Page 1

Direct Coupled Actuator

APPLICATION

The ML6131 Direct Coupl ed Act uator (DCA) is u sed to cont rol

dampers in applications such as variable air volume (VAV)

terminal units. It is suitable for use with single pole double

throw (spdt) floating thermostats or two-position control

systems.

ML6131

PRODUCT DATA

FEATURES

• Mounts directly on damper shaft.

• 6 lb-in. torque.

• Selectable 45°, 60°, and 90° stroke in either clockwise

(cw) or counterclockwise (ccw) directions.

• 15 second timing model s uitab le for use with pressure

independent VAV systems.

• Magnetic coupling typically provides a maximum of

18 lb-in. stall torque eliminating the need for

mechanical stops or limit switch adjustments.

• Two field-addable auxiliary switches.

• Field-addable auxiliary feedback potentiometer.

• Models available with 0° to 30° minimum position

adjustment in cw or ccw directions.

• Compatible for use with Honeywell W7620 Terminal

Unit Controller.

• Can be used with the Commercial Zone Damper in the

W7600 Commercial Zone System.

• Manual declutch on some models.

® U.S. Registered Trademark

Copyright © 2000 Honeywell Inc. • All Rights Reserved

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 3

Operation .......................................................................... 8

Checkout .......................................................................... 8

®

63- 2498-2

Page 2

ML6131 DIRECT COUPLED ACTUATOR

SPECIFICATIONS

Models:

ML6131B: 6 lb-in. torque, selectable 45°, 60°, and 90° stroke

in both cw and ccw directions. 15 second timing, spdt

Floating Series 60, includes auxiliary potentiometer drive

for use with field-adda ble feedback potentiometer. Includes

minimum position adjustment setscrews for cw or ccw

operation. Includes 4074ENJ Bag Assembly.

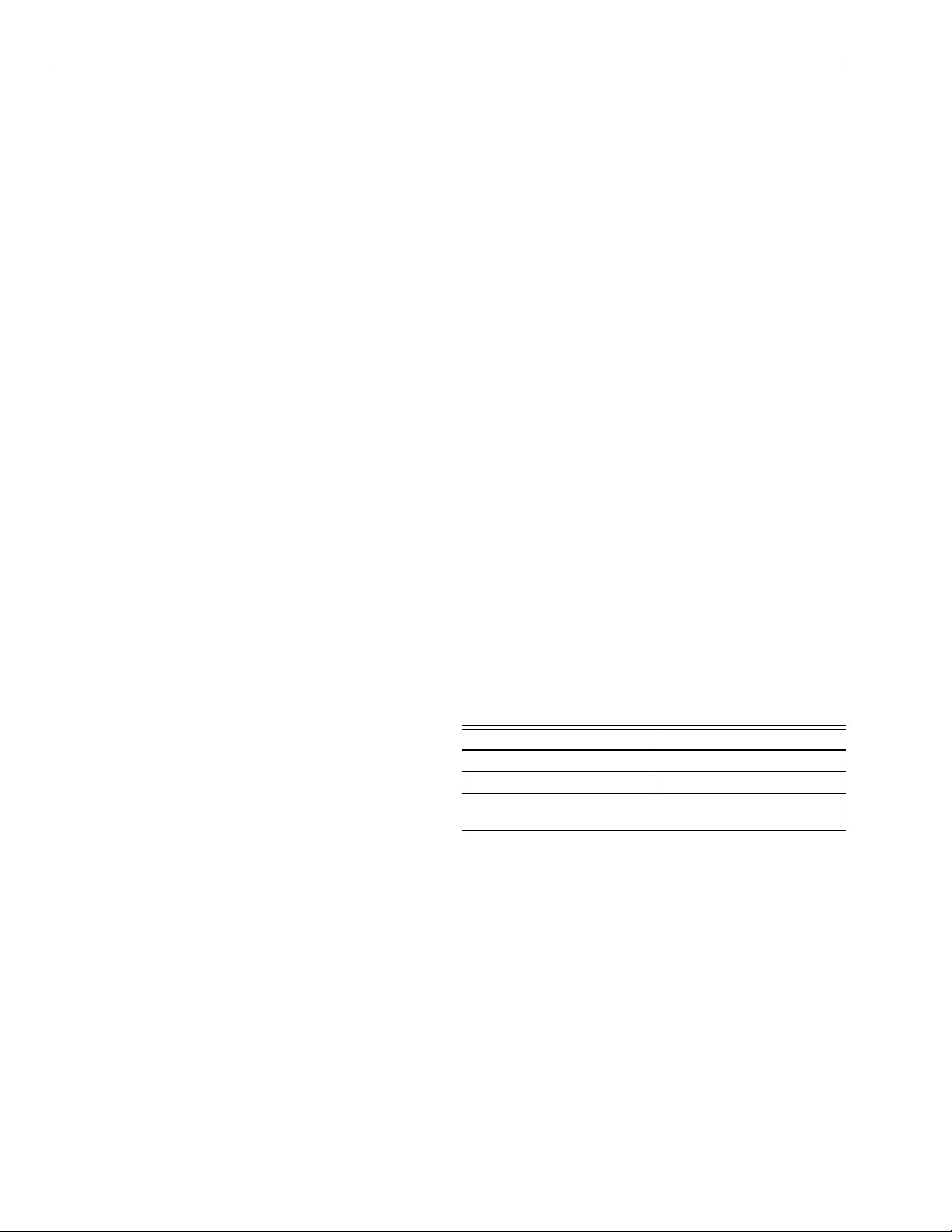

Dimensions:

Electrical Ratings:

Power Consumption (Maximum), at 24 Vac:

2.4 VA.

Ambient Ratings:

Operating Temperature: 32°F to 130°F (0°C to 54°C).

Shipping and Storage: -20°F to 120°F (-29°C to 49°C).

Humidity: 5% to 95% RH noncondensing.

Torque Ratings:

Minimum Life Cycle Rating:

Repositions:

Actuator Timings (At 50 Hz Nominal):

90°-18 sec.

60°-12 sec.

45°-9 sec.

Actuator Timings (At 60 Hz Nominal):

90°-15 sec.

60°-10 sec.

45°-7.5 sec.

See Fig. 1.

Input Voltage: 24 Vac ±20%, 50/60 Hz.

2.2W, 0.095A,

See Table 1.

400,000.

1.5 million.

Feedback Potentiometer Ratings (ML6131B):

200976A,C Electrical Rating: 24 Vac, 50/60 Hz, 2.25 watts.

Resistance Output (Resistance Linear as Measured

Between Terminal R-B):

0 ohms (at 0 degree, cw stroke).

250 ohms (at 45 degree, cw stroke).

333 ohms (at 60 degree, cw stroke).

500 ohms (at 90 degree, cw stroke).

Auxiliary Switch Ratings:

not simultaneous.

Pilot Duty:

Switch Differential:

Approvals:

Underwriters Laboratories Inc. Component Recognized:

File No. E4436; Guide No. XAPX2.

CSA Certified (includes auxiliary switch).

Accessories:

201052A One Auxiliary Switch.

201052B Two Auxiliary Switch.

201052C Three Auxiliary Switch.

200976A 0 to 500 ohm Auxiliary Potentiometer.

200976C 0 to 2000 ohm Auxiliary Potentiometer.

4074ENJ Bag Assembly—includes stop pin, shaft adapter,

and minimum position screw.

4074ENY Bag Assembly—includes stop pin and shaft

adapter.

4074EVK Short Shaft Extensi on Kit—t o a dap t a ctu ato r ou tpu t

hub to short VAV damper shafts.

7640QW Metal Enclosure—for running conduit to actuator.

40 VA, 24 Vac.

Electrically selective NO or NC,

3 angular degrees maximum.

Damper Shaft Mounting:

• Suitable for mounting onto 3/8 to 1/2 in. square or round

damper shafts secured by two 1/4 in. 28 NF Allen screws.

• Minimum damper shaft length 1-3/4 in. (45 mm).

• Actuator may be mounted with actuator shaft in any

position.

Running 6 lb-in. (0.7 N•m)

Breakaway 6 lb-in. (0.7 N•m)

Stall (Typical) 7.5 lb-in. (0.8 N•m) minimum

Table 1. Torque Ratings.

Torque

18 lb-in. (2.0 N•m) maximum

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1.

Your local Home and Building Control Sales Office (check white pages of your phone directory).

2.

Home and Building Control Customer Logistics

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 155 Gordon Baker Road, North York, Ontario M2H 3N7.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2498—2 2

Page 3

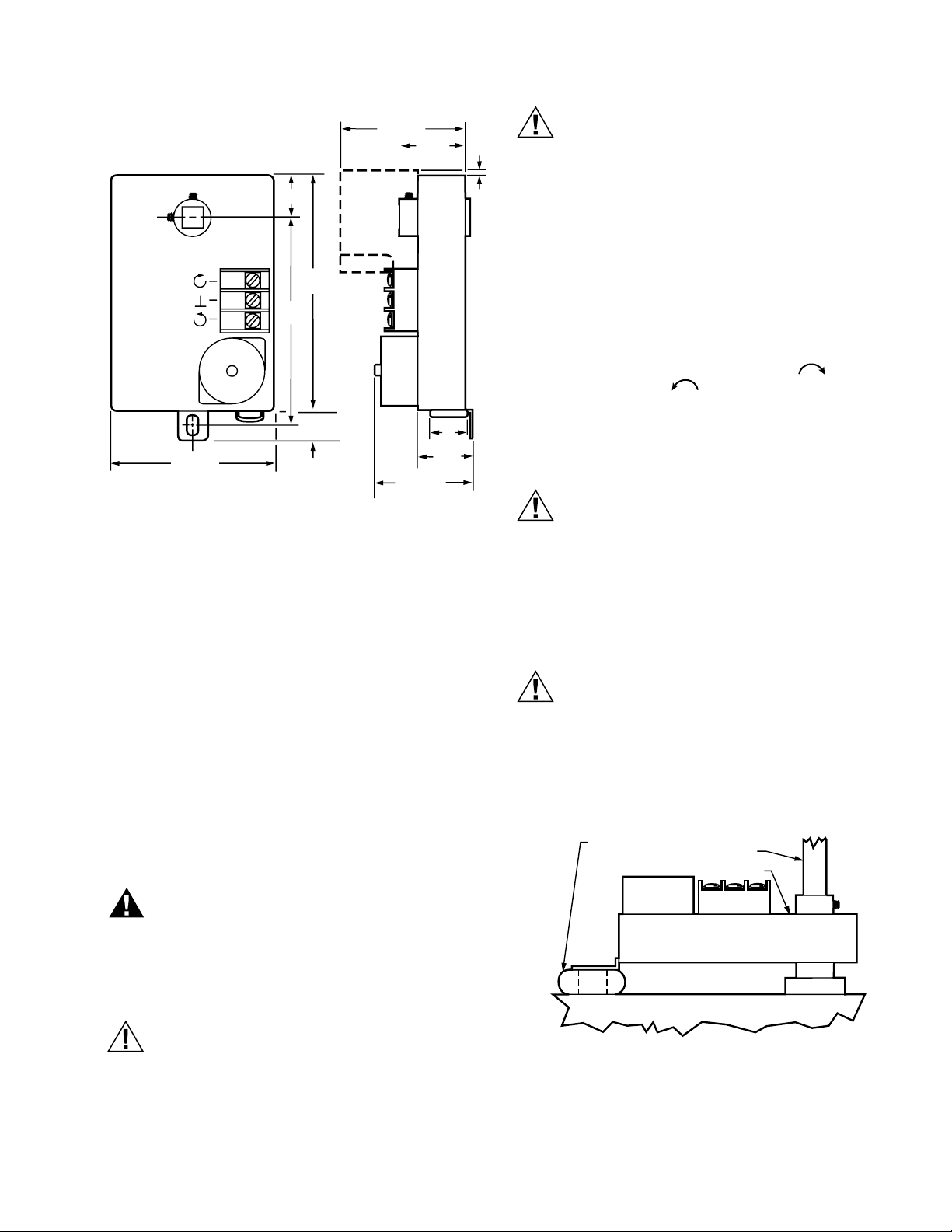

CAUTION

CAUTION

CAUTION

3-3/8 (86)

ADD SPACER BETWEEN

DAMPER BOX AND TAB

DAMPER

SHAFT

ML6131

VAV BOX HOUSING

M4449

CW

COM

CCW

1 (25)

4-1/4

(108)

4-7/8

(123)

11/16

(18)

2-7/8 (73)

OPTIONAL

AUXILIARY

SWITCH

1-11/16

(42)

2-1/2 (64)

7/8

(22)

1-5/16

(33)

M18016

ML6131 DIRECT COUPLED ACTUATOR

Actuator Damage Hazard.

Deteriorating vapors and acid fumes can damage

the actuator metal parts.

1/8

(3)

Install actuator in areas free of acid fumes and

deteriorating vapors.

Location

Choose a location for the actuator that allows enough

clearance for mounting accessories and for servicing.

Mounting

These actuators are designed to open a damper or valve by

driving the shaft in either the clockwise (cw) or

counterclockwise (ccw) direction. The actuator has a

mounting tab on the botto m that sec ures it to a dampe r box or

valve linkage. When mounted correctly, this tab allows the

actuator to float without rota ting relative to the sh aft. The tab is

sized for 1/4 in. self-tapping sheet metal screws (not

included).

Fig. 1. Approximate dimensions of ML6131

Direct Coupled Actuator in in. (mm).

INSTALLATION

When Installing this Product...

1.

Read these instructio ns c aref ull y. Failure to follow them

could damage the product or cause a hazardous

condition.

2.

Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3.

Installer must be a trained, experienced service

technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

WARNING

Explosion Hazard.

A spark from the actu ator or attached accessori es

can result in serious injury or death.

Install the actuator in areas free of escaping gas and

other explosive vapors.

Equipment Damage Hazard.

Tightly securing mounting tab to damper housing

can damage actuator.

Once mounted, the actuator must be allowed to float;

do not fully tighten the screw.

These actuators are ship ped in the fully cl ockwise 90° pos ition

as viewed from the end of the damper shaft.

Equipment Damage Hazard.

Mounting actuator unevenly with damper housing

can damage actuator.

Mount actuator flush with damper housing or add

spacer between mounting tab and damper box

housing (see Fig. 2).

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Actuators with auxiliary switches can have more than

one disconnect.

Fig. 2. Mounting actuator to VAV box when

actuator is not flush with box.

3 63-2498—2

Page 4

ML6131 DIRECT COUPLED ACTUATOR

Preparation

Before mounting the actuator onto the shaft, determine the

following:

1.

Size of the shaft (3/8 in. to 1/2 in.).

2.

Direction the shaft rotates to open the device (cw or

ccw). See Fig. 3.

3.

Degrees of actuator stro ke for openin g device (4 5°, 60°,

or 90°).

If the shaft is 3/8 i n. roun d or square , use pa rt num ber 20 1391

Shaft Adapter provided inside the bag as sem bl y sh ipp ed with

the actuator. Place the adapter opposite the setscrews

(see Fig. 4).

MANUAL

DECLUTCH

LEVER

DIRECT COUPLED ACTUATOR

ML6131

ML6131

M17611

TYPE A DAMPER

COOLING

AIR FLOW

CW TO OPEN, CCW TO CLOSE

TYPE B DAMPER

COOLING

AIR FLOW

CCW TO OPEN, CW TO CLOSE

Fig. 3. Determining direction damper

shaft rotates when opening.

SHAFT ADAPTER

Fig. 4. Using shaft adapter for 3/8 in. shafts.

Manual Operation (Declutch)

M2067A

M2064

Fig. 5. Location of manual declutch lever.

Installation

After determining the direction of the shaft rotation (cw or

ccw), install the device. For valve linkage mounting, refer to

the instructions shipped with the linkage. For damper

mounting, proceed as follows :

1.

Place the actuator onto the damper shaft .

CAUTION

Equipment Damage Hazard.

Improper range stop selection can damage

light-duty dampers.

Be sure to select the proper range stop.

2.

If the angle of the damper opening is either 45° or 60°,

close the actuator using the manual declutch:

a. Disengage the hub using the declutch lever; see

Manual Operation (Declutch) section.

b. Rotate the hub until the actuator gear train passes

the proper 45° or 60° setting. (Do not insert the pin

until after the actuator passes this point.)

c. Release the declutch lever.

NOTE: Dampers with 90° stroke do not require the

3.

Insert the range stop pin into the appropriate (cw or

ccw) 45° or 60° slot. The range stop pin is clipped into

its final position only after the pin passes through both

actuator plates (see Fig. 6). The range stop pin should

snap into position and not be removable manually

(see Fig. 7).

range stop pin.

IMPORTANT

CAUTION

Do not fully tighten the mounting screw; the actuator

must be allowed to float.

Personal Injury and Product Damage Hazard.

Do not use manual declutch without supporting

the load.

Support load independent of actuator immediately

prior to and while using manual declutch lever.

4.

With the actuator placed in its final position, secure the

mounting tab to the damper box with a sheet metal

screw.

5.

Position the damper in the open position and securely

tighten the Allen screws into the damper shaft.

Manual declutch capability is available on some actuators.

Use the manual declutch lev er to manually adjust the actua tor

setting. Fig. 5 show s the l ocation of the manual declutc h lever.

To operate, push the lever in the direction of the arrow on the

lever cover.

63-2498—24

Page 5

ML6131 DIRECT COUPLED ACTUATOR

CAUTION

1.

Determine the direction of the desired closing rotation.

2.

RANGE STOP PIN

Move the actuator to the position fully opposite the

desired closing rotatio n (if cw clo sing rotation is desire d,

move the actuator to the full ccw position).

3.

Determine the correct hole for the sets crew usin g Fig. 8

ACTUATOR PLATES

60

and the results of step 1.

THIS SETSCREW

CORRESPONDS WITH

CLOSING IN THE

CW DIRECTION

THIS SETSCREW

CORRESPONDS WITH

CLOSING IN THE

CCW DIRECTION

45

60

45

CW

COM

CCW

M10246A

Fig. 6. Range stop pin properly inserted.

SCREWDRIVER

M2065

Fig. 7. Lifting a range stop pin out of its slot.

Minimum Position Setscrew

Certain ML6131 models are equipped with two tapped holes

located in the plas tic h ous in g at the top of the actuator. These

holes can be used with the minimum position setscrew and

locknut inside the 4074ENJ Bag Assembly (see Fig. 6). The

setscrew provides for a 0° to 30° minimum position

adjustment.

NOTE: Before starting operation, note that the 1/4 in.

minimum position setscrew limits closing motion,

while the range stop pin limits opening motion.

60

45

60

45

Fig. 8. Setscrew location for ML6131.

Equipment Damage Hazard.

Improper hub positioning or hole selection can

permanently damage the device.

Avoid backdriving the actuator with the setscrew.

4.

Remove the red cap from the desired hole. Leave the

other cap in position. The caps ensure that dust and

other impurities do not enter the gear train through

unused holes.

5.

Thread the locknut fully onto the 1/4 in. setscrew.

6.

Insert the setscrew into the desired hole, turning

clockwise until resistance is encountered or the locknut

contacts the housing.

7.

If resistance is met be fore the setscrew is fully inserted ,

stop and review the initial setup procedures as detailed

in steps 1 through 3.

8.

Determine the angle of minimum position required for

the application. With the setscrew fully inserted, the

minimum position is 30 °. W ith the s etscre w fully out, the

minimum position is 0°.

9.

Using the conversion of approximately 1.7 angular

degrees of shaft rotation per turn of the setscrew, back

the screw out of the housing and stop slightly short of

the calculated position. This allows the setscrew to be

set accurately while taking air flow measurements.

IMPORTANT

After initiating step 10, the setscrew cannot be

turned into the housing without returning the actuato r

to the fully open position (as determined in step 1).

The actuator follows the setscrew without damaging

the housing only when backed out of the housing

(turned ccw).

M10247

5 63-2498—2

Page 6

ML6131 DIRECT COUPLED ACTUATOR

10.

Rotate the actuator to minimum position using the

manual declutch; see Manual Operation (Declutch)

section.

11.

With the actuator at minimum position, adjust the

position more accurately using air flow measurements.

IMPORTANT

— After each adjustment, ensure the actuator is

completely stopped before proceeding with the next

adjustment.

— To reduce the minimum position, turn out the

setscrew (ccw). The actuator then drives toward the

closed position.

— Turning the setscrew in (cw) damages the actuator

housing.

— If the device is too far closed, return to step 1.

12.

When proper air flow is achieved, loosen the locknut

from the setscrew until it contac ts the actua tor hou sing,

then turn it an additional 1/8 turn to lock the setscrew in

place.

IMPORTANT

Run an entire check of the operation after complet ing

this procedure.

Wiring

The 201052A, B and C Auxiliary Switches are field-addable.

For mounting instructions, see form 63-22 18, prov id ed with

the device.

IMPORTANT

When operating an ML6131 from a two-position

controller, a 201052B Auxiliary Switch is required for

proper operation. See Fig. 10.

NOTE: See Fig. 11 for the 201052B Auxiliary Switch wiring.

2

EXTERNAL

SWITCH

1

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

AUXILIARY SWITCHES ARE REQUIRED TO TURN

2

OFF THE MOTOR AT EACH END OF THE STROKE.

T87F

W

Y

R

R8222

ML6131

RED COM

BLUE CW

WHITE CCW

M17613

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Actuators with auxiliary switches can have more than

one disconnect.

All wiring must comply with local electrical codes, ordinances

and regulations. Voltage and frequency of the transformer

used with the actuator must correspond with the

characteristics of both the power supply and the actuator.

Screw terminals are provided for easy hookup. See Fig. 9 for

typical wiring.

Auxiliary Switches

The 201052A, B or C Auxiliary Switch is used in conjunction

with the actuator. It allows for control of equipment ext erna l to

the actuator (for example, electric reheat coils and fan) at an

adjustable point in the stroke (0° to 90°) of the actuator.

Fig. 9. ML6131 used with T87F in heating-only

or cooling-only application.

2

3

ML6131

RED COM

BLUE CW

WHITE CCW

L1

(HOT)

L2

1

4

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

SET SWITCH TO CLOSE WHEN STROKE REACHES FULL CW POSITION.

2

3

SET SWITCH TO CLOSE WHEN STROKE REACHES FULL CCW POSITION.

ON-OFF CONTROL REQUIRES AN R8222 SPDT RELAY IN PLACE OF THE

4

SPDT CONTROL.

SPDT

CONTROL

ON/OFF

CONTROL

201052B

Fig. 10. 201052B Auxiliary Switch wiring.

M17612

63-2498—26

Page 7

ML6131 DIRECT COUPLED ACTUATOR

Auxiliary Potentiometers

The 200976 Auxiliary Potentiometer mounts on the face of

certain ML6131A actuators as shown in Fig. 11. The

potentiometer shaft has a slipping collar, which means that if

one of the two limits of the potentiometer is exceeded, the

collar will continue to rotate, causing no damage to the

potentiometer itself. To mount the potentiometer on the

actuator:

1.

Turn the potentiometer to align the shaft key with the

slot in the potentiometer drive.

2.

Tilt the potentiometer slightly so the key faces down

toward the slot.

3.

Insert the potentiom eter int o the sl ot, and p ush do wn so

the potentiometer is flush with the actuator body and the

bracket is aligned over the screw hole.

4.

Insert the screw provided into the hole and fasten

securely.

IMPORTANT

To Calibrate the 200976A,C:

IMPORTANT

Failure to follow the calibrati on procedures can resu lt

in improper resistance values at desired stroke.

Remove the range stop pins and minimum position

setscrews prior to calibration.

1.

Drive the actuator fully closed (0°) to fully open (90°)

and back again to th e fully cl osed posi tion. This must be

done to receive the correct resistance readings at the

appropriate degree of stroke.

2.

Check the resistance values of the potentiometer with

an ohmmeter at intervals in the stroke while referring to

the table in Fig. 11 and resistance information provided

in the Specifications section.

3.

Replace the range stop pins and/or the minimum

position setscrews using the appropriate procedures.

MOTOR

POSITION

FULLY CW

24V (COM-CW)

FULLY CCW

24V (COM-CCW)

MOTOR

ROTATION

CCW

CW

AUXILIARY POTENTIOMETER

R

W

RB

RESISTANCE

500 OR

2000 OHMS

0 OHMS

DECREASE

INCREASE

45

RW

RESISTANCE

0 OHMS

500 OR

2000 OHMS

AUXILIARY POTENTIOMETER LEADS

RW OHMS RB OHMS

INCREASE

DECREASE

60

45

B

60

CW

COM

CCW

FIELD-ADDABLE AUXILIARY POTENTIOMETER

M10251B

Fig. 11. ML6131 with field-addable potentiometer.

7 63-2498—2

Page 8

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

ML6131 DIRECT COUPLED ACTUATOR

OPERATION

VAV Systems

VAV systems control the temperature within a space by

varying the volume of supply air. Air is delivered to the space

at a fixed temperature. The volume of supply air is controlled

by the space thermostat modulating the supply air damper.

When full heating a nd coolin g flexibi lity is requir ed in a zon e, it

is handled by tempe rature a ir system, o r with reh eat capab ility

in the air terminal units. As individual zones shut down, the

total air flow in the sys tem is regu lat ed b y a c ent ral d uc t sta t ic

pressure controller. The fan system is sized to handle an

average peak load, not the sum of the individual peaks. As

each zone peaks at a different time of day, extra air is

borrowed from the off-peak zones. This transfer of air from

low-load to high-load zo nes occurs only in true VAV systems.

In pressure independent systems, individual zone airflow

sensors are used to m aintain t he zone air fl ow ra te regard less

of fluctuation in the total system pressure.

Pressure independent systems, when used with controllers

such as the W7620, can react faster to changes in air flow

demand. Therefore, these systems can use the faster

15 second ML6131 models.

Parallel Actuators

IMPORTANT

Over time, paralle l-d riv ing actuators can bec ome o ut

of sync with each other. Normally, driving all

actuators to the fully-open or fully-closed position

puts them back in sync.

CHECKOUT

To check out the ML6131, determine the direction the damper

shaft moves to open the damper (cw or ccw). See Fig. 3:

1.

Place 24 Vac across the appropriate COM and CW or

COM and CCW terminals to energize the actuator. The

ML6131 should begin to open the damper.

2.

If the actuator does not run, switch the 24 Vac across

the opposite COM and CW or CO M and CCW termina ls

to determine if the damper will begin to close.

3.

If the actuator does not run in either direction, replace

the ML6131.

In the event the ML6131 is used with a spdt floating wall

thermostat (pressure dependent systems):

1.

Adjust the setpoint of the thermostat to call for cooling.

2.

Observe the operation of the actuator; if the device is

closed, it should begi n to open.

3.

If not, adjust the setpoint of the thermostat higher to

determine if the wiring is correct.

4.

If no movement is observed, check for the presence of

24 volts.

5.

If using the T641 Thermostat, check that 24 volts are

present between terminals C and Y during a call for

cooling. With proper wiring and 24 volts present, the

actuator should operate correctly.

6.

If not, replace the actuator.

NOTE: When the ML6131 is used with electronic

control systems such as the W7620, overri de

the control system by programming the

controller to open/close the zone dam per as

appropriate.

Using Fig. 9, paral lel the C W , C OM and C CW terminal s. Make

certain the total connected load does not exceed the current

capacity of the controller or thermostat.

Home and Building Control Home and Building Control

Honeywell Inc. Honeywell Limited-Honeywell Limi tée

Honeywell Plaza 155 Gordon Baker Road

P.O. Box 524 North York, Ontario

Minneapolis, MN 55408-0524 M2H 3N7

63-2498—2 B.B. Rev. 6-00 www.honeywell.com

Loading...

Loading...