Page 1

Residential Flammable Gas Leakage

Detector (RFR200)

Operation Instructions

Thank you for choosing Honeywell gas leakage alarm system. Please

carefully read through the instructions before using this product, and perform

according to the relevant procedures as provided herein to avoid any damage

to this machine or any other incidents incurred by your inappropriate

operation.

The user shall assume any liability arising from or in connection with his

or her failure to comply with the instructions in this manual and part

installation, repair or replacement by unauthorized person.

For the product, its color and style, please refer to the actual product as

standard.

Please keep this manual in a safe place for future reference. If you should

have any doubt or dissatisfaction with our product or service, including

product technology, quality, installation and maintenance, please contact us

immediately so that we can deal with your suggestions in a proper way.

Product profi le•

As the gas detection expert, Honeywell Analytics brings together nearly

200 collective years of expertise in design, manufacture and technology. As

the leader in gas detection and alarm equipment industry in the world, we

apply high-precision detection standards to domestic gas leakage alarm

systems. By integration of powerful catalytic fl ammable sensing technology

and advanced electronic technology, Honeywell is dedicated to providing

multiple protections for both our customers and their properties.

Function and indication chart•

LED

Operation

Normal

Operation

Successful

Test*

Unsuc-

cessful Test

Alarm

Hush

Function

Trouble

Condition

* Alarm relay shall be teseted often 5 seconds of button when normal conduction.

Description

When no gas is present, the green

LED

On demand test result by press the

button. Red LED and Yellow LED will

be blink in order. After then return to

normal mode

On demand test result by press the

button. After then return to normal

mode

When detects gas, it will give the

alarm signal continuously. The red

LED and sounder will annunciate

When gas level is less then alarm

point, return to normal operation.

If required, the audible alarm can be

silenced for 5 minutes by pushing

the button marked “Test”. The red

alarm will continue to fl ash for 5

minutes

If gas is still present after 5 minutes

hush period, the audible alarm will

sound

End of life time(5 years)

Cell health trouble/No cell

Power trouble

EEPROM CRC fail/ Program

code fail

G

RYAlFt

Y

NN

YYY

Y

Y

N

Y

Y

N

Y

Y

N

Y

Y

N

Y

Y

N

Y

Y

N

Y

N

Y

NNN

Relay

De

En

En

En

De

De

En

En

En

En

En

En

De

De

De

De

De

De

De

De

Power LED (green)

Alarm LES (red)

Fault (yellow)

B

u

Timing/Interval

z

z

Always G LED on if

N

power is normal

8 times beep with red

LED fl ash 4 times and

Y

then yellow LED fl ash

4 times

Same as default condition

N

8 times beep with red

Y

LED fl ash 8 times

Red LED fl ash 4 times

N

each time

Same as alarm condition

Y

Y

3 long chirps/min

Y

1 long chirps/min

Y

2 long chirps/min

Y

Continues beep

Service life and warranty period•

1. The optimal service life is fi ve years (since the purchase, please keep

your invoice).

2. The warranty period for free is one year (since the purchase).

3. User must read through this instruction manual carefully and operate

correctly, and Honeywell will repair or replace for free in case the machine

does not work due to any quality issue at the manufacturer’s side.

• Operation Standard: GB15322.2-2003

• Detection Gas :LNG

• Installation instruction

The detector should be installed in the room with gas consumed

equipment, and the alarm shall have a horizontal distance of 3m or less from

the gas consumed equipment. In case natural gas is used, the detector may

be installed at the height with a 30m distance or less from the ceiling.

30cm or less

3m or less

1.2m-1.6m

Detecting natural gas

Check that each part or component is in good condition before

installation, and get prepared the screws and other attachments we’ve

provided in the toolkit.

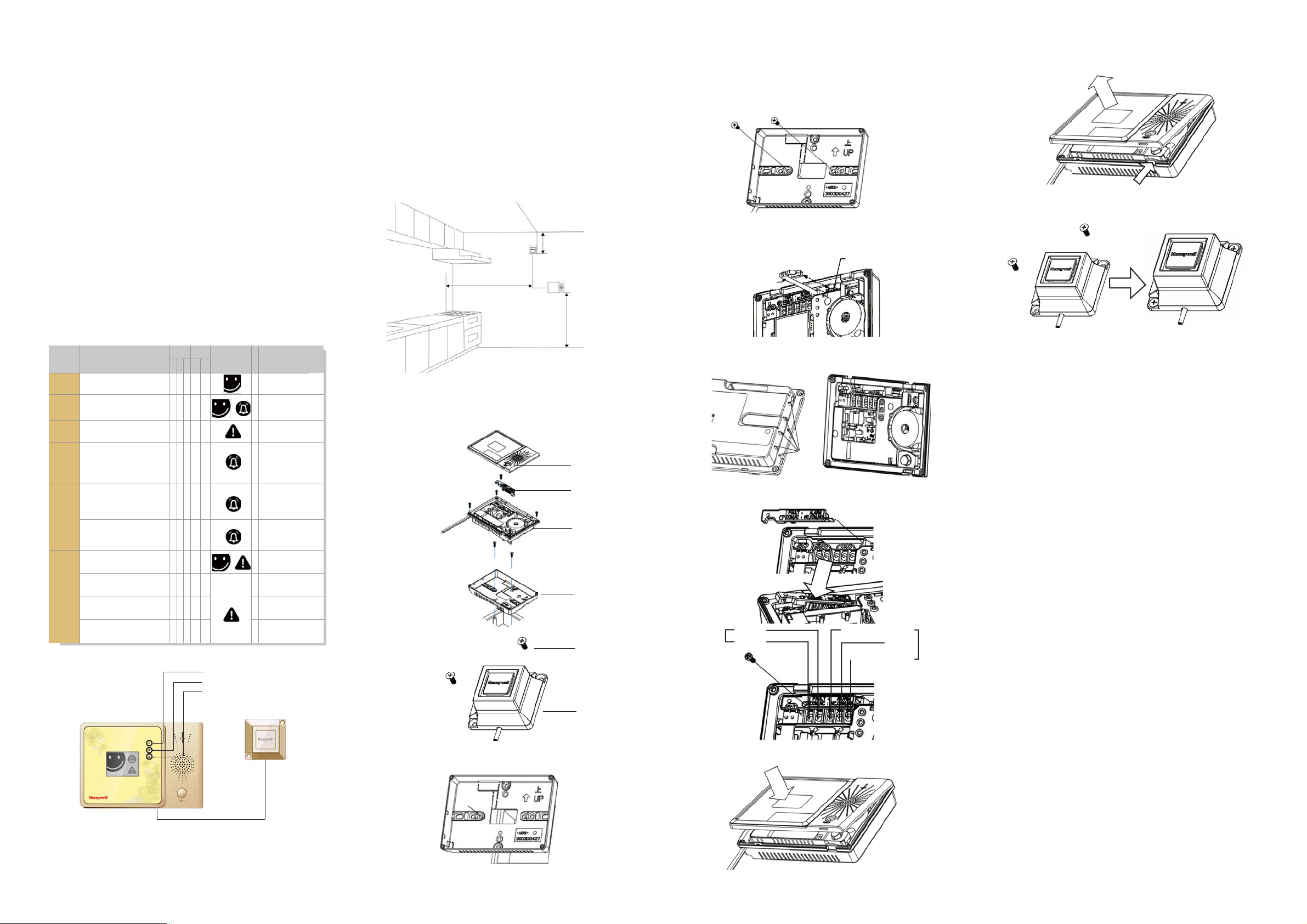

• Part description

Control panel

Front cover assy

Strain relief

Main assy

Adapter

Remote sensor

Screw

Remote sensor

• Procedures for control panel installation

Find an appropriate installation point on the wall.

Fixing the adapter by screw which is offered.

(Must use the machine screw to the outlet box.)

(Must use the tapping screw to the wood wall.)

While installation, ensure the wire is routed out through the reserved hole

before installation. AC wire have to go through the adapter hole. Please

check the direction of adapter and check the arrow and “UP” mark.

Fix the host onto the adapter for mounting with screws.

Flush mounting — in case fl ush mounting is selected, the adapter for

mounting is not necessarily used. You need to dis-connect the AC power wire

and remote sensor wire from main Assy and take off the adapter fi rst.

Remote sensor

connector

Remote sensor

cable

Cut off the strip on the left edge of the host with a knife, and fi xed the

machine body into the groove previously excavated on the wall with screws

(detailed dimensions of the groove: width 134mm~136mm, height 92mm~

93mm).

Cut off

If relay is used for signal output, then remove the wire trunking and fi x it

with screws again after connecting the signal line to the corresponding

connecting terminal.

Fault

NC

NC:Normal close

COMCOM

Alarm

NO:Normal open

Press down the panel onto the host to complete the installation.

To remove the panel, push inward the locking tab and then pull out the

panel towards the opposite side.

• Procedures for remote sensor installation

Fix the sensor onto the ceiling with screws.

• Incorrect mounting position

Places where exhaust, steam and oil smoke from gas appliances may 1.

directly infl uence

Places near to the air inlet, exhaust fan, door and window where 2.

favorable ventilation is ensured

Places which are fenced off by the window curtain, vertical curtain, 3.

cabinet door, ceiling and cross beam, etc.

Places with high temperature and moisture like cooking room and boiler 4.

room, etc.

Places where power supply of the alarm may possibly be switched off5.

Places outdoor or where the temperature is lower than -10 °C or higher 6.

than +55 °C

• Precautions on using

1. Do not switch off the power supply of the alarm, otherwise the alarm may

not work when gas leakage occurs.

2. Do not touch any part of the power supply with wet hand(s) as this could

cause risk of electric shock.

3. Do not remove or retrofi t the alarm.

4. Do not use volatile matters in the vicinity of the alarm, like hair spray,

pesticide, paint, adhesive agent and alcohol, so as to avoid false alarm an

eliminate any infl uence on the service life of the sensitive elements.

5. Do not eject high-concentration gas into the access opening to avoid

performance of the sensor.

6. Frequently check the power LED (green) is always on.

7. Press down the self-test button of the detector once every 6 months to

check it is in normal standby state.

8. In case a fault happens in the alarm, please contact our company or the

local representative offi ce immediately.

9 Never connect the power supply to any signal output terminal.

10. Prevent the product from falling down from a high level during installation

and operation, otherwise the performance of the product may be impaired.

11. Never attempt to replace the remote probe or change the length of its

wire by any unauthorized person.

12. Never clean the alarm with a cleaning agent.

13. Please keep the alarm away from silicon-contained material.

• Our company will not assume any responsibility for

product damage or loss of function caused by the

following reasons:

1. Consumer’s disassembly or intentional damage

2. Force majored like fi re, earthquake, lightening, abnormal voltage, etc.

3. Wrong installation position or failure to switch on power supply of the

detector

4. Expiration of the lifetime

5. Falling down, impact and other faults and damages incurred by the

consumer

6. Other contamination, damages, faults or damages not caused by the

manufacturer

1. Power LED (green): indicates the power system is in normal operation

2. Alarm LED (red): indicates the concentration of combustible gas

leakage reaches the set value

3. Fault LED (yellow): indicates the alarm is in fault condition

Honeywell Trading (Shanghai) Ltd

430 Li Bing Road

Zhangjiang Hi-Tech Park

Shanghai, China

H_RFI Manual_09_V1_AP

Loading...

Loading...