Page 1

MIDAS-M MULTIGAS TRANSMITTER

Fixed Single Point Extracted

Multi Gas Transmitter

3016M5001 Rev A

ECO HAA190080

Page 2

Page 3

Table Of Contents

Introduction

C

HAPTER 1 —

About Us

Product Description

Overview

User Interface

Default Configuration

Installation

C

HAPTER 2 —

Mount the Transmitter Device

Mount the Relay Module

Sample and Exhausting Tubing Calculations 17

7

7

7

8

9

10

11

11

15

In-Line Filters

Local Detector Option

Electrical Installation

Electrical Connection

Wiring The Relay Module

Mount The Sensor Cartridge

Device & Web Operations

C

HAPTER 3 —

Comissioning

Monitoring Mode

Review Information

18

18

19

23

26

28

29

29

30

32

Setup Operations 34

Page 4

Test Mode

36

Calibration Mode

Calibration & Bump Test 39

Bump Test 40

Internal Web Server 41

Physical Network Components 41

Internet Settings 41

Running the Web Server 42

C

HAPTER 4 —

Maintenance

System Leak Check

C

HAPTER 5 —

Additional Information

EU Directive 2012/19/EU: Waste Electrical and Electronic

Equipment (WEEE)

38

65

66

69

69

Troubleshooting and Fault Diagnosis

Specifications

Ordering

Transmitter 77

Cartridge 77

Smart Sensor 78

Accesories 78

Gas Table

Combination Index

Reflex

A Modbus/TCP Interface

70

74

77

82

84

85

86

Security 99

Page 5

Modbus TCP 99

DOS attack 99

Install Web Server Certificate in Google Chrome

Install Web Server Certificate in MS Browsers

101

103

Warranty 105

Sensor Cartridge Warranty 106

107Contact Us

Page 6

Page 7

CHAPTER

Introduction

1

Learn what you need to know about the Honeywell Midas®-M Gas Detector before operating.

About Us

Honeywell Analytics: the global leader in gas detection

While you build a better world, we’re building smarter safety.

For nearly 50 years, Honeywell Analytics has been protecting people who put their lives on the line

every day. It takes a special level of drive and dedication to work in hostile environments, and we

believe your workers deserve the same kind of commitment from us when it comes to securing

their health and safety.

Right from the start, our founders were determined to find better ways to design, build and

manufacture reliable gas detection solutions. Through advanced technology and pure industry

know-how, Honeywell Analytics continues to improve and evolve our products. Today, we’re proud

to partner with customers worldwide who share our vision of vigilance and rely on us to help them

protect what matters most.

From custom-designed solutions to unmatched training and support, Honeywell Analytics is

simply the smartest choice when you demand the best in safety.

Product Description

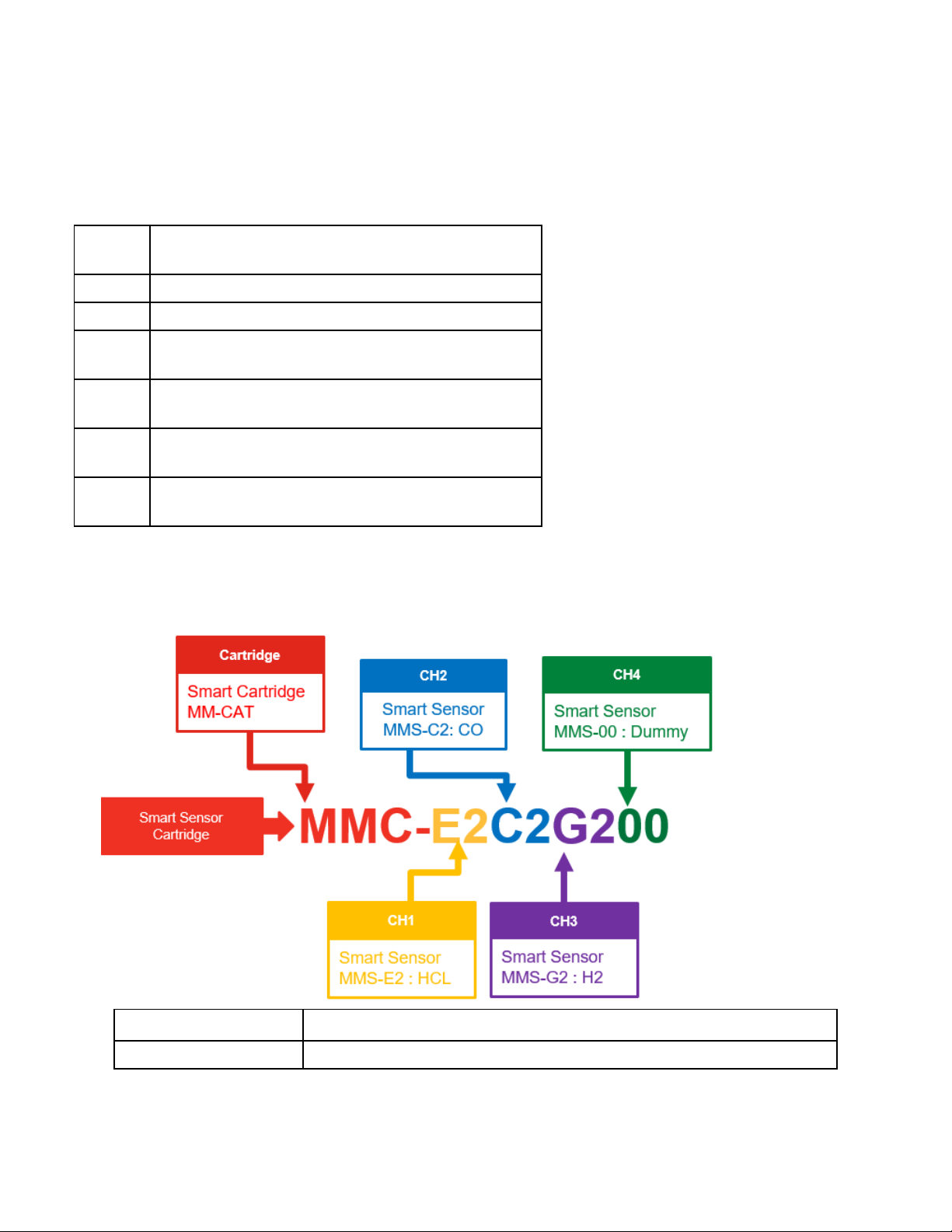

The Honeywell Midas®-M is a Fixed Extractive Single Point with 4-in-1 Multi Gas Detector that

draws a sample locally or from a remote point to a sensor cartridge that is located inside the

detector’s chassis. A wide range of toxic, flammable and oxygen gas sensor cartridges are

available that enable detection of gases used or generated in the Semiconductor and other

manufacturing industries.

Midas-M is shipped from the factory with the security function disabled. We strongly recommend

enabling this function for safe use of the detector. To enable it, select Set up > Security and type an

8 character password.

Midas-M is wall mounted and displays gas concentration, alarm, fault and status information via

its backlit LCD and LEDs. A simple to use 4-button keypad located under the display provides the

facility to set-up, review, operate and make changes to the detector’s configuration.

Midas-M 7 User Manual

Page 8

Midas-M has flexible power and communications capabilities built in as standard. These include

3 on board relays, 0-21 mA analog output, Modbus/TCP outputs for signal and service

connectivity as well as Power over Ethernet (PoE) connection that enables a single Ethernet

connection to be made for all power, control and communication requirements.

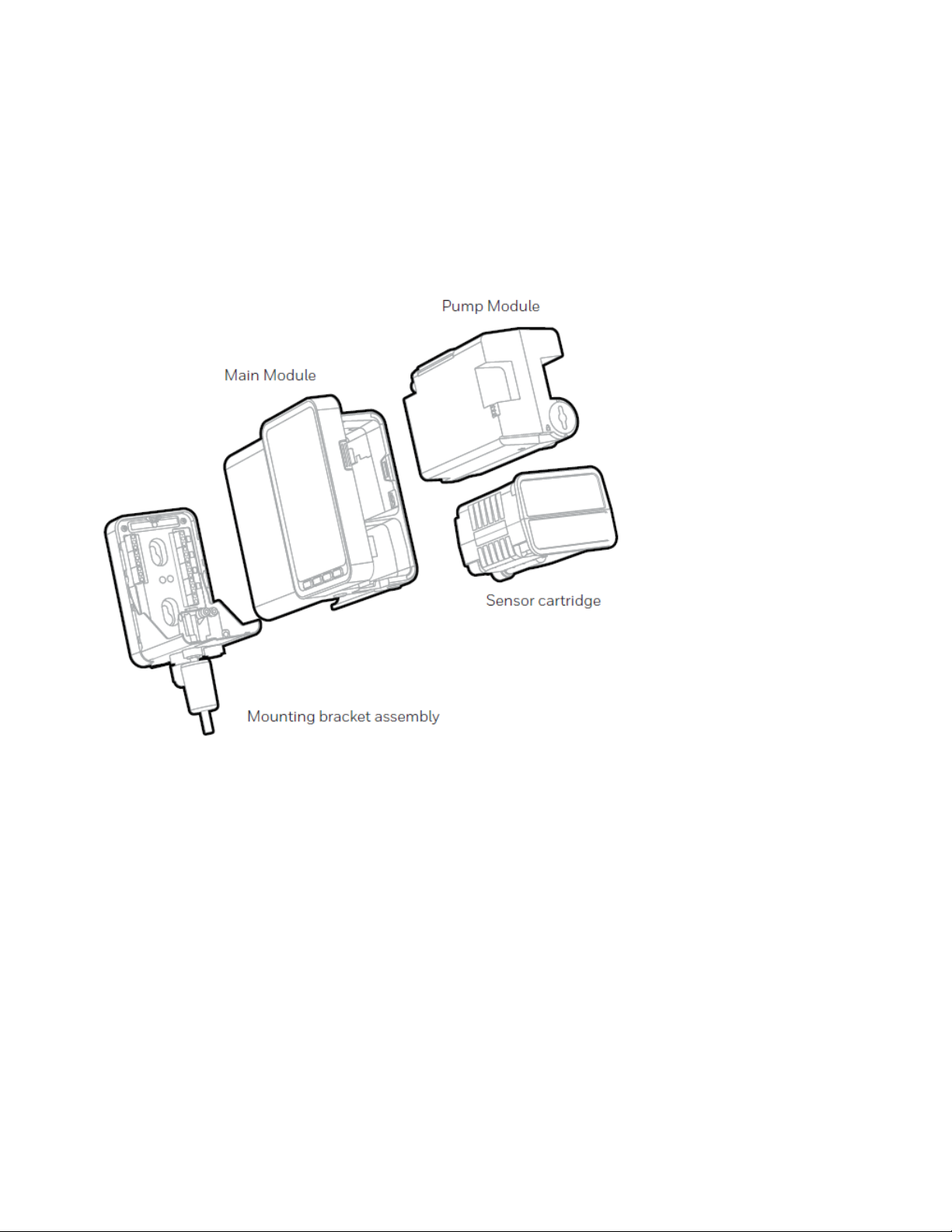

Overview

The Midas-M gas detector comprises of 4 parts: the main module, the mounting bracket

assembly, the sensor cartridge and the pump module.

Midas-M 8 User Manual

Page 9

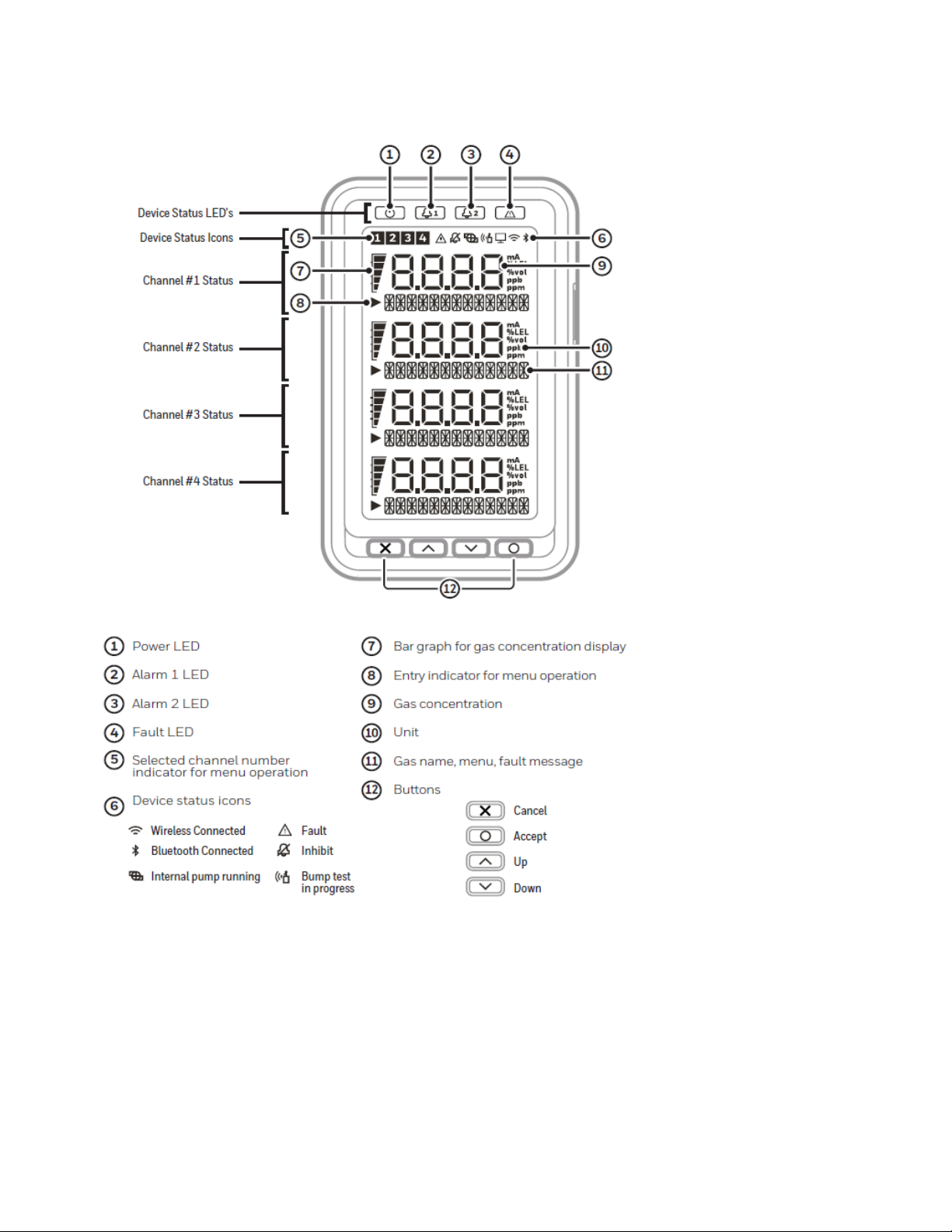

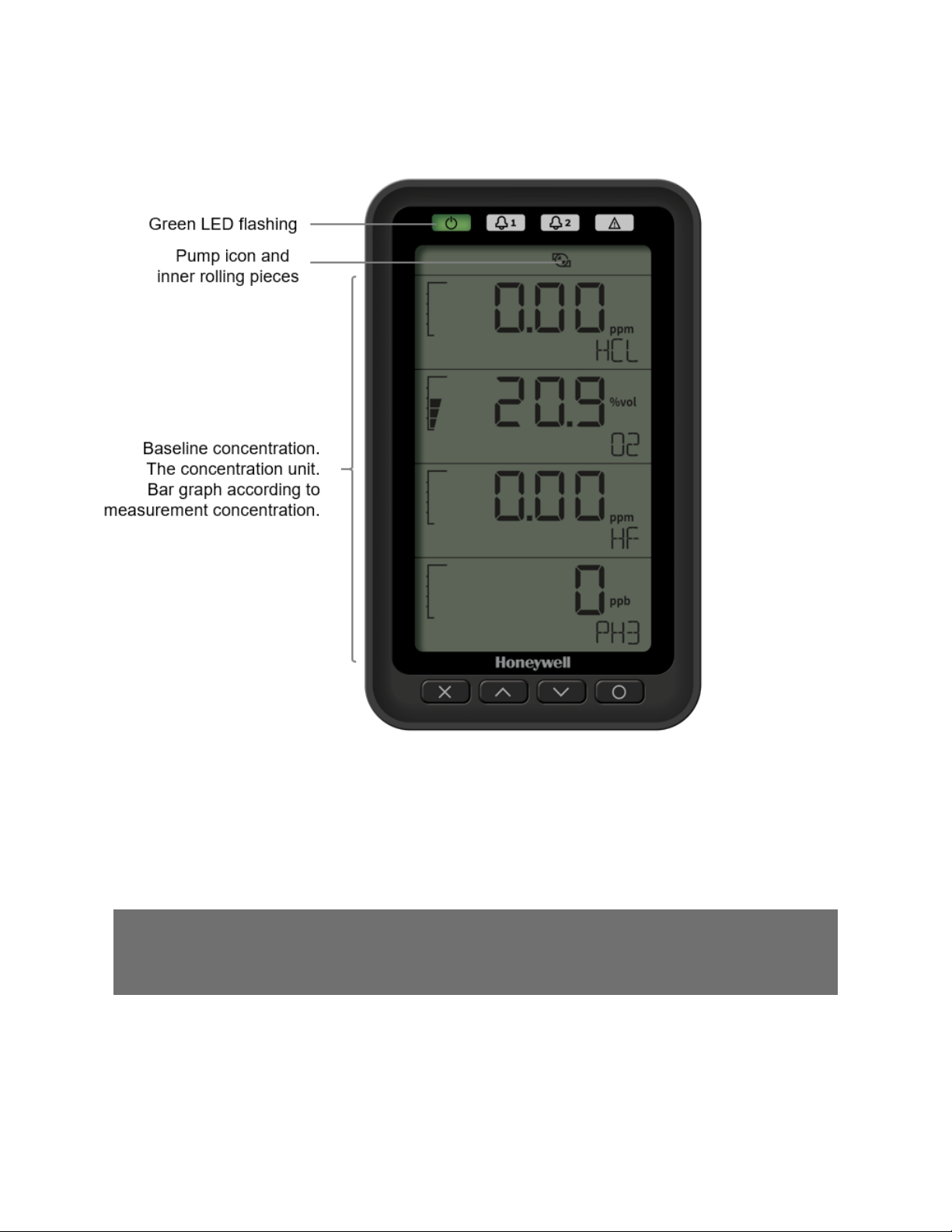

User Interface

Detector's User Interface overview.

Midas-M 9 User Manual

Page 10

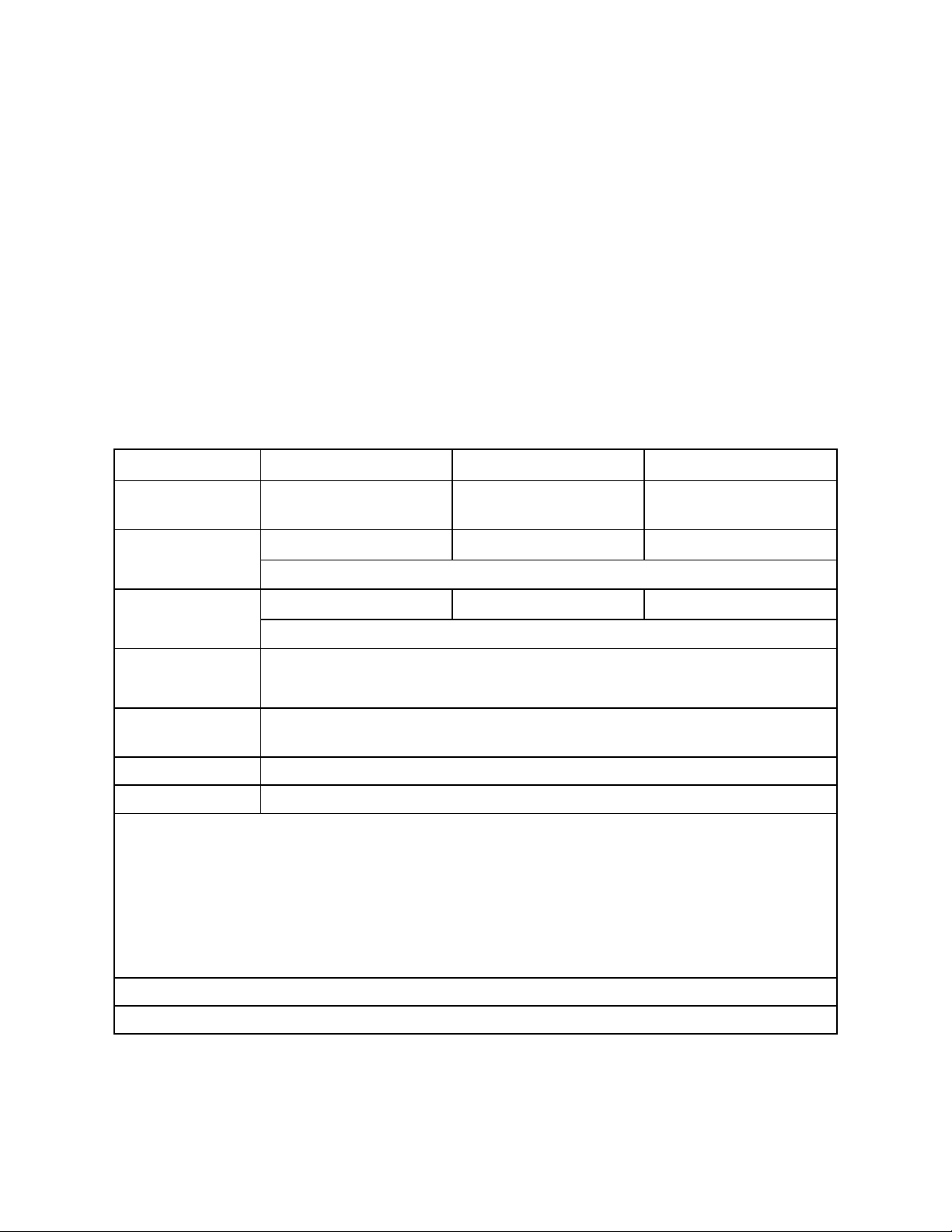

Default Configuration

The Midas-M gas detector is factory-configured.

NOTE: Oxygen levels are 20.9% v/v in a normal atmosphere, equivalent to 17.3 mA. Use caution

when integrating an oxygen Midas-M unit using the 4-20 mA output since fault, inhibit, and no

power conditions are below 4 mA and, by default, an oxygen depletion alarm is triggered on a

falling alarm (default 19.5% v/v). In that case, Honeywell Analytics recommends one of the

following:

• Use Modbus TCP digital communications

• Use discrete relay inputs instead of a 4-20 mA signal to trigger gas alarms

• Program the control system of the 4-20 mA input with logic and a delay (e.g., 1 second) before

triggering an alarm to determine if the 4-20 mA output is at one of the 0-4 mA conditions

described above.

Contact Honeywell Analytics for further information.

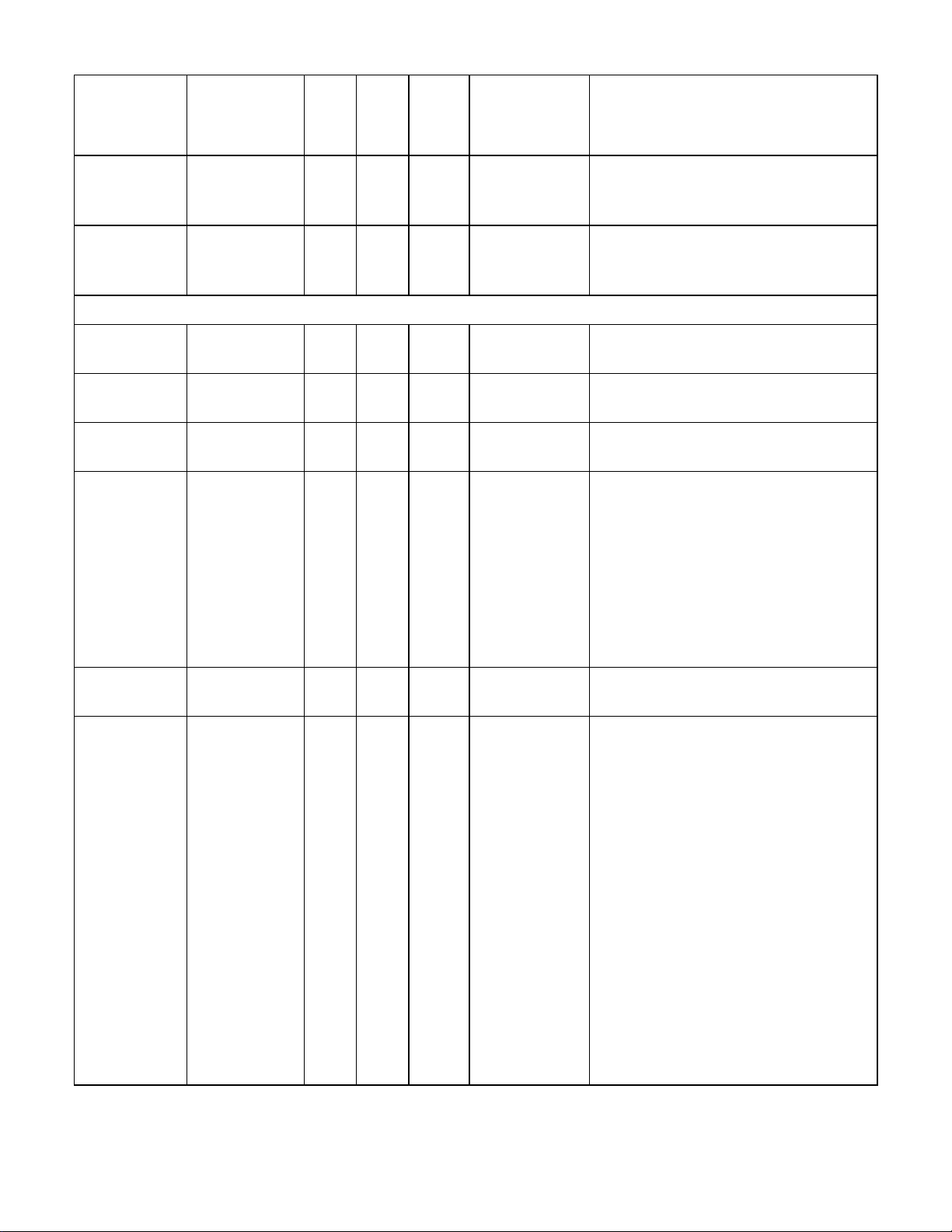

Factory Default Configuration

Toxic Gas flammable gas

1

oxygen

Full Scale (FS) Typically4 x Threshold

LimitValue (TLV)

Alarm 1

(Relay 1)

Alarm 2

(Relay 2)

Fault

(Relay 3)

Latching Latching. Alarm and fault relays DO NOT automatically reset when reading

Passcode No Passcode set.

Address 169.254.60.47 subnet mask 255.255.255.0

Current source with:

1.0 mA Fault

2.0 mA Inhibit

3.0 mA Maintenance Fault

4.0 to 20.0 mA Gas reading (normal operation)

21.0 mA Over range

1/2 TLV 10% LEL 23.5% v/v (Rising)

Normally de-energized, energizeson alarm.

TLV 20% LEL 19.5% v/v (F alling)

Normally de-energized, energizeson alarm.

Normally energizes, de-energizedon fault.

fallsbelow alarm thresholds.Relays MUST be manually reset.

100% Lower Explosive

Limit(LEL)

25% V olume (v/v)

1

Not yet released

Midas-M 10 User Manual

Page 11

CHAPTER

2

For ease of installation Midas-M has been designed to allow the installation of the mounting

bracket assembly and main module separately from the other parts of the detector. The detector

location and hard wiring can therefore be completed before fitting the detector’s main module

and sensor cartridge.

WARNING

Midas-M is designed for installation and use in indoor safe area non-explosive

atmospheres. Installation must be in accordance with the recognized standards of the

appropriate authority in the country concerned. Prior to carrying out any installation

ensure local regulations and site procedures are followed.

Ensure the connection of all modules (e,g pump, and cartridge module) with the main

module. Otherwise, Midas-M can have flow leakage or malfunction.

Installation

Mount the Transmitter Device

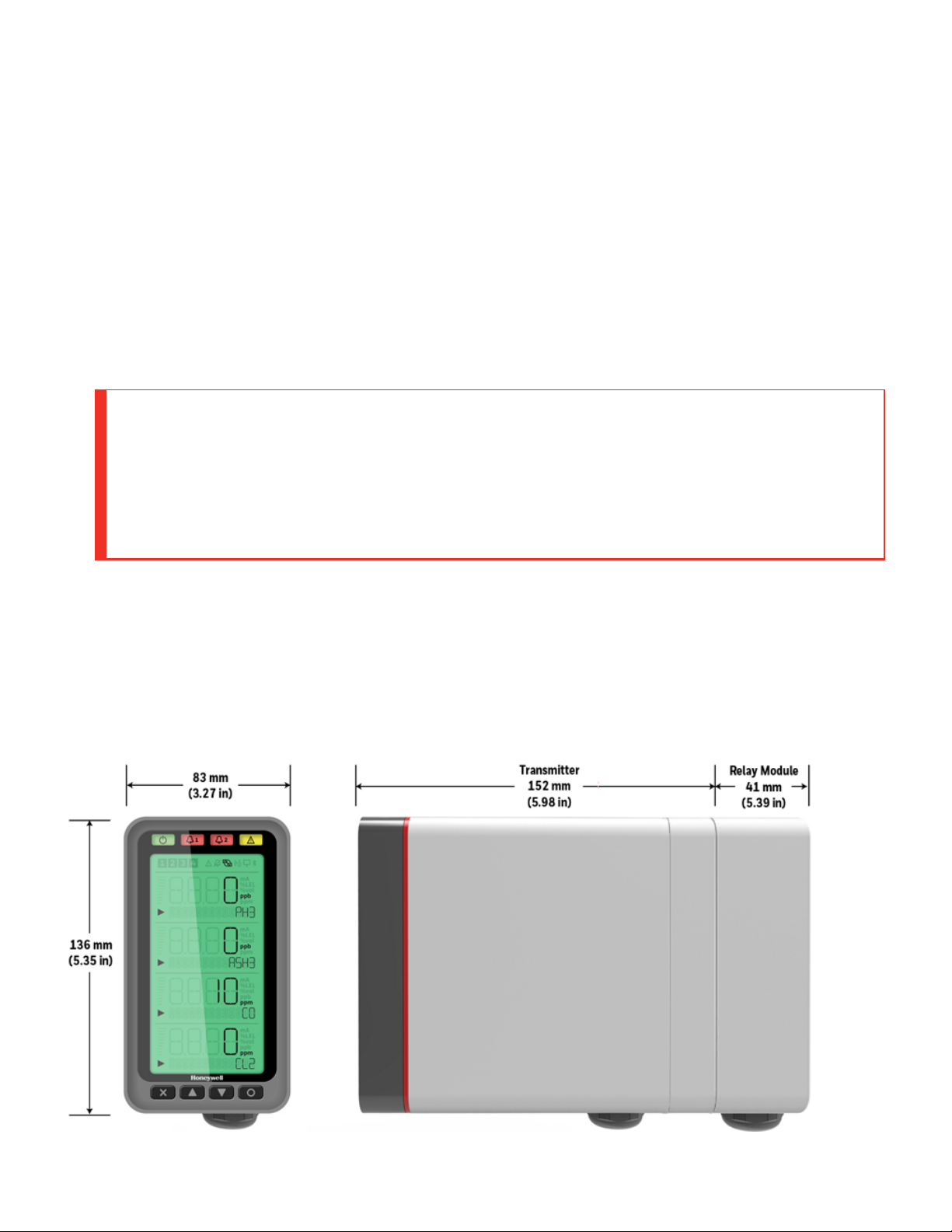

The Midas-M gas detector has an integral mounting bracket assembly that is easily mounted to a

suitable vertical surface such as a wall, tool housing, mounting plate on a pole etc.

Midas-M outline dimensions

Midas-M 11 User Manual

Page 12

NOTE

Notice the space required to install the instrument, open the door, push in/pull out

modules, and tubing.

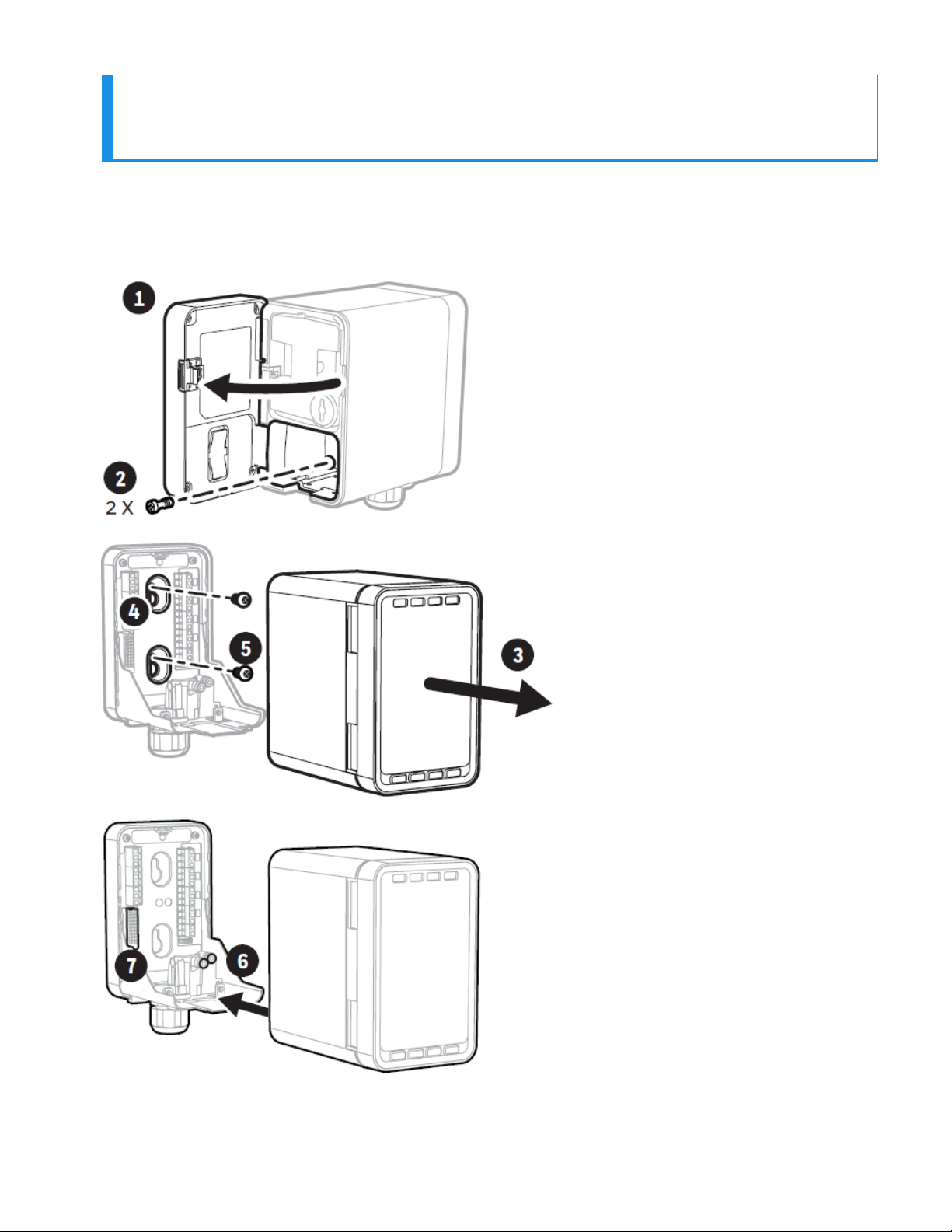

Mounting procedure

Midas-M 12 User Manual

Page 13

1. the door.

2. Un-tight the two screws.

3. Carefully pull the main module forward.

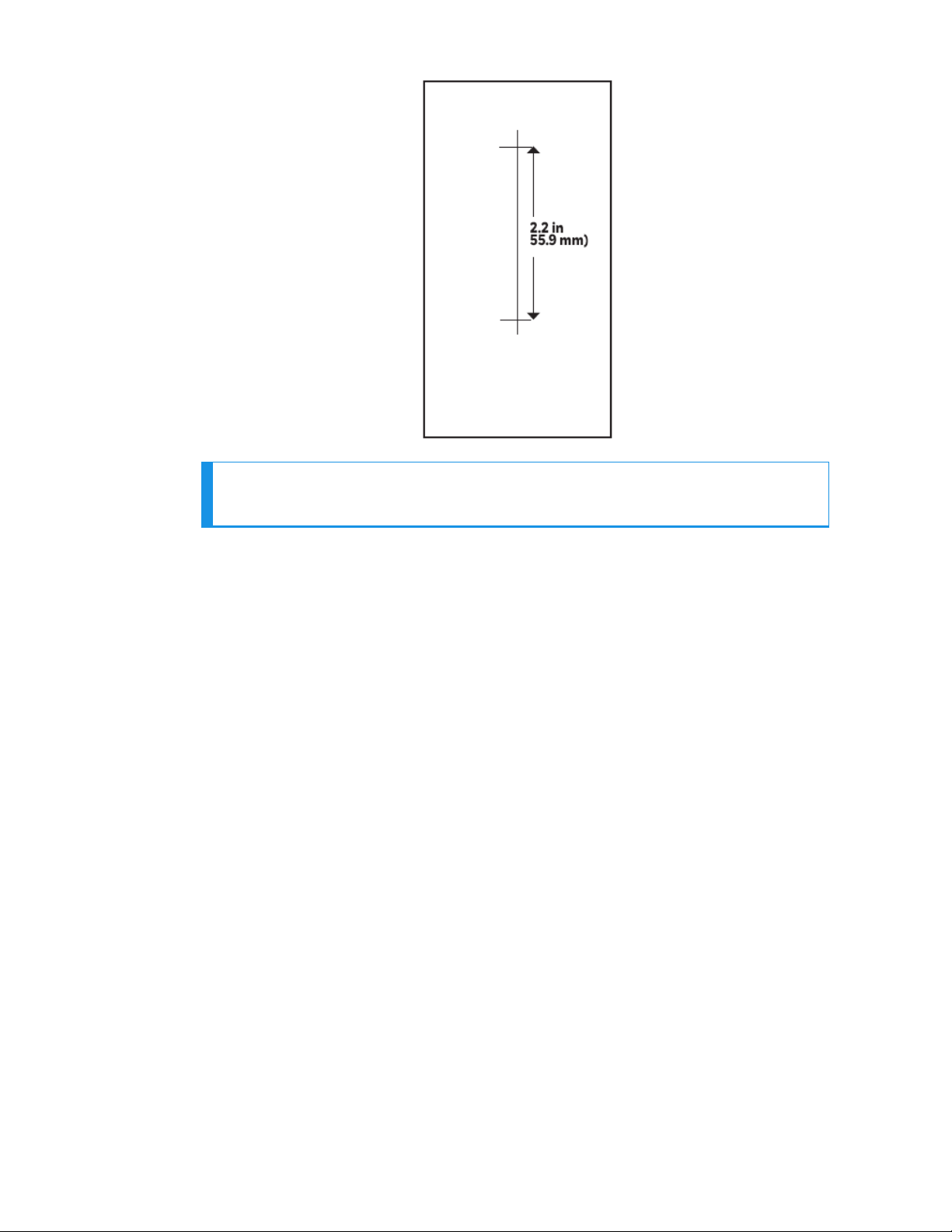

4. Drill two holes 2.2 in (55.9 mm) Use 2 x M4 Screws or equivalent for mounting

(head size 7-11 mm).

Midas-M 13 User Manual

Page 14

NOTE

This drill template is not to scale.

5. a. Partially screw the fixings into the mounting surface.

b. Place the mounting bracket assembly over the screws, so they pass

through the mounting holes and then slide down to locate in the slots.

c. Tighten the screws to secure the mounting bracket assembly.

6. a. Align the rounded corner at the lower of the main module with the similar

rounded corner at the bottom of the mounting bracket assembly

b. Slide the main module backward while pushing the main module up after

connecting with a mounting bracket so that the PCB connector and tubes

engage simultaneously.

7. Ensure the PCB, connector, and tubes are fully engaged by firmly pushing the

main module horizontally backward on the mounting bracket assembly. DO

NOT PUSH ON THE LCD AS THIS MAY DAMAGE IT.

8. a. Align the two fixing screws located at the bottom of the module with the

screw threads on the mounting bracket assembly.

b. Tighten the screws to secure the module to the mounting bracket

assembly.

9. Remove the internal packing card securing the pump. Failure to remove this

packing will result in damage to the Midas-M detector.

Midas-M 14 User Manual

Page 15

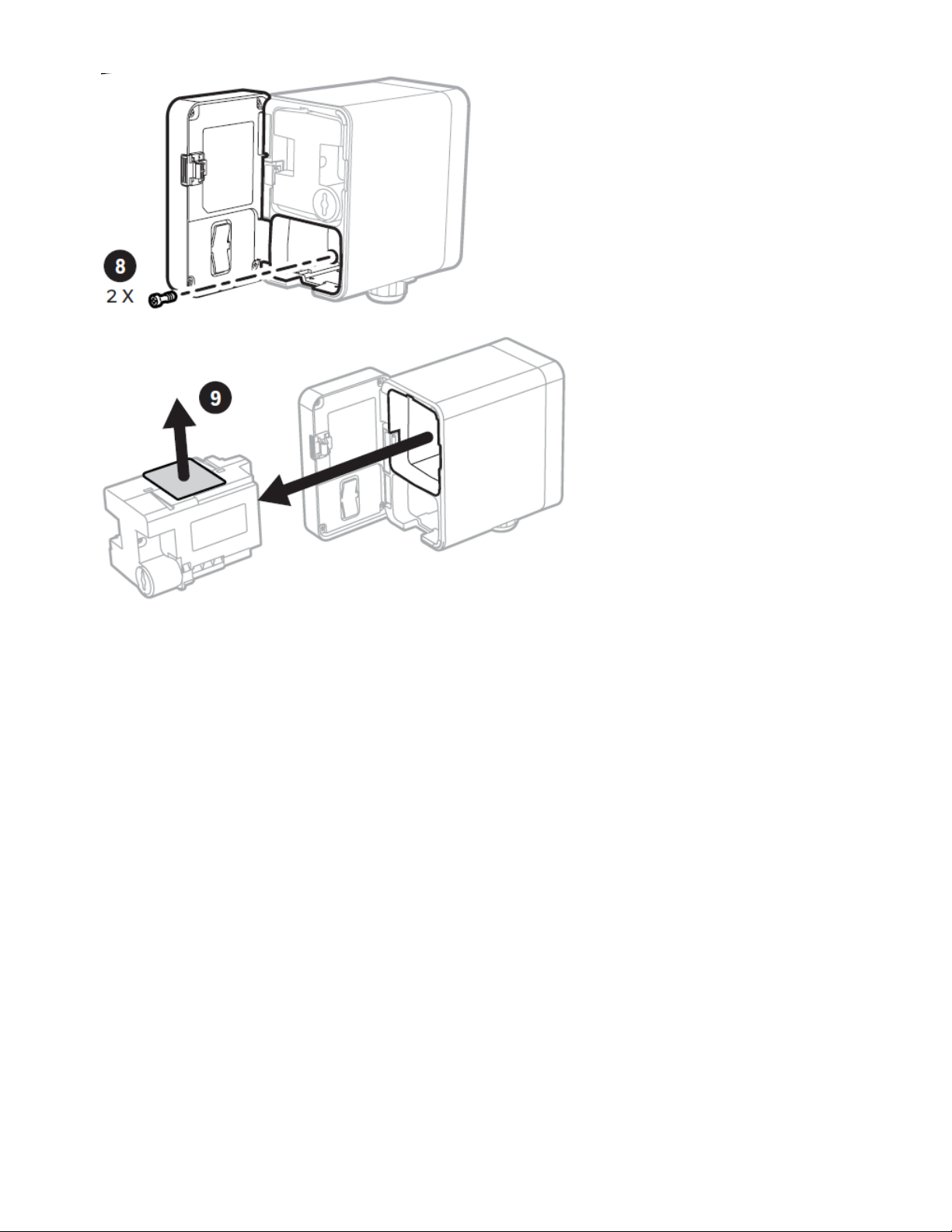

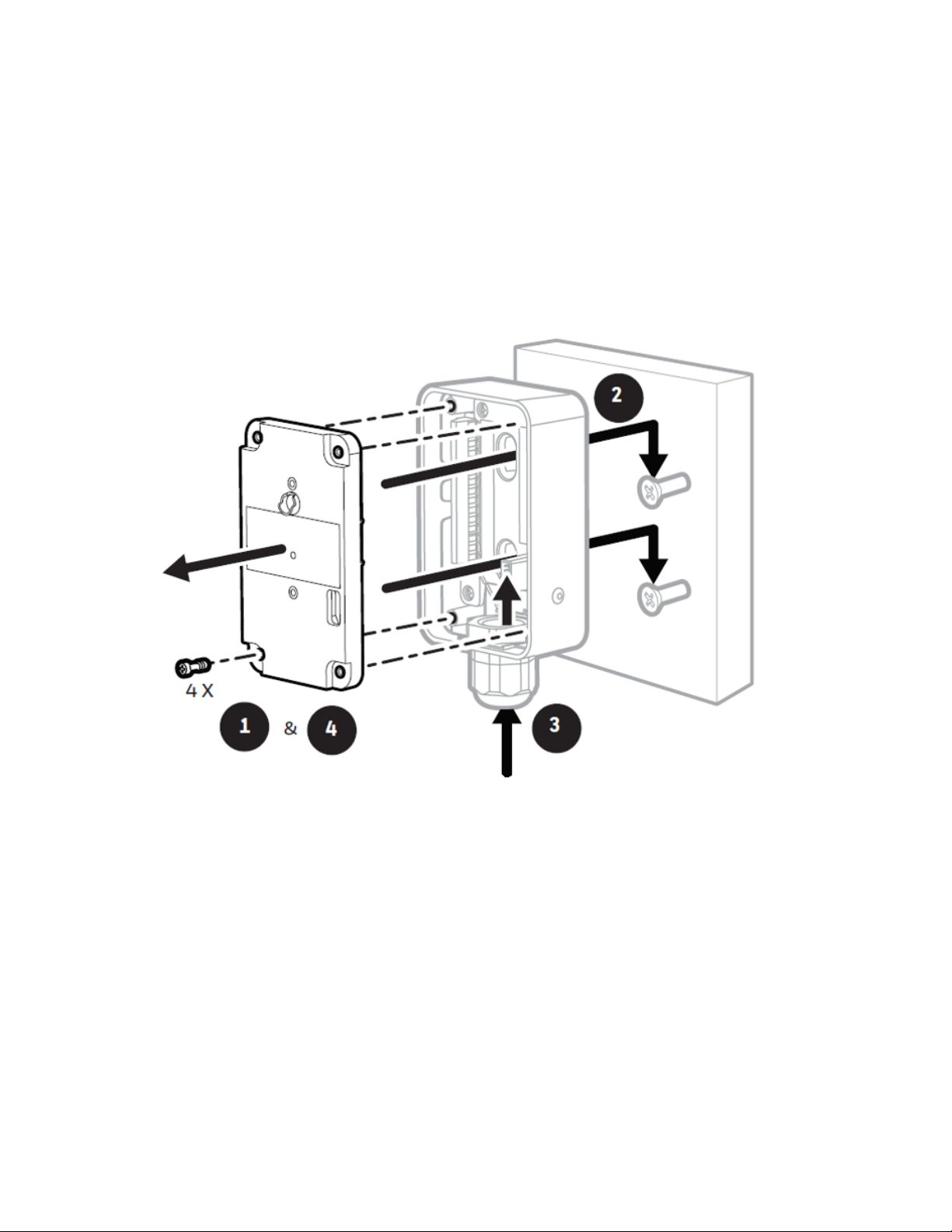

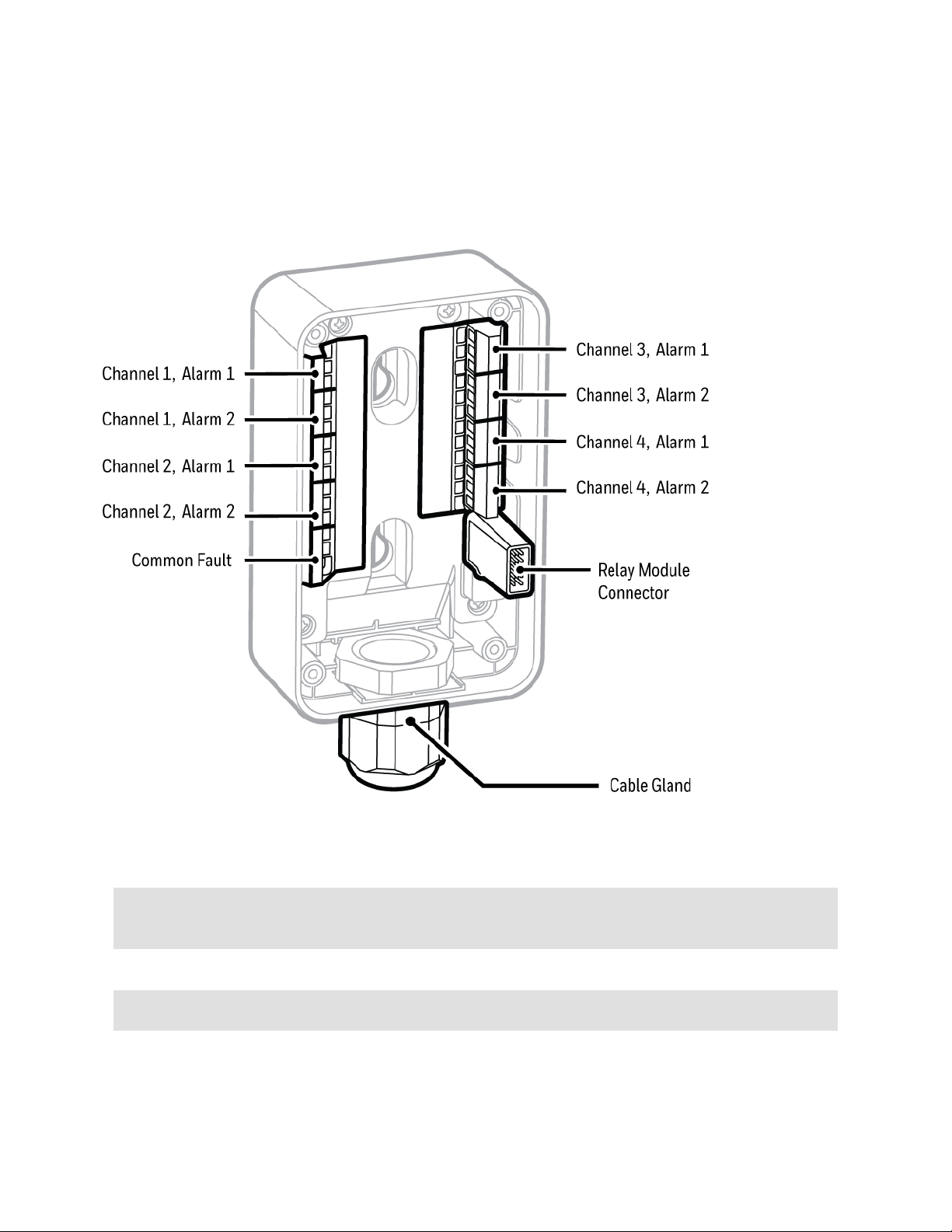

Mount the Relay Module

The Relay Module has an integral mounting bracket assembly that is easily mounted to a

suitable vertical surface such as a wall, tool housing, mounting plate on a pole etc.

1. Pull out the four screws and remove the plate cover.

2. a. Partially screw the fixings into the mounting surface.

b. Place the Relay module over the screws, so they pass through the holes to locate in

the slots.

c. Tighten the screws to fix the Relay Module to the surface.

3. Connect the wire through the cable gland to the terminal block.

4. Place the plate cover in position and screw the four screws you removed in Step 1.

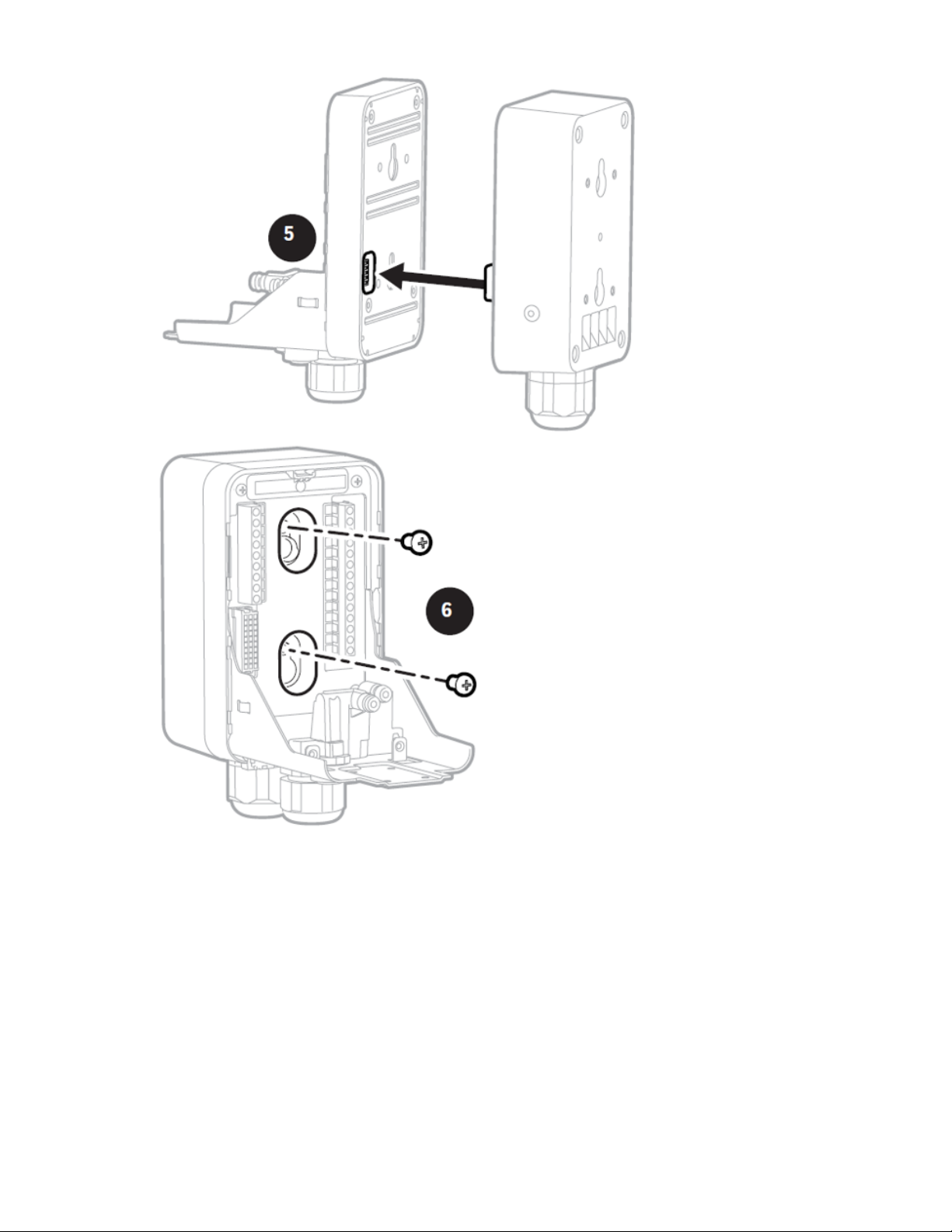

5. Push the mounting bracket assembly horizontally and engage the Relay Module connector.

6. a. Align the screw holes and the slot-boundaries, and tight the machine screws

(3016D0355) provided in packaging.

b. Connect the mounting bracket assembly to the Relay Module.

Midas-M 15 User Manual

Page 16

Midas-M 16 User Manual

Page 17

Sample and Exhausting Tubing Calculations

Description of flow rate, and tubing vacuum at the inlet and exhaust points,

Inlet sample specifications

Description Maximum

Tubing Length, m (ft) 30 (100)

Sample Point Vacuum -25.4 cm H2O (-10 in H2O)

Transport Time (sec), ID 1/8”

Transport Time (sec), ID 3/16” 53

Flow rate, cc/min. 600 (Flow is constant)

Tubing OD, mm (in) 6.35 (0.25)

Tubing ID, mm (in) 3.18 (0.125)

1

Honeywell Analytics recommends thick-wall tubing (1/8” ID) for best speed of response. Due to

its lower surface area, thick- wall tubing may require less conditioning than thin-wall tubing.

2

The flow rate is electronically maintained at approximately 600 cc/min and may vary within

acceptable tolerances.

Tubing lengths vary among gases. See the Gas Chart for recommended lengths.

NOTE

Honeywell Analytics recommends the use of Teflon FEP (Fluorinated Ethylene Polymer)

tubing to assure proper sample transport. The properties of Teflon FEP make it the best

choice for transporting sample toxic gases to instruments when compared with the

properties of other similar tubing materials.

1

25

2

Outlet sample specifications

description maximum

Tubing Length, m (ft) 30 (100)

Back Pressure at Exhaust Point 20.3 cm H2O (8 in H2O)

Flow rate, cc/min 600 (Flow is constant)

Midas-M 17 User Manual

Page 18

description maximum

Tubing OD, mm (in) 6.35 (0.25)

Tubing ID, mm (in) 4.76 (0.188)

Prepare Tubing

1. Cut the tube squarely and remove any burrs.

2. Mark from end of tube the length of insertion. The insertion lenght of Midas-Mfrom the end

of tube is 15.5 mm.

NOTE

When inserting the tube into the inlet/outlet port of the Midas-M, make sure that it is

inserted up to the marked position.

In-Line Filters

External filters must be used to protect the tubing from contamination. Use particulate filter part

number 780248 for normal gases and 1830-0055 or 1991-0147 for corrosive gases. Replace

the filter every 3 months. Refer to the Gases Table for specific gases.

Local Detector Option

The Midas-M gas detector can also be used to monitor for gas at the location of the detector. To

do this, an inline filter is simply connected to the sensor cartridge gas inlet port. The external

dust filter part number is 780248 for normal gases and 1830-0055 or 1991-0147 for corrosive

gases. The area around the detector is then being monitored as opposed to a sample being

drawn from a remote location.

Midas-M 18 User Manual

Page 19

Electrical Installation

Access for the electrical wires to the terminal module is made via the PG16 cable gland located

at the bottom of the mounting bracket assembly. The cable gland can be removed and replaced

with a suitable conduit fitting if required.

Typical wire routing

The terminals used are suitable for conductors of 24 to 14 AWG (0.5 to 1.8mm Dia.). We

recommend using the 16 AWG (1.5 mm Dia.) conductors.

If Power over Ethernet (PoE) is used to power the device, then 24 VDC power must not also be

connected to the device, (or conversely, if 24 VDC is used to power the Midas-M, then electrical

power via the Ethernet port must not be applied). Failure to observe this requirement may cause

damage to the gas detection system and will not be covered by the standard warranty.

When connecting the wires ensure that the power switch is in the off position.

NOTE

Earthing Requirements: If the Midas-M unit’s metal chassis is not connected directly to a

metal surface for earthing purposes, an additional earth wire will be required. Connect a

Midas-M 19 User Manual

Page 20

wire via the PG16 gland to the dedicated earth tag (screw terminal) located on the bottom

bracket and connect the other end of the wire to a dedicated external earthing point. If

Power over Ethernet (PoE) power supply is being used, shielded CAT5 Ethernet cable is

recommended. Please ensure that your wiring avoids earth ground loops that may affect

the performance of your equipment.

NOTE

Instrument grounding is required to ensure stable performance and to limit the effects of

radiofrequency interference before installation.

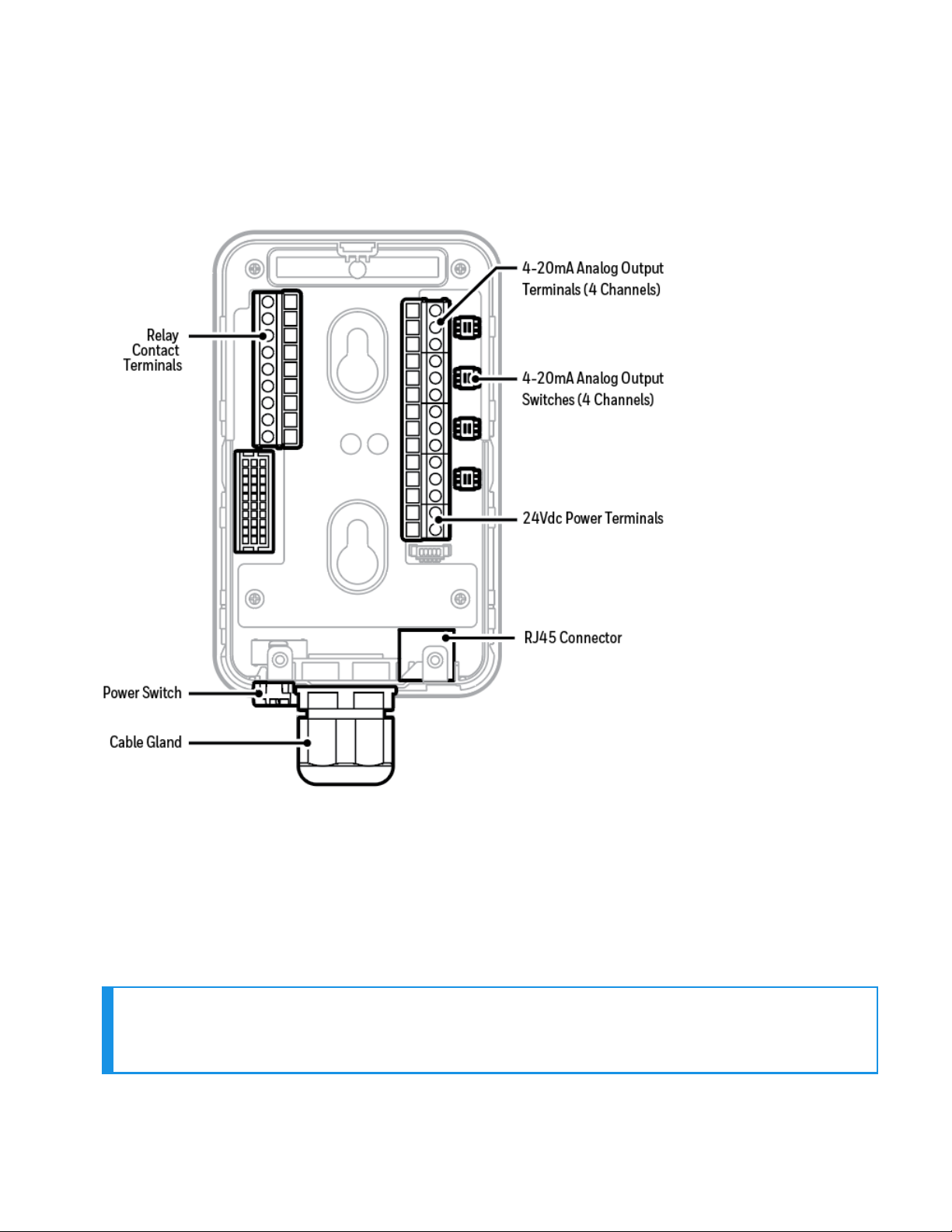

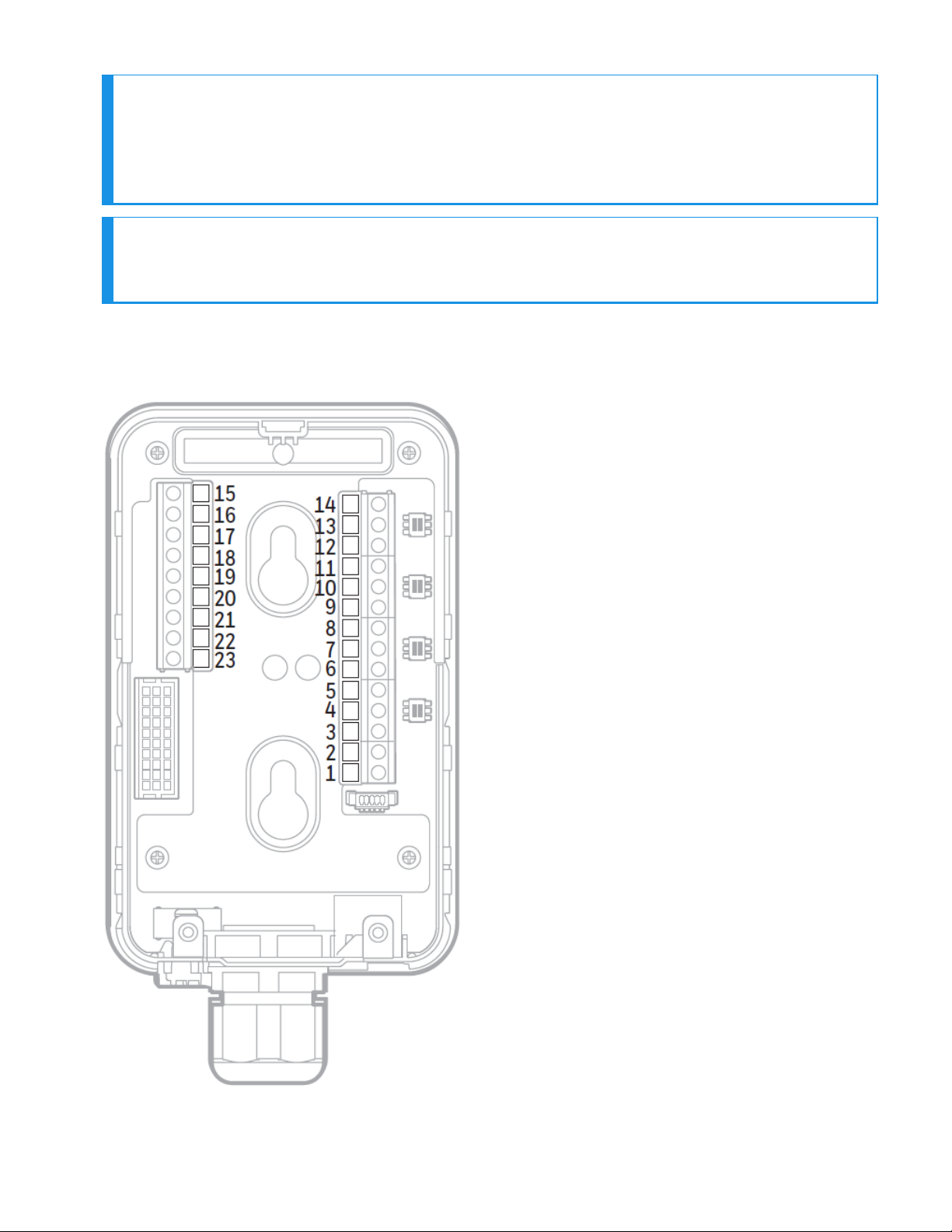

The following diagram shows the terminal module layout and terminal identification as well as

the jumper locations.

Transmitter Terminals

Midas-M 20 User Manual

Page 21

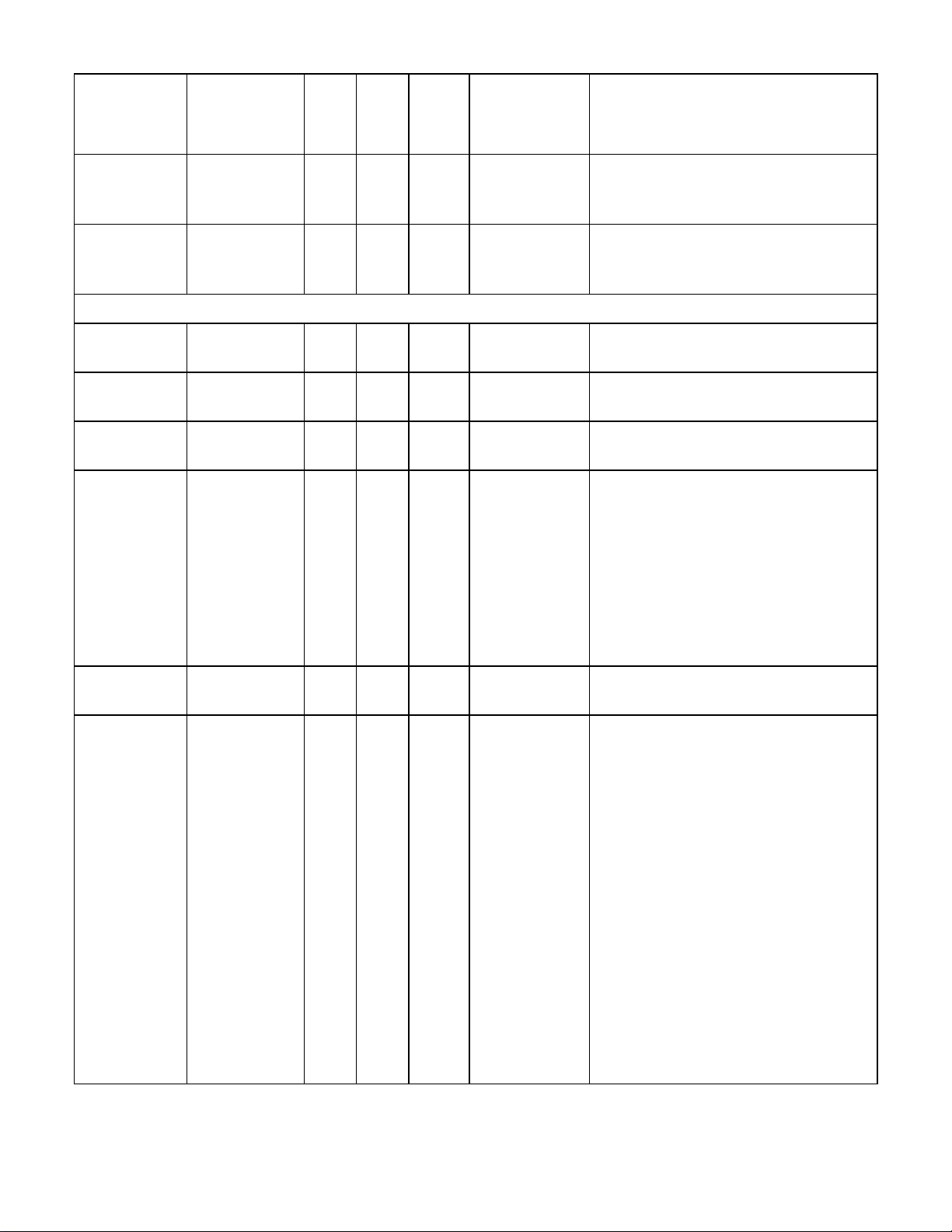

Transmiter Terminals

terminal number function description

1 24Vdc Input 0Vdc

2 24Vdc Input +24Vdc

3 mA output - Channel 1 COM

4 mA output - Channel 1 mA-

5 mA output - Channel 1 mA+

6 mA output - Channel 2 COM

7 mA output - Channel 2 mA-

8 mA output - Channel 2 mA+

9 mA output - Channel 3 COM

10 mA output - Channel 3 mA-

11 mA output - Channel 3 mA+

12 mA output - Channel 4 COM

13 mA output - Channel 4 mA-

14 mA output - Channel 4 mA+

15 Relay 1 Normally Closed

16 Relay 1 Common

17 Relay 1 Normally Open

18 Relay 2 Normally Closed

19 Relay 2 Common

20 Relay 2 Normally Open

21 Relay 3 Normally Closed

Midas-M 21 User Manual

Page 22

terminal number function description

22 Relay 3 Common

23 Relay 3 Normally Open

Relay function table

Display Description Relay 1 Relay 2 Relay 3

INSTRUMENT F

ONLY

SEPARATE F

COMBINED F

Midas-M 22 User Manual

Instrument fault

only

Separate fault

relays

Combined fault

relay

Alarm 1 Alarm 2

Any

alarm

Alarm 1 Alarm 2 Any fault

Maintenance

fault

Instrument

fault

Instrument

fault

Page 23

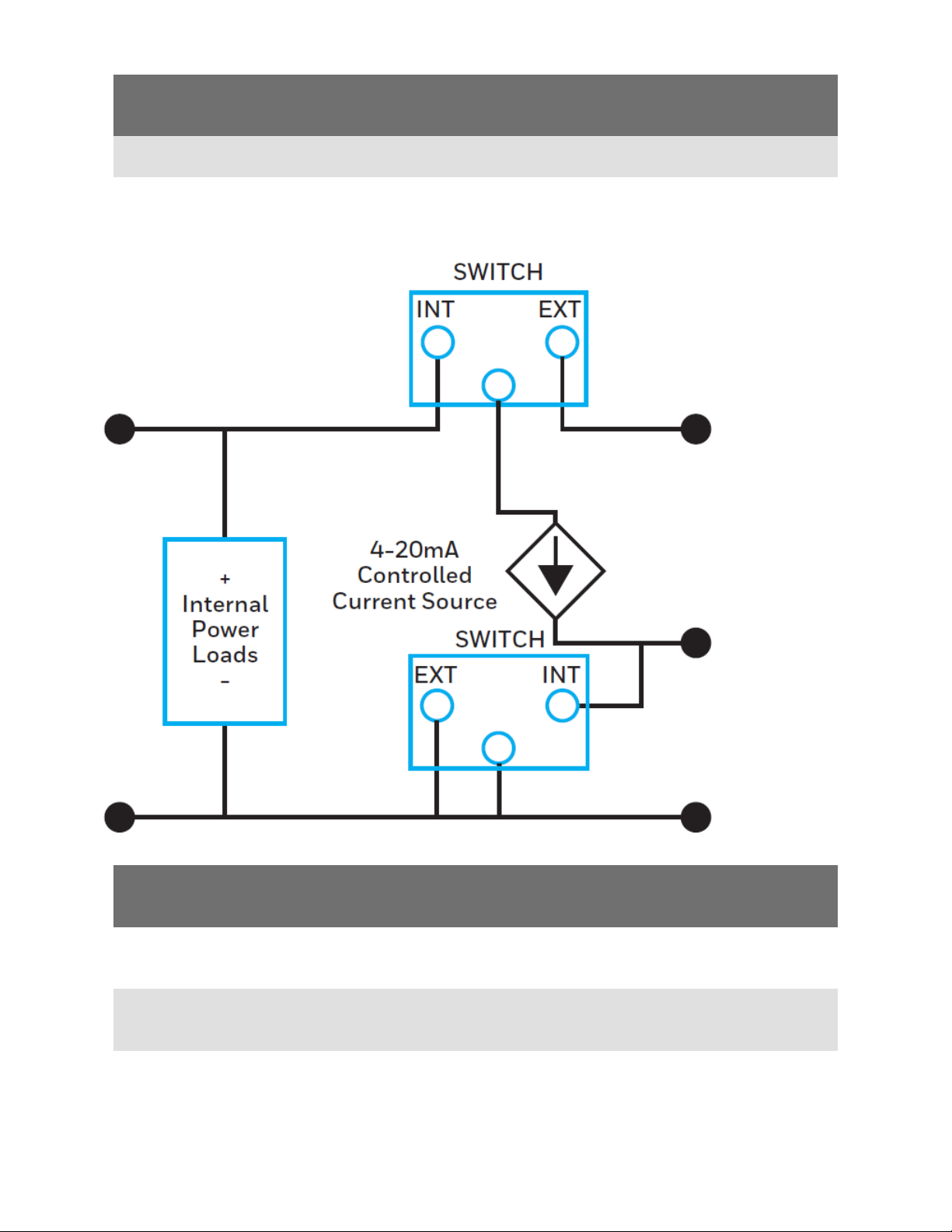

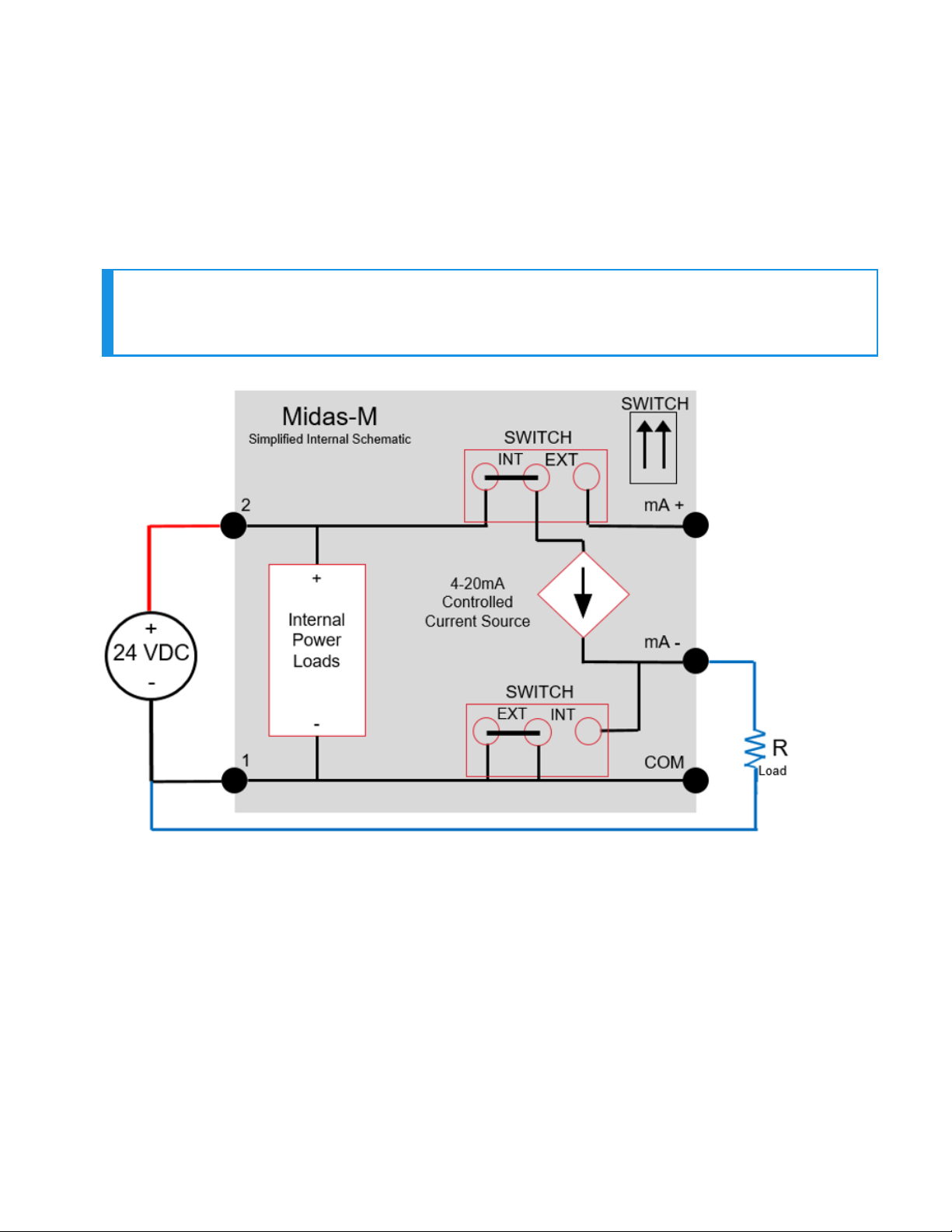

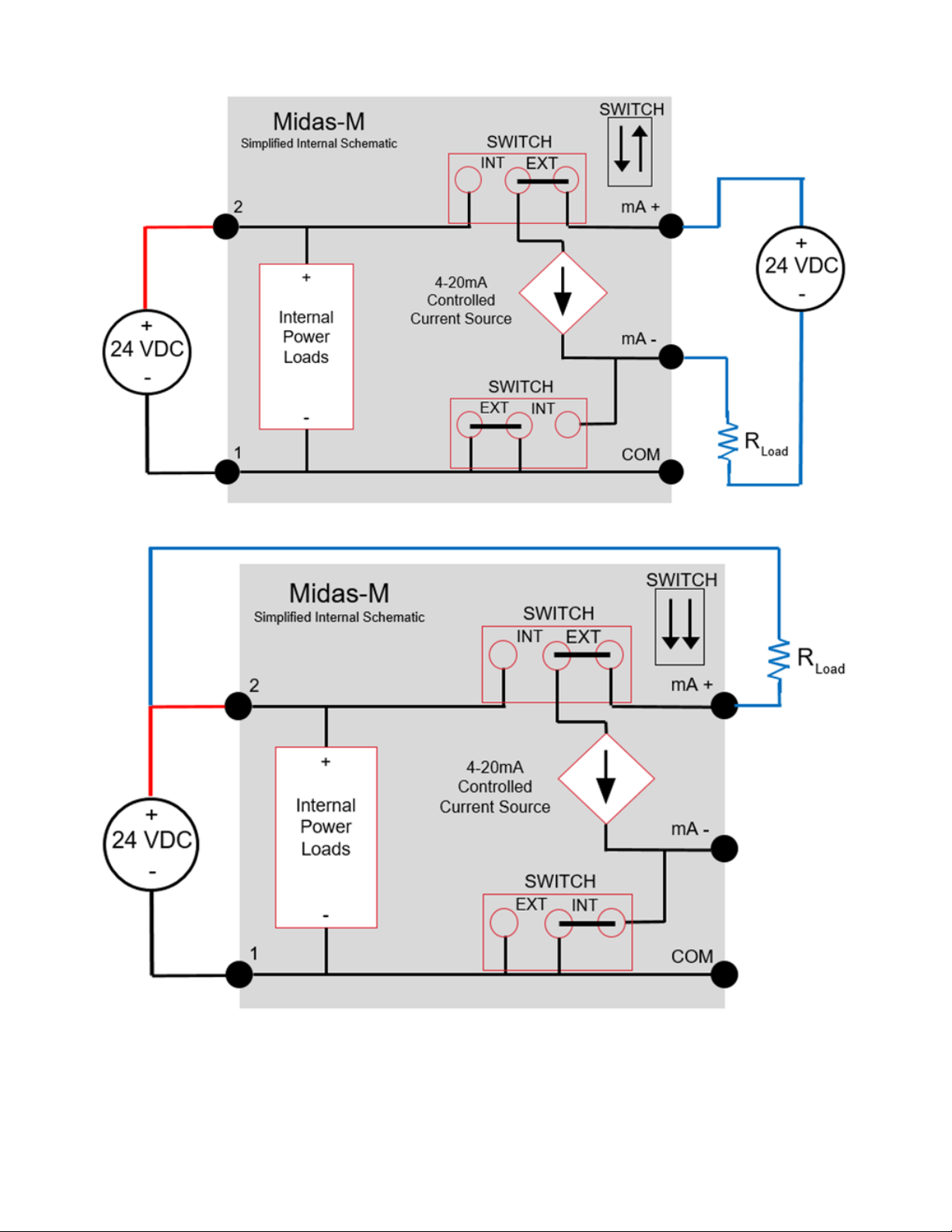

Electrical Connection

Midas-M can be powered by either 24 VDC via traditional discrete wiring or by approximately 48

VDC delivered through the Ethernet cable from a PoE source. In either case, the 4-20 mA analog

output can be used.

The analog output can be configured for fully isolated operation. With 24 VDC power the 4-20

mA output can be configured for sink, source or isolated output operations. Following are some

schematic diagrams of typical electrical connection configuration.

NOTE

When wiring the Midas-M Transmitter to a controller, program the controller for a 1-2

second delay before reporting to prevent false alarms.

Generic example Midas-M 3-wire sourcing

Midas-M 23 User Manual

Page 24

Generic example Midas-M 4-Wire Isolated output

Generic example Midas-M 3-wire Sinking output

Midas-M 24 User Manual

Page 25

Generic example Midas-M Isolated 4-20mA output w/PoE power

Midas-M 25 User Manual

Page 26

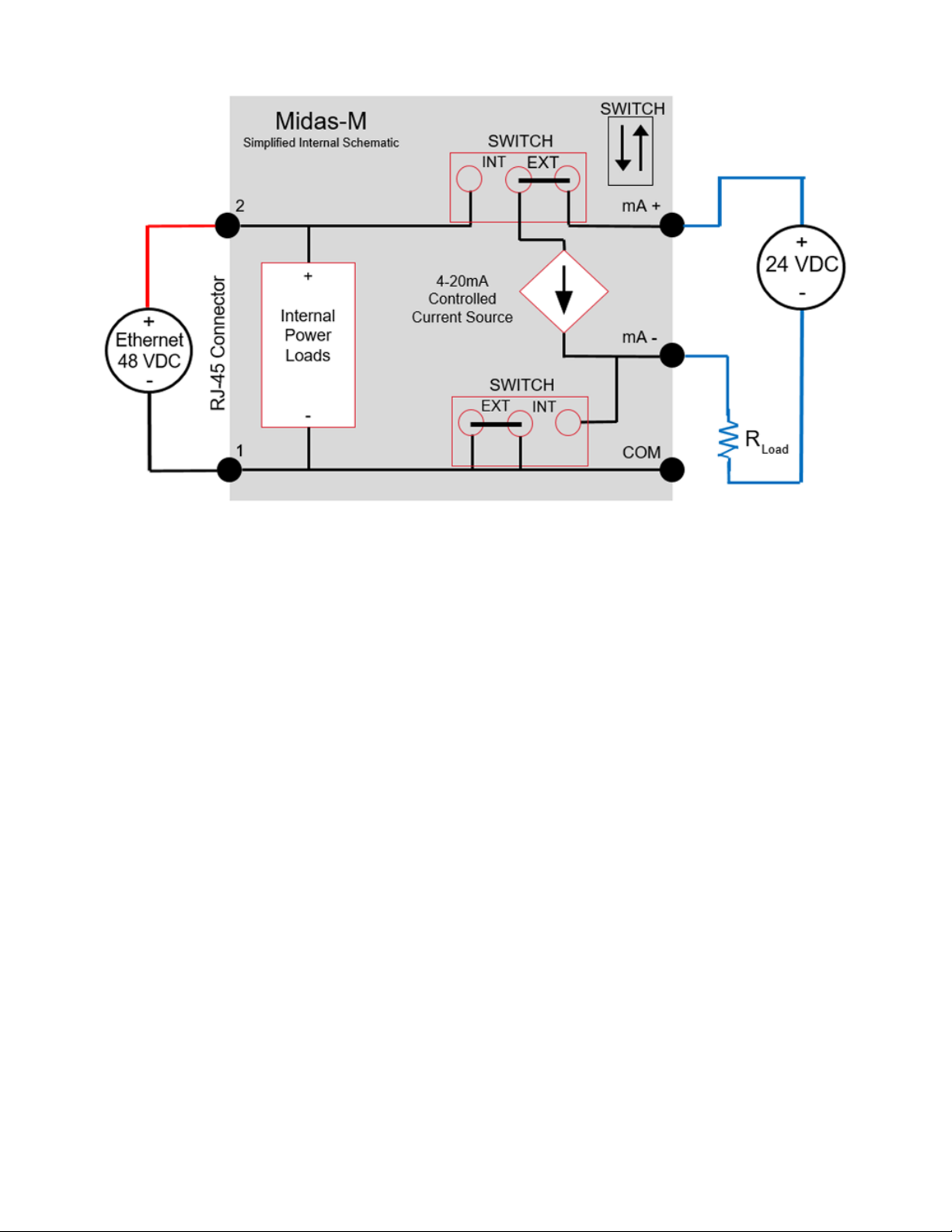

Wiring The Relay Module

The Midas-M relay module contains:

Nine relays to activate external devices.

Eight gas alarm relays which indicate level 1 and level 2 alarms of each channel.

A common fault relay which indicate maintenance fault or instrument fault.

Specifications

Power Supply

Power

consumption

Relay rating 1.0 A @ 30VDC or 0.5 A @ 125 VAC max, 10 uA @ 10 mV minimum

Wiring 14 AWG maximum per each channel

Midas-M 26 User Manual

No separated power supply required Supplied from the Midas-M

transmitter

< 1.45 W

Page 27

Default configuration

All alarm relays Normally de-energized, energized on alarm

Common fault relay Normally energized, de-energized on fault

Midas-M 27 User Manual

Page 28

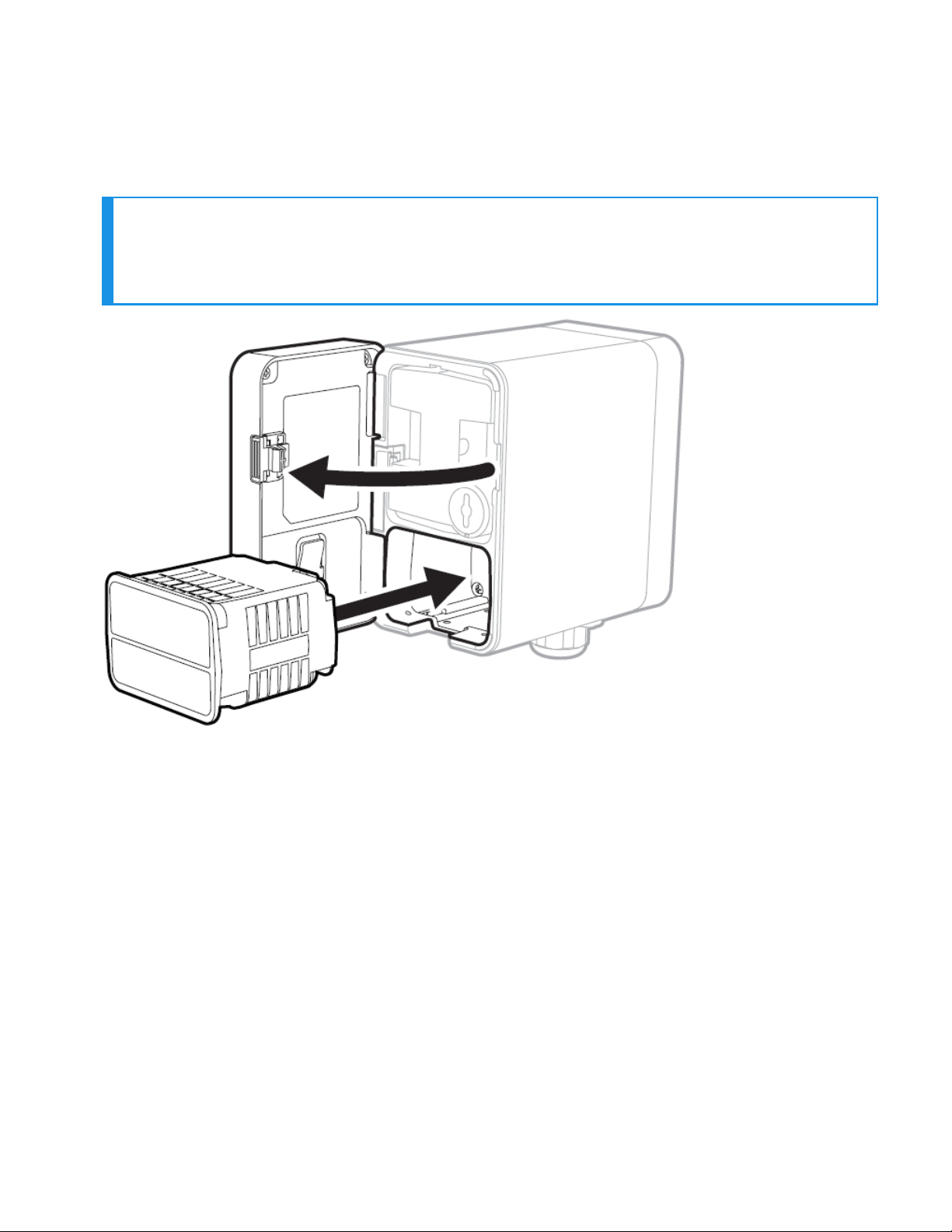

Mount The Sensor Cartridge

The Midas-M Sensor Cartridge enables the detection of a wide range of asphyxiant, toxic,

flammable, pyrophoric, corrosive, and oxidizer (including Oxygen) gases. The plug & play Sensor

Cartridge is located inside the detector’s chassis.

NOTE

The Midas-M sensor cartridge is supplied separately.

Before use, verify the part number and type of sensor cartridge is correct for your

application.

1. Turn the power off.

2. Open the door and remove the BiAS battery module and the two plug caps from the sensor

cartridge.

3. Align the Sensor cartridge pins with the socket in the sensor cartridge chamber and then

push the sensor cartridge gently until fully seated.

4. Close the door.

5. a. Press the ‘O’ button to clear the “Detect New Cartridge ” message.

b. Confirm that the green LED is flashing, and that the yellow and red LEDs are off.

c. Confirm the display shows a concentration of zero as appropriate.

Midas-M 28 User Manual

Page 29

CHAPTER

3

Learn what you can do with your Honeywell Midas®-M Detector, from commissioning to

Maintenance

Device & Web Operations

Comissioning

Comissioning should be followed carefully and only performed by suitably trained personnel.

WARNING

Before carrying out any work, ensure local and site procedures are followed. Ensure that

the associated control panel is inhibited to prevent false alarms.

1. Ensure the detector is wired correctly.

2. Ensure that the correct sensor cartridge is fitted. (If the cartridge has not been stored at room

temperature, allow one hour for equilibration.)

3. Ensure the ON/OFF switch on the bottom of the mounting bracket assembly is in the ON

position.

4. Apply power to the system. Wait for a couple of minutes until the start-up routine completes.

5. After the start-up routine, the detector will display the Normal/Monitoring Operating Mode.

6. Perform a leak test to ensure all connections are secure. ‘Waiting…’ will be displayed on booting

time.

7. Allow the detector to stabilize until the ‘Warm-up’ message is no longer displayed after booting.

The maximum warm-up time is dependent on sensor type. Refer to individual cartridge data

sheets. Warm-up times are typically much faster.

8. Ensure the correct ID code is selected in Set-up > alarm menu

9. If this is a first-time start-up, the “Detect New Cartridge ~” message could be displayed. Press

the ‘O’ button to clear the message.

Midas-M 29 User Manual

Page 30

Monitoring Mode

After commissioning, the Midas-M detector is set in the Monitoring Mode, which is the starting

point for all of the device's operations.

The examples in the following table are for a linear 4-20 mA output over a full scale range of 2

ppm. The current output for a given gas concentration will be different for other full scale

ranges (linear 4 mA = 0 % full scale to 20 mA = 100 % full scale). The alarm and fault relays are

in default (latching) mode.

Normal Operation Display and Outputs.

This table is based on the default configuration of toxic sensor type.

Status Relay Status

Alarm 1

Midas-M 30 User Manual

Alarm relay 1

activated

4-20mA output

mA output to

match the

concentration

LEDs Backlight

Green flash

Alarm 1 Red

on

Red on of the

channel

Page 31

Status Relay Status

Alarm relay 2 deactivated

Fault relay deactivated

4-20mA output

LEDs Backlight

Alarm 2

Greater than

full scale

Inhibit

Alarm relay 1 activated

Alarm relay 2

activated Fault relay

de-activated

Alarm relay 1

activated

Alarm relay 2

activated

Fault relay deactivated

Alarm relay 1 deactivated

Alarm relay 2 deactivated

Fault relay deactivated

mA output to

match the

concentration

21mA

2mA Green flash

Green flash

Alarm 1 Red

onAlarm 2

Red flash

Green

flash

Alarm 1

Red on

Alarm 2

Red flash

Yellow on

Red flash of the

channel

Yellow on of the

channel

Alarm relay 1 deactivated

Green

Maintenance

fault

Instrument

fault

Midas-M 31 User Manual

Alarm relay 2 deactivated

Fault relay deactivated

Alarm relay 1 deactivated

Alarm relay 2 deactivated

Fault relay

activated

3mA

1mA

flash

Yellow on

Green

flash

Yellow

flash

Yellow on of the

channel or all

channels dependent

on fault type

Yellow flash of the

channel or all

channels dependent

on fault type

Page 32

Review Information

From the Review Mode, you can see the information of transmitter, cartridge, alarm, 4-20mA,

relays, fault, calibration, date/time, network, event log, and advance.

1. Go to the Monitoring Mode.

2.

By pressing or buttons you are entered automatically to the Review Mode and one

of the Review options is displayed under Review.

3.

Press or buttons to scroll to your desired option.

4.

Press to accept and enter the selected option.

5. Repeat Steps 3 and 4 to continue exploring more options from the Review Mode.

6.

Optional Step: Press to cancel and return one step back.

From the Review Mode panel, you can review any of the following options:

Option Information you can review from selected option

l FW Revision

l Part Number

Transmitter

Cartridge

l Serial Number

l FW checksum

l Web version

l FW Revision

l Boot loader revision

l Part Number

l Serial Number

l Sensor parameter revision of each channel

Alarms

l Gas type of each channel

Midas-M 32 User Manual

Page 33

Option Information you can review from selected option

l Alarm 1 type and level of each channel

l Alarm 2 type and level of each channel

l Deadband level of each channel

l Alarm latching/non-latching of each channel

l Alarm delay time of each channel

4-20mA Concentration range of 4-20mA output of each channel

Internal Relays

l Relay configuration

l Relay energized/de-energized in normal condition

External Relays Relay energized/de-energized in normal condition

l Latching/Non-latching

Faults

Calibration

l Maintenance fault enable/disable

l Temperature fault enable/disable

l Calibration interval of each channel

l Calibration due days of each channel

l Sensor expired days of each channel

Date/Time Date and Time

l IP obtain method

l IP address

Network

l Subnet Mask

l Gateway

l MAC Address

Event Log Event logs

Advance Channel ON/OFF

Midas-M 33 User Manual

Page 34

Setup Operations

From the Setup Mode, you can configure alarms, 4-20mA, relays, faults, channels, date & time,

network, advance, and security.

1. Go to the Monitoring Mode.

2.

Press or buttons and hold for one second to enter the Main Menu, and one of the

Menu options is displayed.

3.

Press or buttons to scroll to Setup.

4.

Press to accept and enter the Setup menu.

5.

Press or to continue exploring more options from the Setup Mode, and then press

to accep it.

6.

Optional Step: Press to cancel and return one step back.

From the Setup Mode panel, you can review any of the following options:

Option Operations you can Setup from selected option

l Gas type of each channel

l Correlation factor of each channel if gas type is “USER”

l Alarm 1 type and level of each channel

Alarms

4-20mA Concentration range of 4-20mA output of each channel.

l Alarm 2 type and level of each channel

l Deadband level of each channel

l Alarm latching/non-latching of each channel

l Alarm delay time of each channel

Internal

l

Relay configuration (Instrument Fault Only, Separate Fault Relay,

Midas-M 34 User Manual

Page 35

Option Operations you can Setup from selected option

Combined Fault Relay).

Relays

l

Relay energized/de-energized in normal condition.

External

Relays

Faults

Relay energized/de-energized in normal condition.

Latching/Non-latching Maintenance fault enable/disable Temperature fault

enable/disable.

Calibration Calibration interval of each channel

l Date

Date/Time

Network

l Date format (YYYY MM DD, DD MM YYYY, MM DD YYYY)

l Time

l IP obtain method (Manual, Auto)

l IP address

l Subnet Mask

l Gateway

Advance Channel ON/OFF

Security

l Security ON/OFF

l Password

Midas-M 35 User Manual

Page 36

Test Mode

From the TestMode, you can test Bump, Simulation, 4-20mA, and Inhibit.

1. Go to the Monitoring Mode.

2.

Press or buttons and hold for one second to enter the Main Menu, and one of the

Menu options is displayed.

3.

Press or buttons to scroll to Test.

4.

Press to accept and enter the Test menu.

5.

Press or to continue exploring more options from the Test Mode, and then press

to accep it.

6.

Optional Step: Press to cancel and return one step back.

From the Test Mode panel, you can test any of the following options:

Option Operations you can Test from the selected option

Bump Gas bump test

l Alarm 1 of each channel

Simulation

4-20mA Force 4-20mA output of each channel

Inhibit

l Alarm 2 of each channel

l Maintenance Fault

l Instrument Fault

l Inhibit ON/OFF

Midas-M 36 User Manual

Page 37

Option Operations you can Test from the selected option

l Inhibit time

Midas-M 37 User Manual

Page 38

Calibration Mode

From the Configuration Mode, you can configure Zero, Span, Flow, and 4-20mA.

1. Go to the Monitoring Mode.

2.

Press or buttons and hold for one second to enter the Main Menu, and one of the

Menu options is displayed.

3.

Press or buttons to scroll to Calibration.

4.

Press to accept and enter the Calibration menu.

5.

Press or to continue exploring more options from the Calibration Mode, and then

press to accept it.

6.

Optional Step: Press to cancel and return one step back.

From the Calibration Mode panel, you can configure any of the following options:

Option Operations you can calibrate from the selected option

Zero Zero gas calibration of each channel

Span Span gas calibration of each channel

Flow Pump flow calibration

4-20mA 4-20mA output calibration of each channel

Midas-M 38 User Manual

Page 39

Calibration & Bump Test

All Midas-M sensor cartridges are pre-calibrated by Honeywell Analytics using traceable gas

standards and approved calibration methods to a proven ISO 9000 quality controlled procedure.

The Midas-M sensor cartridge design is very robust and resistant to long term drift; in fact in a

normal operating environment it is possible to extend the calibration interval with Midas-M up

to 24 months (subject to local requirements concerning calibrations). This design feature is

another element that supports Midas-M as a long term cost effective gas detection solution.

Honeywell Analytics recommends frequent bump testing to confirm performance.

NOTE

It is the sole responsibility of each user to determine their own calibration and bump test

schedule based on their own safety assessments and understanding of local requirements.

Just prior to commissioning, each Midas-M unit should be zero calibrated to ensure accuracy. It

is recommended that the unit be powered with the cartridge installed for at least 30 minutes

prior to conducting a zero calibration. A second zero calibration may be required after a 24 hour

period which is dependent on the site conditions. O2 sensors are not zero calibrated but should

be span gas calibrated. See the Gas Table for span gas calibration details. If the ambient

condition in the area the detector is monitoring experiences a long-term change, it is necessary

to perform a zero calibration to allow the unit to adjust to the new conditions.

NOTE

When performing a zero calibration, be sure that the area is free of the target gas and/or

interfering gases (refer to the cartridge data sheets for further details), as the presence of a

background gas will affect the ability for the detector to properly calibrate to the correct

levels. If the sample area cannot be verified to be free of the target gas or cross-sensitive

gases, use a cylinder of zero air to perform the calibration

Calibration of an electrochemical sensor cartridge is a relatively complex discipline to master

and it is possible that in less ideal field conditions the calibration can be far less accurate than

under laboratory conditions and therefore substantial inaccuracies can be introduced. In the

absence of any formal calibration policy by the end user, it is preferable to retain the original

factory calibration.

Care must be taken to ensure that the correct materials for an extractive application are

obtained from reputable suppliers and are of proven quality and composition. Inappropriate

calibration equipment will lead to under - or over-presenting the wrong concentration of gas to

the sensor cartridge during the calibration period. Likewise contaminated or inadequately

flushed tubing and other gas-wet surfaces can also introduce errors into the calibration process.

Only qualified, trained personnel should attempt to perform gas calibrations; contact your local

Honeywell Analytics Service Representative for further details on calibration services. Testing

should be performed at the end of the sample tube or at the detector with a short length of

tubing. Applying gas with a short length (less than 5 feet/1.5 meters) of clean FEP tubing will

give optimal results for confirming the accuracy and response time of the cartridge.

Applying gas at the end of the installed sample line will test the full system including the whole

length of tubing. This will verify the integrity of the tubing. Sample line integrity can also be

Midas-M 39 User Manual

Page 40

checked by performing a leak check. Note that there will be additional transport time due to the

tubing length and conditioning the gas-wet surfaces.

Bump tests are also used as an approximate means to present a controlled gas release to the

sensor cartridge in order to verify that the transmitter does respond accordingly. Bump testing

is popular as typical experiences show that a smaller list of easier to handle gases can be used to

provide functional tests on a wider range of gas types. In the absence of a formal calibration

policy from the end user, Honeywell Analytics would recommend a minimum semi-annual

schedule of at least one bump test per sensor with the appropriate test gas.

Bump testing may reduce sensor cartridge lifetime and the accuracy of the calibration if applied

incorrectly or too frequently. Use only the target gas or the recommended bump test gas.

Zero calibration is a recommended procedure that should be performed periodically to improve

the performance of the sensor. This is particularly important when the sensor is operating

outside of normal environmental conditions (20°C, 50% rH).

The Gas Table indicates the recommended calibration or bump test gas for the Midas-M sensor

cartridges:

Consult with your Honeywell Analytics Service Representative for approved methods and

materials before commencing calibrations and bump tests.

Bump Test

A bump test is not intended to be an accurate calibration, but is used as a confidence check to

ensure that the gas detection system is functional. Since some of the target gases are difficult to

handle, bump testing often makes use of cross sensitivities so that more convenient gases can

be used. In bump test mode, the Modbus/TCP outputs are not inhibited. Only the 4-20 mA and

alarm outputs are inhibited. The bump gas test is a functional check only. Consult local

guidelines for recommended best practices. Bump test concentrations are calculated to

generate a minimum first alarm level response.

Preparation

Most of the test gases are highly toxic. It is essential that personnel using these toxic gases be

trained in their use. Ensure that the test gas will be vented safely.

Applying test gas may cause alarm, fault or maintenance fault indications on the 4-20 mA loop,

relays or digital outputs. Before starting a test, ensure that suitable steps have been taken to

prevent these indications from triggering unwanted actions. The Midas-M gas detector has a

special mode for bump testing where the alarm outputs are inhibited.

Finishing

Wait for the gas reading to return to normal levels. This may take some time, especially if

concentrations above the recommended levels have been used or if the test gas has been

applied for an extended period of time.

Ensure that any latched faults or alarms that have been generated by the testing have been

cleared.

Midas-M 40 User Manual

Page 41

Make sure that the gas detection system is fully restored to its normal operating state and that

any control system overrides used during the testing have been removed.

The alarms generated by the testing will have created entries in the transmitter’s history log.

Troubleshooting

If the test does not produce a satisfactory result, check the following points:

l Check the gas cylinder concentration and type are correct

l Check the expiration date of the cylinder.

l Check that there is sufficient gas left in the cylinder.

l Check that there are no leaks on the test system.

l Make sure that the tubing length is as short as possible and that there are no blockages.

l Make sure that the transmitter is not displaying a fault before the test is started.

Internal Web Server

The Midas-M gas detector unit utilizes an Ethernet port with the TCP/IP protocol as standard.

The Midas-M can function as a HTML web page server and these web pages can be viewed on

external computer equipment (PC, PocketPC etc.) by using a standard software program, i.e.;

Microsoft Internet Explorer 11, Safari, or Chrome . These web pages replicate the user interface

on the front panel of the Midas-M in a more flexible and friendly format for diagnostic and data

entry purposes. The web pages also contain additional features not available via the keypad.

This procedure explains how to view web pages for a single Midas-M which is connected to a

single PC only. Of course it is possible to connect hundreds of Midas-M units to an Ethernet

network. More information may be required from the local IT department and Honeywell

Analytics as appropriate.

Physical Network Components

The Ethernet physical network is intended to connect computers to other computers through

hubs. MIDAS-M has a 10/100 Mbps Ethernet transceiver and supports Auto-MDIX. It supports

Auto-Negotiation for selecting the highest performance mode of operation. To use CAT5

standard or higher shield ethernet cable is recommended for the highest efficiency

communication speed.

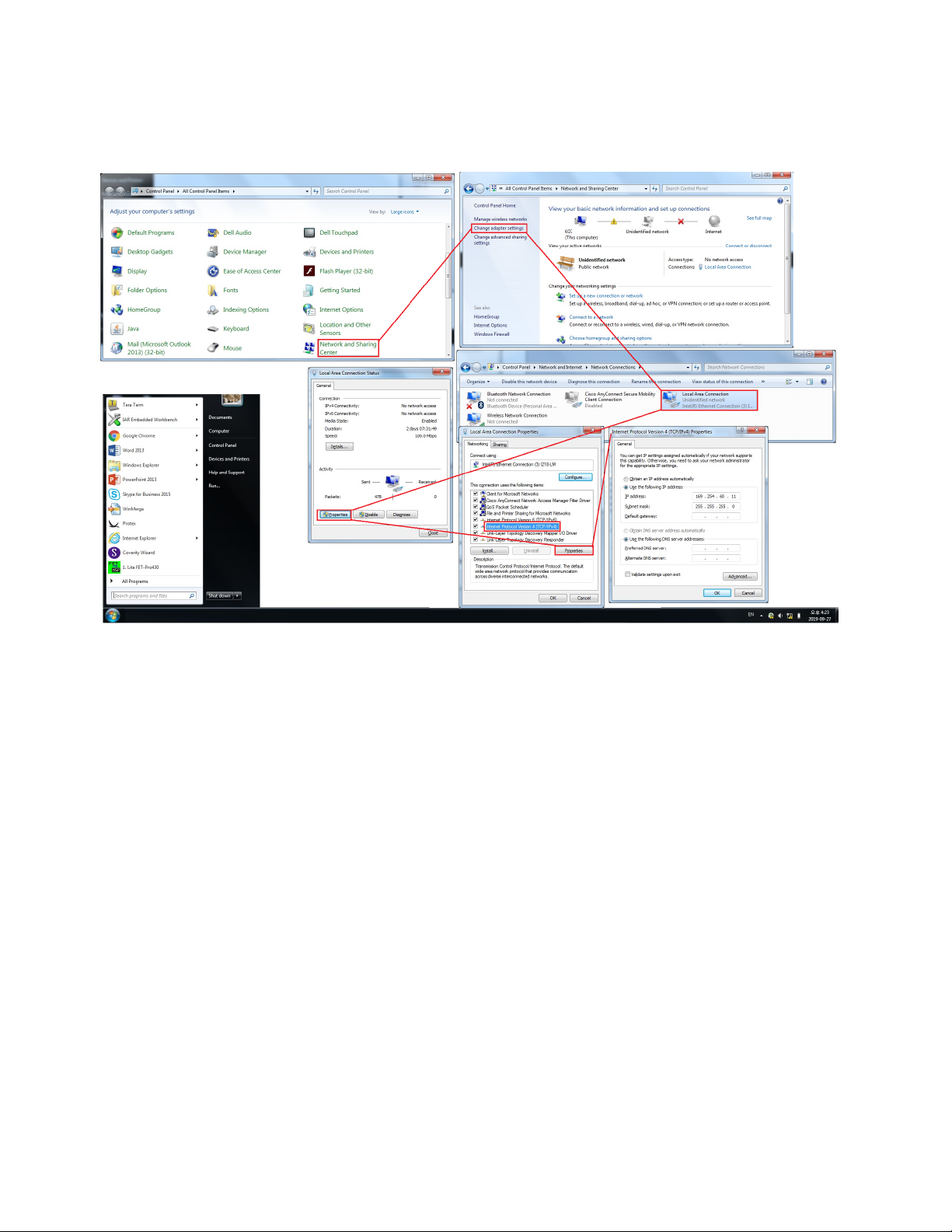

Internet Settings

Communications requires knowledge of the IP address and netmask of both the Midas-M and

the PC. Unless the Midas-M is connected to a network with a DHCP server, the addresses must

be set manually.

The procedure for setting the IP address of a PC is detailed in the following example using a PC

loaded with Microsoft ™ Windows 7 and Internet Explorer version 11.0 or higher as illustrated as

follows.

In the usual case the netmask for both computers should be set to 255.255.255.0. The mostsignificant three bytes of the IP address must be identical and the least-significant byte must be

Midas-M 41 User Manual

Page 42

unique. For example, if the IP address of the Midas-M was set to 169.254.60.47 (the factory

default) then an appropriate IP address for the PC would be 169.254.60.42.

IP Address setting in Windows 7

Running the Web Server

In a web browser, set the URL to “http://xxx.xxx.xxx.xxx” where the “xxx” fields are replaced with

the IP address of the Midas-M.

Device's Overview

Display general information about the device and gas information of each channel.

From the home page, select General > Status > Overview.

The following image shows the information you can review from the Overview page.

Midas-M 42 User Manual

Page 43

Option Description

Overview page

Channels

General Device's general information

Summary

& Print

Reset

Alarm

Midas-M 43 User Manual

The gas information for each channel is displayed. The color bar under each box

shows the status of the channel.

A print-ready summary of device's information.

If alarms are occurring, reset the alarms.

Page 44

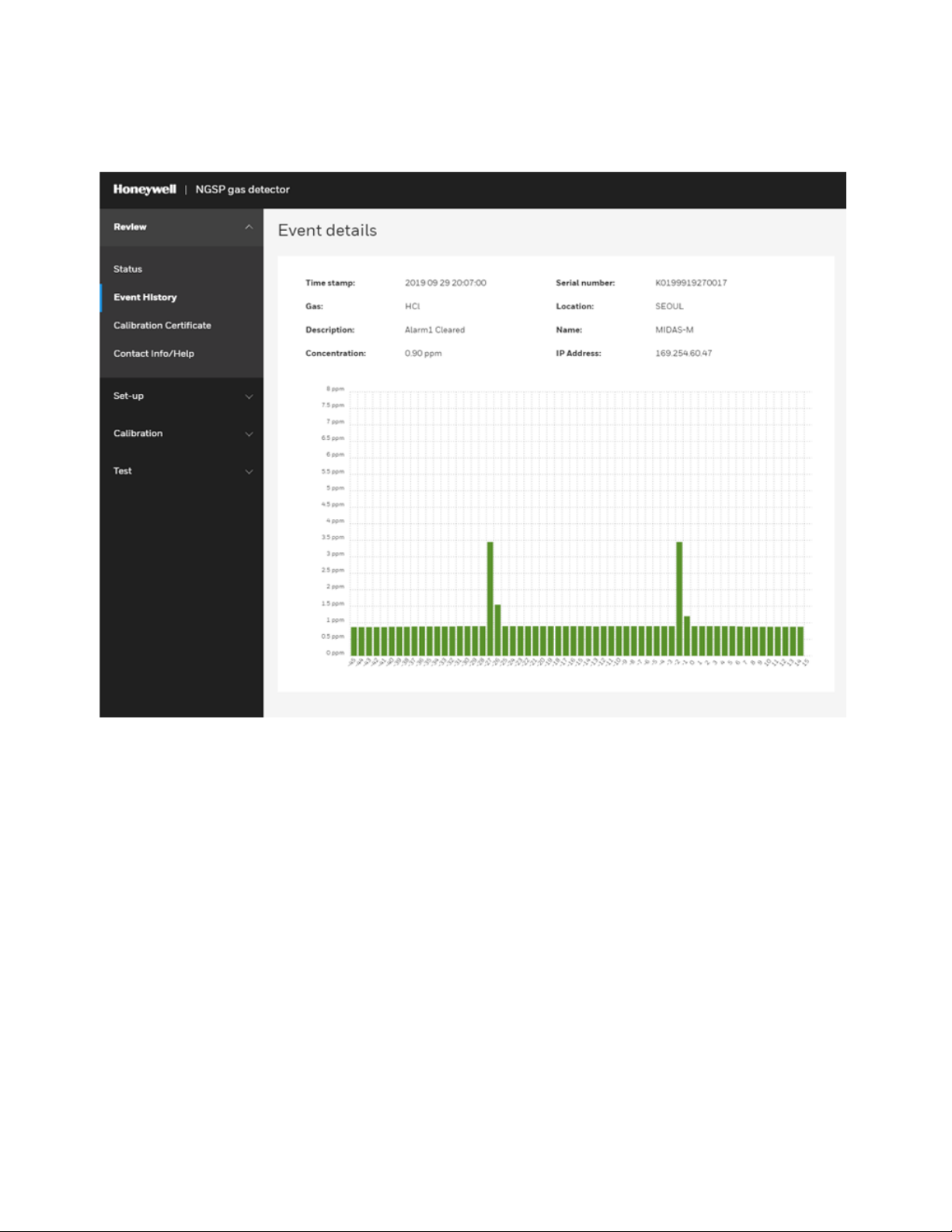

Log Review

On this page, you can view information about records in text format and as a detailed graph.

From the home page, select General > Event History.

Midas-M 44 User Manual

Page 45

The following graph shows detailed information about the selected log. The graphic displays the

gas concentration before and after a specific time from when the event occurred.

Midas-M 45 User Manual

Page 46

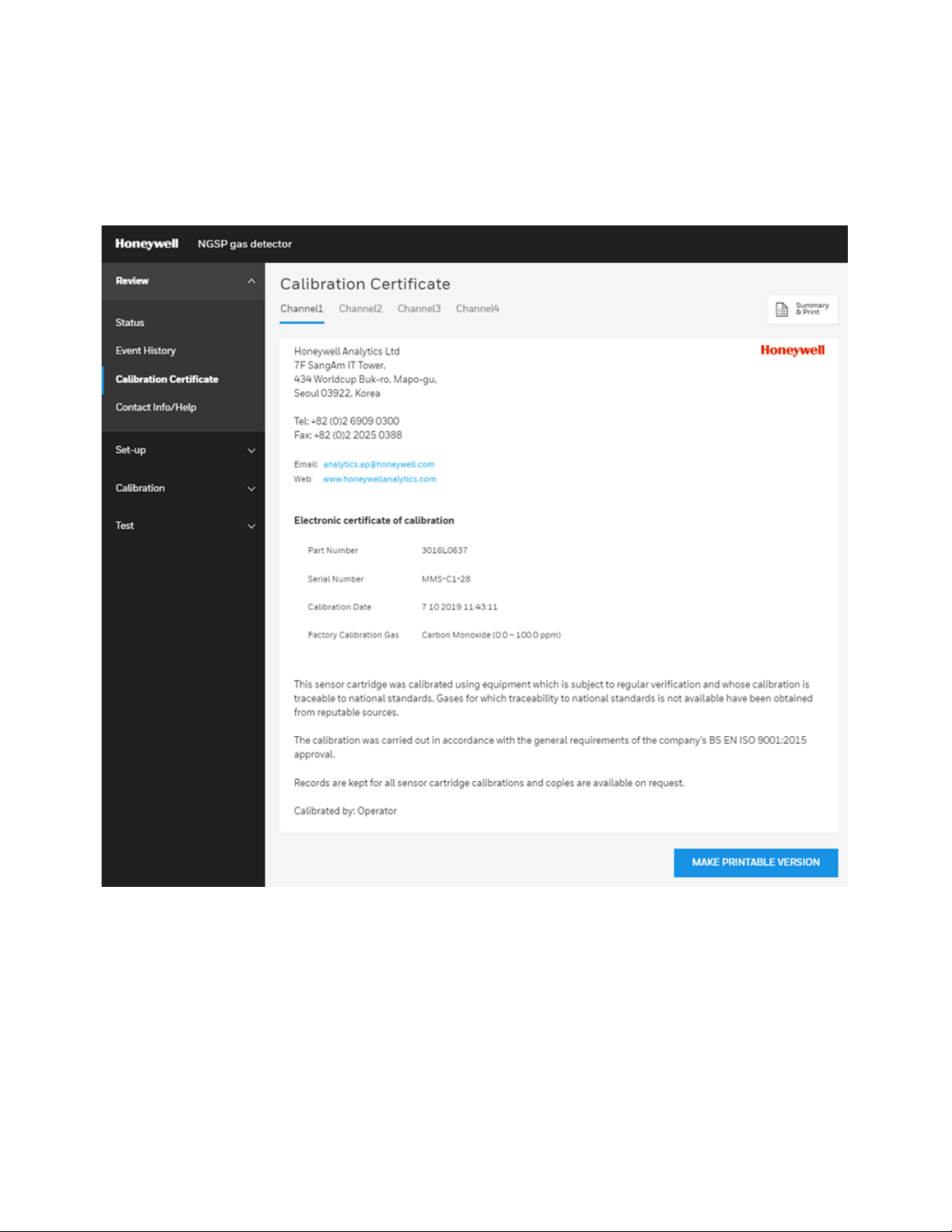

Get a Calibration Certificate

Get the calibration information implemented on a per-channels basis when the device was

manufactured.

On this page, you can view information from the producer, device, and name of the calibrator.

From the home page, select General > Calibration Certificate.

Midas-M 46 User Manual

Page 47

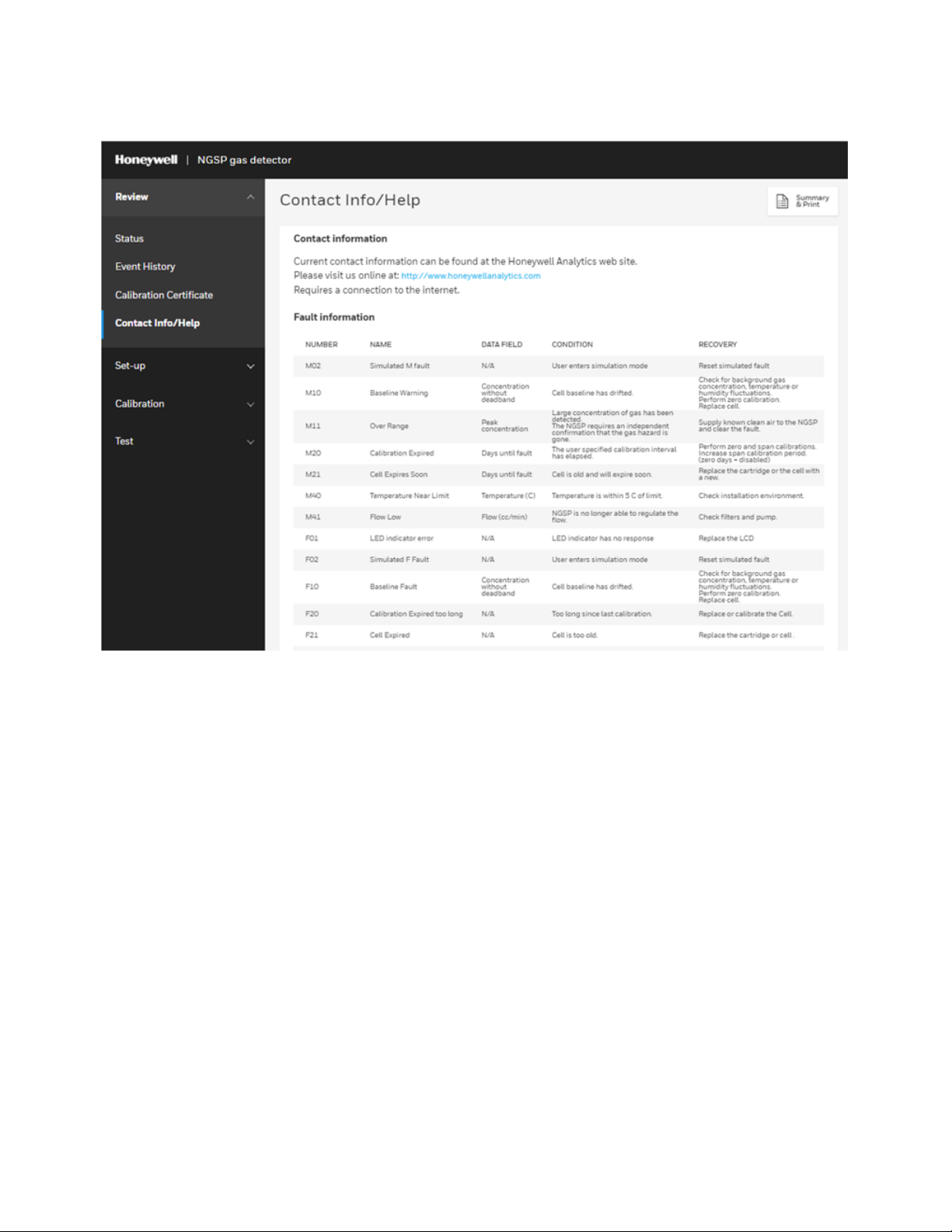

Get Fault and Contact information

To get fault's list and Contact info, select General > Contact Info/Help.

Midas-M 47 User Manual

Page 48

Set up Gas and Alarm

Set up gas detection and alarm set for each channel.

On the home page, select Set-up>Gas/Alarm.

1. Set the desired channel.

2. Gas: Set the gas you want to detect on each channel. Gas-name and K-factor (weight value

for gas value) can be set only for User-gas.

Note: You cannot set the range.

3. Set the concentration at which Alarm1 occurs.

4. Set the concentration at which Alarm2 occurs.

5. Enter the Dead band.

6. Enter the Alarm delay. When an alarm condition is reached, an alarm occurs at a delayed

time.

7. Set up Latching in an alarm situation.

8. Set the time for calibrating the progress alarm.

9. Click Accept.

Midas-M 48 User Manual

Page 49

Configure the Relays

Set the Alarm and Fault relays.

On the home page, select Set-up > Relays.

You can set the relays as follows:

l Relay configuration: Set the operation conditions for Relay 1,2,3.

l Alarm relay: Set whether to generate alarm relay.

l Fault relay: Set whether to generate a fault relay.

Midas-M 49 User Manual

Page 50

Set up the 4-20 mA

Set the ratio of mA and concentration values.

On the home page, select Set-up > 4-20 mA.

You can set the 4-20MA as follows:

l Channel: Select the channel to set.

l Output 4 mA: Set the gas concentration for 4mA.

l Output 20 mA: Set the gas concentration for 20mA.

Midas-M 50 User Manual

Page 51

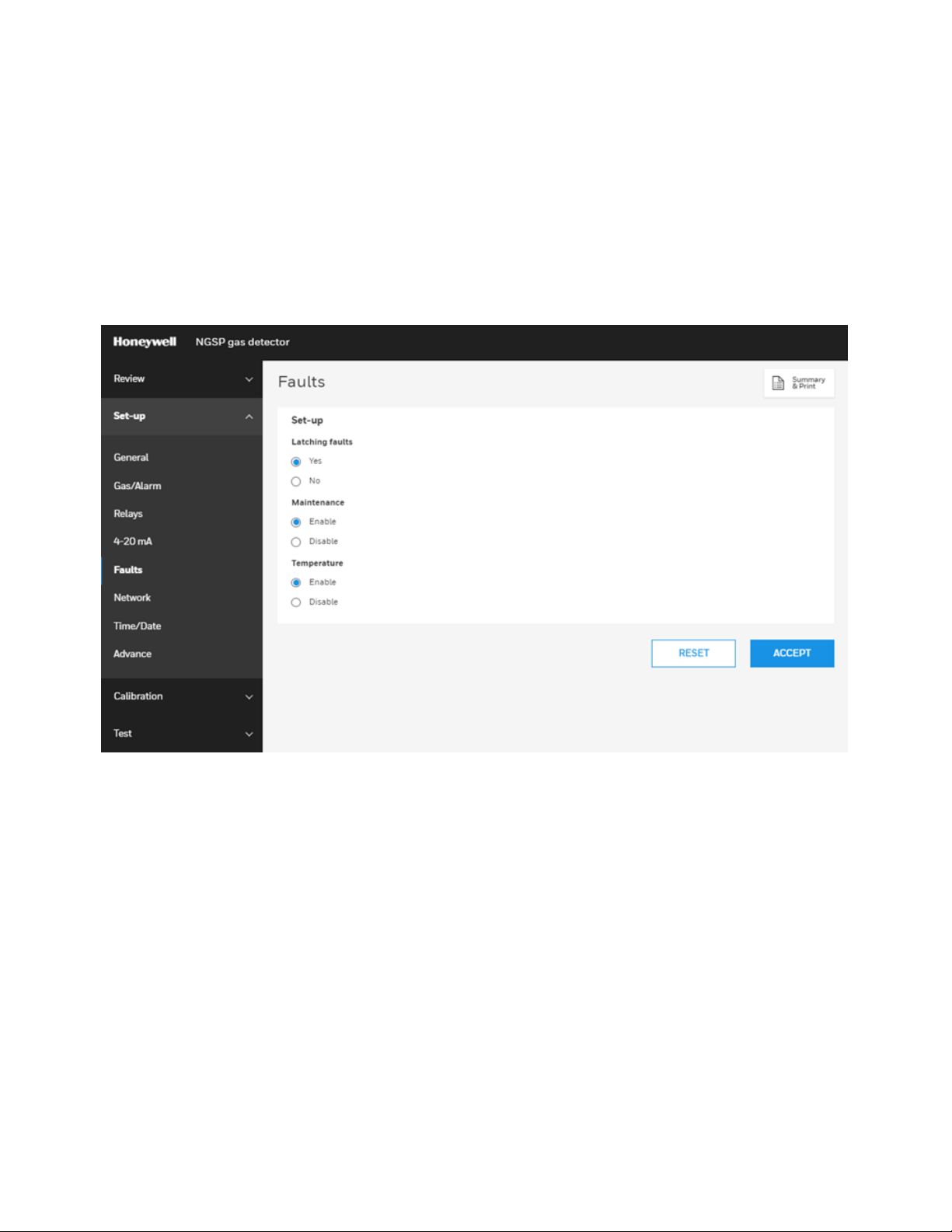

Set up Faults

Set a Fault Occurrence

On the home page, select Set-up > Faults.

You can set the faults as follows:

l Latching faults: Set whether to perform latching when faults occur.

l Maintenance: Set whether to generate a fault for maintenance

l Temperature: Set whether to generate a fault for Temperature. This option is enabled if the

Maintenance setting is allowed too.

Midas-M 51 User Manual

Page 52

Set up the Network

Set an specific network.

On the home page, select Set-up > Network.

You can set the network as follows:

l Obtain IP: You can select whether Manual or Automatic.

l Ip address, Subnet, and Default gateway are enabled only when the Obtain IP option is set to

Manual.

l Hostname: Hostname setting.

Midas-M 52 User Manual

Page 53

Set up the Time and Date

Set the time and date.

On the home page, select Set-up > Time/Date.

You can set the Time and Date in a 24 hour format and synchronize it with the computer.

Midas-M 53 User Manual

Page 54

Turn Channels on/OFF

You can turn ON/OFF an individual channel.

On the home page, select Set-up > Advance.

Zero Calibration

Perform Zero calibration for a specific channel or all at once.

1. On the home page, select Calibration > Zero Calibration.

2. Select the channel or channels to zero calibrate, and then click Start.

Midas-M 54 User Manual

Page 55

3. Wait until the gas reading is stable, and then click Accept.

Midas-M 55 User Manual

Page 56

4. On the Result window the status of zero calibration is displayed. Click Finish.

5. In the Inhibit window you have the option to check Inhibit, and then click Accept.

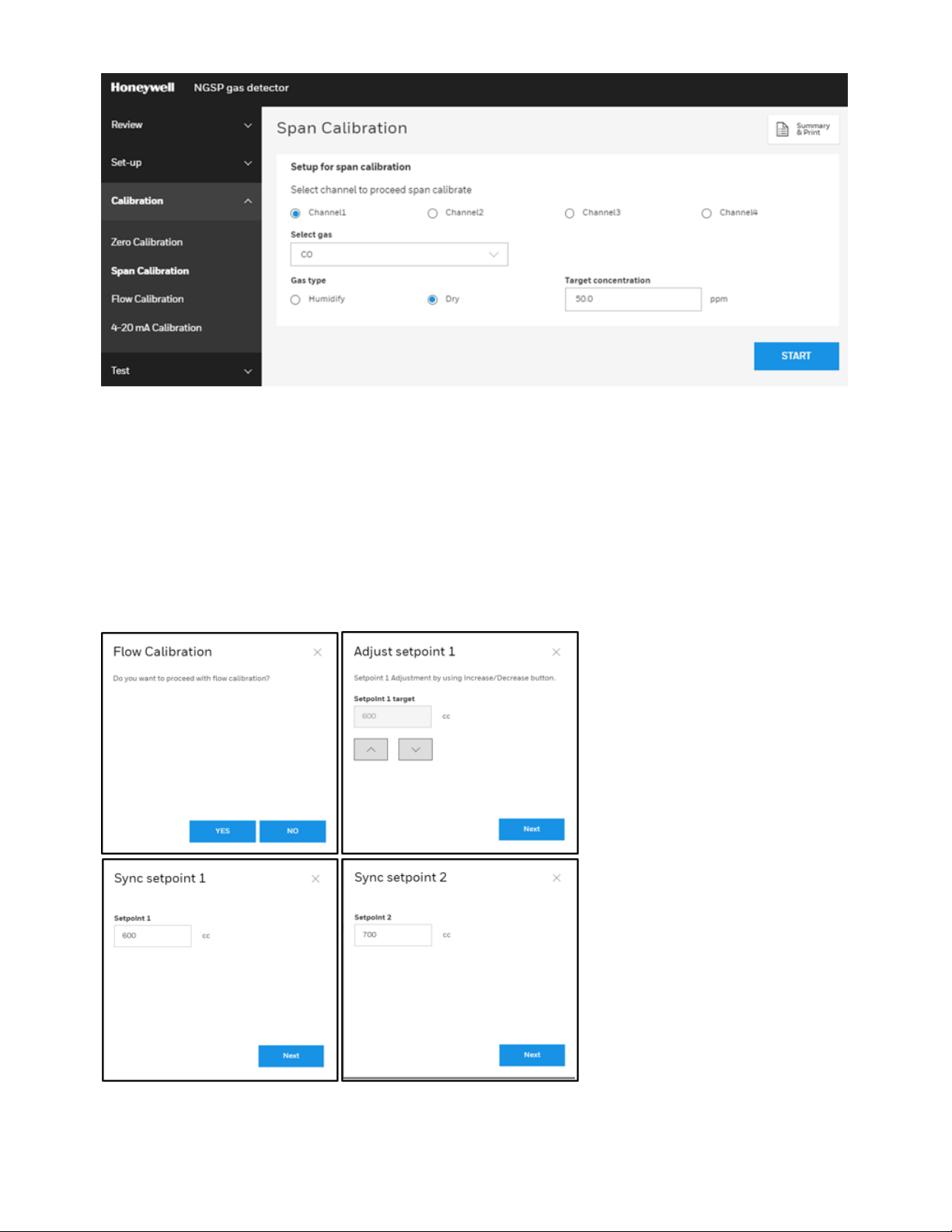

Span Calibration

Perform an span calibration for each channel of the device.

1. On the home page, select Calibration > Span Calibration.

2. On the Span calibration page, you can select the gas, the gas type, and the target

concentration.

3. Click Start and then follow screen instructions.

Midas-M 56 User Manual

Page 57

Flow Calibration

Calibrate the amount of gas entering the device.

On the home page, select Calibration > Flow Calibration, and then follw screen instructions. You

can adjust setpoints,and sync setpoints.

Midas-M 57 User Manual

Page 58

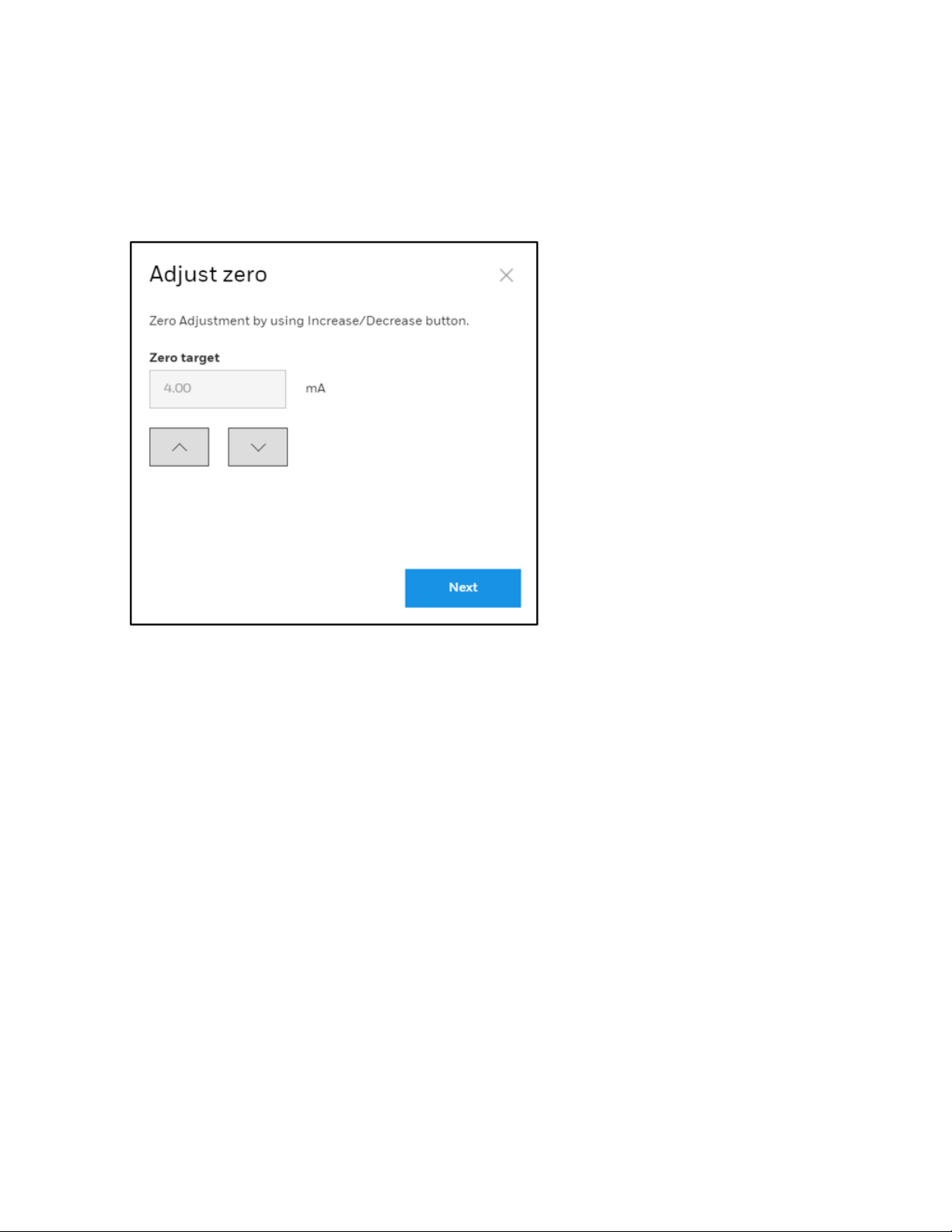

Calibrate 4-20 mA

Perform a mA calibration for each channel of the device.

1. On the home page, select Calibration > 4-20mA Calibration.

2. Select a channel, and then click Start.

3. Increase or decrease the mA value, and then click Next to Zero calibration (4 mA).

Midas-M 58 User Manual

Page 59

4. Increase or decrease the mA value, and then click Next to calibrate the span (20mA).

Perform a Bump Test

Perform a Bump Test on diverse channels.

1. On the home page, select Test > Bump Test.

2. Click Enter Bump Test Mode.

3. Optional Step. You can click Stop Bump Test to cancel the procedure.

Midas-M 59 User Manual

Page 60

Perform an Alarm or Fault Simulation

Simulate function for testing alarm faults.

1. On the home page, select Test > Alarm/Fault Simulation.

2. Select a Channel.

3. Select whether the simulation should be on an Alarm or a Instrument fault.

4. Click Accept.

Midas-M 60 User Manual

Page 61

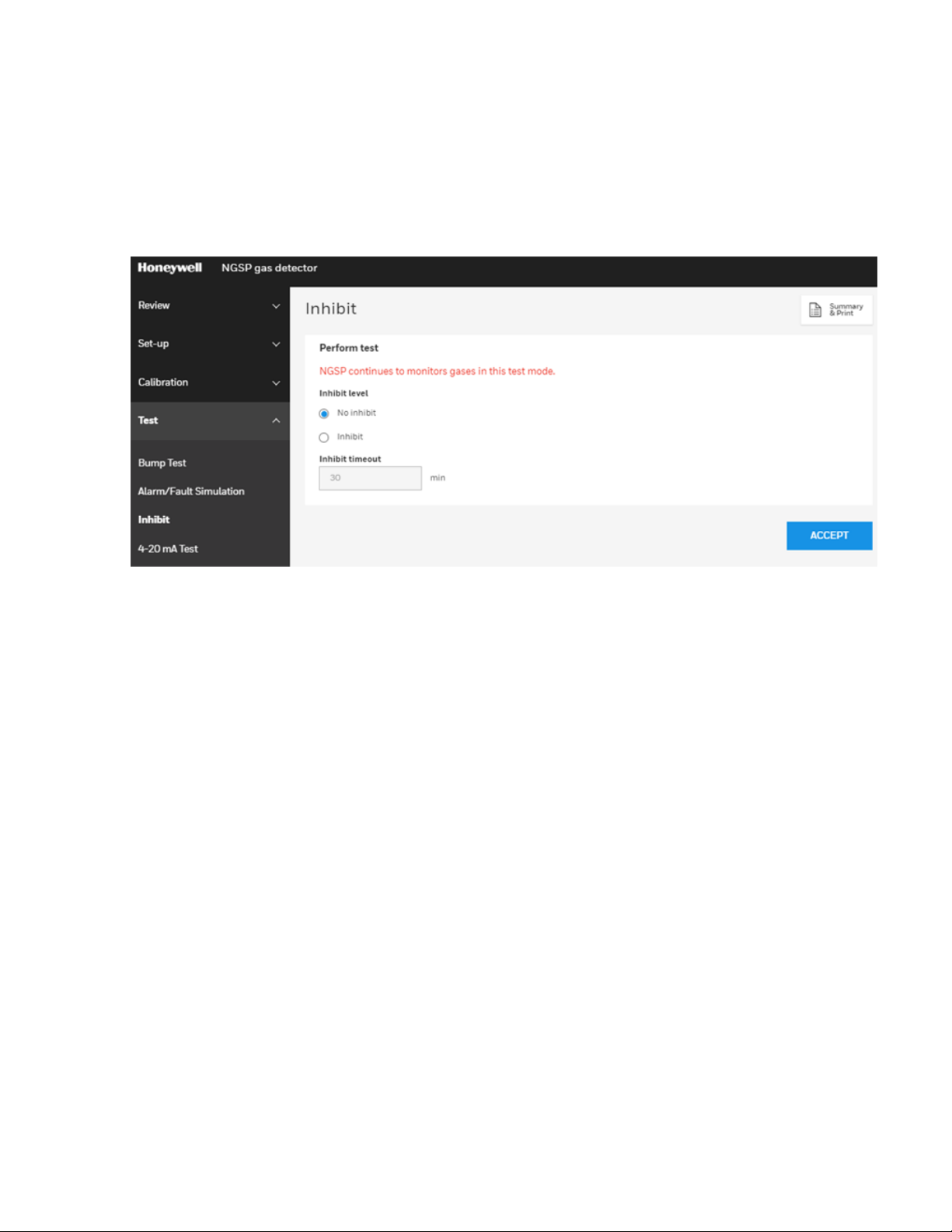

Perform Inhibit Test

Enable or disable the inhibit state.

1. On the home page, select Test > Inhibit.

2. From the Inhibit level option, select No inhibit or Inhibit.

3. Select the Inhibit timeout in minutes.

4. Click Accept.

Midas-M 61 User Manual

Page 62

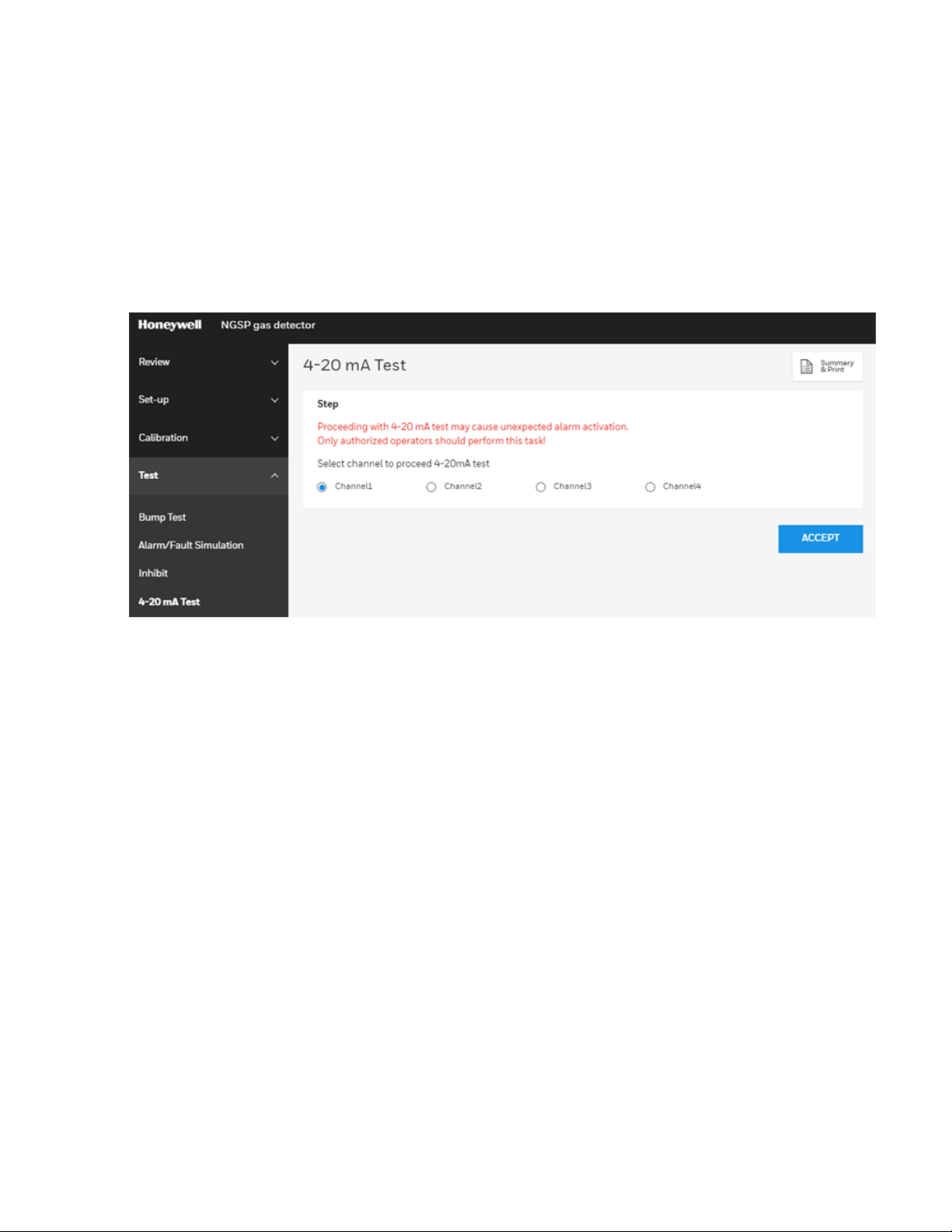

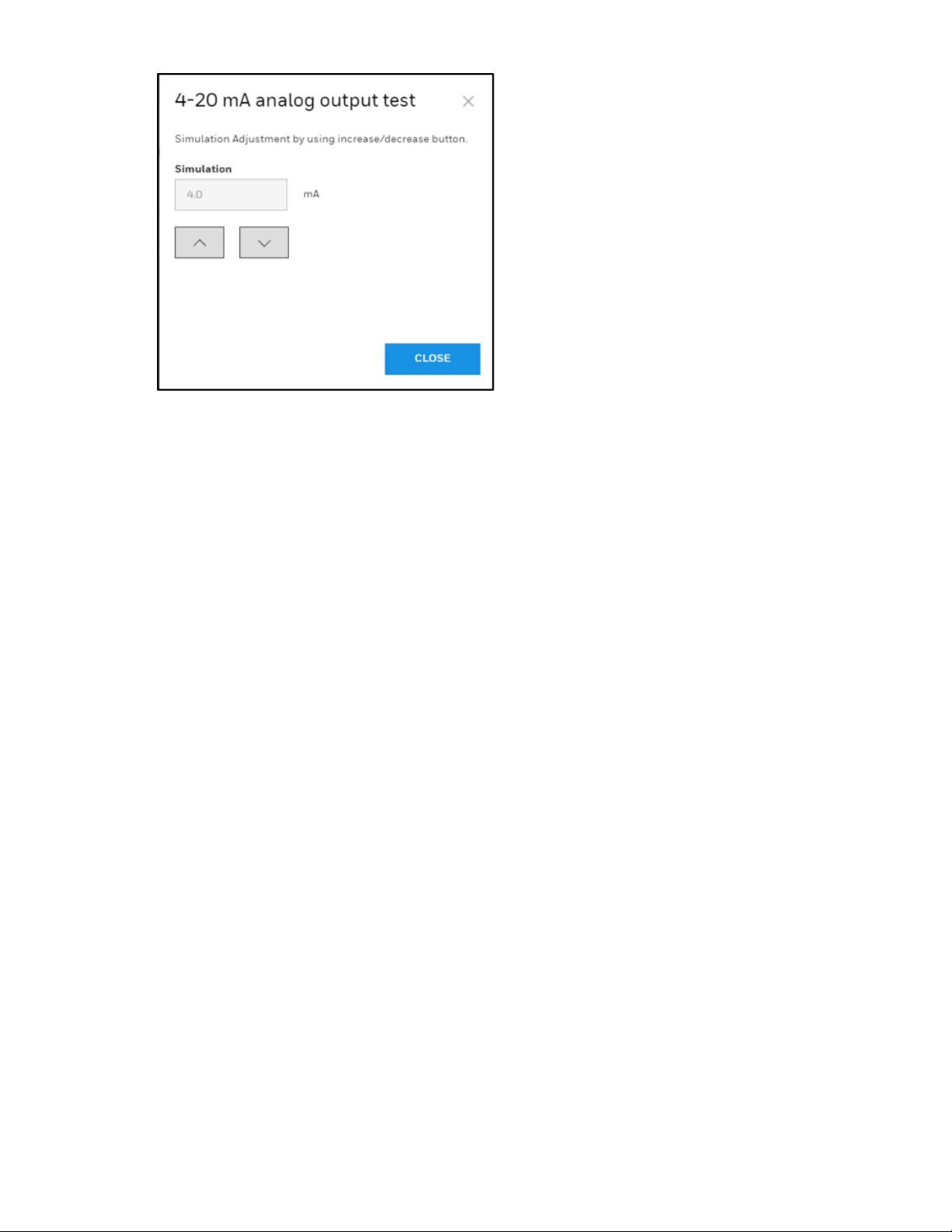

Perform a 4-20mA test

Test the mA value on a channel.

Note: The 4-20 MA test may cause unexpected alam activation. Only authorized operators should

perform this task.

1. On the home page, select Test > 4-20 mA Test.

2. Select a Channel.

3. Click Accept.

4. Increase or decrease the mA value.

5. Click Close.

Midas-M 62 User Manual

Page 63

Midas-M 63 User Manual

Page 64

Page 65

CHAPTER

Maintenance

4

Midas-M is a fully serviceable product designed with modular components that can be readily

replaced by trained service personnel so as to minimize the time that the gas detector is not

available.

External in-line air filters should be replaced every three months or more frequently if the system

is sampling in environments that have high levels of particulate matter or very acidic / wet

atmospheres. Similarly, the internal particulate filter should be replaced every two years or more

frequently if the sample lines are prone to heavy contamination. Refer to the following table.

Every sensor cartridge is shipped with a 2 years warranty. All sensor cartridges are factory

calibrated to traceable national standards before shipment to the end user.

Note that testing or calibrating with the wrong (incorrect, out of date, non-traceable) calibration

gases, calibration equipment, methods or operating conditions can actually damage the sensor

cartridge’s lifetime and alter the calibration adversely. Only qualified calibration technicians

should attempt to calibrate the Midas-M gas detector.

The internal pump module is designed to operate for a minimum of 24 months and it is

recommended that this pump module (part number MM-PM ) be replaced every 2 years.

Recommended maintenance schedule

Component Frequency

Pump 2 years or as needed

Internal filter 2 years or as needed

Part Number 780248, every 3-6 months

External Sample Line Filter

Leak Check Leak Check every 6 months or after replacing any component.

Bump Test 6 months

Flow Calibration Flow Calibrate after pump, internal and external filter replacement.

Part Number 1991-0147, every 3-6 months

Part Number 1830-0055, every 3-6 months

Midas-M 65 User Manual

Page 66

See the Gas Table for the correct filter requirement for your application.

NOTE

Every sensor cartridge warranty: Typically, two years depending on the sensor type. The Bias

battery will last only about six months. After replacement, allow at least a day for the

cartridge to reach equilibrium.

System Leak Check

When performing a leak check, the Midas-M must be placed in Inhibit mode to prevent false

concentrations or faults to be activated when plugging the Sample or Exhaust Lines. Example:

O2 (oxygen) – plugging of the ports causes the O2 levels within the Midas-M flow path to be

depleted as the sample becomes stagnant. The result is the concentration levels begin to fall and

trigger the alarms for the O2 depletion.

1. Place the Midas-M into Inhibit.

2. Plug the Inlet Sample line.

3. The flow meter indicators will begin to drop and ultimately disappear within seconds.

4. Continue to keep the port plugged until the Midas-M reports an “F41” (Flow Fail) –

approximate time to fault is 24 seconds.

5. Remove the plug.

6. Allow 15 seconds or so to allow the Midas-M flow to stabilize then clear the fault by pressing

and holding ‘X’

7. Plug the Outlet Exhaust line.

8. The flow meter indicators will begin to drop and ultimately disappear within seconds.

9. Continue to keep the port plugged until the Midas-M reports an “F41” (Flow Fail) –

approximate time to fault is 24 seconds.

10. Remove the plug.

Midas-M 66 User Manual

Page 67

11. Allow 15 seconds or so to allow the Midas-M flow and concentrations to stabilize then clear

the fault by pressing and holding ‘X’

12. Return the unit to the Monitoring Mode.

Midas-M 67 User Manual

Page 68

Page 69

CHAPTER

5

Learn from about strategic information related to the Honeywell Midas®-M Detector.

Additional Information

EU Directive 2012/19/EU: Waste Electrical and Electronic Equipment (WEEE)

This symbol indicates that the product must not be disposed of as general industrial

or domestic waste. This product should be disposed of through suitable WEEE disposal facilities.

For more information about disposal of this product, contact your local authority, distributor or

the manufacturer.

Midas-M 69 User Manual

Page 70

Troubleshooting and Fault Diagnosis

General troubleshooting guide and specific fault code table for the Midas-M gas detector.

Fault code descriptions

Number Date Data Field Condition Recovery

M02

M10

M11 Over Range

M20

Simulated M

fault

Baseline

warning

Calibration

expired

N/A

Concentration

without

Deadband

Peak

concentration

Days until

fault

User enters simulation

mode

Cell baseline has drifted.

Large concentration of

gas has been detected.

The Midas-M requires

an independent

confirmation that the gas

hazard is gone.

The user-specified

calibration interval has

elapsed.

Reset simulated fault

Check for background

gas concentration,

temperature, or

humidity fluctuations.

Perform zero

calibration. Replace

cell.

Supply clean air to the

Midas-M and clear the

fault.

Perform zero and span

calibrations. Increase

span calibration

period. (zero days =

disabled)

M21

M40

M41 Flow Low Flow (cc/min)

F01

F02

Midas-M 70 User Manual

Cell expires

soon

Temperature

Near Limit

LED

indicator

error

Simulated F

Fault

Days until

fault

Temperature

(C)

N/A

N/A

Cell is old and will expire

soon.

Temperature is within 5

C of limit.

Midas-M is no longer

able to regulate the flow.

LED indicator has no

response.

User enters simulation

mode

Replace the cartridge

or the cell with a new.

Check installation

environment.

Check filters and

pump.

Replace the LCD

Reset simulated fault

Page 71

Number Date Data Field Condition Recovery

Check for background

gas concentration,

F10

Baseline

Fault

Concentration

without

Deadband

Cell baseline has drifted.

temperature or

humidity fluctuations.

Perform zero

calibration. Replace

cell.

Calibration

F20

F21 Cell expired. N/A Cell is too old.

F40

F41 Flow Fail Flow (cc/min)

F42

F43

F44 LIT test fail N/A LIT test failed Check a flow path

Expired too

long.

Temperature

Limits

Exceeded

Pump

Memory

error

Pump

absent

N/A

Temperature

(C)

N/A

N/A There is no pump

Too long since last

calibration.

Temperature is out of

limit.

Flow < 70% of nominal

for 24 seconds

Pump memory has no

response or corrupted

data

Replace or calibrate

the Cell.

Replace the cartridge

or cell.

Check installation

environment.

Check filters and

pump.

Reboot

Device Power off and

then insert the pump

F50 Cell Failure N/A

F51

F52

F53

F54

Midas-M 71 User Manual

Cell comm.

Failure

Cell memory

error

Cell Memory

Invalid

Cell IR

N/A

N/A

N/A Checksum error. Replace cell

N/A

Reflex test fail of toxic

cell

It has failed to

communicate with IR

cell

Cell memory has no

response or corrupted

data

Cell IR voltage is out of

Replace cell

Replace IR cell

Replace cell

Replace cell

Page 72

Number Date Data Field Condition Recovery

voltage error range

F60

F61

F62 No valid cell N/A

F63

F64

F65

F66

The absent

cartridge

Cartridge

wrong type

Cartridge

Memory

Invalid

Cartridge

app Memory

Invalid

Cartridge

3.3V error

Cartridge 5V

error

N/A No communications.

Cell ID

N/A Checksum error. Reboot

N/A Checksum error. Replace cartridge.

Voltage

Voltage

Cartridge has one or

more empty channel

Cartridge has no valid

cell

Cartridge 3.3V is out of

range

Cartridge 5V is out of

range

Reset cartridge.

Replace cartridge.

Replace cartridge.

Replace cartridge.

Replace cartridge.

Replace cartridge.

F67

F80

F81

F82

F83

F84

Cartridge

app failed

Transmitter

NOR flash

error

Transmitter

memory

invalid

Transmitter

memory

comm. Error

Transmitter

app memory

invalid

Transmitter

3.3V error

N/A

N/A No communication

N/A Checksum error. Reboot

N/A Communication failed Reboot

N/A Checksum error.

Voltage

Cannot start cartridge

app

Transmitter 3.3V is out

of range

Update the latest

cartridge app

Replace the

transmitter

Replace transmitter or

update the latest

version

Replace Transmitter

Midas-M 72 User Manual

Page 73

Number Date Data Field Condition Recovery

F85

F86

Transmitter

24V error

Transmitter

5V error

Voltage

Voltage

Transmitter 24V is out of

range

Transmitter 5V is out of

range

Replace Transmitter

Replace Transmitter

Midas-M 73 User Manual

Page 74

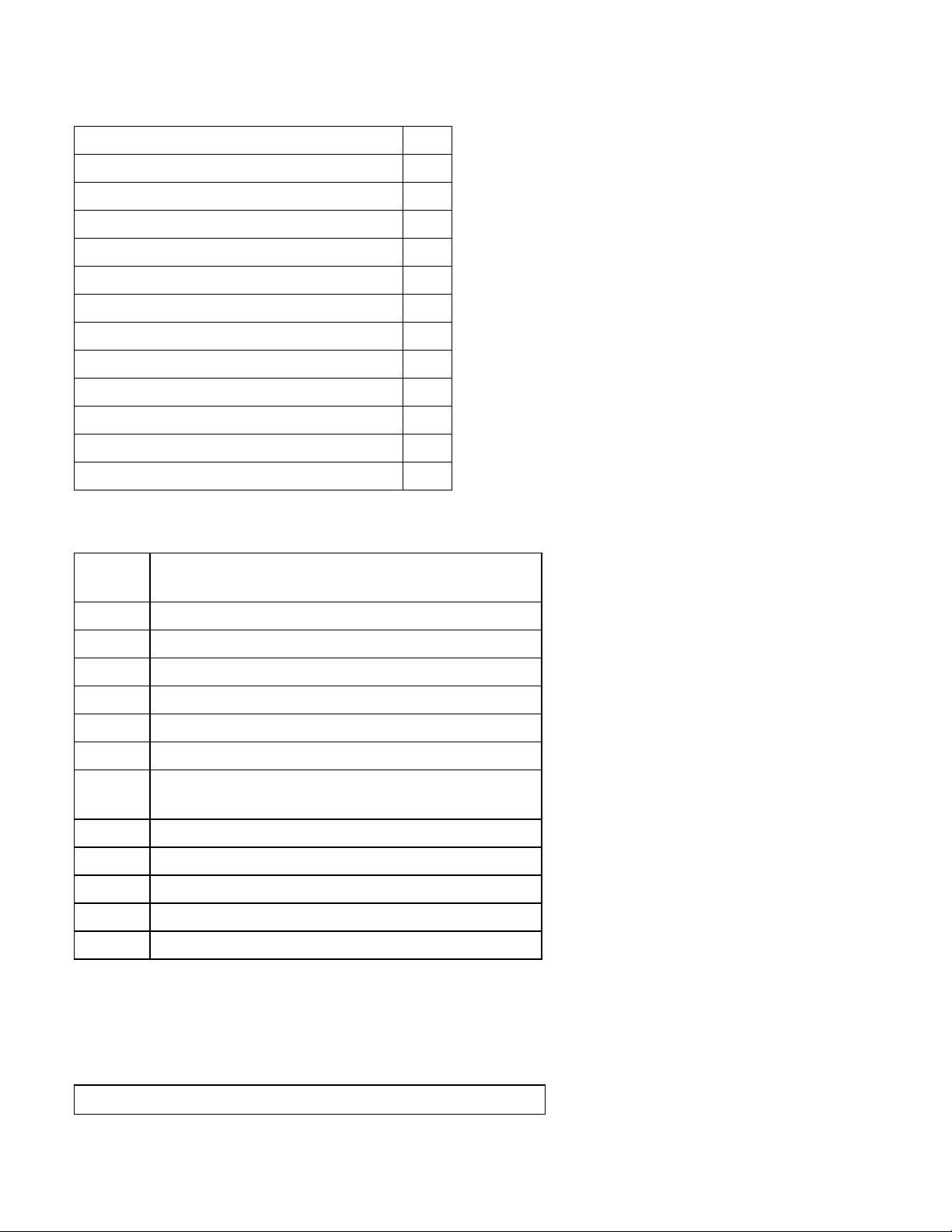

Specifications

Transmitter Dimension

Specifications

Size (unit with

Cartridge)

Weight Transmitter

Weight Cartridge

Optional Relay Dimension

Size "137 mm (H) X 84 mm (W) X 41 mm (D) (5.39 X 3.31 X 1.61 in)"

Weight 0.31 kg (0.68 lb)

Power Requirements

Operating

Voltage

"Operating

Voltage with

Power over

Ethernet (PoE)"

"136 mm (H) X 83 mm (W) X 152 mm (D) (5.35 X 3.27 X 5.98 in)"

1.3 kg (2.87 lb)

0.17 ~ 0.22 kg (0.38 ~ 0.49 lb) dependent on sensor type

24 VDC Nominal, -15 to +10% (20.4 to 26.4 VDC)

48 VDC PoE (IEEE 802.3af compliant)

Power Consumption

Transmitter unit

(normal

condition)

Transmitter unit

(full load

condition)

Transmitter with

Optional Relay

Outputs

Visuals

Relays in

Transmitter

1

2

Typ. 5W

≤ 11.45W

≤ 12.9 W

"Alarm, power, fault LEDs, and LCD with all the gas readings and

events. LEDs: Power (Green), Alarm 1 (Red), Alarm 2 (Red), Fault

(Yellow)"

"Alarm1, Alarm2, Fault Relays (3) rated 1.0 A @ 30Vdc or 0.5A @

125Vac Max 10uA @ 10mV minimum, configurable as normally open

or closed, latched or unlatched"

Midas-M 74 User Manual

Page 75

Relays in

Optional Relay

Specifications

"8 relays for Alarm1 and Alarm2 of each channel and a relay for

common fault rated 1.0 A @ 30Vdc or 0.5 A @ 125 Vac Max 10uA @

10mV minimum, configurable as normally open or closed, latched or

unlatched"

Analog

Digital

Communications Modbus / TCP Ethernet / Power over Ethernet (PoE)

Certification and Specification

Performance

Transport System

Flow Rate 600 mL/min

Transport Time 2 to 25 seconds maximum

Sample Line

Tubing

Tubing Length Up to 30 m (100 ft) with FEP tubing

3 wire sink, 3 wire source, or 4 wire fully isolated; 0 to 21 mA for each

channel

"CE marked Meets EN 50270:2015+AC:2016 and EN61000-64:2007+A1 ETL approved UL 61010-1:2012 Ed.3 IEEE 802.3af-2003"

Refer to Individual sensor datasheets

3.18 mm ID X 6.35 mm OD (0.125 X 0.25 in)

Exhaust Line

Tubing

Exhaust Length Up to 30 m (100 ft)

Ambient Point In line air filter required

Operating Temperature

Wiring Requirement

4-20mA 2 wire, 14 AWG maximum

Digital CAT5 Cable or equivalent: RJ45 connector

Gas Concentration Display and Interface

Instrument

Midas-M 75 User Manual

4.76 mm ID X 6.35 mm OD (0.188 X 0.25 in)

0°C to +40°C (32°F to 104°F)

"4-digit alphanumeric display with separate units, concentration bar

graph for each channel and other icon driven indicators 4 button

interface keypad"

Page 76

Specifications

Remote Internet browser access via Ethernet

Installation Details

Mounting Wall mounted using pre-drilled holes on chassis. Options for DIN rail.

Material

"Cover: Plastic (Polycarbonate) Chassis/Mounting Bracket: Zinc plated

steel Red frame : Liquid coated Aluminum "

Warranty

Transmitter unit 1 year

Sensor cartridge 2 years

1

Normal condition: (1) No gas alarm, (2) Without tube and pressure/vacuum

2

Full load condition: (1) All 4 channels gas alarm are on, (2) Maximum tubing length and

pressure/vacuum on the inlet/exhaust line

Midas-M 76 User Manual

Page 77

Ordering

This section contains details of how to order complete Midas-M detector and sensor cartridge

kits, separate transmitters and sensor cartridges as well as spares and accessories.

Transmitter

Part

Number

MMT-01 Midas-M 4-20mA Extractive Transmitter

MMT-02 Midas-M TCP/IP Modbus Extractive Transmitter

MMT-

T01

MMT-

T02

MMT-

B01

MMT-

B02

Description

Midas-M 4-20mA Extractive Transmitter with Tube

Midas-M TCP/IP Modbus Extractive Transmitter

with Tube

Midas-M 4-20mA Extractive Transmitter Bulk

Package (6pcs)

Midas-M TCP/IP Modbus Extractive Transmitter

Bulk Package (6pcs)

Cartridge

Part Number Description

MMC-xxxxxxxx Midas-M Sensor Cartridge with Smart Sensors

Midas-M 77 User Manual

Page 78

Smart Sensor Code

Dummy 00

Hydrogen Chloride (HCI) 0 - 8ppm, 2 years E2

Silane (SiH4) 0 -20 ppm, 2 years X2

Hydrogen (H2) 0 - 1000ppm, 2 years G2

Chlorine (CI2) 0 - 2ppm, 2 years L2

Ammonia(NH3) 0 - 100ppm, 2 years A2

Carbon Monoxide (CO) 0 - 100ppm, 2 years C2

Phosphine (PH3) 0 - 1200ppb, 2 years R2

Ozone (O3) 0 - 0.4ppm, 2 years U2

Oxygen (O2) 0 - 25%v/v, 3 years D2

Sulphur D ioxide (SO2) 0 - 8ppm, 2 years S2

Hydrogen Flouride (HF) 0 - 12ppm, 2 years Z2

Smart Sensor

Part

number

MMS-00 Midas-M Dummy Sensor

MMS-E2 Midas-M Hydrogen Chloride (HCI) 0 - 8ppm, 2 years

MMS-X2 Midas-M Silane(SiH4) 0 -20 ppm, 2 years

MMS-G2 Midas-M Hydrogen (H2) 0 - 1000ppm, 2 years

MMS-L2 Midas-M Chlorine (CI2) 0 - 2ppm, 2 years

MMS-A2 Midas-M Ammonia (NH3) 0 - 100ppm, 2 years

MMS-C2 Midas-MCarbon Monoxide (CO) 0 - 100ppm, 2

MMS-R2 Midas-MPhosphine (PH3) 0 - 1200ppb, 2 years

MMS-U2 Midas-MOzone (O3) 0 - 0.4ppm, 2 years

MMS-D2 Midas-MOxygen (O2) 0 - 25%v/v, 3 years

MMS-S2 Midas-M Sulphur Dioxide (SO2) 0 - 8ppm, 2 years

MMS-Z2 Midas-M HydrogenFlouride (HF) 0 - 12ppm, 2 years

Description

years

Accesories

Modules / Replacements

Midas-M 78 User Manual

Page 79

Part

number

MM-REL Midas-M R elay Module

MM-PM Midas-M Pump Module

MM-FIL Midas-M Filter Module

MM-FRT Midas-M Front Module

MM-B01 Midas-M 4-20mA Base Module

MM-B02 Midas-M TCP/IP Base Module

MM-M01 Midas-M 4-20mA Main Module

MM-M02 Midas-M TCP/IP Main Module

MM-CAT Midas-M Cartridge wo Smart Sensors

Mounting Accessories

Part number Description

MIDAS-A-036 MIDAS DIN Rail Mounting Kit

0235-0128 Flexible Conduit 21" - length

0235-0163 Flexible Conduit 27" - length

Description

MVIP3632-2A 2A 24VDC power supply in vented

NEMA 4 enclosure

MVIP3632-5A 5A 24VDC power supply in vented

NEMA 4 enclosure

Duct Sampling Adaptors

Part number Description

1283K1090 Duct Adapter for 1/4" O.D. tubing for 4-

16" round ducts

0235-0095 UnionFitting 1/4" tube, polypropylene

Tubing and ExternalSample Line Filters

Part number Description

780248 End of Line Particulate Filter, Disposable

1991-0147 End of LineParticulate F ilter for Corrosive

Gases, DisposableThis disposable filter

provides protection against particulate build

up in the sample line when monitoring for

Corrosive Gases.

0235-0095 Union Fitting- Use to connect disposable

filter to end of line

Midas-M 79 User Manual

Page 80

1830-0055 End of LineParticulate F ilter for Corrosive

Gases, Reusable This reusable filter housing

provides protection against particulate build

up in the sample line when monitoring for

Corrosive Gases. Replaceable filter element

(P/N 0235-1072) purchasedseparately

0235-1072 Replacement "Corrosive" Filter Elements

(pk 100) For use in 1830-0055 filter housing

102599 Tubing Teflon® FEP 1/4" OD x 1/8" ID

(Sample inlet) (Price per Foot)

1991-0136 Tubing Teflon® FEP 1/4" OD x 1/8" ID

(Sample Inlet) (100' continuouslength)

100440 Tubing Polypropylene 1/4" OD X 3/16" ID

(Exhaust) (Price per Foot)

1991-0137 Tubing Polypropylene 1/4" OD X 3/16" ID

(Exhaust) (100' continuouslength)

Midas-M 80 User Manual

Page 81

Page 82

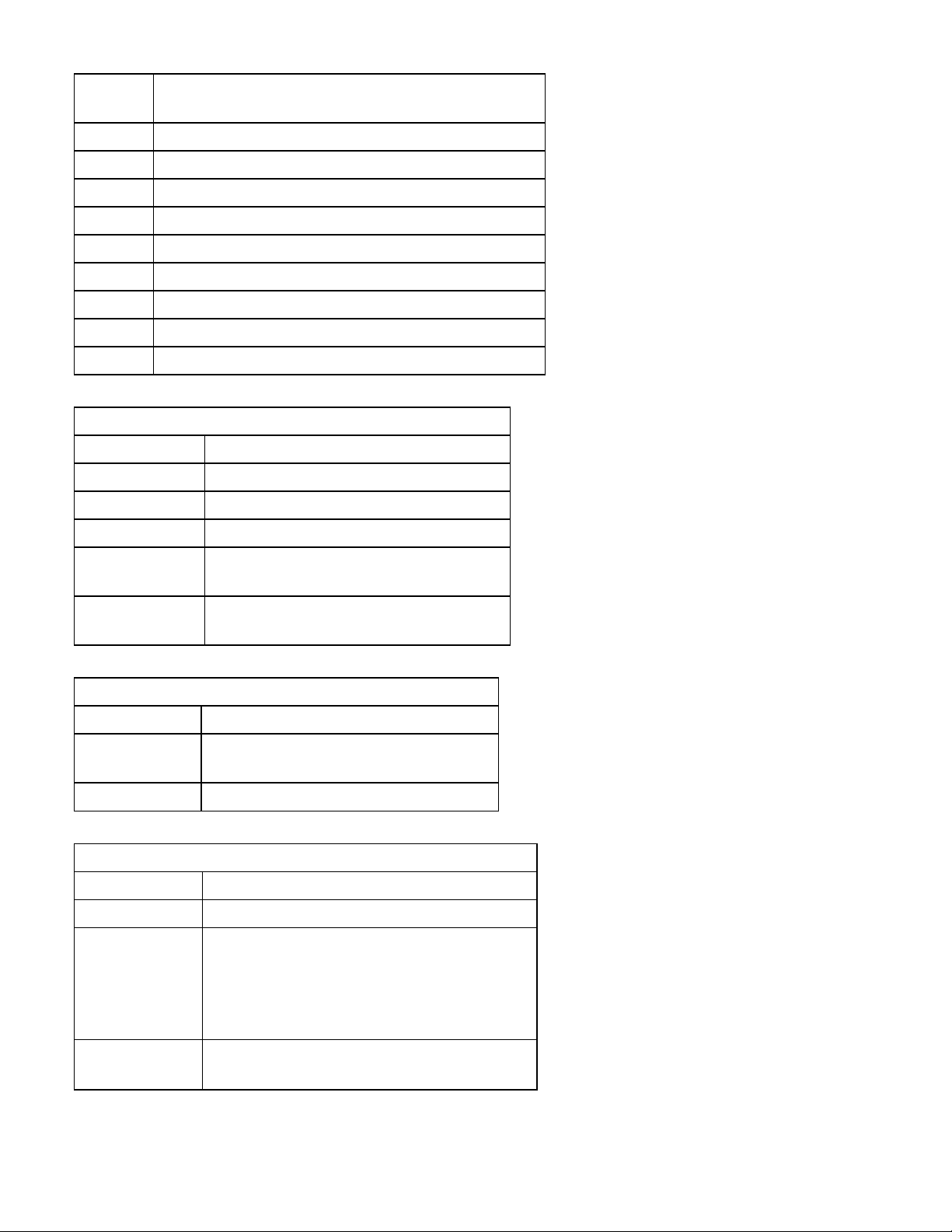

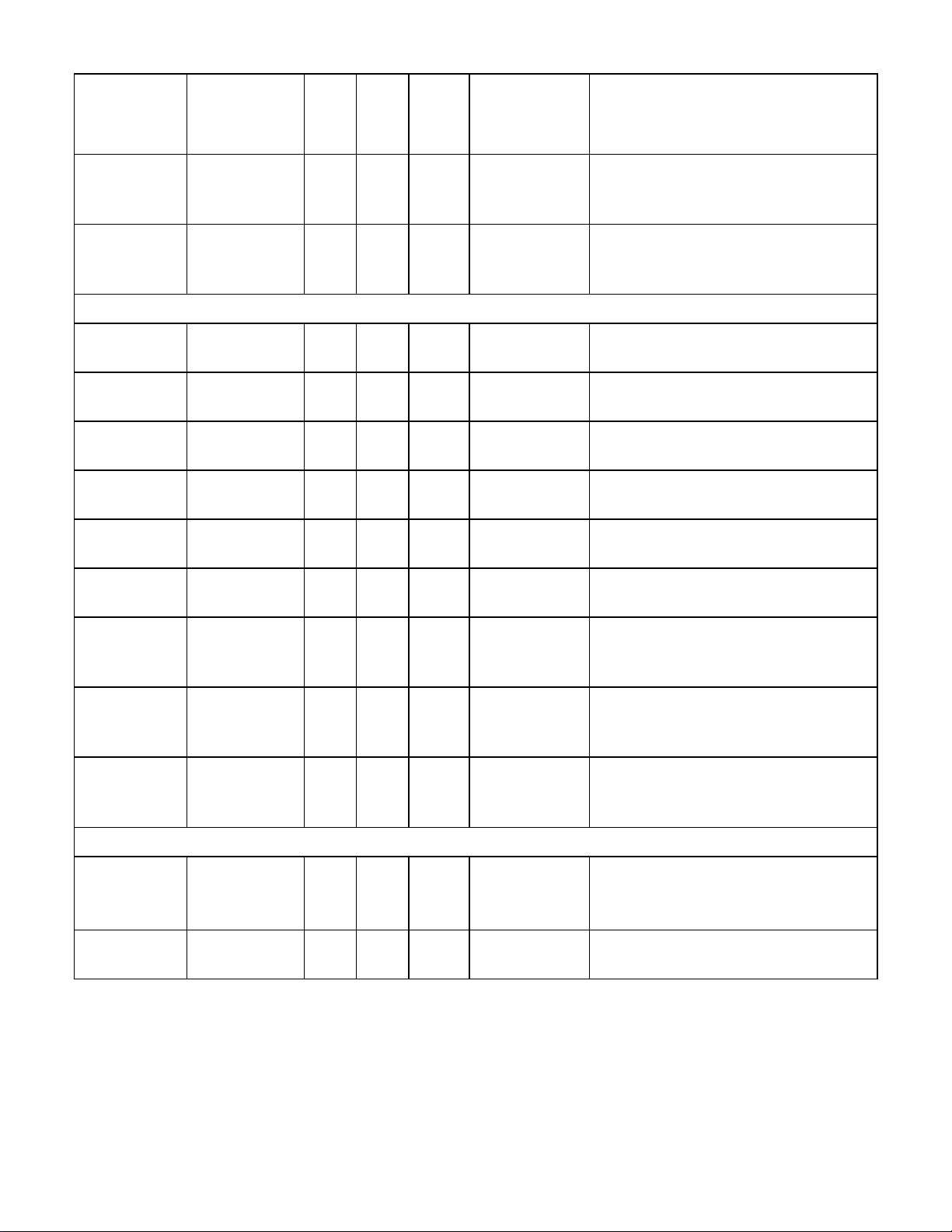

Gas Table

Gas Name Formula

Hydrogen

Chloride

Boron

Trichloride

Dichlorosilane SiH2Cl2

Hydrogen

Bromide

Silane SiH4

HCI

BCI3

HBr

Range Resolution

0 - 8

ppm

0 - 8

ppm

0 - 8

ppm

0 - 8

ppm

0 - 20

ppm

0.05 ppm 1 ppm 2 ppm

0.05 ppm 1 ppm 2 ppm

0.05 ppm 1 ppm 2 ppm

0.05 ppm 1 ppm 2 ppm

0.01 ppm

Default

Alarm

1

2.5

ppm

Default

Alarm

2

5 ppm

Sensor

Part

Number

MMSE2

MMSE2

MMSE2

MMSE2

MMSX2

Maximum

Sensor

Warm-up

Time(minutes)

20 600 HCl 4 4 300 HCl 4-6 180 5

20 600 HCl 4 4 300 HCl 4-6 180 5

20 600 HCl 4 4 300 HCl 4-6 180 5

20 600 HCl 4 4.5 300 HCl 4-6 180 5

20 600 SiH4 10 10 300 SiH4 10 180 30

Flow

Rate

(cc/min)

Calibration

Gas

Calibration Bump Test

Conc.

Output

Equiv.

(ppm)

Exp

Time

(sec)

Recommended

Bump Test

Gas

Conc

(ppm)

Recommended

Max

Time

(sec)

Maximum

Sample Line

Length(m)

1

1

1

1

End of line filter

1991-0147

1991-0147

1991-0147

1991-0147

"780248, 19910147 or 18300055""780248,

1991-0147 or

1830-0055"

Disilane Si2H6

Hydrogen

(ppm)

Chlorine Cl2

Ammonia NH3

Carbon

Monoxide

Phosphine PH3

Ozone O3

H2

CO

0 - 20

ppm

0 1000

ppm

0 - 2

ppm

0 100

ppm

0 100

ppm

0 1200

ppb

0 - 0.4

ppm

0.05 ppm 1 ppm 2 ppm

5 ppm

0.01 ppm

0.5 ppm

0.5 ppm

5 ppb

0.002

ppm

125

ppm

0.25

ppm

12.5

ppm

12.5

ppm

150

ppb

0.05

ppm

250

ppm

0.5

ppm

25

ppm

25

ppm

300

ppb

0.1

ppm

MMSE2

MMSG2

MMSL2

MMSA2

MMSC2

MMSR2

MMSU2

20 600 SiH4 4 4 300 SiH4 10 180 10

10 600 H2 500 500 300 H2 500 180 30

10 600 Cl2 1 1 300 Cl2 1 180 10

10 600 NH3 50 50 300 NH3 50 180 10

10 600 CO 50 50 300 CO 50 180 30

20 600 PH3

10 600 O3 0.2 0.2 300 NO2

600

ppb

600

ppb

300 PH3 600 180 30

2

1 180 5 1830-0055

"780248, 19910147 or 18300055"

"780248, 19910147 or 18300055"

1991-0147 or

1830-0055

"780248, 19910147 or 18300055"

"780248, 19910147 or 18300055"

"780248, 19910147 or 18300055"

Oxygen

Proficiency &

Deficiency

Sulfur Dioxide SO2

Hydrogen

O2

HF

0 - 25

%vol

0 - 8

ppm

0 - 12

0.1 %vol

0.05 ppm 1 ppm 2 ppm

0.05 ppm

23.5

%vol

1.5

19.5

%vol

3 pmm

MMSD2

MMSS2

MMS-

30 600 O2 Air

10 600 SO2 4 4 300 SO2 4 180 30

20 600 HF 6 6 300 Cl2 10 180 5

20.9

%vol

300 O2 Air 180 30

"780248, 19910147 or 18300055"

1991-0147 or

1830-0055

1

1991-0147 or

Page 83

Default

Alarm

Gas Name Formula

Range Resolution

1

Fluoride ppm ppm Z2 1830-0055

Default

Alarm

2

Sensor

Part

Number

Maximum

Sensor

Warm-up

Time(minutes)

Flow

Rate

(cc/min)

Calibration

Gas

Calibration Bump Test

Conc.

Output

Equiv.

(ppm)

Exp

Time

(sec)

Recommended

Bump Test

Gas

Conc

(ppm)

Max

Time

(sec)

Recommended

Maximum

Sample Line

Length(m)

End of line filter

Boron

Trifluoride

Tungsten

Hexafluoride

Bump Testing Notes:

As an alternative, the actual target gas can always be used instead of a cross-sensitive gas.

Higher concentrations than the recommended ones can be used if necessary, but extra time may be needed for the reading to recover to zero.

IMPORTANT: this should only be done once to avoid the danger of poisoning the sensor.

BF3

WF6

1

Recommended to keep the sample lines as short as possible where the RH condition at the sample point is high (above %50 RH); there will be some sample loss due to absorption onto the

sample line.

2

An ozone generator can be used instead of 1 ppm NO2.

0 - 8

ppm

0 - 12

ppm

0.05 ppm 1 ppm 2 ppm

0.05 ppm

1.5

ppm

3 ppm

MMSZ2

MMSZ2

20 600 HF 4 5.2 300 Cl2 5 180 5

20 600 HF 6 6 300 Cl2 10 180 5

1

1

1991-0147 or

1830-0055

1991-0147 or

1830-0055

Page 84

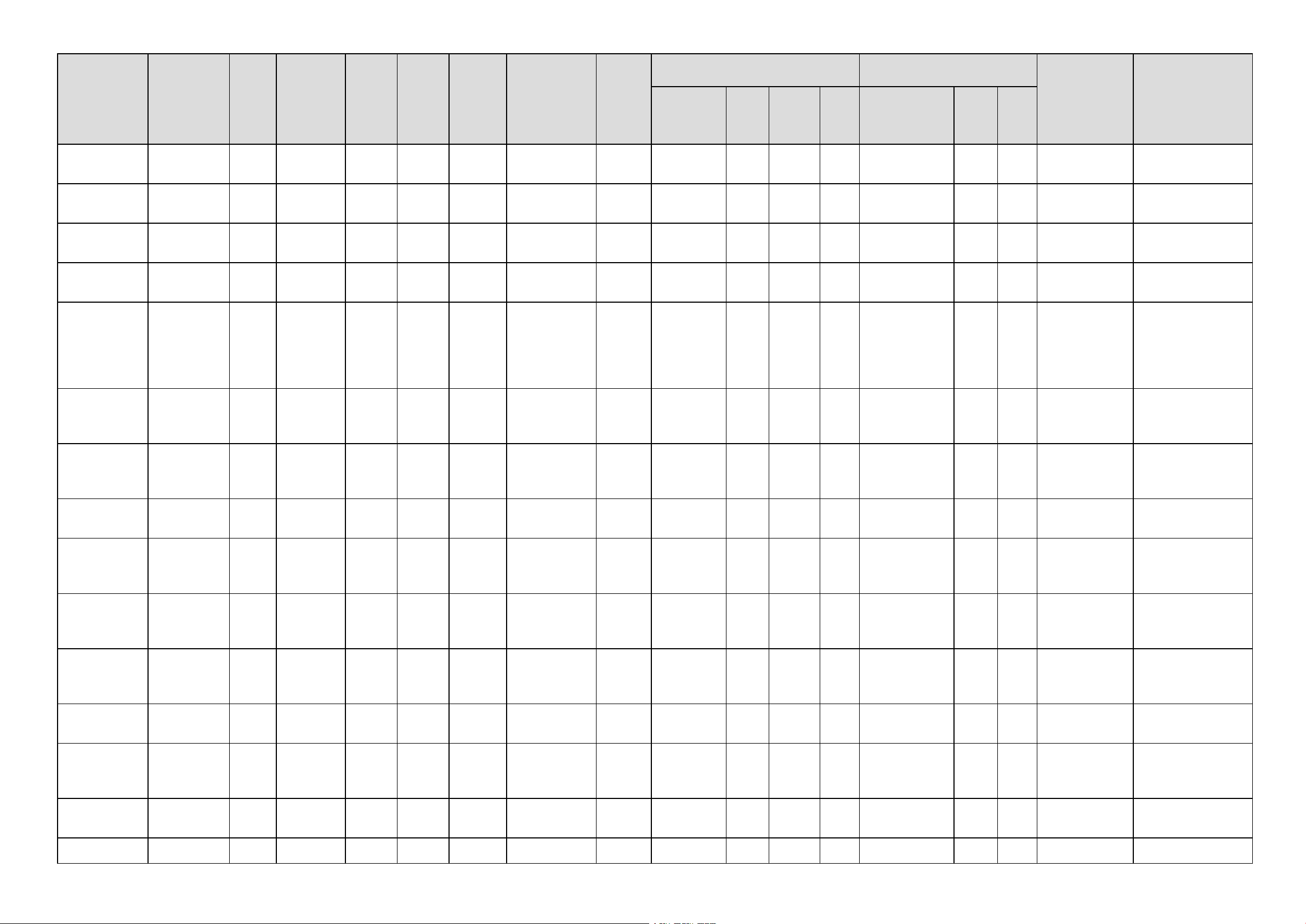

Combination Index

HCl

(MMSE2)

SiH4

(MMSX2)

H2

(MMSG2)

Cl2

(MMSL2)

NH3

(MMSA2)

CO

(MMSC2)

HCl

(MMSE2)

NO NO NO

SiH4

(MMSX2)

H2

(MMSG2)

Cl2

(MMSL2)

NH3

(MMSA2)

NO

NO

CO

(MMSC2)

PH3

(MMSR2)

O3

(MMSU2)

O2

(MMSD2)

SO2

(MMSS2)

HF H

(MMSZ2)

PH3

(MMSR2)

O3

(MMSU2)

O2

(MMSD2)

SO2

(MMSS2)

HF H

(MMSZ2)

NO

NO

NO

Midas-M 84 User Manual

Page 85

Reflex

Midas-M uses patented Honeywell Analytics technology to continuously monitor the health

check status of specific electrochemical cells and alert the user if a cell enters a variety of fault

conditions (such as open or short circuit etc.) which would leave the cell unable to detect gas

and raise an appropriate alarm signal.

REFLEX® overcomes this unseen failure mode by applying periodically a special electronic pulse

to the cell and reviewing the ‘echo’ from the cell as it responds to the applied signal. If the cell is

deteriorating within certain pre-set limits based on the received signals then Midas-M will

decrease the REFLEX sampling interval in order to establish the actual viability of the cell. Within

a relatively short time, Midas-M will be able to alert the user via fault codes that the

electrochemical cell is likely to be requiring replacement and is possibly unable to correctly

detect gas.

REFLEX is not required for pellistors, IR, oxygen electrochemical cell or bias electrochemical

cell as these sensor cartridges provide alternative electronic means to indicate open circuits and

other sensor cartridge damage issues.

Midas-M 85 User Manual

Page 86

A Modbus/TCP Interface

The Midas-M gas detector can report concentration information in a variety of formats

including relay contact closure, an analog 4-20 mA loop, Ethernet/ IP/HTML web pages and via

the Modbus/TCP networking protocol. This section defines the format of data in Modbus/TCP

registers. More information about Modbus/TCP can be obtained from www. modbus.org.

The Midas-M is a Modbus/TCP “server” as defined in the MODBUS Application Protocol

Specification V1.0 . It supports command 03 (“read holding registers”) for registers 40001 to

40122 as listed in the following table.

The Midas-M reports floating-point concentration numbers in little-endian or Intel format. This

is scaled in units of ppm for gasses which have display units of ppm or ppb. For other display

units the concentration is scaled directly in display units. This applies to registers Gas

Concentration and Alarm Threshold.

The Midas-M fills 122 Modbus/TCP holding registers as listed in Table 1. The Monitoring Status

register is a concise summary of Midas-M status. The other registers provide more complete

information.

Midas-M Modus Register Map

Midas-M Modbus Register Map : Register 40001 is mapped with base address (zero)

(If channel is disabled, channel information is 0).

ModBus

Register

Number

Device St atus

40001 Reserved for

Information R/W

future

expansion

Data

Type

R 2

Data

Size

Description Note

(Byte)

Holding Register

Midas-M 86 User Manual

Page 87

ModBus

Register

Number

Information R/W

Data

Type

Data

Size

(Byte)

Description Note

40002 Monitoring

Status

40003 Alarm State R u16 2 bit 0 : Ch1 Alarm 1 active bit 1 : Ch1

R u16 2 bit 0 : Warmup bit 1 : Inhibit Mode bit 2

: Alarm/Fault simulation bit 3 : 4-20mA

calibration mode bit 4 : 4-20mA test

mode bit 5 : Flow calibration mode bit

6 : LIT calibration mode (Reserved) bit

7 : LIT Enabled (Reserved) bit 8 : Gas

calibration mode bit 9 : Gas bump test

mode bit 10 : Alarm bit 11 : Fault bit 12

~ 15 : for future expansion

Alarm 2 activebit 2 : Ch2 Alarm 1

active bit 3 : Ch2 Alarm 2 active bit 4 :

Ch3 Alarm 1 activebit 5 : Ch3 Alarm 2

active bit 6 : Ch4 Alarm 1 active bit 7 :

Ch4 Alarm 2 activebit 8~15 : for future

expansion

40004 Fault State R u16 2 bit 0 : Ch1 fault active bit 1 : Ch2 fault

active bit 2 : Ch3 faultactive bit 3 : Ch4

fault activebit 4 : Device fault active bit

5~15 : for future expansion

40005 Top Fault R u16 2 Number of

most important

active fault

Midas-M 87 User Manual

Page 88

ModBus

Register

Number

Information R/W

Data

Type

Data

Size

(Byte)

Description Note

40006 Channel

Enabled State

40007 to

40008

40009 to

40010

Gas

Concentration

Ch1

Gas

Concentration

Ch2

R u16 2 This is the bit

representation

information of

channel

enabled. If

dummycellis

attached or

channel is

disabled bit

value is set.

R f32 4 Value in float

R f32 4 Value in float

bit 0 : Ch1 Dummy cell bit 1 : Ch1

Disabled bit 2 : Ch1 Reservedfor

futher expansion bit 3 : Ch2 Dummy

cellbit 4 : Ch2 Disabled bit 5 : Ch2

Reserved for futher expansion bit 6 :

Ch3 Dummy cell bit 7 : Ch3 Disabled

bit 8 : Ch3 Reserved for futher

expansion bit 9 : Ch4 Dummy cell bit

10 : Ch4 Disabled bit 11 : Ch4

Reserved for futher expansion bit

12~15 : for future expansion

40011 to

40012

40013 to

40014

40015 to

40016

40017 to

40018

40019 to

40020

40021 to

40022

Gas

Concentration

Ch3

Gas

Concentration

Ch4

Gas

Concentration

Ch1

Gas

Concentration

Ch2

Gas

Concentration

Ch3

Gas

Concentration

Ch4

R f32 4 Value in float

R f32 4 Value in float

R u32 4 Value in fixed

point

R u32 4 Value in fixed

point

R u32 4 Value in fixed

point

R u32 4 Value in fixed

point

Conversion equation: ppm value =

Value * 1/10 DECP

Conversion equation: ppm value =

Value * 1/10 DECP

Conversion equation: ppm value =

Value * 1/10 DECP

Conversion equation: ppm value =

Value * 1/10 DECP

Midas-M 88 User Manual

Page 89

ModBus

Register

Number

Information R/W

Data

Type

Data

Size

(Byte)

Description Note

40023 Decimal Point

Indicator

40024 Heat beat

Counter

40025 to

40026

Device

Maintenance

Fault

R u16 2 Decimalpoint

indicator of

DisplayGas

Concentration

R u16 2 Systemtime in

seconds.

Range of this

value is from 0

to 59

R u32 4 This is the bit

order

representation

of the

maintenance

fault status.If

any fault exists

this will take a

value in each

bit. if any

maintenance

fault exists, this

will take a

value zero.

The meaning

of bit will be

described as

fault code in

more detail

bit 0 ~ 2 : Ch1 Decimalpoint indicator

(0, 1, 2, 3) bit 3 ~ 5 : Ch2 Decimal

point indicator (0, 1, 2, 3) bit 6 ~ 8 :

Ch3 Decimalpoint indicator (0, 1, 2, 3)

bit 9 ~ 11 : Ch4 Decimal point