Page 1

Protocol for Testing Toxic Gas

1998-0219 Rev 5 August 2012

Technical Note

Introduction

This protocol provides a method to evaluate the performance of toxic gas detectors. A

worksheet is included; this is a useful guide in recording the performance of gas detection

sensors. It is also useful as part of a maintenance log for complete gas detection systems.

To understand the merits of specific gas detection equipment, several parameters must be

tested. These factors include response time, environmental conditions, affects of temperature,

accuracy and sensitivity to potential interfering substances, recovery time, failure indication,

stability (drift) and repeatability over time. Test conditions must simulate the real world;

therefore the test conditions must simulate the working environment (temperature and

humidity). Supplies and materials must be selected accordingly.

The gases utilized may be very toxic. It is therefore essential that a thoroughly trained

safety engineer or industrial hygienist be responsible for the generation of these gases

and that the gas is generated in a well-ventilated area and exhausted safely.

Equipment and Test Gas

1. Zero Air for zero calibration

In applications where the ambient air is normally containing a low level of target gas,

some sensors may require zero calibration with “clean air”.

a. Compressed air

(Filtered through activated charcoal to remove most of unwanted gases and water

vapor)

b. Zero Air in Lecture bottle

2. Span Gas for Bump Test and Calibration

To achieve the best accuracy, a mixture of the target gas balanced in the background

environmental air is the best calibration gas. However, it usually requires that the

operators be more skilled, with precise equipment and reference standard method to

analyze the gas concentration. The following are recommended methods of gas setup

for bump and calibration.

Technical Note 1998-0219

Page 1 of 12

Page 2

Technical Note

a. Disposable Calibration Gas Bottle

(Low pressure, premixed with Air or Nitrogen)

This method with fixed flow or demand flow regulator is easiest and practical way to

bump test EC sensors (both extractive system and passive sensor wit h calibration

cap or flow housing).

For extractive sampling systems when the concentration of gas lecture bottle is

higher than the detection range, test gas can be diluted with fixed flow rate regulator

and T fitting in sample line. Use fixed flow regulator having lower flow rate than

extracting sample flow rate and attached clean air bag at T fitting. (ex. Using 0.25

L/min regulator with clean air at T fitting, the sample test gas concentration for a

MIDAS with ~0.5 L/min flow is approximately half of the concentration of bottle.)

A zero air lecture bottle with fixed flow regulator can be used for dilution (and use

another T fitting to vent overflow with extractive systems). This method would also

work with passive detection systems.

The lecture bottle dilution method is suitable only for bump testing as the gas mixture

accuracy depends on the flow rate precision.

The type and concentration of calibration gas, sample tubing, flow regulators and

calibration adapters are key links in the calibration chain. The instrument can only be

as accurate as the gas used to calibrate it.

As concentration stability and shelf life is dependent on the mixture of gas and bottle

type, do not use uncertified and/or expired gas cylinders. Most highly reactive

chemicals are mixed with nitrogen.

Check that all gas wet materials including regulator and tubing are preconditioned

with the gas sample before applying gas to sensor.

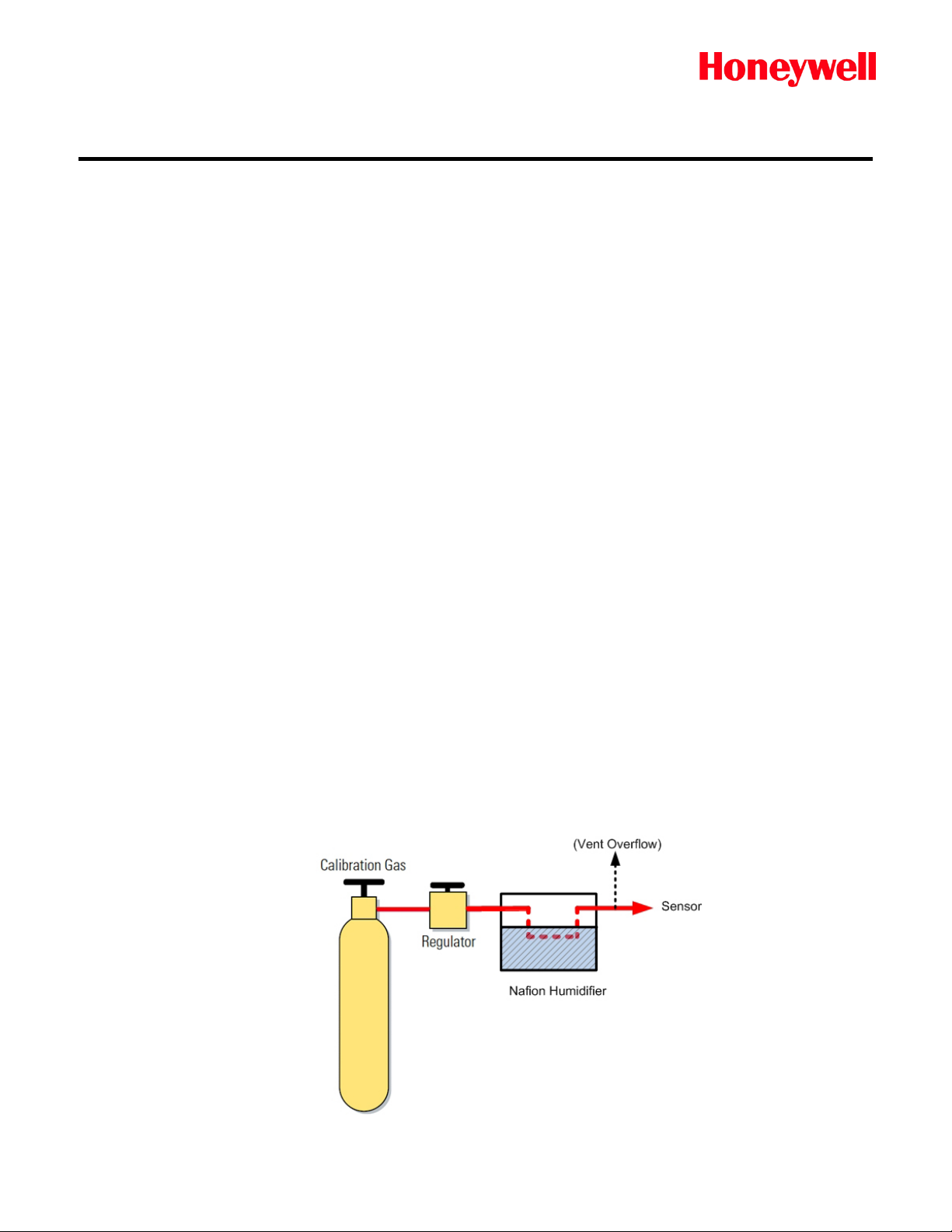

Some sensors may need moisture to get a proper reading. A humidifier, such as a

“Nafion®” humidifier, can be added in sample line. Check the compatibility of the

humidifier with the target gas before use.

Technical Note 1998-0219

Page 2 of 12

Page 3

Technical Note

b. Sampling Bag (Tedlar or Teflon)

This method is good for both extractive systems and non-reactive gases fill i ng fr om a

gas cylinder, diluted gas, or permeation device. Some gas bag materials are

permeable and have gas adsorption characteristics.

c. Permeation/Diffusion Device

A permeation device has some advantages over a calibration standard cylinder;

providing precise concentrations and a wide range of concentrations easily generated

by varying the dilution flow rate and or the set point of oven temperature.

At a known rate of permeation and a given temperature, a constant flow rate of air

mixed with the permeated chemicals forms a constant stream of calibration gas. A

calibrator with constant temperature and flow regulation is needed. Portable

permeation devices are commercially available.

Prior to use, permeation devices should be conditioned at the calibration temperature

and carrier flow to bring the rate to its equilibrium value. Most devices require 30

minutes to 3 hours to reach equilibrium. Heavy wall tubes, low vapor pressure

compounds, and halogenated compounds typically take longer. The best procedure is

to set up the calibration system the day before it is needed, allowing the system to

equilibrate overnight. Conduct repeated tests over a period of time to ensure that

equilibrium has been achieved. Test gas can be filled in a sample gas bag, or feed

sample gas to passive sensor, or extract test gas directly connecting at T fitting in

Span with Overflow (Vent) output mode.

There may be an activated charcoal scrubber for carrier/dilution air before the

permeation chamber in commercially available portable permeation gas generator; the

generated test gas will be dryer than ambient air, requiring additional humidification

(such as Nafion® humidifier) for some gases and sensors.

d. High Pressure Gas Cylinder

High-Pressure Cylinders are designed for hazardous chemicals and for high

concentration mixture which is much stable than above mentioned methods.

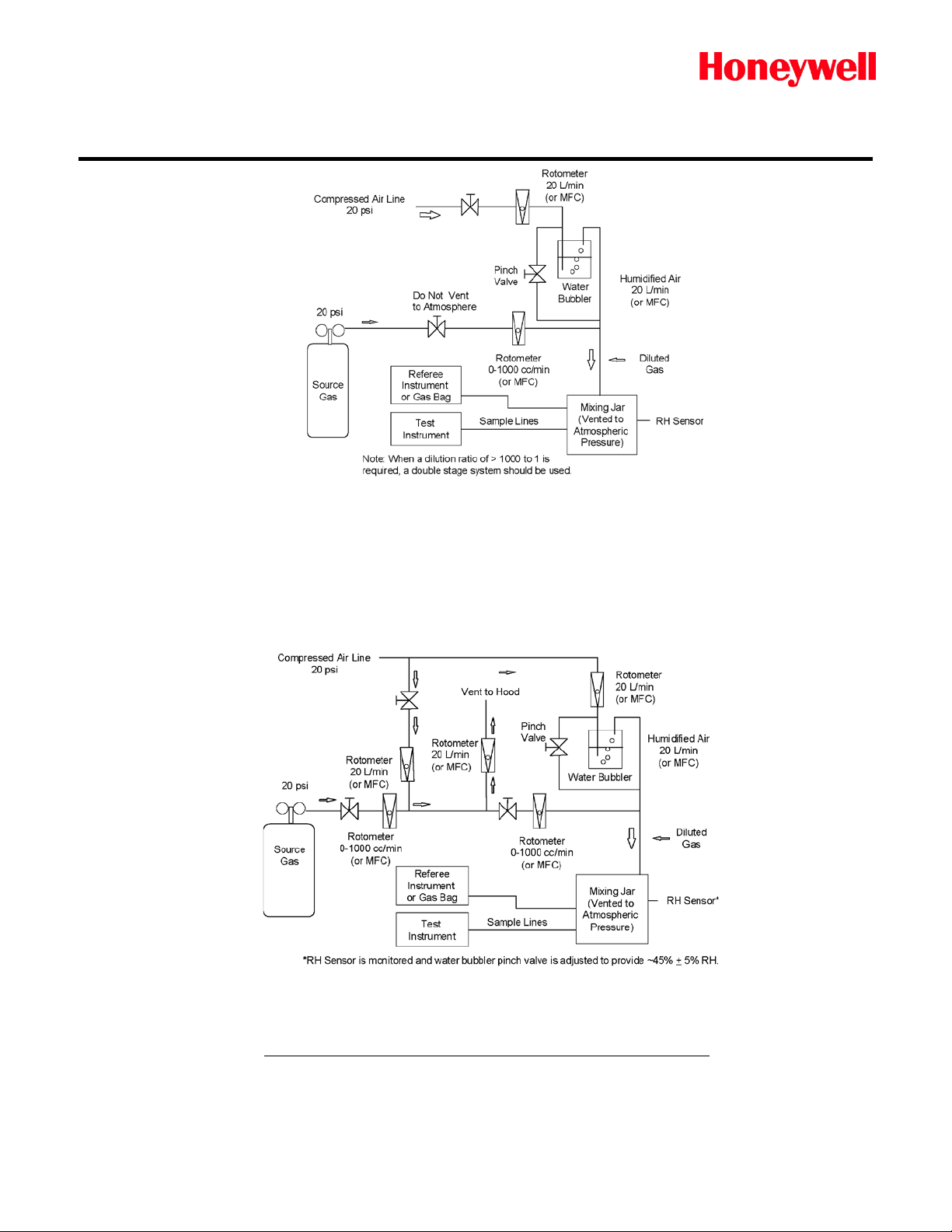

d-1. High Pressure Gas Cylinder - Single Stage Dilution Method

This method is good for both passive or extractive system, and Gas Bag filling for

remote test. Schematics of the recommended gas generation and dilution system

are provided in Figures 1 and 2.

Figure 1 shows a typical single stage dilution gas generation rig. This is best

utilized when diluting c once nt rat e d cyli nd er s at rati os bel ow 10 00-to-1.

Technical Note 1998-0219

Page 3 of 12

Page 4

Technical Note

d-2. High Pressure Gas Cylinder - Double Stage Dilution Method

This method is good for both passive or extractive system, and Gas Bag

filling for remote test.

Figure 2 shows a typical double stage dilution rig. This is utilized for diluting

cylinders at ratios greater than 1000-to-1. Double stage dilution is the best

method when generating low level concentrations is required.

The concentration of calibration gas can be calculated as follows:

Concentration (ppm) =

Cylinder Flow (cc/min) * Cylinder Concentration (ppm)

Total Flow [Cylinder +Dilution F low] (cc/min)

Note:

Multiply gas concentration in ppm units by 1000 to obtain concentration in ppb units.

Technical Note 1998-0219

Page 4 of 12

Page 5

Technical Note

Performing a Bump Test or Calibration

Gas should be supplied from a reliable source. To achieve accuracy and consistency, it must

be assured that the source is stable and within date code (e.g. for cylinders and permeation

tubes).

Whenever possible, primary target gases should be used for calibration. Cross-calibrations

(non target gases which can cause a quantifiable response, but that are typically easier to

handle) should be used only when gas detection manufacturers confirm accuracy of response.

It is better if these cross-cali brat ions be used for semi-quantitative or qualitative work, such as

triggering alarms and relays.

If cylinder gas is used, a “referee” method must be used to ensure that accurate concentrations

are being produced. Even certified cylinders may not provide the expected gas concentration,

especially after storage. Good laboratory practice indicates the use of a referee method. It

should also be noted that high quality permeation devices can provide excellent accuracy for

many gases.

For most applications, the sample gas should be prepared using humidified dilution air (to

approximately 30-60% RH; with 45% RH being optimal). This simulates real world conditions

that are likely to be encountered during an actual event. All materials must be selected to

ensure that any "wetted" surfaces in contact with the supplied gas are inert to the compound

being tested. For example, when supplying HCl, tubing, fittings and all other wetted surfaces

should be constructed of FEP Teflon; stainless steel is not appropriate, since it will react with

HCl and other common industrial gases at ppm concentrations.

Active / sample-draw instruments often pull high volumes of sample (several liters per minute).

The volume of test gas generated must exceed or exactly match the monitor’s sample flow

intake.

When using low volume permeation devices to test these instruments, it will be necessary to

collect several liters of sample gas in a Tedlar® or Teflon® bag (refer to Table 1 for gas

suitability); then draw the sample gas from the bag. This bag could typically be 100 liters in

size. For some reactive, adsorptive gases the sample bag should be preconditioned to

establish equilibrium between the sample gas and the surfaces of the bag. This will help to

ensure that the concentration of the generated gas is maintained. The material of the bag

should be suitable for the target gas; since some reactive gases may be adsorbed onto some

materials. The bag should be checked with a referee method to ensure appropriate

concentrations and efficient transfer from the sour c e.

The sample line should be kept as short as 5ft, minimizing the transport time and reducing

adsorption effects for sensor performance test.

For passive (non-sample draw) sensors, the manufacturer's recommended calibration cap

(flow-through housing) should be used. In order to simulate typical field conditions, NIOSH

protocol suggests a minimum face velocity. The face velocity is calculated by dividing the flow

rate by the cross-sectional area of the flow housing.

Technical Note 1998-0219

Page 5 of 12

Page 6

Technical Note

Table 1 provides guidance when selecting gas generation equipment. The gases that are listed

are commonly found or used in industrial environments. Information on these compounds is

included to satisfy the need for cross-interferenc e tes ti n g.

If cross-interferences are present in ambient air or in the dilution air, another source of clean,

humidified air or nitrogen should be used.

The mass flow controlled output should be verified against an independent flow calibrator. A

primary standard bubble flow meter can be utilized for this purpose.

Technical Note 1998-0219

Page 6 of 12

Page 7

Tubing and other

with sample gas

Ammonia (NH3)

Aluminum cylinders, N2 balance;

device

FEP Teflon,

Refer to Note 1.

Arsine (AsH3)

Aluminum cylinders, N2 balance,

mass flow controller

FEP Teflon®,

polypropylene, Kynar®,

brass

Boron Trifluoride

Aluminum cylinders, N2 balance

with Teflon gasket; stainless steel or

use is not allowed.

FEP Teflon and Monel

Do not use sample bags.

utilized regardless of generation

Carbon Monoxide

Aluminum cylinders; stainless

or Monel mass flow controller

FEP Teflon,

Tedlar, Monel, brass

Chlorine (Cl2)

Aluminum cylinders, N2 balance;

FEP Teflon, Kynar

Stainless steel and most other

Nafion® can be used.

Diborane (B2H6)

Aluminum cylinders, N2 balance,

mass flow controller

FEP Teflon,

Hydrogen (H2)

Aluminum cylinders; stainless steel

mass flow controller

FEP Teflon,

Kynar, Monel, brass

Do not use Tedlar bag.

Hydrogen Bromide

Aluminum cylinders, N2 balance;

FEP Teflon, Kynar

Stainless steel and most other

Refer to Note 2.

Hydrogen Chloride

Aluminum cylinders, N2 balance;

FEP Teflon, Kynar,

Stainless steel and most other

be used, high purge flow req’d.

Technical Note

Table 1. Calibration Considerations for Common Gases

Gas Source(s)

stainless steel or Monel regulator,

mass flow controller, Permeation

stainless steel regulator with

Teflon® gasket; stainless steel

(BF3)

(CO)

stainless steel or Monel regulator

Monel mass flow controller.

Permeation devices are best

method for field testing if cylinder

steel regulator; stainless steel

stainless steel regulator; corrosive

mass flow controller. Permeation

device

materials in contact

polypropylene, Kynar

Tedlar®, Monel®,

polypropylene, Kynar,

Special considerations

Do not use Nafion® humidifier

(Note 3).

Refer to Note 2

Referee instrument must be

method to verify concentration.

metals are not acceptable.

Concentration in cylinders may

not be stable.

Do not use Tedlar bag.

See Note 1.

Refer to Note 2. Note 3;

stainless steel regulator with Teflon

gasket; stainless steel or Monel

regulator; stainless steel or Monel

(HBr)

(HCl)

regulator with Teflon gasket and

corrosive mass flow controller.

Permeation device

regulator with Teflon gasket and

corrosive mass flow controller.

Permeation device

polypropylene, Kynar,

Tedlar, Monel, brass

polypropylene,

metals are not acceptable.

Diffusion vials are

recommended.

Do not use sample bags.

metals are not acceptable.

Do not use sample bags

Diffusion vials are

recommended.

Refer to Note 2.

Note 3; Nafion® humidifier can

Technical Note 1998-0219

Page 7 of 12

Page 8

Tubing and other

with sample gas

Hydrogen Fluoride

Aluminum cylinders, N2 balance;

FEP Teflon, Kynar,

Stainless steel and most other

Nafion® can be used.

Isopropyl Alcohol

Syringe injection into gas bag

FEP Teflon,

Tedlar, Monel, brass

Readily available liquid.

Humidifier.

Phosphine (PH3)

Aluminum cylinders, N2 balance,

mass flow controller

FEP Teflon,

Silane (SiH4)

Aluminum cylinders, N2 balance,

mass flow controller

FEP Teflon,

Difficult to achieve high

Technical Note

(HF)

(IPA)

Gas Source(s)

regulator with Teflon gasket and

corrosive mass flow controller.

Permeation device

stainless steel regulator with

Teflon gasket; stainless steel

stainless steel regulator with

Teflon gasket; stainless steel

materials in contact

polypropylene, Kynar,

polypropylene, Kynar,

Tedlar, Monel, brass

polypropylene, Kynar,

Tedlar, Monel, brass

Special

considerations

metals are not acceptable.

Do not use Tedlar bags.

Refer to Note 2. Note 3;

Do not use Nafion®

volumes with permeation

devices.

Notes

1. Permeation d evices have low volu me output. Gas b ags need to be use d to acc umulate th e large s ample

volumes needed for gas t esting. Fill and flush Teflon bag several ti mes for reactive gas conditioning,

and use the gas within 30 minutes.

2. Gas Cylinder regulator must be dedicated to the gas type and to be clea n and kept dry, and require a

long time for conditioning to get stable gas concentration.

3. Nafion® humidifier can be used for all above mentioned test gases except Ammonia and IPA.

Response Time

Response time may be measured in three basic ways.

1. One method of response time specification is provided as follows:

e.g.: T90 = x seconds; e.g.: T50 = y seconds

The term T90 provides the amount of time in which 90% of the actual concentration is

reported. The term T50 provides the amount of time required in which 50% of the actual

concentration is reported. In essence a T100 time would provide the time it takes to

indicate the true concentration of gas present.

2. A second method of providing response time is the amount of time required to indicate a

1 TLV concentration of gas when a 1.6 level of gas has be en appl ied (T62.5). This is the

standard method of specifying response times in Japan.

3. The third way is to simply state the response time. This generally indicates the amount of

time required to display an accurate reading of the actual concentration (similar to the

T100 concept described above). This provides a straightforward specification for accurate

response indication.

Test the speed of response throughout the useful life of the sensor, as the response time

of a sensor may change as the detector ages. The sensor should be tested just prior to

Technical Note 1998-0219

Page 8 of 12

Page 9

Technical Note

the calibration or replacement of the existing sensor. This test indicates, before

adjustment, how well a sensor has been performing during the time it has been in

service.

Note:

Some detectors may need to be "conditioned" before they will reasonably respond to

gas. The response time should be noted for the first application of gas. Under field

conditions there is normally no target gas present, so it is important to replicate this by

taking the data upon the first exposure of the sensor to the target gas.

Accuracy, Drift and Repeatability

Accuracy is tested by comparing a known concentration against the stabilized reading of the

sensor with a known concentration of test gas. This test should be performed before calibration

and several months after calibration to ensure that the instrument will perform acceptably

throughout its life.

Any calibration adjustments that are made to the detector are primarily done to ensure

accuracy at the time of calibration. On occasion the detector may be adjusted t o prov i de a

quicker response by sacrificing accuracy; the instrument will read higher than the actual

concentration.

Drift occurs when, under a no-gas condition, any non-zero readings are observed. Drift can add

to, or subtract from, the reported concentration. Excessive drift can cause false alarms, false

negative readings, or instrument faults.

Repeatability describes how closely a sensor can read to a gas concentration that it previously

reported. This test does not necessarily ensure accuracy.

Lowest Detectable Limits

The Lowest Detection Limit (LDL) is important. Several manufacturers provide a published

range of detection, but they do not provide this minimum detection limit. The capability to detect

low level concentrations under operating conditions means earlier detection, before a small

leak becomes a significant pr obl em .

Cross-Sensitivity to Potential Interferences

Many areas that require toxic and combustible gas detection have the potential for other, nontarget gases to be present. These potential interferences include solvents (eg.: acetone,

isopropyl alcohol), ammonia, hydrogen, hydrogen peroxide and carbon monoxide. Some

interferent gases may have a permanent poisoning effect on the sensor. Consult product

literature on cross-sensitivity information.

As previously indicated, potential interferent gases which are easier to handle are sometimes

used to test or calibrate sensors. This may not be an accurate method of calibrating, since the

correlation factor may dep end on the characteristics of the individual sensor.

Life Testing

Several of the above sections include testing for performance characteristics that need to be

Technical Note 1998-0219

Page 9 of 12

Page 10

Technical Note

checked upon initial installation. These parameters should also be checked just prior to

maintenance. It is important to check these parameters before and after maintenance. After a

period of three or six months, the detector should perform virtually as well as it did during its

last calibration.

Other Performance Considerations

Performance considerations are not limited to those outlined above. Other features of a gas

detector which should be considered include real-time failsafe fault or failure warnings,

verifiable proof of the gas release, ownership costs, suitability for environment, cross

interference or drift issues, and EMI/RFI susceptibility.

Technical Note 1998-0219

Page 10 of 12

Page 11

Sensor Serial Number/ I.D.:

Location:

Gas Type:

Testing to be repeated before

recalibration on (date):

Test Procedure

Results

Calibration

Results

Calibration

Results

Calibration

Results

Calibration

Date:

Tested By:

Verified By:

Zero Reading:

Response Time:

T50:

T90:

T100:

Time (sec) to TLV given 1.6 TLV gas:

Accuracy:

Actual Gas Concentration:

% deviation:

Recovery Time:

Time (sec) to return to zero after test gas is

removed:

Other Considerations:

Potential Interferents:

Proof of Gas Presence? (y/n):

Lowest Detectable Limit:

Resolution (ppb or ppm):

EMI/RFI susceptibility? (y/n):

Self Diagnostics/Failsafe Capability:

Technical Note

Gas Testing Checklist

Immediately

Before

Immediately

After

3 Months

After

6 Months

After

Note:

The last four items may not be easily verified in the field. Individual manufacturers may

need to be consulted.

Technical Note 1998-0219

Page 11 of 12

Page 12

Technical Note

Data may change, as well as legislation, and you are strongly advised to obtain copies of the most recently issued regulations, standards and guidelines.

This publication is not intended to form the basis of a contract and the company reserves the right to amend the design and specification without notice.

While every effort has been made to ensure accuracy in this publication, no responsibility can be accepted for errors or omissions.

www.honeywellanalytics.com

Find out more

Contact Honeywell Analytics:

Americas

Honeywell Analytics Inc.

405 Barclay Blvd.

Lincolnshire, IL 60069

USA

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8210

detectgas@honeywell.com

Europe, Middle East, Africa

Life Safety Distribution AG

Weiherallee 11a

8610 Uster

Switzerland

Tel: +41 (0)44 943 4300

Fax: +41 (0)44 943 4398

gasdetection@honeywell.com

Asia Pacific

Honeywell Analytics Asia Pacific

#508, Kolon Science Valley (I)

187-10 Guro-Dong, Guro-Gu

Seoul, 152-050

Korea

Tel: +82 (0)2 2025 0307

Fax: +82 (0)2 2025 0329

analytics.ap@honeywell.com

Technical Services

ha.us.service@honeywell.com

www.honeywell.com

Technical Note 1998-0219

Page 12 of 12

Loading...

Loading...