Page 1

MC ToolKit

User Manual

Doc. No.: 34-ST-25-20

Release: 3

Last Revision Date: 9/06

Release 3 34-ST-25-20 MC Toolkit User Manual i

9/06

Page 2

Notices and Trademarks

Copyright 2006 by Honeywell International Inc.

Release 3 September, 2006

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact

your local sales office for warranty information. If warranted goods are returned to Honeywell during the period of

coverage, Honeywell will repair or replace without charge those items it finds defective. The foregoing is Buyer's sole

remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and

fitness for a particular purpose. Specifications may change without notice. The information we supply is believed

to be accurate and reliable as of this printing. However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web site, it is up to the

customer to determine the suitability of the product in the application.

Industrial Measurement & Control

Honeywell

2500 W. Union Hills Drive

Phoenix, AZ 85027

Honeywell is a U.S. registered trademark of Honeywell

Other brand or product names are trademarks of their respective owners.

Page ii 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 3

About This Document

Contacts

World Wide Web

The following lists Honeywell’s World Wide Web sites that will be of interest to our industrial automation and

control customers.

Honeywell Organization WWW Address (URL/e-mail)

Corporate http://www.honeywell.com

Industrial Measurement and Control http://content.honeywell.com/imc/

International http://www.honeywell.com/Business/global.asp

Technical Assistance Center ACE@Honeywell.com

(e-mail)

Telephone

Contact us by telephone at the numbers listed below.

Organization Phone Number

United States and Canada Honeywell Inc.

Industrial Automation and Control

Technical Assistance Center

Solution Support Center

Asia Pacific Honeywell Asia Pacific Inc.

Hong Kong

Europe Honeywell PACE

Brussels, Belgium

Latin America Honeywell Inc.

Sunrise, Florida U.S.A.

1-800-343-0228 Sales

1-800-525-7439 Service

1-800-423-9883

1-602-313-3578

(852) 8298298

[32-2] 728-2111

(305) 364-2355

Release 3 34-ST-25-20 MC Toolkit User Manual iii

9/06

Page 4

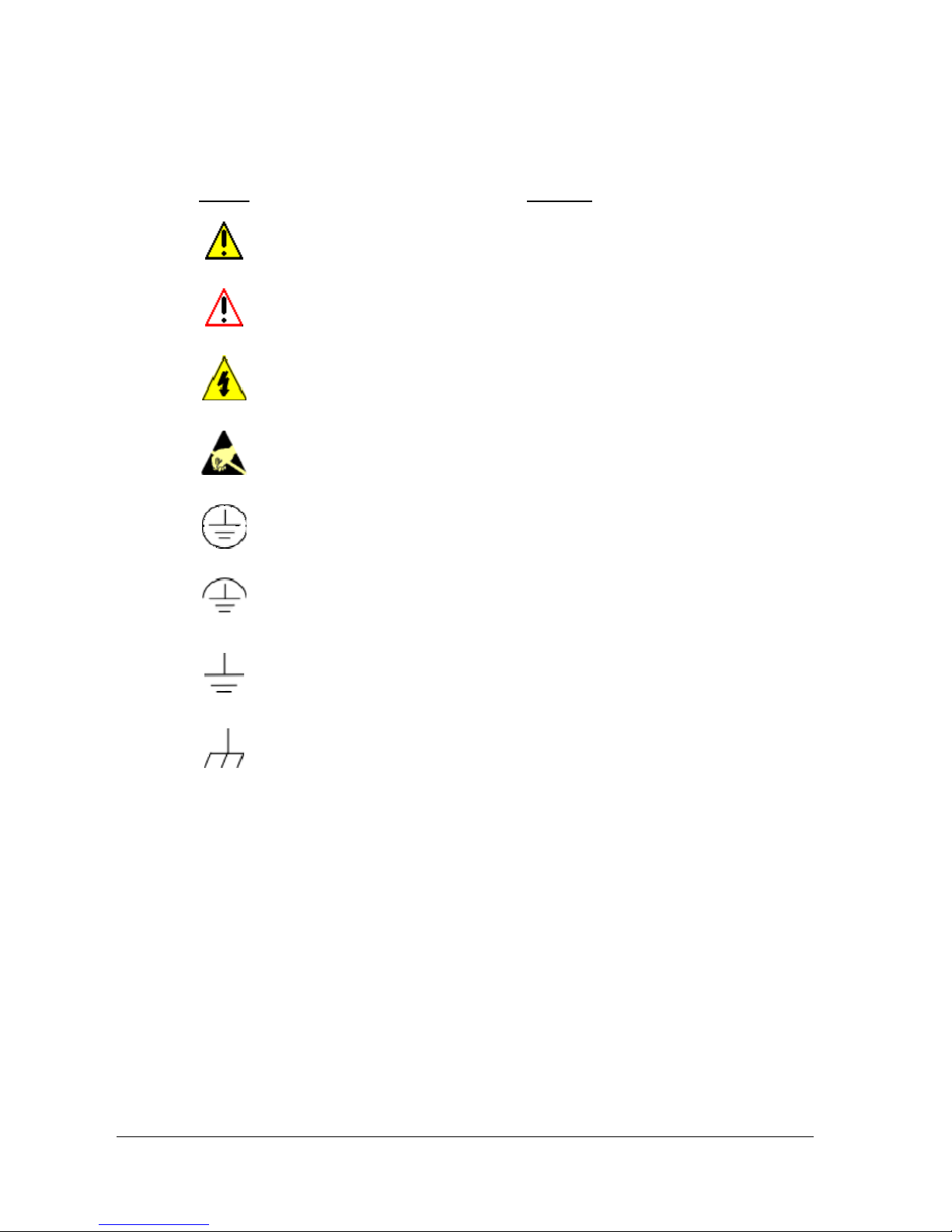

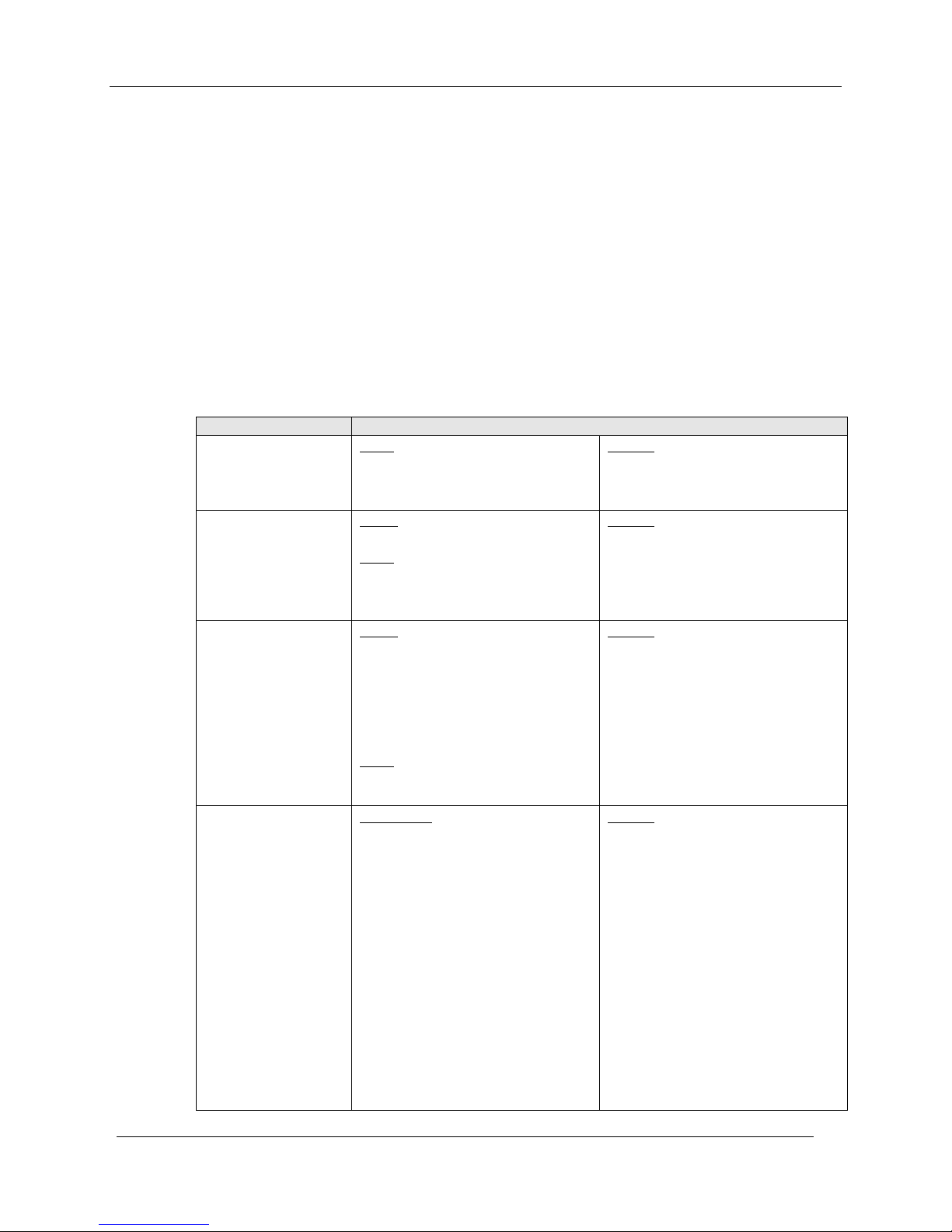

Symbol definitions

The following table lists those symbols used in this document to denote certain conditions.

Symbol Definition

This CAUTION symbol on the equipment refers the user to the Product Manual for

additional information. This symbol appears next to required information in the manual.

This WARNING symbol on the equipment refers the user to the Product Manual for

additional information. This symbol appears next to required information in the manual.

WARNING: risk of electrical shock. This symbol warns the user of a potential shock

hazard where HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or 60

VDC may be accessible.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precautions for

handling electrostatic sensitive devices

Protective Earth (PE) terminal. Provided for connection of the protective earth (green

or green/yellow) supply system conductor.

Functional earth terminal. Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to protective earth at the

source of supply in accordance with national local electrical code requirements.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded to

Protective earth at the source of supply in accordance with national and local electrical

code requirements.

Chassis Ground. Identifies a connection to the chassis or frame of the equipment shall

be bonded to Protective Earth at the source of supply in accordance with national and

local electrical code requirements.

Page iv 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 5

Contents

Introduction ................................................................................................................1

Purpose/Scope ....................................................................................................................................1

Product Description .............................................................................................................................2

Procedural Considerations ..................................................................................................................3

Transmitter Type and Communication Mode...................................................................................3

Type of Procedure and Prerequisites ..............................................................................................3

Special Equipment and/or Environment for Calibration...................................................................3

Transmitter/Communications Characteristics......................................................................................4

Honeywell Transmitter (Analog Mode) ............................................................................................4

General Procedures .................................................................................................10

Overview............................................................................................................................................10

Primer for MC Toolkit & SDC 625 Application Software ...................................................................10

Start-Up and Basic Operation and Navigation...............................................................................10

Input Methods: Letter, Numbers, Symbols ....................................................................................11

MC Toolkit Application Software Display Conventions .....................................................................13

Navigation ......................................................................................................................................13

Data Entry and Display ..................................................................................................................15

SDC 625 Application Software Display Conventions ...............................................16

Navigation..........................................................................................................................................16

Introduction........................................................................................................................................17

Summary of Operating Procedures...................................................................................................18

Procedural Considerations ................................................................................................................20

Input calibration..............................................................................................................................20

Output Calibration..........................................................................................................................20

MC Toolkit Software with Honeywell HART Transmitters.........................................36

Introduction........................................................................................................................................36

General Procedures ..........................................................................................................................38

Procedural Considerations ................................................................................................................40

Input Calibration.............................................................................................................................40

Output Calibration..........................................................................................................................41

Using SDC 625 Application Software with all HART Transmitters and Devices....... 61

Introduction........................................................................................................................................61

Release 3 34-ST-25-20 MC Toolkit User Manual v

9/06

Page 6

Messages and Diagnostic Codes............................................................................. 65

Messages and Diagnostic Codes......................................................................................................65

Reference Data ........................................................................................................ 75

Honeywell DE Fields and Values ......................................................................................................77

Honeywell HART Fields and Values .................................................................................................79

Generic HART Fields and Values .....................................................................................................82

XML Database (Samples) .................................................................................................................89

XML Sample - Honeywell DE ........................................................................................................89

XML Sample - non-Honeywell HART ............................................................................................89

MCT101 Maintenance..............................................................................................91

Modem Battery Replacement............................................................................................................91

MC Toolkit Software Installation/Maintenance ..................................................................................92

Overview 92

MCT202 Maintenance..............................................................................................93

Battery Replacement.........................................................................................................................93

SD Card Replacement.......................................................................................................................93

Replacement Parts................................................................................................... 93

MCT101 Replacement Parts .............................................................................................................93

MCT202 Replacement Parts .............................................................................................................95

Page vi 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 7

Tables

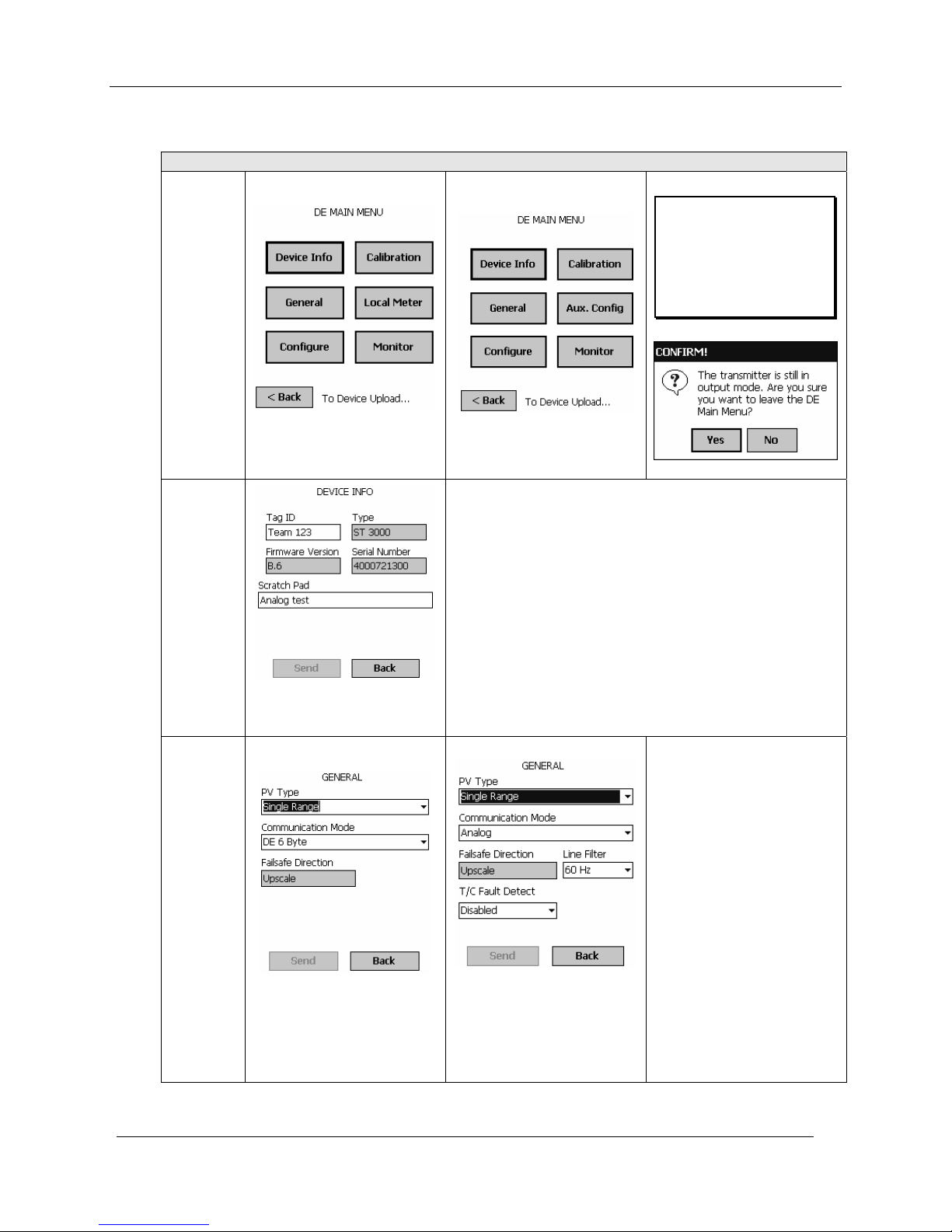

Table 1 DE Displays / Tasks Summary......................................................................................................................18

Table 2 DE Upload Procedures ..................................................................................................................................21

Table 3 DE Main Menu Procedures ...........................................................................................................................22

Table 4 Input Calibration (DE Transmitters) - Correct Input (Zero), LRV, URV; Reset Corrects ............................25

Table 5 Output Calibration - Loop Test......................................................................................................................30

Table 6 DE Output Calibration - Trim DAC Current.................................................................................................32

Table 7 DE Calibration - Apply Values......................................................................................................................34

Table 8 HART Displays / Tasks Summary ................................................................................................................39

Table 9 HART Device UPLOAD Procedure..............................................................................................................42

Table 10 Honeywell HART Main Menu Procedure...................................................................................................44

Table 11 Honeywell HART Diagnostics/Service Menu Procedures ..........................................................................49

Table 12 Honeywell HART Calibration - Zero Trim .................................................................................................51

Table 13 Honeywell HART Calibration - LRV and URV..........................................................................................53

Table 14 Honeywell HART Calibration - Reset corrects ...........................................................................................54

Table 15 Honeywell HART Calibration - Loop Test .................................................................................................55

Table 16 Honeywell HART Calibration - D/A Trim..................................................................................................56

Table 17 Honeywell HART Calibration - Apply Values............................................................................................58

Table 18 MC Toolkit/SDC 625 Error Messages.........................................................................................................65

Table 19 DE Messages ...............................................................................................................................................68

Table 20 HART Messages..........................................................................................................................................69

Table 21 ST 3000 Device Status Messages (DE).......................................................................................................71

Table 22 STT Device Status Messages (DE)..............................................................................................................72

Table 23 ST 3000 Device Status Messages (HART)..................................................................................................73

Table 24 STT Device Status Messages (HART) ........................................................................................................74

Table 25 Glossary.......................................................................................................................................................75

Table 26 DE Fields and Values ..................................................................................................................................77

Table 27 HART Fields and Values.............................................................................................................................79

Table 28 Generic HART Fields and Values...............................................................................................................82

Table 29 HART Universal Commands.......................................................................................................................87

Table 30 HART Common Practice Commands..........................................................................................................88

Table 31 Battery Removal and Replacement Procedure ............................................................................................91

Table 32 MCT101 Replacement Parts........................................................................................................................93

Table 33 MCT202 Replacement Parts........................................................................................................................95

Release 3 34-ST-25-20 MC Toolkit User Manual vii

9/06

Page 8

Figures

Figure 1 Components of the MC Toolkit........................................................................................................................1

Figure 2 MCT202 (rugged and intrinsically safe models)..............................................................................................1

Figure 3 Honeywell ST 3000 Smart Transmitter - Analog mode...................................................................................4

Figure 4 Honeywell Analog Value Scaling ....................................................................................................................6

Figure 5 Honeywell DE Mode Value Scaling ................................................................................................................8

Figure 6 Honeywell (HART) Transmitter Diagram ........................................................................................................8

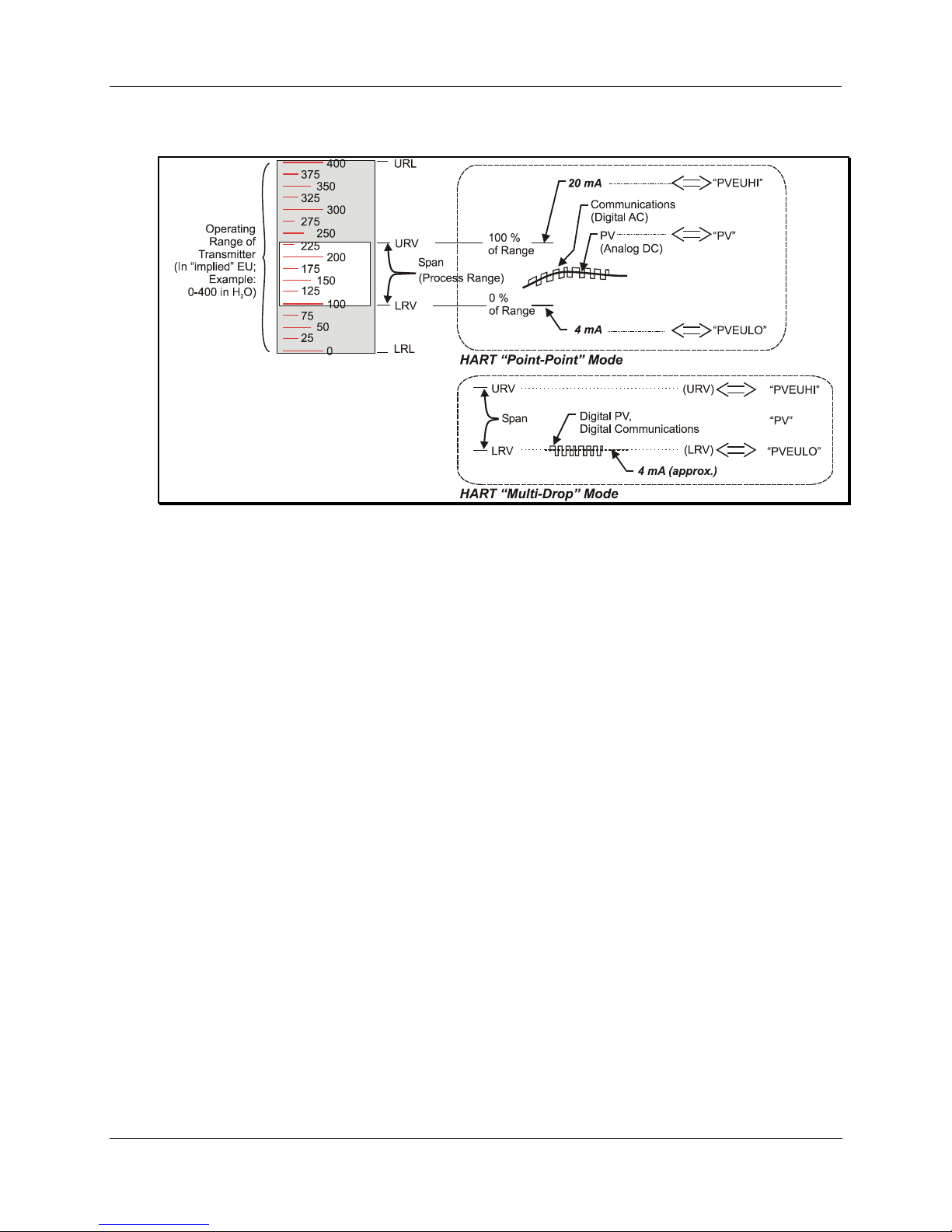

Figure 7 HART Point-point and Multi-Drop Value Scaling...........................................................................................9

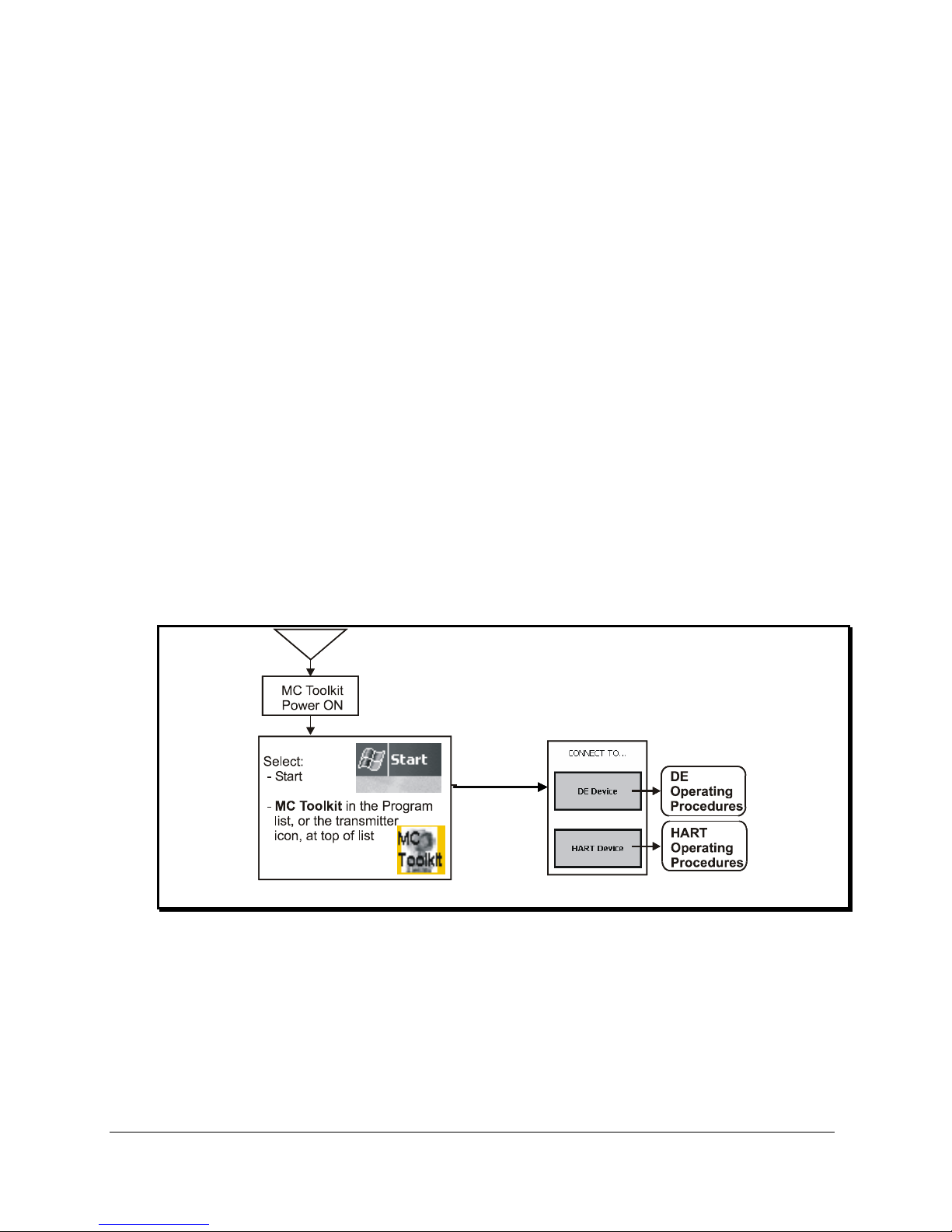

Figure 8 Start-up - MC Toolkit Application.................................................................................................................10

Figure 9 Menu Tree - Honeywell DE Displays ............................................................................................................17

Figure 10 Menu Tree - Honeywell HART Displays.....................................................................................................36

Figure 11 Menu Tree: non-Honeywell HART Displays...............................................................................................37

Figure 12 HART Menus (Display Summary)...............................................................................................................38

Page viii 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 9

Purpose/Scope

This manual is intended to facilitate the use of the Honeywell MC Toolkit communications tool. It is

assumed that the user is skilled in the use and maintenance of process transmitters in process control, or

that he/she is under direct supervision of others with such skills.

The MC toolkit, with MC Toolkit Application Software and SDC 625 Application Software, enables

communication with several types of smart transmitters (pressure, temperature, etc) that are available for

use in the process control industry.

The emphasis of the information in this manual is directed primarily on the features and use of the

MC Toolkit in performing common maintenance tasks relating to transmitter devices, rather than on the

features and installation of specific transmitter devices.

It is recommended that that user should have the appropriate manuals available for specific transmitter

devices. For background information such as HART communications protocol and network wiring, it is

also recommended that the user should obtain publications available from agencies such s the HART

Communication Foundation.

Introduction

Ruggedized

Zone 2

Zone 1

Figure 1 Components of the MC Toolkit Figure 2 MCT202 (rugged and

intrinsically safe models)

This manual includes information of two types:

• background material that enables a skilled user to select the appropriate procedures in this manual and

to apply them in the appropriate sequence, and

• detailed descriptions of the MC Toolkit regarding functions, features, and procedures for applying

them

Release 3 34-ST-25-20 MC Toolkit User Manual 1

9/06

Page 10

Product Description

Product Description

The Honeywell MC Toolkit is a handheld communication package that enables convenient and reliable

communications with smart transmitters (temperature, pressure, and others). It consists of two software

applications – MC Toolkit Application Software and SDC 625 Application Software. The MC Toolkit

Application Software can be used to configure, monitor and calibrate Honeywell DE and HART

transmitters. The SDC 625 Application, utilizing HART Device Description (DD) technology, can be used

to configure, monitor and calibrated all HART devices – Honeywell or non-Honeywell devices. The MC

Toolkit can communicate to:

• any Honeywell analog transmitter with Honeywell proprietary digital communications protocol or with

DE (Digital Enhanced) communications protocol.

• any Honeywell transmitters with HART communications protocol

• Any HART transmitter from other manufacturers.

The MCT101 includes the following (separately orderable) components:

• a PDA (Personal Digital Assistant)

• a DE/HART Modem

• a Handheld Connector Cable that connects the PDA to the Modem

• Holster for PDA and Modem

• Honeywell MC Toolkit application software (CD ROM)

• Honeywell SDC 625 application software (on same CD ROM as MC Toolkit application software)

• Modem Battery

The MC Toolkit MCT202 version includes the following features:

• Ruggedized version- Environmentally hardened with no approvals.

• Zone 2 approvals: Intrinsically-safe version available with FM Class I, Div 2 and ATEX Zone 2 approvals.

• Zone 1 approvals: Intrinsically-safe version available with FM Class I, Div 1 and ATEX Zone 1 approvals.

The MCT202 includes the following components:

• An iroc PDA with integrated DE/HART modem

• Honeywell MC Toolkit CD ROM with MC Toolkit and SDC625 application software

• Test leads for the electrical connection from the PDA to the field device

All versions of the PDA incorporate the Microsoft Pocket PC 2003 or 2005 Operating System. Honeywell

software operates as an application package in the familiar MS Windows environment, and is virtually

identical for all versions of the PDA. The MC Toolkit application or SDC 625 application can run

simultaneously with other Pocket PC applications.

Page 2 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 11

Procedural Considerations

CAUTION! WARNING!

In some cases, the use of a field communicator with a transmitter that is connected on-line can have an

adverse effect on process operations.

Before using the MC Toolkit, be certain that you know the potential consequences of each procedure, and

that you use the appropriate safeguards to prevent problems. For example, if the transmitter is an element

of a control loop, the loop should be placed in the manual operating mode, and alarms and interlocks

("trips") should be disabled as appropriate before beginning the procedure.

The primary factors to be considered are separated into three categories under the following three headings.

The information under the following headings is intended as background for use of the DE Procedures and

HART Procedures, which are given in separate sections of this manual.

Transmitter Type and Communication Mode

The MC Toolkit can be used with various types of field transmitters, most of which can be operated in

more than one mode.

• Honeywell DE transmitter operating in Smart Analog Mode

Introduction

• Honeywell DE transmitter operating in Digital Enhanced (DE) Mode

• Honeywell (and other) HART transmitter operating in point-to-point (Analog w/ HART digital mode)

• Honeywell (and other) HART transmitter operating in multi-drop (HART-only digital mode)

The salient characteristics of each item listed, and the implications of each characteristic in procedures are

described under Transmitter/Communications Characteristics

Type of Procedure and Prerequisites

The MC Toolkit is designed to provide three basic functions:

• Monitoring

• Configuration

• Calibration

Depending on combinations of factors such as transmitter type, and communications mode, some

procedures such as monitoring the performance of a transmitter can be straightforward and innocuous, but

in some cases can also require special preparation and precautions.

Special Equipment and/or Environment for Calibration

Typically, a smart transmitter delivered by a major manufacturer today is designed to provide a high degree

of precision throughout its operating range, and has been calibrated to a high level of accuracy that is not

easy to duplicate in the user's plant process areas. Moreover, the design, materials, and manufacturing

process employed will ensure that the instrument will stay within calibration limits for an extended period.

Typically, calibration of a process-connected transmitter will degrade, rather than augment, the capability

of a smart transmitter. For this reason, the calibration procedures in this MC Toolkit User Manual include

a recommendation that the transmitter is removed from service and is calibrated only in a controlled

laboratory environment, using equipment whose precision is certified.

Release 3 34-ST-25-20 MC Toolkit User Manual 3

9/06

Page 12

Transmitter/Communications Characteristics

Transmitter/Communications Characteristics

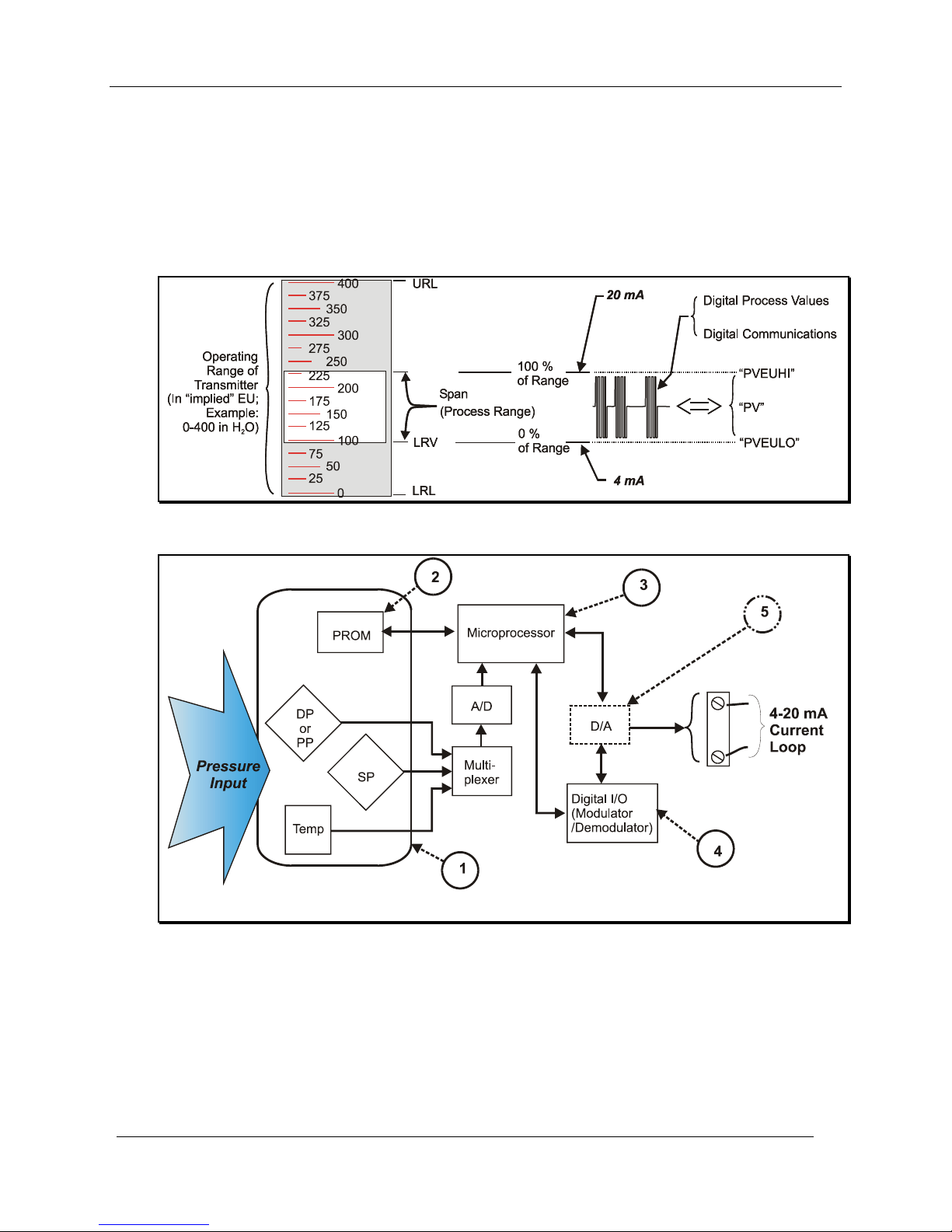

The characteristics of a typical Honeywell Smart Pressure Transmitter are summarized in Figure 3 through

Figure 7, following.

Honeywell Transmitter (Analog Mode)

Analog-to-Digital Sensing

As indicated by key number (1) in Figure 3, the sensor is a sealed assembly that typically includes three

separate sensors: Differential Pressure (DP), Static Pressure (SP) and Temperature (Temp).

Input Characterization

The sensor also includes a PROM, (2), which is Non-Volatile Memory (NVM) that stores

"characterization" constants written at the factory, and calibration constants, which can be written at the

factory and/or at the user's site. The data in NVM is used in an algorithm in the microprocessor, (3), which

is executed continuously to calculate the input value.

Figure 3 Honeywell ST 3000 Smart Transmitter - Analog mode

The characterization constants, which are written at the factory, are derived from highly precise testing of

the sensor's response over a range of temperatures, and from the Lower Range Limit (LRL) to the Upper

Range Limit (URL) of the sensor. The purpose of the characterization constants is to compensate for very

small inaccuracies in the sensor that are introduced by variations inherent in construction materials, and to

ensure that the calculated input is a high-fidelity representation of the analog input (linear or square root),

with a precise "zero" reference.

Input Calibration ("Corrects")

To optimize accuracy, the PROM includes storage for calibration constants: Correct Input Zero, Correct

LRV, and Correct URV.

The corrects constants provide for optimum accuracy in that they enable fine-tuning of the input

calculations, by first correcting at zero input, then bounding the input calculations at the user's operating

Page 4 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 13

Introduction

range. That is, corrections are applied at the Lower Range Value (LRV) and the Upper Range Value

(URV).

Factory calibration can be specified in the purchase order. Also, if precision equipment, suitable

environment, and required skill are available at the user's site, input calibration can be done locally.

Reset Corrects

In some cases, the calibration procedure yields unsatisfactory results such that the Corrects constants must

be removed from memory. The Reset Corrects erases all three corrects constants, so that only the factorywritten characterization constants will be retained in the PROM.

Digital Communication Path

As indicated at key number (4) in Figure 4, the Honeywell Smart Transmitter includes a path for digital

communications between the sensor (via the microprocessor) and the 4-20 mA current loop that connects

the transmitter to external communications devices such as process control equipment ("receiver") and/or to

a MC Toolkit.

Digital to-Analog Conversion and Transfer

The digital-to-analog converter (D/A) shown at key number (5) in Figure 3 is shown as a box with a dotted

line to indicate that analog output mode is a user-selectable feature, for use in an application whose

receiving equipment requires an analog input.

Note that the Digital I/O (Comm) (communications) box is shown in Figure 3 with solid line to indicate

that the digital communications path is available at all times, even when analog mode is selected.

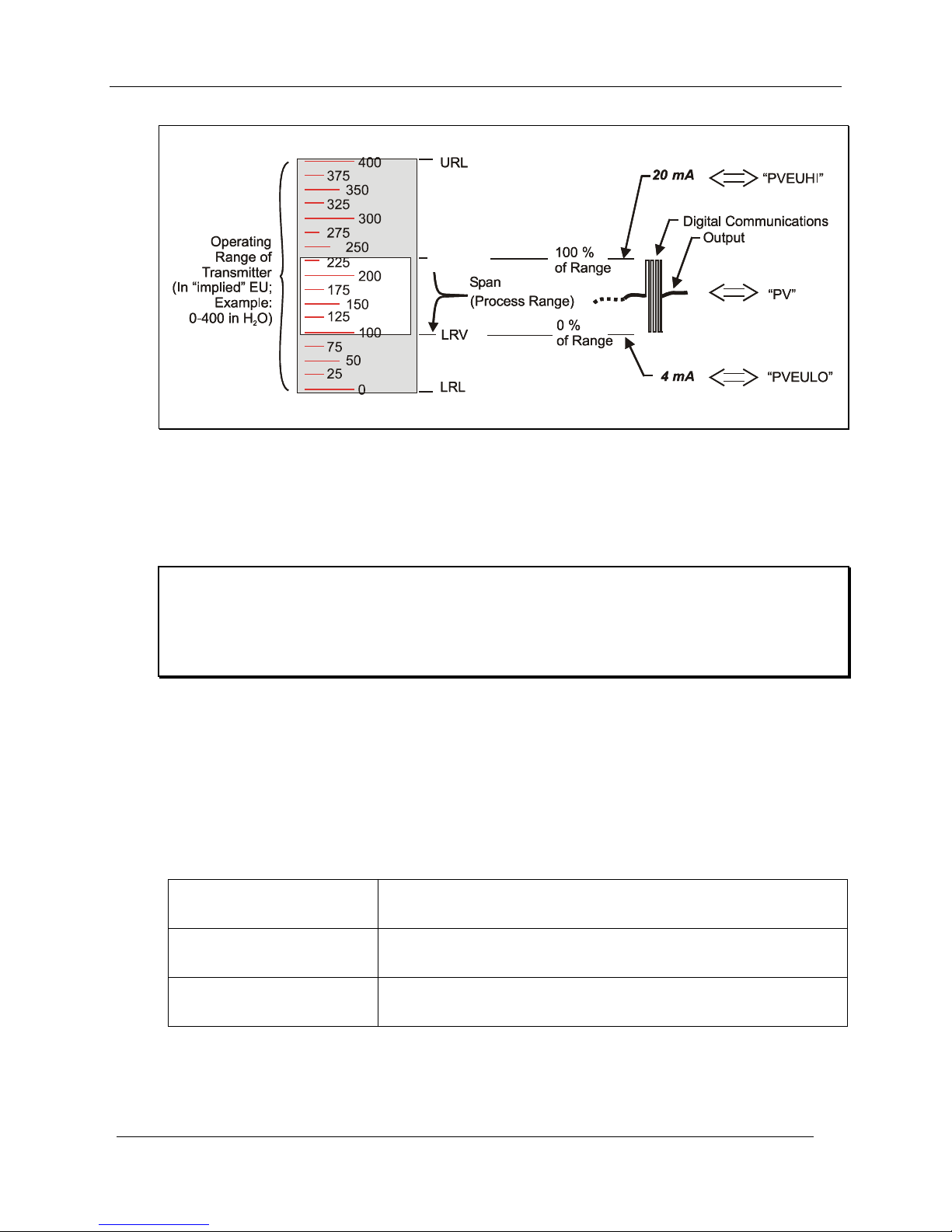

Honeywell Transmitter Output - Analog Mode

The diagram in Figure 4 provides an overview of a Honeywell transmitter operating in the analog mode.

Analog (PV Signal) Output

The vertical scale at the left of Figure 4 is an example of the available range (LRL to URL) of a pressure

transmitter sensor as built and characterized at the factory. The area of this scale that is highlighted in

white represents the configured process operating range (LRV to URV) - in this case, from 100 in H

225 in H

2

O.

Note that Engineering Units (EUs) shown in Figure 4 are included here only for reference. The transmitter

does not perform any conversion of the base units value to Engineering Units. All conversion to EUs is

performed in the MC Toolkit and/or in other receiving devices such as operating panels associated with

control equipment. Default conversion is to inches-H2O @39F.)

The output of a Honeywell transmitter operating in the analog mode is a scaled value (0% - 100%) of

current (4 mA to 20 mA), whose lower and upper limits correspond to the configured operating range

(LRV-URV), respectively.

At the right of Figure 4, "PVEULO", "PV", and "PVEUHI" are examples of parameter names that appear

on Honeywell control equipment, which are used as follows.

Parameter Name Parameter Description Display Examples

O to

2

PVEULO Process Value , Engineering Units, Low

PV Process Value

PVEUHI Process Value , Engineering Units, Low

Release 3 34-ST-25-20 MC Toolkit User Manual 5

9/06

PVEULO 100 in H20

PV 175 in H20

PVEUHI 225 in H20

Page 14

Transmitter/Communications Characteristics

Figure 4 Honeywell Analog Value Scaling

Digital (Communications Signal) Input/Output

As indicated at the right of Figure 4, communications between the MC Toolkit and the Honeywell Smart

Transmitter consist of digital pulse strings, with rapid transitions of current level between (approximately)

4 mA and 20 mA.

URVURV

Caution:

These rapid transitions provide for effective communications, but will interfere adversely with a transmitter

operating on-line in a control loop.

The MC Toolkit communicates digitally; exercise caution and good judgment when connecting the unit to

an on-line transmitter operating in the analog mode.

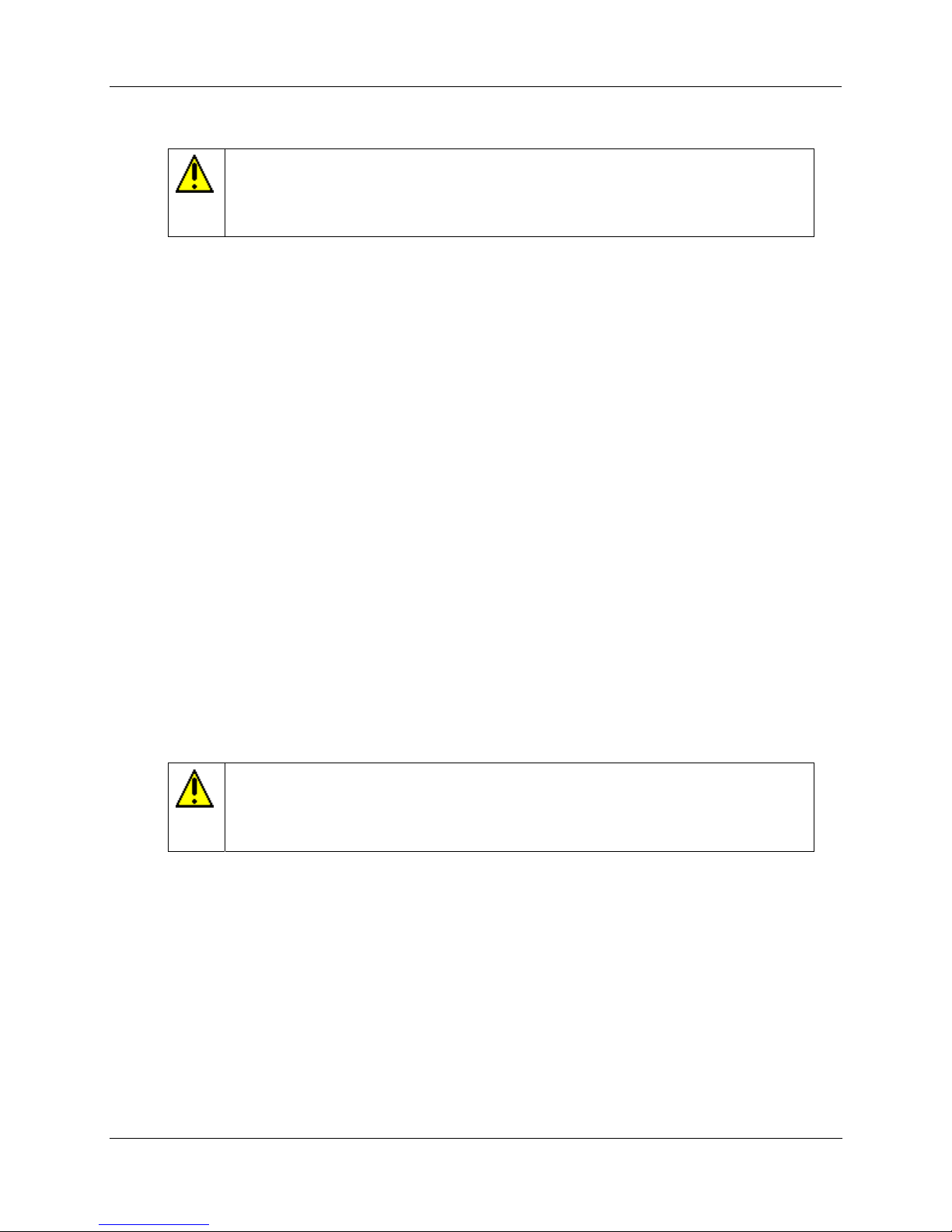

Honeywell Transmitter Output - Digital Enhanced Mode

Most of the operation of the Honeywell Smart Pressure Transmitter Digital Enhanced (DE) mode is similar

to that of operation in the analog mode. The essential characteristics of operation in DE mode are shown in

Figure 5.

As indicated at the right of Figure 5, output values of process variables, as well as digital communications,

are transferred to a receiving device digitally. The digital coding is Honeywell proprietary, which requires

the use of DE-capable Honeywell control equipment.

The use of DE mode offers several advantages:

process safety

Unlike in the analog mode, communications devices do not "bump" the

value of the PV.

accuracy is retained with less

maintenance

facilitates maintenance tasks

Digital communications are relatively immune to small variations in

circuit resistance or supply voltage.

Honeywell control systems include operating displays that enable direct

communication with transmitters operating in DE mode.

Page 6 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 15

Introduction

CAUTION:

Although it in not necessary to put a control loop in manual before communicating with a

transmitter operating in DE mode, caution is required if there is any potential for error in

identifying operating mode.

Honeywell HART Transmitters

Transmitters with HART capability have features that vary among manufacturers and with the

characteristics of specific devices. The MC Toolkit supports the HART Universal, Common Practice, and

Device Specific Commands that are implemented in Honeywell HART transmitters.

As the diagram in Figure 6 shows, the Honeywell HART Transmitter is virtually identical to non-HART

transmitters, except that the HART version includes a Digital I/O Modulator/Demodulator block (key

number (4) instead of the Honeywell DE communications block.

As indicated in Figure 7, the output of the HART includes two primary modes:

• Point-to-Point Mode, in which one transmitter is connected via a two-conductor, 4-20 mA current loop

to one receiver.

• Multi-Drop Mode, in which several transmitters are connected via a two-conductor network to a

multiplexed receiver device.

In point-to-point mode, the value of the primary PV is represented by a 4-20 mA current loop, almost

identical to that of the Honeywell Transmitter operating in analog mode. In this case however, the analog

signal is modulated by Frequency Shift Keying (FSK) methods, using frequencies and a current amplitude

that do not affect analog sensing at the receiver.

Note that the accuracy of the analog level must be precisely controlled for accurate sensing, but that HART

communications will not "bump" the process variables.

In multi-drop mode, up to 16 transmitters (addresses 0-15) can exist on the two-conductor network, which

precludes analog transmission methods. In this case, the same FSK modulation method is used for

conveying levels of PV (and other variables) and also for communications.

CAUTION:

Before connecting to a HART transmitter, ensure that the MC Toolkit is not set up for DE

communications, whose current amplitude can "bump" process variables in either point-topoint mode or in multi-drop mode.

Non-Honeywell HART Transmitters and Devices

HART-capable transmitters from any manufacturer and for any specific purpose are designed to commonagreement standards that provide for inter-operability.

Guidelines published by the HART Communication Foundation enables manufacturers to design devices

that communicate via a set of standard commands and responses.

The standard set of commands is an integral component of the Honeywell MC Toolkit that enables

communication with many HART transmitters from other manufacturers.

The MC Toolkit application software supports the HART Revision 5.0 Universal Commands and HART

Revision 5.0 Common Practice Commands. However, the MC Toolkit supports only a recommended

number of Common Practice commands. The MC Toolkit does not support device-specific commands for

Release 3 34-ST-25-20 MC Toolkit User Manual 7

9/06

Page 16

Transmitter/Communications Characteristics

non-Honeywell transmitters. For more information, refer to tables in the Reference Data section of this

manual.

It is recommended that the SDC 625 application software, based on DD-IDE/SDC-625 technology and

"OPEN" tools standard, be used with non-Honeywell HART devices. The SDC 625 is based on HART

Revision 5.0 and uses Device Descriptions stored in the Pocket PC to communicate to all universal,

common and specific device commands. MC Toolkit will come with all HART Registered (updated once

per quarter) Device Descriptions pre-loaded.

URVURV

Figure 5 Honeywell DE Mode Value Scaling

Figure 6 Honeywell (HART) Transmitter Diagram

Page 8 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 17

Introduction

Figure 7 HART Point-point and Multi-Drop Value Scaling

Release 3 34-ST-25-20 MC Toolkit User Manual 9

9/06

Page 18

General Procedures

Overview

The Honeywell MC Toolkit includes MC Toolkit application software and SDC 625 application software

running in the PDA, a general-purpose, hand-held computing device.

This section highlights some of the general-purpose features that facilitate use of the MC Toolkit software.

Primer for MC Toolkit & SDC 625 Application Software

The following is intended as a primer for using selected Pocket PC features with the MC Toolkit

application software.

Each of the following descriptions of features includes only the name of the feature and its functionality as

it is used with the MC Toolkit. The details of each feature are provided in the HELP information that is

included with the PDA.

As you become familiar with the MC Toolkit, you may want to explore other features that are listed and

described in the PDA HELP information.

Start-Up and Basic Operation and Navigation

The sequence for starting the Pocket PC and the MC Toolkit application Software is illustrated in Figure 8

Start-up - MC Toolkit Application.

Figure 8 Start-up - MC Toolkit Application

Similarly to the MC toolkit application software, the SDC 625 application software can be started up. Turn

on the PDA and click on the SDC 625 icon. The SDC 625 icon can be found by selecting Start and then

Programs. The SDC 625 executable file can also be found in the Storage Card under File Explorer.

Release 3 34-ST-25-20 MC Toolkit User Manual 10

9/06

Page 19

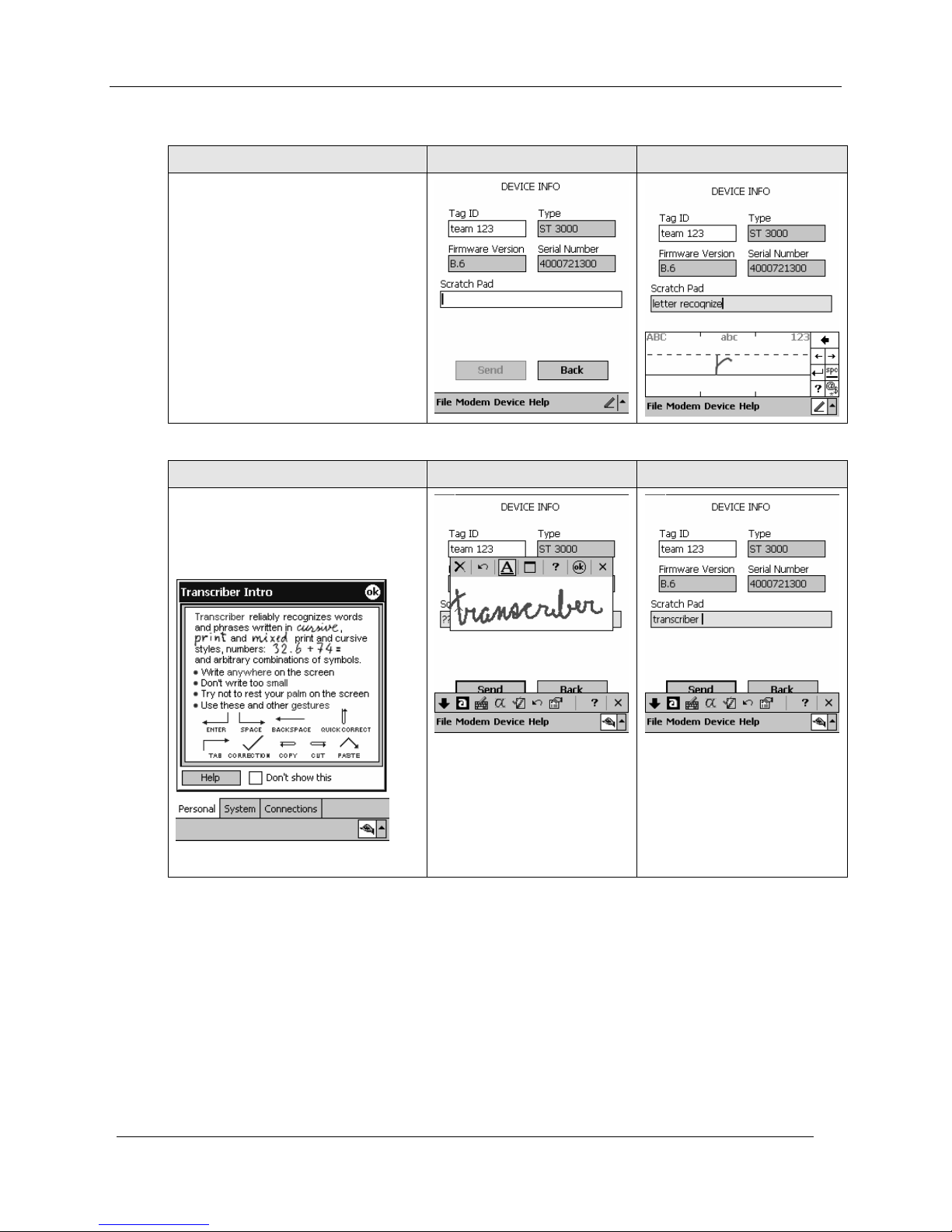

Input Methods: Letter, Numbers, Symbols

The PDA includes four methods for character input: Block Recognizer, Keyboard, Letter Recognizer, and

Transcriber.

In the Keyboard method, the user selects a text field in display, and then selects a character at a time from a

virtual keyboard. Using the keyboard involves familiar concepts that will enable quick and accurate

entries.

In the other three methods, the stylus is used to write the desired input directly onto the screen, and each

requires some adaptation of user skills. Of these, the Transcriber is probably the most efficient and easiest

to use.

Input Methods: Selections and Options (Examples)

Overview Display - Input Selection Display - Input Options

To select an input method, tap the

General Procedures

arrow

at the lower-right of

the display, then tap the name of the

desired input method.

To select an option for the selected

input method, select Settings from the

Start Menu, Input from the Settings

menu, and then select the desired

input options.

Note that the icon next to the selection

arrow changes with the method

selected.

Block Recognizer

Overview Display - Input Selection Display - Input Options

In the Block recognizer, the stylus is

used to write characters into a letter

pad (the box at bottom, on the left) or

a numeric pad (on the right).

The "

?" icon is a link to HELP; the

@$ icon is a link to a table of

symbols.

Release 3 34-ST-25-20 MC Toolkit User Manual 11

9/06

Page 20

Primer for MC Toolkit & SDC 625 Application Software

Letter Recognizer

Overview Empty Text Input Port Completing Entry

In the Letter Recognizer method,

characters are simply selected from a

virtual QWERTY keyboard.

As indicated at right, options include

small keys or large keys. Short-cut

options such as "gestures" (stylus

motion on the screen) and others are

also available via the Settings menu.

Transcriber

Overview Display - Input Selection Display - Input Options

Transcriber facilitates entry of text in

letters, numbers, and entire words.

Extensive HELP is provided for very

handy features.

Page 12 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 21

MC Toolkit Application Software Display Conventions

Navigation

Menu Buttons

In general, selecting a button in a display will call up the next-lower-level display, whose title is the same

or similar to the label on the button. A menu tree for Honeywell DE Displays is given Figure 9, and a

menu tree for HART display is given in Figure 10.

Back Button

In general, selecting the Back button at the bottom of any display will call up the next-higher-level

(previous) display.

In most displays, the Back button is at bottom-right or bottom-center. When it appears at bottom-left,

along with a left-pointing arrow, it indicates that selecting the Back button will necessitate a new Upload

of data from the transmitter to the MC Toolkit (~ 60 seconds).

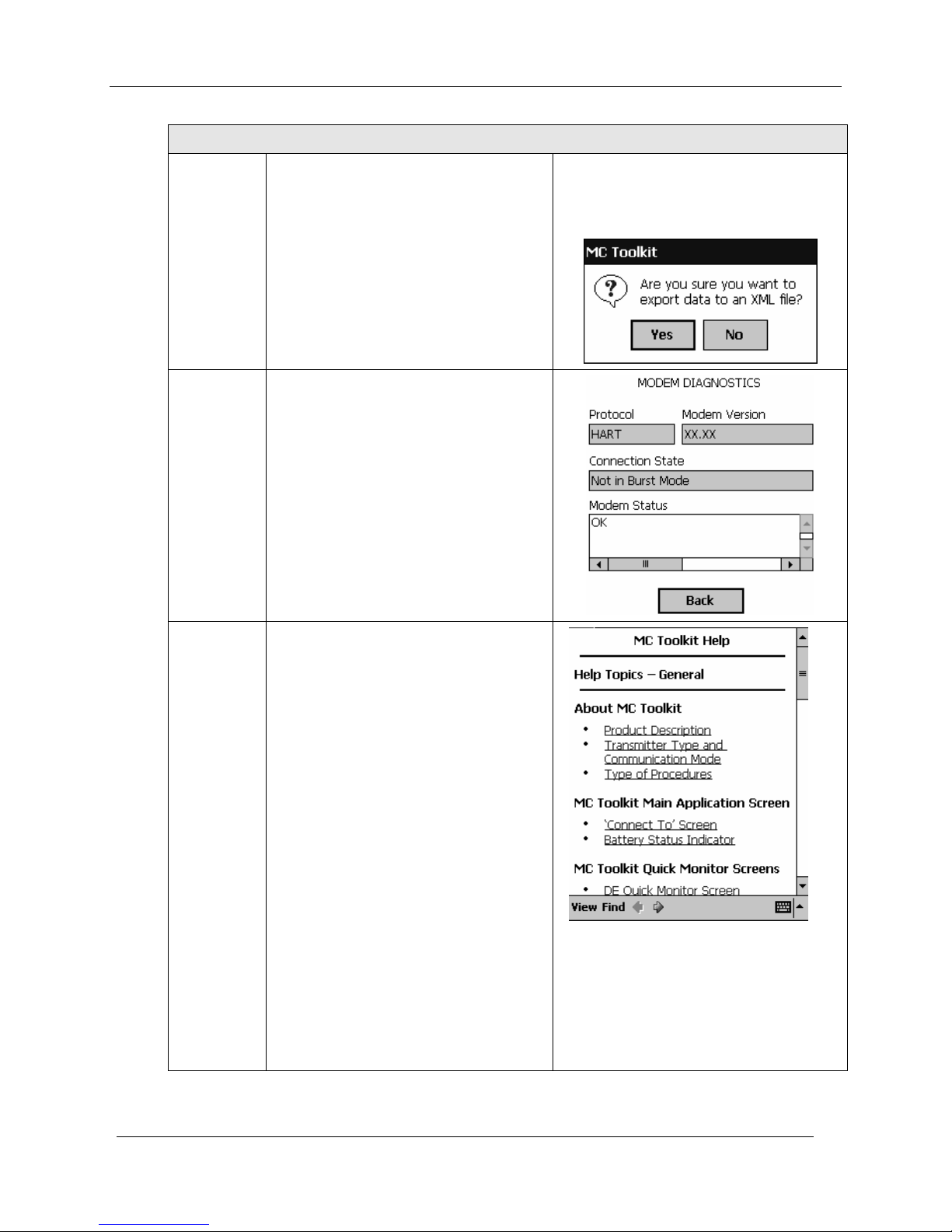

Menu Bar

Menu Bar, Menu Selections, and HELP display

General Procedures

Menu

selections

The menu bar, at the bottom of each

display, enables the user to perform file,

diagnostic, and utility functions.

A typical display is shown below. Menu

selections are shown in detail at right

Release 3 34-ST-25-20 MC Toolkit User Manual 13

9/06

Page 22

MC Toolkit Application Software Display Conventions

Menu Bar, Menu Selections, and HELP display

File

Modem

Diagnostics

HELP

display

Exit

Closes the MC Toolkit application

Export

Enables export of database parameters in

XML format, which can be used by other

programs such as DocuMint. (Refer to the

Reference Data section for more

information.)

The Export selection is not available until a

transmitter database has been uploaded.

In DE Mode, the Connection State may be:

• Analog

• 4 Byte DE

• 6 Byte DE

In HART mode, the Connection State may

be:

• Burst Mode

• Not in Burst Mode

The Help display is available whenever the

MC Toolkit is active.

To export an XML file, select File, Export.

A popup message appears.

Select the

OK button.

It includes three groups of topics, each of

Selectable from the Help Menu

- General

- DE

- HART

Each group includes a list of topics. Each

topic (in blue, underlined letters) is

selectable to provide direct access to the

Help information.

Dragging the cursor in the scrollbar at right

enables viewing of all three groups of

topics. At the bottom of each group, a

Teh

Back to Top selection moves the display to

the beginning of the first group of topics.

Note:

The View, Find and (arrows) selections at

the bottom of the screen apply to the Help

that applies to the Pocket PC, and not to

the MC Toolkit application.

Page 14 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 23

General Procedures

Data Entry and Display

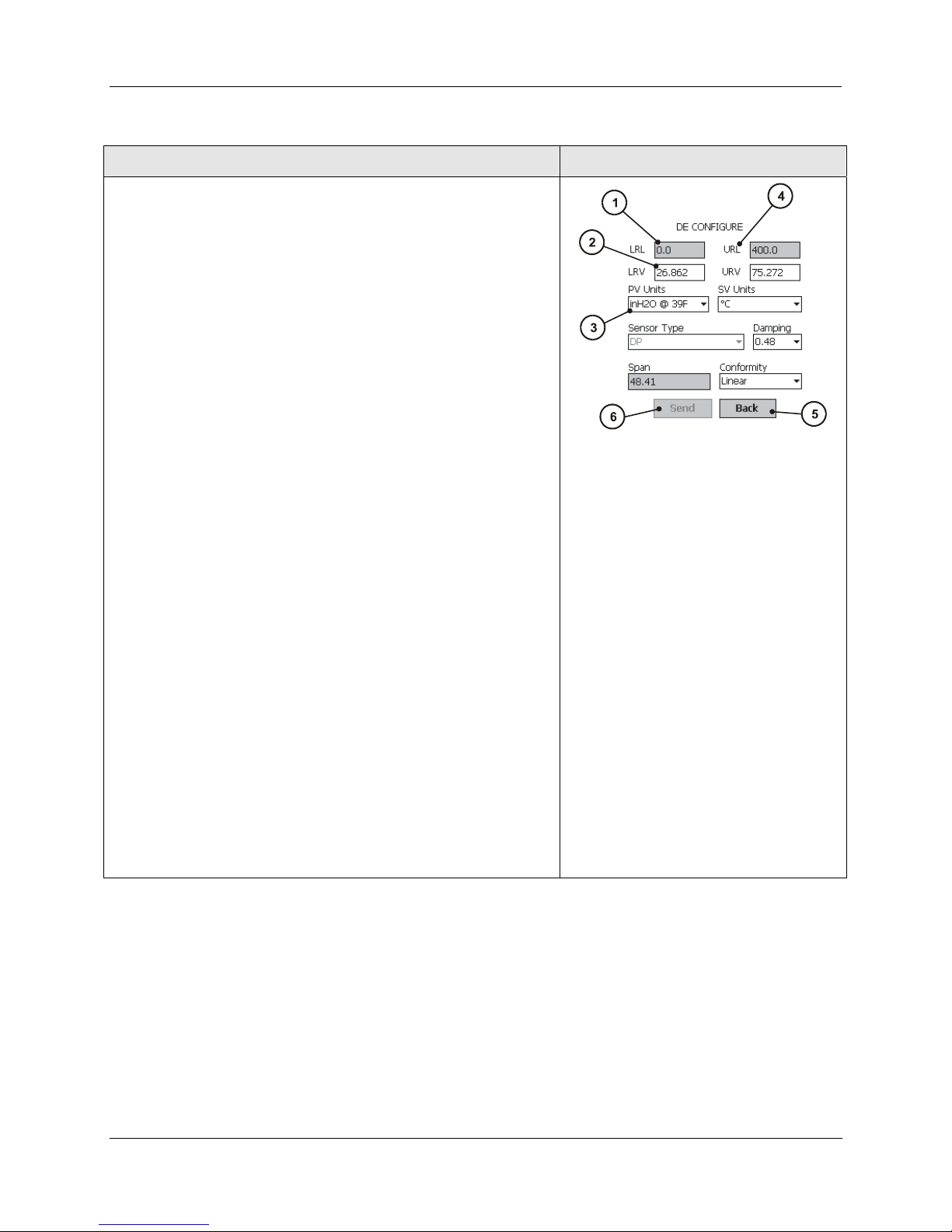

Key number / Description Illustration: Key Numbers

1. Box with no arrow and with gray background indicates a read-

only (R/ ) field. Numeric or text values in transmitter are

displayed only; user entry or modification is not permitted.

2. Box with white background and with no arrow indicates

Read/Write (R/W) text or numeric input field. Values previously

stored in memory (of the transmitter or of the MC Toolkit) are

displayed. The user can enter or modify values using an

appropriate Input Method (e.g., Keyboard).

Entering a new value turns the background yellow, indicating that

the value in the box is different from the value in memory.

When the Send button (6) is selected, the value in the box is

copied to memory in the transmitter, and the background color

returns to white.

If the user exits the screen before using the Send button, the

changes will be ignored.

3. Box with white background and arrow at right indicates a

read/write (R/W) selection list. The value previously selected

and stored in memory is displayed. Selecting the arrow at right

presents a list of available selections, and selecting an item from

the list places it in the selection box.

If the user exits the screen before using the Send button, the

changes will be ignored.

4. The label above the box indicates the meaning of the data inside

the box.

5. The Back button at the bottom of the display causes the display

that was viewed previously to return the screen.

6. The Send button is at half intensity when no values have been

changed. It changes to full intensity when one or more of the

boxes contain a changed value. Selecting the Send button when

it is highlighted will copy all changed values to memory, and the

button will return to half-intensity.

Release 3 34-ST-25-20 MC Toolkit User Manual 15

9/06

Page 24

MC Toolkit Application Software Display Conventions

SDC 625 Application Software Display Conventions

Navigation

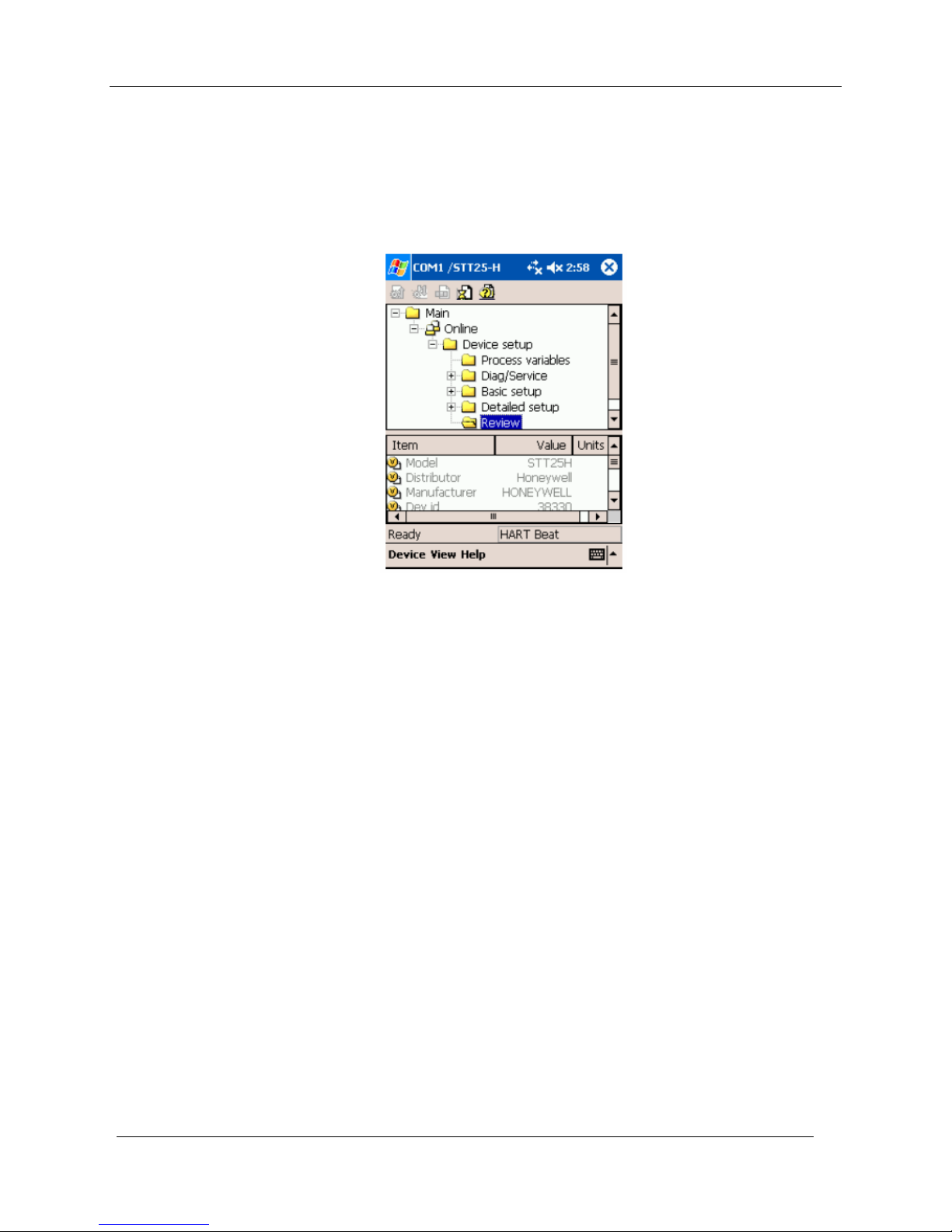

The SDC 625 Menu Bar can be located at the bottom of the Main screen. The menu selection consists of

the Device, View and Help options.

Device

The main purpose of the Device Menu is to Exit the program. Choosing Exit from the Device Menu will

end the SDC 625 program. Choose Preferences in the Device menu to access SDC Port Preferences.

View

The view selection can be used to check device/communication status by selecting Device Condition. One

can also view all HART Device Descriptions (DD) by selecting Available DDs. Device Descriptions,

obtained from the official HART communication CD-ROM, are listed by Manufacturer and Product. For

example, there is a folder listed as Honeywell. ST 3000 is listed as one product of four (with DD) under

this folder. Other Manufacturers with DDs are listed also. If you are working with a HART Device and

cannot find the DD in the list, please contact the Device Manufacturer. You can use the DD Copier

program when the manufacturer provides the device description.

Help

Choosing About SDC 625 will provide the Software Version.

Page 16 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 25

General Procedures

Using MC Toolkit Application Software with Honeywell DE

Introduction

This section contains procedures for using the MC Toolkit application software to communicate with

Honeywell DE Transmitters.

For specific data relating to parameters involved in the procedures, refer to

Transmitters

Reference Data.

Figure 9 Menu Tree - Honeywell DE Displays

Release 3 34-ST-25-20 MC Toolkit User Manual 17

9/06

Page 26

Summary of Operating Procedures

Summary of Operating Procedures

To access displays for Honeywell DE Transmitters:

• Start the MC Toolkit application; the CONNECT TO ... display will appear. (Refer to Figure 8

Start-up - MC Toolkit Application.)

• Upload the database from the transmitter. (The QUICK MONITOR display will enable viewing of

key parameters before taking the time for database uploading.) The DE MAIN MENU appears. (Refer

to Figure 9 Menu Tree - Honeywell DE Displays in this section.)

• Select the appropriate display from the DE MAIN MENU. (Refer to Table 3 DE Main Menu

Procedures in this section, and to the list of DE displays .)

The content of each display is summarized in Table 1.

Table 1 DE Displays / Tasks Summary

Menu Item Task

DEVICE INFO

GENERAL

DE CONFIGURE

CALIBRATION

Enter:

Device Type:

• Tag ID

• Message (in Scratch Pad)

Select:

• PV Type

Enter:

• Comm Mode

• Line Filter (STT)

• T/C Fault Detect (STT)

Select:

• PV Units

• SV Units

• Conformity (ST)

• Damping

• Sensor Type (STT)

• Linear

Enter:

• LRV

• URV

Enter/Select:

• Correct Input (Zero)

• Correct Input (LRV)

• Correct Input (URV)

• Reset Corrects (Zero, LRV, URV)

• Loop Test (Check

• Trim DAC Current (Calibrate

output current)

• Apply Values (that is, re-range

LRV and URV to PV input)

Observe (Read):

• Type

• Serial Number

• Firmware Version

Observe

• Failsafe Direction

Observe

• LRL

• URL

• Span

• Sensor Type (ST)

Observe

• Input at Zero, LRV, and URV

• (Verify) Reset Corrects

• Loop Current (continuity)

• Output Current level (at 0 %,

• Applied values of LRV and URV

(Read):

(Read):

(Read):

100%)

Page 18 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 27

Menu Item Task

LOCAL METER

Select:

• Meter Units (EU)

Enter:

• Custom Units

• (Custom) Flow (EU) value: Upper,

Lower

MONITOR

Auxiliary

Configuration

(STT 3000)

Observe

Select:

• Critical Status Latching

• Write Protection

• NAMUR

• CJ Compensation

Enter:

• CJ Temp

• Password (Write Protection)

• New Password

General Procedures

Observe

(Read):

• Meter Hardware Type

•

(Read):

• Input value

• Output value

• Secondary (Input) value

• Gross Status (code)

• Device Status (Messages)

Observe

(Read):

• High/Low PV Values

Release 3 34-ST-25-20 MC Toolkit User Manual 19

9/06

Page 28

Procedural Considerations

Procedural Considerations

Input calibration

Input calibration of pressure transmitters should be done only when necessary, and should be done only

under conditions that will ensure accuracy:

• The transmitter should be taken out of service, and should be moved to an area with favorable

environmental conditions: clean, dry, and temperature-controlled.

• The source for the input pressure must be very precise, and certified for correct operation.

• The procedures should be done by qualified personnel.

Details of requirements and procedure are given in Table 4.

Output Calibration

The Loop Test procedure is intended as a check for continuity and condition of components in the output

current loop. The Loop Test procedure is given in Table 5.

The Trim DAC Current procedure calibrates the output of the Digital to Analog converter for minimum

(0%) and maximum (100%) values of 4 mA and 20 mA, respectively. This procedure is used for

transmitters operating on-line in analog mode, to ensure proper operation of the transmitter with all

associated circuit components (wiring, power supply, control equipment, etc). It is necessary to use

precision test equipment (an ammeter or a voltmeter in parallel with precision resistor). The Trim DAC

procedure is given in Table 6.

The Apply Values procedure uses actual Process Variable input levels for calibrating the range of a

transmitter. To measure a liquid level for example, a sight-glass can be used to determine the minimum

(0%) and maximum (100%) level in a vessel. The Process Variable is carefully adjusted to stable

minimum and maximum levels, and the LRV and URV values are then set by commands from the MC

Toolkit. The DE Apply Values procedure is given in Table 7.

Page 20 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 29

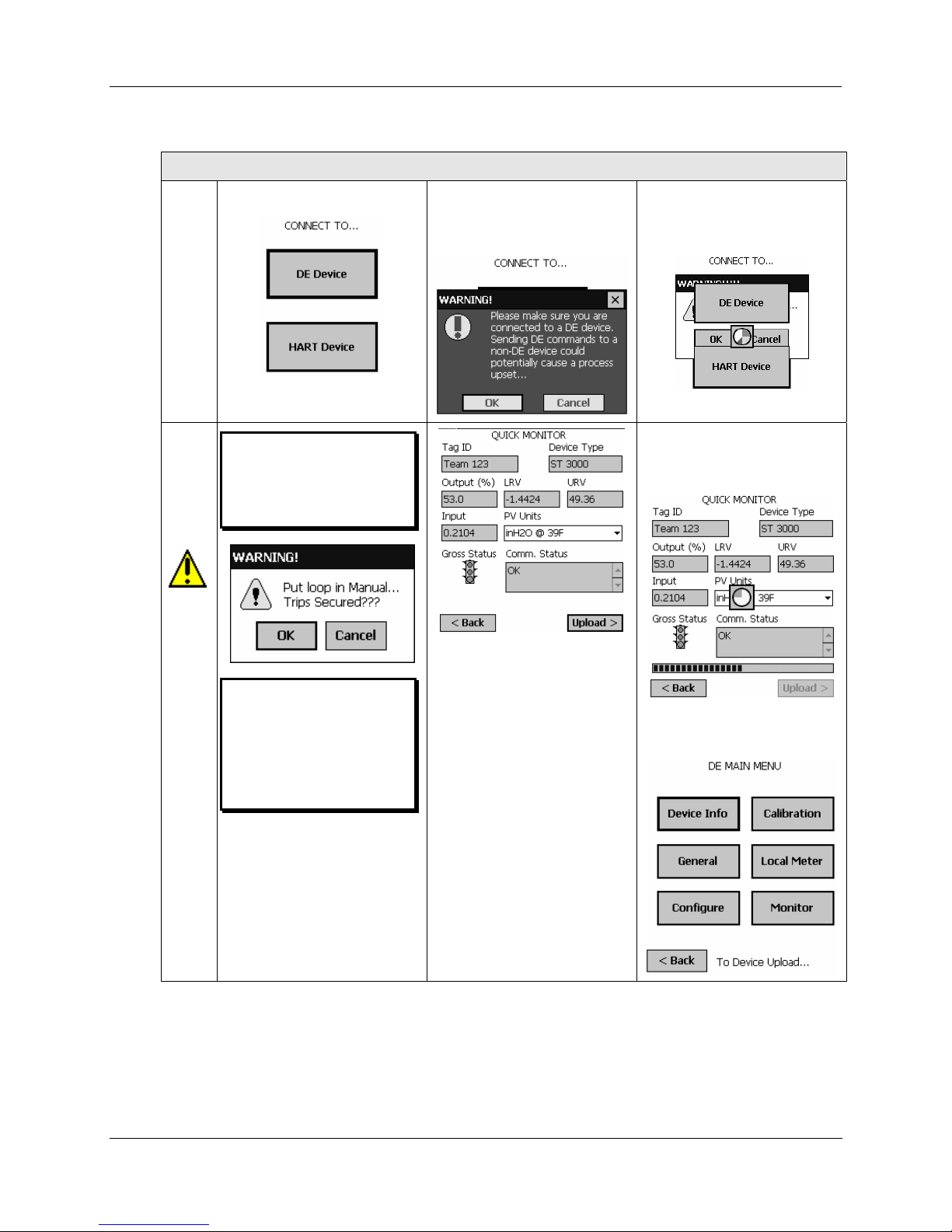

Table 2 DE Upload Procedures

General Procedures

DE Upload Procedures

Note:

This Warning appears only

if the transmitter is

configured for operation in

analog mode.

Select the DE Device button

This Warning message

appears.

If the MC Toolkit is connected

to a DE Device, select the

OK

button.

Select the

Upload button; the

wait cursor and progress bar

appear.

Use this display to

WARNING!

Before proceeding, if the

transmitter is part of a

control loop, ensure that

interlocks and alarms are

secured and that the loop is

in Manual control.

Then, select the OK button in

- Verify device

identification and to

monitor Gross Status

process conditions

- Select the desired Units

for the Process Variable

input using the PV Units

drop-down list.

Then, the Main Menu for an

ST 3000 Transmitter appears.

the popup message. The

display at right appears.

Release 3 34-ST-25-20 MC Toolkit User Manual 21

9/06

Page 30

Procedural Considerations

Table 3 DE Main Menu Procedures

DE Main

Menu

(ST 3000)

DE Main Menu Procedures

(STT 3000)

Note:

This message appears if the

<Back button is selected if

the transmitter was set to

Output Mode (in Calibration

procedures), and the Output

was not later cleared.

Device

Info

General (ST 3000)

Tag ID (r/w)

User ID up to 8 alphanumeric characters (suggestion: relate

to functional process entities and/or plant areas).

Type (r)

Manufacturer's device type identifier (typically, a model

number)

Firmware Version (r)

Manufacturer's Firmware version identifier

Serial Number (r)

Manufacturer

Scratch Pad (r/w)

Up to 32 alphanumeric characters (suggestion: messages

to control room regarding observed/assigned operational

status)

(STT 3000)

PV Type (r/w)

Select: Dual Range

(STDC) or Single Range or

Single Range w/SV

Communication Mode

(r/w) Select: Analog or DE

4 Byte or DE 6 Byte

FS Direction (r)

(Upscale or Downscale;

selection is jumpered in the

transmitter).

Line Filter (r)

Select: 50hz or 60hz.

T/C Fault Detect (r/w):

Select: Enabled or

Disabled.

Page 22 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 31

DE

Configure

General Procedures

DE Main Menu Procedures

ST 3000

LRL (r): Lower Range Limit

URL (r): Upper Range Limit

LRV (r/w): Lower Range Value

URV (r/w): Upper Range Value

PV Units (r/w)

Selection of scaling value (default: inches of H2O@39)

SV Units (r/w)

Selection of scaling value (

Sensor Type (r)

0C/0

F)

Sensor Type associated with the transmitter

Damping (r/w)

STT 3000

Selection of level of digital noise reduction

Span (r)

Process Range (URL - LRL)

Conformity (r/w) (ST 3000)

Selection of conformity to input form: Linear or Square

Root

Linearization (r/w) (STT 3000)

Selection of conformity to input form: Linear or Non Linear

Calibration

Local

Meter

(ST 3000)

For more information, refer

to:

Table 4, Table 5, Table 6,

Table 7.

Meter Hardware (r)

Type designation of meter

associated with the transmitter

Meter Units (r/w)

Selection EUs for Local Meter

Custom Units (r/w)

(Refer to Transmitter User

Manual).

Flow EU Upper Value (r/w)

Selection of standard

Engineering Units for Flow

Upper Value

Flow EU Lower Value (r/w)

Selection of standard

Engineering Units for Flow

Lower Value

Release 3 34-ST-25-20 MC Toolkit User Manual 23

9/06

Page 32

Procedural Considerations

Local

Meter

(ST 3000

example)

DE Main Menu Procedures

Auxiliary

Configure

Monitor

Critical Status Latching

Enabled or Disabled.

Select

NAMUR

Enabled or Disabled.

Select

(Disable requires that Write

Protect is set to Not Write

Protected.)

CJ Temp.

Enter External Cold

Junction Temperature.

Select the

Read HI/LO

button to call up the READ

HIGH/LOW PV display.

SV (r)

Secondary Variable in

Engineering Units

Gross Status (r)

Gross transmitter status.

Select the

Device Status

button to call up the Device

Status display.

Select the Read button to

display the lowest and the

highest PV values since last

read.

Input (r)

Sensor input in Engineering

Units

Output (r)

Loop output as percent of

Span

Page 24 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Communication Status (r)

For status information, refer

to the section on

Messages and

Diagnostic Codes.

Page 33

General Procedures

Table 4 Input Calibration (DE Transmitters) - Correct Input (Zero), LRV, URV; Reset

Corrects

Input Calibration (De Transmitters) - Correct Input (Zero), LRV, URV; Reset Corrects

Requirements:

• Input source, with accuracy of at least

0.04%

• resistor, at least 250-ohms

• Voltmeter or Ammeter

• 24 Vdc Power Supply (nominal)

• Clean work area with suitable

environmental conditions.

• Pressure Transmitter must be level.

Overview of Procedures:

The Zero-Correct procedure establishes the

correct vertical positioning of the response

profile.

The LRV Correct and URV Correct

procedures establish the correct slope of the

response profile in the process operating

range by rotating the response profile

around the zero-reference point as a pivot.

The Zero-Correct procedure can be done at

any time during the Correct LRV and

Correct URV procedures in the same

calibration session.

The Correct LRV and Correct URV

procedure should never be performed

without first performing the Correct Input

(Zero) procedure in the same calibration

session.

Objective(s):

Using a precision PV input source as a reference, command

the transmitter to write calibration coefficients to NonVolatile Memory associated with transmitter input

hardware and software.

• Correct Input (Zero)

• Correct LRV

• Correct URV

Release 3 34-ST-25-20 MC Toolkit User Manual 25

9/06

Page 34

Procedural Considerations

Input Calibration (De Transmitters) - Correct Input (Zero), LRV, URV; Reset Corrects

Set-Up On Bench

A typical bench set-up is shown at right.

Connect the MC Toolkit as indicated, and

establish communication with the

transmitter.

For these procedures, components in the

current loop are not critical, provided that

they support reliable communication

between the transmitter and the MC Toolkit.

If a Honeywell ST 3000 Pressure

Transmitter is being calibrated, positioning

(leveling) is important, because the meter

body contains fluids that can affect zero

sensing.

Enter

(configure)

values for

LRV and

URV

From the DE MAIN MENU, select Configure to call up the

DE CONFIGURE display.

a. Use the

PV Units to select the appropriate Engineering

Units.

b. Using the keyboard, enter the desired LRV and URV

values.

c. Select the Send button to copy all newly entered values to

the transmitter. When the copy operation is complete,

Send will be displayed in half intensity.

Page 26 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 35

Input Calibration (De Transmitters) - Correct Input (Zero), LRV, URV; Reset Corrects

Call up

Calibration

display

Correct

Input at

Zero

Navigate to the DE

Calibration display as

follows.

Select Back (go to DE Main

Menu), then select the

Calibration button.

Select Corr. Input (zero).

This message appears.

General Procedures

As indicated below, this procedure will shift the slope up

or down to eliminate the error at the zero reference. The

slope (angle) of the response is unchanged.

NOTE:

The PV Input (Zero) refers

to a known standard such

as zero pressure (e.g.: vent

`

both sides of a DP

transmitter).

Select Yes in the message box

above; this message appears.

At this point, ensure that the value of the PV applied at the

input is exactly Zero.

Then, select the OK button in the popup message.

This action sends the Correct Input (Zero) command to the

transmitter, which adjusts the input calculation.

Wait until this message

appears.

When the transmitter has

completed the Zero

Correction, this message

appears.

Select the

OK button to

acknowledge.

Release 3 34-ST-25-20 MC Toolkit User Manual 27

9/06

Page 36

Procedural Considerations

Input Calibration (De Transmitters) - Correct Input (Zero), LRV, URV; Reset Corrects

Correct

Input at

LRV

(ST 3000)

Select the

button. This message appears.

Adjust the PV input pressure

to the exact value of the LRV

entered in the DE

CONFIGURE display.

Correct LRV

Select the

OK button; this

message appears.

Observe the input pressure

at the applied value; when

it is stable, select the

button.

OK

When the transmitter has

completed the LRV

correction, this message

appears.

Select

OK to

acknowledge.

Correct

Input at

LRV

(STT 3000)

Correct

Input at

URV

(ST 3000)

Correct

Input at

URV

(STT 3000)

Select the Correct LRV

button. This message appears.

Select the

Correct URV

button. This message appears.

Select the Correct URV

button. This message appears.

Adjust the input

temperature to the exact

value of the LRV entered in

the DE CONFIGURE

display.

Adjust the PV input

pressure to the exact value

of the URV entered in the

DE CONFIGURE display.

Select the

OK button.

Adjust the input

temperature to the exact

value of the URV entered

in the DE CONFIGURE

display.

Select the

OK button; this

message appears.

Select the

OK button to

acknowledge

When the transmitter has

completed the URV

correction, this message

appears.

OK to

Select

acknowledge.

Select the

OK button; this

message appears.

Page 28 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Select the

OK button to

acknowledge

Page 37

General Procedures

Input Calibration (De Transmitters) - Correct Input (Zero), LRV, URV; Reset Corrects

Reset

Corrects

Note:

This function commands

the transmitter to

overwrite all user input

corrections with factory

default

("characterization")

values.

It is intended for use only

when excessive

corrections render the

transmitter inaccurate.

If corrects should not be

overwritten with factory

values, select the

No button.

If corrects need to be

overwritten, select the

button. The timer will

appear briefly, indicating the

operation is performed.

Yes

Release 3 34-ST-25-20 MC Toolkit User Manual 29

9/06

Page 38

Procedural Considerations

Table 5 Output Calibration - Loop Test

Output Calibration - Loop Test

Objective

Loop Test

Verify the integrity of

electrical components in

the output current loop.

Connect the MC Toolkit

as indicated, and establish

communication with the

transmitter.

For these procedures,

values of components in

the current loop are not

critical, provided that

they support reliable

communication between

the transmitter and the

MC Toolkit.

In the Output Calibration

box, select the

Loop Test

button; the display at

right appears.

Select the desired

constant-level Output:

%, 100 %, or Other (any

0

of 0 % - 100 %).

Select the

Select the

Set button.

Yes button, and

observe the output current at

0%, 100%, or Other (userentered) %.

Note:

If the transmitter is in

Analog mode, you can

observe the output on

an externally

connected meter or on

a Local Meter.

To view the Monitor display,

navigate Back from the

LOOP TEST display and

select the MONITOR

display.

This popup appears; select

Yes to continue.

Example:

DE output (100 %), as

viewed on the MC Toolkit.

In DE Mode, the

output can be observed

on the Local Meter or

on the Monitor display

on the MC Toolkit.

Page 30 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 39

Example

Output Calibration - Loop Test

The displays at right

illustrate a

Set Output

selection and setting of

Other, at 57 %.

General Procedures

!!

Unintended

exit in

Output

Mode?

!!

Caution:

If Yes was selected as

above in the

CONFIRM! popup

message, it is possible

to exit MC Toolkit

application while the

Output is fixed at

constant current.

This message at right

appears if the user performs

an operation on the MC

Toolkit that will terminate

the connection to the

transmitter while the

transmitter is in output mode.

Select

Yes button only if

constant-current Output with

the MC Toolkit is intended.

Otherwise, select the No

button, go back to the LOOP

TEST display, and select the

Clear Output button.

Release 3 34-ST-25-20 MC Toolkit User Manual 31

9/06

Page 40

Procedural Considerations

Table 6 DE Output Calibration - Trim DAC Current

DE Output Calibration - Trim DAC Current

Overview

of

Objectives

For a DE transmitter operating in analog mode in a user's application, calibrate the analog

output current to the PV input range. That is, adjust the output such that 4 mA corresponds

to 0% (LRV), and 20 mA corresponds to 100% (URV).

Call up

display

In the DE MAIN

MENU, select the

Calibration button.

Select the Trim DAC Curr.

button; this display appears.

The CALIBRATION

menu appears.

Page 32 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 41

DE Output Calibration - Trim DAC Current

General Procedures

Trim

Output

Current

Select the

Set Output To 0% button or the 100% button.

The message popup at right appears.

Caution:

In Output Mode, output current is fixed at 0% or

100%. Ensure that the loop is in Manual control.

Select the Yes button, and at the meter, observe the level

of loop current.

NOTE:

On the voltmeter, 4 mA corresponds to 1 volt.

Using the MC Toolkit, adjust the loop current to the

Zero Percent level (4 mA). If the current is low, tap the

Increment button; if it is high, tap the Decrement

button, and observe the change on the meter.

NOTE:

If the error is large, you can accelerate the

adjustment rate by changing the Step Size to 10 or

to 100.

When the zero current level (4 mA) is achieved, select

the Set Output To 100 % button.

NOTE:

On the voltmeter, 20 mA corresponds to 5 volts.

Change

display

while in

Output

Mode

Use the Increment and/or Decrement buttons to adjust

the output current to 20 mA.

When the 100% current level (20 mA) is achieved,

select the Clear Output button. (Note that the button

changes to half intensity.)

If you select the Back button before selecting the Clear

Output button, the display at right will appear.

If you are sure that you want to remain in Output Mode

while viewing other displays, select the

Yes button;

otherwise, select the No button, and the Clear Output

button

Release 3 34-ST-25-20 MC Toolkit User Manual 33

9/06

Page 42

Procedural Considerations

Table 7 DE Calibration - Apply Values

DE Calibration - Apply PV values to Set LRV and Set URV

Overview

of

Objectives:

• Manually set the Process Variable input to 0%, and apply this value to Set LRV;

• Manually set the Process Variable input to 100%, and apply this value to Set URV.

NOTE:

This procedure applies to DE Transmitters operating in DE Mode as well as to those

operating in Analog (current) Mode.

On the DE MAIN MENU,

select the

Calibration

button.

In the Apply Values group,

select the

Set LRV button.

The popup message at right

appears.

Note:

The value of the Input

indicated in this message

updates only when the

popup message is called

up.

To update this value,

select the No button, and

again select the Set LRV

button in the

CALIBRATION

display.

Page 34 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 43

DE Calibration - Apply PV values to Set LRV and Set URV

Set LRV

Set URV

Verify

settings

While observing the PV value at the physical process

element, (using a sight glass, for example) adjust the

Process Variable to the desired Minimum (0 %) level,

then select Set LRV

If the displayed value is satisfactory, select Yes to

copy the Input Value to the LRV in the transmitter. If

not, select NO and repeat this step.

While observing the PV value at the physical process

element, (using a sight glass, for example) adjust the

process variable to the desired Maximum level, then

select Set URV.

If the displayed value is satisfactory, select Yes to

copy the Input Value to the URV in the transmitter. If

not, select NO and repeat this step.

The results of the

Set LRV and Set

URV actions can be

verified by calling

up the DE

CONFIGURE

display.

Release 3 34-ST-25-20 MC Toolkit User Manual 35

9/06

Page 44

Introduction

MC Toolkit Software with Honeywell HART Transmitters

Introduction

This section contains procedures for using the MC Toolkit application software to communicate with

Honeywell and non-Honeywell Transmitters with HART communications protocol. In some cases, the

Honeywell transmitters differ somewhat from non-Honeywell transmitters, separate procedures are

provided as appropriate. It is recommended that you use SDC 625 application software when

communicating with non-Honeywell devices. For specific data relating to parameters involved in the

procedures, refer to

Reference Data.

Figure 10 Menu Tree - Honeywell HART Displays

Page 36 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 45

MC Toolkit Software with Honeywell HART Transmitters

Figure 11 Menu Tree: non-Honeywell HART Displays

Release 3 34-ST-25-20 MC Toolkit User Manual 37

9/06

Page 46

General Procedures

Honeywell HART Transmitters

Figure 12 HART Menus (Display Summary)

Other HART Transmitters

General Procedures

To access displays for HART Transmitters:

• Start the MC Toolkit application; the CONNECT TO ... display will appear. (Refer to Figure 8

Start-up - MC Toolkit Application).

• Upload the database from the transmitter. (Refer to Table 9 in this section.)

− (The QUICK MONITOR display will enable viewing of key parameters before beginning other

procedures.)

− The HART MAIN MENU appears.

• Select the appropriate display from the HART MAIN MENU. (Refer to Table 10 Honeywell HART

Main Menu Procedure in this section, and to the following task list.)

NOTE:

Although some of the MC Toolkit displays (and procedures) for Honeywell transmitters differ from those

for non-Honeywell transmitters, the MC toolkit automatically provides the appropriate displays. Although

the user is not required to make any selections in the displays, he must be aware of transmitter type to select

the appropriate procedures in this manual.

Page 38 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 47

MC Toolkit Software with Honeywell HART Transmitters

Table 8 HART Displays / Tasks Summary

Menu Item Task

DEVICE INFO

BASIC SETUP

OUTPUT

CONDITION

ALARM (STT 3000)

DIAGNOSTICS

/SERVICE

CALIBRATION

Enter:

Device Type:

• Tag ID

• Message

• Descriptor

Enter:

• LRV

• URV

Select:

• Damping

• PV Sensor Units (ST 3000,

STT25H, Generic

• PV1 & PV2 Units(STT25T)

• SV units (ST 3000)

• Transfer Function (ST 3000,

Generic)

• CJT Units (STT25H, STT25T)

• PV Units Type (Generic)

Select:

• Poll Adrs (0-15)

• Scaled D/A Trim (Output

Calibration procedure)

• NAMUR (STT 3000)

Select:

• Break Detect (STT25H)

• Latching Alarm

• Clear Latching

• XS Delta Detection (STT25T

Select (Procedure):

• Master Reset

• Device Status

• Monitor (Output: mA, %; PV, PV2

[STT25T}, SV)

• Write Protect (Enter/Change

Password) (STT25H)

Select (Procedure):

Input Calibration

• Zero Trim (ST 3000 and Generic)

• Correct Input LRV (ST3000 and

STT25H)

• Correct Input URV (ST3000 and

STT25H)

• Reset Corrects (ST3000 and

STT25H)

Output Calibration

• Loop Test

• D/A Trim

Input (Re-Range to PV)

• Apply Values (LRV, URV)

Observe (Read):

• Model

• Device ID

• Manufacturer

Observe

(Read):

• LRL

• URL

• Sensor Type (ST 3000)

Observe

(Read):

• PV Output

• PV2 (STT25T)

• Alarm Direction

• Requested Preambles

Release 3 34-ST-25-20 MC Toolkit User Manual 39

9/06

Page 48

Procedural Considerations

Menu Item Task

Local Meter

(ST 3000 only)

Sensor

(STT 3000)

EXTENDED INFO

DYNAMIC VARS

BURST MODE

SPEC. MONITOR

Select:

• Meter Units (EU)

Enter:

• Custom Units (conversion constant)

• (Custom) EU Flow: Low/High

Select:

• Sensor Type

• Line Filter

• CJ Mode Comp

• Mode Selection (STT25T)

• Match PV’s (STT25T)

Observe (Read):

Enter:

• Primary Variable Code

• Secondary Variable Code

• Tertiary Variable Code

• Quaternary variable Code

Select:

• Burst Mode

• Burst Options

Select:

• No. of Var's Query

• Device variable

Observe

• Meter Type

Observe

• RTD Wire Selection (STT25H)

• Universal Rev.

• Software Rev.

• Field Device Rev.

• Poll Address

• PROM ID

• # Req. Preams

• PV Sensor S/N

• Final Assembly #

Observe (Read)_:

• Values of selected variables

(Read):

(Read):

Procedural Considerations

The details of procedures vary with device type. This section contains a set of procedures for Honeywell

HART Transmitters, and separate set of procedures for non-Honeywell HART devices.

Input Calibration

Input calibration of transmitters should be done only when necessary, and should be done only under

conditions that will ensure accuracy:

• The transmitter should be taken out of service, and should be moved to an area with favorable

environmental conditions: clean, dry, and temperature-controlled.

• The source for the input pressure must be very precise, and must be certified for correct operation.

• The procedures should be done by qualified personnel.

For Honeywell HART devices, input calibration procedures are given in Table 12 through Table 14, and

for non-Honeywell HART devices, consult the manufacturer’s User Manual..

Page 40 34-ST-25-20 MC Toolkit User Manual Release 3

9/06

Page 49

Output Calibration