Page 1

Automatic Test and Calibration Station

Quick R eference Guide

Page 2

BW Technologies LP (BW) warrants the product to be free from defects in material and workmanship under normal use and service for a period of two

Limited Warranty and Limitation Liability

years, beginning on the date of shipment to the buyer. This warranty extends only to the sale of new and unused products to the original buyer. BW’s

warranty obligation is limited, at BW’s option, to refund of the purchase price, repair or replacement of a defective product that is returned to a BW

authorized service center within the warranty period. In no event shal l BW’s liability hereunder exceed the purchase price actually paid by the buyer for

the Product.

This warranty does not include:

a) fuses, disposable batteries or the routine replacement of parts due to the normal wear and teat of the product arising from use;

b) any product which in BW’s opinion, has been misused, altered, neglected or damaged, by accident or abnormal conditions of operation,

handling or use;

c) any damage or defects attributable to repair of the product by any person other than an authorized dealer, or the installation of unapproved parts

on the product; or

The obligations set forth in this warranty are conditional on:

a) property storage, installation, calibration, use, maintenance and compliance with the product manual instructions and any other applicable

recommendations of BW;

b) the buyer promptly notifying BW of any defect and, if required, promptly making the product available for correction. No goods shall be returned

to BW until receipt by the buyer of shipping instructions from BW; and

c) the right of BW to require that the buyer provide proof of purchase such as the original invoice, bill of sale or packing slip to establish that the

product is within the warranty period.

THE BUYER AGREES THAT THIS WARRANTY IS THE BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. BW SHALL NOT BE LIABLE FOR ANY

SPECIAL, INDIRECT, INCIDENTAL, OR BASED ON CONTRACT, TORT OR RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or consequential

damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this warranty is held invalid or unenforceable

by a court of competent jurisdiction, such holding will not affect the validity or enforceability of any other provision.

Contacting BW Technologies by Honeywell

USA: 188-749-8878 Canada: 1-800-663-4164

Europe: +44(0) 1295 700300 Other countries: +1-403-248-9226

Email us at: info@gasmonitors.com

Visit BW Technologies by Honeywell website at: www.gasmonitors.com

Page 3

MicroDock II

Introduction

To ensure personal safety, read Safety Information - Read

First before using the MicroDock II base station.

The MicroDock II Automatic Test and Calibration Station (“the

base station”) provides automated calibration and bump testing

for the GasAlert Extreme, GasAlertClip Extreme, GasAlertMicro, GasAlertMicro 5/PID/IR, GasAlertMicroClip, and GasAlertMax XT detectors. The system is expandable to include up to

10 docking modules (maximum six charging docking modules

plus four non-charging docking modules.

a Warning

Safety Information - Read First

Use the station only as specified in this guide. Read the following Cautions before using the station.

a

Cautions

• If the base station is damaged or parts are missing,

contact BW Technologies by Honeywell

• This equipment uses potentially harmful gas for

calibration. Use in a well-ventilated area only.

immediately.

a Cautions

• The base station must be attached to a venting system or

the base station must be used in a well-ventilated area.

• Do not immerse the station in liquids.

• The maximum recommended exhaust line length is

15.24 m (50 ft.).

• Ensure that the inlet filter is clean.

• Ensure that all gas cylinders contain enough gas.

• A demand flow regulator must be used with all gas

cylinder connections.

• Calibrate and bump test only in a safe area that is free

of hazardous gas.

• Do not expose the station to electrical shock or severe

continuous mechanical shock.

• The base station warranty will be void if the unit is

disassembled, adjusted, or serviced by non-BW

Technologies by Honeywell personnel.

• Ensure the exhaust line is not connected to a negative

pressure system.

1

Page 4

MicroDock II

Quick Reference Guide

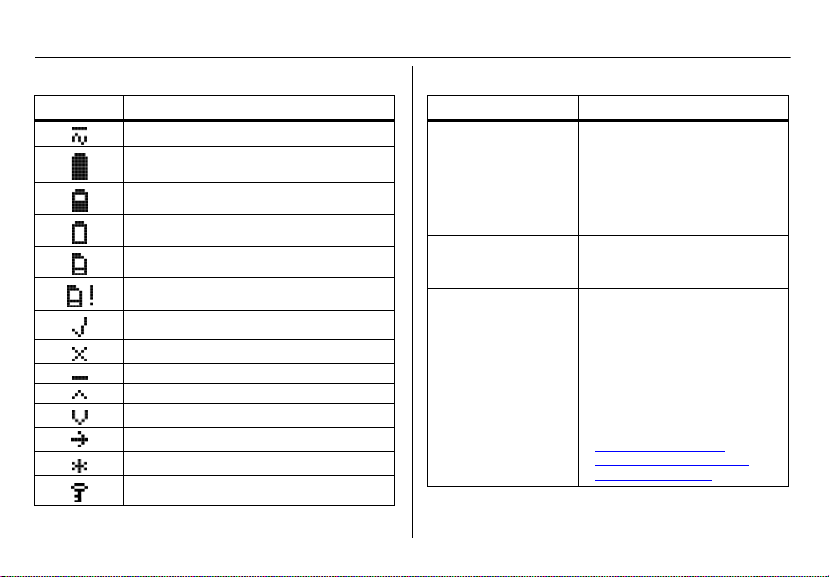

Display Elements Pushbuttons

Item Function

AC power

Batteries fully charged

Batteries half-charged

Batteries at low level

MultiMediaCard (MMC)

MultiMediaCard (MMC) not inserted

Test pass and option enabled

Test fail and option disabled

Cursor and sensor disabled

Scroll up

Scroll down

Selection arrow

Selected to be modified

Passcode protected

2

Pushbutton Description

C

BUMP CHECK

C

CALIBRATION

C

DATA TRANSFER

To bump test a detector, press C

BUMP CHECK.

When connecting a new docking

module, press and hold

C BUMP CHECK to send a

confirmation signal back to the

base station.

To calibrate a detector, press

C CALIBRATION (all models

excluding GasAlertClip Extreme).

To transfer datalog information

from a detector, press C DATA

TRANSFER

Extreme, GasAlertMicroClip, and

GasAlertMax XT only).

The Automatic Datalog Download option is available for the

GasAlertMicroClip and GasAlertMax XT docking modules only.

For more information, refer to

Data Transfer (GasAlert

Extreme, GasAlertMicroClip,

GasAlertMax XT only).

. (GasAlert

Page 5

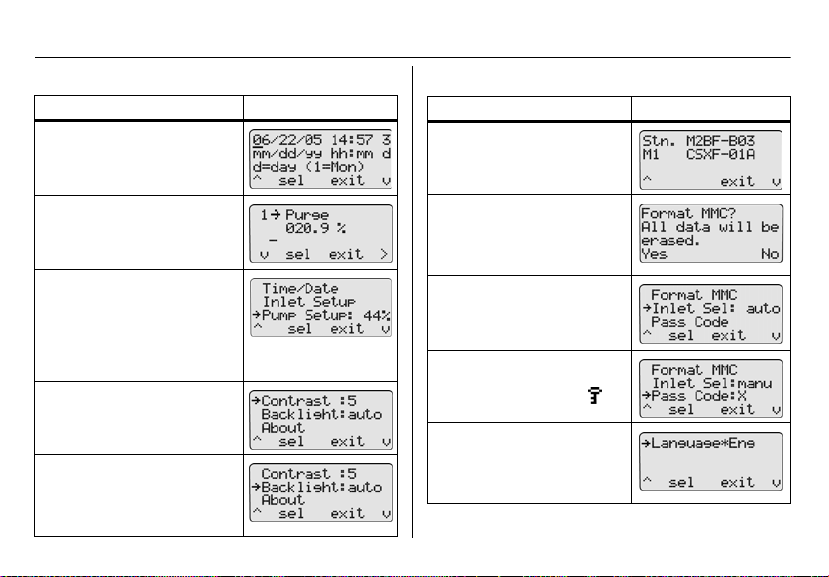

User Options Menu

Description Display

Time/Da te modifies the time and

date of the base station.

Description Display

About

displays the firmware

revision for the base station and

the docking module(s).

MicroDock II

User Options Menu

Inlet Setup enters the gas type,

the gas concentration levels, and

the gas cylinder lot numbers.

Pump Setup

pump speed. Recommended

pump speeds are 40-45% (350

ml/min.). The pump speed must

be set for each new docking module that is added to the station.

NOTE: A flow meter is required.

Contrast brightens or dims the

text of the LCD.

Backlight enables/disables the

LCD backlight. When enabled,

the auto option automatically

deactivates the backlight when

the base station is not in use.

modifies the station

Format MMC formats the Mul-

tiMediaCard (MMC). NOTE:

This feature erases all current

data. Refer to the MicroDock II

User Manual.

Inlet Sel selects a gas inlet. If

auto is displayed, the base sta-

tion automatically selects the

correct inlet for the test.

Pass Code prevents unauthorized access to the menu

options. The LCD displays

when it is pass code protected.

Language displays all LCD

text in one of five languages:

Eng (English), Fran (French),

Deut (German), Port (Portuguese), and Espa (Spanish).

3

Page 6

MicroDock II

Quick Reference Guide

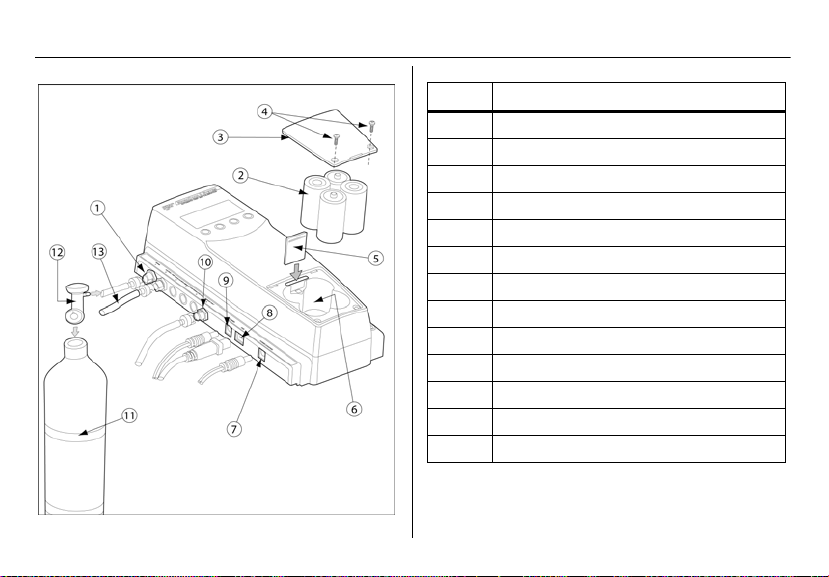

Installation

4

Item Description

1 Inlet filter assembly

2 C-cell batteries (4)

3 Battery cover

4 Philips pan head retaining screws (2)

5 MultiMediaCard (MMC)

6 Battery compartment

7 Charger port

8 USB port

9 Power port

10 Exhaust outlet

11 Gas cylinder

12 Demand flow regulator

13 Calibration gas hose

Page 7

The atmosphere must be free of background gas. Do not

use the base station in a hazardous area.

All required National Electrical Codes (NEC) and safety

standards must be followed.

The base station can operate from either an electrical

power source or batteries. The batteries will provide

automatic backup power if the main power fails.

1. Connect the power cord to the POWER port on the

base station, and then plug the cord into an AC outlet.

To install the batteries, refer to Battery Installation

2. Connect the charger cord to the CHARGER port on

the base station first, and then plug the cord into an

AC outlet.

3. Attach all gas connections. Inlet 1 (PURGE) is configured for ambient air and inlets 2-5 are configured for

calibration/test gases. Refer to Confirm Inlet Setup

4. A demand flow regulator must be used with all gas

cylinder connections.

5. Ensure the exhaust line is not connected to a negative pressure system.

For AC main installation, a circuit breaker must be integrated in the

building installation as a disconnect device for the base station.

a Warni ng

Note

.

.

MicroDock II

Installation

The disconnect device must be installed in close proximity to

the base station and must be marked as a disconnecting

method for the base station.

Battery Installation

To install batteries in the base station, complete the following:

Warn ing

Only install batteries in a safe area that is free of

hazardous gas. Failure to adhere to this warning can

result in personal injury and/or property damage.

Use only BW approved batteries; do not use alkaline or

other rechargeable batteries with this charger.

1. Loosen the retaining screws from the battery cover.

Do not remove the screws from the cover.

2. Remove the battery cover and insert four C-cell batteries into the battery compartment.

3. Replace the battery cover and tighten the retaining

screws. Do not overtighten.

a

Mounting the MicroDock II Base Station and Docking Modules

For wall mounting instructions, refer to the MicroDock II Base

Station User Manual.

5

Page 8

MicroDock II

Quick Reference Guide

Inserting the Detector

Infrared or intense ambient light (sun or halogen) may

interfere with the base station/detector communication.

To insert a detector into a docking module, complete the following:

1. Activate the detector and wait until it is in normal

operation.

2. Ensure the alligator clip is closed and the ring is resting flat on the detector.

3. Press the two release tabs on the docking module

and open the lid.

• If inserting the GasAlertMax XT, move the pump

4. Refer to the following sections to insert the detectors

into the docking modules.

GasAlertClip Extreme / GasAlert Extreme

• Lower the detector (serial number face up) into the

detector bay.

• Push forward to ensure the top of the detector connects

with the top of the bay.

• Close the lid and press until the release tabs click.

• When the detector has been inserted correctly, the RUN

LED(s) on the docking module light yellow and Unit

Inserted displays on the base station LCD. The base

6

a Caution

connector to the open position (red).

station LCD displays the docking module number, and

the type and serial number of the detector.

GasAlertMicro

• Insert the bottom of the detector (serial number face up)

into the detector bay first and then lower the top into

place.

• Close the lid and press until the release tabs click.

• When the detector has been inserted correctly, the RUN

LED(s) on the docking module light yellow and Unit

Inserted displays on the base station LCD. The base

station LCD displays the docking module number, and

the type and serial number of the detector .

GasAlertMicro 5/PID/IR

Important: If the GasAlertMicro 5/PID/IR detector is fitted with

a pump module, the diffusion adapter must be removed from

the docking module. Refer to the MicroDock II Base Station

User Manual.

• Insert the GasAlertMicro 5/PID/IR (LCD facing up) at a

45° angle and insert the bottom into the docking bay.

Ensure the connector outlets on the bottom of the detector lock into place over the connector pins in the docking

bay.

• Close the lid and press until the release tabs click.

Page 9

• When the detector has been inserted correctly, the RUN

LEDs light yellow, Unit Inserted displays on the base

station LCD, and MicroDock displays on the detector

LCD. The base station LCD displays the docking module number, and the type and serial number of the

detector.

GasAlertMicroClip

Important: If the GasAlertMicroClip is fitted with a calibration

cap or an auxiliary filter, it must be removed prior to inserting it

into the docking module. Refer to the GasAlertMicroClip User

Manual and the MicroDock II Base Station User Manual.

• Insert the bottom of the detector (serial number face up)

at a 30° angle into the detector bay.

Note

The docking module lid only raises upward 30°. Do

not force the lid beyond its limit.

• Close the lid and press until the release tabs click.

• When the detector has been inserted correctly, the RUN

LEDs on the docking module light yellow and Unit

Inserted displays on the base station LCD. The base

station LCD displays the docking module number, and

the type and serial number of the detector.

GasAlertMax XT

• Insert the bottom of the detector (serial number face up)

at a 30° angle into the detector bay.

Using the Base Station

MicroDock II

Note

The docking module lid only raises upward 30°. Do

not force the lid beyond its limit.

• Close the lid and press until the release tabs click. Push

the pump connector towards the detector pump.

Ensure green is visible in the lower indicator in the

pump connector. If it is not visible, the MicroDock II base

station will not recognize the detector.

Note

The detector will briefly alarm when the pump

connector is indicated. This is normal. The alarm will

deactivate when the detector is properly inserted into

the docking module.

• When the detector has been inserted correctly, the RUN

LEDs on the docking module light yellow and Unit

Inserted displays on the base station LCD. The base

station LCD displays the docking module number, and

the type and serial number of the detector.

Using the Base Station

To prevent possible personal injury and/or property

damage, only use the station in a safe area that is free of

hazardous gas.

Ensure that the station is attached to a venting system or

used in a well ventilated area.

a Warn ing

7

Page 10

MicroDock II

Quick Reference Guide

The base station pushbuttons are not labelled. The base station

is operated by pressing the C pushbutton that is located

directly below the option that displays on the LCD.

Activating the Station

1. To activate the station, press and hold C (the left-

most button) until the following screen displays.

The normal operation screen then displays.

Deactivating the Station

To deactivate the station, complete the following:

1. Access the normal operation screen (the station can

only deactivate from the normal operation screen).

2. Press C off.

Confirm Inlet Setup

For initial station activation, ensure the inlets are installed correctly.

• Inlet 1—default connection for ambient air.

• Inlet 2—default connection for four-gas mix (unless otherwise specified when purchased).

• Inlets 3-5—designed connection for additional gases.

However, unless specified at purchase, inlets 3-5 will be

configured for ambient air.

Warn ing

Failed bump tests and calibrations can result if the inlets

are not setup correctly.

To confirm that the inlets are set correctly, complete the following:

1. Press C menu to access the user options menu.

2. Press C or to scroll to InletSetup.

3. Press C sel to access the inlet 1 screen.

a

4. Press the C

screens.

to scroll to the inlet 2, 3, 4, and 5

8

Page 11

5. Press C exit to return to normal operation.

For more information on setting up inlets, gas types, and concentration levels, refer to Inlet Setup in the MicroDock II Base

Station User Manual.

Bump Test

A bump test is performed to confirm that the detector is

responding to gas, and that the audio and visual alarms are

operational.

Caution

Ensure the detector is not in a low battery state prior to

performing a bump test.

To perform a bump test, complete the following:

1. From the docking module of the applicable detector,

press C BUMP CHECK.

2. The gas is automatically applied.

a

MicroDock II

Bump Test

The LCD displays the results of the bump test.

If any test fails, refer to Troubleshooting in the

MicroDock II Base Station User Manual.

3. Press C OK to return to normal operation.

4. After 5 minutes of inactivity, the detector deactivates.

For additional information, refer to the MicroDock II

Base Station User Manual.

Calibration (excluding GasAlertClip Extreme)

Warn ing

BW recommends using premium grade calibration gases

and cylinders that are certified to National Standards. The

calibration gases must meet the accuracy of the detector.

All calibration cylinders must be used with demand flow

regulators and must meet the following maximum inlet

pressure specifications

• Disposable cylinders 0-1000 psig/70 bar

• Refillable cylinders 0-3000 psig/207 bar

Ensure the detector is not in a low battery state prior to

performing a calibration.

a

Caution

a

9

Page 12

MicroDock II

Quick Reference Guide

A calibration adjusts the sensor sensitivity to ensure an accurate response to gas.

To calibrate a detector, complete the following:

1. From the docking module of the applicable detector,

press C CALIBRATION.

2. The gas is automatically applied.

3. When the calibration is complete, the system purges.

The countdown for time remaining displays beside

Purge.

= calibration has passed

= calibration has failed

10

If any test fails, refer to Troubleshooting in the

MicroDock II Base Station User Manual.

4. The detector deactivates.

Data Transfer (GasAlert Extreme, GasAlertMicroClip,

GasAlertMax XT only)

This feature transfers datalogs from the detector to the base

station MultiMediaCard (MMC).

To transfer a datalog, complete the following:

1. Activate the detector and insert it into the docking

module.

2. Press C DATA TRANSFER. The RUN LED flashes

rapidly. The base station LCD displays the following

screen:

Depending upon how many logs are stored on the

MMC, the data transfer may require 12-14 minutes to

complete (1-2 minutes for the GasAlertMicroClip and

GasAlertMax XT).

Note

A maximum of ten datalogs from all modules

combined can be stored on an MMC (100 datalogs

for GasAlertMicroClip and GasAlertMax XT).

Page 13

Automatic Datalog Download (GasAlertMicroClip and GasAlertMax XT docking module only)

Successful Data Transfer: The PASS LED lights green on the

docking module and Pass displays on the base station LCD.

From the LCD, press C Pass to return to normal operation.

Unsuccessful Data Transfer: The FAIL LED lights red on the

docking module. Attempt to transfer the data again. If the second data transfer is unsuccessful, ensure the detector is activated. If the problem persists, contact BW Technologies by

Honeywell.

3. To transfer the datalogs to Fleet Manager II, refer to

the Importing Data into Fleet Manager II in the Fleet

Manager II Technical Reference Guide.

4. To view the data that was transferred to the MMC,

refer to Viewing Data in Fleet Manager II in the Fleet

Manager II Technical Reference Guide.

Maximum Storage Capacity

When the maximum storage is reached, the base station

replaces the oldest datalogs with the new datalogs.

Automatic Datalog Download (GasAlertMicroClip

and GasAlertMax XT docking module only)

The Automatic Datalog Download option is enabled/disabled

through Fleet Manager II. If the option is enabled, datalogs are

transferred every time a bump test or calibration is performed.

After performing a bump test or calibration on the GasAlertMicroClip and GasAlertMax XT docking module, the PASS LED

lights green. The DATA TRANSFER RUN LED then lights yellow as the transfer begins.

MicroDock II

Caution

Do not remove the GasAlertMicroClip and GasAlertMax

XT from the docking module until the DATA TRANSFER

PASS LED lights green to indicate the transfer is

complete.

After the data transfer is complete, the detector deactivates

after 5 minutes of inactivity.

For more information about the Automatic Datalog Download

option, refer to the MicroDock II Base Station User Manual.

a

Eventlogging

Bump tests and calibrations are recorded on a

MultiMediaCard (MMC). The MMC is located on the base station in the battery compartment. It stores test records that can

be downloaded from the base station to a PC.

Access Test Results

To access and view test results, refer to Importing Data into

Fleet Manager II and Viewing Data in Fleet Manager II in the

Fleet Manager II Technical Reference Guide.

Configuring the Detector (Not applicable to the

GasAlertClip Extreme)

Use Fleet Manager II to configure the following detectors:

• GasAlert Extreme

• GasAlertMicro

• GasAlertMicro 5/PID/IR

11

Page 14

MicroDock II

Quick Reference Guide

• GasAlertMicroClip

• GasAlertMax XT

The detector can be configured prior to performing a bump test

or calibration to

• change user options,

• sensor options, and

• program options.

The detector can also be configured to disallow bump tests or

calibrations unless performed with the MicroDock II. For more

information, refer to Configuring Detectors in the Fleet Manager

II Technical Reference Guide.

Charging the Battery Pack (Optional)

There is a maximum of six charging docking modules can

be installed on the MicroDock II base station (six charging

modules plus four non-charging modules for a maximum

of ten docking modules per station).

To charge successfully, the temperature must be between

50°F to 95°F (10°C to 35°C). Charge the battery

immediately when the detector emits a low battery alarm.

The charger is for indoor use only.

The detector will not charge while bump tests or

calibrations are being performed. If the battery is low,

12

a Warni ng

Caution

a

Note

charge the detector for 30 minutes, then begin a test.

When the test is complete resume charging the

battery.

When charging a new battery for the first time, ensure the battery obtains a full charge. For more information, refer to the

detector’s user manual or operator’s manual.

Note

Up to six GasAlertMicro and GasAlertMicro 5/PID/IR

detectors can charge simultaneously.

Up to four GasAlertMicroClip and GasAlertMax XT

can charge simultaneously.

For more information, refer to the MicroDock II Base

Station User Manual.

To charge the battery pack, complete the following:

1. Connect the charger adaptor cord into the CHARGE

port on the station, and then plug into an AC outlet.

The CHARGE LED briefly lights red then green during the self-test. The LED then powers off (not applicable to the GasAlertMicroClip and GasAlertMax XT

modules).

2. Deactivate the detector. Insert the detector into the

charging cradle.

3. The CHARGE LED lights red (all charging modules).

Page 15

4. Allow the battery to obtain a full charge (2 to 4 hours,

depending upon how many docking modules are connected to this station).

If a docking module is in queue waiting to charge, the

CHARGE LED flashes red (all charging modules).

When the docking module begins charging, the

CHARGE LED stops flashing and lights solid red.

The CHARGE LED lights green when the charging

process is complete. If there are other docking modules in queue, waiting to charge, they will begin

charging.

The CHARGE LED deactivates when the detector is

removed.

MicroDock II

Maintenance

Maintenance

No user-serviceable parts inside.

Confirm that the inlet filter is free of dirt and replace if

required. To order replacement parts, refer to

Replacement Parts and Accessories in the MicroDock II

Base Station User Manual.

To maintain the station in good operating condition, perform the

following basic maintenance as required.

• Clean the exterior with a soft, damp cloth. Do not use solvents, soaps, or polishes.

• Do not immerse the station in liquids.

a Warn ing

a

Caution

13

Page 16

MicroDock II

Quick Reference Guide

Specifications

The MicroDock II base station and docking modules are for

indoor use only.

Instrument dimensions: (w x l x h) 21.2 x 26.3 x 8.2 cm

(8.3 x 10.4 x 3.2 in.) base station and one docking module

Weight: 0.98 kg (2.15 lb.)

Base system ingress protection: IP20

Operating temperature: +10°C to +35°C (+50°F to +95°F)

Humidity: 0 to 50%

Altitude: 2000 m (6561.66 ft.)

Storage temperature: -10°C to +60°C (+14°F to +140°F)

Power supply: 6 Vdc , 1.5 A wall adapter or four C-cell

batteries (be advised that the main supply voltage fluctuations

are not to exceed 10% of the nominal supply)

Pollution Degree: 2

Installation Category: I

Real-time clock: Provides time and date stamp

Data storage: Automatic (instrument and base station)

128 MB Delkin MMC data storage system

External interface: USB interface for PC

Pump: DC motor, micro-diaphragm, 3V PCB mount

Flow rate: Maximum recommended 350 ml/min.

Calibration gas cylinder inputs:

• 2-gas inlets (standard)

• 4-gas + air inlets (maximum)

Automatic tests: Functional bump, calibration, audible alarm,

visual alarm

14

Configuration recognition: Automatic (instrument and sensor)

Alarm/calibration parameters: User defined

Calibration gas connections: Built-in (base station)

Gas connection: 1/8” SMC connect sub-miniature coupling

Solenoid: Built-in (docking modules)

LED indicators: (on each docking module)

Yellow - Test

Green - Pass

Red - Fail

Command keys:

Base station: Menu navigation

Docking module: One touch bump-test initiation

One touch calibration initiation: not applicable to the

GasAlertClip Extreme

One touch data transfer initiation: GasAlert Extreme,

GasAlertMicroClip, and GasAlertMax XT only

Communications method: Infrared (two-way)—between

docking module and detector (not applicable to the GasAlertClip Extreme—one way communication only).

USB port for connection to a:

• Personal computer (PC), or

• USB over IP HUB

Sensors: Audio and optical

LCD: 4 line x 16 characters, wide viewing angle, user-defined

backlighting

Enclosure: Impact resistant PC/ABS (polycarbonate)

Warranty: 2 years

Page 17

Charger Specifications

Size: 8.6 x 8.2 x 7.8 cm (3.4 x 3.2 x 3.1 in.)

Weight: 97 g (3.4 oz.) per model

Charger system ingress protection: IP20

Operating temperature: 10°C to 35°C (50°F to 95°F)

Humidity: 0 to 50%

Altitude: 2000 m (6561.66 ft.)

Power: 6 Vdc , 2.5 A

Charging LED: Color-coded LED indicates charging, charge

complete, and charger fault

Charge time: Typically 2-6 hours

Pollution Degree: 2

Installation Category: I

This device complies with the FCC Part 15 and ICES-003

Canadian EMI requirements. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. this device must accept any interference received,

including interference that may cause undesired

operation.

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules and ICES-003 Canadian EMI requirements.

These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in

a commercial environment.

Charger Specifications

MicroDock II

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio

communications.

Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at his/her own expense.

Warn ing

This product is designed for installation in an indoor

location only. All required National Electrical Codes and

Safety Standards must be followed.

For ac main installation, a circuit breaker should be

included in the building installation as a disconnect

device for the equipment. The disconnect device should

be installed in close proximity to the equipment and the

device should be marked as a disconnecting means for

the equipment.

a

15

Page 18

MicroDock II

Quick Reference Guide

16

Page 19

iERP: 126102

D5618/7 [English]

© BW Technologies 2008. All rights reserved.

Loading...

Loading...