Page 1

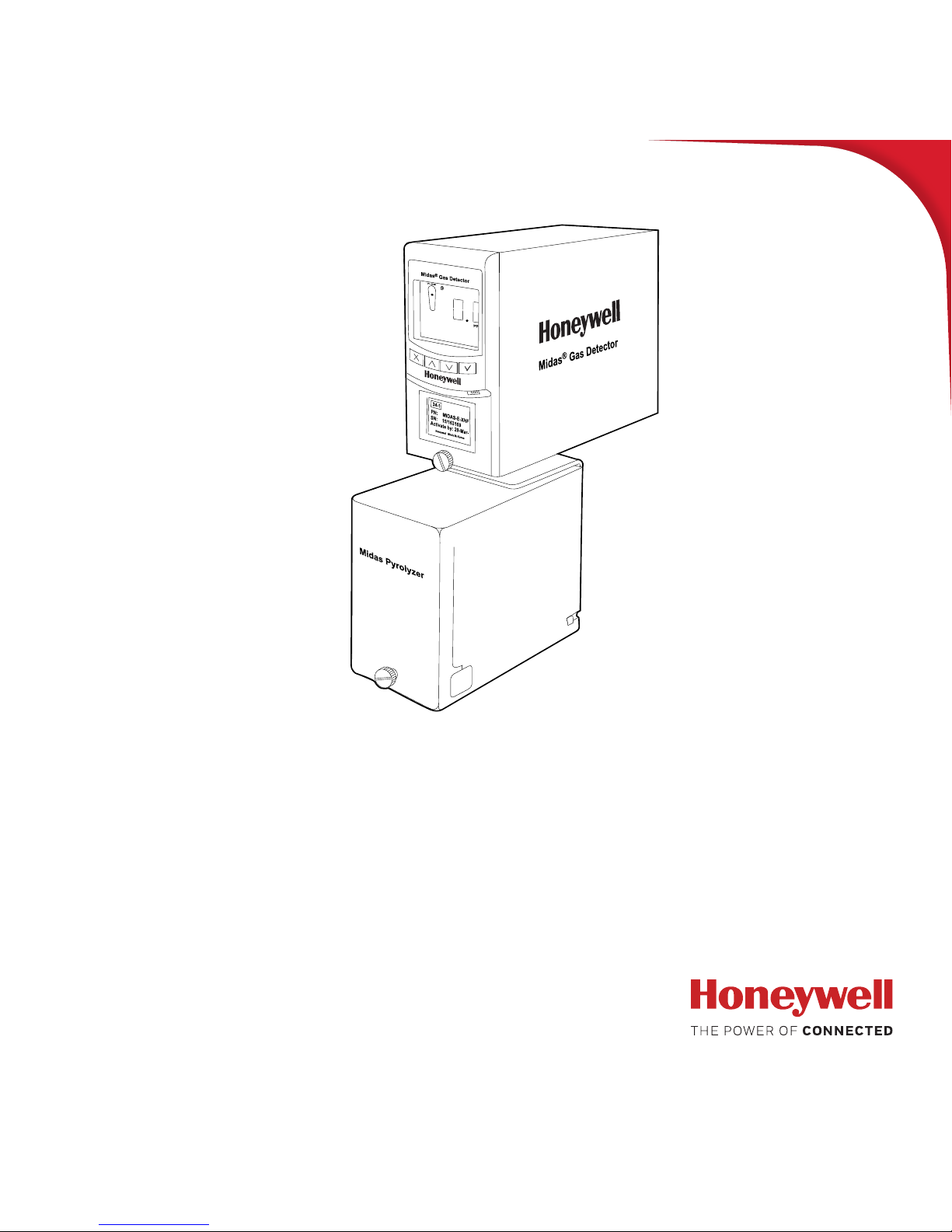

Midas Gas Detector

User Manual

• Table of Contents

• Description

• Overview

• Default Configuration

• Installation

• Startup

• Operation

• Navigating Menus

• Maintenance

• Pyrolyzer Module Options

• LonWorks Interface

• Troubleshooting/Faults

• REFLEX

• Internal Web Server

• Installation Topologies

• Ordering Information

• Specifications

• Calibration/Bump Testing

• Modbus/TCP Interface

• Gas Tables

• Warranty

Page 2

Midas® Gas Detector

i

1 Description ���������������������������������������������������������������������������������������������������������������������� 1-2

2 Overview �������������������������������������������������������������������������������������������������������������������������� 2-2

2�1 Chassis ������������������������������������������������������������������������������������������������������������������� 2-2

2.1.1 Display ............................................................................................................ 2-2

2.1.2 Pump Module .................................................................................................. 2-3

2.1.3 Sensor Cartridge Chamber ............................................................................. 2-3

2�2 Mounting Bracket Assembly ��������������������������������������������������������������������������������� 2-3

2.2.1 Mounting Bracket ............................................................................................ 2-4

2.2.2 Terminal Module .............................................................................................. 2-4

2�3 Sensor Cartridge ��������������������������������������������������������������������������������������������������� 2-4

2.3.1 Biased Sensor Cartridges ............................................................................... 2-4

2�4 Cover ����������������������������������������������������������������������������������������������������������������������� 2-5

3 Default Configuration ����������������������������������������������������������������������������������������������������� 3-2

4 Installation ����������������������������������������������������������������������������������������������������������������������� 4-2

4�1 Mounting and Location of Detector ��������������������������������������������������������������������� 4-2

4�2 Mechanical Installation ������������������������������������������������������������������������������������������ 4-4

4�3 Sample and Exhaust Tubing Calculations ���������������������������������������������������������� 4-7

4�5 Local Detector Option ������������������������������������������������������������������������������������������� 4-8

4�6 Electrical Installation ��������������������������������������������������������������������������������������������� 4-8

4�7 Electrical Connections ���������������������������������������������������������������������������������������� 4-11

4�8 Refitting the Main Chassis ���������������������������������������������������������������������������������� 4-23

4�9 Installing the Sensor Cartridge ��������������������������������������������������������������������������� 4-23

5 Startup ���������������������������������������������������������������������������������������������������������������������������� 5-2

Table of Contents

Page 3

Midas® Gas Detector

ii

6 Operation ������������������������������������������������������������������������������������������������������������������������� 6-2

6�1 Normal Operation Mode ��������������������������������������������������������������������������������������� 6-2

6.1.1 Resetting Alarms, and Faults .......................................................................... 6-4

6�2 Review Mode ��������������������������������������������������������������������������������������������������������� 6-4

6.2.1 Review Mode Menu Overview ....................................................................... 6-4

6�3 Overview of Set-up, Calibration, and Test Mode ����������������������������������������������� 6-6

6.3.1 Set-up Menu Overview .................................................................................. 6-6

6.3.2 Calibration Menu Overview ............................................................................ 6-8

6.3.3 Test Menu Overview ..................................................................................... 6-10

7 Navigating Modes and Submenus �������������������������������������������������������������������������������� 7-2

7�1 Review Mode �������������������������������������������������������������������������������������������������������� 7-2

7.1.1 Review Software ............................................................................................ 7-2

7.1.2 Review Alarms ............................................................................................... 7-3

7.1.3 Review 4-20 mA Output ................................................................................. 7-3

7.1.4 Review Faults ................................................................................................. 7-3

7.1.5 Review Calibration .........................................................................................7-4

7.1.6 Review Date and Time ................................................................................... 7-4

7.1.7 Review Detector Address ............................................................................... 7-5

7.1.8 Review Event Log .......................................................................................... 7-5

7.1.9 Review LCD Backlight Mode .......................................................................... 7-6

7�2 Set-up, Calibration, and Test Modes ������������������������������������������������������������������� 7-6

7.2.1 Set-up Menu ................................................................................................... 7-7

7.2.2 Set Alarms ..................................................................................................... 7-7

7.2.3 Set 4-20 mA output ........................................................................................ 7-9

7.2.4 Set Faults ....................................................................................................... 7-9

7.2.5 Set Calibration Interval ................................................................................. 7-10

7.2.6 Set Date and Time ....................................................................................... 7-10

7.2.7 Set Address .................................................................................................. 7-11

7.2.8 Set pass code .............................................................................................. 7-12

7.2.9 Set LCD Backlight mode ............................................................................... 7-13

7.2.10 Set Pump control frequency ........................................................................ 7-13

Page 4

Midas® Gas Detector

iii

7�3 Calibration Menu ������������������������������������������������������������������������������������������������� 7-14

7.3.1 Zero Calibration ............................................................................................ 7-14

7.3.2 Span Calibration ........................................................................................... 7-15

7.3.3 Flow Calibration ........................................................................................... 7-17

7.3.4 mA Calibration .............................................................................................. 7-18

7�4 Test Menu ������������������������������������������������������������������������������������������������������������ 7-18

7.4.1 Bump Test .................................................................................................... 7-19

7.4.2 Alarm/Fault Test ........................................................................................... 7-19

7.4.3 Inhibit State .................................................................................................. 7-20

7.4.4 Stimulate 4-20mA ......................................................................................... 7-21

8 Maintenance �������������������������������������������������������������������������������������������������������������������� 8-2

8�1 Sensor Cartridge Replacement ���������������������������������������������������������������������������� 8-3

8.1.1 Sensor Cartridge Fitting/Replacement ............................................................ 8-3

8�2 Pump Replacement ������������������������������������������������������������������������������������������������ 8-4

8�3 Reassembling the Detector ����������������������������������������������������������������������������������� 8-6

8�4 Filter Replacement ������������������������������������������������������������������������������������������������� 8-6

8�5 System Leak Check Procedure ���������������������������������������������������������������������������� 8-7

9 Pyrolyzer Module Options ��������������������������������������������������������������������������������������������� 9-2

9�1 Fitting the Pyrolyzer Module ��������������������������������������������������������������������������������� 9-4

9�2 Reassembling the Detector ����������������������������������������������������������������������������������� 9-6

9�3 Configuring the Detector ��������������������������������������������������������������������������������������� 9-7

10 Midas LonWorks Interface Module ��������������������������������������������������������������������������� 10-2

10�1 LonWorks Installation ��������������������������������������������������������������������������������������� 10-2

10.1.1 Fitting the LonWorks Module ..................................................................... 10-2

10.1.2 Wiring the Midas for LonWorks .................................................................. 10-3

10.1.3 Configuring the Midas for LonWorks ......................................................... 10-3

10�2 LonWorks Software ������������������������������������������������������������������������������������������ 10-4

10.2.1 LonWorks®Overview ................................................................................... 10-4

10.2.2 Network Variable Behaviors ........................................................................ 10-5

10.2.3 Other Characteristics .................................................................................. 10-9

Page 5

Midas® Gas Detector

iv

11 Troubleshooting and Fault Diagnosis ���������������������������������������������������������������������� 11-2

12 REFLEX ����������������������������������������������������������������������������������������������������������������������� 12-2

13 Internal Web Server ���������������������������������������������������������������������������������������������������� 13-2

13�1 Physical Network Components ������������������������������������������������������������������������ 13-2

13�2 Internet Settings ������������������������������������������������������������������������������������������������� 13-2

13�3 Running the Web Browser �������������������������������������������������������������������������������� 13-4

14 Typical Installation Topologies ��������������������������������������������������������������������������������� 14-2

14�1 Conventional Installation ���������������������������������������������������������������������������������� 14-2

14�2 Modbus/TCP Installation ����������������������������������������������������������������������������������� 14-3

14�3 Power over Ethernet (PoE) Installation ������������������������������������������������������������ 14-3

15 Ordering information �������������������������������������������������������������������������������������������������� 15-2

15�5 Midas Complete Gas Detector Kits ������������������������������������������������������������������ 15-3

15�6 Accessories and Spares ����������������������������������������������������������������������������������� 15-4

16 Specifications ������������������������������������������������������������������������������������������������������������� 16-2

17 Calibration and Bump Testing ����������������������������������������������������������������������������������� 17-2

A Modbus/TCP Interface ���������������������������������������������������������������������������������������������������A-2

A.1 Reading Status from the Midas ........................................................................A-2

A.2 Sending Commands to the Midas .....................................................................A-6

A.3 Determining the MAC Address ..........................................................................A-7

B Gas Tables ����������������������������������������������������������������������������������������������������������������������B-2

C Warranty ��������������������������������������������������������������������������������������������������������������������������C-2

Sensor Cartridge Warranty ����������������������������������������������������������������������������������������C-3

Pyrolyzer Warranty �����������������������������������������������������������������������������������������������������C-3

Page 6

Midas® Gas Detector

v

This symbol indicates that the product must not be disposed of as general industrial

or domestic waste. This product should be disposed of through suitable WEEE disposal

facilities. For more information about disposal of this product, contact your local authority,

distributor or the manufacturer.

EU Directive 2012/19/EU: Waste Electrical and Electronic Equipment (WEEE)

Page 7

Midas® Gas Detector

1-1

1 Description

Page 8

Midas® Gas Detector

1-2

1 Description

The Midas® gas detector is an extractive gas sampling system that draws a sample locally or from a remote

point to a sensor cartridge that is located inside the detector’s chassis. A wide range of Asphyxiant, Toxic,

Flammable, Pyrophoric, Corrosive, and Oxidizer (including Oxygen) gas sensor cartridges are available

that enable detection of gases used or generated in the Semiconductor and other industries.

Midas® is wall mounted and displays gas concentration, alarm, fault and status information via its backlit

LCD and LEDs. A simple to use 4-button keypad located under the display provides the facility to set-up,

review, operate and make changes to the detector’s configuration.

Midas® has flexible power and communications capabilities built in as standard. These include 3 on board

relays, 0-21 mA analog output, Modbus/TCP outputs for signal and service connectivity as well as the

innovative Power over Ethernet (PoE) connection that enables a single Ethernet connection to be made

for all power, control and communication requirements. An optional LonWorks® interface is available.

Page 9

Midas® Gas Detector

2-1

2 Overview

Page 10

Midas® Gas Detector

2-2

2 Overview

The Midas® gas detector comprises of 4 parts: the

main chassis, the mounting bracket assembly, the

sensor cartridge and the unit cover. Diagram 2-1

details the Midas® general arrangement. Additionally,

optional Pyrolyzer modules for the detection of NF

3

or various PFCs and an optional LonWorks® module

are available. Please refer to Section 9 and 10

respectively for details of these options.

Diagram 2-1. Midas® general arrangement exploded view

?

?

?

??

?

?

?

??

?

?

??

? ?

?

?

?

?

?

?

?

??

????

?

???

?

???

?

?

?

?

?

?

?

?

??

?

?

?

??

?

?

?

?

?

??

??

?

?

?

??

?

?

???

???

?

?

??

?

??

?

?

?

?

??

?

?

?

?

?

??

??

??

??

?

?????

??????

?

?

?

??

?

???

2.1 Chassis

The chassis comprises the display, pump assembly,

and plug in sensor cartridge chamber.

Diagram 2-2. Main chassis

Display

Sensor cartridge chamber

Pump module

Service Port

Caution

The Service Port is only for use with

approved connectors by Honeywell

Analytics service personnel operating a

system diagnostic. Unauthorized connection

to this port may lead to damage of the

Midas® and external equipment and will not

be covered by the normal product warranty

conditions.

2.1.1 Display

The display is located at the front of the main

chassis and consists of a large alphanumerical

and graphical backlit LCD, 3 LED indicators and a

4-button keypad. Under normal operation the LCD

and LEDs display gas concentration, alarm and

system status. In set-up, review, calibration and test

modes, the LCD shows the relevant menu options.

These menus are simply navigated using the ‘s’ up,

‘t’ down, ‘3’ accept and ‘X’ cancel buttons.

Page 11

Midas® Gas Detector

2-3

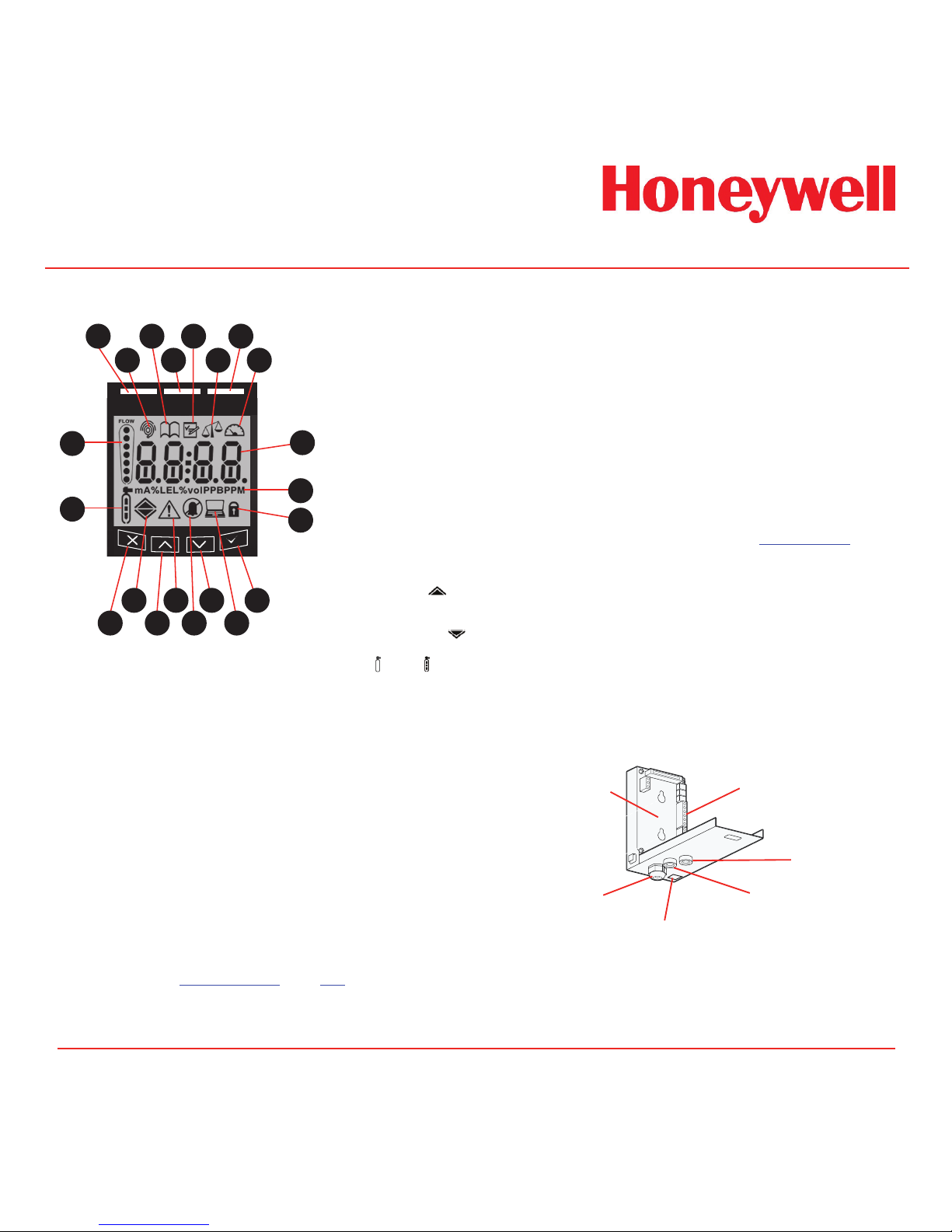

Diagram 2-3. Midas® display module layout

1

21

1

20

1

9

1

10

1

11

MDA Scientific Midas

1

2

1

3

1

5

1

4

1

6

1

7

1

8

1

1

1

12

1

13

1

14

1

15

1

16

1

17

1

19

1

18

2.1.2 Pump Module

The pump module is located at the back of the

main chassis. It draws the gas sample from the inlet

port located at the bottom of the mounting bracket

assembly via an inline filter to the sensor cartridge

chamber located at the front of the main chassis.

The inline filter is to protect the elements after the

sensor. The sample goes from the inlet straight to

the sensor face, and then through the rest of the

flow system. The sample is then exhausted via the

exhaust port located at the bottom of the mounting

bracket assembly. The pump and filter assemblies

are designed for easy replacement. For replacement

details refer to Sections 8.2 and 8.4.

2.1.3 Sensor Cartridge Chamber

The sensor cartridge chamber is located at the front

of the main chassis below the display module. The

plug in sensor cartridge is fitted into this area which

makes the electrical connection between the sensor

cartridge and the rest of the electronics as well as

providing the chamber where the sensor cartridge

is exposed to the sampled gas. This connection is

lightly lubricated for ease of sensor replacement.

Avoid contact of sensor cartridge chamber with

contaminants (such as dust and debris). For details

of fitting sensor cartridge refer to Section 4.9.

2.2 Mounting Bracket Assembly

The mounting bracket assembly comprises of the

detector mounting bracket, the terminal module, the

gas sample inlet and outlet ports, the cable/conduit

entry and Ethernet (Modbus/TCP) communications

socket.

Diagram 2-4. Mounting bracket assembly

Ethernet/PoE socket

Gas outlet port

Gas inlet port

Terminal module

Mounting bracket

Cable entry

1. Red alarm LED

2. Normal operation icon

3. Review mode icon

4. Green power LED

5. Set-up mode icon

6. Calibration mode icon

7. Yellow Fault LED

8. Test mode icon

9. Gas concentration and

message display area

10. Displayed units

11. Pass code icon

12. Accept button

13. Network icon

14. Down button

15. Inhibit icon

16. Fault icon

17. Up button

18. Alarm level 1 icon s

Alarm level 2 icon

(For flammable and toxic)

Depletion level 1 icon t

Depletion alarm level 2

19. Cancel button

20. Zero and Span calibration

icons

21. Flow indicator

Page 12

Midas® Gas Detector

2-4

2.2.1 Mounting Bracket

The metal mounting bracket has two slots that allow

the detector to be easily mounted to a wall using

two suitable screws (DIN rail or horizontal mounting

options are also available). For further details of

mounting the detector refer to Section 4.

2.2.2 Terminal Module

The terminal module is located on the mounting

bracket. All electrical connections to Midas® are

made via this module. Wire entry to the terminal

module area is via the PG16 cable entry/conduit

entry located at the bottom of the mounting bracket

assembly.

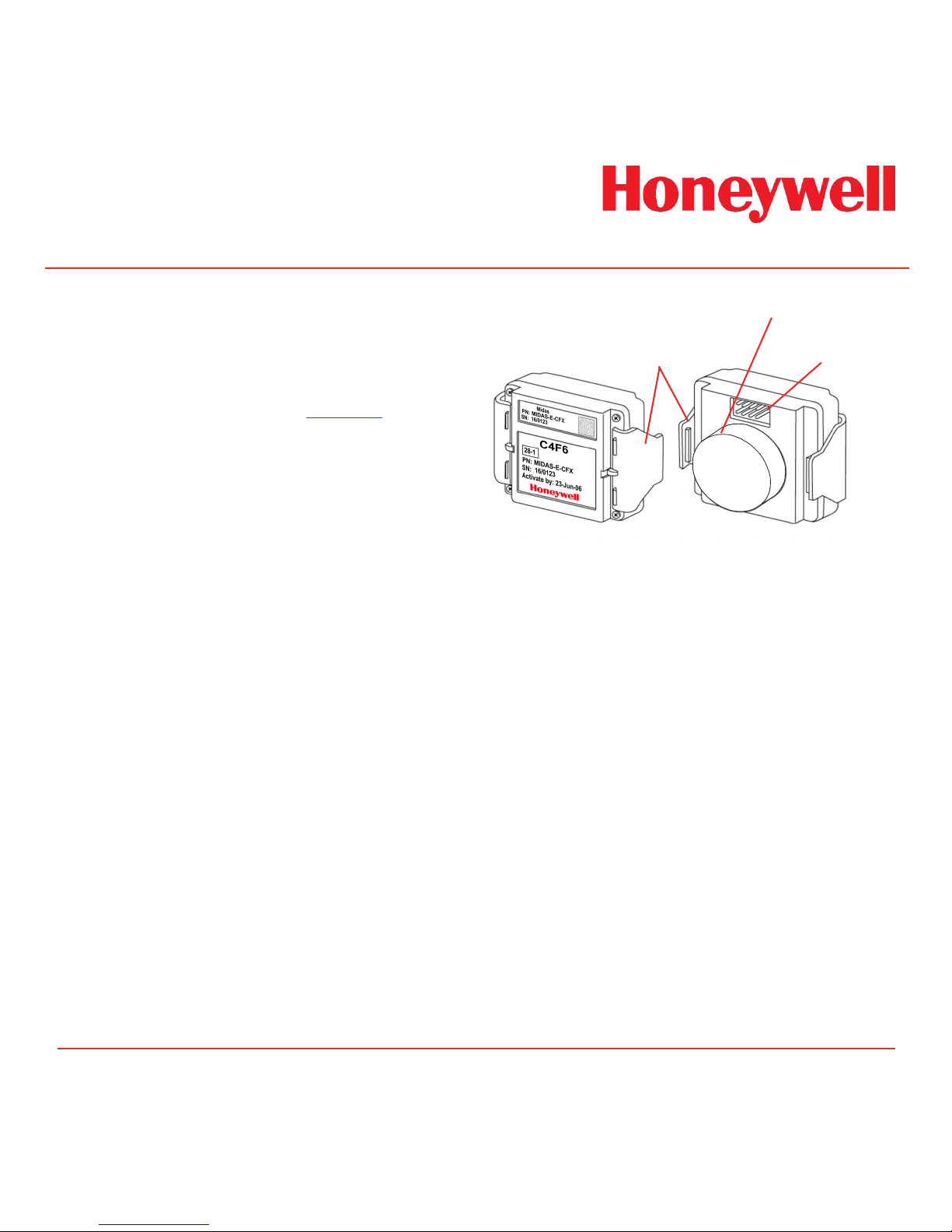

2.3 Sensor Cartridge

A wide range of Flammable, Pyrophoric, Corrosive,

and Oxidizer (including Oxygen) sensor cartridges

can be fitted to Midas®. The plug in sensor cartridges

are fitted in the sensor cartridge chamber at the

front of the main chassis. To access the chamber

the unit cover is removed by unscrewing the

thumbscrew located at the front of the detector. The

pre-calibrated smart sensor cartridges can easily

be fitted or replaced as they simply plug into the

detector without the need for any tools. The sensor

cartridge is firmly held in place by two locking tabs.

Some cartridges are shipped with a protective cap

to shield them from contaminants during shipping.

This cap must be removed before inserting the

cartridge into the Midas® unit, failure to do so may

damage the Midas® transmitter.

Diagram 2-5. Sensor cartridge

REMOVE

AT TIME OF

INSTALLATION

Front Back

Connector

Locking tabs

Protective Cap

(remove before use)

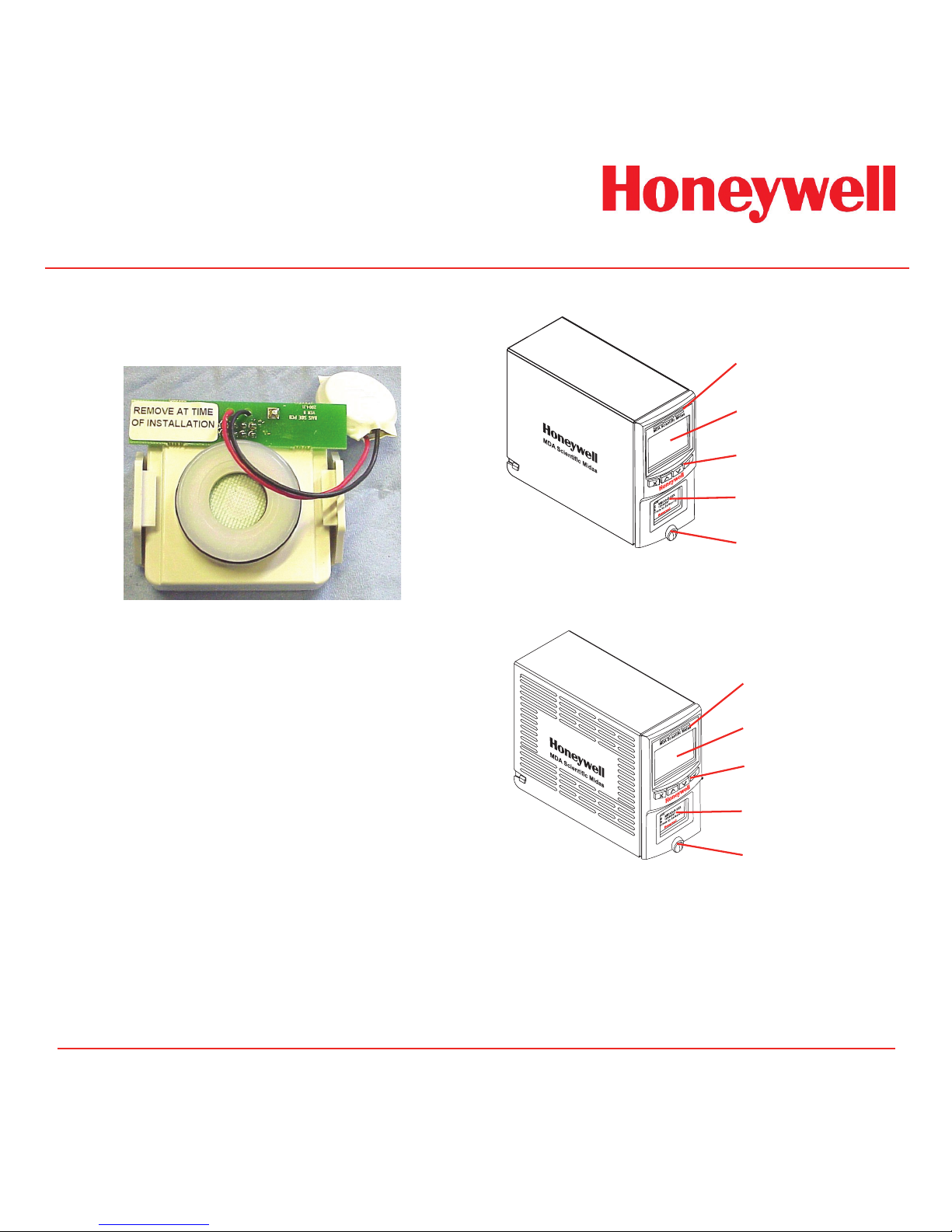

2.3.1 Biased Sensor Cartridges

Some sensor cartridges are shipped with a battery

powered electrical supply in order to keep the cell

effectively ‘warmed up’ and ready to monitor once

installed in the Midas® unit. Battery powered bias

circuits are supplied for TEOS, NO, and CO2. The

bias circuit is removed just before insertion into

the Midas® system and the sensor cartridge is thus

ready sooner for effective gas detection.

Should a bias voltage not be applied (e.g. during

a power failure), the cell will take a longer time to

recover before effective gas detection can take

place. The longer the loss of applied power, the

longer the recovery time. During this recovery time,

there is a chance for false/inaccurate readings.

Refer to the relevant sensor cartridge data sheet for

information on each sensor cartridge.

In order to avoid the risk of loss of gas detection

due to unforeseen power loss, we recommend that a

power management solution such as uninterruptible

power supplies are used.

Page 13

Midas® Gas Detector

2-5

Note

Sensor warranty is void if the sensor cartridge

is opened by unauthorized user.

Diagram 2-6. Biased Sensor.

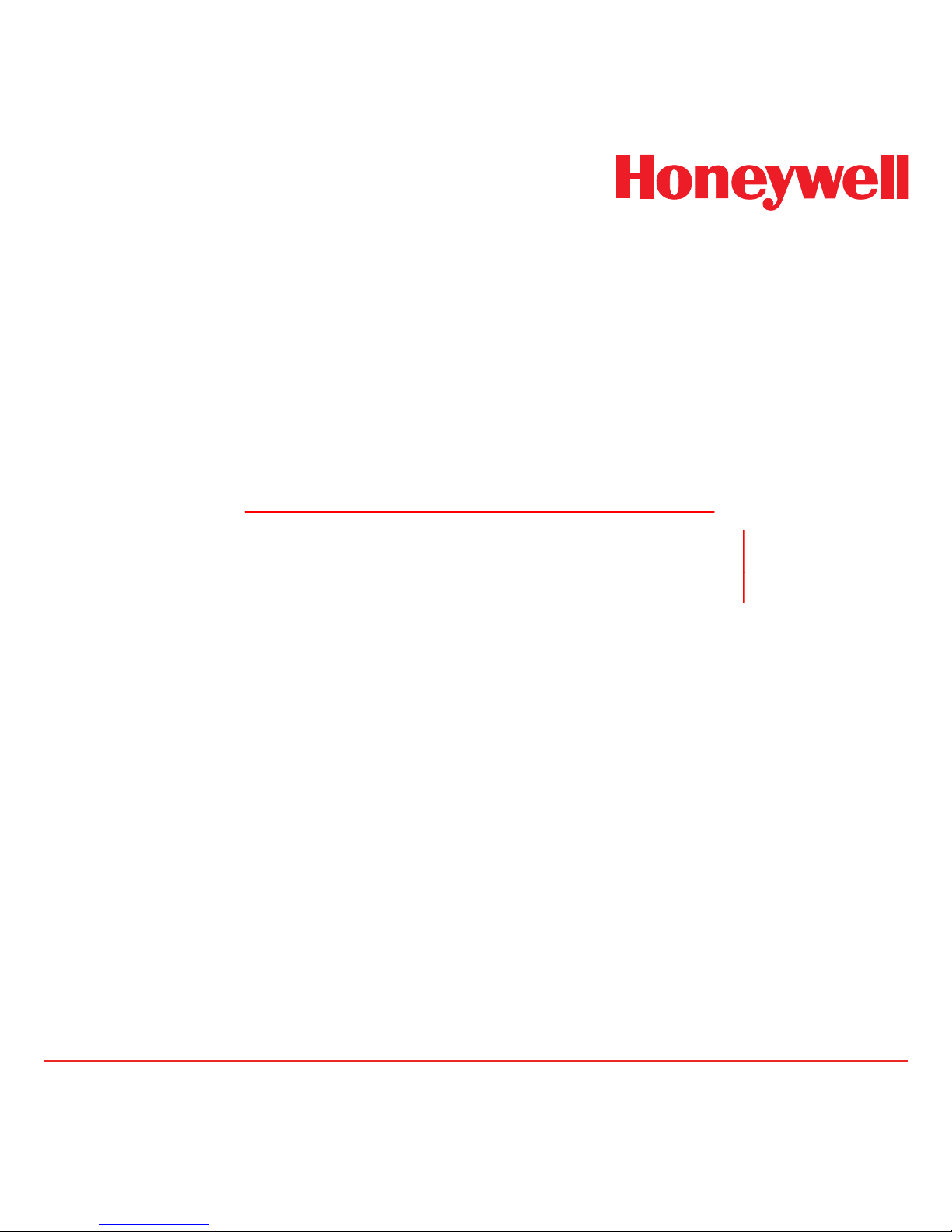

2.4 Cover

The standard cover provides environmental

protection and fits over the top, front and sides

of the main chassis. The front panel has viewing

windows for the LCD, LEDs and sensor cartridge

fitted in the sensor cartridge chamber. Underneath

the LCD window are the 4 push buttons used for

navigating the detector’s software menus. The cover

is easily removed to allow access to the chassis by

unscrewing the thumbscrew on the front panel and

pulling the cover forwards off the main chassis.

Midas units fitted with a pyrolyzer utilize a ventilated

cover due to the high temperatures generated by

the pyrolyzer unit (See Diagram 2-7)

Diagram 2-7. Midas® covers

LED Windows

LCD Window

Pushbuttons

Sensor Cartridge

viewing window

Thumbscrew

Standard Cover

LED Windows

LCD Window

Pushbuttons

Sensor Cartridge

viewing window

Thumbscrew

Ventilated Pyrolyzer Cover

Page 14

Midas® Gas Detector

3-1

3 Default Configuration

Page 15

Midas® Gas Detector

3-2

3 Default Configuration

NOTE: Oxygen levels are 20.9% v/v in a normal atmosphere, equivalent to 17.3 mA. Use caution when

integrating an oxygen Midas unit using the 4-20 mA output since fault, inhibit, and no power conditions

are below 4 mA and, by default, an oxygen depletion alarm is triggered on a falling alarm (default 19.5%

v/v). In that case, Honeywell Analytics recommends one of the following:

• Use Modbus TCP digital communications

• Use discrete relay inputs instead of a 4-20 mA signal to trigger gas alarms

• Program the control system of the 4-20 mA input with logic and a delay (e.g., 1 second) before

triggering an alarm to determine if the 4-20 mA output is at one of the 0-4 mA conditions described

above.

Contact Honeywell Analytics for further information.

The Midas® gas detector is factory-configured as described in Table 3-1 on the following page.

Page 16

Midas® Gas Detector

3-3

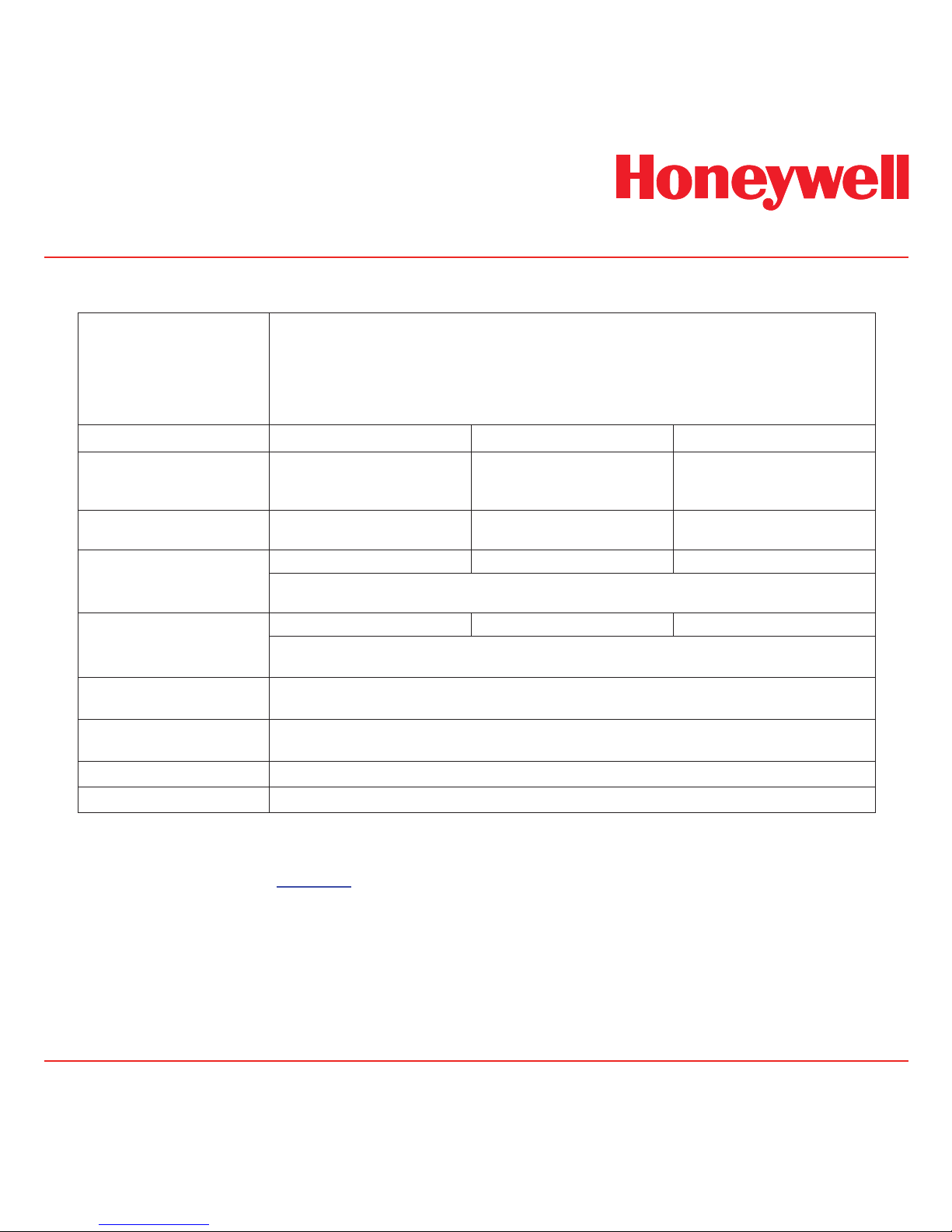

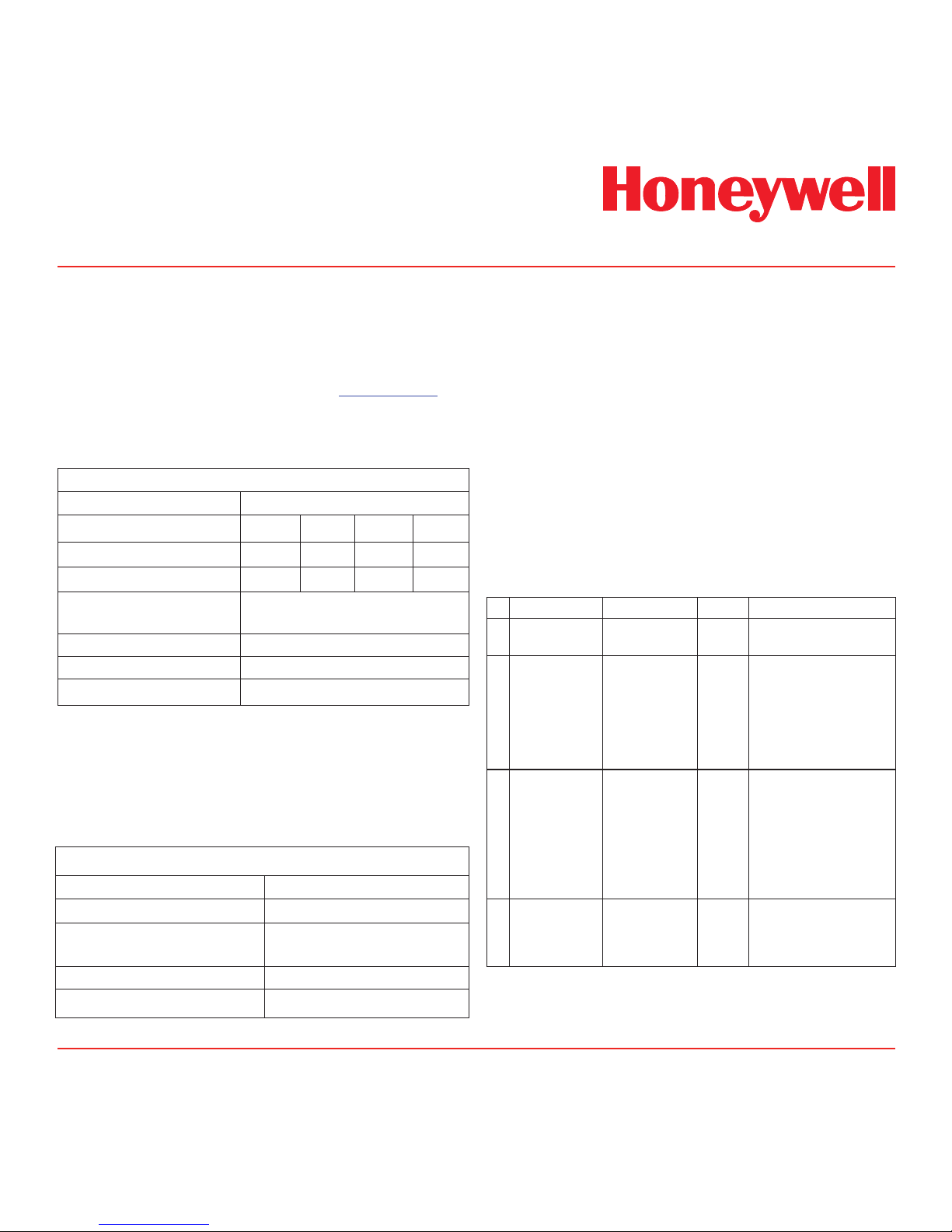

Table 3-1. Midas® default conguration

Current source with:

1.0 mA Fault

2.0 mA Inhibit

3.0 mA Maintenance Fault

4.0 to 20.0 mA Gas reading (normal operation)

21.0 mA Over range

Toxic Gas Flammable Gas Oxygen

Full Scale (FS)

Typically 4 x Threshold Limit

Value (TLV)

100% Lower Explosive Limit

(LEL)

1

25% Volume (v/v)

Lowest Alarm Level (LAL)

Typically 1/2 TLV 10% LEL 5% v/v

Alarm 1

(Relay 1)

1/2 TLV 10% LEL 23.5% v/v (Rising)

Normally de-energized, energizes on alarm.

Contact Normally Open (NO), closes on alarm.

Alarm 2

(Relay 2)

TLV 20% LEL 19.5% v/v (Falling)

Normally de-energized, energizes on alarm.

Contact Normally Open (NO), closes on alarm.

Fault

(Relay 3)

Normally energized, de-energizes on fault.

Contact Normally Open (NO). Instrument Fault Only

Latching

Latching. Alarm and fault relays DO NOT automatically reset when reading falls below alarm

thresholds. Relays MUST be manually reset.

Pass code

No pass code set.

IP Address

169.254.60.47 subnet mask 255.255.255.0

1

Midas

®

detectors are not ETL approved for monitoring in or sampling from classied areas above 25% LEL

See Table 7-3 for more information on Relay Configuration

Page 17

Midas® Gas Detector

4-1

4 Installation

Page 18

Midas® Gas Detector

4-2

4 Installation

For ease of installation Midas® has been designed

to allow the installation of the mounting bracket

assembly and terminal module separately from the

other parts of the detector. The detector location and

hard wiring can therefore be completed before fitting

the detector’s main chassis and sensor cartridge.

WARNING

Midas® is designed for installation and use in

indoor safe area non-explosive atmospheres.

Installation must be in accordance with the

recognized standards of the appropriate

authority in the country concerned. Prior

to carrying out any installation ensure local

regulations and site procedures are followed.

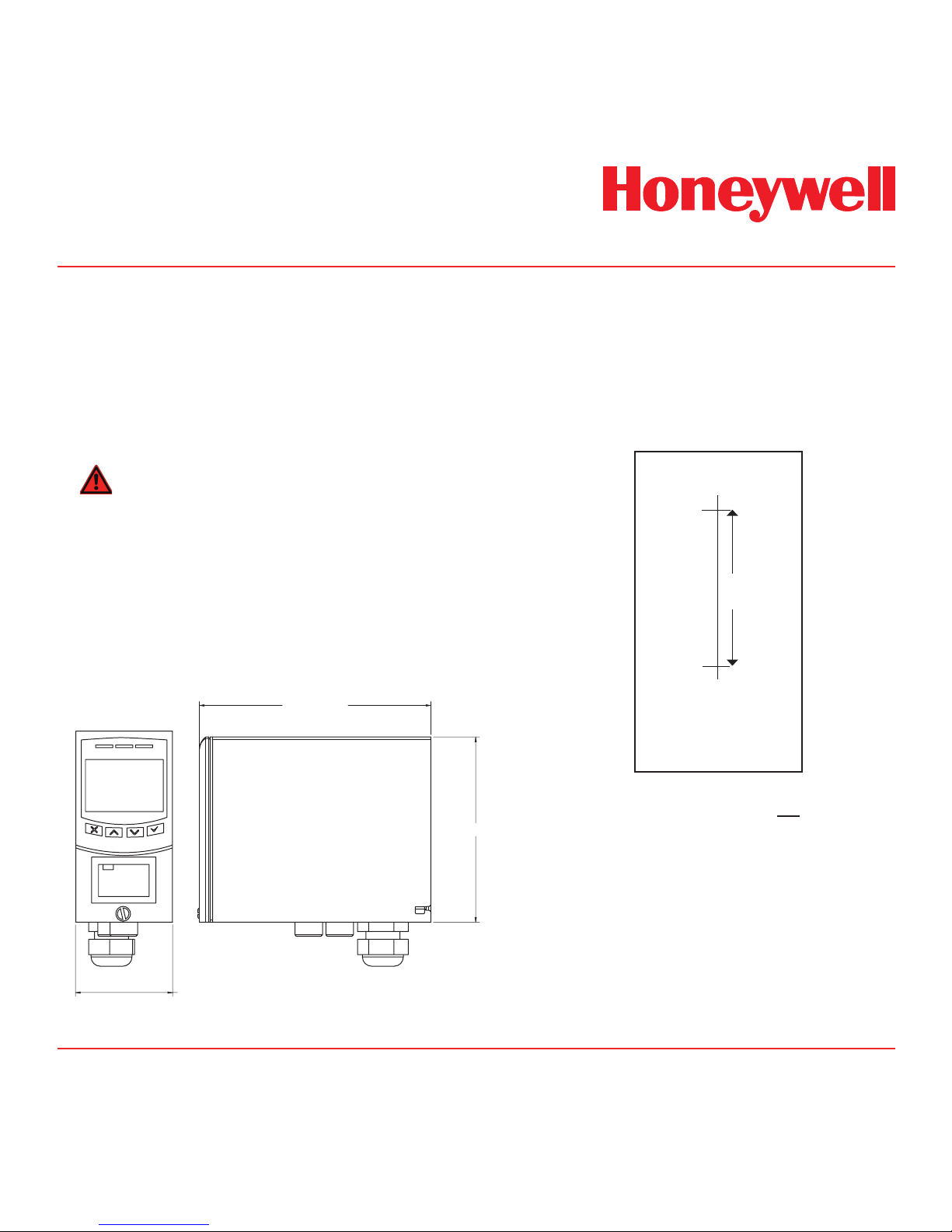

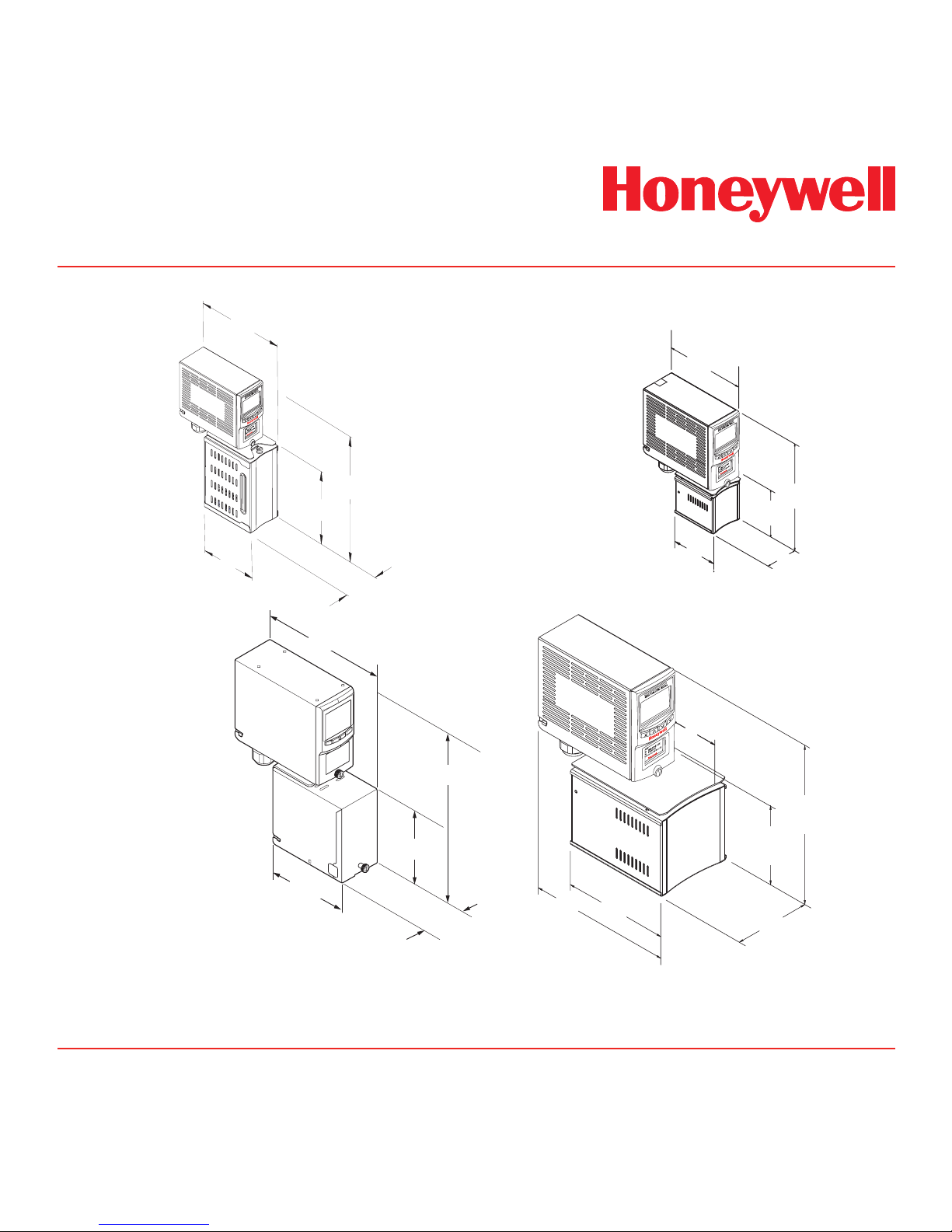

Diagram 4-1. Midas® outline dimensions

zellweger analytics

z

GAS DETECTOR

5.91 in [150.00mm]

4.72 in [120.00mm]

2.48 in [63.00]

honeywell

honeywell

MDA Scientific Midas

PN: MIDAS-E-CDX

SN: 12K-48397

Activate by 24-Nov-12

4.1 Mounting and Location of Detector

The Midas® gas detector has an integral mounting

bracket assembly that is easily mounted to a

suitable vertical surface such as a wall, tool housing,

mounting plate on a pole etc.

Drill Template

Drill 2 x

M4 holes

2.3 in

(58.50mm)

Note

This drill template is not to scale.

The Midas Quick Start Guide

(MIDAS-A-020) contains a full

scale drawing.

Ensure all measurements are

correct before using as an actual

drill template.

Use 2 x M4 Screws or equivalent

for mounting (head size 6-12

mm (1/4” - 1/2”))

Page 19

Midas® Gas Detector

4-3

7.9 in

(201 mm)

6.0 in

(152 mm)

3.2 in

(81 mm)

2.5 in

(62 mm)

3.2 in

(83 mm)

Midas® Transmitters and Pyrolyzers

4.0 in.

(101 mm)

8.2 in.

(209 mm)

5.5 in.

(140 mm)

4.4 in.

(113 mm)

9.1 in.

(233 mm)

2.3 in.

(59 mm)

MIDAS-T-HTP

Note: Heat shield not present on all pyrolyzers.

3.9 in.

(205 mm)

3.9 in.

(98 mm)

2.4 in.

(60 mm)

5.2 in.

(132 mm)

9.6 in.

(244 mm)

Midas-T-00P

MIDAS-A-

103

honeywell

honeywell

MDA Scientific Midas

PN: MIDAS-E-CDX

SN: 12K-48397

Activate by 24-Nov-12

MIDAS-T-0P3

MIDAS-A-039

MIDAS-T-NP1

LQ

PP

LQ

PP

LQ

PP

LQ

PP

LQ

PP

Page 20

Midas® Gas Detector

4-4

Below are some considerations when installing the

Midas® Gas Detector:

1. Mount the detector on a surface that is flat,

firm and suitable for its size and weight.

2. Use the drill template supplied to drill the holes

for the fixings.

3. Use fasteners appropriate for the surface

being mounted to.

4. Ensure the head size of fastener used will not

snag the terminal PCB 6-12 mm (.25 in - .5 in).

5. Consider the conduit/cable weight and its

stress on the installation.

6. Position the detector so that it can be easily

accessed.

7. Position the detector so that it is at a suitable

height (normally eye level) for the display to

be clearly seen.

8. Take into consideration the space required

to remove the detector’s cover and locking/

unlocking the sensor cartridge locking clips.

Minimum recommended spacing between

multiple Midas® units is 82 mm (3.23 in).

9. Take into consideration the space required for

sample inlet and exhaust tubing (for remote

monitoring), and for the inlet filter (for local

monitoring).

10. Take into consideration the space required for

cable or conduit access.

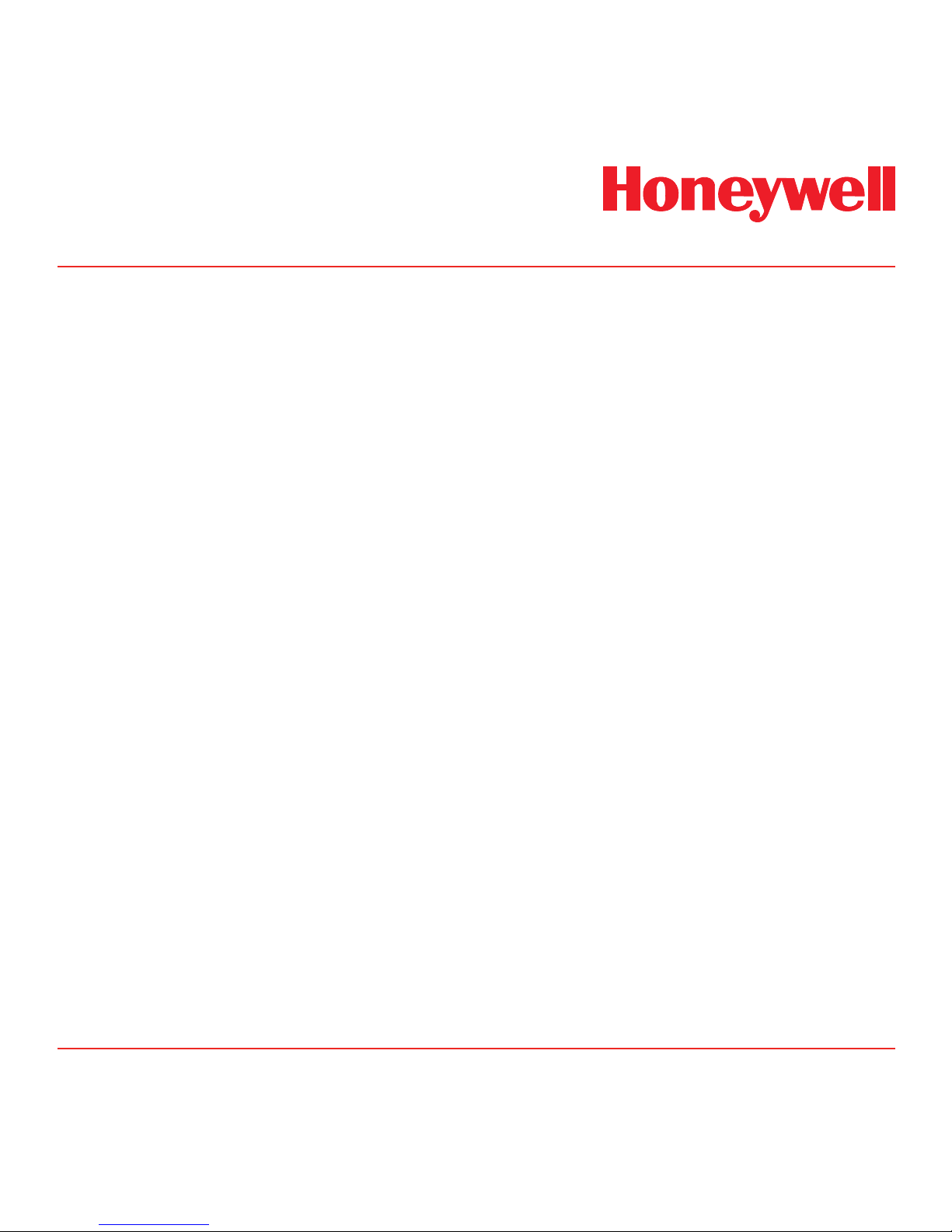

4.2 Mechanical Installation

The following steps and diagrams show how to separate

the mounting bracket assembly from the main chassis

and mount it on a vertical flat surface.

1. Unscrew the thumbscrew located on the front

panel.

2. Remove the cover by pulling it forwards off the

main chassis. Be sure to remove the internal

packing card securing the pump. Failure to

remove this packing will result in damage to

the Midas® unit. (See Diagram 4-2)

3. Unscrew the two retaining screws located at

the bottom front of the chassis.

4. Holding the mounting bracket assembly with

one hand use the other to carefully pull the

main chassis forward to disconnect it from the

mounting bracket assembly.

5. Using the drill template provided drill two holes

58.50 mm vertically apart for 2 x round head M4

fixing screws.

6. Partially screw the fixings into the mounting

surface.

7. Place the mounting bracket assembly over

the screws so they pass through the mounting

holes and then slide down to locate in the slots.

8. Tighten the screws to secure the mounting

bracket assembly.

Page 21

Midas® Gas Detector

4-5

Diagram 4-2. Mechanical installation

Removing cover

mounting

bracket

chassis

cover

loosen

IMPORTANT NOTICE !

Remove internal

shipping protection from

the pump module brf

ore

installation

Removing chassis

mounting

bracket

chassis

IMPORTANT NOTICE !

Remove internal

shipping protection from

the pump module brf

ore

installation

Internal packing card

Remove before use.

Internal packing card

Remove before use.

Chassis Mounting Screws

Page 22

Midas® Gas Detector

4-6

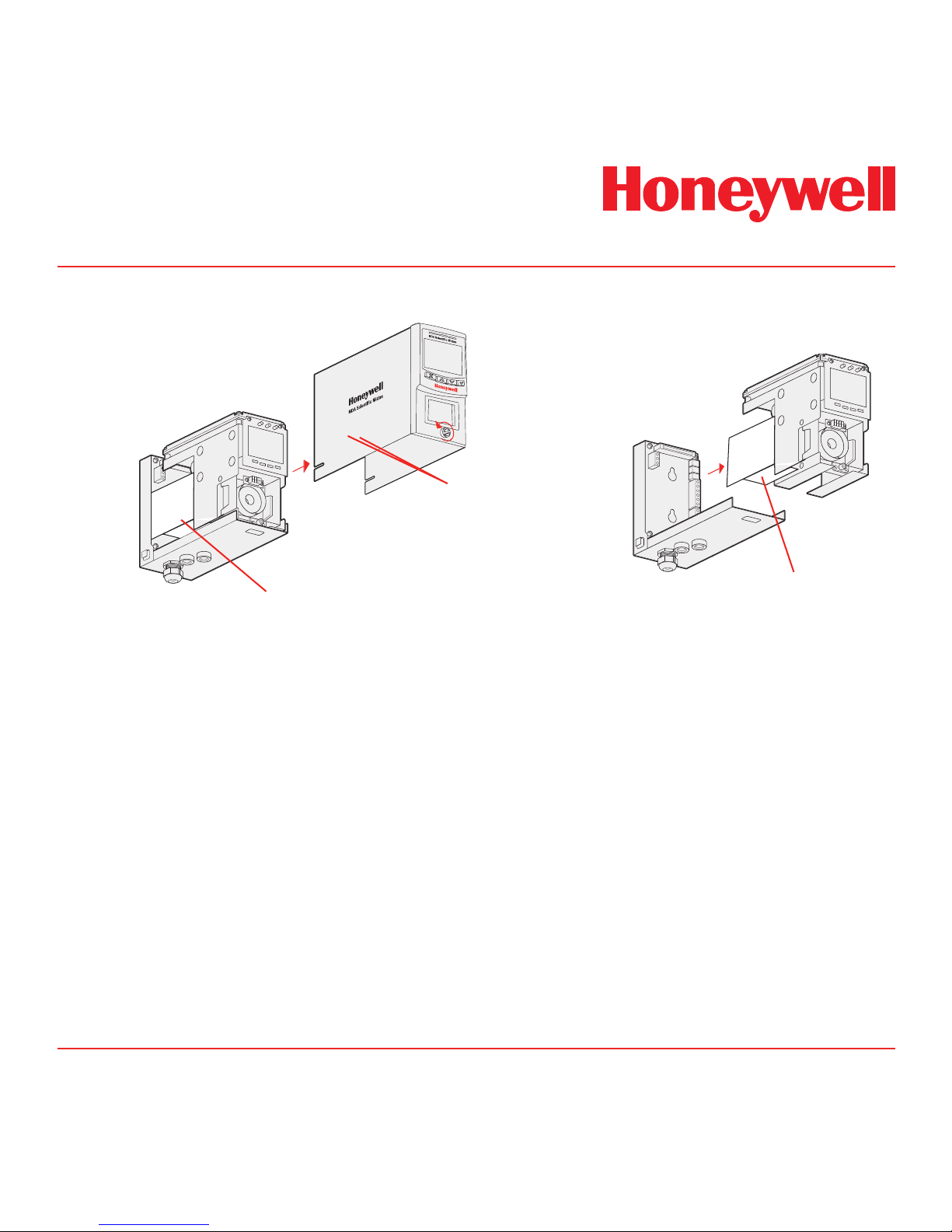

DIN Rail Bracket

Spacer Bracket

2x M4 Screws

Secures Midas

®

to

Spacer Bracket

4x M3 Screws

Secures DIN Rail

to Spacer Bracket

Optional Midas® DIN Rail Mount

Optional Midas

®

Pyrolyzer Adjustable “L” Bracket Mount

Optional Midas® Adjustable “L” Bracket Mount

mounting bracket

screws

Standard Midas® Wall Mount

Diagram 4-3. Mechanical installation

Note:

When using the Adjustable

“L” bracket with the HighTemperature Pyrolyzer

unit, (2) Top Access Tubing

Connectors (MIDAS-A-

031) must be used to insure

proper operation.

Top Access Tubing Connector

(MIDAS-A-031)

honeywell

honeywell

MDA Scientific Midas

PN: MIDAS-E-CDX

SN: 12K-48397

Activate by 24-Nov-12

Page 23

Midas® Gas Detector

4-7

4.3 Sample and Exhaust Tubing Calculations

The following tables show the flow rate, tubing

length, transport time, and maximum pressure and

vacuum at the inlet and exhaust points. Tubing

lengths vary among gases. See Appendix B for

recommended lengths.

Table 4-1. Inlet sample specications

Inlet Sample Specifications:

Maximum

Tubing Length, m (ft)

30 (100) 20 (66) 10 (33) 0

Transport Time (sec), ID 1/8”

1

28 19 10 1

Transport Time (sec), ID 3/16”

63 43 23 1

Sample Point Vacuum

(Negative pressure)

-25.4 cm H2O (-10 in H2O) Maximum

Flow rate, cc/min.

500 (Flow is constant)

2

Tubing OD, mm (in)

6.35 (0.25)

Tubing ID, mm (in)

3.18 (0.125)

1

Honeywell Analytics recommends thick-wall tubing (1/8” ID)

for best speed of response. Due to its lower surface area, thickwall tubing may require less conditioning than thin-wall tubing.

2

The ow rate is electronically maintained at approximately

500 cc/min and may vary within acceptable tolerances.

Table 4-2. Outlet sample specications

Outlet Sample Specifications:

Maximum

Tubing Length, m (ft)

30 (100)

Back Pressure at Exhaust Point

(Excluding tubing)

20.3 cm H2O (8 in H2O) Maximum

Tubing OD, mm (in)

6.35 (0.25)

Tubing ID, mm (in)

4.76 (0.188)

Note

Honeywell Analytics recommends the use of

Teon FEP (Fluorinated Ethylene Polymer)

tubing to assure proper sample transport.

The properties of Teon FEP make it the

best choice for transporting sample toxic

gases to instruments when compared with the

properties of other similar tubing materials.

If the pressure/vacuum on the inlet/exhaust lines

does not meet the recommended values in Tables

4-1 and 4-2, the following chart describes potential

fault conditions that may be brought on by the

external influences thus resulting in an F81 Flow

Fault.

External Flow Fluctuation Fault 81 Explanation

1

Low

(0-150 cc/min)

None No Midas® will auto-adjust

2

Low

(0-150 cc/min)

Yes

(up to 100 cc/

min flow swings)

Likely

Midas® changes the flow

gradually. If external flow

changes are large and rapid,

the final reading will be

different from what Midas

®

expected. Midas® will issue

Fault 81.

3

Medium

(~200-450 cc/

min)

Yes and No Yes

Minimum flow rate for the

pump is ~300 cc/min. With

this external flow, the autoadjust cannot work because

the pump cannot produce

a flow at this low level. The

problem is worse if there are

flow fluctuations.

4

High

(> 600 cc/min)

Yes and No Yes

Midas® cannot reduce the

external flow. Midas® will

issue Fault 81 due to high

flow

Page 24

Midas® Gas Detector

4-8

4.4 In-line Filters

External filters must be used to protect the

tubing from contamination. Use particulate

filter part number 780248 for normal gases and

1830-0055 or 1991-0147 for corrosive gases.

Replace the filter every 3 months. Refer to

Appendix B for specific gases.

4.5 Local Detector Option

The Midas® gas detector can also be used to

monitor for gas at the location of the detector. To

do this an inline filter is simply connected to the

sensor cartridge gas inlet port. The external dust

filter part number is 780248 for normal gases and

1830-0055 or 1991-0147 for corrosive gases. The

area around the detector is then being monitored

as opposed to a sample being drawn from a remote

location.

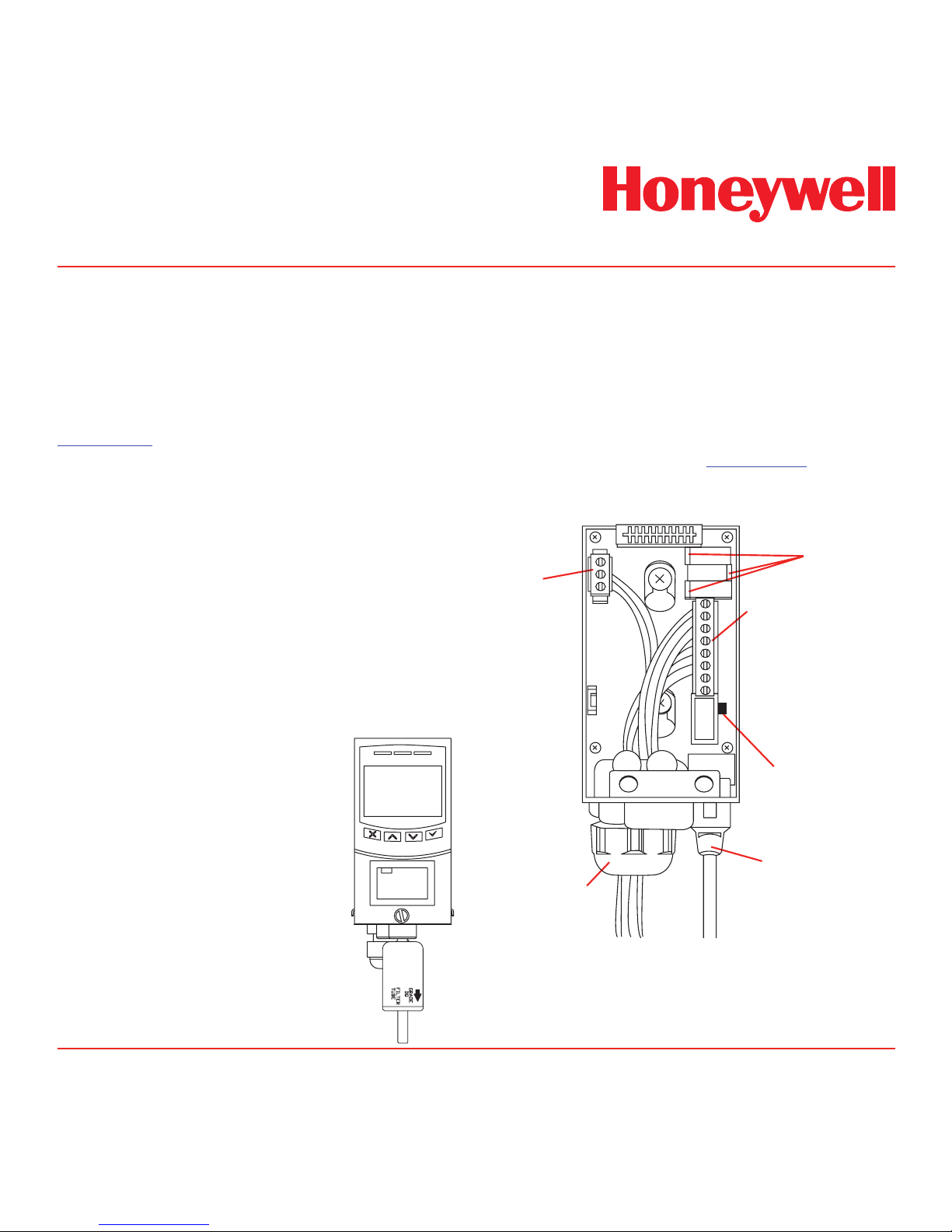

Diagram 4-4. Local gas detector option

MIDAS-T-001 transmitter

installed with in line particulate

lter for local ambient monitoring

mode

4.6 Electrical Installation

Access for the electrical wires to the terminal module

is made via the PG16 cable gland located at the

bottom of the mounting bracket assembly. The

cable gland can be removed and replaced with a

suitable conduit fitting if required. The wire routing of

a typical installation is shown in the diagram below,

wiring details are shown in Diagram 4-6.

Diagram 4-5. Typical wire routing

4-20mA

Analog

Output

Terminals

Relay NO/NC

Jumpers

Relay Contact

Terminals

Cable Gland

Ethernet Cable

Power Switch

The terminals used are suitable for conductors of 24

to 14 AWG (0.5 to 1.8mm Dia.). The use of 16 AWG

(1.5 mm Dia.) conductors is recommended.

honeywell

honeywell

MDA Scientific Midas

PN: MIDAS-E-CDX

SN: 12K-48397

Activate by 24-Nov-12

Page 25

Midas® Gas Detector

4-9

If Power over Ethernet (PoE) is used to power

the device, then 24 VDC power must not also be

connected to the device, (or conversely if 24 VDC

is used to power the Midas®, then electrical power

via the Ethernet port must not be applied). Failure

to observe this requirement may cause damage to

the gas detection system and will not be covered

by the standard warranty.

When connecting the wires ensure that the power

switch is in the off position.

Diagram 4-5 shows the terminal module layout

and terminal identification as well as the jumper

locations.

Note: Earthing Requirements

If the Midas® unit’s metal chassis is not

connected directly to a metal surface for

earthing purposes, an additional earth wire

will be required. Connect a wire via the

PG16 gland to the dedicated earth tag (screw

terminal) located on the bottom bracket

and connect the other end of the wire to a

dedicated external earthing point.

If Power over Ethernet (PoE) power supply

is being used, shielded CAT5 Ethernet cable

is recommended.

Please ensure that your wiring avoids earth

ground loops that may aect the performance

of your equipment

Page 26

Midas® Gas Detector

4-10

Diagram 4-6. Midas® terminal layout and identication

RJ-45

8

7

2

3

4

5

6

1

DC

PWR

+24 V

COM

NO

NC

Relay3

Relay2

Relay1

ON

SW

OFF

11

10

9

Analog Current

Loop 4-20 mA

INT EXT

EXT INT

-supply

J5

J4

+supply

J1

NO

NC

J2

NO

NC

J3

PYROLYZER

CONNECTOR

Relay1

}

Relay2

}

Relay3

}

See Relay

function

table below

Relays

are user

congurable

Note

The 3 relays onboard the Midas® unit can be controlled remotely from a separate controller system using

Modbus/TCP commands (or via LonWorks® if the optional interface is used). In this remote mode, the relays

cannot be controlled by the Midas® itself and only by the remote controller device (PLC, SCADA, etc.)

Display Description Relay 1 Relay 2 Relay 3

1FLt

Instrument Fault

Only

Alarm 1 Alarm 2

Instrument

Fault

2Flt

Separate Fault

Relays

Any Alarm

Maintenance

Fault

Instrument

Fault

CmbF

Combined Fault

Relay

Alarm 1 Alarm 2 Any Fault

nEtr

Remote control of

relays via Modbus/

TCP or LonWorks

®

Relays respond to Modbus or

LonWorks® holding registers only.

Page 27

Midas® Gas Detector

4-11

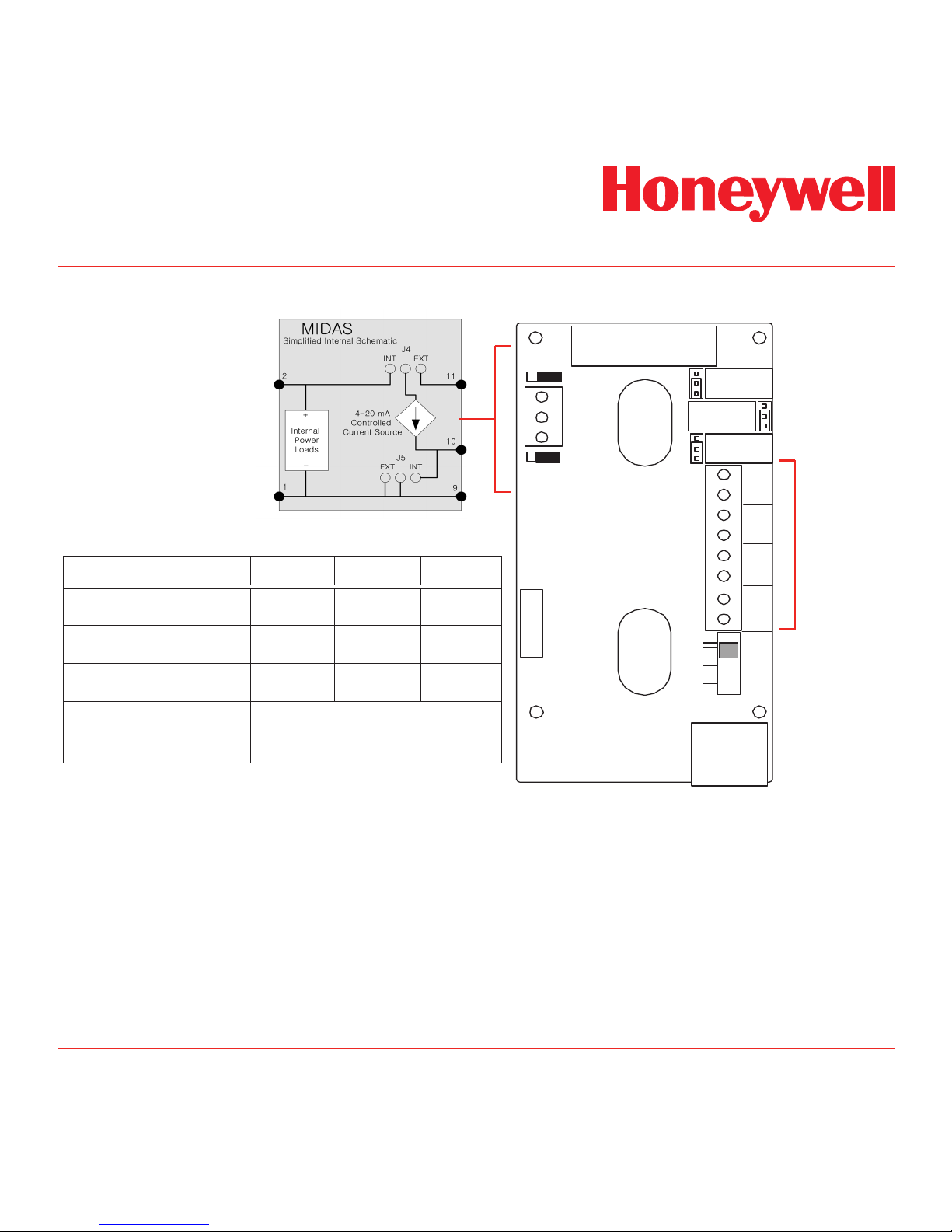

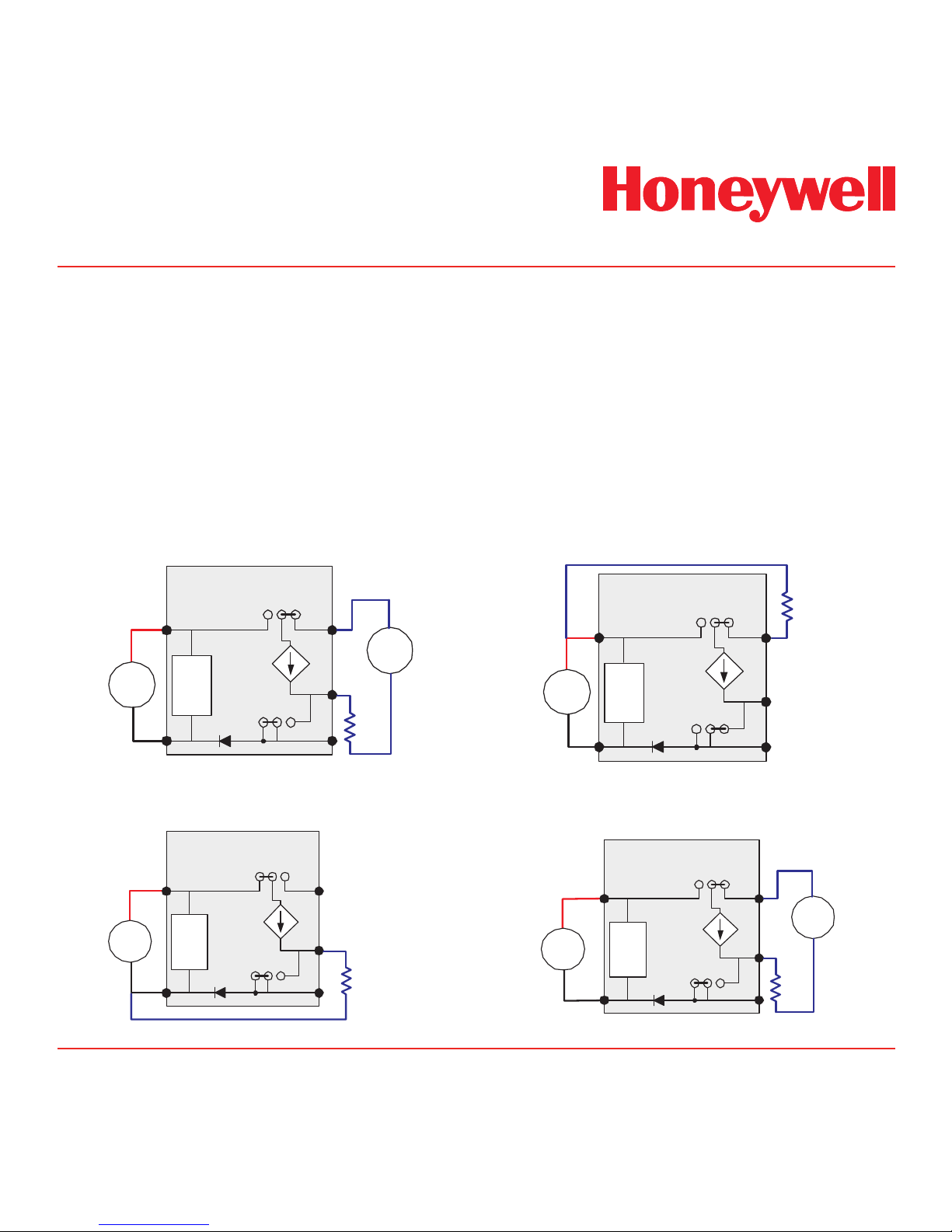

Diagram 4-7. Generic Example

Midas® 4-Wire Isolated Output

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

+

-

24 VDC

+

-

24 VDC

R

Load

Diagram 4-8. Generic Example

Midas® 3-Wire Sourcing

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

+

-

24 VDC

R

Load

Diagram 4-9. Generic Example

Midas® 3-Wire Sinking Output

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

+

-

24 VDC

R

Load

Diagram 4-10. Generic Example

Midas® Isolated 4-20 mA Output w/PoE Power

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

+

-

Ethernet

+

-

24 VDC

R

Load

RJ-45 Connector

48 VDC

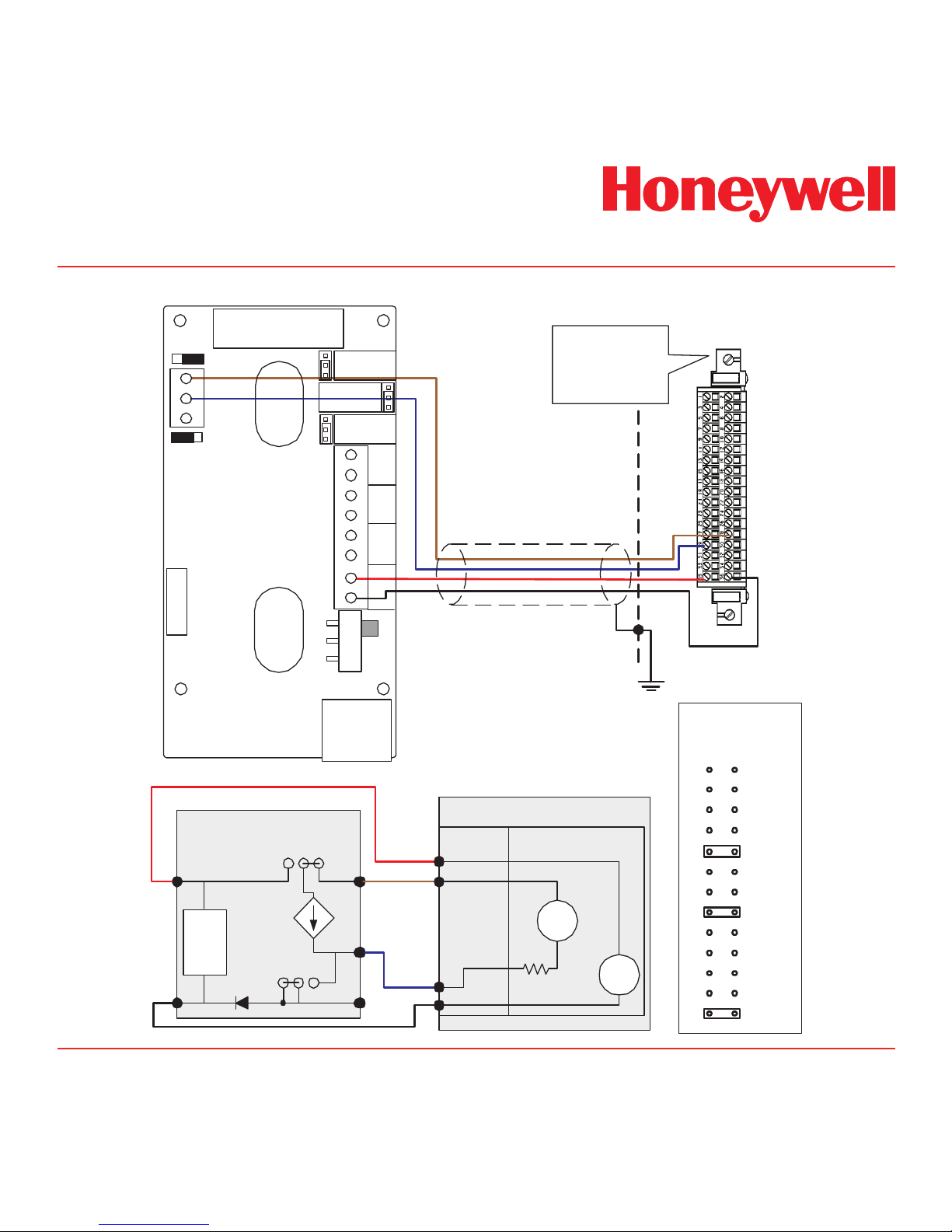

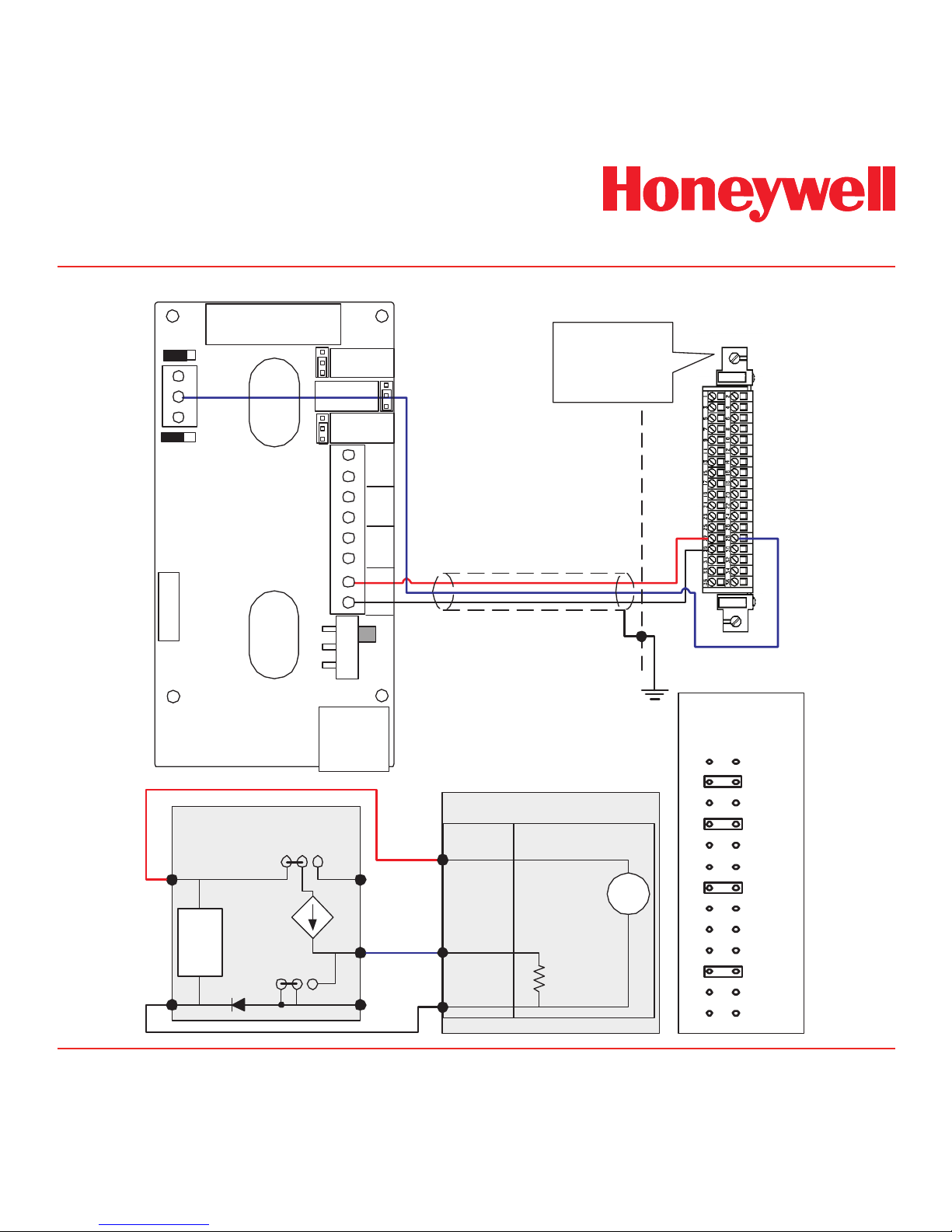

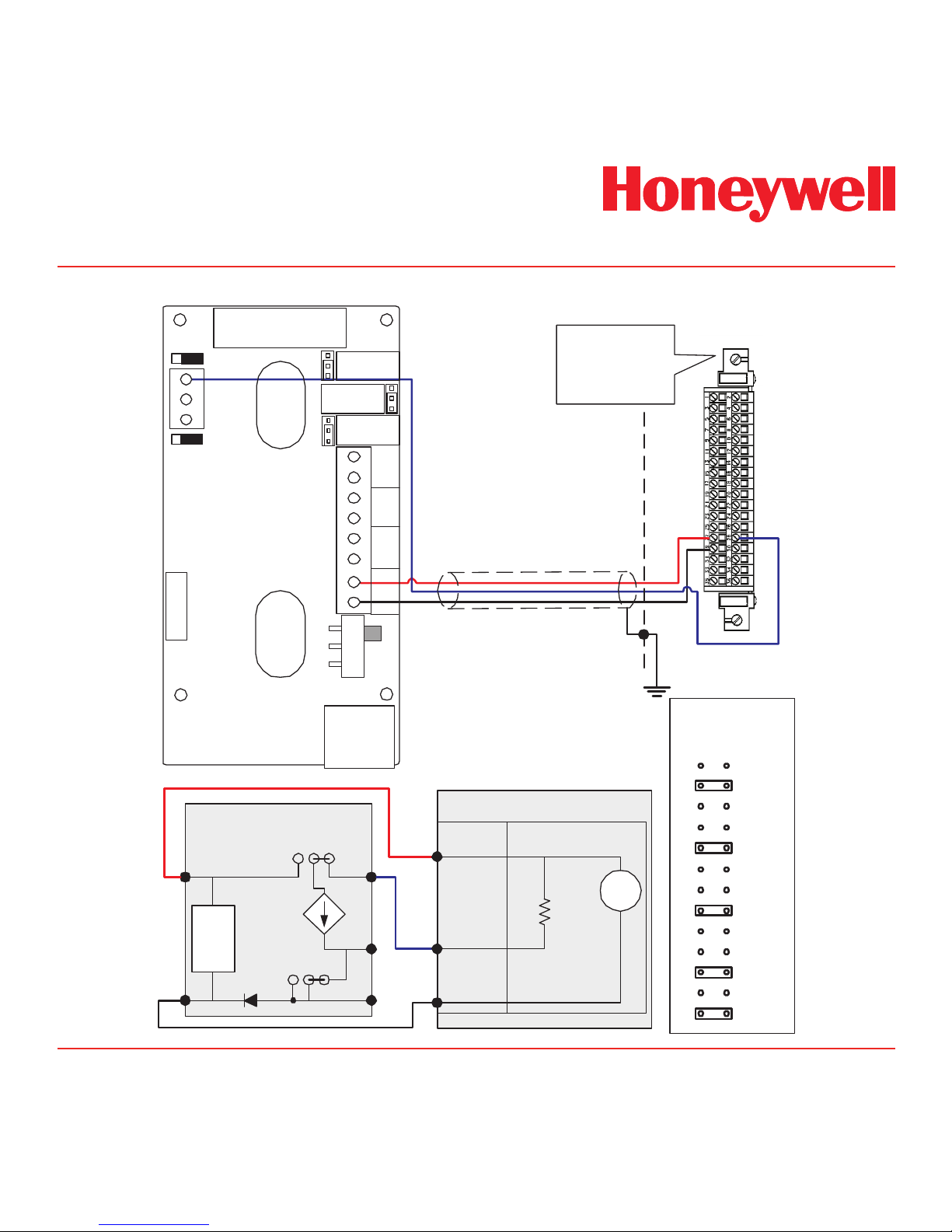

4.7 Electrical Connections

Midas® can be powered by either 24 VDC via

traditional discrete wiring or by approximately 48

VDC delivered through the Ethernet cable from

a PoE source. In either case the 4-20 mA analog

output can be used. This can be configured for

fully isolated operation. With 24 VDC power the

4-20 mA output can be configured for sink, source

or isolated output operations. Below are some

schematic diagrams of typical electrical connection

configurations. Specific wiring instructions for

connecting a Midas to a Honeywell Analytics Sieger

System-57TM are provided on pages 4-12 to 4-16.

Specific instructions for connection to a Honeywell

Analytics TouchPointTM are provided on pages 4-17

and 4-18 and the HA71 on pages 4-19 and 4-20.

Note:

When wiring the Midas Transmitter to a

controller, program the controller for a 1-2

second delay before reporting to prevent

false alarms.

Page 28

Midas® Gas Detector

4-12

Diagram 4-11. Midas® to 5701 4-Wire Isolated Connection

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

Sieger System 57

Relay/Field Interface Card

05701-A-0326

05701-A-0327

05701-A-0328

05701-A-0329

05701-A-0330

System 57

Relay/Field

Interface Card

5701 Control Card

+

24

VDC

-

35

36

29

28

+

24

VDC

-

Sense

Resistor

Cabinet

29

35

28

36

Shielded Cable

Isolated Loop

Supply

~40 mA max

Transmitter

Supply

5701 Card

Sensor Drive Module

Link Positions

LK12

LK5

LK6

LK7

LK8

LK9

LK10

LK11

LK1

LK2

LK3

LK4

LK13

RJ-45

8

7

2

3

4

5

6

1

DC

PWR

+24 V

COM

NO

NC

Relay3

Relay2

Relay1

ON

SW

OFF

11

10

9

Analog Current

Loop 4-20 mA

INT EXT

EXT INT

-supply

J5

J4

+supply

J1

NO

NC

J2

NO

NC

J3

PYROLYZER

CONNECTOR

Relay1

}

Relay2

}

Relay3

}

Page 29

Midas® Gas Detector

4-13

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

Sieger System 57

Relay/Field Interface Card

05701-A-0326

05701-A-0327

05701-A-0328

05701-A-0329

05701-A-0330

System 57

Relay/Field

Interface Card

5701 Control Card

+

24

VDC

-

27

29

28

Sense

Resistor

~170 Ohm

Cabinet

29

2827

Shielded Cable

Transmitter

Supply

5701 Card

Sensor Drive Module

Link Positions

LK12

LK5

LK6

LK7

LK8

LK9

LK10

LK11

LK1

LK2

LK3

LK4

LK13

RJ-45

8

7

2

3

4

5

6

1

DC

PWR

+24 V

COM

NO

NC

Relay3

Relay2

Relay1

ON

SW

OFF

11

10

9

Analog Current

Loop 4-20 mA

INT EXT

EXT INT

-supply

J5

J4

+supply

J1

NO

NC

J2

NO

NC

J3

PYROLYZER

CONNECTOR

Relay1

}

Relay2

}

Relay3

}

Diagram 4-12. Midas® to 5701 3-Wire Sourcing Connection

Page 30

Midas® Gas Detector

4-14

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

Sieger System 57

Relay/Field Interface Card

05701-A-0326

05701-A-0327

05701-A-0328

05701-A-0329

05701-A-0330

System 57

Relay/Field

Interface Card

5701 Control Card

+

24

VDC

-

27

29

28

Sense

Resistor

~170 ohm

Cabinet

29

28

27

Shielded Cable

Transmitter

Supply

5701 Card

Sensor Drive Module

Link Positions

LK12

LK5

LK6

LK7

LK8

LK9

LK10

LK11

LK1

LK2

LK3

LK4

LK13

RJ-45

8

7

2

3

4

5

6

1

DC

PWR

+24 V

COM

NO

NC

Relay3

Relay2

Relay1

ON

SW

OFF

11

10

9

Analog Current

Loop 4-20 mA

INT EXT

EXT INT

-supply

J5

J4

+supply

J1

NO

NC

J2

NO

NC

J3

PYROLYZER

CONNECTOR

Relay1

}

Relay2

}

Relay3

}

Diagram 4-13. Midas® to 5701 3-Wire Sinking Connection

Page 31

Midas® Gas Detector

4-15

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

Sieger System 57

Quad Relay Interface Card

05704-A-0121

with

4 Channel Control Card

05704-A-0145

Cabinet

(01) 17

(S) 15

36

Shielded Cable

RJ-45

8

7

2

3

4

5

6

1

DC

PWR

+24 V

COM

NO

NC

Relay3

Relay2

Relay1

ON

SW

OFF

11

10

9

Analog Current

Loop 4-20 mA

INT EXT

EXT INT

-supply

J5

J4

+supply

J1

NO

NC

J2

NO

NC

J3

PYROLYZER

CONNECTOR

Relay1

}

Relay2

}

Relay3

}

+

24

VDC

-

+

24

VDC

-

Note:

The above schematic shows the MIDAS connected

to channel 1 on the 5704 card. The terminal numbers

for all four channels are as follows:

MIDAS Function Loop + Loop Midas Terminal Number

Color in this figure

5704 Channel 1 Ter minal

5704 Channel 4 Ter minal

5704 Channel 3 Ter minal

5704 Channel 2 Ter minal

11

Brown

15

22

21

16

System 57 Function S

10

Blue

17

24

23

18

01

17

15

System 57

Relay/Field

Interface Card

5704 Control Card

+

24

VDC

-

Sense

Resistor

Loop

Supply

Not optically isolated

Diagram 4-14. Midas® to 5704 4-Wire Connection

Page 32

Midas® Gas Detector

4-16

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

System 57

Relay/Field

Interface Card

5704 Control Card

19

17

Sense

Resistor

Cabinet

(NS) 19

(01) 17

Shielded Cable

RJ-45

8

7

2

3

4

5

6

1

DC

PWR

+24 V

COM

NO

NC

Relay3

Relay2

Relay1

ON

SW

OFF

11

10

9

Analog Current

Loop 4-20 mA

INT EXT

EXT INT

-supply

J5

J4

+supply

J1

NO

NC

J2

NO

NC

J3

PYROLYZER

CONNECTOR

Relay1

}

Relay2

}

Relay3

}

Sieger System 57

Quad Relay Interface Card

05704-A-0121

with

4 Channel Control Card

05704-A-0145

+

24

VDC

-

+

24

VDC

-

Note:

The above schematic shows the MIDAS connected

to channel 1 on the 5704 card. The terminal numbers

for all four channels are as follows:

MIDAS Function Analog Out Common

Midas Terminal Number

Color in this figure

5704 Channel 1 Ter minal

5704 Channel 4 Ter minal

5704 Channel 3 Ter minal

5704 Channel 2 Ter minal

10

Blue

17

24

23

18

System 57 Function 01

1

Black

19

26

25

20

NS

Diagram 4-15. Midas® to 5704 3-Wire Sourcing Connection

Page 33

Midas® Gas Detector

4-17

Shielded

Cable

+

-

24 VDC

Power Supply

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

touchpoint1

Simplified Internal Schematic

1

3

2

+

-

24 VDC

signal

+

-

24 VDC

External

Customer-Provided

Power Supply

touchpoint 1

RJ-45

8

7

2

3

4

5

6

1

DC

PWR

+24 V

COM

NO

NC

Relay3

Relay2

Relay1

ON

SW

OFF

11

10

9

Analog Current

Loop 4-20 mA

INT EXT

EXT INT

-supply

J5

J4

+supply

J1

NO

NC

J2

NO

NC

J3

PYROLYZER

CONNECTOR

Relay1

}

Relay2

}

Relay3

}

Diagram 4-16. Midas® to Touchpoint1 4-Wire Connection

Page 34

Midas® Gas Detector

4-18

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

touchpoint 1

Shielded Cable

touchpoint1

Simplified Internal Schematic

1

3

2

+

-

24 VDC

signal

RJ-45

8

7

2

3

4

5

6

1

DC

PWR

+24 V

COM

NO

NC

Relay3

Relay2

Relay1

ON

SW

OFF

11

10

9

Analog Current

Loop 4-20 mA

INT EXT

EXT INT

-supply

J5

J4

+supply

J1

NO

NC

J2

NO

NC

J3

PYROLYZER

CONNECTOR

Relay1

}

Relay2

}

Relay3

}

Diagram 4-17. Midas® to Touchpoint1 3-Wire Sourcing Connection

Page 35

Midas® Gas Detector

4-19

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

Shielded Cable

EXC

LO

HI

+

-

24 VDC

signal

RJ-45

8

7

2

3

4

5

6

1

DC

PWR

+24 V

COM

NO

NC

Relay3

Relay2

Relay1

ON

SW

OFF

11

10

9

Analog Current

Loop 4-20 mA

INT EXT

EXT INT

-supply

J5

J4

+supply

J1

NO

NC

J2

NO

NC

J3

PYROLYZER

CONNECTOR

Relay1

}

Relay2

}

Relay3

}

HA71

Analog Input Card

R2

R1

ANALOG INPUTS

R3

R4

R7

R6

R5

+EXC-

DC PWR

TB2

R8

JP1

ST-71 ANALOG INPUT BOARD

0010-1115 ASSY# 10-0158

J2

J1

CH1/9

EXC HI

CH7/15

HIEXC

CH3/11

EXC LOHILO

CH5/13

LOHI EXC LO

CH2/10

HIEXC

CH8/16CH4/12

EXC LOHI CXEOL

CH6/14

EXC LO OLIH HI

3 Wire 4-20mA

Transmitter

EXC LOHI

+Pwr

Sig

Com

Diagram 4-18. Midas® to HA71 3-Wire Sourcing Connection

Page 36

Midas® Gas Detector

4-20

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

Cabinet

Shielded Cable

RJ-45

8

7

2

3

4

5

6

1

DC

PWR

+24 V

COM

NO

NC

Relay3

Relay2

Relay1

ON

SW

OFF

11

10

9

Analog Current

Loop 4-20 mA

INT EXT

EXT INT

-supply

J5

J4

+supply

J1

NO

NC

J2

NO

NC

J3

PYROLYZER

CONNECTOR

Relay1

}

Relay2

}

Relay3

}

+

24

VDC

-

HI

EXC

+

24

VDC

-

Sense

Resistor

Loop

Supply

Not optically isolated

HA71

Analog Input Card

R2

R1

ANALOG INPUTS

R3

R4

R7

R6

R5

+EXC-

DC PWR

TB2

R8

JP1

ST-71 ANALOG INPUT BOARD

0010-1115 ASSY# 10-0158

J2

J1

CH1/9

EXC HI

CH7/15

HIEXC

CH3/11

EXC LOHILO

CH5/13

LOHI EXC LO

CH2/10

HIEXC

CH8/16CH4/12

EXC LOHI CXEOL

CH6/14

EXC LO OLIH HI

EXC LOHI

4 Wire 4-20mA

Transmitter

+Pwr

Sig

+

-

24 VDC

Power Supply

Diagram 4-19. Midas® to HA71 4-Wire Connection

Page 37

Midas® Gas Detector

4-21

Diagram 4-20. Midas® to Touchpoint4 4-Wire Connection

touch point4

Shielded

Cable

+

-

24 VDC

Power Supply

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

touchpoint4

Simplified Internal Schematic

1

3

2

+

-

24 VDC

signal

+

-

24 VDC

External

Customer-Provided

Power Supply

RJ-45

8

7

2

3

4

5

6

1

DC

PWR

+24 V

COM

NO

NC

Relay3

Relay2

Relay1

ON

SW

OFF

11

10

9

Analog Current

Loop 4-20 mA

INT EXT

EXT INT

-supply

J5

J4

+supply

J1

NO

NC

J2

NO

NC

J3

PYROLYZER

CONNECTOR

Relay1

}

Relay2

}

Relay3

}

Page 38

Midas® Gas Detector

4-22

Diagram 4-21. Midas® to Touchpoint4 3-Wire Sourcing Connection

touchpoint 4

4-20 mA

Controlled

Current Source

Internal

Power

Loads

J4

INT EXT

J5

EXT INT

11

10

9

MIDAS

Simplified Internal Schematic

2

1

-

+

touchpoint4

Simplified Internal Schematic

1

3

2

+

-

24 VDC

signal

Shielded Cable

RJ-45

8

7

2

3

4

5

6

1

DC

PWR

+24 V

COM

NO

NC

Relay3

Relay2

Relay1

ON

SW

OFF

11

10

9

Analog Current

Loop 4-20 mA

INT EXT

EXT INT

-supply

J5

J4

+supply

J1

NO

NC

J2

NO

NC

J3

PYROLYZER

CONNECTOR

Relay1

}

Relay2

}

Relay3

}

Page 39

Midas® Gas Detector

4-23

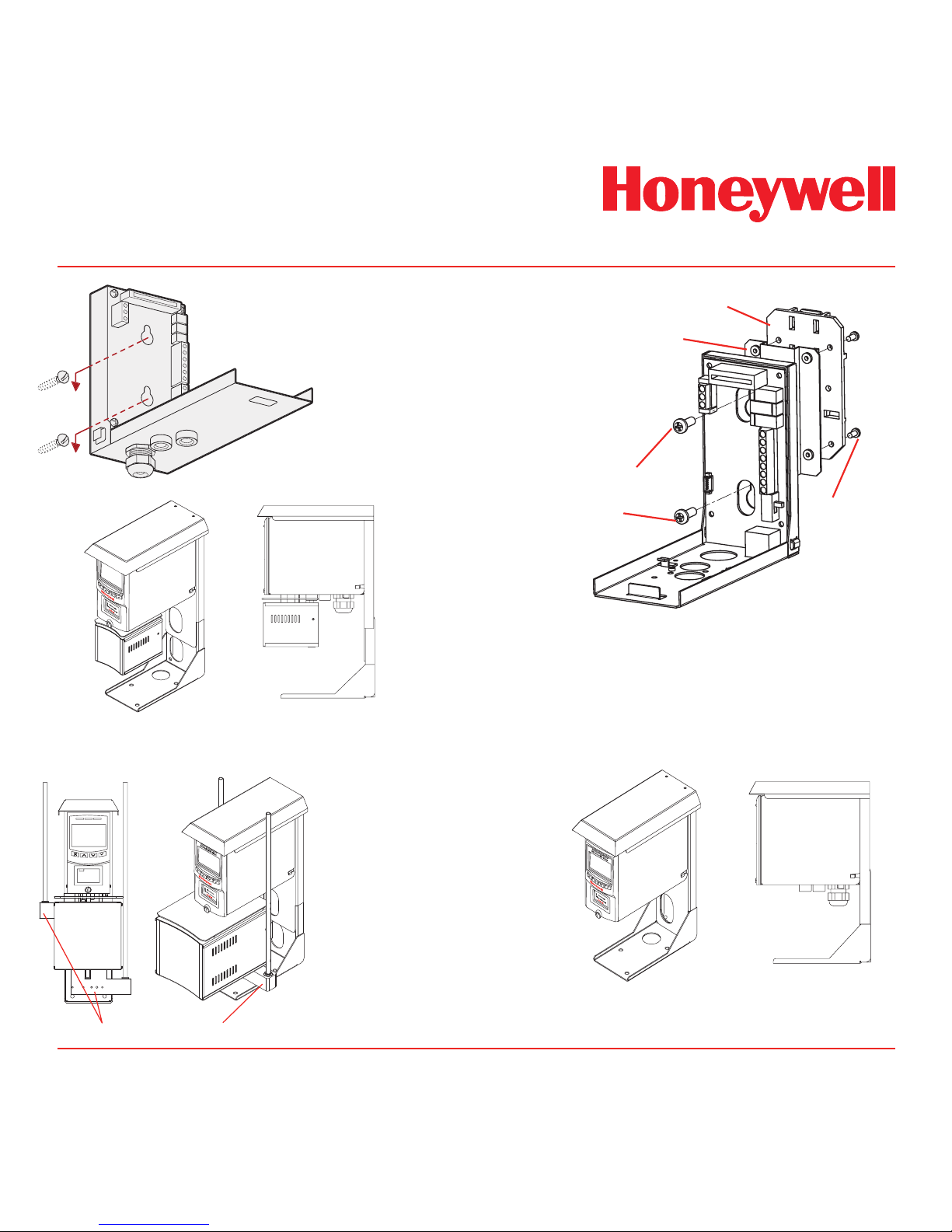

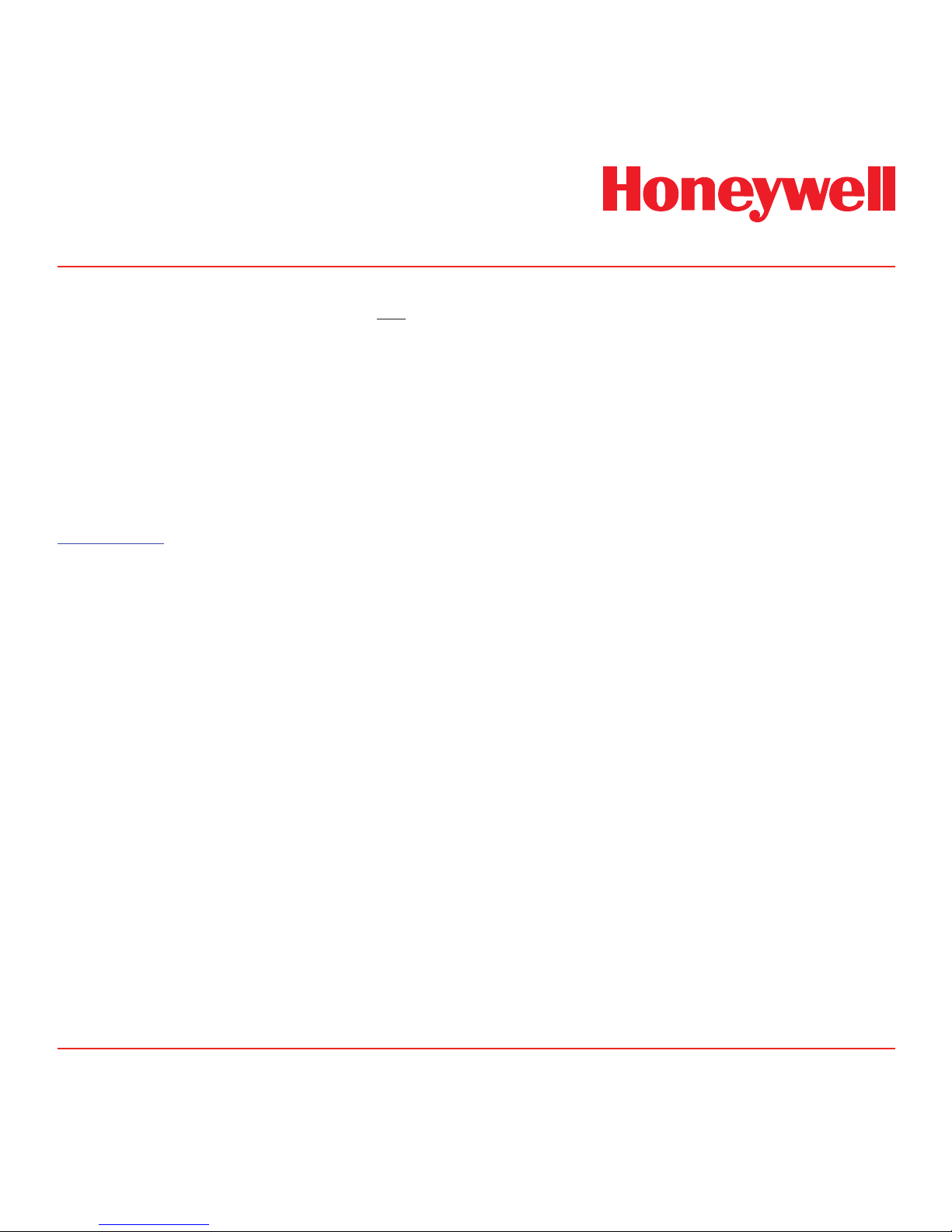

4.8 Refitting the Main Chassis

The main chassis can be refitted to the mounting

bracket assembly using the following steps.

1. Align the PCB at the top rear of the main

chassis with the connector located at the

top of the mounting bracket assembly

2. At the same time align the two tubes at

the bottom rear of the main chassis with

the two tubes located on the bottom of the

mounting bracket assembly.

3. Slide the chassis backwards on the

mounting bracket assembly so that the

PCB and connector and tubes engage

simultaneously. (See diagram below).

4. Ensure the PCB, connector and tubes are

fully engaged by firmly pushing the main

chassis horizontally backward on the

mounting bracket assembly

(WARNING: DO NOT PUSH ON THE LCD

AS THIS MAY CAUSE DAMAGE).

5. Align the two attaching screws located at

the bottom of the chassis with the screw

threads on the mounting bracket assembly.

6. Tighten the screws to secure the chassis

to the mounting bracket assembly.

Diagram 4-20. Retting the chassis.

PCB

CONNECTOR

TUBES

4.9 Installing the Sensor Cartridge

The Midas® sensor cartridge is supplied separately

and needs to be fitted to the detector’s main chassis.

The following steps and diagrams detail the procedure

for installing the sensor cartridge for the first time.

This procedure is carried out with the power off and

the detector cover removed.

1. Verify the part number and type of sensor

cartridge is correct for your application, then

remove sensor cartridge from its packaging.

Sensor Cartridge ID Number

Gas ID Number

2. Remove cap from cartridge and bias battery

(if applicable).

3. Add label for secondary gases (if necessary).

4. Align pins at the top of the sensor cartridge

with the socket in the sensor cartridge

chamber.

Page 40

Midas® Gas Detector

4-24

5. Carefully push the sensor cartridge into the

sensor cartridge chamber until fully seated.

6. Lock the sensor cartridge in place using the

tabs on either side of the sensor cartridge to

secure the cartridge to the main chassis.

7. Switch the power switch on the terminal

module to the ‘on’ position.

8. Reattach the detector cover by aligning the

slots on either side with the locating tabs on

the mounting bracket assembly.

9. Push the cover horizontally until fully seated.

10. Tighten the thumbscrew on the front panel.

Diagram 4-21. Installing the sensor cartridge

chassis

cartridge

?????

??????????????? ?????

????????????????????

???

????????????????

???????????????

???????????????????

slots

tighten

How cover is fitted

tabs

cartridge fitted

midas

Gas

Sen

sor

C

ar

tr

idg

e

NITROGE

N T

RIFLUORIDE

NF3

PN

: MIDAS-S-H

FX

SN :

0

2344

5667

0

Use by : 07-09

2006

ze

llweger analytics

Caution

When retting the cover to the Midas® unit,

use caution to prevent damage to the RFI

shielding tabs attached to the chassis.

Page 41

Midas® Gas Detector

5-1

5 Startup

Page 42

Midas® Gas Detector

5-2

5 Startup

WARNING

Prior to carrying out any work ensure local

and site procedures are followed. Ensure

that the associated control panel is inhibited

so as to prevent false alarms.

The following procedure should be followed carefully

and only performed by suitably trained personnel.

1. Ensure the detector is wired correctly

according to Sections 4.6 and 4.7.

2. Ensure that the correct sensor cartridge is

fitted. (If the cartridge has not been stored

at room temperature, allow one hour for

equilibration.)

3. Ensure the on/off switch on the mounting

bracket assembly is in the on position.

4. Apply power to the system.

5. After the startup routine the detector will

display normal operating mode as shown

in Section 6.

6. Perform a leak test as shown in Section 8.5

to ensure all connections are secure.

6. If using a multi gas sensor cartridge refer

to Section 7.2.2 to ensure the correct gas

ID code is selected.

7. Allow the detector to stabilize until the

‘WArm’ message is no longer displayed.

The maximum warm up time is listed in

Appendix B. Warm-up times are typically

much faster.

8. If this is a first-time startup, an F49 or F88

fault code may be displayed; there is no

actual fault and the fault message can

be cleared by depressing the ‘X’ cancel

button for 2 seconds.

To properly activate the Midas® with a

cartridge for the first time:

• When ‘Change Gas’ scrolls on the

display, hit the ‘3’ on the Midas® front

panel.

• When the ‘reboot’ completes then press

and hold the ‘X’ to clear any latched

fault(s).

• If “FIrSt CEll” is displayed, press ‘3’.

The cartridge has now been accepted by the

Midas® as the correct type to be used.

Page 43

Midas® Gas Detector

6-1

6 Operation

Page 44

Midas® Gas Detector

6-2

6 Operation

After applying power to the detector, the display

will go through a startup test routine illuminating

in sequence all the LEDs, icons and digits of

the display. The display will show the message

‘WAIt’ and ‘LoAd’ as it checks for cartridge

data, typically less than 180 seconds. It will

then display the message ‘WArm’ until the

sensor cartridge reaches operating temperature.

When complete, the detector will enter normal

monitoring mode indicated by the ‘ ’ icon on the

display cycling through three states (2 rings, 3

rings, 4 rings). The measured gas concentration

will be shown on the display. The green LED will

flash once every second indicating power and

the sample flow rate indicator will be displayed.

If monitoring is interrupted due to a fault, a test

or calibration process or a user requested inhibit,

the display will flash. For details of fault and

maintenance fault codes refer to Section 11.

Note

The rst time the Midas® is started with a

new sensor cartridge, an F49 or F88 fault

code may be displayed; there is no actual

fault and the fault message can be cleared

by depressing the ‘X’ cancel button for two

seconds.

Final Start Up Routine Screen

Normal Operation

6.1 Normal Operation Mode

In this mode the detector displays gas

concentration, alarm, fault and status information

via its backlit LCD and front panel LEDs. Typical

normal operation display and output states are

shown below. See Section 11 for a full list of fault

codes.

Note:

The examples in Table 6-1 are for a linear

4-20 mA output over a full scale range of

2 ppm. The current output for a given gas

concentration will be dierent for other full

scale ranges (linear 4 mA = 0 % full scale to

20 mA = 100 % full scale). The alarm and

fault relays are in default (latching) mode.

Page 45

Midas® Gas Detector

6-3

Table 6-1. Normal operation display and output states.

Operational

State

Relay status

4-20 mA output

(for 2ppm range)

LEDs

Backlight

Display

Classic Mode Multi Color Mode

Alarm 2 Alarm relay 1 activated

(common case)

Alarm relay 2 activated

Fault relay activated

8 mA

(proportionate to

concentration)

Green

flash

Red flash

Green

Red flash

White flash

Greater

than full

scale

Alarm relay 1 activated

Alarm relay 2 activated

Fault relay activated

21 mA

Green

flash

Red flash

Green

White flash

Yellow flash

Inhibit Alarm relay 1

de-activated

Alarm relay 2

de-activated

Fault relay activated

2 mA

Green

flash

Green Green

Low flow

rate

Alarm relay 1

de-activated

Alarm relay 2

de-activated

Fault relay activated

3 mA

Green

flash

Yellow on

Green Yellow

Low flow

fault

Alarm relay 1

de-activated

Alarm relay 2

de-activated

Fault relay de-activated

1 mA

Green

flash

Yellow

flash

Green

White flash

Yellow flash

Page 46

Midas® Gas Detector

6-4

6.1.1 Resetting Alarms, and Faults

The alarm function of Midas® can be set to latching

(See Section 7.2.1) so that when an alarm occurs

the associated outputs remain activated even if the

gas reading has dropped below the alarm level. To

reset the latched alarm press the ‘X’ cancel button

for 2 seconds. If the gas level is still above the alarm

point you can reset the associated relay but it will

activate again after the elapse of any alarm on delay

that has been set.

If the alarm function is set to non-latching, the

display will automatically clear when the alarm

condition is cleared.

The fault function can also be set to latching. It

can be reset by pressing the ‘X’ cancel button for 2

seconds. If the fault conditions persist, the fault will

be reappear quickly.

If the fault operation is set to non-latching, the

display will automatically clear when the fault

condition is cleared.

6.2 Review Mode

The detector settings can be reviewed safely without

the possibility to make changes by using review mode.

To select review mode press the ‘s’ up or ‘t’ down

button once. The review mode icon ‘ ’ will show

on the display and the first review mode menu icon

is displayed.

6.2.1 Review Mode Menu Overview

The menu is simply navigated by using the ‘s’ up

and ‘t’ down buttons to select the required menu,

and then using the ‘3’ accept button to enter that

submenu and scroll through to view the settings. The

‘X’ cancel button can be used to exit the submenu

and allow selection of a different submenu, or can

be pressed again to exit to normal operating mode.

When in review mode the unit will automatically

return to the main normal operation status display

if either an alarm level is exceeded or no button is

pressed for 60 seconds.

Table 6-2 shows an overview of the different review

menus and how they are navigated. For a detailed

step-by-step instruction of how to review the

detector setting in review mode refer to Section 7.1.

Page 47

Midas® Gas Detector

6-5

Table 6-2. Review menu overview.

Software

SW

Transmitter

software

revision

Checksum Password

key 1

Password

key 2

Alarms

ALm

Gas Selection Alarm 1

direction:

U: rising

d: falling

Alarm 1

threshold

Alarm 2

direction:

U: rising

d: falling

Alarm 2

threshold

Alarm delay

time

Alarm

latching

Alarm relays

normally

energized/de-

energized

Faults

FLt

Fault relay

configuration

Faults

latching/non-

latching

Fault relays

normally

energized/de-

energized

Fault m12

occurrence

frequency

Calibration

CAL

Days to

calibration due

Days to

cartridge

expire

Year of last

calibration

Month and

day of last

calibration

Date/Time

tImE

Year

Month - Day

Time

Address

nEt

Shows web

access level

Use DHCP

server for IP

parameters

IP address

byte 1

IP address

byte 2

IP address

byte 3

IP address

byte 4

Subnet mask

byte 1

Subnet mask

byte 2

Subnet

mask

byte 3

Subnet

mask

byte 4

Event Log

hiSt

Date of latest

event

Time of latest

event

Description of

latest event

Date of

second latest

event

Time of

second event

Description of

second event

Repeat for

events 3-7,

3 Displays per

event

LCD

Shows LCD

Backlight Mode

m15 and F80

enable/disable

Display Screen 1 Screen 2 Screen 3 Screen 4 Screen 5 Screen 6 Screen 7 Screen 8

Screen9Screen

10

4-20 mA

Output

mA

4 mA

gas

corresponding

to

4 mA

20 mA

gas

corresponding

to

20 mA

Page 48

Midas® Gas Detector

6-6

6.3 Overview of Set-up, Calibration,

and Test Mode

WARNING

Set-up, calibration and test modes are

intended for use by trained personnel or

service engineers only. Access to these

modes can be pass code protected by

following the procedure in Section 7.2.7.

Set-up, calibration and test modes are used to make

setting changes, calibrate and test the detector.

To select set-up, calibration and test mode press

and hold the ‘s’ up button or ‘t’ down button for

one second. The unit will automatically go to the

main normal operation status display from setup/

calibration/test menus (but not from inside a setup/

calibration/test function) if no button is pressed for

5 minutes or if an alarm level is exceeded.

PASS CODE: If a pass code has been set the display

will show 0000 with the first 0 flashing. Use the ‘s’ up

or ‘t’ down buttons to set the first digit of the pass

code. Press ‘3’ to enter the first digit. The second

digit will then flash. Repeat the process until all four

pass code digits have been entered. Please record

your pass code in a separate archive that can be

securely retrieved. Failure to be able to retrieve your

pass code may lead to delays in gaining access to

all the protected functions in each Midas® unit. If

an incorrect code is entered the display will show

‘Err’ and return to the normal operation mode. If a

pass code is forgotten contact your local Honeywell

Analytics service department.

After successfully entering the pass code (if set)

the first menu ‘ SET’ set-up icon will show on the

display.

The ‘ CAL’ calibration or ‘ tESt’ test menu can

also be selected using the ‘s’ up or ‘t’ down buttons.

Press the ‘3’ accept button to enter the selected

menu or the ‘X’ cancel button to return to normal

operation mode.

6.3.1 Set-up Menu Overview

The set-up menu allows changes to be made to the

detector alarm, fault, calibration interval, date/time

and digital address settings. The menu is navigated

using the ‘s’ up and ‘t’ down buttons to select

the required submenu and then using ‘3’ accept

button to enter that submenu. The ‘s’ up and ‘t’

down buttons are used to make changes to the

selected setting and are confirmed using the ‘3’

accept button. The ‘X’ cancel button can be used to

exit the submenu and allow selection of a different

submenu, or can be pressed again to exit to the main

set-up, calibration and test menu. Pressing the ‘X’

cancel button again returns the detector to normal

operating mode.

Note

All settings in a submenu are accepted when

the ‘3’ accept button is pressed after the last

submenu setting. This saves the changes

and is indicated by displaying ‘UPdt’ on the

LCD. If however the ‘X’ cancel button is

pressed at any time before the changes are

accepted, this will cause any changes to be

cancelled in that particular submenu.

Table 6-3 shows an overview of the set-up submenus

and how they are navigated. For a detailed

step-by-step instruction of how to change the

detector settings using the set-up menu refer to

Section 7.2.

Page 49

Midas® Gas Detector

6-7