Page 1

MetroSelect®

Area Imaging Supplemental

Configuration Guide

Page 2

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in

specifications and other information contained in this document without prior

notice, and the reader should in all cases consult HII to determine whether any

such changes have been made. The information in this publication does not

represent a commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained

herein: nor for incidental or consequential damages resulting from the furnishing,

performance, or use of this manual.

This document contains propriety information that is protected by copyright.

All rights reserved. No part of this document may be photocopied, reproduced,

or translated into another language without the prior written consent of HII.

© 2009 Honeywell International Inc. All rights reserved.

Web Address: www.honeywellaidc.com

Trademarks

Omniplanar, MetroSet2, Metrologic, MetroSelect, RangeGate, Genesis,

CodeSelect, and Focus are trademarks or registered trademarks of Metrologic

Instruments, Inc. or Honeywell International Inc.

Microsoft and Windows are trademarks or registered trademarks of Microsoft

Corporation.

IBM is a trademark of International Business Machines Corporation.

The Bluetooth word mark is owned by the Bluetooth SIG, Inc. and any use of

such marks by Metrologic Instruments, Inc. or Honeywell International Inc. is

under license.

Other product names mentioned in this manual may be trademarks or

registered trademarks of their respective companies and are the property of their

respective owners.

Page 3

Table of Contents

Imager Operation

Presentation and Trigger Modes

In-Stand......................................................................................................... 1

Out-of-Stand.................................................................................................. 2

Out-of-Stand / In-Stand Mode Match............................................................. 2

Pass-Through Settings (MS7580 Only)......................................................... 5

Omnidirectional and/or Linear Imager Modes................................................... 6

Aiming and Illumination .................................................................................... 8

Data Output .................................................................................................... 10

Character Suppression................................................................................... 11

Code Bytes 0 – 9............................................................................................ 12

Same Symbol Timeouts ................................................................................. 13

LED Options ................................................................................................... 13

Imager Operation – MS1633

Power Save Modes ........................................................................................ 15

RangeGate Mode ........................................................................................... 16

Firmware Version and Address ...................................................................... 17

Inventory Mode............................................................................................... 18

Code Types and Decode Rules

Data Matrix ..................................................................................................... 23

QR Code ........................................................................................................ 26

MaxiCode ....................................................................................................... 26

Aztec .............................................................................................................. 27

Postal ............................................................................................................. 29

Codablock Options ......................................................................................... 32

iii

Page 4

PDF Options................................................................................................... 32

RS232

Software Handshaking ................................................................................... 33

Multifunctional USB/IBM Interface.................................................................. 33

Interfaces

Additional Interfaces....................................................................................... 35

MS7580 Genesis Specific .............................................................................. 37

Enter/Exit Configuration Mode ............................................................39

Contact Information ..............................................................................41

iv

Page 5

Imager Operation

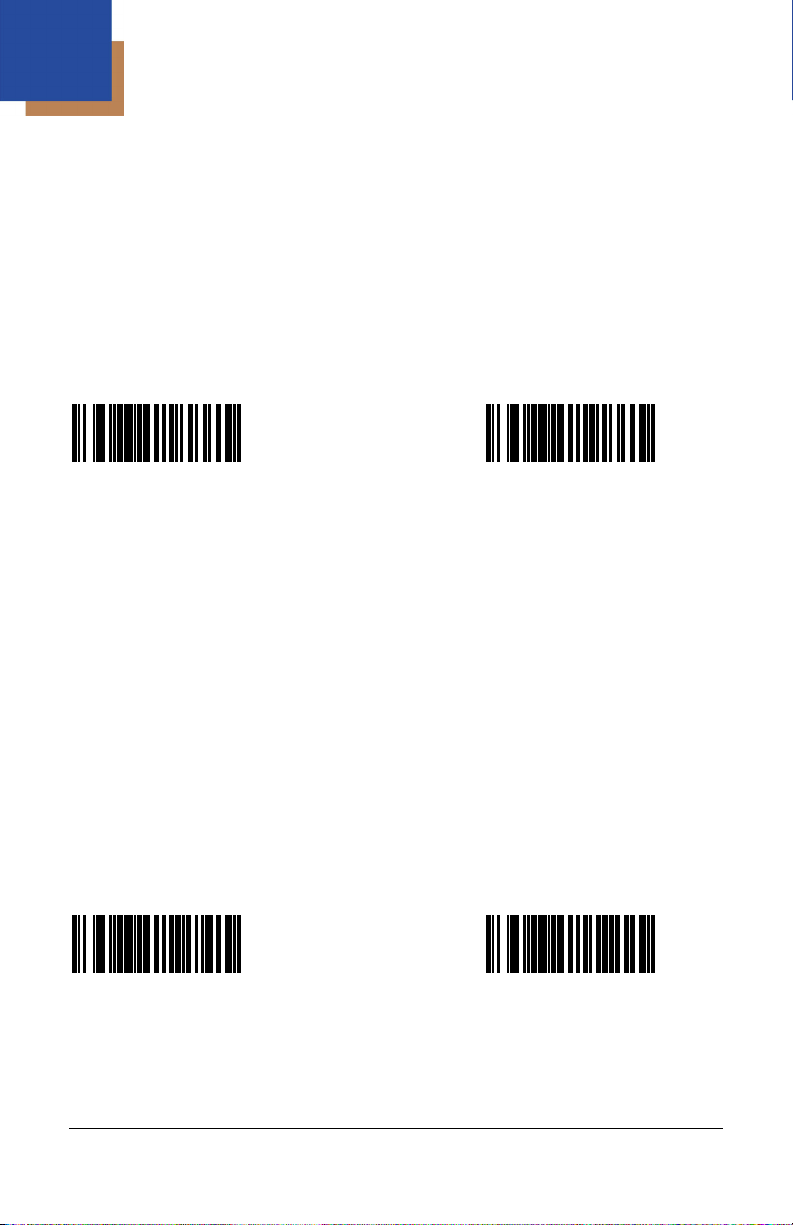

Presentation and Trigger† Modes

There are four configurable modes for scanning: the presentation mode,

the multi-try trigger mode, the continuous trigger mode, and the single-trigger

mode. These modes can be configured separately for in-stand and out-of-stand

imager operation

In-Stand‡

‡

.

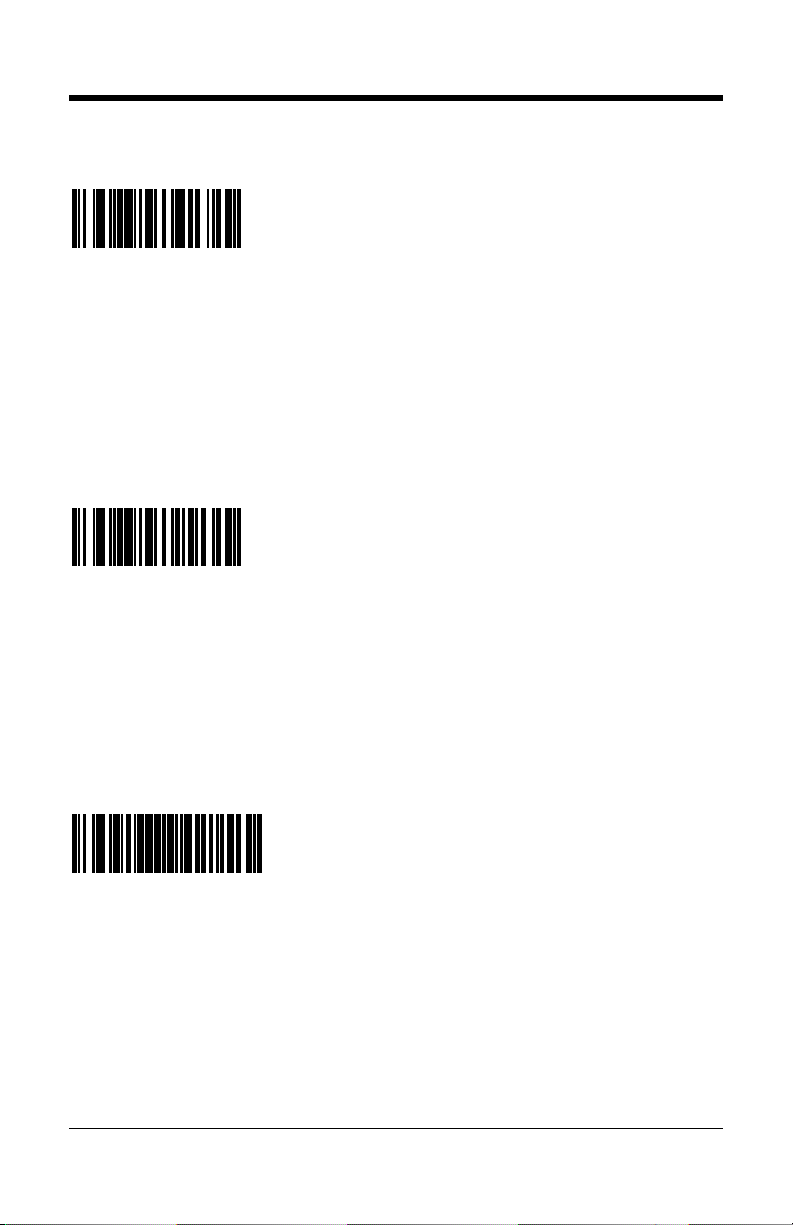

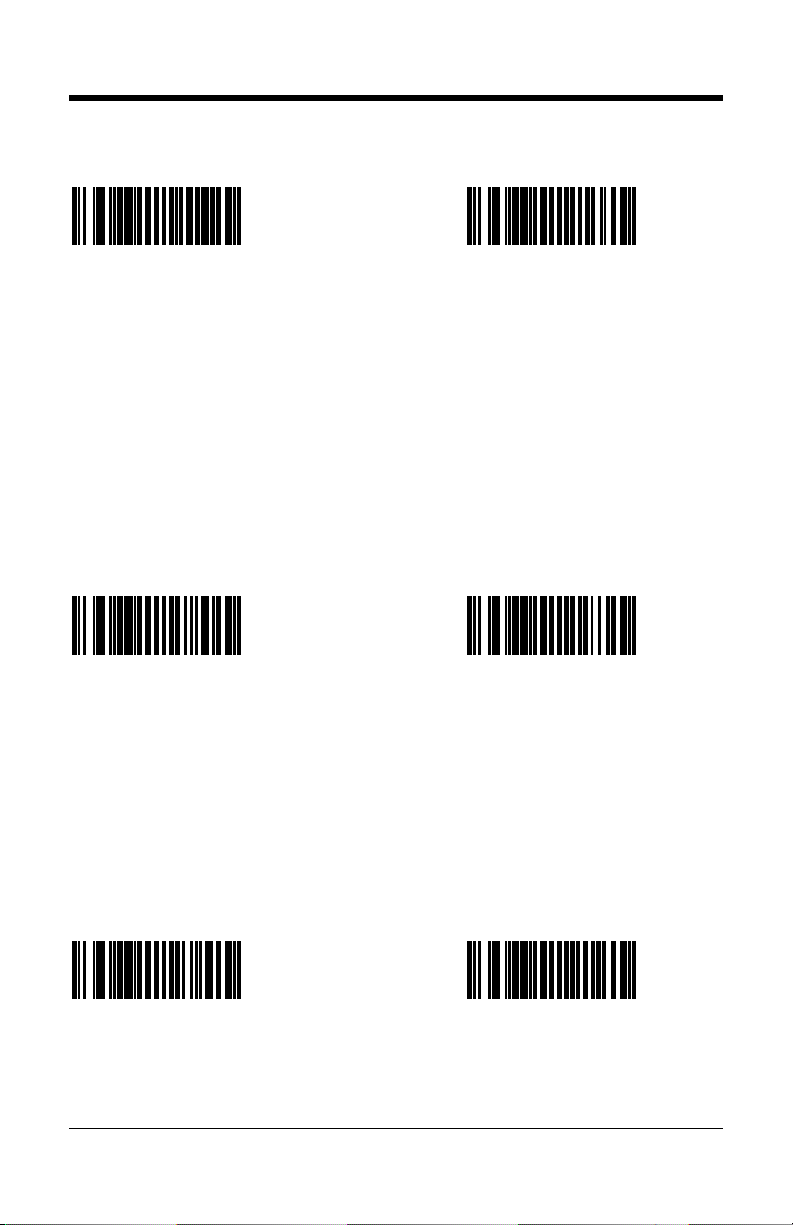

* Presentation Mode

In-Stand

³420204

Continuous Trigger Mode

In-Stand

Multi-Try Trigger Mode

In-Stand

³420224

Single Trigger Mode

In-Stand

³420254

³420244

* Factory default configuration.

†

The term trigger and button are synonymous.

In-Stand and Out-of-Stand references are not applicable for all products.

‡

1

Page 6

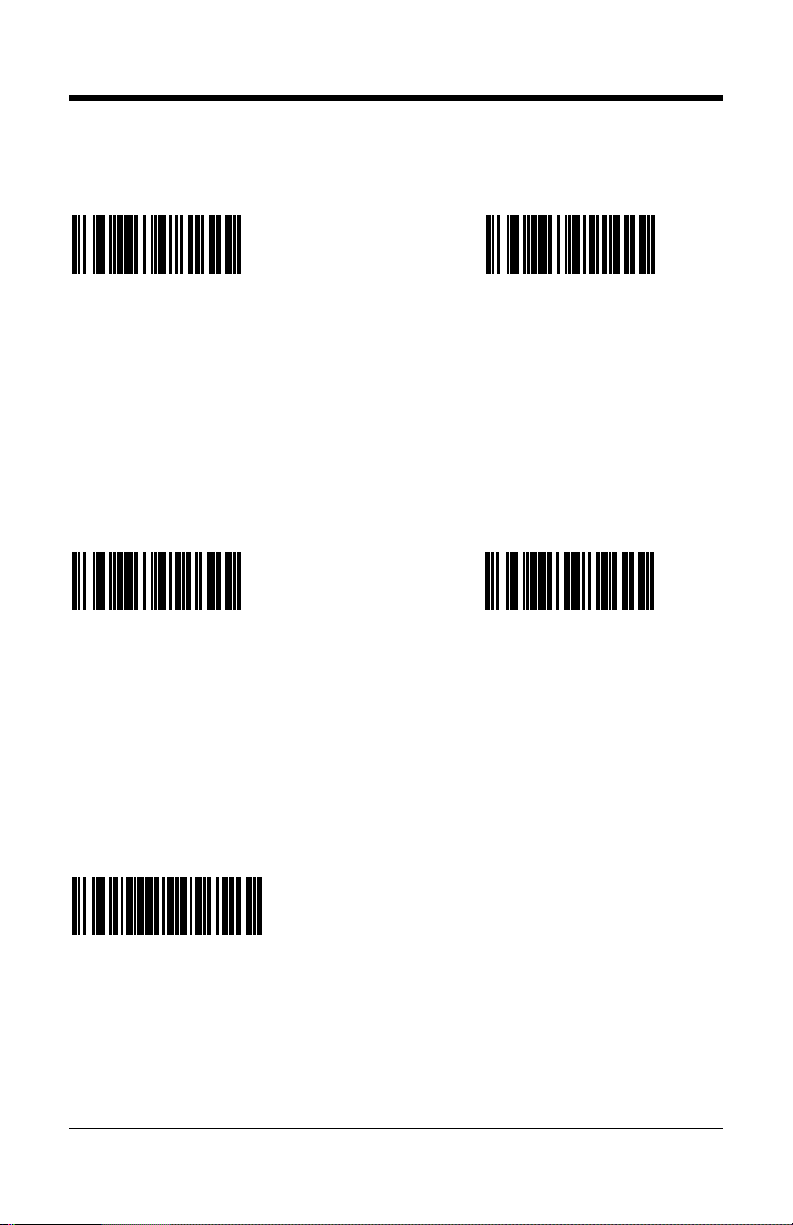

Out-of-Stand‡

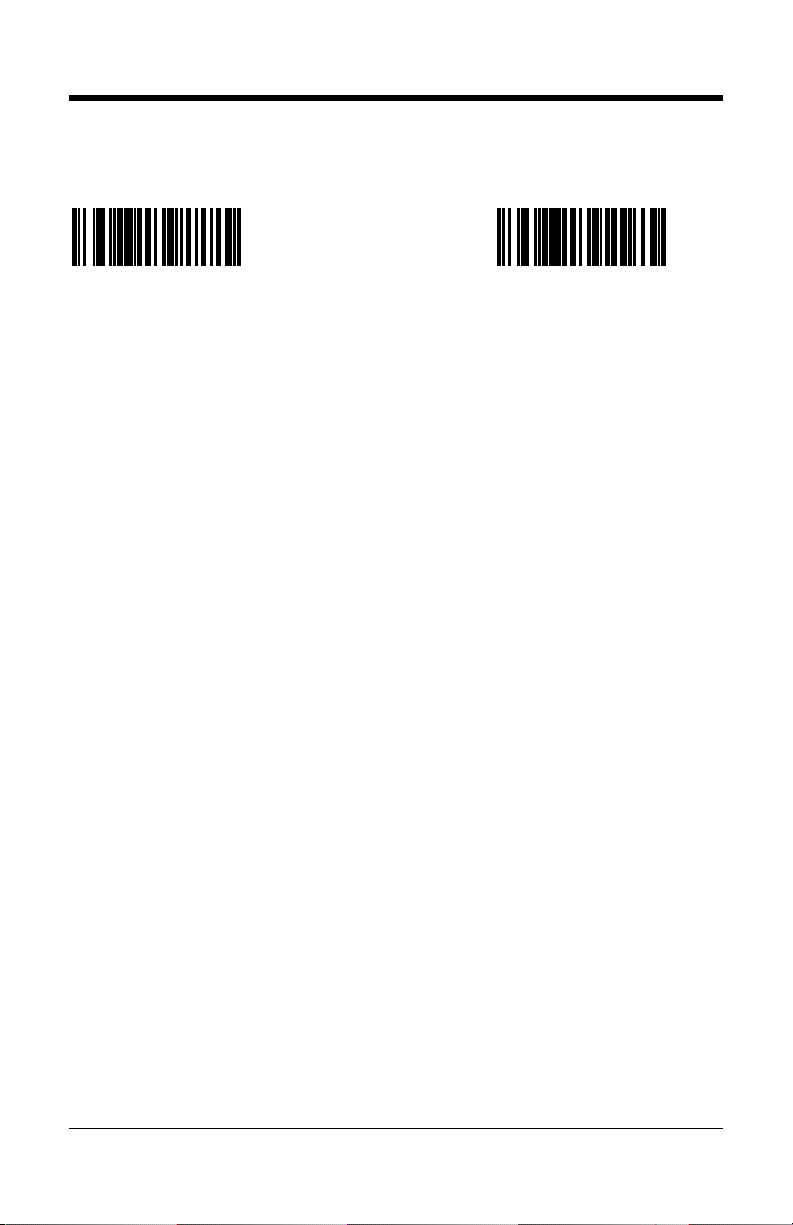

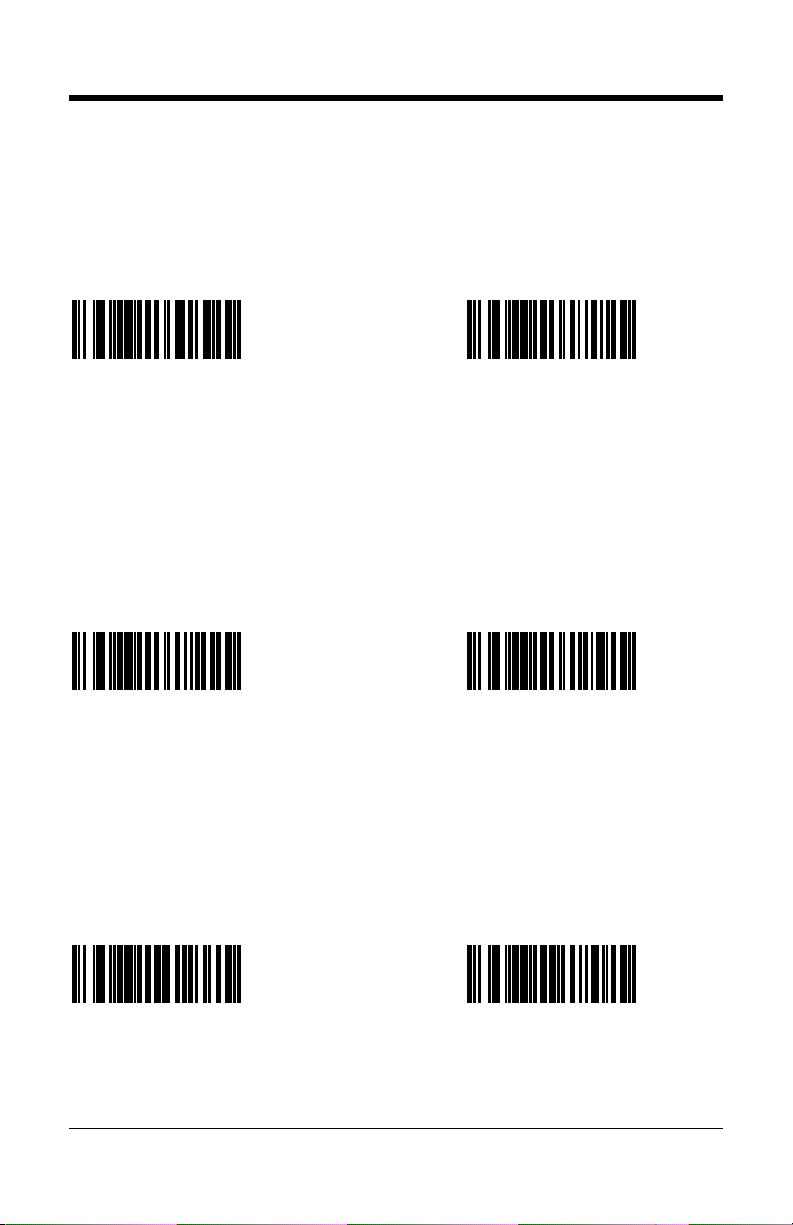

Presentation Mode

Out-of-Stand

* Multi-Try Trigger Mode

Out-of-Stand

³418304

Continuous Trigger Mode

Out-of-Stand

³418354

In-Stand/Out-of-Stand Mode Match

Set In-Stand Mode to Match

Out-of-Stand Mode

³418324

Single Trigger Mode

Out-of-Stand

³418344

³4202154

* Factory default configuration for the MS1690, MS1890, and the MS1633.

Factory default configuration for the IS1650.

In-Stand and Out-of-Stand references are not applicable for all products.

‡

2

Page 7

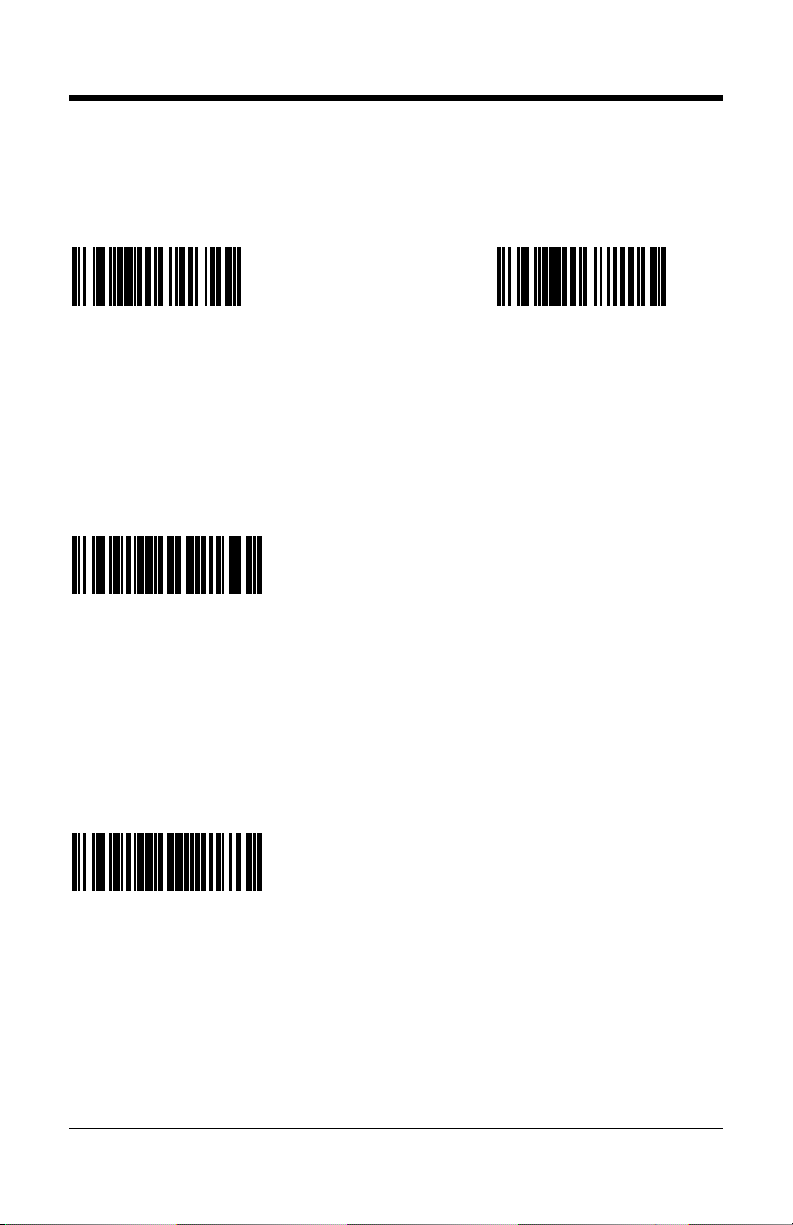

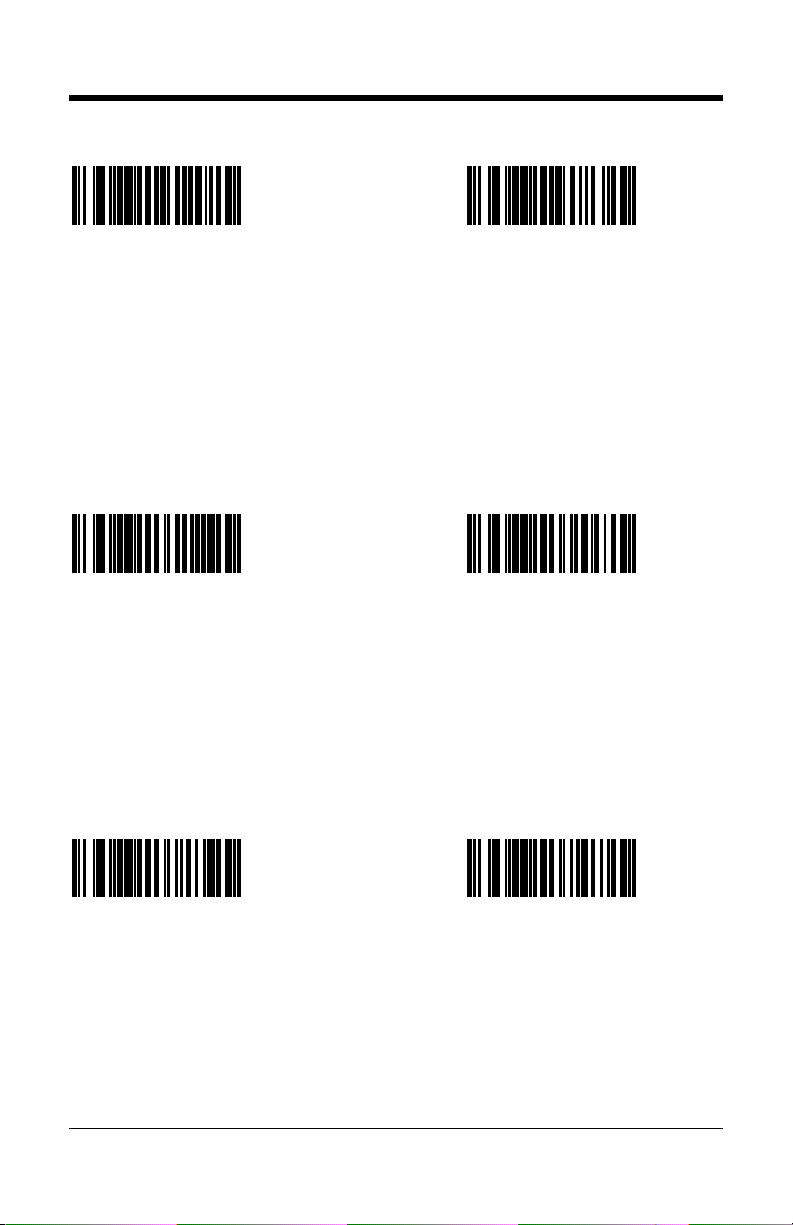

* Presentation Mode

Immediately After Button† Release

³823800

The imager immediately reverts to

presentation mode when the button

is released.

Presentation Mode

1 second After Button Release

³823820

The imager reverts to presentation

mode 1 second after the button is

released.

Presentation Mode

5 seconds After Button Release

³8238100

The imager reverts to presentation

mode when 5 seconds after the

button is released.

* Factory default configuration.

The term trigger and button are synonymous.

†

This feature is only supported in the MS7580 Genesis™.

3

Page 8

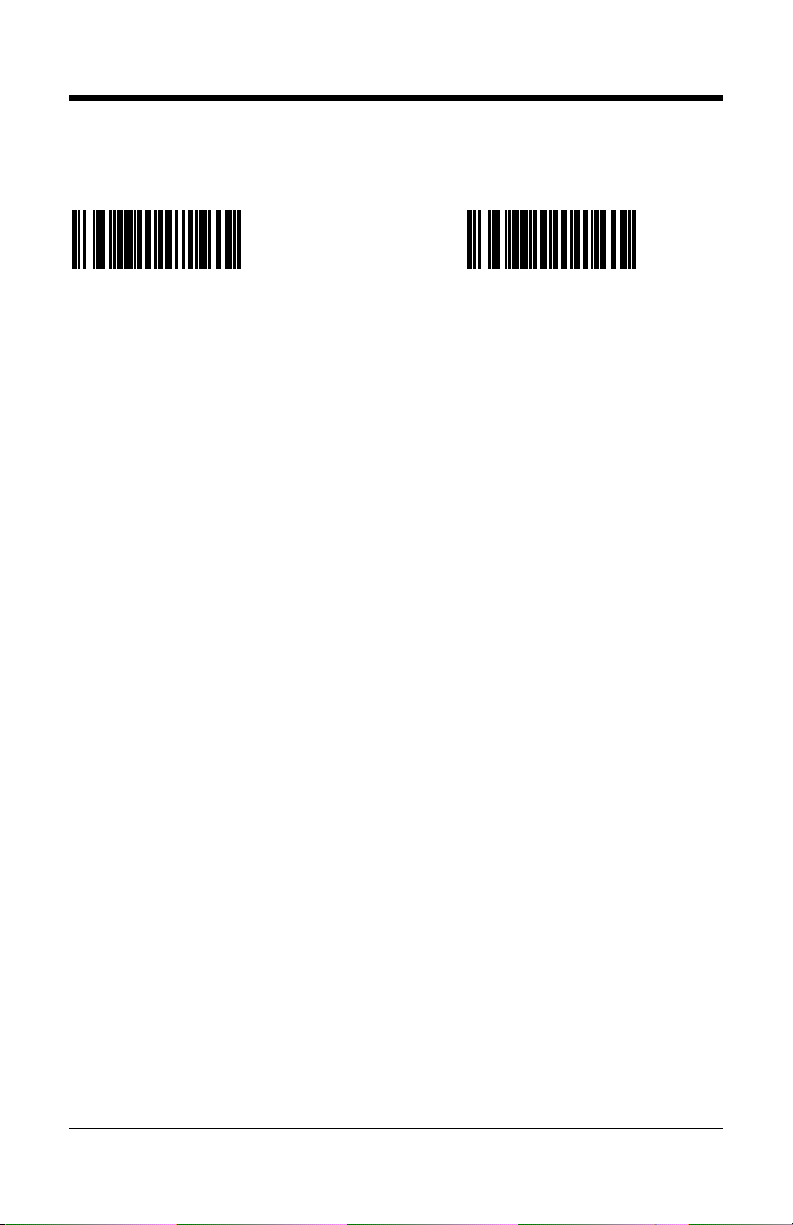

* Enable

Trigger Press Timeout

In Presentation Mode

Disable

Trigger Press Timeout

In Presentation Mode

³124403

³124413

* Factory default configuration.

This feature is only supported in the Focus® product series (i.e., IS1650, MS1890,

MS1633, and the MS1690).

4

Page 9

Pass-Through Settings

* Enable

Pass-Through Scanning

In Presentation Mode

Disable

Pass-Through Settings

In Presentation Mode

³127015

Enable 300 milliseconds

Pass-Through Timeout

³8439300

Enable 100 milliseconds

Pass-Through Timeout

³127005

³8439100

* Factory default configuration for the MS7580.

†

The term trigger and button are synonymous.

This feature is only supported in the MS7580 Genesis.

Contact a customer service representative for information on additional pass-through

timeout values.

5

Page 10

Omnidirectional and/or Linear Imager Modes

The area imager can be configured to operate as an omnidirectional imager, or a

linear imager, or a combination of both. Trigger

†

and presentation operations can

be configured separately for omnidirectional and linear scan modes.

• When a unit is configured to operate as an omnidirectional imager, all

1D and 2D bar codes are scanned omnidirectionally. The only

exceptions are Code 128 scanner configuration labels, which must be

linearly aligned for successful scanning.

Note: The IS4900 area-imaging engines do not require linear

alignment of Code 128 scanner configuration labels. The bar

code should be placed near the center of the engine's field of

view indicated by the targeting dot.

• When a unit is configured to operate as a linear imager, 1D bar codes

must be linearly aligned for successful scanning. In linear configuration

2D bar codes cannot be scanned.

• When a unit is configured to operate as both a linear and

omnidirectional imager, 1D bar codes have to be linearly aligned for

successful scanning while 2D bar codes are scanned omnidirectionally.

By default, the Focus product series

is configured for omnidirectional scanning

for trigger and presentation operations. By default, the MS7580 is configured to

omnidirectional scanning for presentation and pass-through operations and with

1D linear scanning/2D omnidirectional scanning for button

†

operations.

Enable Linear Only

in Trigger Operations

Disable Linear Only

in Trigger Operations

³120213

³120203

† The term trigger and button are synonymous.

The Focus product series includes the IS1650, MS1890, MS1633, and the MS1690.

6

Page 11

Enable 1D Linear Only

in Trigger Operations

Disable 1D Linear Only

in Trigger Operations

³120212

Enable Linear Only

in Presentation Operations

³120211

³120202

Disable Linear Only

in Presentation Operations

³120201

Enable 1D Linear Only

in Presentation Operations

³120210

Disable 1D Linear Only

in Presentation Operations

³120200

7

Page 12

Aiming and Illumination

Trigger and presentation operations can be configured separately to use the

imager’s linear illumination as an aiming instrument.

* Enable Aiming in

Trigger Operations

Disable Aiming in

Trigger Operations

³124000

* Enable Aiming in

Presentation Operations

³124011

* Enable FirstFlash

®

³124010

Disable Aiming in

Presentation Operations

³124001

Disable FirstFlash®

³125401

* Factory default configuration.

8

³125411

Page 13

* Enable Auto Gain Disable Auto Gain

³125101

* Enable Illumination

Group 1

³124002

* Enable Illumination

Group 2

³125111

Disable Illumination

Group 1

³124012

Disable Illumination

Group 2

³124003

³124013

* Factory default configuration.

This feature is only supported in the Focus product series (i.e., IS1650, MS1890,

MS1633, and the MS1690).

9

Page 14

Data Output

* Enable Data Output Disable Data Output

³121205

*

Factory default configuration.

³121215

10

Page 15

Character Suppression

Enable the

Suppression of 1 Character

* Disable the

Suppression of 1 Character

³115111

³115101

To suppress 1 character:

1. Scan the Enter/Exit Configuration Mode bar code, on page 39.

2. Scan the Enable the Suppression of 1 Character bar code.

3. Scan the Character 1 bar code (below left).

4. Scan the three code bytes that represent the character to be

suppressed, on page 12.

5. Scan the Enter/Exit Configuration Mode bar code, on page 39.

Enable the

Suppression of 2 Characters

³115112

* Disable the

Suppression of 2 Characters

³115102

To suppress 2 characters:

1. Scan the Enter/Exit Configuration Mode bar code, on page 39.

2. Scan the Enable the Suppression of 2 Character bar code above.

3. Scan the Character 1 bar code (below left).

4. Scan the three code bytes, on page 12, that represent the

st

character to be suppressed.

1

5. Scan the Character 2 bar code (below right).

6. Scan the three code bytes, on page 12, that represent the

2nd character to be suppressed.

7. Scan the Enter/Exit Configuration Mode bar code, on page 39.

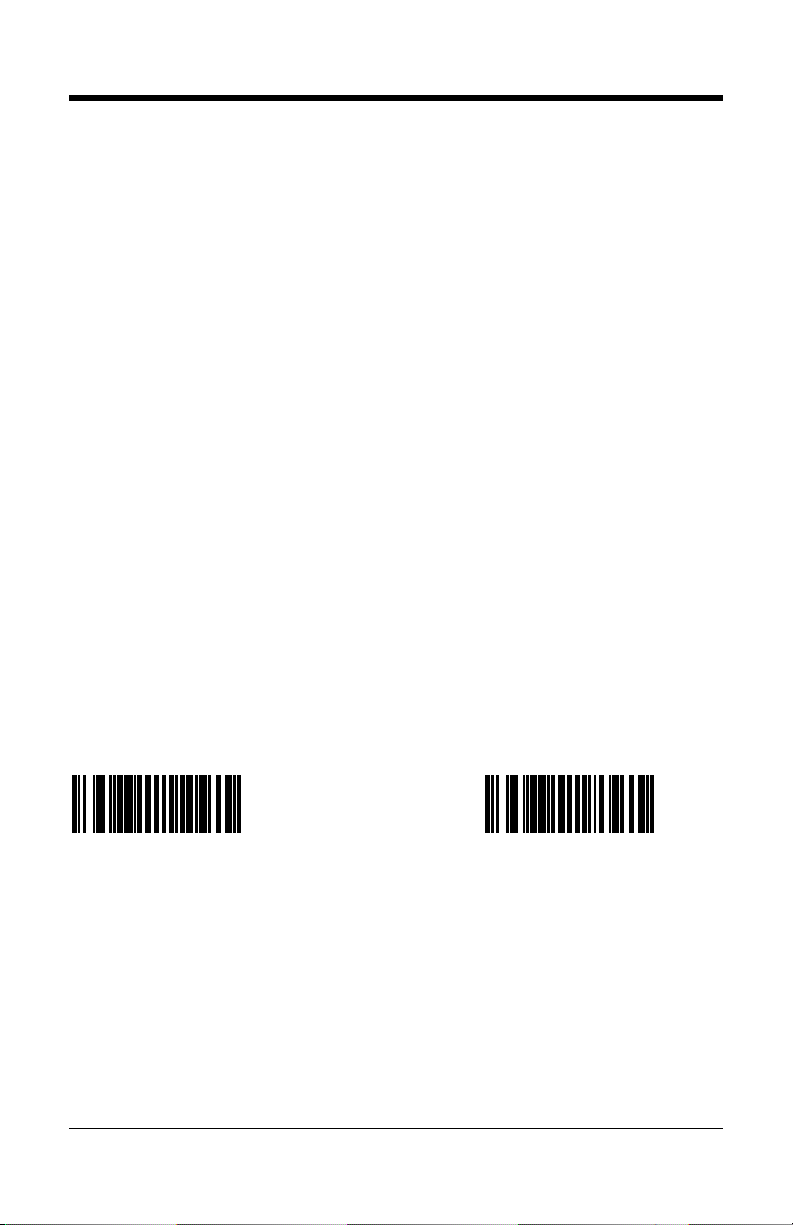

Character 1 Character 2

³915200

* Factory default configuration.

³915300

11

Page 16

Code Bytes 0 – 9

Notes: For additional information on Code Bytes, refer to the Code Bytes

Usage section of the MetroSelect Configuration Guide (PN 00-02544).

Code Byte 0

³0

³1

³2

³3

³4

³5

³6

Code Byte 1

Code Byte 2

Code Byte 3

Code Byte 4

Code Byte 5

Code Byte 6

³7

³8

³9

12

Code Byte 7

Code Byte 8

Code Byte 9

Page 17

Same Symbol Timeouts

Retain Same Symbol

Timeout on Trigger

* Reset Same Symbol

Timeout on Trigger

³120013

The same-symbol timeout

is not restarted when the

trigger is pulled.

LED Options

* Normal

Blue LED Intensity

³143100

³120003

The same-symbol timeout is

restarted when the trigger is

pulled.

Low

Blue LED Intensity

³143110

* Normal

White LED Intensity

³143102

* Factory default configuration.

This feature is only supported in the MS7580 Genesis.

Low

White LED Intensity

³143112

13

Page 18

14

Page 19

Imager Operation – MS1633

Power Save Modes††

Enable

Trigger Power-Save

* Disable

Trigger Power-Save

³125315

When enabled, the

MS1633 will enter sleep

mode after the trigger is

held for 10 seconds.

Enable

IR Power-Save

³125314

When enabled, the

MS1633 will enter sleep

mode after the IR has

been activated 5 times

without a successful

decode.

³125305

Disable

IR Power-Save

³125304

* Factory default configuration.

†† These features are not for use with the MS1690, MS1890, or the IS1650.

15

Page 20

RangeGate® Mode††

Enable

RangeGate

Disable

RangeGate

³123707

³123717

When enabled, the

MS1633 will store scanned bar

codes into non-volatile memory

if the wireless connection has

been interrupted.

Note: RangeGate and Inventory Mode are mutually exclusive. If both are

enabled, Inventory Mode takes priority.

RangeGate Delay = 1 sec. RangeGate Delay = 500 ms

³ 82612000

The MS1633 will pause

1 sec. between transmitting

individual bar codes in

RangeGate mode.

³ 82611000

The MS1633 will pause

500 ms. between transmitting

individual bar codes in

RangeGate mode.

RangeGate Delay = 0 sec.

³ 82610000

The MS1633 will not pause

between transmitting individual

bar codes in RangeGate mode.

††

These features are not for use with the MS1690, MS1890, or the IS1650.

16

Page 21

Firmware Version and Address††

Transmit the Firmware Version of the

Imager with Bluetooth

®

Wireless Technology

³998044

Transmit the Address of the

Imager with Bluetooth Wireless Technology

³998045

††

These features are not for use with the MS1690, MS1890 or the IS1650.

17

Page 22

Inventory Mode††

In Inventory mode, there is a quantity field associated with each bar code.

When an item’s bar code is scanned, the MS1633 automatically stores the bar

code data in its non-volatile memory with a quantity field set to 1. The quantity

field can then be modified using the quantity bar codes on page 20. The bar

code data is not automatically transmitted to the host. To transmit the stored

data, the Transmit All Records bar code (below) must be scanned.

Enable

Inventory Mode

* Disable

Inventory Mode

³123910

³123900

Note: RangeGate and Inventory Mode are mutually exclusive.

If both are enabled, Inventory mode takes priority.

Transmit

Quantity Field

³123915

The item’s bar code data will be

stored and transmitted once with

a user selectable numerical

quantity added to the end of the

data string. See page 19 for

information on quantity input.

If a quantity is not entered, the

* Do Not Transmit

Quantity Field

³123905

The item’s bar code data will

be stored and transmitted as

many times as the quantity

indicates.

If a quantity is not entered,

the quantity will default to 1.

quantity will default to 1.

Transmit All Records

³998050

Transmits all stored data records.

This feature is not for use with the MS1690, MS1890, or the IS1650.

††

18

Page 23

The quantity bar codes on page 20 enable the user to enter a quantity for the

last item scanned. The item’s bar code data will be stored and transmitted as

many times as the quantity indicates. If the Transmit Quantity Field feature

(on page 18) has been enabled then the bar code data will be stored and

transmitted once with a numerical quantity added to the end of the data string.

If a quantity is not entered, a value of 1 will be entered as the default.

The quantity maximum value is 9999. Quantity digits are shifted from right to left

so if a 5th digit is scanned the 1st digit scanned will be discarded and the 2nd, 3rd

th

digits will be moved to the left to accommodate the new digit.

and 4

For example, if the Quantity 5 bar code is scanned after the quantity has been

set to 1234 then the 1 will be dropped and the quantity will become 2345.

Examples

To add a quantity of 5

1. Scan the item’s bar code

To correct an incorrect quantity using the quantity codes, scan the Quantity 0 bar

code to replace the incorrect digits then scan the correct Quantity bar codes

located on page 20.

Example

The Delete Last Record bar code, on page 22, can also be used to delete the

incorrect record and quantity. Just re-scan the bar code with the correct quantity

after using the Delete Last Record bar code.

2. Scan the Quantity 5 bar code (on page 20)

To add a quantity of 1,500

1. Scan the item’s bar code

2. Scan the Quantity 1 bar code (on page 20)

3. Scan the Quantity 5 bar code (on page 20)

4. Scan the Quantity 0 bar code (on page 20)

5. Scan the Quantity 0 bar code (on page 20)

To change a quantity of 103 to 10 using the quantity codes

1. Scan the Quantity 0 bar code to change the quantity to 1030

2. Scan the Quantity 0 bar code to change the quantity to 0300

3. Scan the Quantity 1 bar code to change the quantity to 3001

4. Scan the Quantity 0 bar code to change the quantity to 0010

19

Page 24

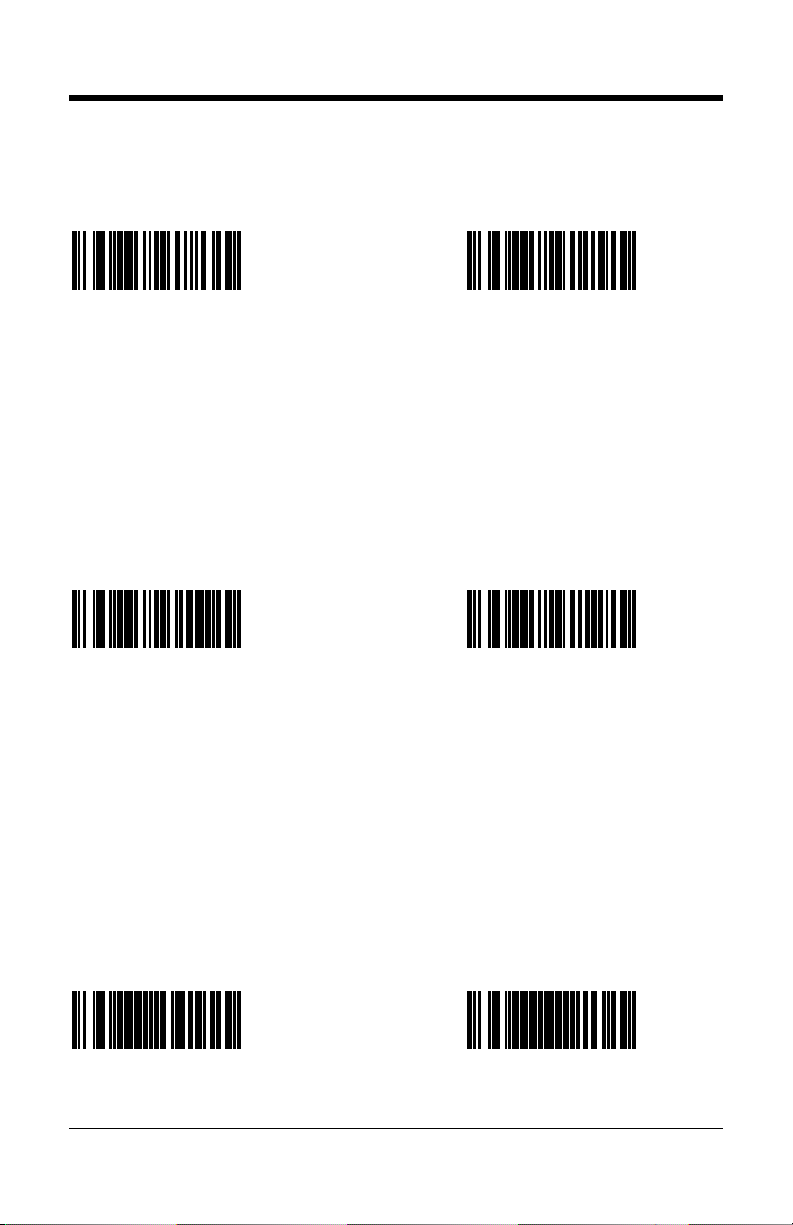

Quantity Codes††

Quantity 0 Quantity 5

³Q0

³Q5

Quantity 1 Quantity 6

³Q1

³Q6

Quantity 2 Quantity 7

³Q2

³Q7

Quantity 3 Quantity 8

³Q3

³Q8

Quantity 4 Quantity 9

³Q4

³Q9

†† This feature is not for use with the MS1690, MS1890, or the IS1650.

20

Page 25

Transmit

Entry Counter

††

* Do Not

Transmit Entry Counter

³123914

Optional field transmitted

with the bar code data that

is a count of the number of

transmissions used to

transmit the entire buffer.

Transmit

Number of Records

³998051

††

Will transmit the number of

records and the number of

bar codes currently stored

as a 5-digit number

separated by a space.

³123904

Transmit

Inventory Records LIFO††

³123911

Data is transmitted on a

last-in, first-out basis.

These features are not for use with the MS1690, MS1890, or the IS1650.

††

* Transmit

Inventory Records FIFO

³123901

Data is transmitted on a

first-in, first out basis.

21

Page 26

Enable Inventory Beep††

* Disable Inventory Beep

³123912

When enabled MS1633 will

beep after transmitting each

inventory record.

Delete Last Record††

³998063

When scanned, this

bar code will delete the

last bar code stored.

³123902

Clear Inventory Records††

³998049

When scanned, this bar

code will clear all stored

bar code data in memory.

These features are not for use with the MS1690, MS1890, or the IS1650.

††

22

Page 27

Code Types and Decode Rules

Data Matrix

Enable Normal Color

Data Matrix Decoding

Enable Inverse Color

Data Matrix Decoding

³200522

Enable Normal and Inverse

Color Data Matrix Decoding

³200532

³200512

* Disable

Data Matrix Decoder

³200502

Enable Rectangular

Data Matrix Symbol

Decoding

³100511

* Factory default configuration.

* Disable Rectangular

Data Matrix Symbol

Decoding

³100501

23

Page 28

Enable Low-Contrast

Data Matrix Decoding

†

* Disable Low-Contrast

Data Matrix Decoding

³125417

Improves decoding

†

of

low-contrast Data

Matrix symbols.

Enable Data Matrix

Non-Square Modules†

³125416

Improves decoding

†

of

Data Matrix symbols

when individual modules

in the symbol are nonsquare.

Enable Data Matrix

Shifted Tiles

†

³125407

* Disable Data Matrix

Non-Square Modules

³125406

* Disable Data Matrix

Shifted Tiles

³125415

Improves decoding

†

of Data

³125405

Matrix symbols when the

upper tiles in the symbol are

shifted in the symbol

relative to the bottom tiles.

Factory default configuration

*

†

Enabling these options will increase decoding time for all bar codes.

24

Page 29

* Enable Data Matrix,

Normal Size

³325402

The following bar codes improve decoding of Data Matrix symbols when the

length of a symbol size is small. To disable either of these options scan the

Enable Data Matrix Normal Size bar code above.

Enable Data Matrix,

Small Size

³325412

†

Enable Data Matrix

Very Small Size†

³325422

*

Factory default configuration.

† Enabling these options will increase decoding time for all bar codes.

25

Page 30

QR Code

Enable Normal

Video QR Code

Enable Inverse

Video QR Code

³200612

Enable

Normal and Inverse QR Code

³200632

³200622

* Disable QR Code

³200602

MaxiCode

Enable MaxiCode * Disable MaxiCode

³100614

* Factory default configuration.

26

³100604

Page 31

Aztec

Enable Normal

Video Aztec Decoding

* Disable Normal

Video Aztec Decoding

³100610

³100600

Enable Inverse

Video Aztec Decoding

³100611

Factory default configuration

*

* Disable Inverse

Video Aztec Decoding

³100601

27

Page 32

Enable Aztec Structure

Append Decoding

* Disable Aztec Structure

Append Decoding

³124416

³124406

When this feature is enabled, Aztec bar codes with a structured append header

will be stored in the imager’s memory buffer. The imager will transmit the

concatenated message once every component of the structured append bar

code has been read. Up to 16 components can be stored.

If this feature is disabled, Aztec bar codes with structured append header will be

read as normal Aztec bar codes. However, in this case, the structured append

header will be sent as part of the bar code data.

Notes: CodeSelect

®

and structured append features cannot be used

concurrently. If both CodeSelect and structured append are enabled,

CodeSelect feature will not work.

The CodeSelect timeout setting determines how much time will be

allowed between individual components of the same bar code

(similar to CodeSelect operation).

By default, the imager will emit an intermediate beep when each component is

scanned. When only one scan buffer is enabled, the user will be required to

release the trigger after reading each bar code component.

* Enable

Intermediate Beep

³124405

Disable

Intermediate Beep

³124415

Note: If the intermediate beep is disabled and the number of scan buffers is

increased (compare buffers in MetroSet2) – all components of a

structured append bar code can be read with a single trigger activation,

and only one audible beep will be produced, as if a regular bar code

was scanned.

Factory default configuration.

*

28

Page 33

Postal

Enable

Australia Post

* Disable

Australia Post

³126217

³126207

Enable Japan Post * Disable Japan Post

³126216

³126206

Enable KIX Code * Disable KIX Code

³126215

³126205

*

Factory default configuration.

29

Page 34

Enable

PLANET Code

* Disable

PLANET Code

³126214

Enable

POSTNET Code

³126213

³126204

* Disable

POSTNET Post

³126203

Enable B & B’

Fielded POSTNET

³126212

*

Factory default configuration

30

* Disable B & B’

Fielded POSTNET

³126202

Page 35

Enable

UPU Decoding

* Disable

UPU Decoding

³126211

Enable

Royal Mail 4 Code

³126210

³126201

* Disable

Royal Mail 4 Code

³126200

Enable

Zero-FCC Australia Post

³126412

*

Factory default configuration.

* Disable

Zero-FCC Australia Post

³126402

31

Page 36

Codablock Options

Enable

Codablock A

* Disable

Codablock A

³126410

Enable

Codablock F

³126411

PDF Options

Enable

Transmit \ as \

³115113

³126400

* Disable

Codablock F

³126401

* Enable

Transmit \ as \\

³115103

* Factory default configuration.

32

Page 37

RS232

Software Handshaking

Enable

]V Handshaking

Disable

]V Handshaking

³125210

An “]V” response from

the host indicates

reception of imager data.

³125200

Multifunctional USB/IBM® Interface†

Dual Interface Defaults†

³999923

†

This feature is not for use with the MS1633.

33

Page 38

34

Page 39

Interfaces

Additional Interfaces†

Enable Beeper

ON/OFF Commands

* Disable Beeper

ON/OFF Commands

³125211

Enables beeper on/off

commands with internal

USB and IBM interfaces.

rd

3

Generation

IBM 46xx Defaults

³999952

First, scan the 3rd Generation IBM

46xx Default bar code. Then,

scan the IBM Reserved Code #2.

IBM Reserved Code #2

³125201

³317210

First, scan the 3rd Generation IBM

46xx Default bar code. Then, scan

the IBM Reserve code #2.

* Factory Default Configuration

†

These features are not for use with the MS1633.

35

Page 40

IBM 46xx-SIOC RS485 Interface

Send 30H for Last Block

Label Identifier 4680

³117215

Note: Feature is for PDF

codes only.

IBM-OEM USB Interface

Send 30H for Last Block

Label Identifier USB

³116300

Note: Feature is for PDF

codes only.

* Send 00 for Last Block

Label Identifier 4680

³117205

Note: Feature is for PDF

codes only.

* Send 00 for Last Block

Label Identifier USB

³116310

Note: Feature is for PDF

codes only.

Full Speed USB Keyboard Interface

Enable Full Speed USB

Keyboard Interface Defaults

³999940

* Factory Default Configuration

† These features are not for use with the MS1633.

36

Page 41

MS7580 Genesis Specific

Load RS232

Configuration Settings

Load USB

Configuration Settings

³998071

Load Keyboard Wedge

Configuration Settings

³998073

Recall Configuration for

Currently Connected Interface

³998072

Load RS485

Configuration Settings

³998074

³998080

This feature is only supported in the MS7580 Genesis.

37

Page 42

Apply Settings

to All Interfaces

Apply Settings to

the Current Interface

³998075

Apply Settings

to RS232 Interface

³998076

³998081

Apply Settings

to USB Interface

³998077

Apply Settings

to Keyboard Wedge

³998078

This feature is only supported in the MS7580 Genesis.

38

Apply Settings

to RS485 Interface

³998079

Page 43

Enter/Exit Configuration Mode

Enter Exit Configuration Mode

³999999

39

Page 44

40

Page 45

Contact Information

The Americas (TA) Omniplanar, Inc. Spain

USA

Tel: 800.436.3876 Fax: 856.374.5576 Fax: +34 913 273 829

(Customer Service) Email: Email:

866.460.8033 info@omniplanar.com

(Customer Support)

888.633.3762 NOVODisplay United Kingdom

(Technical Support) Tel: 856.537.6139 Tel: +44 (0) 1256 365900

Fax: 856.228.6673 Fax: 856.537.6116 Fax: +44 (0) 1256 365955

(Sales) Email: Email:

856.228.1879 info@NOVOdisplay.com

(Marketing)

856.228.0653 Europe, Middle East, Asia Pacific

(Legal/Finance) and Africa Australia

France Tel: 1 800 99 88 38

Brazil Tel: +33 (0) 1 48.63.78.78 Fax: +61 2 8916-6471

Tel: 55.11.5185.8222 Fax: +33 (0) 1 48.63.24.94 Email:

Fax: 55.11.5185.8225 Email: info@au.metrologic.com

Email: info@fr.metrologic.com

info@br.metrologic.com

Germany Tel: 86-21-58356616

Mexico Tel: 49-89-89019-0 86-21-58358830

Tel: 55.5365.6247 Fax: 49-89-89019-200 Fax: 86-21-58358873

Fax: 55.5362.2544 Email: Email:

Email: info@de.metrologic.com

info@mx.metrologic.com

Italy Suzhou Sales Office

North America Tel: +39 0 51 6511978 Tel: 86-512-67622550

Tel: 856.537.6400 Fax: +39 0 51 6521337 Fax: 86-512-67622560

866.460.8033 Email: Email:

(Customer Service) info@it.metrologic.com

888.633.3762

(Technical Support) Poland Guangzhou Sales Office

Fax: 856.537.6474 Tel: +48 (22) 545 04 30 Tel: 86-20-38823476

Email: Fax: +48 (22) 545 04 31 Fax: 86-20-38823477

info@us.metrologic.com

South America

(Outside Brazil) Russia Beijing Sales Office

Tel: 55.11.5182.7273 Tel: +7 (495) 737 7273 T el: 010-82253472/84583280

Fax: 55.11.5182.7198 Fax: +7 (495) 737 7271 Fax: 010-82253648/84583102

Email: Email: Email:

info@sa.metrologic.com

Tel: 856.374.5550 Tel: +34 913 272 400

info@es.metrologic.com

info@uk.metrologic.com

China

info@cn.metrologic.com

info@cn.metrologic.com

Email: Email:

info@pl.metrologic.com

info@ru.metrologic.com info@cn.metrologic.com

info@cn.metrologic.com

41

Page 46

Chengdu Sales Office Japan Singapore

Tel: 028-66135066/86786348 Tel: 81-3-3839-8511 Tel: (65) 6842-7155

Fax: 028-86787061 Fax: 81-3-3839-8519 Fax: (65) 6842-7166

Email: Email: Email:

info@cn.metrologic.com

Hong Kong Korea Thailand

Tel: 852-2331-9133 Korea Sales Office Tel: +662-610-3787

Fax: 852-2511-3557 Tel: (82) 2-6205-5379 Fax: +662-610-3601

Fax: (82)-2-3444-3980 Email:

India Email: info@th.metrologic.com

India Sales Office info@kr.metrologic.com

Tel: +91 80 4125 6718

Fax: +91 80 4125 6719

Email:

info@in.metrologic.com

info@jp.metrologic.com info@sg.metrologic.com

42

Page 47

Page 48

Honeywell Scanning & Mobility

90 Coles Road

Blackwood, NJ 08012-4683

00-05252 Rev B

June 2009

Loading...

Loading...