Backplate (3) No. 6-32 x

Cover,

Cdver, RP908B

Cover,

Screw, Cover (2)

Screw, Bracket

Manifold,

Manifold,

Manifold, RP908A Limit (RED), with Check Valve 315918

Screw, Manifold, 8-32 x 1

Repair Kit-includes

Screens, 4 Filters 9 and 4 Washers)

Gasket

O-Ring

Restriction

Screen

Filter

and B Con-

Table 3. RP908 Parts List.

(RP908A)

(RP908B)

RP908A

RP908A,

without CPA

without CPA

B with CPA

(4))

RP908A

RP908B

Description

l/4

Panhead

No. 8-32 Oval Undercut Head

l/16

Panhead

Iteas*

through 13 (1 Gasket, 4 O-Rings, 2 Restrictions, 4

75-553

1

8

Page 9

Fig. 9

Ref. No.

Part Number

Table 3.

RP908

Parts List. (Continued)

Description

13

-

-

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

3.5

36

37

38

39

40

41

42

43

44

45

46

47

304963-001

316165A

316165B

-

-

3 15224

303634

-

3 15240

315233

316155A

3 15239

-

304721

3 15247

-

3

15280A

3

15280B

3

1528OC

3 15242

-

14001848-001

14001258-001

315260-00101

-

316157

3 15285-00605

-

3 15252A

-

-

14001846-001

3 15278-00062

3 152 1 o-00062

315215-00021

315214-00606

-

316162A

-

-

-

Washer

Body Repair Assembly for

Body Repair Assembly for

Tube,

RP908B

RP908A-includes

RP908B-includes

Items 15 through 26

Items 14 through 26

Body, RP908A, B

Pivot Screw (2)

Spring

Lever Assembly

Screw (2)

Gasket

Cover Assembly

Nut

Screw, 8-32 x 1 l/ 16

Panhead

Tension Nut

Tension Screw, PB Adj.

Upper Lever Assembly

Lever Assembly

Lever Assembly

Lever Assembly

(RP908A)

(RP908A

(RP908B)

wit

h

CPA)

Proportional Band Adjustment Knob

Indicator Assembly

Bias Spring

Reverse Acting Spring (2)

CPA Housing (CPA models)

Screw, 8-32 x

l/2

Fillister Head (CPA Models)

CPA Seal (CPA Models)

Scaleplate

Screw,

Body Assembly

RP908B,

8-32 x 5/16 Oval Head (3)

(RP908B)-includes

Diaphragm 3 15225, Washer 304573-124, and

Connecting Tube O-Ring 3 10779

Screw,

Authority Adjustment Lever Assembly

Setpoint

Setpoint

Setpoint Screw,

Setpoint

Setpoint

Setpoint

Setpoint Screw Assembly (CPA Models), with Aluminum Plug 3

RP908B, 8-32 x

l/4 Panhead

Knob (non-CPA models)

Screw,

Spring,

Spring,

RP908A

(non-CPA models)

RP9CX3 1003

RP908A

RP908A

(non-CPA)

(CPA) and

and

Nut

(2)

(RP908B)

RP908B

RP908B

1029

15243-101

Bracket

Screw, 6-32 x

3/8

Panhead

Nut (Tinnerman Clip)

75-5531

Page 10

Page 11

I

I

I

_--_

0

16

(lo-J

-

PORT 2,

>!i+PORT

I

I

I

i

\

Fig. 9 (Part 3 of 4). RP908 Controller-Exploded View.

11

I

J

w

x2101

75-553 1

Page 12

Fig. 9 (Part 4 of 4). RP908 Controller-Exploded View.

20888

ACCESSORIES

1

_

Scaleplate Decals.

Table 4 lists the scaleplate decals that are available for

the RP908.

2. Blank Orifice 316125-00606 (field installed).

3. Self-rewinding Rapid Adjustment Knob 3

4. Gages.

Table 5 lists gages that are applicable for use with the

F

RP908

75-553

1

16479A,

Table 4. Scaleplate Decals

No. 315993A:

Oto2OOF

40 to 160F

40 to 240F

50 to

1OOF

3 to 15psig

0.2 to 1 .O

-

20 to 80C

-

40 to 60C

kg/cm2

5 to 105c

No. 316005: - 1 to

No l 316089:

12

-25 to

lOto4OC

WARMER/COOLER

15 to 85% RH

-

20 to 80F

-

30 to 30F

25 to 125F

-5to55C

15 to 75% RH

65 to 95% RH

’

6

in.H20 (D.A.)

1SOmm Hz0

b

(D.A.)

Page 13

Part No.

(l-1/2

in. dia.

back

corm.

l/8

NPT)

14000786-001

14000786-002

305929

305932

30593

1

305934

305986

305987

305930

305933

305972

305973

14000786-0051 15 to 85

14000786-003[ 15 to 75

14000786-0041 65 to 95

305988

Scale Range

Temperature

25 to

I

1 -5

to 55C

1 -4oto

160F

1

-4Oto60C

t

40 to 240F

5to 115c

I

1

-2Oto80F

1

-3oto30c

1

Oto 200F

1

20to 80C

1

50to

1OOF

1

lOto38C

Relative Humidity

40 to 75F TP925A1018

Table 5. Gages.

I

125F

I

I

1

LP914

1

LP914

I

LP914

I

1

LP914

1

LP914

1

LP915

I

LP915

1

TP924, TP974, TP925

1

TP924, TP974, TP925

-

-

-

Dewpoint

1

HP971

1

HP971

I

For Use with Sensor

LP914

LP914

LP914

HP971

305965

305615

305616

305617

305618

305624

305619

305625

305620

305626

I

I

50to

I

1

75 to 125 mm of WC I PP905

I

I

lOOto

0 to30psi

- 1to1 in.ofWC

0 to 2 in. of WC

1 to 3 in. of WC

2to4in.ofWC

IOOmmofWC

3to5in.ofWC

4to6in.ofWC

150mmofWC 1 PP905

PP9C

I

PP905

PP905

PP905

I

PP905

1

PP905

I

PP905

13

75-553 1

Page 14

ALABAMA

Bxmingham, AL

(2051

323.2431

Mobile, AL

(800) 633-l 644

ALASKA

Anchorage, AK

(907) 2740551

ARIZONA

Phoenlw,

AZ

(602) 8614512

Tucson, AZ

(602) 7954209

AR KANSAS

LIttIe Rock, AR

1501) 6644070

CALIFORNIA

Irwne.

CA

(714)

557-6392

Los Angeles, CA

(213)

7266161

Sacramento, CA

(916) 485.2221

San

Dlego,

CA

(714) 292.5311

San Jose, CA

(415)

957-2674

San

Franc~sco,

DC

827.3705

CA

(415) 957.2674

COLORADO

Denver, CO

(303) 7796295

CONNECTICUT

Hartford, CT

(203) 549.3800

DELAWARE

Wllmlngton, DE

(302) 762.3100

DISTRICT OF COLUMBIA

WashIngton

(703)

FLORIDA

JacksonwIle, FL

(904) 3966971

Miami, FL

(305) 592.8140

Orlando, FL

(305) 894-3131

Tampa, FL

(813) 877-6426

GEORGIA

Atlanta, GA

(404) 982.2495

HAWAII

Honolulu, HI

(808) 537-5514

IL

.LINOIS

Chrcago

1312)

478-9266

ChIcago

(312) 568-4200

Elgln,

IL

(312) 697.7880

Peona.

1309)

692-0610

INDIANA

Fort Wayne, IN

(219) 482.9654

Indianapolls, IN

(317) 243.0831

IOWA

Davenport, IA

(319) 359-3441

Des Moines, IA

(515) 288-3601

KENTUCKY

~ouw~lle, KY

(502) 459-5970

LOUISIANA

Baton Rouge, LA

(504) 9248626

New Orleans, LA

(504) 456-7232

Shreveport, LA

(214) 387-5467

North, IL

South (Lar

IL

Irlngl,

I

MAINE

Ponland, ME

(2071

775-3501

MARY LAND

Baltimore, MD

(301) 828-0900

MASSACHUSETTS

Boston, MA

(617) 962-0250

MICHIGAN

Detrort, Ml

(313) 478.1600

Grand

RapIds,

1616)

2474811

Saginaw,

MI

(517) 792.8707

MINNESOTA

Duluth, MN

(612) 770-8557

Mmneapol~s,

MN

(6121

830-3880

St. Paul, MN

(6121

770-8557

MISSISSIPPI

Jackson, MS

(601) 982-2090

MISSOURI

Kansas

City,

MO

(816) 35842GO

St

LOUIS,

MO

(314) 576-2635

NEBRASKA

Omaha, NE

(402) 331-3200

NEW HAMPSHIRE

Bedford, NH

(603)

6256502

NEW JERSEY

Mr

Laurel, NJ

(609) 234-2224

Pars~ppany,

NJ

(201) 263.2225

WestfIeld,

NJ

(201) 233.9200

NEW MEXICO

Albuquerque, NM

(505)

NEW YORK

Albany, NY

(5 18)

Buffalo, NY

(716) 689-0200

Brooklyn, NY

(212l3924300

Manhattan, NY

(212) 3924300

MI

Rochester, NY

(716) 424-2700

Syracuse, NY

(315) 4514000

White

(914) 948-7511

Woodbury, NY

(516) 931.1506

NORTH CAROLINA

Charlotte, NC

(70413644770

Greensboro, NC

(919) 292-1556

NORTHDAKOTA

Fargo, ND

(701) 2354221

OHIO

Akron, OH

(216) 733.2244

Cmclnnatr. OH

(513) 745-7151

Cleveland, OH

(216) 459.6057

Columbus, OH

(614) 4865971

Dayton, OH

(513) 2374035

Toledo, OH

(419) 473.9721

8841070

456.7000

Plams,

NY

OKLAHOMA

Oklahoma

Cw.

(405) 848.2811

Tulsa, OK

(918) 437-5934

OREGON

Eugene, OR

(503) 485-2251

Portland, OR

(5031

245-0731

PENNSYLVANIA

Harrrsburg,

PA

(717) 564-8000

Phrladelphla,

PA

(2151

666.8302

Pntsburgh,

PA

(412) 928.4235

Wilkes-Barre, PA

(717) 654-2477

PUERTO RtCO

San Juan, PR

(809) 792-7075

RHODE ISLAND

Prowdence,

RI

(401) 438-6ooa

SOUTH CAROLINA

Columbia, SC

(803) 765.9426

Greenville, SC

(803) 232-2437

SOUTH DAKOTA

SIOUX Falls, SD

(605) 336-0986

TENNESSEE

Memphis,

TN

(901) 345-6222

Nashvrlle.

TN

(6151

385-3400

OK

TEXAS

Dallas, TX

(214) 387-5467

El Paso, TX

(9 15)

533.9924

Houston, TX

(713)

7806603

Lubbock, TX

(806) 762.5202

San Antonio, TX

(512) 3414691

UTAH

Salt Lake GIN. UT

(801) 487-0681

VtRGINIA

Richmond, VA

(804) 285.8211

Rowroke,

VA

(703) 989.5201

Vrginra

Beach,

(804) 461-0263

WASHINGTON

Seattle, WA

(206) 233-2150

Spokane, WA

(509) 534-5022

WEST VIRGINIA

Charleston, WV

(513) 745-7151

Clarksburg,

(3W) 623-6551

WISCONSIN

Appleton, WI

(414) 7334499

Madwn,

WI

(608) 2223400

Milwaukee, WI

(414) 7848260

WYOMING

C&per, WY

(307) 265.9374

VA

WV

HONEYWElL l

ARGENTINA

BUENOS AIRES

AUSTRALIA

WATERLOO, N.S.W.

Adalalde

Brisbane

Canberra

Darwin

Hobart

Melbourne

NeV&ZaStie

Perth

Townsv~ile

AUSTRIA

VIENNA

Graz

Innsbruck

Klagenfurt

LlllZ

BELGIUM

BRUSSELS

Gent

LwgeiGrwegnee

Luxembourg

BRAZIL

SAO PAU LO

RIO de

Jane~ro

Mmneapolls,

Mrnnesota 55408

DENMARK ITALY

COPENHAGEN MILAN

Aarhus

Frederlcla

DOMINICAN REPUBLIC

SANTO DOMINGO

FINLAND

ESPOO

Tampere

FRANCE

BOIS D’ARCY

LYOfl

MarSellle

GERMANY

OFFENEACHlMaln

Dusseldorf

Echterdlngen

Hamburg NETHERLANDS

Mannhelm Schlphol-Centrum

Muenchen

Nuernberg

GREECE

ATHENS

HONG KONG

0

Bologna

F1renze

Padova

ROtW2

Tonno

JAPAN

TOKYO

Hroshlma

Kokura

Nagoya

Osaka

KUWAIT

MEXICO

MEXICO CITY, D.F.

Monterrey,

AMSTERDAMHannow-Langcnhagen

NEW ZEALAND

HUCKLAND

Christchurch

DunedIn

WellIngron

Scarborough.

Ontarro

Nuevo

MIP

Leon

2V9

NORWAY

OSLO

Bergen

sravanger

Tr0m$.0

Trondheim

PUERTO RICO

Sdn

Juan

SAUDI ARABIA

DAMMAM (Dhahran)

SINGAPORE

SOUTH AFRICA

JOHANNESBURG

Cape

Town

Durban

Port Elizabeth

Pretoria

SPAIN

MADRID

Barcelona

Glron

Las Arenas (Bllbao)

SWEDEN

STOCKHOLM

Goteborg

Malmo

Sundsvall

l

Subsidiaries

(Transvall)

and

Afflllates

SWITZERLAND

ZURICH

Base1

Bern

Geneva

YAIWAN

TAIPE;

UNITED ARAB

SHARJAH

UNITED KINGDOM

LONDON

Abetdeen (Scotland)

Belfast (N. Ireland)

Card,ff

Cheadle

Dublin (Ireland)

East Kllbrlde, Glasgow

Erdington, Blrmlngham

Maidenhead,

Sheffield, Yorkshre

Swckton-on-Tees. Cleveland

VENEZUELA

CARACAS

Maracatbo

Puerto

ValenCia

Around the World

EMIRATES

(BRACKNELL)

IS.

Wales)

Hulme,

Berkthrre

Ordaa

Chesrre

(Scorland)

l

Prrnted rn U.S.A.

Loading...

Loading...