Page 1

MCR 200 - SERVICE INSTRUCTIONS

CONTENTS

HEATING CONTROL

HEAT CONSUMERS........................................................................................................................................................... 3

HEATING CIRCUIT CONTROL........................................................................................................................................... 5

Time program ........................................................................................................... 3

Outside temperature controlled cut-off ..................................................................... 3

Room temperature controlled cut-off........................................................................ 4

Optimization.............................................................................................................. 4

Outside temperature controlled flow temperature control......................................... 5

Heating characteristic .......................................................................................... 5

Automatic adaptation of the heating characteristic .............................................. 7

Room temperature control......................................................................................13

Limitation of the heating up speed.....................................................................14

Maximum limitation of the room temperature..................................................... 14

Minimum limitation of the room temperature...................................................... 14

Overtime compensation with TF 26 ................................................................... 14

Overtime compensation via room sensor input.................................................. 15

Statistics................................................................................................................. 15

Determining the number of degree days............................................................ 15

Counter for operating hours ............................................................................... 15

External temperature demand ................................................................................ 16

Overlapping mixing circuit functions, sensors, device connections ................... 17

Passing on the outside temperature sensor value through the C bus ............... 17

Signal: Hot water priority switching and system overheating,

corrosion protection .............................................................................. 17

Janitor function, heating limits ................................................................................ 18

Flow temperature control........................................................................................ 19

Setpoint ramp (flow temperature)....................................................................... 19

Limitations, special functions.................................................................................. 20

Limitation of the heating flow temperature - minimum and maximum................ 20

Pump logic ......................................................................................................... 20

Boiler excess...................................................................................................... 20

Screed drying heating function according to DIN 4725/T4................................. 20

Protective functions................................................................................................ 21

Frost protection.................................................................................................. 21

Pump actuation.................................................................................................. 21

Mixing valve and pump forced operation ........................................................... 21

Domestic hot water control ..................................................................................... 22

Standard control................................................................................................. 22

Domestic hot water priority settings ................................................................... 22

Domestic hot water charging pump.................................................................... 22

Pump forced operation....................................................................................... 23

BOILER / BOILER SEQUENCE CONTROL ..................................................................................................................... 24

(EN\2R\EN2R1120.DOC) 01.04.98

Setpoint setting....................................................................................................... 24

1. Flow temperature demand from other MCR 200 controllers

through the LC or C bus................................................................................. 24

2. Flow temperature demand through analog voltage signal

(only for MCR 200-71).................................................................................... 24

3. Flow temperature demand by floating normally open contact

(only for MCR 200-71).................................................................................... 25

4. Minimum demand (only MCR 200-71) ........................................................... 27

5. Flow demand by EXCEL 5000 system.......................................................... 27

6. Flow demand by an internal heating circuit program HKZ ............................ 27

Setpoint formation .................................................................................................. 28

Excess................................................................................................................ 28

Limitations.......................................................................................................... 28

Minimum limitation / Boiler corrosion protection ................................................ 28

Maximum limitation / Boiler overheating (for single boiler)................................. 28

Boiler overheating for boiler sequence (MCR 200-71 only ................................ 28

Return temperature limitation control ..................................................................... 29

Minimum switch-on time of the burner (Code 706 / 806) ................................... 29

Minimum switch-off time of the burner (Code 707 / 807) ................................... 29

1 EN 2R-1120

Page 2

MCR 200 - SERVICE INSTRUCTIONS

Total shutdown of the boiler (Code 703 / 802) ................................................... 29

Boiler sequence exchange (only MCR 200-71).................................................. 29

Leading boiler .................................................................................................... 30

Parallel / sequential boiler sequence ................................................................. 30

Outside temperature blockage of the 2nd boiler................................................ 30

Strategy function (only MCR 200-71) ..................................................................... 31

Heating up time (Code 921)............................................................................... 31

Gradient waiting time (Code 708 / 808) ............................................................. 31

Overheating of strategy temperature ................................................................. 31

Control range strategy (Code 914)..................................................................... 32

PID method (only MCR 200-71) ............................................................................. 34

Starting circuit for modulating burner (MCR 200-71/22)......................................... 34

Boiler control for single-boiler systems:.................................................................. 35

Boiler sensor / Sensor detection:....................................................................... 35

Outside sensor:.................................................................................................. 35

Pump run-on time (only MCR 200-71) ............................................................... 35

Using a heating controller as boiler return temperature controller ..................... 35

Alarms / Faults........................................................................................................ 36

Burner fault ........................................................................................................ 36

Boiler pump fault ................................................................................................ 36

Status displays in the.............................................................................................. 36

operating sequence................................................................................................ 36

WE (total heat generator / strategy) only for MCR 200-71................................. 36

WE1 / WE2 ........................................................................................................ 36

DISTRICT HEATING CONTROLLER...................................................................................................... .......................... 37

Return temperature limitation ................................................................................. 37

Return interval flushing........................................................................................... 38

100 % function........................................................................................................ 38

Control parameters for district heating valve.......................................................... 39

Unmixed domestic hot water storage tank control.................................................. 39

Manuelle Warmwasserladung............................................................................ 39

Switch on conditions for the secondary loading pump....................................... 39

Sollwertbegrenzung Warmwasserladung........................................................... 39

Protection against calcification........................................................................... 40

Boiler or flow temperature requirement of the hot water control ....................... 40

Minimum valve lift for incidental amount suppression........................................ 40

Heat meter connection ........................................................................................... 41

Electrical connection.......................................................................................... 41

Computing the heat power and the volume flow.................................................... 42

AIR CONDITION CONTROL........................................................................................................................................................ 43

HARDWARE ................................................................................................................................................................................ 44

COMMUNICATION

CONTROLLER TO CONTROLLER SIGNALS .................................................................................................................. 45

MCR 200 Fax Controller...................................................................................... 46

MCR 200 Voice Controller................................................................................... 47

MCR 200 EXCEL................................................................................................. 47

C-Bus................................................................................................................. 47

Outside temperature indications............................................................................. 48

INSTALLATION CHECKLIST ...................................................................................................................................................... 49

CODE TABLES............................................................................................................................................................................ 50

EN 2R-1120 2

01.04.98 (EN\2R\EN2R1120.DOC)

Page 3

MCR 200 - SERVICE INSTRUCTIONS

HEATING CONTROL

Heat consumers

Time program

Different room temperatures can be selected in the time program of the MCR 200.

According to setting, one refers to heating operation (normal operation), tempera-

ture reduction (reduced operation) or cut-off. MCR 200 has time programs for every

mixing circuit for the switching points of which an individual setpoint can be set.

Example:

gymnastics hour in a multipurpose building (heating operation). In school sports

events on the other hand, a setpoint of 18 °C can be set. The heating is then oper-

ated reduced.

The corresponding time program looks like the following:

09:00 Setpoint 21 °C

10:00 Setpoint 18 °C

The heating can also be switched off with the time program for optimizing the en-

ergy consumption. The heating circuit pump is switched off and the mixing valve

closed for this purpose. If the heating is switched off, only frost protection functions

which prevent the heating system freezing are active.

So that the heating is switched off, the optimization for heating up must be switched

on in the time program.

Example:

09:00 Setpoint 21 °C Opt: yes

10:00 Setpoint 18 °C Opt: no

12:00 Setpoint 15 °C Opt: yes

According to the temperature sensors present, the controller switches off outside

temperature controlled or room temperature controlled.

A room temperature of 21 °C should be guaranteed in the senior citizens

after the school sports, the heating is switched off completely.

optimized heating up,

so that 21°C are reached

by 9.00 am

only reducing the room

setpoint to 18 °C

early cut-off

Outside temperature controlled cut-off

(EN\2R\EN2R1120.DOC) 01.04.98

So that the residual heat of the building is utilized optimally, the heating switches on

or off already before the switching points. Naturally the time period for optimization

with room temperature sensor is calculated depending upon the momentary tem-

peratures. In the case of optimization without room temperature sensor, the time

period is calculated only depending upon the outside temperature.

The outside temperature controlled cut-off function is activated if no room tempera-

ture sensor is present and "

If the outside temperature drops below the frost protection limit of 2 °C, for in-

stance, the heating circuit pump is switched on. The flow temperature is controlled

so that the heating system does not freeze.

3 EN 2R-1120

Opt: yes

" is selected.

Page 4

MCR 200 - SERVICE INSTRUCTIONS

Room temperature controlled cut-off

Optimization

The room temperature controlled cut-off function is activated automatically if a

room temperature sensor is connected to the corresponding heating circuit and

"

Opt:yes"

If the time program switches the heating off, the control is switched over to room

temperature control. In this way the heating is switched off in the night until the

temperature has dropped to the corresponding setpoint. To avoid the room cooling

down too much, the pump is switched on and the mixing valve opened.

If the outside temperature drops below the frost protection limit of 0 °C, for in-

stance, the heating circuit pump is switched on continuously.

The switching times of the time program can be shifted corresponding to the tem-

peratures to opimize the energy consumption. Since there can be heating circuits

without room temperature sensors, a distinction is made between optimization with

room temperature sensor and optimization without room temperature sensor.

CODE - 133 - 233 - 333 - 433

Room temperature sensor for optimization

=1

=0

is selected. (The

→

→

Optimization with room temperature sensor

Optimization without room temperature sensor

Code No. 133, 233, 333, 433

must also stand at 1).

EN 2R-1120 4

01.04.98 (EN\2R\EN2R1120.DOC)

Page 5

MCR 200 - SERVICE INSTRUCTIONS

Heating circuit control

Outside temperature controlled

flow temperature control

The heating circuits serve for temperature control with a mixing valve. The following

controls can be implemented by setting code values:

CODE 117 - 217 - 317 - 417

Type of control

=2

=1

=3

=4

=5

The MCR 200 control units are set in the factory as outside temperature controlled

flow temperature control, i.e. a certain flow temperature is assigned to each outside

temperature by the heating characteristic. If a room temperature sensor is con-

nected in addition, then the controller can automatically set (adapt) its heating

characteristic. The room temperature can be set for different requirements with a

time program. The night cut-off and optimizing the switching times enables energy

to be utilized optimally.

→

→

→

→

→

Outside temperature controlled flow temperature control

Room temperature control

Constant flow temperature control,

internal 0...10 V signal

External requirement with switching contact, outside

temperature controlled

External requirement with switching contact, independent of

outside temperature

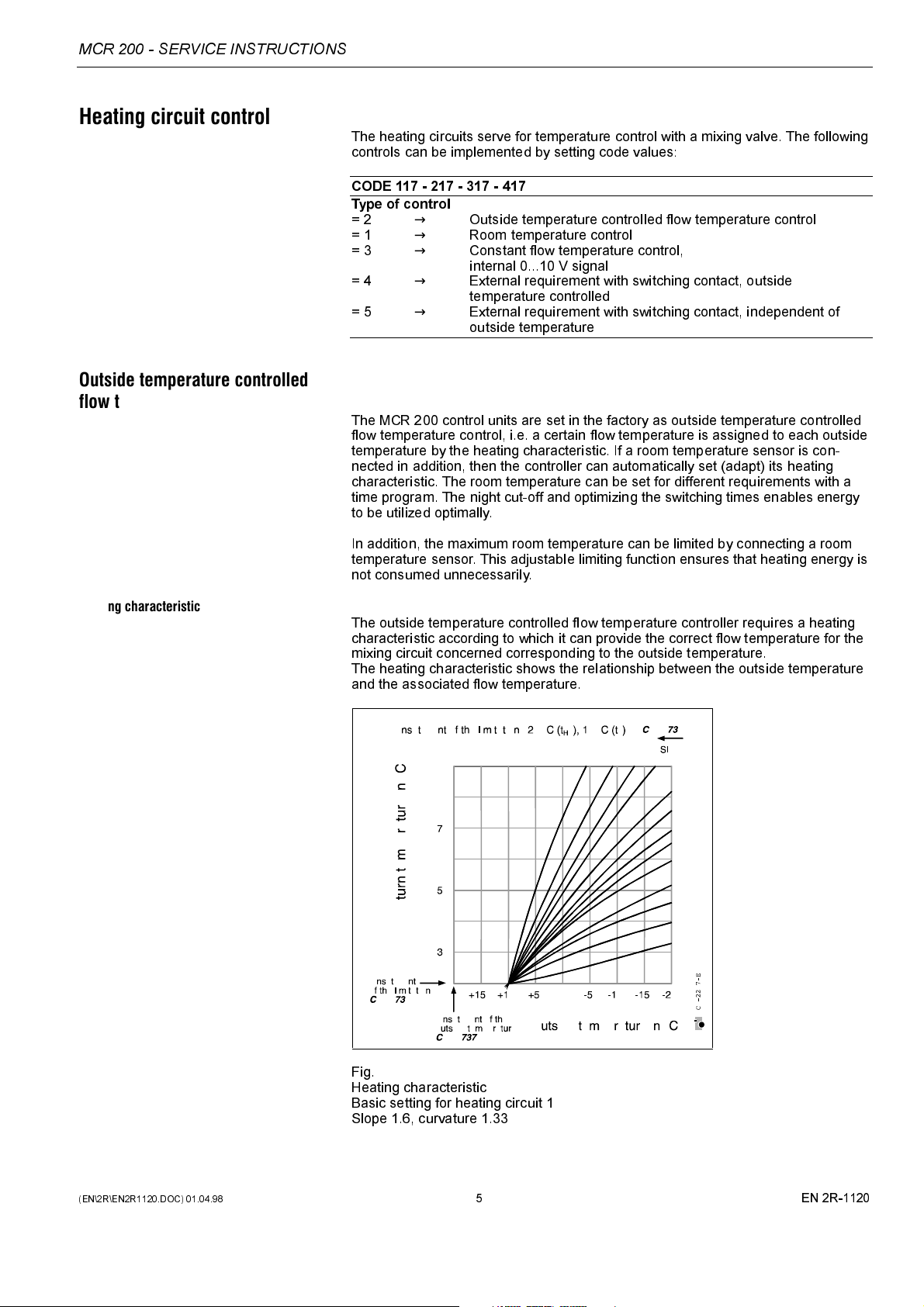

Heating characteristic

In addition, the maximum room temperature can be limited by connecting a room

temperature sensor. This adjustable limiting function ensures that heating energy is

not consumed unnecessarily.

The outside temperature controlled flow temperature controller requires a heating

characteristic according to which it can provide the correct flow temperature for the

mixing circuit concerned corresponding to the outside temperature.

The heating characteristic shows the relationship between the outside temperature

and the associated flow temperature.

(EN\2R\EN2R1120.DOC) 01.04.98

Fig.

Heating characteristic

Basic setting for heating circuit 1

Slope 1.6, curvature 1.33

5 EN 2R-1120

Page 6

MCR 200 - SERVICE INSTRUCTIONS

Basic setting

Setting recommendation

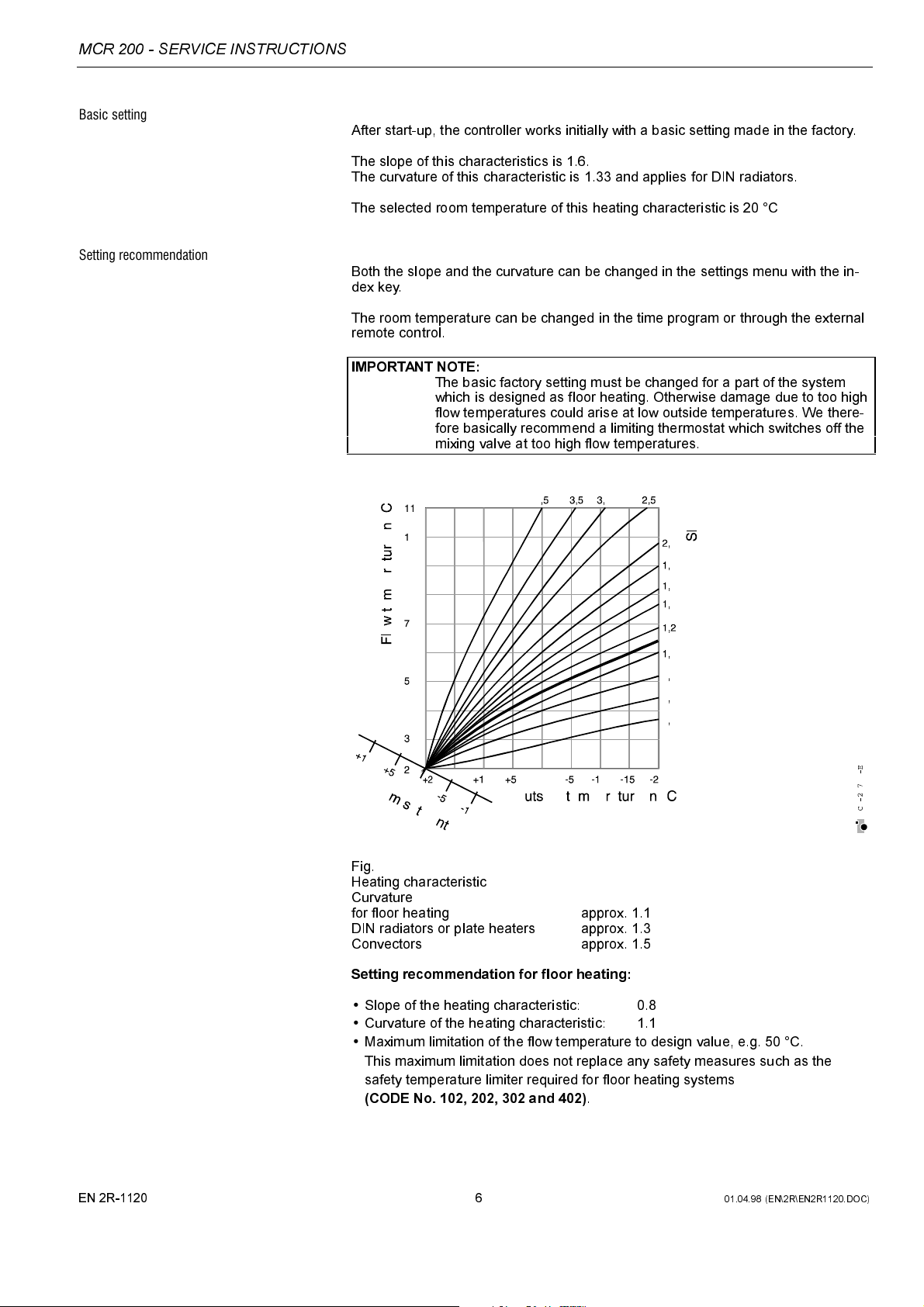

After start-up, the controller works initially with a basic setting made in the factory.

The slope of this characteristics is 1.6.

The curvature of this characteristic is 1.33 and applies for DIN radiators.

The selected room temperature of this heating characteristic is 20 °C

Both the slope and the curvature can be changed in the settings menu with the in-

dex key.

The room temperature can be changed in the time program or through the external

remote control.

IMPORTANT NOTE:

The basic factory setting must be changed for a part of the system

which is designed as floor heating. Otherwise damage due to too high

flow temperatures could arise at low outside temperatures. We there-

fore basically recommend a limiting thermostat which switches off the

mixing valve at too high flow temperatures.

Fig.

Heating characteristic

Curvature

for floor heating approx. 1.1

DIN radiators or plate heaters approx. 1.3

Convectors approx. 1.5

Setting recommendation for floor heating:

•

Slope of the heating characteristic: 0.8

•

Curvature of the heating characteristic: 1.1

•

Maximum limitation of the flow temperature to design value, e.g. 50 °C.

This maximum limitation does not replace any safety measures such as the

safety temperature limiter required for floor heating systems

(CODE No. 102, 202, 302 and 402)

EN 2R-1120 6

.

01.04.98 (EN\2R\EN2R1120.DOC)

Page 7

MCR 200 - SERVICE INSTRUCTIONS

Automatic adaptation of the heating characteristic

The basic setting does not have to be changed for all other types of system in

which higher flow temperatures are permitted. The controller corrects the heating

characteristic by the adaptation automatically.

The curvature depends exclusively upon the type of heating system or upon the

type of the radiators. The larger the numerical value, the more is the heating char-

acteristic curved.

CODE 102 - 202 - 302 - 402

Maximum limitation [°C]

The ability of the controller to adapt the default heating characteristic (heating

curve) step by step automatically to the building heating characteristic is called ad-

aptation. The mean values of the room temperature, of the outside and flow tem-

perature are the working variables for the adaptation.

Adaptation with room temperature sensor

If a room temperature sensor is connected, then the adaptation for the control loop

concerned is automatic. The temperature is measured during the entire daily opera-

tion.

The correction of the heating characteristic by adaptation is not made until the 3rd

day. If the basic setting (1.6) is too high, it can be that too high flow temperatures

occur in the first days. If the adaptation has already been running over a longer pe-

riod, a well adapted heating characteristic has become established.

No thermostatic valve may be effective in the room (test room) in which the room

sensor is installed. The radiator in the test room must always be fully opened, oth-

erwise the automatic adaptation cannot work or leads to faulty interpretations.

Open fire places, tile stoves and too frequent airing in the initial phase after starting

the application can lead to faulty interpretations.

Prerequisites for each mixing circuit are:

•

A room sensor must be connected.

•

The room temperature setpoint must be higher than 18 °C and the heating circuit

pump running time must be at least 6 hours per day.

•

The outside temperature averaged during the heating circuit pump running time

must be below 15 °C.

•

The adaptation must be allowed

(CODE No. 131, 231, 331, 431)

.

If these conditions are fulfilled, then automatic adaptation takes place.

Adaptation must have taken place at least three times before the basic setting of

the heating characteristic can be changed.

The controller corrects the heating characteristic around midnight. In this case the

corrections for each following adaptation day are always weaker.

Note

The curvature can be changed only manually through the operating

unit and is preallocated with 1.33 for all heating circuits

(DIN radiators).

The curvature depends exclusively upon the type of the heating system or upon the

type of the radiators. The larger the numerical value, the more is the heating char-

acteristic curved.

(EN\2R\EN2R1120.DOC) 01.04.98

CODE 131 - 231 - 331 - 431

Allow / prevent adaptation

=0

=1

=2

→

→

→

Adaptation not allowed

Adaptation allowed

New start of the adaptation

7 EN 2R-1120

Page 8

MCR 200 - SERVICE INSTRUCTIONS

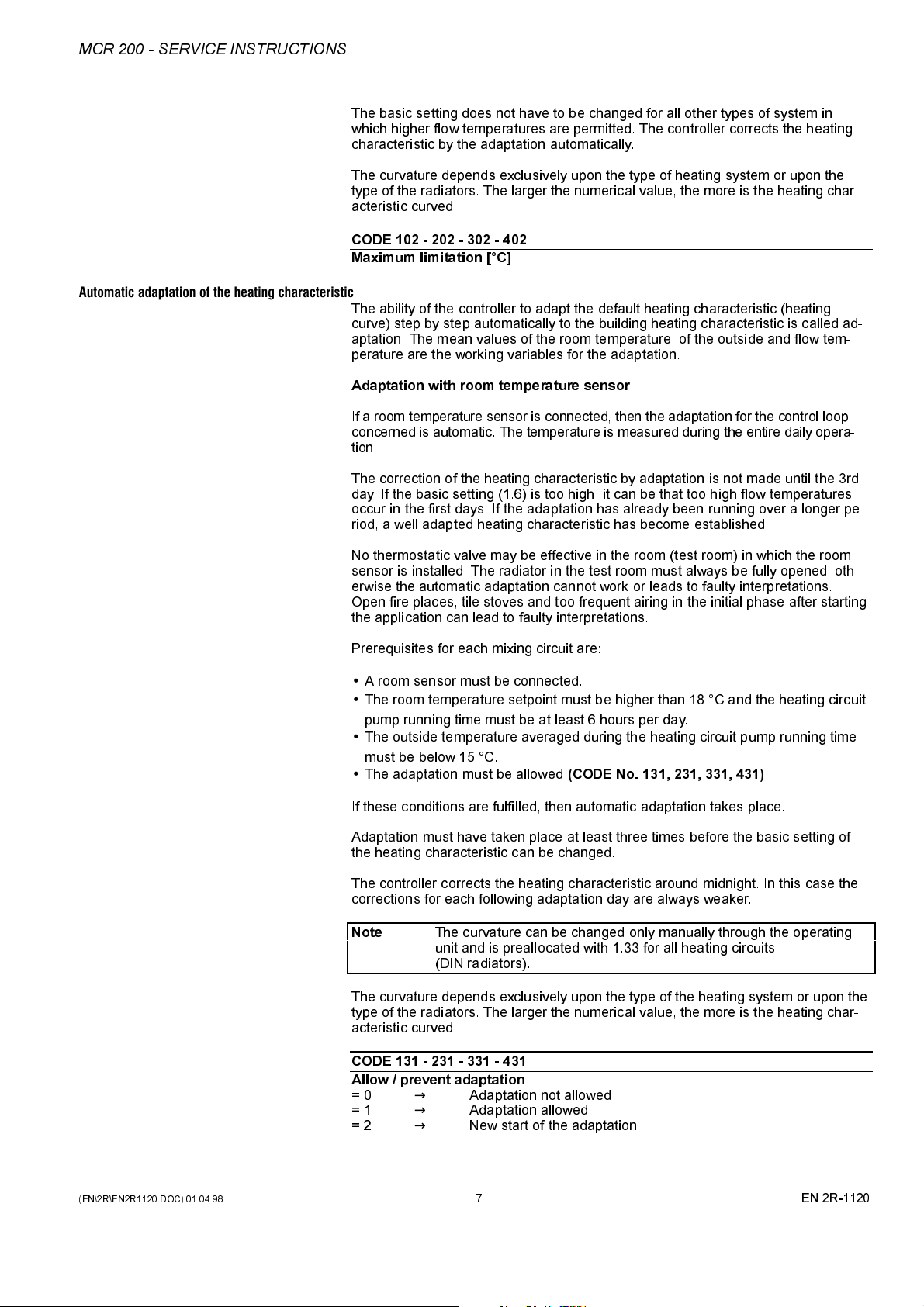

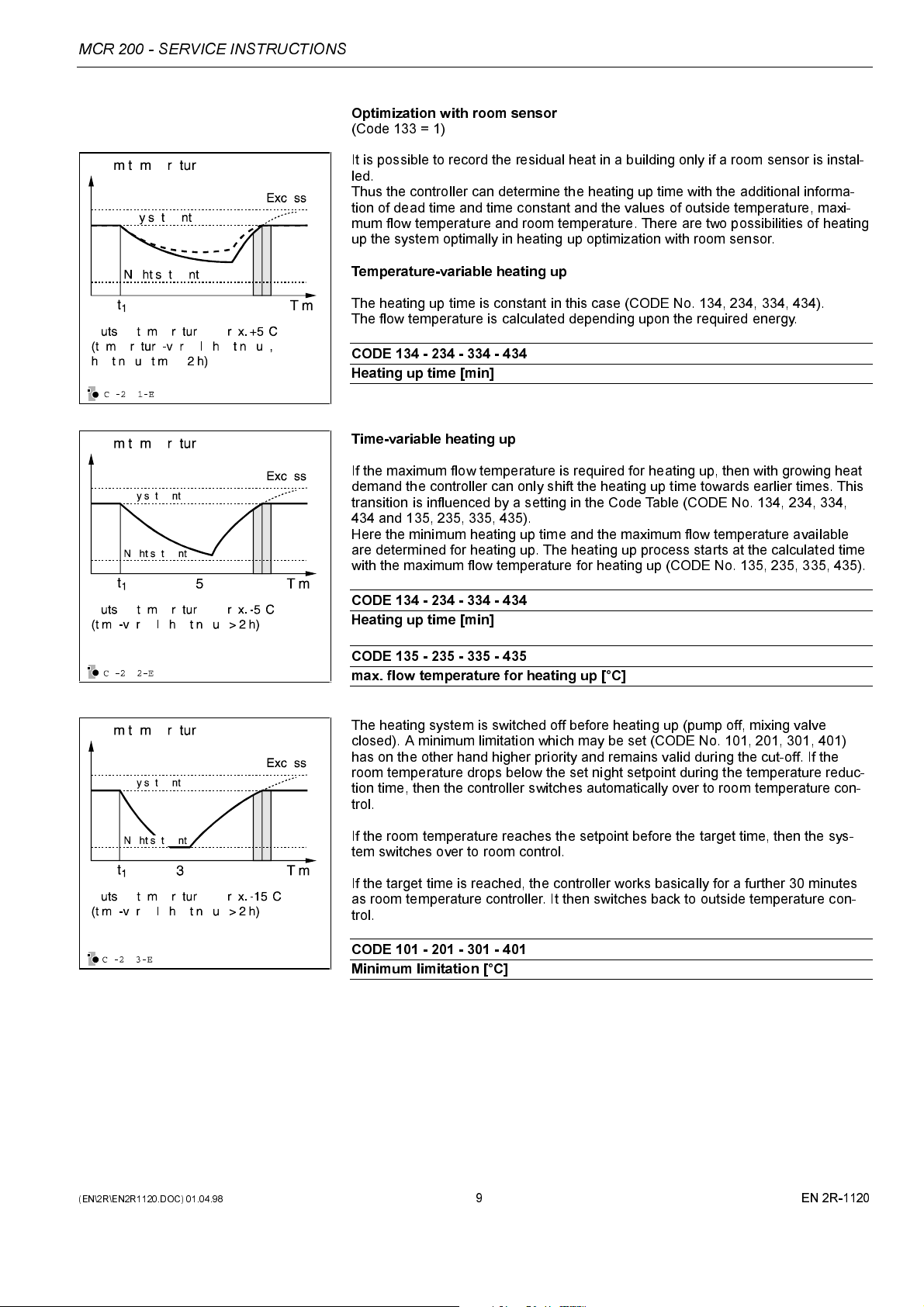

Optimization without room sensor (floor heating, ...)

(Code 133 = 0)

Heating up

The controller works in the heating up process with a fixed adjustable room tem-

perature excess (CODE No. 136, 236, 336, 436) and varies the heating up time

with the outside temperature.

The heating time at 0 °C outside temperature (Fig. on the left) can be set in the

Code Table (CODE No. 137, 237, 337, 437).

CODE 136 - 236 - 336 - 436

Room temperature excess [°C]

CODE 137 - 237 - 337 - 437

Heating up time at 0 °C [min]

The flow temperature for heating up is established according to the heating charac-

teristic plus the set room temperature excess. The settings of the time constants

and dead times are not relevant for this heating up optimization. If the target time is

reached (as in the example diagram 8.00 am), then the controller switches back to

normal control.

This type of optimization is recommended for floor heating systems, for instance.

Large dead times, as are customary in floor heating systems, have no influence on

the switch-on time in this method.

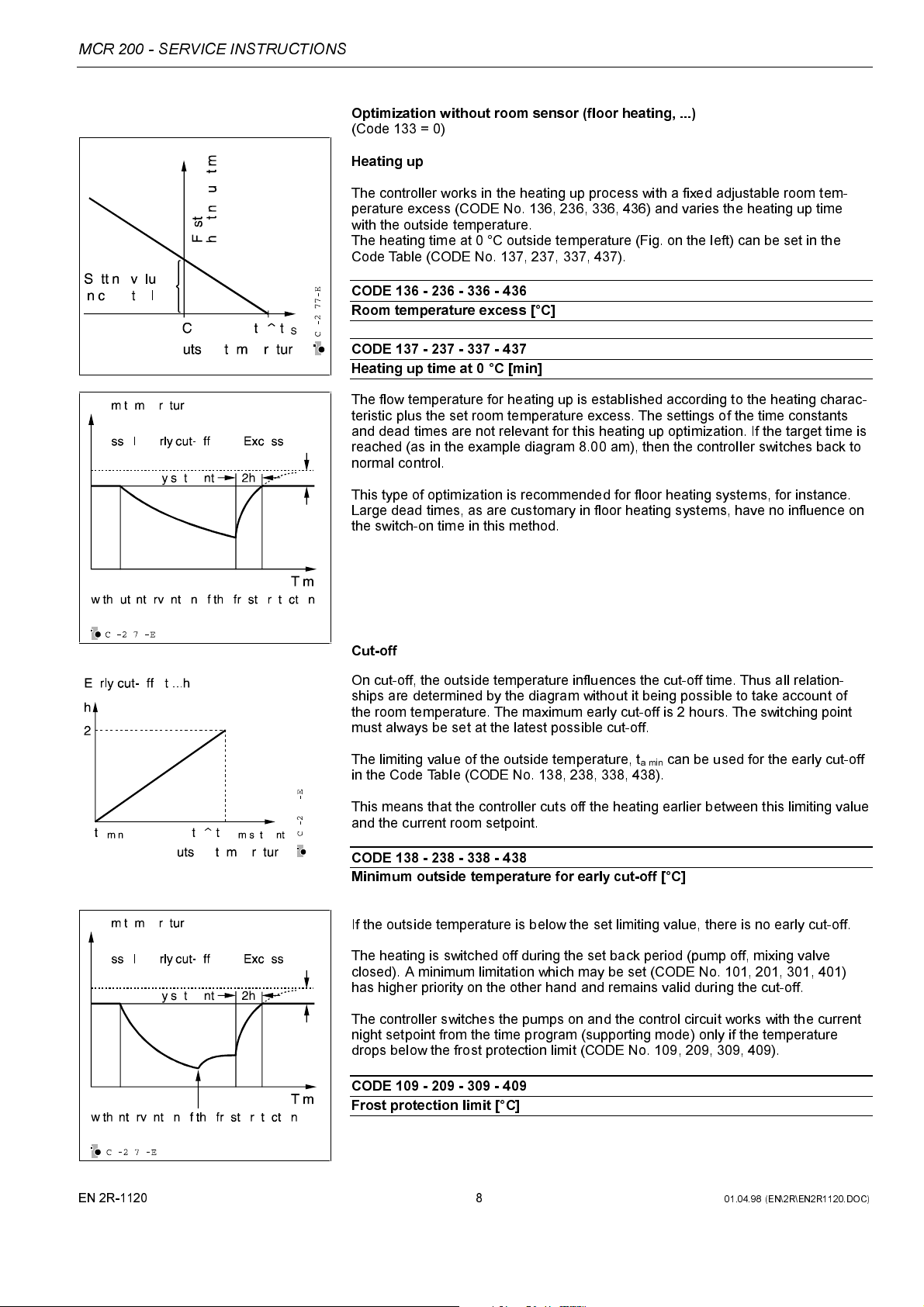

Cut-off

On cut-off, the outside temperature influences the cut-off time. Thus all relation-

ships are determined by the diagram without it being possible to take account of

the room temperature. The maximum early cut-off is 2 hours. The switching point

must always be set at the latest possible cut-off.

The limiting value of the outside temperature, t

can be used for the early cut-off

a min

in the Code Table (CODE No. 138, 238, 338, 438).

This means that the controller cuts off the heating earlier between this limiting value

and the current room setpoint.

CODE 138 - 238 - 338 - 438

Minimum outside temperature for early cut-off [°C]

If the outside temperature is below the set limiting value, there is no early cut-off.

The heating is switched off during the set back period (pump off, mixing valve

closed). A minimum limitation which may be set (CODE No. 101, 201, 301, 401)

has higher priority on the other hand and remains valid during the cut-off.

The controller switches the pumps on and the control circuit works with the current

night setpoint from the time program (supporting mode) only if the temperature

drops below the frost protection limit (CODE No. 109, 209, 309, 409).

CODE 109 - 209 - 309 - 409

Frost protection limit [°C]

EN 2R-1120 8

01.04.98 (EN\2R\EN2R1120.DOC)

Page 9

MCR 200 - SERVICE INSTRUCTIONS

Optimization with room sensor

(Code 133 = 1)

It is possible to record the residual heat in a building only if a room sensor is instal-

led.

Thus the controller can determine the heating up time with the additional informa-

tion of dead time and time constant and the values of outside temperature, maxi-

mum flow temperature and room temperature. There are two possibilities of heating

up the system optimally in heating up optimization with room sensor.

Temperature-variable heating up

The heating up time is constant in this case (CODE No. 134, 234, 334, 434).

The flow temperature is calculated depending upon the required energy.

CODE 134 - 234 - 334 - 434

Heating up time [min]

Time-variable heating up

If the maximum flow temperature is required for heating up, then with growing heat

demand the controller can only shift the heating up time towards earlier times. This

transition is influenced by a setting in the Code Table (CODE No. 134, 234, 334,

434 and 135, 235, 335, 435).

Here the minimum heating up time and the maximum flow temperature available

are determined for heating up. The heating up process starts at the calculated time

with the maximum flow temperature for heating up (CODE No. 135, 235, 335, 435).

CODE 134 - 234 - 334 - 434

Heating up time [min]

CODE 135 - 235 - 335 - 435

max. flow temperature for heating up [°C]

The heating system is switched off before heating up (pump off, mixing valve

closed). A minimum limitation which may be set (CODE No. 101, 201, 301, 401)

has on the other hand higher priority and remains valid during the cut-off. If the

room temperature drops below the set night setpoint during the temperature reduc-

tion time, then the controller switches automatically over to room temperature con-

trol.

If the room temperature reaches the setpoint before the target time, then the sys-

tem switches over to room control.

If the target time is reached, the controller works basically for a further 30 minutes

as room temperature controller. It then switches back to outside temperature con-

trol.

CODE 101 - 201 - 301 - 401

Minimum limitation [°C]

(EN\2R\EN2R1120.DOC) 01.04.98

9 EN 2R-1120

Page 10

MCR 200 - SERVICE INSTRUCTIONS

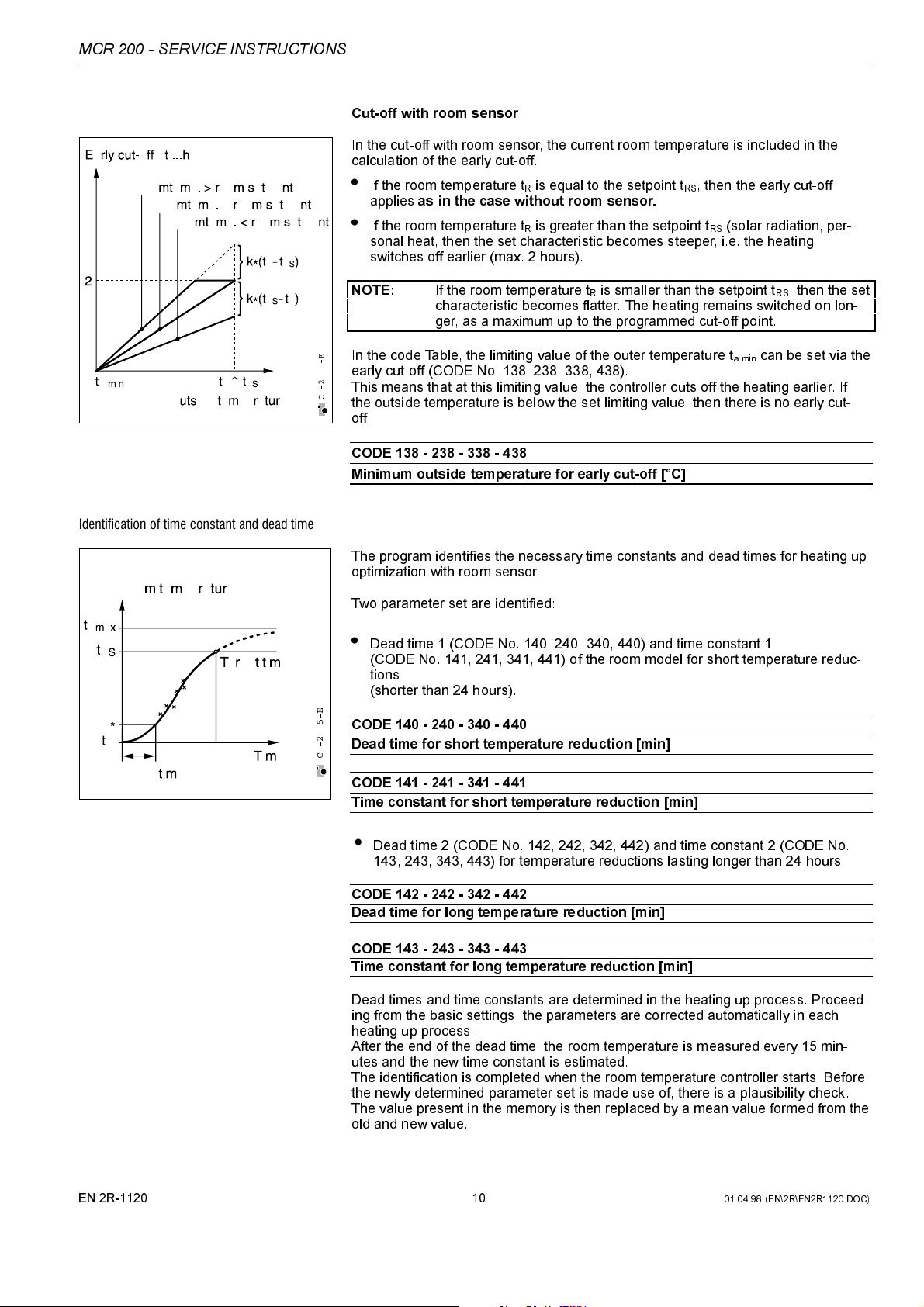

Cut-off with room sensor

In the cut-off with room sensor, the current room temperature is included in the

calculation of the early cut-off.

•

If the room temperature tRis equal to the setpoint tRS, then the early cut-off

applies

•

If the room temperature tRis greater than the setpoint tRS(solar radiation, per-

sonal heat, then the set characteristic becomes steeper, i.e. the heating

switches off earlier (max. 2 hours).

as in the case without room sensor.

Identification of time constant and dead time

NOTE:

In the code Table, the limiting value of the outer temperature t

early cut-off (CODE No. 138, 238, 338, 438).

This means that at this limiting value, the controller cuts off the heating earlier. If

the outside temperature is below the set limiting value, then there is no early cut-

off.

CODE 138 - 238 - 338 - 438

Minimum outside temperature for early cut-off [°C]

The program identifies the necessary time constants and dead times for heating up

optimization with room sensor.

Two parameter set are identified:

•

Dead time 1 (CODE No. 140, 240, 340, 440) and time constant 1

(CODE No. 141, 241, 341, 441) of the room model for short temperature reduc-

tions

(shorter than 24 hours).

CODE 140 - 240 - 340 - 440

Dead time for short temperature reduction [min]

If the room temperature t

characteristic becomes flatter. The heating remains switched on lon-

ger, as a maximum up to the programmed cut-off point.

is smaller than the setpoint tRS, then the set

R

can be set via the

a min

CODE 141 - 241 - 341 - 441

Time constant for short temperature reduction [min]

•

Dead time 2 (CODE No. 142, 242, 342, 442) and time constant 2 (CODE No.

143, 243, 343, 443) for temperature reductions lasting longer than 24 hours.

CODE 142 - 242 - 342 - 442

Dead time for long temperature reduction [min]

CODE 143 - 243 - 343 - 443

Time constant for long temperature reduction [min]

Dead times and time constants are determined in the heating up process. Proceed-

ing from the basic settings, the parameters are corrected automatically in each

heating up process.

After the end of the dead time, the room temperature is measured every 15 min-

utes and the new time constant is estimated.

The identification is completed when the room temperature controller starts. Before

the newly determined parameter set is made use of, there is a plausibility check.

The value present in the memory is then replaced by a mean value formed from the

old and new value.

EN 2R-1120 10

01.04.98 (EN\2R\EN2R1120.DOC)

Page 11

MCR 200 - SERVICE INSTRUCTIONS

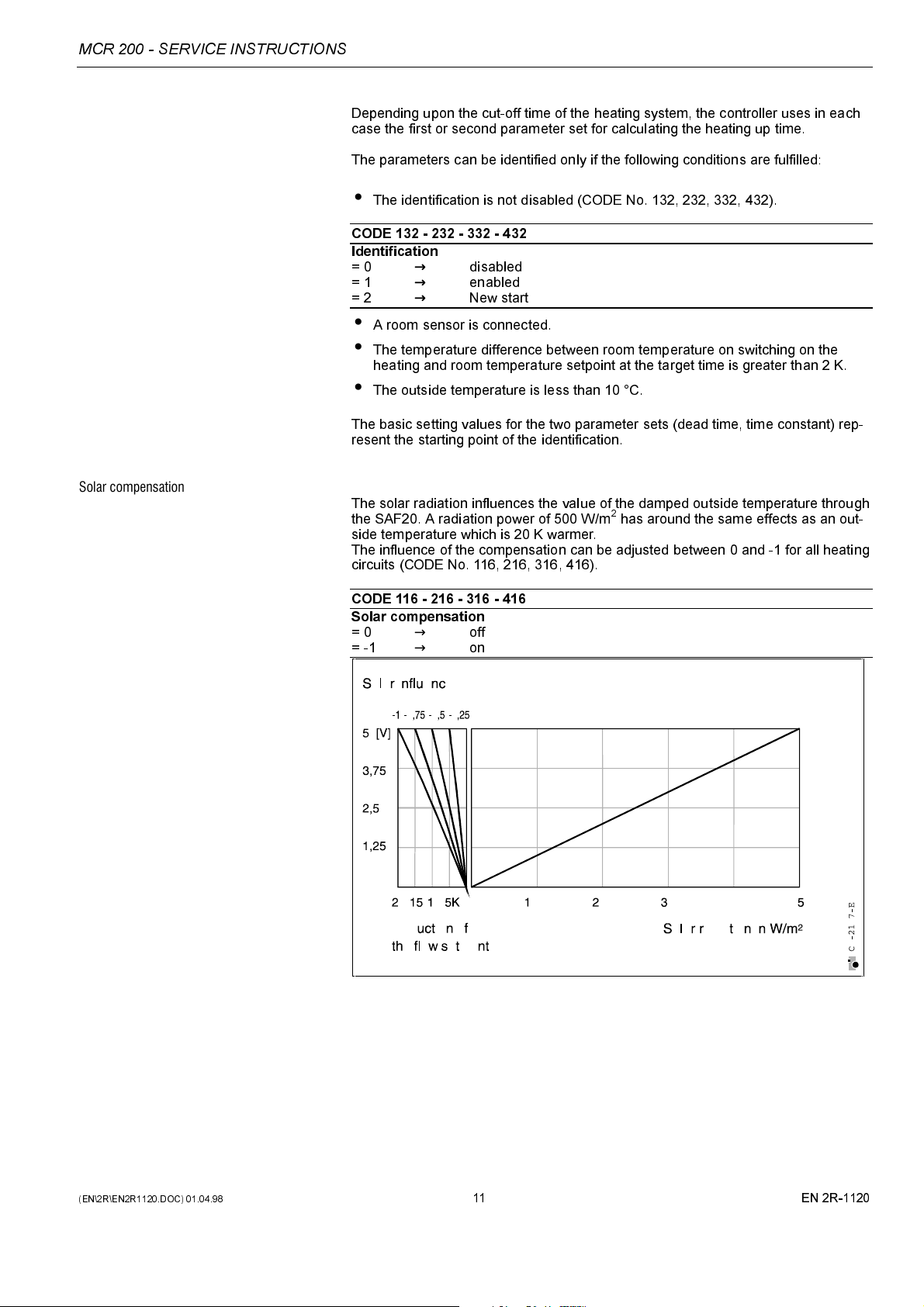

Solar compensation

Depending upon the cut-off time of the heating system, the controller uses in each

case the first or second parameter set for calculating the heating up time.

The parameters can be identified only if the following conditions are fulfilled:

•

The identification is not disabled (CODE No. 132, 232, 332, 432).

CODE 132 - 232 - 332 - 432

Identification

=0

=1

=2

•

•

•

The basic setting values for the two parameter sets (dead time, time constant) rep-

resent the starting point of the identification.

The solar radiation influences the value of the damped outside temperature through

the SAF20. A radiation power of 500 W/m2has around the same effects as an out-

side temperature which is 20 K warmer.

The influence of the compensation can be adjusted between 0 and -1 for all heating

circuits (CODE No. 116, 216, 316, 416).

→→

→→

→→

A room sensor is connected.

The temperature difference between room temperature on switching on the

heating and room temperature setpoint at the target time is greater than 2 K.

The outside temperature is less than 10 °C.

disabled

enabled

New start

CODE 116 - 216 - 316 - 416

Solar compensation

=0

=-1

→

→

off

on

(EN\2R\EN2R1120.DOC) 01.04.98

11 EN 2R-1120

Page 12

MCR 200 - SERVICE INSTRUCTIONS

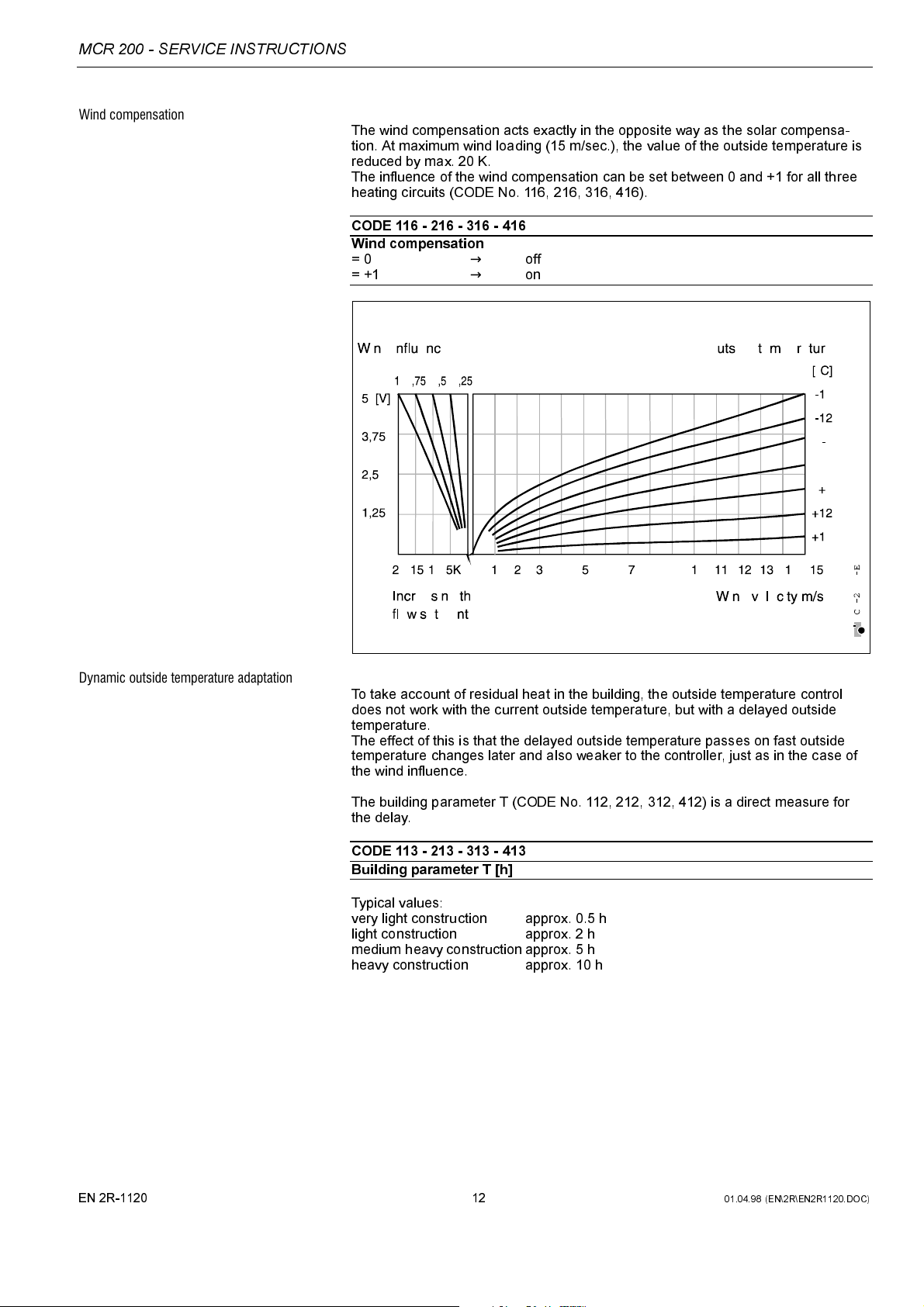

Wind compensation

The wind compensation acts exactly in the opposite way as the solar compensa-

tion. At maximum wind loading (15 m/sec.), the value of the outside temperature is

reduced by max. 20 K.

The influence of the wind compensation can be set between 0 and +1 for all three

heating circuits (CODE No. 116, 216, 316, 416).

CODE 116 - 216 - 316 - 416

Wind compensation

=0

=+1

→

→

off

on

Dynamic outside temperature adaptation

To take account of residual heat in the building, the outside temperature control

does not work with the current outside temperature, but with a delayed outside

temperature.

The effect of this is that the delayed outside temperature passes on fast outside

temperature changes later and also weaker to the controller, just as in the case of

the wind influence.

The building parameter T (CODE No. 112, 212, 312, 412) is a direct measure for

the delay.

CODE 113 - 213 - 313 - 413

Building parameter T [h]

Typical values:

very light construction approx. 0.5 h

light construction approx. 2 h

medium heavy construction approx. 5 h

heavy construction approx. 10 h

EN 2R-1120 12

01.04.98 (EN\2R\EN2R1120.DOC)

Page 13

MCR 200 - SERVICE INSTRUCTIONS

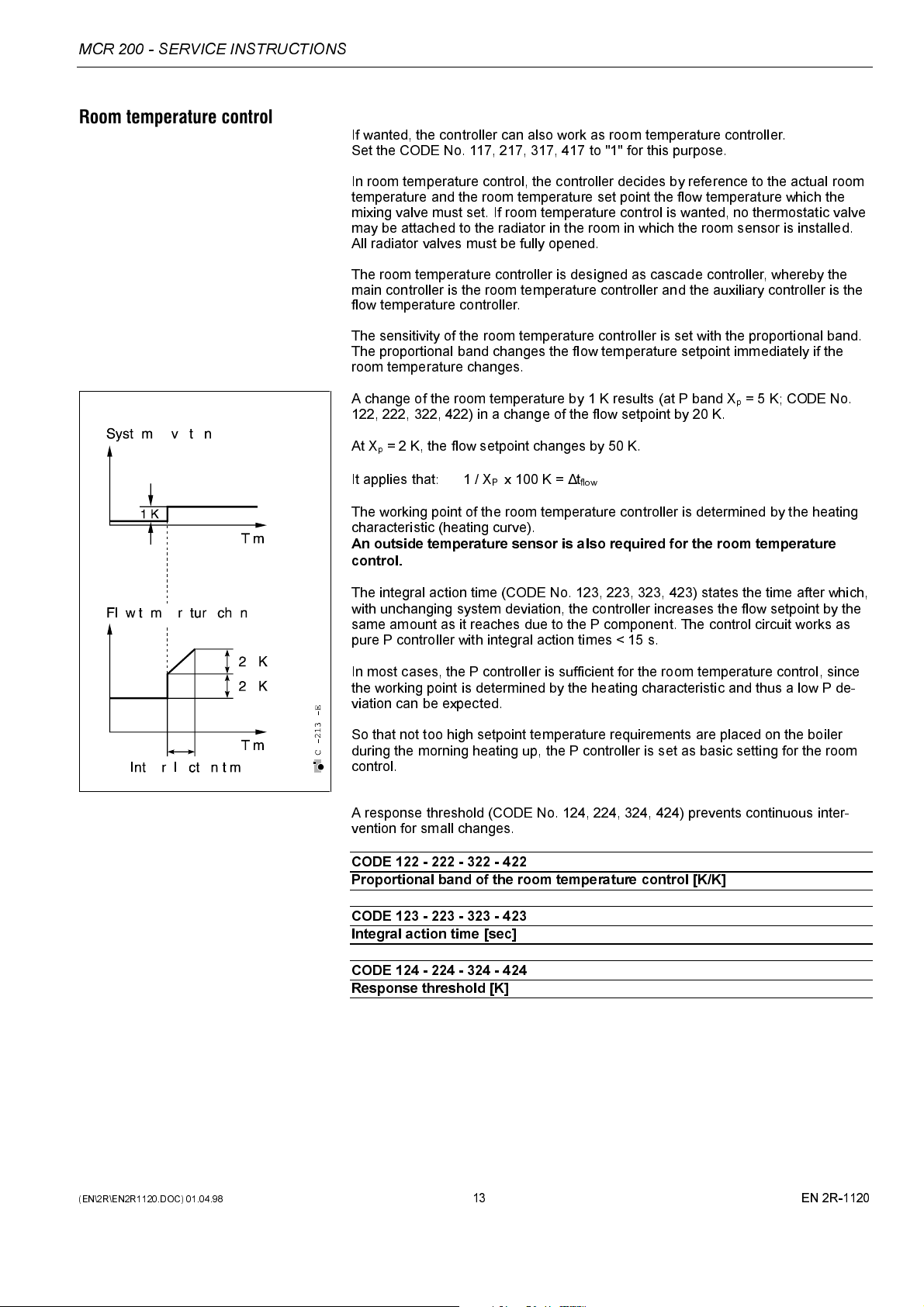

Room temperature control

If wanted, the controller can also work as room temperature controller.

Set the CODE No. 117, 217, 317, 417 to "1" for this purpose.

In room temperature control, the controller decides by reference to the actual room

temperature and the room temperature set point the flow temperature which the

mixing valve must set. If room temperature control is wanted, no thermostatic valve

may be attached to the radiator in the room in which the room sensor is installed.

All radiator valves must be fully opened.

The room temperature controller is designed as cascade controller, whereby the

main controller is the room temperature controller and the auxiliary controller is the

flow temperature controller.

The sensitivity of the room temperature controller is set with the proportional band.

The proportional band changes the flow temperature setpoint immediately if the

room temperature changes.

A change of the room temperature by 1 K results (at P band X

= 5 K; CODE No.

p

122, 222, 322, 422) in a change of the flow setpoint by 20 K.

At Xp= 2 K, the flow setpoint changes by 50 K.

It applies that: 1 / XPx100K=∆t

flow

The working point of the room temperature controller is determined by the heating

characteristic (heating curve).

An outside temperature sensor is also required for the room temperature

control.

The integral action time (CODE No. 123, 223, 323, 423) states the time after which,

with unchanging system deviation, the controller increases the flow setpoint by the

same amount as it reaches due to the P component. The control circuit works as

pure P controller with integral action times < 15 s.

In most cases, the P controller is sufficient for the room temperature control, since

the working point is determined by the heating characteristic and thus a low P de-

viation can be expected.

So that not too high setpoint temperature requirements are placed on the boiler

during the morning heating up, the P controller is set as basic setting for the room

control.

A response threshold (CODE No. 124, 224, 324, 424) prevents continuous inter-

vention for small changes.

(EN\2R\EN2R1120.DOC) 01.04.98

CODE 122 - 222 - 322 - 422

Proportional band of the room temperature control [K/K]

CODE 123 - 223 - 323 - 423

Integral action time [sec]

CODE 124 - 224 - 324 - 424

Response threshold [K]

13 EN 2R-1120

Page 14

MCR 200 - SERVICE INSTRUCTIONS

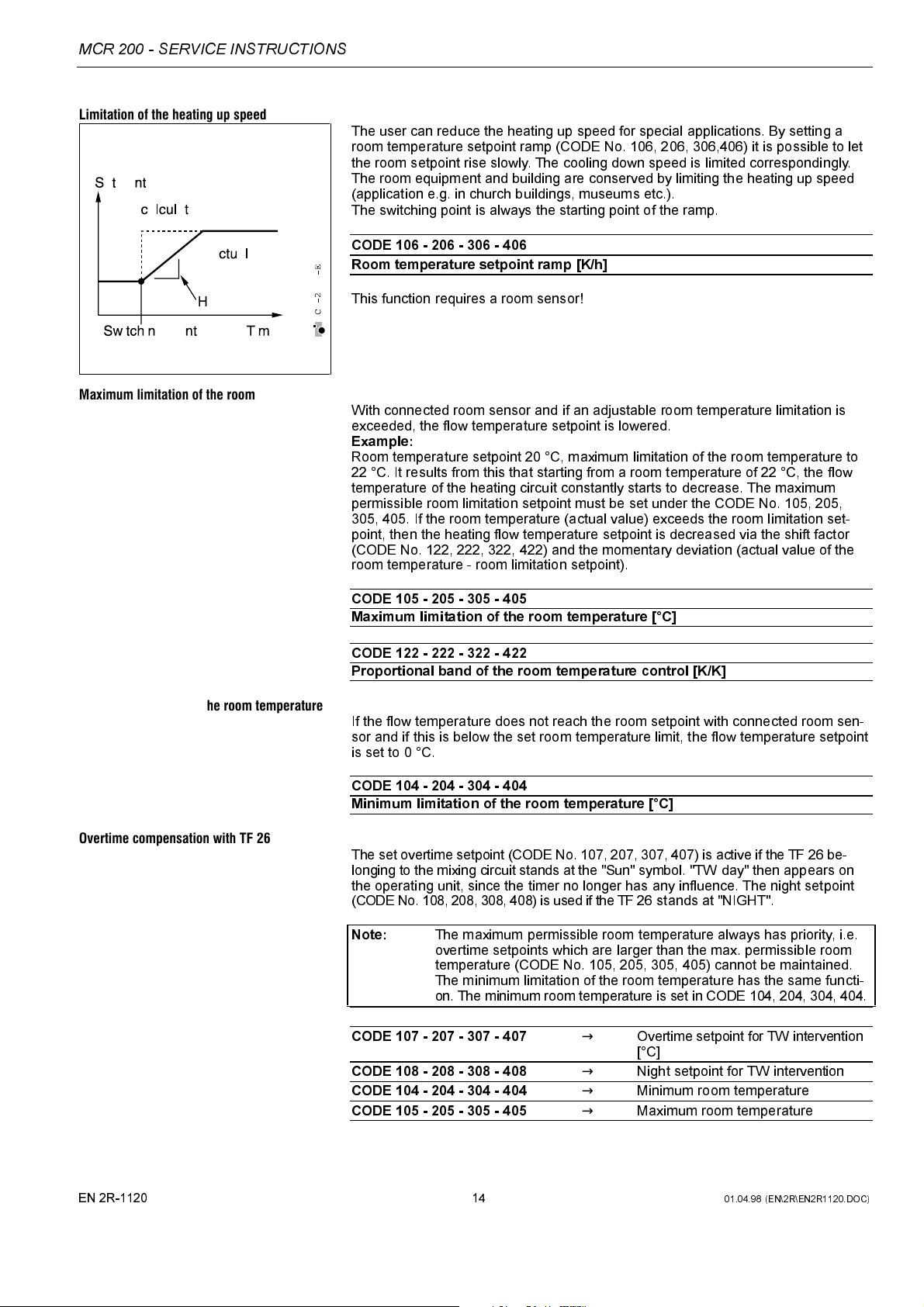

Limitation of the heating up speed

Maximum limitation of the room temperature

The user can reduce the heating up speed for special applications. By setting a

room temperature setpoint ramp (CODE No. 106, 206, 306,406) it is possible to let

the room setpoint rise slowly. The cooling down speed is limited correspondingly.

The room equipment and building are conserved by limiting the heating up speed

(application e.g. in church buildings, museums etc.).

The switching point is always the starting point of the ramp.

CODE 106 - 206 - 306 - 406

Room temperature setpoint ramp [K/h]

This function requires a room sensor!

With connected room sensor and if an adjustable room temperature limitation is

exceeded, the flow temperature setpoint is lowered.

Example:

Room temperature setpoint 20 °C, maximum limitation of the room temperature to

22 °C. It results from this that starting from a room temperature of 22 °C, the flow

temperature of the heating circuit constantly starts to decrease. The maximum

permissible room limitation setpoint must be set under the CODE No. 105, 205,

305, 405. If the room temperature (actual value) exceeds the room limitation set-

point, then the heating flow temperature setpoint is decreased via the shift factor

(CODE No. 122, 222, 322, 422) and the momentary deviation (actual value of the

room temperature - room limitation setpoint).

Minimum limitation of the room temperature

Overtime compensation with TF 26

CODE 105 - 205 - 305 - 405

Maximum limitation of the room temperature [°C]

CODE 122 - 222 - 322 - 422

Proportional band of the room temperature control [K/K]

If the flow temperature does not reach the room setpoint with connected room sen-

sor and if this is below the set room temperature limit, the flow temperature setpoint

is set to 0 °C.

CODE 104 - 204 - 304 - 404

Minimum limitation of the room temperature [°C]

The set overtime setpoint (CODE No. 107, 207, 307, 407) is active if the TF 26 be-

longing to the mixing circuit stands at the "Sun" symbol. "TW day" then appears on

the operating unit, since the timer no longer has any influence. The night setpoint

(CODE No. 108, 208, 308, 408) is used if the TF 26 stands at "NIGHT".

Note:

The maximum permissible room temperature always has priority, i.e.

overtime setpoints which are larger than the max. permissible room

temperature (CODE No. 105, 205, 305, 405) cannot be maintained.

The minimum limitation of the room temperature has the same functi-

on. The minimum room temperature is set in CODE 104, 204, 304, 404.

CODE 107 - 207 - 307 - 407

→

Overtime setpoint for TW intervention

[°C]

CODE 108 - 208 - 308 - 408

CODE 104 - 204 - 304 - 404

CODE 105 - 205 - 305 - 405

→

→

→

Night setpoint for TW intervention

Minimum room temperature

Maximum room temperature

EN 2R-1120 14

01.04.98 (EN\2R\EN2R1120.DOC)

Page 15

MCR 200 - SERVICE INSTRUCTIONS

Overtime compensation via room sensor input

Statistics

Determining the number of degree days

In order to start the overtime function, the room sensor input of the control circuit

has to be short circuited for at least 10 seconds. This will start a timer, starts coun-

ting back to zero from the time set under

CODE 129 - 229 - 329 - 429

time for overtime function

During this period of time the overtime setpoint under Code 107 - 207 - 307 - 407 is

activated.

The number of degree days is required for determining the energy consumption of

an appliance for a heating period. The MCR200 controllers can determine the real,

system-specific number of degree days. The number of degree days is the product

of the heating days of a heating period and the temperature difference between the

fixed room setpoint of 18 °C and the mean outside temperature (the base tempera-

ture is adjustable, Code 1650).

The calculations required for this are performed by the controller. The correspond-

ing information can be called up in the text field of the operating unit. For this pur-

pose the computer measures the outside temperature every five minutes and aver-

ages these measurements at the end of the day.

Counter for operating hours

These measurements are made in the time window from September 1 to May 31,

provided the outside temperature is below +15 °C (time window according to VDI

2067 BL 1).

In code 1650 the basic outdoor temperature for the degree day calculation can be

set:

CODE 1650

degree day calculation: basic temperature [°C]

One counter each is available in the MCR200 for recording the operating hours of

the individual control circuits. The counter registers all times in which the pumps or

burners are in operation.

(EN\2R\EN2R1120.DOC) 01.04.98

15 EN 2R-1120

Page 16

MCR 200 - SERVICE INSTRUCTIONS

External temperature demand

The heating circuit control system also offers the possibility of reacting to external

setpoint demand. This external setpoint demand can be triggered by different func-

tions:

1. by a temperature selector

2. by a 0...10 V signal

3. by a switching contact (e.g. of a ventilation device)

The settings for the relevant function must be made in Code 117.

External room setpoint

(Code 117, 217, 317, 417=1or2)

The room setpoint setting of the time program can be overwritten by a temperature

selector (TF 26).

The TF 26 has a selector switch with the following functions:

auto automatic operation according to time program

Day constant day setpoint (overtime)

Night constant night setpoint

The setpoints for "Day" and "Night" can be set in the Code Table. The setpoint of

the time program and the overtime setpoint can be changed in 1 °C steps with the

setting knob of the TF 26.

The TF 26 can be used only for room controlled and outside temperature controlled

control.

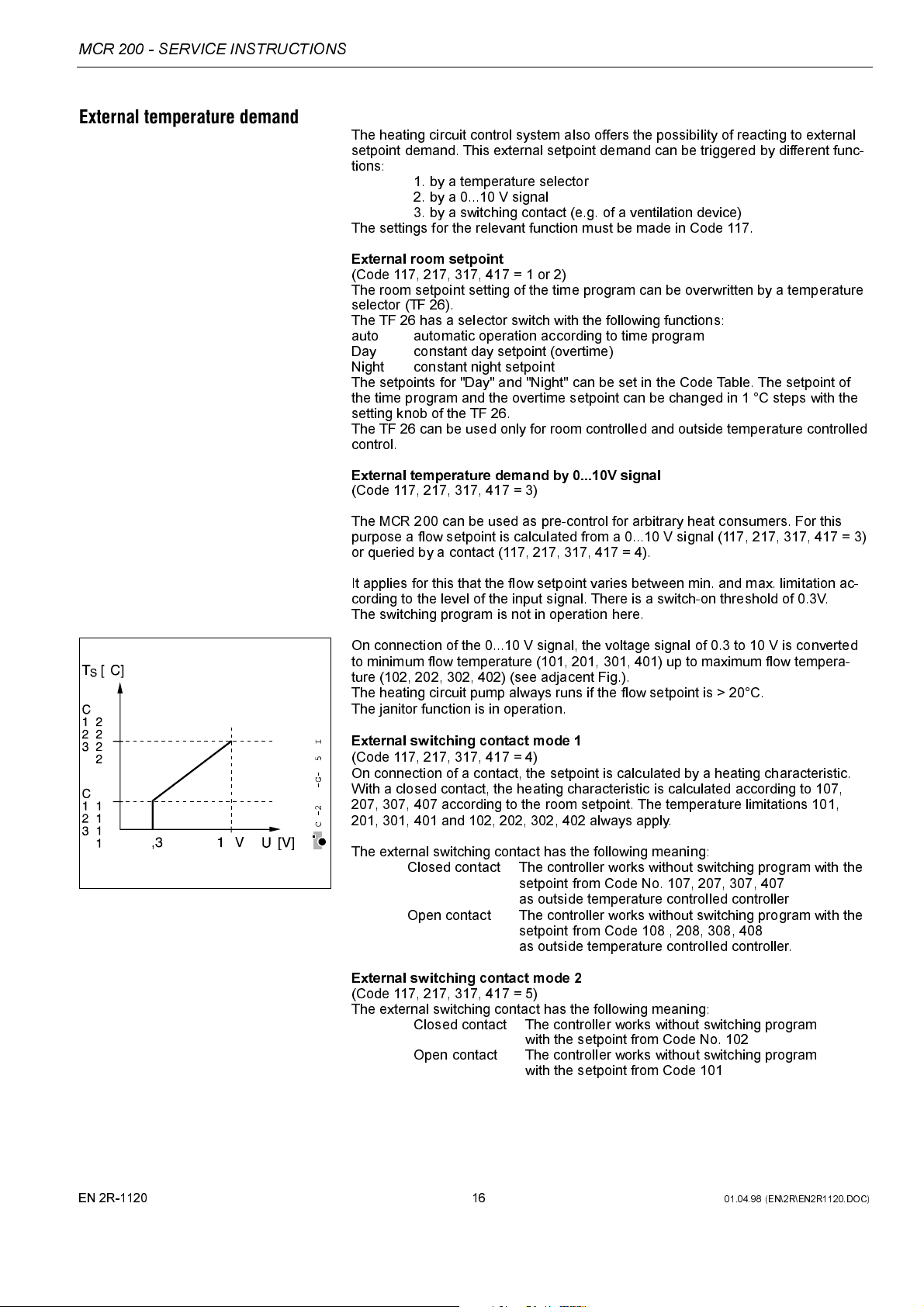

External temperature demand by 0...10V signal

(Code 117, 217, 317, 417 = 3)

The MCR 200 can be used as pre-control for arbitrary heat consumers. For this

purpose a flow setpoint is calculated from a 0...10 V signal (117, 217, 317, 417 = 3)

or queried by a contact (117, 217, 317, 417 = 4).

It applies for this that the flow setpoint varies between min. and max. limitation ac-

cording to the level of the input signal. There is a switch-on threshold of 0.3V.

The switching program is not in operation here.

On connection of the 0...10 V signal, the voltage signal of 0.3 to 10 V is converted

to minimum flow temperature (101, 201, 301, 401) up to maximum flow tempera-

ture (102, 202, 302, 402) (see adjacent Fig.).

The heating circuit pump always runs if the flow setpoint is > 20°C.

The janitor function is in operation.

External switching contact mode 1

(Code 117, 217, 317, 417 = 4)

On connection of a contact, the setpoint is calculated by a heating characteristic.

With a closed contact, the heating characteristic is calculated according to 107,

207, 307, 407 according to the room setpoint. The temperature limitations 101,

201, 301, 401 and 102, 202, 302, 402 always apply.

The external switching contact has the following meaning:

Closed contact The controller works without switching program with the

setpoint from Code No. 107, 207, 307, 407

as outside temperature controlled controller

Open contact The controller works without switching program with the

setpoint from Code 108 , 208, 308, 408

as outside temperature controlled controller.

External switching contact mode 2

(Code 117, 217, 317, 417 = 5)

The external switching contact has the following meaning:

Closed contact The controller works without switching program

Open contact The controller works without switching program

EN 2R-1120 16

with the setpoint from Code No. 102

with the setpoint from Code 101

01.04.98 (EN\2R\EN2R1120.DOC)

Page 17

MCR 200 - SERVICE INSTRUCTIONS

The heating circuit pump always runs if the flow setpoint is > 20°C.

The janitor function is in operation.

Overlapping mixing circuit functions,

sensors, device connections

Passing on the outside temperature sensor value

through the C bus

CODE 101 - 201 - 301 - 401

CODE 102 - 202 - 302 - 402

CODE 107 - 207 - 307 - 407

CODE 108 - 208 - 308 - 408

→

→

→

→

Minimum limitation [°C]

Maximum limitation [°C]

Overtime setpoint TW

Night setpoint for TW intervention [°C]

In an extensive system with several control groups, different sensors can be used

jointly. This means: a common outside sensor can be used for several MCR 200.

The same applies, for instance, also for the wind or the solar sensor.

The MCR 200 allows the boiler to be controlled according to a maximum selection;

i.e. the MCR 200 control circuit which requires currently the highest setpoint con-

trols the boiler.

For the signal transmission, the MCR 200 must be equipped in each case with a

plug-in module GV1, for longer distances (> 2 m) also with GV2 and be connected

with one another through a cable.

If several MCR 200 are connected through GV1 (GV2), the measured outside tem-

perature of a device is passed on to all other MCR 200. If outside temperature sen-

sors are connected to several devices, the locally connected outside temperature

sensor is used as standard for the control system. Should a certain sensor be se-

lected for several outside temperature sensors, CODE No. 115, 215, 315, 415 must

be changed. The

highest

of all values in each case is transmitted through the de-

vice connection (GV1/GV2).

Signal: Hot water priority switching

and system overheating, corrosion protection

CODE 115 - 215- 315 - 415

Number of the valid outside temperature sensor

=0

=1

=2

→

→

→

local

bus

automatic

Signals can be branched in an extensive system with several control groups. This

means that the hot water priority of a MCR 200 acts on all connected MCR 200.

Since individual mixing circuits must also continue to be supplied with hot water

priority, the influence (CODE No. 114, 214, 314, 414) of the hot water priority can

be changed continuously.

CODE 114 - 214- 314 - 414

Hot water priority

=0

=1

>2

The priority signal is also used simultaneously as

corrosion protection signal

→

→

→

off

on

intensified

overheating signal

and

boiler

.

In the case of boiler overheating, the allowed heating circuits open (see also Maxi-

mum limitation / Boiler overheating).

In the case of boiler corrosion protection (boiler temperature < boiler minimum

temperature), the allowed heating circuits close (see also Maximum limitation /

Boiler corrosion protecting).

(EN\2R\EN2R1120.DOC) 01.04.98

17 EN 2R-1120

Page 18

MCR 200 - SERVICE INSTRUCTIONS

Janitor function, heating limits

Because of the storage masses of the building, a reduction of the outside tempera-

ture does not immediately affect the room temperature. Thus not only the momen-

tary outside temperature is a measure for switching on but in addition the outside

temperature delayed by the storage masses of the building. Under this we under-

stand averaging the outside temperature or assessment of the time constant of the

building.

For instance, the limiting value of the delayed outside temperature prevents the

heating switching on too early and thus unnecessary energy consumption if it be-

comes colder outside.

A building no longer loses heat if the room temperatures are just as high as the

outside temperatures. Heating energy is no longer required at the latest at this

time. However, external heat is always available in a residential building: direct or

diffuse solar radiation, personal heat, heat from lighting or possibly existing electri-

cal machines.

Since these internal heat loads cover the losses starting from an outside tempera-

ture of approx. 17...18 °C, the heating can be switched off correspondingly already

at around this outside temperature. This cut-off point is defined as heating limit.

The momentary and the delayed outside temperature run differently and are phase-

shifted. Therefore both temperatures must also be set separately.

For switching on and off it applies that:

•

If one of the two temperatures rises above the relevant set value, then the

heating switches off (e.g. point A).

•

If the momentary outside temperature (ta- CODE No. 110, 210, 310, 410) and

the delayed outside temperature (t

low its relevant set value, then the heating is switched on (e.g. point B).

- CODE No. 111, 211, 311, 411) drops be-

am

Caution: Hysteresis??

CODE 110 - 210 - 310 - 410

Momentary outside temperature heating limit [°C]

CODE 111 - 211 - 311- 411

Delayed outside temperature heating limit [°C]

Example:

set value and the heating is switched off (point A). At around 2.45 am, the delayed

outside temperature drops below the set value, the momentary outside temperature

has already been below the set value since 6.45 pm, the heating is switched on

(point B).

At around 10.30 am, the momentary outside temperature ta exceeds the

EN 2R-1120 18

01.04.98 (EN\2R\EN2R1120.DOC)

Page 19

MCR 200 - SERVICE INSTRUCTIONS

Flow temperature control

The controller computes the setpoint for the flow temperature control from several

variables. Flow setpoints of heating characteristic, optimization, room temperature

control, room temperature limitation, 0...10 V input or contact requirement are

available for selection. The controller decides which of the flow setpoints is valid.

The current flow setpoint for each heating circuit is stated in the system

status menu (index key and 2).

The sensitivity of the flow temperature controller is set with the proportional band

and the integral action time.

The proportional band has a basic setting of 100 K, i.e. a system deviation of 2K,

for instance, means that the servomotor opens or closes the mixing valve by 2 %.

To pass the manipulated variable on to the mixing valve motor, the controller con-

verts the manipulated variable into an actuating time. The motor running time of the

servomotor used (CODE No. 121, 221, 321, 421) must be set for this purpose.

Deviations between the actual and the set motor running time are critical only if the

set motor running time is significantly larger (or shorter) than the actual motor run-

ning time. The calculated actuating time is then too long; oscillations of the control

system occur. If the deviation is significantly smaller, the control response of the

control system becomes more inert.

CODE 118 - 218 - 318 - 418

Proportional band of the flow temperature controller [%/K]

Setpoint ramp (flow temperature)

CODE 121 - 221 - 321 - 421

Motor running time [sec]

The integral action time (CODE No. 119, 219, 319, 419) states the time after which

with unchanging system deviation the controller increases the manipulated value

by the same amount which is given by the gain factor multiplied by the system de-

viation.

Integral action times < 15 sec are not taken into account, the controller then works

as pure P controller.

A response threshold (CODE No. 120, 220, 320, 420) prevents continuous inter-

vention for small changes of the system deviation.

CODE 119 - 219 - 319 - 419

Integral action time [sec]

CODE 120 - 220 - 320 - 420

Response threshold [K]

Limiting the heating up speed

The user can reduce the heating up speed for special applications and to reduce

crackling noises in the pipelines. It is possible by setting a flow temperature set-

point ramp (CODE No. 103, 203, 303, 403) to let the flow setpoint rise slowly

(12...500 K/h). The cooling down speed is limited correspondingly.

CODE 103 - 203 - 303 - 403

Flow temperature setpoint ramp [K/h]

(EN\2R\EN2R1120.DOC) 01.04.98

19 EN 2R-1120

Page 20

MCR 200 - SERVICE INSTRUCTIONS

Limitations, special functions

Limitation of the heating flow temperature minimum and maximum

In some systems, the heating flow temperature must not be less than or exceed

certain limits. For example, the maximum limitation of the heating flow temperature

is very expedient in floor heating systems. An additional temperature sensor is not

required, since the limiting temperature is acquired with the existing flow tempera-

ture sensor. If minimum limitation is set, then it is constantly effective. Only the

heating limits determined by the controller can put the minimum limitation out of

force.

Pump logic

Boiler excess

Screed drying heating function

according to DIN4725/T4

Note:

CODE 101 - 201 - 301 - 401

Heating flow temperature minimum limitation [°C]

CODE 102 - 202 - 302 - 402

Heating flow temperature maximum limitation [°C]

To prevent the heating pump running unnecessarily, the controller decides whether

heat is required or not. The pump is switched off if heat is no longer required.

When the last heating circuit pump switches off, it runs on for 15 minutes (CODE

No. 128, 228, 328, 428) to utilize the residual heat from the hydraulic network.

CODE 128 - 228 - 328 - 428

Pump cut-off delay [min]

The highest of all temperature demands is passed on to the boiler controller (in the

case of several MCR 200 controllers through GV1 / GV2). An adjustable excess

ensures simultaneously that pipe losses up to the consumers are compensated for.

Screeds must be dried before starting up the floor heating. They are dried by con-

trolled heating up according to DIN 4725 / T4. In this case the flow temperature in

the first days is regulated to 25 °C for instance (CODE No. 130, 230, 330, 430 =

25). After 72 h, the flow setpoint is raised to the maximum allowed value (CODE

No. 102, 202, 302, 402).

The limitation does not replace safety measures, such as the limiting

thermostat of a floor heating system.

The screed drying heating function starts as soon as CODE No. 130, 230, 330, 430

is > 2 °C.

Note

: Do not forget to set the maximum flow temperature

(CODE 102, 202, 302, 402).

CODE 130 - 230 - 330 - 430

Flow temperature for floor heating function [°C]

CODE 102 - 202 - 302 - 402

Maximum limitation [°C]

EN 2R-1120 20

01.04.98 (EN\2R\EN2R1120.DOC)

Page 21

MCR 200 - SERVICE INSTRUCTIONS

Protective functions

Frost protection

Pump actuation

Mixing valve and pump forced operation

Important note:

To avoid the heating circuit freezing at unfavourable places of the piping system,

the frost protection function bypasses the

If the outside temperature drops below a value to be set (frost limit), the circulating

pump is switched on forcibly, even if there is no heat demand.

If the flow temperature drops below 10 °C (CODE 101, 201, 301, 401) or below the

minimum room temperature setpoint (CODE 104, 204, 304, 404), the flow tempera-

ture is regulated to the setpoint from the time program according to the heating

characteristic. The flow temperature control is switched off again after two hours

until the flow temperature drops below one of the limiting values again.

To avoid the mixing valve seizing (e.g. during the summer), the mixing valve is

opened once daily and closed again in heating breaks. To avoid the heating circuit

pump seizing, it is switched on if it has been switched off for one week (= 168 h).

The pump switches on for 60 sec (CODE H26 and H27, see also pump forced op-

eration).

The protective functions are always active. The protective functions

are not performed only in the 0 position of the operating mode switch.

demand driven pump actuation.

CODE 126 - 226 - 326 - 426

Pump protection interval [h]

CODE 127 - 227 - 327 - 427

Running time of the pump protective function [sec]

(EN\2R\EN2R1120.DOC) 01.04.98

21 EN 2R-1120

Page 22

MCR 200 - SERVICE INSTRUCTIONS

Domestic hot water control

Standard control

Domestic hot water priority settings

If a standard hot water storage tank (hot water storage tank with integrated heat

exchanger) is installed in the heating system, the charging pump is switched on as

soon as the temperature drops below the temperature set point.

So that the hot water charging process takes place as quickly as possible, the set-

point of the heat generator for the time of hot water charging is raised to a value

15 K above the hot water setpoint (CODE No. 504, 604, and 503, 603).

CODE 504 - 604

Hot water charging excess [°C]

CODE 503 - 603

Switching hysteresis [°C]

It is possible to choose between three types of hot water priority (see "Settings"

operating instructions):

•

Absolute hot water priority: As long as hot water charging is taking place, the

mixers are closed continuously. If the hot water temperature rises, the mixers

open again.

•

Parallel operation: Hot water charging has no influence on the mixing circuits.

•

Time-dependent hot water priority parallel operation e.g. for 20 minutes. If the

set hot water temperature is not reached within this time, the system switches

over to absolute hot water priority.

Domestic hot water charging pump

Switch-on conditions

Cut-off condition

In the factory setting, the MCR 200 works with time-dependent hot water priority.

The hot water priority is switched off in all cases 60 minutes after starting hot water

charging.

Example:

means no priority, "40 min." means 40 minutes priority. Thus the priority circuit

starts 20 minutes after start of hot water charging.

CODE 501 - 601

Hot water priority [min]

Prerequisites for switching on the hot water charging pumps are:

•

•

CODE 506 - 606

Boiler temperature influence

=0

=1

The hot water temperature must be greater than or equal to the water temperature

plus a switching difference (CODE No. 503, 603).

The duration of the hot water priority can be set in CODE 501, 601. "0"

The hot water setpoint must be higher than the current water temperature at the

sensor

The boiler temperature must be higher than the measured water temperature at

the sensor (only for MCR 200-12, -13, -22, -32 and CODE No. 506 = 1).

→

→

off

on

CODE 503 - 603

Switching difference [°C]

Charging pump run-on

EN 2R-1120 22

01.04.98 (EN\2R\EN2R1120.DOC)

Page 23

MCR 200 - SERVICE INSTRUCTIONS

Boiler setpoint for hot water charging

Automatic anti-legionnaire's bacteria system

This function enables the boiler residual heat to be utilized in hot water charging in

summer operation and in the transitional period. The charging pump runs on until

the temperature in the storage tank no longer rises.

The charging pump does not run on if other control circuits require heat.

There is an additional max. running time to be set under Code 521. If this time has

elapsed, the pump will stop even the temperature in the tank is still rising.

The boiler temperature setpoint required for hot water charging is calculated from

the hot water setpoint plus a boiler temperature excess (CODE No. 504, 604) plus

the switching difference (CODE No. 503, 603).

CODE 503 - 603

Switching hysteresis [°C]

CODE 504 - 604

Hot water charging temperature excess [°C]

To kill off legionnaire's bacteria, DVGW Worksheet 551 for hot water heaters > 400

litres water contents requires certain heating up temperatures which must be

reached once daily. The temperatures are set in the time program of the hot water

temperature. To avoid the risk of scalding in smaller systems, no heating up to high

temperature is preset as standard.

Hot water heating with separately

heated hot water storage tank

(special application)

Pump forced operation

There are heating systems in which the hot water is not heated by the boiler, e.g.

with a free standing hot water storage tank with its own atmospheric gas burner or

with an electrical heating element. In the case of hot water charging, the gas burner

is actuated instead of the charging pump.

The requirements for an increased boiler temperature setpoint is thus not applica-

ble.

It can be set with CODE 505, 605 of the MCR 200 whether the boiler temperature

setpoint is influenced or not during hot water charging.

CODE 505 - 605

Boiler requirement

=0

=1

→

→

off

on

To prevent the charging pump seizing, it is switched on if it was off for one week

(Code 507). The pump switches on for 60 sec (Code 508).

CODE 507 - 607

Pump protection interval [h]

CODE 508 - 608

Running time of the pump protective function [sec]

(EN\2R\EN2R1120.DOC) 01.04.98

23 EN 2R-1120

Page 24

MCR 200 - SERVICE INSTRUCTIONS

Boiler / Boiler sequence control

Setpoint setting

1. Flow temperature demand from other

MCR 200 controllers through the LC or C bus.

2. Flow temperature demand through analog

voltage signal (only for MCR 200-71)

The setpoint setting can be made in 6 different ways.

Each of these possibilities can also arise simultaneously in an arbitrary combina-

tion. The highest value from the flow temperature demands described below is

processed.

The highest demand in each case of a heat consumer is automatically transmitted

through GV 1. The controller with the heat generator(s) controls according to the

highest demand which is received through GV 1.

An analog voltage signal which is connected through the input EX1 to the

MCR 200-71.

This signal places a demand on the heat generator(s) according to the simple rela-

tionship:

The boiler pumps switch off if the analog signal is < 0.3 V.

0...10 V input

E.g. all MCR 32 / 33 or other controllers installed in the field can pass on their heat

demand through a 0...10 V signal (see also MCR 32 operating instructions).

This signal can be impressed at the MCR 200-71, input EX1 to pass on a flow set-

point to the boiler controller.

Note:

To quickly pass on from the outside a higher demand to the boiler

controller, it is important to activate its output through Code 922. With

activated input and open contact, the demand is automatically approx.

80 °C. There is no demand with closed contact. This function can be

used, for instance, for an external hot water heater.

EN 2R-1120 24

01.04.98 (EN\2R\EN2R1120.DOC)

Page 25

MCR 200 - SERVICE INSTRUCTIONS

3. Flow temperature demand by floating

normally open contact (only for MCR 200-71)

A floating normally open contact, which is connected through the input EX2. (E.g.

from MCR 52 or ZG devices). In this case the demand is calculated using an addi-

tional integral function.

A heating characteristic serves as basis for determining the common flow setpoint.

This heating characteristic is set with Code 904 - 905 - 906.

The maximum shift of the setpoint from this heating characteristic, up or down, is

set by Code 907.

From this results a "Working band" outside the set heating characteristic, which is

also restricted by the min. and max. limitation of the common flow temperature.

A minimum setpoint can be determined by the MCR 200-71 time program (day-year

program) or via the code table Code 901. The setpoint applies for the common flow

temperature in the hydraulic crossover.

What happens when the floating contact closes?

1. The demand for the boiler sequence circuit starts on the heating charac-

teristic (I).

2. According to the time the contact is closed, the setpoint is increased con-

stantly with Code 908 until the next burner stage switches on (II).

(EN\2R\EN2R1120.DOC) 01.04.98

25 EN 2R-1120

Page 26

MCR 200 - SERVICE INSTRUCTIONS

3. The setpoint remains constant as long as either the gradient waiting time

or minimum on or minimum off time are active (III).

4. The setpoint increases further with the same slope only after the waiting

time has elapsed provided the external contact is still closed.

5. If the demand contact is open (IV), then the setpoint requirement de-

creases initially slowly and then increasingly faster.

6. If the burner switches off during this phase, only the minimum off time runs

down and the setpoint remains constant for this time (V).

7. After each waiting time, the setpoint demand decreases further with the

last slope (VI). The setpoint requirement is limited by strategy minimum

temperature and the maximum shift of the heating characteristic (Code

907).

Setting recommendations when using the switching contact:

Code Setting

904 20 °C

905 1.6 (maximum selection)

906 1.3

907 20 °C (without hot water charging)

908 1

Note:

We recommend a separate connection through the input EX

for the

1

hot water charging of the external controllers to improve the dynamic

response

EN 2R-1120 26

01.04.98 (EN\2R\EN2R1120.DOC)

Page 27

MCR 200 - SERVICE INSTRUCTIONS

4. Minimum demand (only MCR 200-71)

5. Flow demand by

EXCEL 5000 system.

A minimum demand can be determined through the MCR 200-71 time program

WEZ (day/year program). The setpoint applies for the common flow temperature in

the hydraulic crossover. These setpoints are always fixed flow setpoints and

not

outside temperature dependent.

A data point of an EXCEL 5000 system can transfer the setpoint to the MCR 200-

71 heat generator, so that the MCR 200 heat generator receives the correct flow

setpoint.

For this purpose there is a user adress defined as VA_EXCEL________XX, where-

by XX is the controller number.

6. Flow demand by an

internal heating circuit program HKZ

An outside temperature controlled demand can be determined through the MCR

200-71 time program HKZ.

This internal heating circuit program also works with an independent year timer and

serves for generating an internal flow demand if the controller should work "alone".

The heating circuit therefore has no outputs for mixing valve and pump and also no

inputs for room sensor and flow temperature sensor.

Functions such as switching on and off optimization, janitor function, room control,

adaptation of the heating characteristic, solar and wind influence, delayed outside

temperature and number of degree days calculation are not integrated.

(EN\2R\EN2R1120.DOC) 01.04.98

27 EN 2R-1120

Page 28

MCR 200 - SERVICE INSTRUCTIONS

Setpoint formation

Excess

Limitations

Minimum limitation / Boiler corrosion protection

The setpoint of the boiler or of the boiler sequence results from the maximum heat

demand of the consumers and an adjustable excess.

For the single boiler controllers this is Code 709 and for the boiler sequence Code

903.

The excess takes account of piping losses.

In all boiler controllers, both the minimum (701 / 801) and maximum (702 / 802)

boiler setpoint temperature can be limited.

In addition, in the boiler sequence circuit, the minimum (901) and maximum (902)

common flow setpoint can be limited.

If there is a condition in which the minimum boiler temperature is not reached, then

the actuators in the series connected control circuits close constantly.

The reaction depends upon the setting under Code 114 / 214 / 314 / 414 and the

temperature difference between setpoint and actual value.

Example:

If the actual boiler temperature drops by 10 K below the minimum setpoint and if

the setting is Code 114 = 5, then the momentary output signal of this heating circuit

is reduced by 10 K×5=50%.

At the same time as this proportional reaction, there is an adjustable integrating

time under CODE 753.

To obtain stable operation, the boiler corrosion protection function can be delayed

with CODE 754 (overheating function).

Maximum limitation / Boiler overheating

(for single boiler)

Boiler overheating for boiler sequence

(MCR 200-71 only

If there is a condition in which the maximum boiler temperature is exceeded, then

the actuators in the connected control circuits open constantly.

The reaction depends upon the setting under Code 114, 214, 314, 414 and the

temperature difference between setpoint and actual value.

Example:

If the actual boiler temperature rises by 10 K above the max. setpoint and if the

setting is Code 114 = 5, then the momentary output signal of this heating circuit is

increased by 10 K×5=50%.

At the same time as this proportional reaction, there is an adjustable integrating

time under CODE 753.

To obtain stable operation, the boiler overheating function can be delayed with

CODE 754 (overheating function).

If the boiler temperature is above the max. limit then the following will happen:

EN 2R-1120 28

01.04.98 (EN\2R\EN2R1120.DOC)

Page 29

MCR 200 - SERVICE INSTRUCTIONS

Return temperature limitation control

Minimum switch-on time of the burner

(Code 706 / 806)

Minimum switch-off time of the burner

(Code 707 / 807)

Total shutdown of the boiler

(Code 703 / 802)

Boiler sequence exchange

(only MCR 200-71)

A constant return temperature control is provided for the boilers of the boiler se-

quence circuit in controller MCR 200-71. The setpoint is entered under Code 717 /

817. The controller is a fixed value controller with adjustable P band and fixed inte-

grating time(2 min.).

(The working point is the setpoint and corresponds to 0 % output).

This return limitation can be switched off through Code 718 / 818, i.e. the output

can be used for a butterfly valve. The butterfly valve opens if the minimum tempera-

ture is reached after heating up the boiler. If the temperature drops below the mini-

mum temperature in further operation, then the butterfly valve remains open.

However, the actuators of the heat consumers react through the "boiler corrosion

protection" function.

To ensure economic combustion, for the safe drying out of the combustion space

and to avoid chimney sooting, it is expedient to set the burner a longer running

time. The minimum switch-on times and / or minimum exhaust gas temperatures

can be set for this. After switching on, the burner remains in operation until the

minimum switch-on time has ended. The minimum exhaust gas temperature must

also be reached before it switches off. Switching off earlier is possible only on

reaching the maximum permissible boiler temperature.

The adjustable minimum switch-off time for the burner ensures that the switching

frequency is reduced. Even if the temperature is below the temperature setpoint,

the burner cannot start before the minimum switch-off time has ended. Thus too

frequent pulsing around the setpoint is reduced and uneconomic heating operation

is avoided.

If the boiler is suitable for low or extra low temperature operation, it can also shut

down heat generation completely to save energy outside the times of use. This

must be notified to the controller at start-up through the parameter. If because of

the temperature conditions the conditions for total shutdown are fulfilled, the con-

troller ensures that the possibly set minimum limitation is ineffective in the shut-

down times. However, the controller constantly performs the frost protection func-

tion, it has absolute priority. As soon as the heat generation plant has to switch on

because of the frost protection function, the minimum limitations are also in opera-

tion again (Code 913). When heat is required by the consumer circuits, the boiler,

as long as it has not reached the minimum temperature, will send a priority signal

(influence adjustable under Code 114, 214, 314, 414) to the consumers, which at a

high setting results in the consumers not receiving heat until the boiler minimum

temperature is reached.

Code 909 determines the conditions for the boiler sequence exchange:

0 = no exchange

i.e. the sequence of the boilers always remains the same. Boiler 1 is required

firstly; if the heat output is not reached, boiler 2 switches on.

1 = according to operating hours

If the set operating time (Code 716, 816) of the base load boiler has ended, the se-

quence of the boiler requirement changes at the next switch-on and the previous

following boiler becomes the base load boiler.

2 = according to outside temperature

If the 72h mean value of the outside temperature exceeds the set limit of Code 912,

then the 1st boiler becomes the base load boiler and the 2nd boiler the following

boiler. The sequence of the requirement is the other way round below this outside

temperature limit.

(EN\2R\EN2R1120.DOC) 01.04.98

CAUTION:

If boilers are of different size, the summer boiler must always be con-

nected to the electrical connections for boiler 1.

29 EN 2R-1120

Page 30

MCR 200 - SERVICE INSTRUCTIONS

Leading boiler

In systems without hydraulic crossover, it is necessary that system water can

circulate through a boiler (the heating circuit pump runs with flow temperature de-

mands > 15°C).

For this reason a leading boiler is defined under Code 920, i.e. the base load boiler

is always connected hydraulically with the heating circuit distributor, so that system

water can flow through it.

In the case of boilers which are shut off with butterfly valves, the butterfly valve is

open. In boilers with return temperature control, the three-way valve opens.

This means that cold system water may come into the boiler return since the return

temperature control for the leading boiler is not in operation.

Parallel / sequential boiler sequence

Outside temperature blockage of the 2nd boiler

NOTE:

We therefore urgently recommend installing a hydraulic crossover for

each boiler sequence circuit, since without hydraulic crossover, relia-

ble control of the return temperature and all flow temperatures is not

possible in all operating conditions.

In special cases it is possible with Code 910 to change the sequence of the stages

from sequential to parallel. In parallel operation, the stages are called up in the fol-

lowing sequence:

Boiler 1, stage a

Boiler 2, stage a

Boiler 1, stage b

Boiler 2, stage b

NOTE:

Manual sequence exchange: If the second boiler must always start

first for technical reasons, then this is possible by setting Code 912 to

"100" and Code 909 to "2". In this way the winter condition is always

simulated (boiler 2 = base load).

The summer / winter switch-over has a hysteresis of 2 K.

CAUTION:

An hydraulic crossover is not always the ideal solution with regard to

energy for condensing boilers.