Page 1

L

MagneW 3000

PLUS

Smart Electromagnetic

Flowmeter Specification

and Application Guide

36-KI-29-02

1/98

T tal P lan t

Page 2

Copyright, Notices, and Trademarks

Copyright 1998 by Honeywell Inc.

Revision 1.0 – January 5, 1998

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in its

written agreement with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special or consequential

damages. The information and specifications in this document are subject to

change without notice.

TotalPlant, TDC 3000 and SFC are U.S. registered trademarks of Honeywell Inc.

Other brand or product names are trademarks of their respective owners.

Honeywell

Industrial Automation and Control

Automation College

2820 West Kelton Lane

Phoenix, AZ 85023

(602) 313-5669

ii MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 3

Table of Contents

INTRODUCTION.....................................................................................................................1

COMPONENTS......................................................................................................................1

PRINCIPLE OF OPERATION...................................................................................................2

HARDWARE CONFIGURATION ..............................................................................................2

FEATURES............................................................................................................................3

DETECTOR ...........................................................................................................................3

CONVERTER.........................................................................................................................3

OPERATOR INTERFACE .......................................................................................................4

DIAGNOSTICS .......................................................................................................................5

COMMUNICATIONS SUMMARY..............................................................................................5

SUMMARY OF MAGNEW 3000

WIRING SUMMARY.................................................................................................................7

Electrical Connection Considerations .................................................................................8

Cable Types......................................................................................................8

Laying of Cables................................................................................................8

Cable Lengths...................................................................................................8

Grounding.........................................................................................................8

Terminal Connections ..........................................................................................................9

Cabling for Remote Detector/Converter..............................................................................10

RANGING FUNCTION............................................................................................................1 1

SELECTION OF CORROSION RESISTANT MATERIALS.......................................................12

APPLICATION DATA WORKSHEET......................................................................................13

INSTALLATION PLANNING CONSIDERATIONS ....................................................................14

Environmental Conditions ...............................................................................................14

Fluid to be Measured.........................................................................................................15

Measured Liquid Flow Conditions.......................................................................................15

Detector Location in Piping................................................................................................1 6

Clearance for Maintenance.................................................................................................18

PLUS

FEATURES...................................................................6

SPECIFICATIONS ................................................................................................................19

Performance ...................................................................................................................19

Design ......................................................................................................................... .....1 9

Environmental and Operating Conditions ............................................................................2 3

DIMENSIONS25

ORDERING DATA AND SPECIAL INSTRUCTIONS.................................................................36

1/98 MagneW 3000

PLUS

Specification and Application Guide iii

Page 4

Table of Contents

MODEL SELECTION GUIDES

MagneW 3000

PLUS

Integral Converter and MGG18D Wafer Style Detector,

Size 2.5-200mm..............................................................................36-KI-16-24

MagneW 3000

PLUS

Integral Converter and MGG18F Flange Style Detector,

Size 15-200mm...............................................................................36-KI-16-25

MagneW 3000

PLUS

Remote Converter .......................................................36-KI-16-26

MagneW 3000

PLUS

Remote Detector Wafer Type, Size 2.5-200mm .............. 36-KI-16-29

MagneW 3000

PLUS

Remote Detector Flange Type, Size 25-400mm ..............36-KI-16-30

MagneW 3000

PLUS

Remote Detector Wafer Type, Size 2.5-200mm .............. 36-KI-16-31

MagneW 3000

PLUS

Remote Detector Flange Type, Size 25-600mm ..............36-KI-16-32

MagneW 3000

PLUS

Submersible Detector Wafer Type, Size 15-200mm ........ 36-KI-16-33

MagneW 3000

PLUS

Submersible Remote Detector Flange Type,

Size 25-600mm...............................................................................36-KI-16-34

MagneW 3000

PLUS

Cables.............................................................................36-KI-16-35

MAGNEW 3000

PLUS

APPLICATION DATA SHEET............................................36-KI-08-01

iv MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 5

Figures and Tables

Figure 1 MagneW 3000

Figure 2 Principle of Operation.....................................................................................2

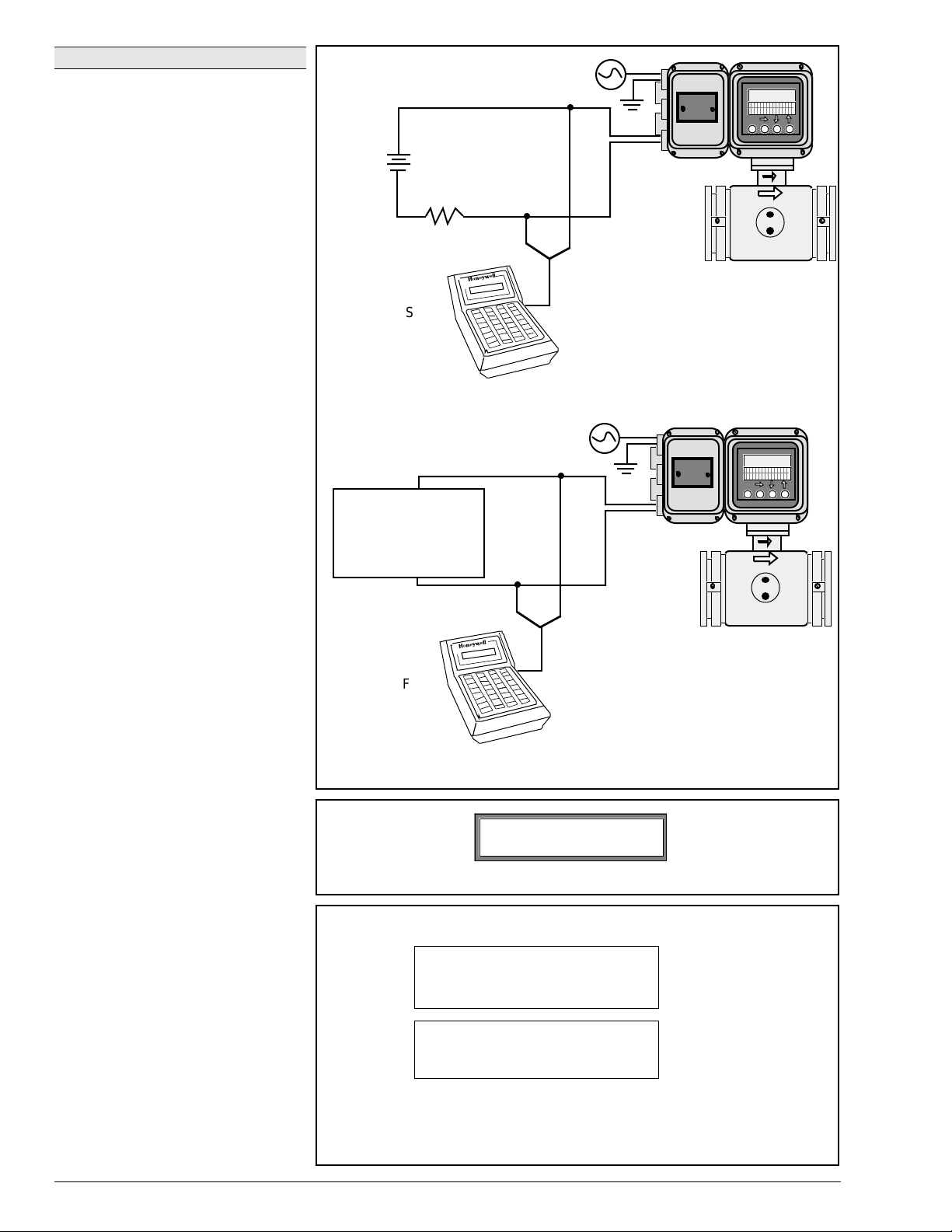

Figure 3 Typical SFC Connection to the 4 to 20 mA Loop...............................................4

Figure 4 Typical SFC Prompts.......................................................................................4

Figure 5 Digital Operator Panel Display (configured for % flow range)...............................4

Figure 6 MagneW 3000

Figure 7 Overview of MagneW 3000

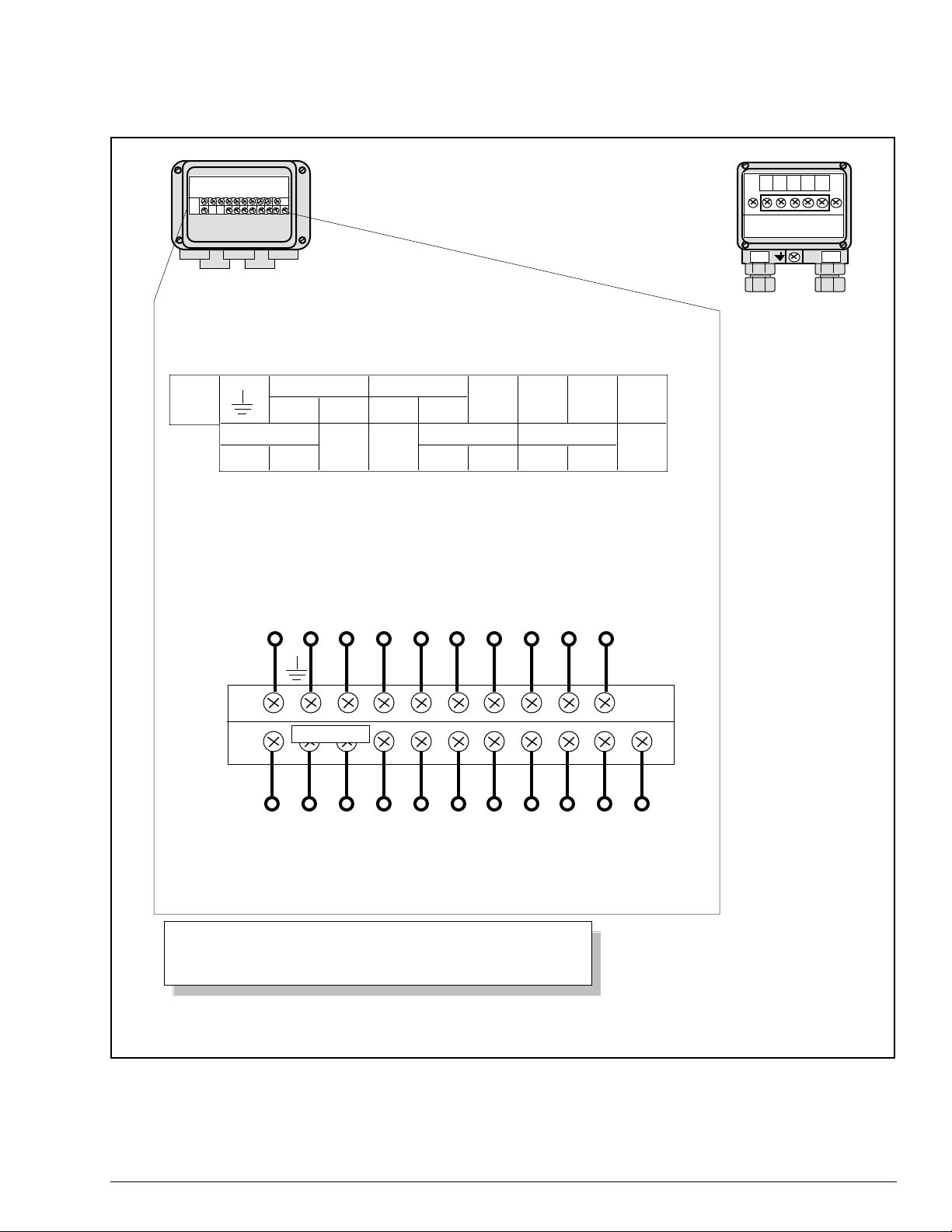

Figure 8 Typical Wiring Connections for the MagneW 3000

Integral Flowmeters.........................................................................................9

Figure 9 Cable Length Versus Fluid Conductivity.........................................................10

Figure 10 Direct Direction, Automatic Dual Range Transfer Hysteresis.............................1 1

Figure 11 Direct/Reverse Transfer Hysteresis................................................................1 1

Figure 12 Wall Mounting Dimensions............................................................................25

Figure 13 2-inch Pipe Mounting Dimensions.................................................................2 6

Figure 14 Dimensions for Integral Model—Refer to Table 8.............................................27

Figure 15 Union Joint Dimensions – 2.5 mm to 15 mm (0.1 in. to 0.6 in.)..........................28

Figure 16 Hose Joint Dimensions – 2.5 mm to 15 mm (0.1 in. to 0.6 in.)...........................29

Figure 17 IDF/Tri-Clamp Dimensions – 2.5 mm to 15 mm (0.1 in. to 0.6 in.).......................30

Figure 18 Wafer Dimensions – 2.5 mm to 15 mm (0.1 in. to 0.6 in.) and 25 mm to

200 mm (1 in. to 7.9 in.)—Refer to Table 8.....................................................31

Figure 19 Flange Dimensions – 25 mm (1 in.).................................................................33

Figure 20 Flange Dimensions – 40 mm to 140 mm (1.6 in. to 3.9 in.) and 150 mm to

600 mm (5.9 in. to 23.6 in.)—Refer to Table 9.................................................34

Table 1 Available Models.............................................................................................3

Table 2 Summary of Major MagneW 3000

Table 3 Summary of Range Function Options.............................................................11

Table 4 Characteristics of Wet Contact Materials..........................................................12

Table 5 Summary of Installation Considerations..........................................................1 4

Table 6 Specifications for MagneW 3000

Table 7 Minimum and Maximum Ranges.....................................................................24

Table 8 Dimensions for Figures 14 and 18..................................................................32

Table 9 Dimensions for Figure 20..............................................................................3 5

PLUS

Components..................................................................1

PLUS

Communications Hierarchy for TPS..................................5

PLUS

Wiring Requirements ...................................7

PLUS

Remote and

PLUS

Features.............................................6

PLUS

..........................................................19

1/98 MagneW 3000

PLUS

Specification and Application Guide v

Page 6

Page 7

Introduction

The MagneW 3000

electromagnetic flowmeter consists of a

detector/converter combination that

operates on the principles of Faraday’s

Law. Based on Honeywell’s proven

MagneW 3000 flow measurement

technologies, the

expanded flow rate and process

measurement capabilities when used

with the new range of

PLUS

PLUS

detectors offer

PLUS

converters.

The MagneW 3000

• a wide range of wafers and flanges,

• IDF and Tri-Clamp couplings,

• local data setting device,

• batch control with preset counter trip,

• automatic dual-range switchover with

reverse flow,

• high and low alarm settings,

• continuous self-diagnostics, and

• remote communication with SFC.

The MagneW 3000

TotalPlant Solution (TPS) system.

TPS is the evolution of TDC 3000

PLUS

offers

PLUS

is part of the

X

.

Integral Converter/Detector

Components

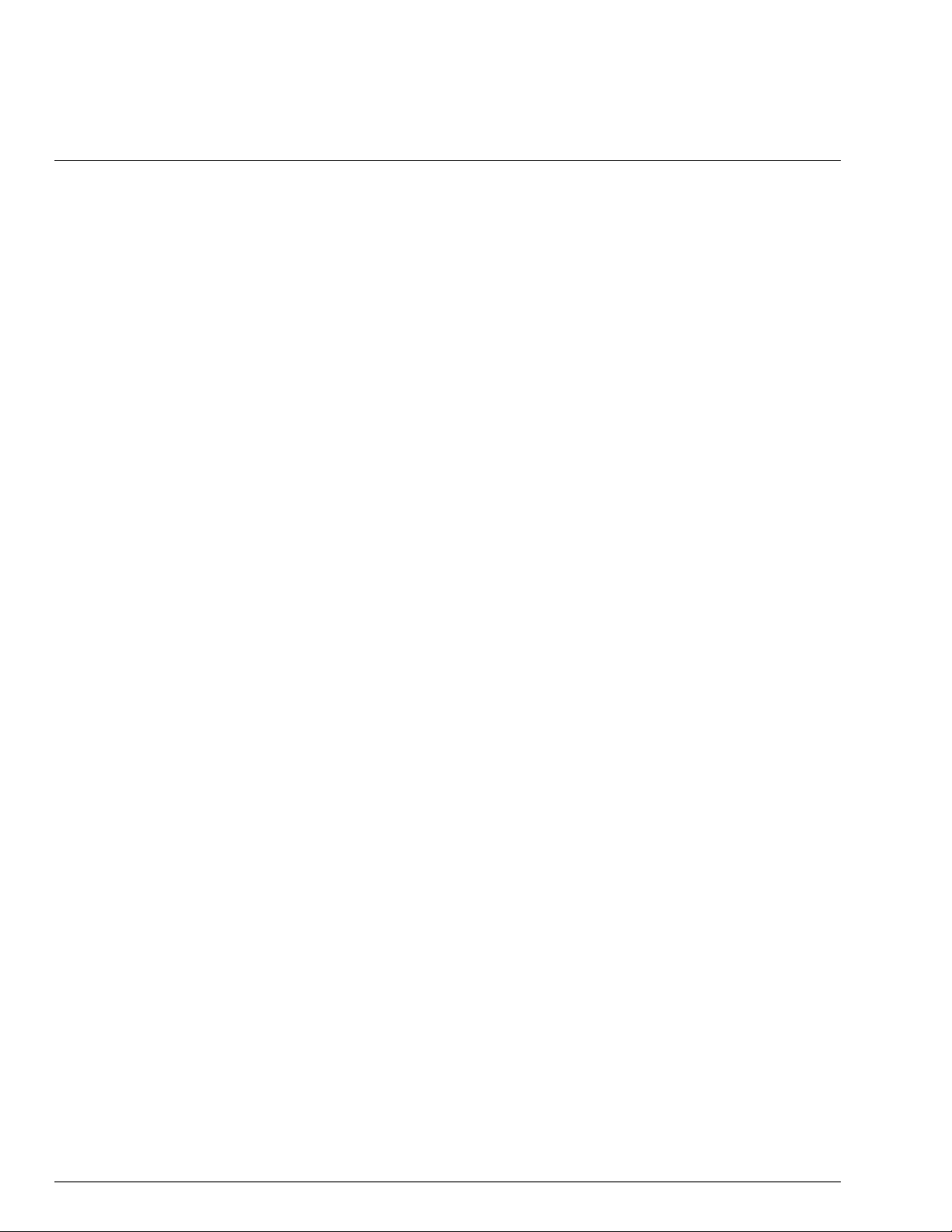

As shown in Figure 1, the MagneW 3000

PLUS

flowmeter includes a detector and

converter available in an integral-type

or a remote-type configuration.

With an integral-type configuration, the

converter mounts directly onto the

detector.

With a remote-type configuration, the

detector is connected by cables to the

converter which can be mounted up to

300 meters (984 feet) away, depending

on the application.

Remote Converter

8888888888888888888888

88

8888888888888888888888

Remote Detector

88

Figure 1—MagneW 3000

PLUS

Components

1/98 MagneW 3000

23441

PLUS

Specification and Application Guide 1

Page 8

Principle of Operation

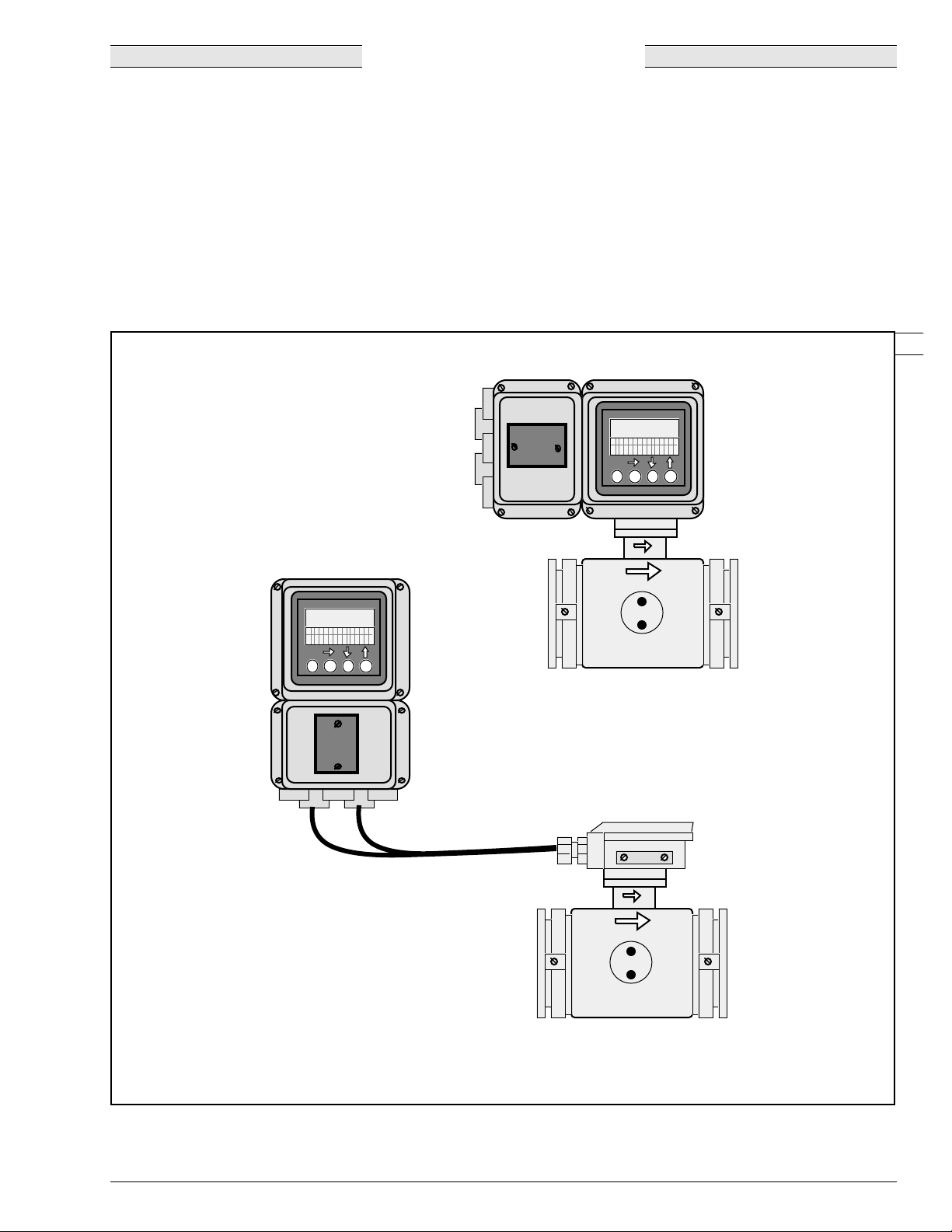

The MagneW 3000

operating principle is based on

Faraday’s Law:

PLUS

flowmeter’s

The voltage induced

across any conductor, as it moves at

right angles through a magnetic field, is

proportional to the conductor’s velocity.

The detector fits on the pipe and

measures the flow. The detector’s

excitation coils receive power from the

converter. These coils create a

magnetic field at a right angle to the flow

direction.

As the conductive liquid flows through

this magnetic field, a voltage which is

proportional to the liquid flow velocity is

produced across the electrodes. The

detector sends these voltage signals to

the converter. Refer to Figure 2.

The converter, which holds the circuitry

that calculates and displays the flow

data, converts the detector signals into

outputs for recording and control

instrumentation.

The relationship between the liquid flow

velocity and the voltage is expressed in

Faraday’s formula:

E is proportional to V x B x D

where:

E = Induced Electromagnetic

Voltage

Voltage generated by the flow of

the conductive liquid through the

magnetic field of the flowmeter.

V = Average Flow Velocity (m/s)

The average velocity of the liquid

through the cross section of the

flowmeter.

B = Magnetic Flux Density

The strength of the magnetic

field generated by the field coils.

D = Inside Diameter of the Pipe

The distance between the

electrodes which detect the

signal voltage (E) that is

generated.

This means that the voltage (E)

depends on the average flow velocity

(V), the magnetic flux density (B), and

the inside diameter of the pipe (D).

Detector

Core

Exciting

current

Power

Supply

Liquid Flow

(average velocity V)

Figure 2—Principle of Operation

Measuring Pipe

(inside diameter D)

Magnetic Field

(flux density B)

Converter

Electrode (emf E)

Output

Signal

21701

Hardware Configuration

The MagneW 3000

• an integral unit—converter mounted on detector, or

• a remote converter/remote detector.

The detector is mounted to the process piping, using one of the following types of

connections:

• wafer,

• flange,

• union,

• hose, or

• IDF or Tri-clamp.

The type of connection used is dependent upon diameter size and the application.

Where applicable, gaskets are supplied unless the grounding rings are made of

SUS material.

If using the remote converter/remote detector combination, either a wall- or pipemounting kit for the converter and cables to connect the converter and detector

are needed.

PLUS

flowmeter is available as either:

2 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 9

Features

)

Liquid crystal display with backlighting

(optional)

• In direct sunlight or in a dark room,

the backlit liquid crystal display (LCD)

can be read easily.

• Simultaneous display of

instantaneous flow volume in %,

actual flow volume in a variety of

engineering units, and indication of

total flow volume.

• When an integral model is installed on

vertical or horizontal pipes, its

display can be rotated through 90

degrees for better visibility.

Setting parameters by infrared touch

sensor (optional)

• Parameters can be set without

opening the cover of the converter.

• A special security feature has been

incorporated to prevent inadvertent

operation of the infrared touch

sensor.

Field-replaceable electrodes

Electrodes are field-replaceable.

High performance lining

• High-quality PFA lining has excellent

electrical and heat resistant

characteristics, low surface friction,

and high anti-adhesive properties.

• The PFA lining is particularly

applicable for measurement of sticky

pulps and gypsum slurries.

• PFA linings with diameter ranges from

2.5 to 600 mm (0.1 to 23.6 in.)

available, making selection of the

best lining easy for a wide variety of

applications.

• The successful, embedded punch

plate offers proven performance

under conditions of rapid thermal

change and/or negative pressure.

Rugged detector structure

• A stainless steel case is used for

diameters of 2.5 to 200 mm (0.1 to

7.9 in.).

A wide variety of piping connections

• A hose, union joint, or clamp can be

selected for very small diameter

models [diameters of 2.5 to 15 mm

(0.1 to 0.6 in.)].

• A flange structure is available for

diameters of 25 to 600 mm (1 to

23.6 in.).

• A wafer construction can also be

selected for diameters of 2.5 to

200 mm (0.1 to 7.9 in.).

• Diameters of 65, 125, and 450 mm

(2.6, 5, and 17.7 in.) have been

added to the existing product line.

Interchangeability

Can be used in combination with

previous model detectors and

converters.

Please consult your Honeywell

representative for details.

Detector

Because the detector does the actual

measuring of the flow rate, it serves as

the primary element for MagneW 3000

PLUS

flowmeters.

The detector measures the current

generated by the conductive fluid as it

moves through a magnetic field and

sends this signal to the converter.

Available models are listed in Table 1.

Converter

The converter takes the electromotiveforce signal from the detector and

converts it to the instantaneous flow

rate. That flow rate is output to the

control equipment as either an analog or

digital signal.

The converter also provides optional

pulse outputs to drive counters and

totalizers.

The converter has an optional Digital

Operator Panel (DOP) which indicates

the instantaneous flow rate or the

integrated flow rate.

Because the converter is a current

output-based device, the flowmeter can

be configured and operated using the

SFC. Or, the flowmeter can be

configured and operated locally using

the DOP.

The converter also supports the digital

enhanced (DE) mode for direct digital

communications with Honeywell’s TPS

system.

Available models are listed in Table 1.

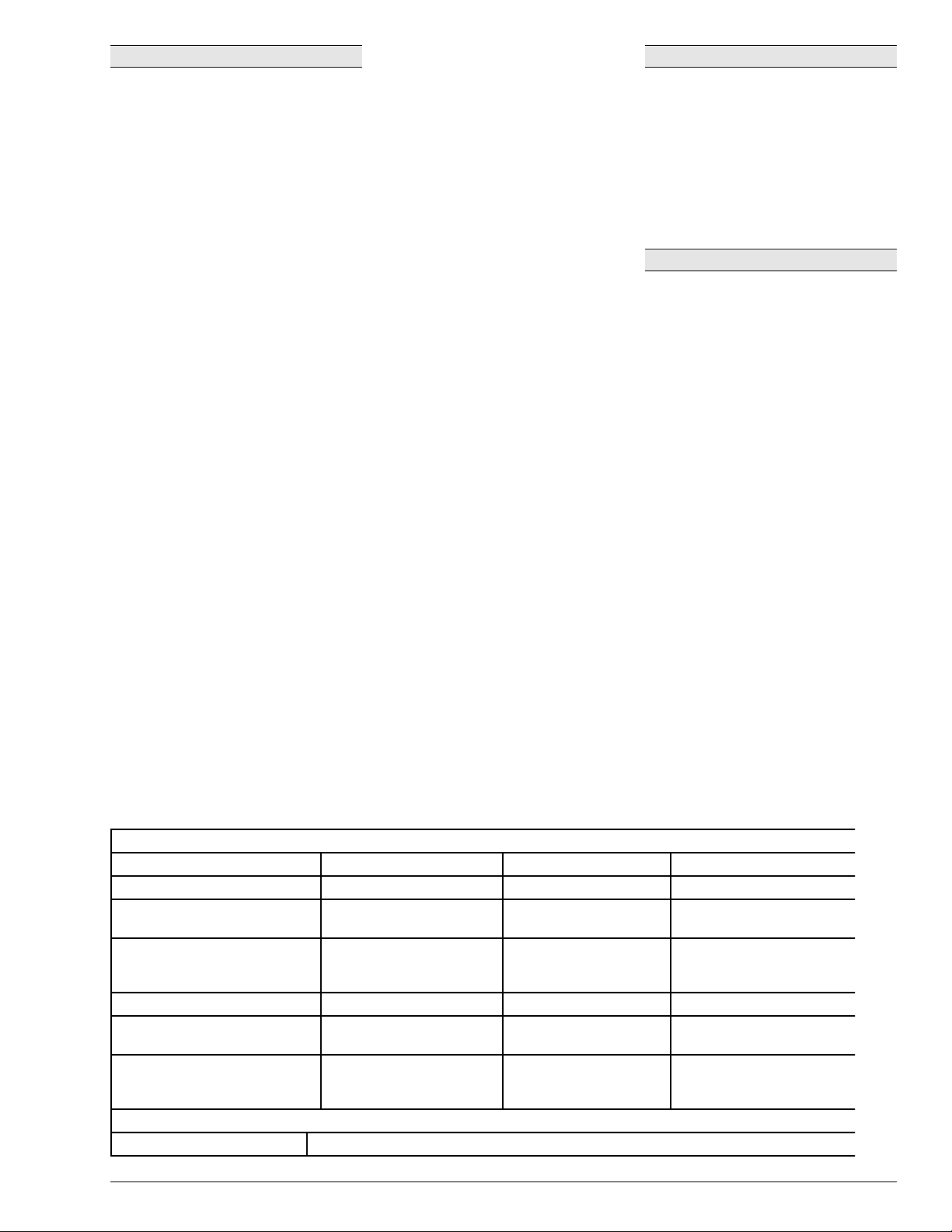

Table 1—Available Models

DETECTORS

Model Lining Pipe Connection Diameter—mm (inches

General/watertight PFA Union/hose/clamp 2.5 to 15 (0.1 to 0.6)

General/watertight PFA

General/watertight PFA

General/submersible PFA Union/hose/clamp 15 (0.6)

General/submersible PFA

General/submersible PFA

General Integral or remote type

1/98 MagneW 3000

Polyurethane rubber

Polyurethane rubber

Chloroprene rubber

Polyurethane rubber

Polyurethane rubber

Chloroprene rubber

PLUS

CONVERTERS

Specification and Application Guide 3

Wafer 2.5 to 200 (0.1 to 7.9)

25 to 200 (1 to 7.9)

Flange 25 to 600 (1 to 23.6)

25 to 200 (1 to 7.9)

250 to 600 (10 to 23.6)

Wafer 15 to 200 (0.6 to 7.9)

25 to 200 (1 to 7.9)

Flange 250 to 600 (10 to 23.6)

25 to 200 (1 to 7.9)

250 to 600 (10 to 23.6)

Page 10

Operator Interface

The MagneW 3000

PLUS

flowmeter can

be configured, communicated with, and

operated using

• a hand-held Smart Field

Communicator (SFC),

• the flowmeter’s optional Digital

Operator Panel (DOP), and/or

• Honeywell’s TPS system.

Communications can be quickly

established with the MagneW 3000

PLUS

through the SFC. It connects to

the output terminals on the converter or

anywhere along the 4 to 20 milliampere

current line. Refer to Figure 3.

Operating parameters can be

configured or operating data can be

read by initiating simple keystroke

sequences on the SFC. As shown in

Figure 4, English language prompts in a

two-line display guide the entry of

configuration data such as:

• Pulse Parameters

• Detector Parameters

• Low Flow Cutoff

• Damping Time

• Range Parameters

• Input and Output Options

• Failsafe Mode

Pertinent operating data values are

displayed in percent or user-selected

engineering units for volume flow, mass

flow, or time.

The optional DOP, allowing local

configuration and operation of the

flowmeter, contains

• a 7-segment, 6-digit main display,

and

• a 16-digit, 2-line auxiliary display.

Analog Mode

+

Red

External

Power

Supply

24 Vdc

+

_

4-20 mA

Output 1

–

250 Ω

Black

L

SFC

(Model

STS103)

DE Mode

+

Process Manager (PM)/

Advanced Process Manager

(APM)/High-Performance

Process Manager (HPM)

internal 24/42 Vdc power

supply with 250Ω resistor

_

–

Black

L

SFC

(Model

STS103)

Figure 3—Typical SFC Connections to the 4 to 20 mA Loop

Red

+

Digital

Output 1

MagneW

PLUS

Integral Model

(or

Remote Model)

MagneW

PLUS

Integral Model

(or

Remote Model)

23442

The main display indicates the

instantaneous flow rate in percent of

span, the instantaneous actual flow

volume in selected engineering units,

and the totalized flow volume (when

pulse output is selected).

Figure 4—Typical SFC Prompts

The auxiliary display allows the operator

to monitor actions for entering/

changing configuration, operation, and

calibration data, as well as checking

diagnostic functions. These actions are

performed using the DOP’s four infrared

touch sensor keys. Refer to Figure 5.

In the DE (Digital Enhanced) mode, the

flowmeter can communicate digitally

with Honeywell’s TPS, and through a

custom field termination assembly

(FTA) to Allen-Bradley controllers.

Figure 5—Digital Operator Panel Display (configured for % flow range)

4 MagneW 3000

DE CONF SFM 1001

F/S = B/O HI

23443

Main

Display

%00.

0.00 m3/h

Auxiliary

0000123456 TOTAL

PLUS

Specification and Application Guide 1/98

Display

23444

Page 11

Diagnostics

k

k

In the event of a malfunction,

diagnostic messages speed up the

troubleshooting process. Messages are

available locally when using the optional

DOP and via the SFC.

When operating in the DE mode, similar

interface operations are possible

through displays at the Universal

X

Station

Station (GUS) in the TPS system.

(UXS) or the Global User

Digital Communications

Summary

The SFC (model STS103) can be used

to “talk” to a flowmeter operating in

either the analog or the DE (Digital

Enhanced) mode. The SFC is

connected across the current line at the

flowmeter or any convenient point in the

line. See Specification 34-ST-03-55 for

more details about the SFC.

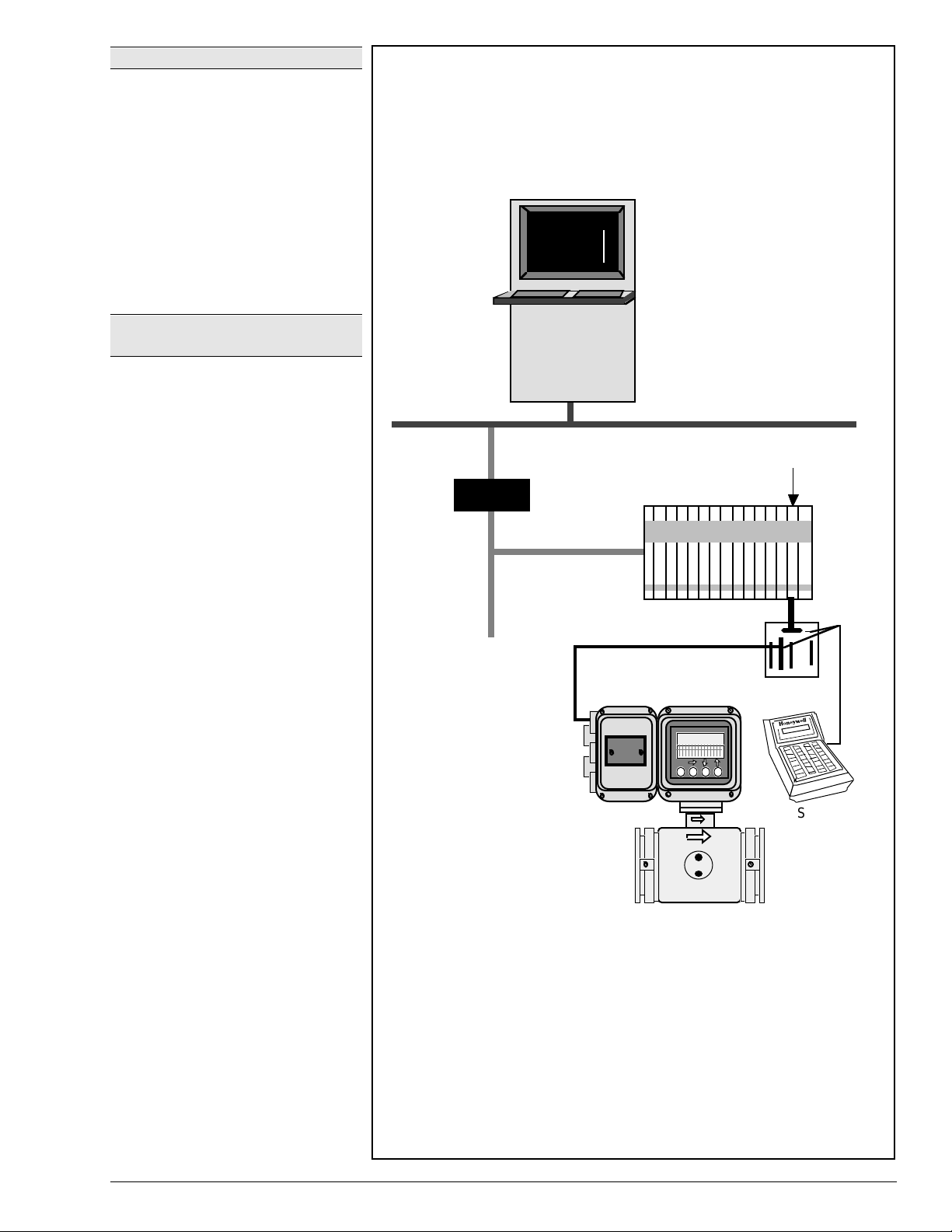

To “talk” to a flowmeter through displays

at the Universal Station or GUS, the

transmitter is connected to a Smart MV

Transmitter Interface Input/Output

Processor (STI IOP) in the Process

Manager (PM), Advanced Process

Manger (APM), or High-Performance

Process Manager (HPM) through an

FTA as shown in Figure 6. The flowmeter

must be in the DE mode to communicate

with the STI IOP.

Also, through a custom FTA the

flowmeter, in the DE mode, can

communicate with Allen-Bradley

controllers.

Universal

Station

or Global

User

Station

(GUS)

Network

Interface

Module

Universal

Networ

Control

DE/ Digital

Communications

Process Manager or

Advanced Process Manager

(or High-Performance Process

Manager)

Link

TPS Process Networ

Smart MV Transmitter

Interface I/O Processor

STI FTA

L

SFC (Model

MagneW

Integral Model

(or

Remote Model)

Figure 6—Typical MagneW 3000

1/98 MagneW 3000

PLUS

Specification and Application Guide 5

PLUS

PLUS

Communications Hierarchy for TPS

STS103)

23445

Page 12

Summary of MagneW 3000

PLUS

Features

Table 2 provides a summary of major MagneW 3000

Table 2—Summary of Major MagneW 3000

Feature Function

Operating principle based on Faraday’s Law Provides accurate and reliable measurement of process fluid flow rate.

Flange-mounted detector Provides a variety of process connections to match installation

4 to 20 milliampere signal or digital-enhanced

output

SFC and TPS communications Provide means to configure, operate, and troubleshoot MagneW through

Optional built-in counter for pulse output

models

Optional 1- or 2-contact input • External 0% lock input: Locks the flow rate signal (display, analog

PLUS

features and functions.

PLUS

Features

The unit of flow indication can be in percentage, volume flow, mass flow, or

time.

requirements.

Provides signal proportional to flow measurement in analog or digital form

depending upon configuration.

SFC and Universal Station or GUS in TPS system.

• Totalizer: Depending on pulse direction setting, it totals one count at a

time, for forward and reverse flows.

• Totalizer with preset function: A preset value (target total) can be set

between 000000 and 999999. Each forward and reverse flow signal is

counted.

• Forward/reverse flow difference totalizer: The difference in flow volumes

in the forward and reverse directions is calculated and counted.

output, and pulse output) at 0%.

• External zero adjustment input: Allows a zero point adjustment from a

remote location.

• External range switching input: Factory setting is

– Range No. 1 or forward direction when opened

– Range No. 2 or reverse direction when closed.

• Built-in counter reset input (optional for pulse output model): Reset

occurs when contact is ON for 0.2 seconds or more. Counting starts

from counter reset value when contact turns OFF.

Optional 1- or 2-contact output • Alarm contact output: An alarm is output when one of the following

abnormal states occurs.

– flow value alarm

– self-diagnosis—coil disconnection, ROM error, RAM error, NVM error,

ADC error, or

– empty pipe detection.

• Range switching output: Factory setting is

– Range No. 1 or forward direction—when open

– Range No. 2 or reverse direction—when closed

• Counter preset status output (for pulse output model): Activates when

the built-in counter reaches the preset value.

• Self-diagnosis alarm output: Activates when the self-diagnosis function

detects an abnormality.

• Empty pipe detection alarm output (with empty-status detection):

Activates when the fluid level in the detector goes below the electrode

level. Alarm is available only when the electrical conductivity of the

liquid is greater than 150µS/cm.

• High/Low limit alarm: Activates when the flow volume exceeds the set

upper and lower limit values.

• Two-stage flow value alarm output (with two contact outputs): An alarmactuating contact is output when the simultaneous flow value exceeds

the set two upper limits (H and HH) or the two lower limits (L and LL).

6 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 13

Wiring Summary

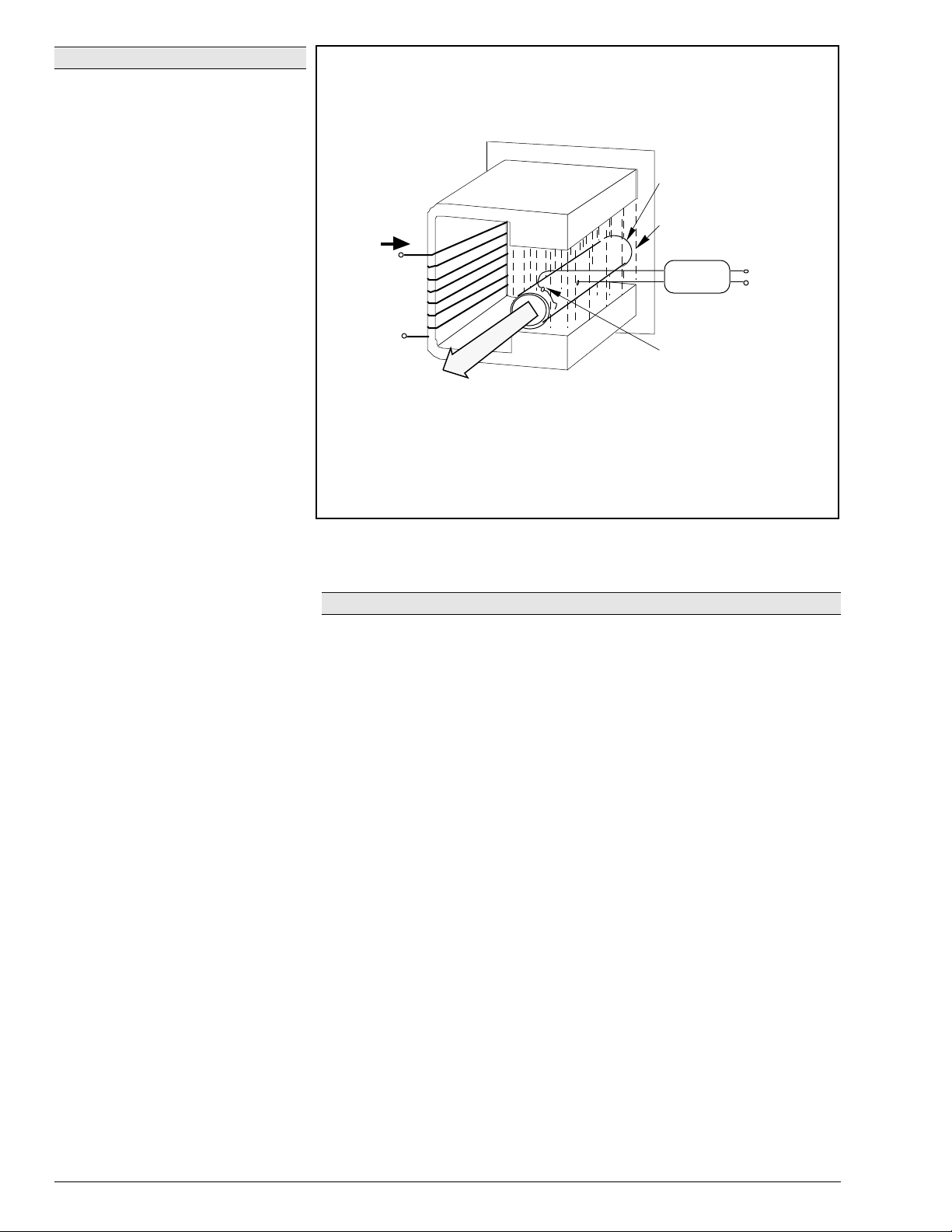

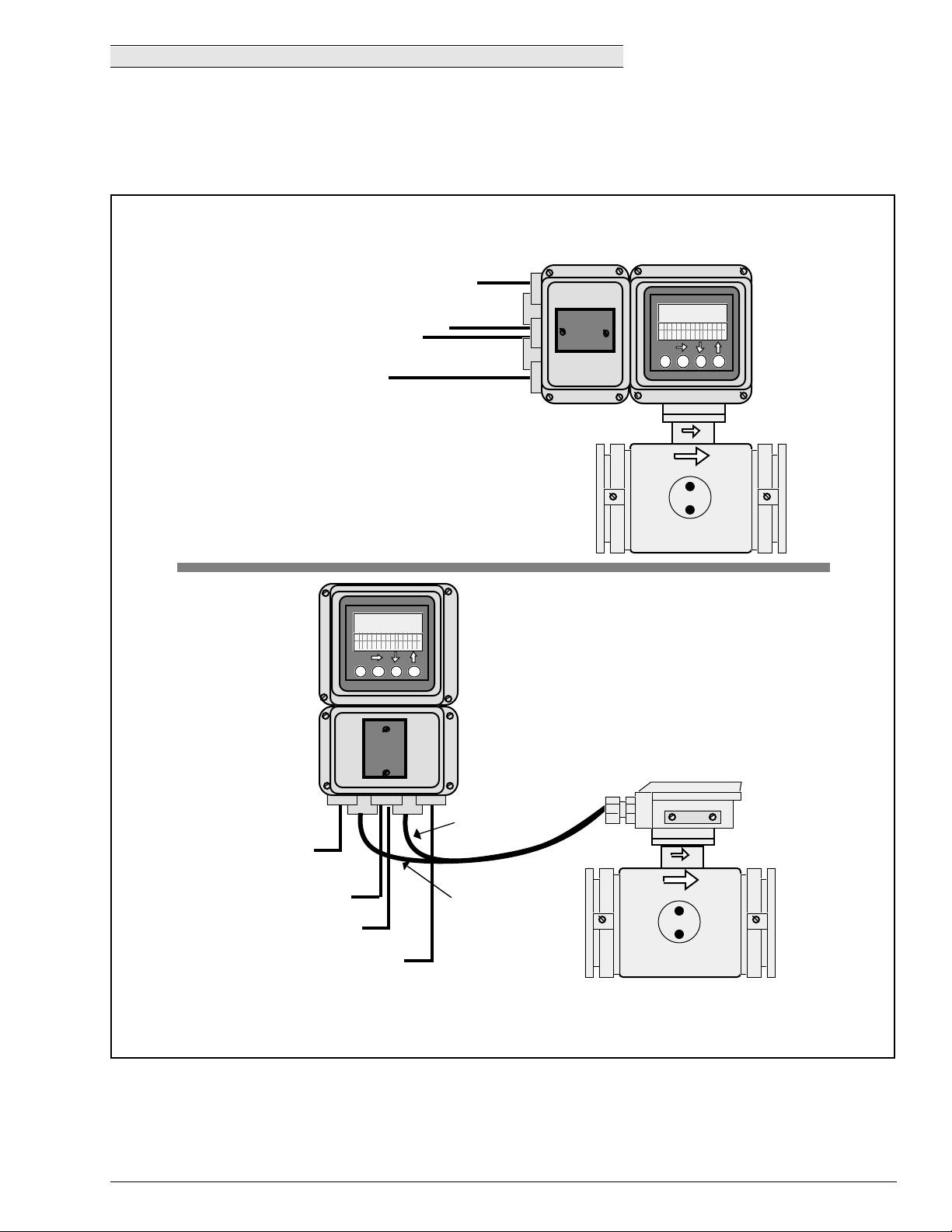

External excitation and signal cables are required when connecting the remote

detector/converter model.

Figure 7 provides an overview of possible wiring requirements for either model.

Integral Converter/Detector

Power supply

Vac or 24 Vdc

Pulse output

Contact input/output

4 to 20 mA/DE output

8888888888888888888888

88

Remote Converter

and

Remote Detector

Power supply

Vac or 24 Vdc

Pulse output

Contact input/output

4 to 20 mA/DE output

Figure 7—Overview of MagneW 3000

8888888888888888888888

PLUS

Wiring Requirements

88

Signal cable

Excitation cable

23446

1/98 MagneW 3000

PLUS

Specification and Application Guide 7

Page 14

Electrical Connection Considerations

For electrical connections of the

converter/detector the following should

be checked:

• Cable types

• Laying of cables

• Cable lengths

• Grounding

Cable Types

The standard cables for the instrument

are as follows:

Signal cable:

•

double-shielded cable

Excitation cable:

•

cabtyre cable

If standard cables are unavailable,

contact Honeywell for

recommendations.

Laying of Cables

• Do not lay the cables near a motor, a

transformer, or a large-current cable

which may cause induction noise.

Lay the cables 1 meter (3.3 feet) or

more away from heavy-duty power

cables.

• Lay the signal cable in a metallic

conduit, a flexible tube, or a duct,

separately from the excitation current

cable or any other power cables.

• Wire with electrical tube and duct to

keep out water and protect the wire

from external damage. Lay the tube

so that no water gets into the unit.

• Use a waterproof gland at the conduit

connection.

• Do not employ any junction point for

connection of the signal cable or the

exciting cable between the detector

and the converter. When it is

unavoidable to employ a junction

point, use Cable Junction Box (Part

No. 80720002-000) which has been

designed specifically for this

purpose.

• Do not short the excitation current

terminals X and Y of the converter.

2-core individually

2-core chloroprene

Cable Lengths

• The length of the cable between the

detector and the converter depends

on the electrical conductivity (µS/m)

of the fluid to be measured. (Refer to

Figure 9 on page 10.)

In general, the electrical conductivity

of potable water or sewage water is of

a level of 10000 µS/m (100 µΩ/cm).

Therefore, for a detector of 15 mm

(0.6 in.) diameter or over, the

maximum allowable cable length is

300 meters (984 feet).

• Signal Cable

If a signal cable is required to be laid

more than 500 meters (1640 feet),

select a cable cross section so that

the voltage drop in the cable does not

exceed 5V.

To calculate the excitation cable

cross section area, use the following

formula:

A (cross section area: mm

35.6 x L (cable distance: m) x 0.4 (A)

1000 x 5 (V)

• Current output cable (4-20 mA)

The allowable current output load of

the converter is 0 to 600Ω. The sum of

the cable resistance plus load

resistance must be within this range.

With a 2 mm

cable resistance for both-ways

between 1 km (3.281 ft.) distance is

approximately 20Ω. When the

receiver load is 400Ω, the current

output cable can be extended up to 10

km (6.2 miles).

• Pulse output cable

Can be extended up to 1 km

(3,281 ft.).

Grounding

• The grounding circuit should be less

than 100Ω.

• At the converter side, ground the

meter at the E terminal of the terminal

block or the ground terminal of the

case. The E terminal and the ground

terminal are mutually connected in the

unit.

2

(0.003 in2) cable, the

2

) =

8 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 15

Terminal Connections

Figure 8 shows typical wiring connections for both the integral and remote types.

REMOTE CONVERTER

ABCXY

TERMINAL CONNECTOR BOX

SIG EX

REMOTE

DETECTOR

TERMINALS

STATUS IN

STATUS IN1

OR

STATUS OUT2

OR

*

STATUS OUT

STATUS IN2

STATUS OUT1

—1-contact input and 1-contact output

—2-contact inputs

—2-contact outputs

**

E

+–+–

POWER

LN

Not used

XY

Contact input,

Class 3 grounding

input 1, or output 2

Contact output,

SB SA C A

I.OUTP.OUT

+–+–

Flow rate

input 2, or output 1

signal input

B

E SB SA C A

Not used

Power supply

AC or DC 24V

+–+–

WARNING

LN

XY

Excitation output

Pulse output

NOTE: FOR INTEGRAL CONVERTER/DETECTOR:

Terminal symbols X, Y, SB, SA, A, B, C, and E are not indicated

because these terminals are not used.

Figure 8—Typical Wiring Connections for the MagneW 3000

+–+–

Current output

PLUS

Remote and Integral Flowmeters

B

Flow rate

signal input

Not used

23447

1/98 MagneW 3000

PLUS

Specification and Application Guide 9

Page 16

Cabling for Remote Detector/Converter

Honeywell offers the excitation and signal cables as a set under a separate model

number (Model Number KIW-XXX-XXX). Commercially available cables can be

used. The selection of the signal cables depends on certain conditions:

• fluid conductivity,

• length of cable, and

• diameter of the detector.

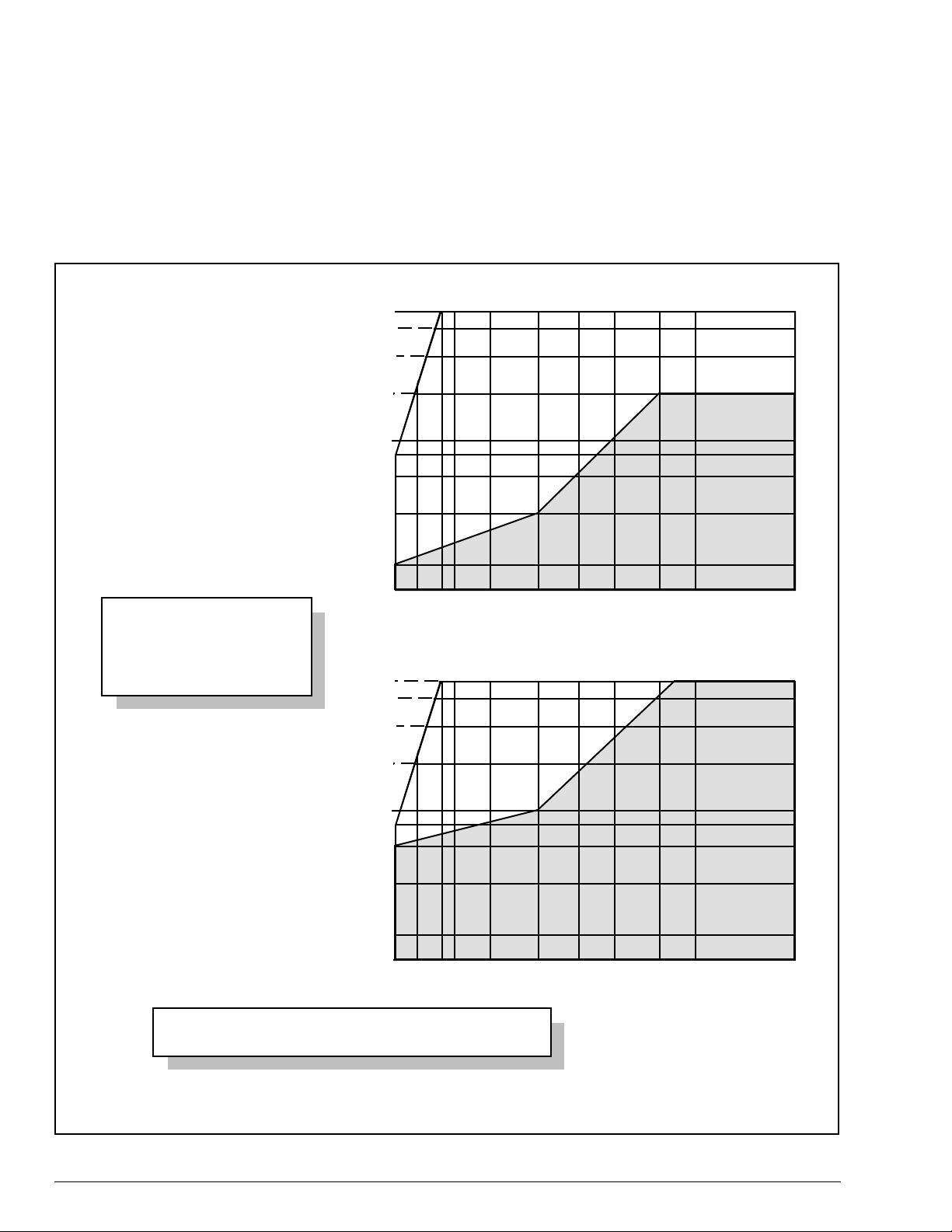

Figure 9 shows the relation between fluid conductivity and cable length.

The shaded portions are the

areas where commercially

available cables or cables

without shield drives can be

used.

Cable

Length

mft

300 984

200 656

100 328

50 164

20 65.6

15 49.2

10 32.8

5 16.4

2 6.6

1 3.3

mft

300 984

200 656

100 328

Detector Sizes: 2.5 and 5mm (0.1 and 0.2 in)

3 5 10 20 50 100 200 500 1000

Electrical Conductivity (µΩ/cm)

Detector Sizes: 10mm (0.4 in) and greater

Cable

Length

NOTE: Empty pipe detection alarm is available only when the

electrical conductivity of the fluid is greater than 150 µS/cm.

Figure 9—Cable Length Versus Fluid Conductivity

50 164

20 65.6

15 49.2

10 32.8

10 MagneW 3000

5 16.4

2 6.6

1 3.3

3 5 10 20 50 100 200 500 1000

Electrical Conductivity (µΩ/cm)

PLUS

Specification and Application Guide 1/98

23448

Page 17

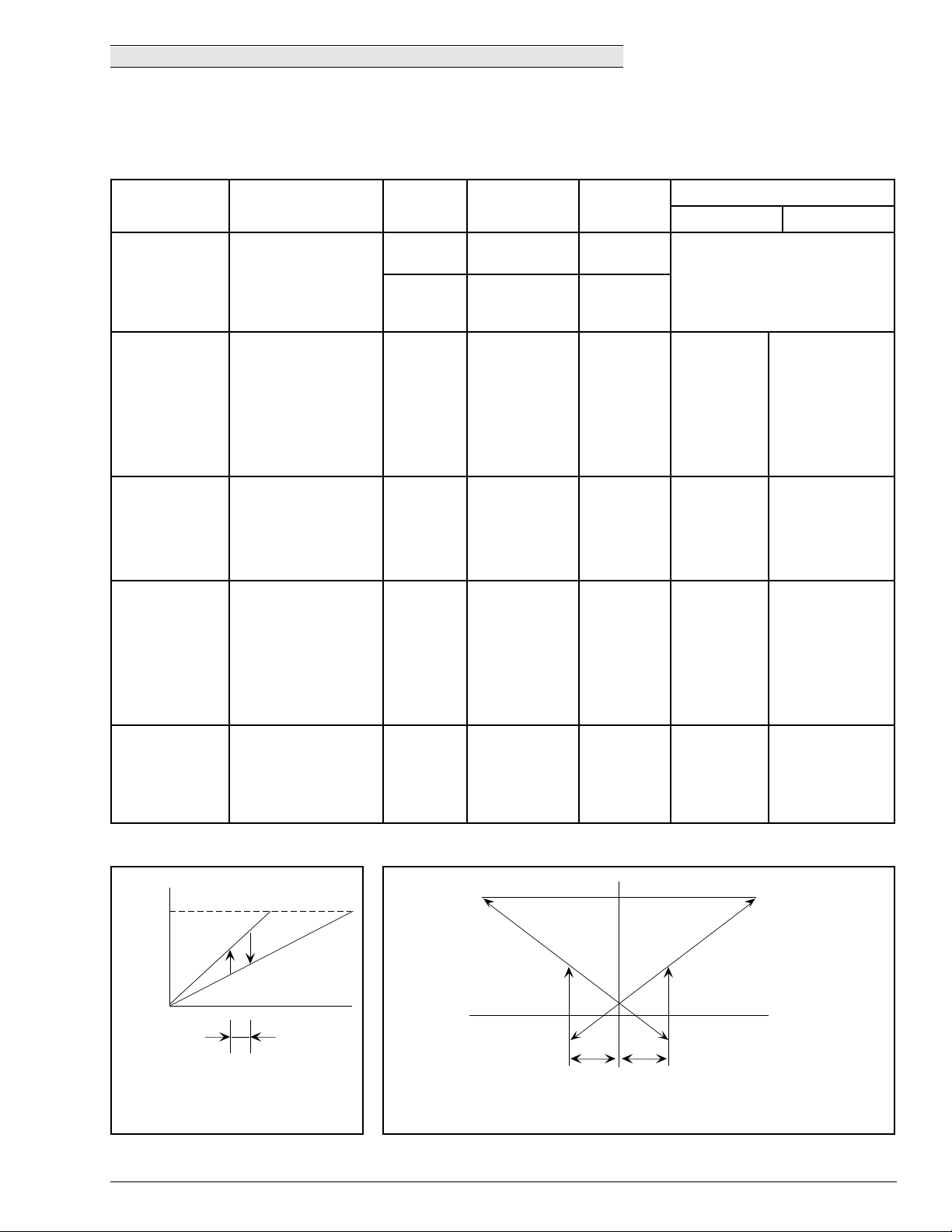

Ranging Function

The range function allows the operator to define the basic operating

characteristics of the flowmeter. Table 3 explains the various function options

that are available.

Table 3—Summary of Range Function Options

Analog

Type Description Output Pulse Display

Single Range • Direct flow only with

one 4 to 20 range

Forward:

4-20 mA dc

Reverse:

Proportional Positive No effect

Not delivered Minus

–20%

(0.8 mA)

Direct, Dual

Range, Auto

Selection

• Direct flow only with

two ranges

• Switching between

Both 4 to

20 mA dc

Pulse weight for

both ranges is

the same

measuring ranges is

automatic

(Hysteresis is

illustrated in Figure

10.)

Direct, Dual

Range, External

Selection

• Direct flow only with

two ranges

• Switching between

Both 4 to

20 mA dc

Pulse weight for

both ranges is

the same

ranges is done

externally

Direct/Reverse,

Dual Range,

Auto Selection

• Direct and reverse

flow with two ranges

• Switching between

measuring ranges is

Both 4 to

20 mA dc

Pulse weight is

same

regardless of

flow direction

automatic

(Hysteresis

illustrated in Figure

11)

Minus sign

appears

when flow is

in reverse

direction

Contact

Input Output

No effect Factory setting

1st range: open*

2nd range:

closed*

Range select

1st range:

open

2nd range:

closed

Factory setting

1st range: open*

2nd range:

closed*

contact outputs

(optional)

No effect Factory setting

direct: open*

reverse: closed*

Direct/Reverse,

Dual Range,

External

Selection

• Direct and reverse

flow with two ranges

• Switching between

ranges is done

externally

*Reverse setting is also possible.

Output

20 mA

4 mA

Adjustable by 0-20%

Figure 10—Direct Direction, Automatic

Dual Range Transfer Hysteresis

Input

23449

Both 4 to

20 mA dc

Pulse weight is

same

regardless of

flow direction

Minus sign

appears

when flow is

in reverse

direction

Output20 mA

Reverse

direction

With respect to direct

direction range,

adjustable by 0-20%

Figure 11—Direct/Reverse Transfer Hysteresis

Range select

direct: open

reverse:

closed

Factory setting

direct: open*

reverse: closed*

contact output

(optional)

Direct

direction

Input

With respect to reverse

direction range,

adjustable by 0-20%

23450

1/98 MagneW 3000

PLUS

Specification and Application Guide 11

Page 18

Selection of Corrosion-

Resistant Materials

The corrosiveness of fluids used under

practical conditions may vary according

to the type and amount of impurities

present, the operating temperatures,

the variances in flow rate, and the

concentration of fluids.

Selection of Lining Materials

The lining materials for use in the

MagneW 3000

PFA, alumina ceramic, polyurethane

rubber, and chloroprene rubber. Their

general characteristics are shown in

Table 4.

PLUS

include Teflon

Selection of Materials for Electrodes

Selection of Ground Ring Material

The same material for ground rings as

for electrodes should be selected since

both come in contact with fluids.

and Wet Contact Rings

The general characteristics of electrode

materials is shown in Table 4.

Table 4—Characteristics of Wet Contact Materials

Material Main Component Characteristics Recommended Environment

Lining Materials

Polyurethane rubber Polyurethane A synthetic elastic rubber. Excellent

Teflon PFA Tetrafluoroethyl

Ceramic Alumina ceramic

ene resin

Al

: 99.7%

2O3

abrasion resistance. Little chemical

resistance.

A synthetic polymer containing fluorine

(F) in the molecule. Resistant to almost

all chemicals except for hightemperature fluorine, molten alkalis,

and some halogen compounds.

Excellent heat resistance together with

a low friction characteristic and nonadhesiveness.

Excellent friction resistance. Suited for

high temperatures and high pressures.

Chemical resistance is slightly lower

than that of Teflon PFA. Weak to alkali

fluids.

Temperature:

+122°F)

Pressure:

NOTE: Provides heat resistance in hot

atmospheres.

–40 to +50°C (–40 to

426 psi maximum

Temperature:

–40 to +100°C (–40 to +212°F) for

diameters 2.5 to 10 mm (0.1 to 0.4 in.)

–40 to +160°C (–40 to +320°F) for

diameters 15 to 200 mm (0.6 to 7.9 in.)

–40 to +100°C (–40 to +212°F) for

diameters 2.5 to 10 mm (0.1 to 0.4 in.)

Pressure:

Temperature:

(–40 to +356°F)

Pressure:

Refer to Table 5, page 15.

–40 to +180°C

1 to 40 kg/cm

14 psi maximum

2

Chloroprene rubber Chloroprene The friction and chemical resistances

are almost comparable to those of

polyurethane rubber.

Electrode Materials

SUS316L Cr : 17%

Ni : 13%

Mo : 2.25%

C : <0.03%

Fe : Remainder

Titanium Ti : >99.3% Resistant to corrosion in an oxidizing

Hastelloy C-276 Mo : 16%

Cr : 16%

Fe : 5%

W : 4%

Ni : Remainder

Resistant to corrosion in a weak alkali

or acidic atmosphere.

Unusable in inorganic and organic

acids, chlorides, etc.

atmosphere.

In particular, usable in the presence of

chlorine ions. Unusable in sulfuric acid,

nitric acid, etc.

(The empty-detection function of the

converter cannot be used.)

A wide range of uses since it is usable

in moderately oxidizing and reducing

atmospheres.

Weak to sulfides, sulfuric acid, etc.

Temperature:

Pressure:

Water (tap and sewage) and weak alkalis

(such as caustic soda of 50% or less)

A variety of chloride solutions

(ammonium chloride, potassium

chloride, ferrous chloride, etc.), sea

water, etc.

A variety of organic and inorganic acids,

alkalis, etc.

–10 to +70°C (14 to 158°F)

142 psi maximum

12 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 19

Table 4—Characteristics of Wet Contact Materials, continued

Material Main Component Characteristics Recommended Environment

Electrode Materials (continued)

Tantalum

For Teflon PFA

lining:

Ta : >99.5%

For ceramic use:

Ta : 90%

W : 10%

Resistant to corrosion in strongly

oxidizing and reducing atmospheres,

but unusable in alkalis, fluorides, and

fuming sulfuric acid.

Because an insulating film may form on

these electrodes, pay special attention

to process conditions when selecting

this material.

(The empty-detection function of the

converter cannot be used.)

Concentrated hydrochloric acid, sulfuric

acid, nitric acid, aqua regia, etc.

Platinum-iridium alloy Pt : 90%

Ir : 10%

Tungsten carbide Highly abrasion-resistant and causes

Nickel Highly corrosion-resistant against

Zirconium Corrosion-resistant against various

Resistant to corrosion in almost all

acids and alkalis except for aqua regia

and ammonium salts. Very expensive.

less slurry noise. Cannot be used for

corrosive fluids.

strong alkali fluids, especially against

caustic soda and fluoric acid as

compared with corrosion resistances of

other metals.

chemicals, especially against sulfides.

Application Assistance

While the technical information provided in this guide is usually adequate for

sizing a meter for a particular application, Honeywell has Application Assistance

available. An Application Data Sheet (36-KI-08-01) is included at the end of this

document. When completed it provides the information necessary for a thorough

review by our Field Instrument Application Engineers. Using your application and

installation information, process fluid data, and cost and operation objectives,

these engineers will apply their wide industry experiences and various application

software programs to assist in determining the most cost-effective flow solution

available. To use this Honeywell service, please complete the Application Data

Sheet and forward it to your Honeywell Representative for submission to Field

Instrument Application Engineering.

Phosphoric acid, nitric acid, fluoric acid,

hydrochloric acid, sulfuric acid, alkalis,

etc.

Cement slurry, muddy slurry, filthy

slurry, earth/sand slurry, etc.

Caustic soda, fluoric acid, alkali fluids,

etc.

Copper sulfide, formic acid, potassium

hydroxide, etc.

1/98 MagneW 3000

PLUS

Specification and Application Guide 13

Page 20

Installation Planning Considerations

w

e

The MagneW 3000

and operation, the following installation conditions should be reviewed:

• Environmental conditions

• Fluid to be measured

• Measured liquid flow conditions

• Detector location in piping

• Clearance for maintenance and inspection

PLUS

planning considerations are summarized in Table 5. To ensure proper flowmeter selection

Table 5—Summary of Installation Considerations

Factor Consideration

Environmental conditions The following should be considered when installing the MagneW 3000

• The ambient temperature should be within the following ranges:

–

Integral model:

–25 to +60°C (–13 to +140°F)

–

Remote converter:

–25 to +60°C (–13 to +140°F)

–

Remote detector:

PLUS

.

PFA lining:

–30 to +80°C (–22 to +176°F)

Polyurethane rubber or Chloroprene rubber lining:

–30 to +60°C (–22 to +140°F)

• Whenever possible, the flowmeter should not be exposed to direct sunlight, rain, or other

unfavorable weather.

• The flowmeter should be installed as far from any pump in the line as practical, so that the flo

does not pulsate.

• The flowmeter must not be subjected to severe vibration, as equipment damage could result.

• The flowmeter must not be subjected to a highly corrosive atmosphere, as equipment damag

could result.

• The flowmeter must be installed sufficiently apart from high-current power lines, motors,

transformers, or any other source of electromagnetic interference.

14 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 21

Table 5—Summary of Installation Considerations, continued

.

Factor Consideration

Fluid to be measured The fluids to be measured must fall within MagneW 3000

• electrical conductivity—3µS/cm or greater

• temperature

• pressure

kPapsig This area (120 to 160°C/

+2937

+426

+1958

+284

Pressure

+142

LEGEND

+979

-14

-97

-40 0 +50 +100 +160+120

°C

-40 +32 +122 +212 +320+248

°F

Code Liner

Polyurethane

Rubber

Teflon PFA

Teflon PFA

Teflon PFA

Chloroprene

Rubber

Temperature (Degrees)

Detector Size

mm (in.)

25 to 200

(1 to 7.9)

2.5 to 10

(0.1 to 0.4)

15 to 200

(0.6 to 7.9)

250 to 600

(9.8 to 236)

250 to 600

(9.8 to 23.6)

PLUS

specifications for:

248 to 320°F) applies to

remote detectors only with

PFA liner and detector

size 15 to 200 mm (0.6 to

7.9 inches)

Temperature Range

°C °F

–40 to 50

–40 to 100

–40 to 160

–40 to 120

–10 to 70

–40 to 212

–40 to 320

–40 to 248

14 to 158

–40 to 122

23451

Measured liquid flow

conditions

The following liquids may not be successfully measured by MagneW 3000

PLUS

, even if their

conductance, temperature, and pressure fall within its limits.

• Fluids that have sufficient conductivity at high temperatures but not at room temperature,

approximately 20°C (68°F).

EXAMPLE: fatty acids and soap

• Fluids that contain surface active agents

EXAMPLE: shampoo, rinse, and soap material liquids

• Conductive adherents

EXAMPLE: deposition of rosin plus conductive material

• Insulating adherents

EXAMPLE: oil, kaolinite, kaolin, and calcium stearate

When determining the piping location for the flowmeter, make sure the measured liquid flow

meets the following conditions:

• The fluid has the required conductivity for measurement and the distribution of conductance

is uniform.

• The fluid is electrochemically uniform. For example, if two fluids are mixed at an upstream

point, the two fluids should be uniformly mixed by the time they reach the measurement point

• The distribution of suspended solids is uniform.

1/98 MagneW 3000

PLUS

Specification and Application Guide 15

Page 22

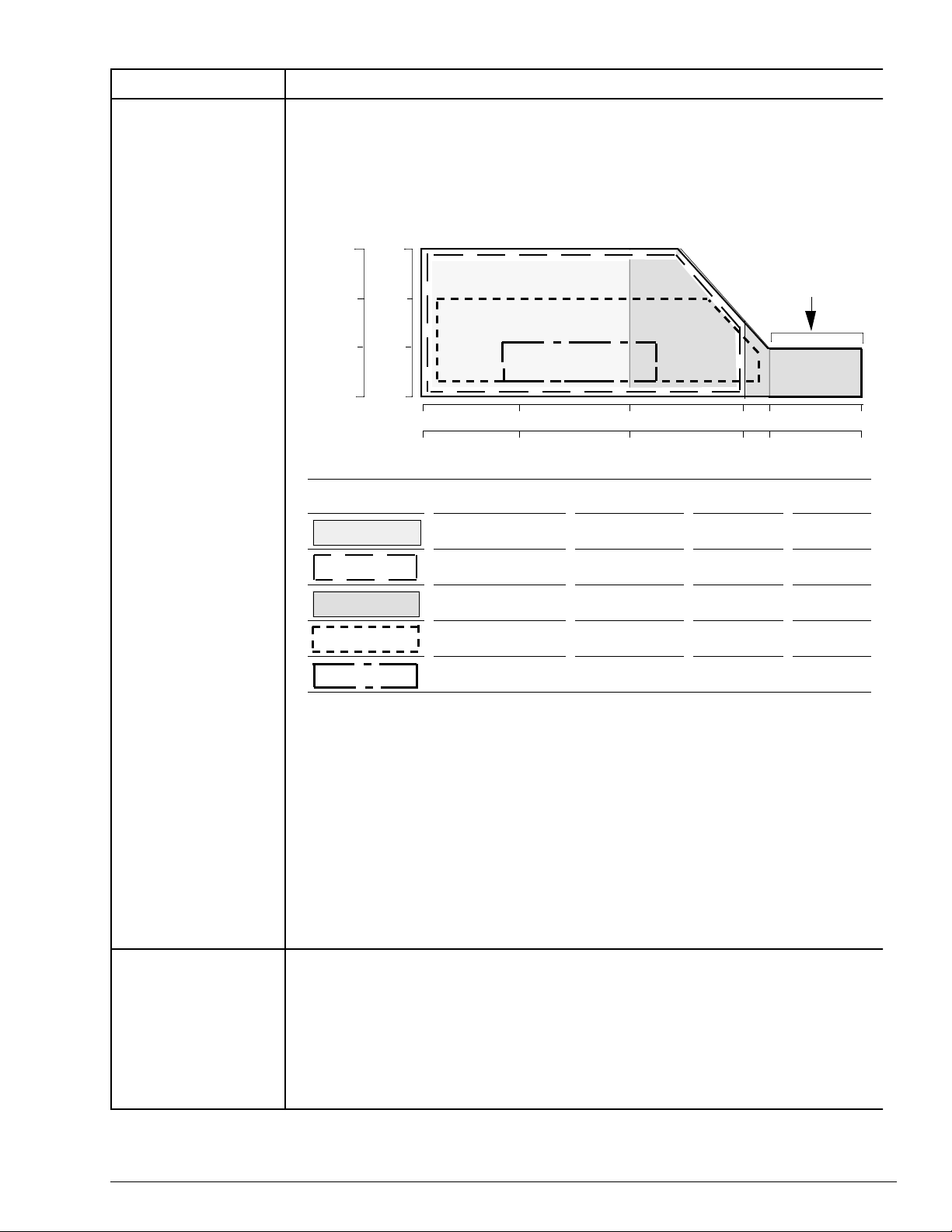

Table 5—Summary of Installation Considerations, continued

Factor Consideration

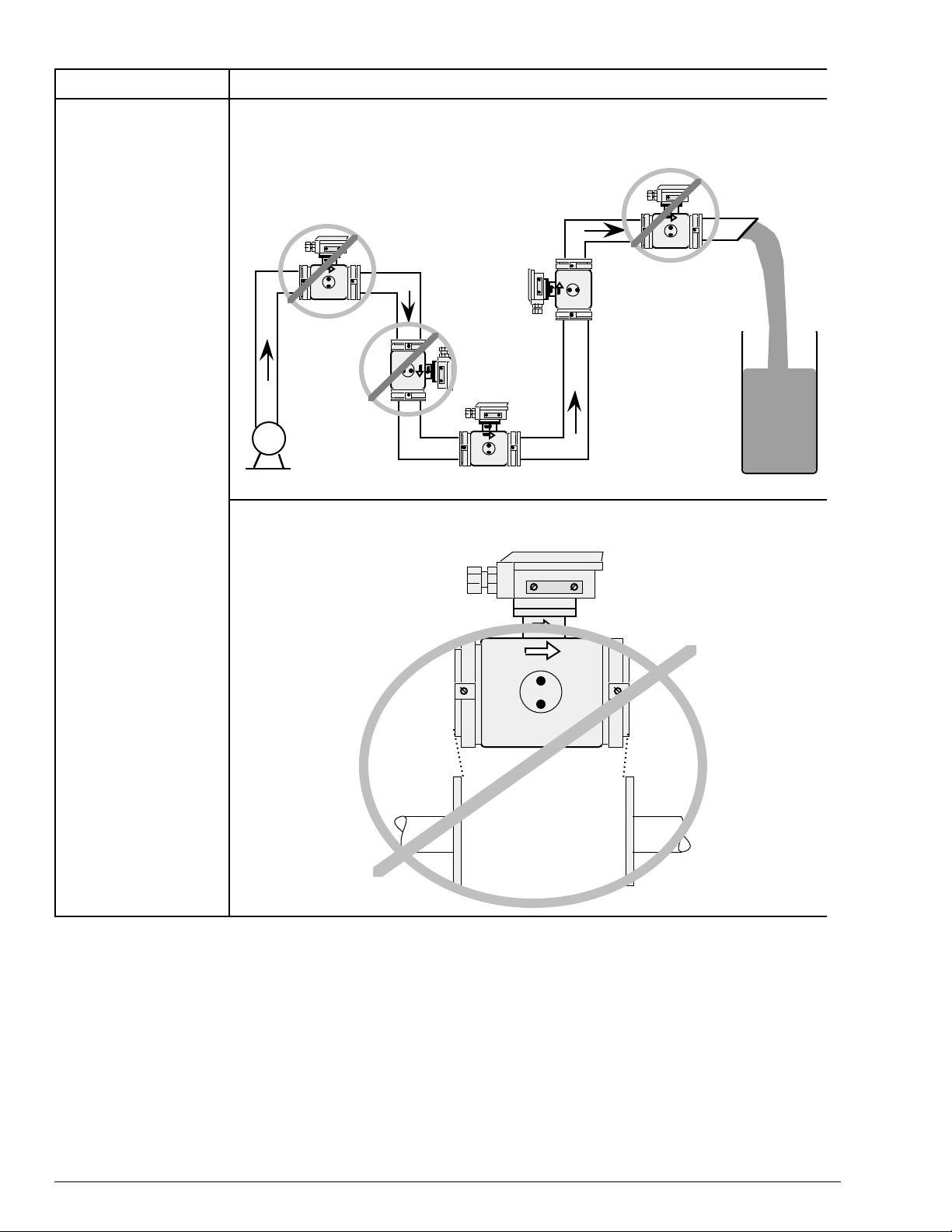

Detector location in

piping

The detector should be installed in the pipeline where it will always be filled with the measured

fluid.

Not filled with liquid

Air may be entrapped

May not be

filled with liquid

Good

location

Pump

Good location

23452

The face-to-face space between the flanges must be sufficient for the given detector size.

Never force the detector into an insufficient face-to-face space.

16 MagneW 3000

23453

PLUS

Specification and Application Guide 1/98

Page 23

Table 5—Summary of Installation Considerations, continued

r

Factor Consideration

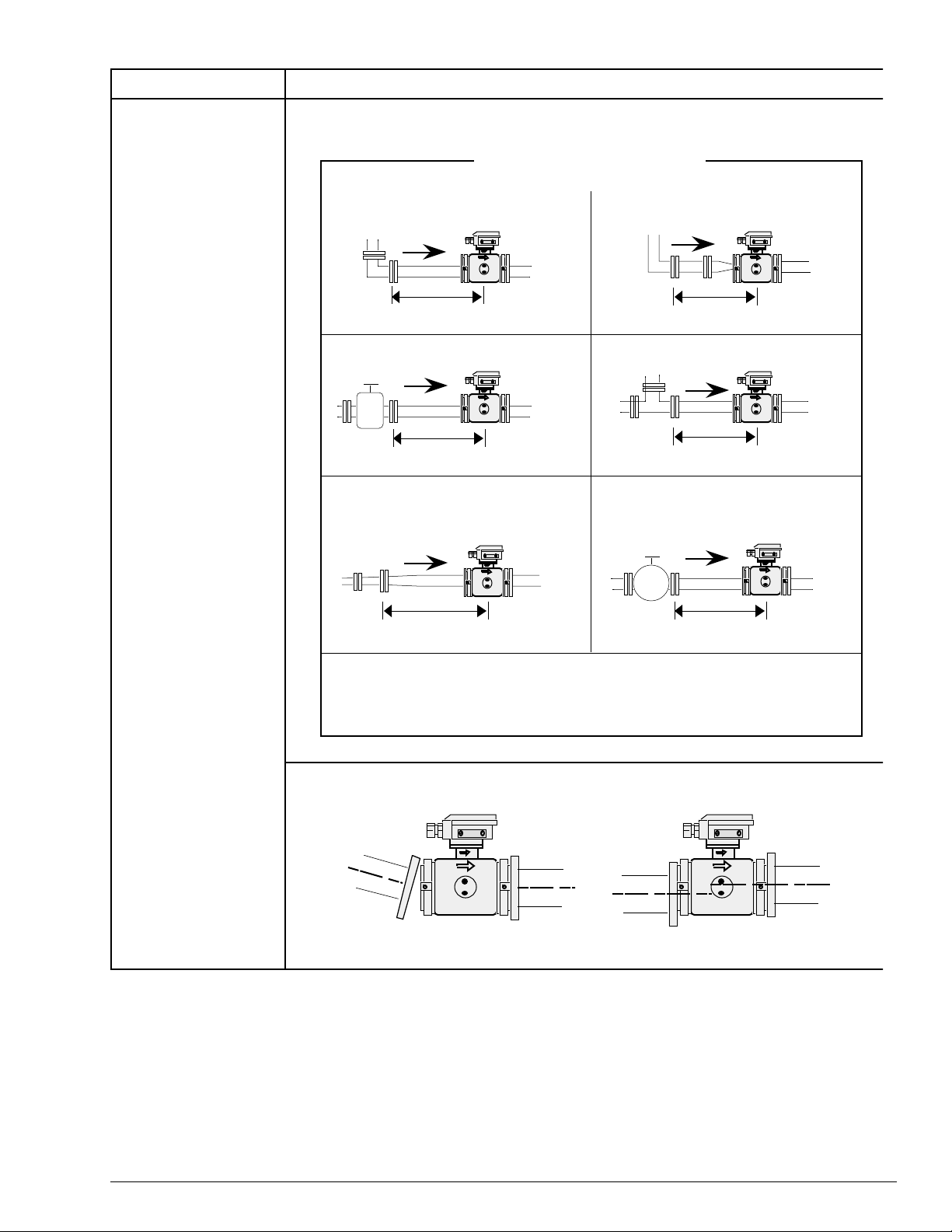

Detector location in

piping (continued)

Straight pipe sections must be provided on the upstream and downstream sides of the detector

as shown.

UPSTREAM SIDE

(D = Nominal diameter of detector)

90-degree elbow

5D or greater

Sluice valve (full open)

5D or greater

Expansion pipe with cone angle 15 degrees

or more (if the cone angle is less than 15

degrees, can be regarded as a straight pipe

section)

Reducer pipe (can be regarded

as a straight pipe section)

5D or greater

Tee

5D or greater

Valve other than a sluice type

5D or greater

10D or greater

DOWNSTREAM SIDE

(D = Nominal diameter of detector)

2D or greater (minimum 2D if drift current or the like is possible)

23454

The process piping with flanges must be straight and centered. Below are examples of imprope

alignments.

Tilted pipe

Off-centered

23455

1/98 MagneW 3000

PLUS

Specification and Application Guide 17

Page 24

Table 5—Summary of Installation Considerations, continued

Factor Consideration

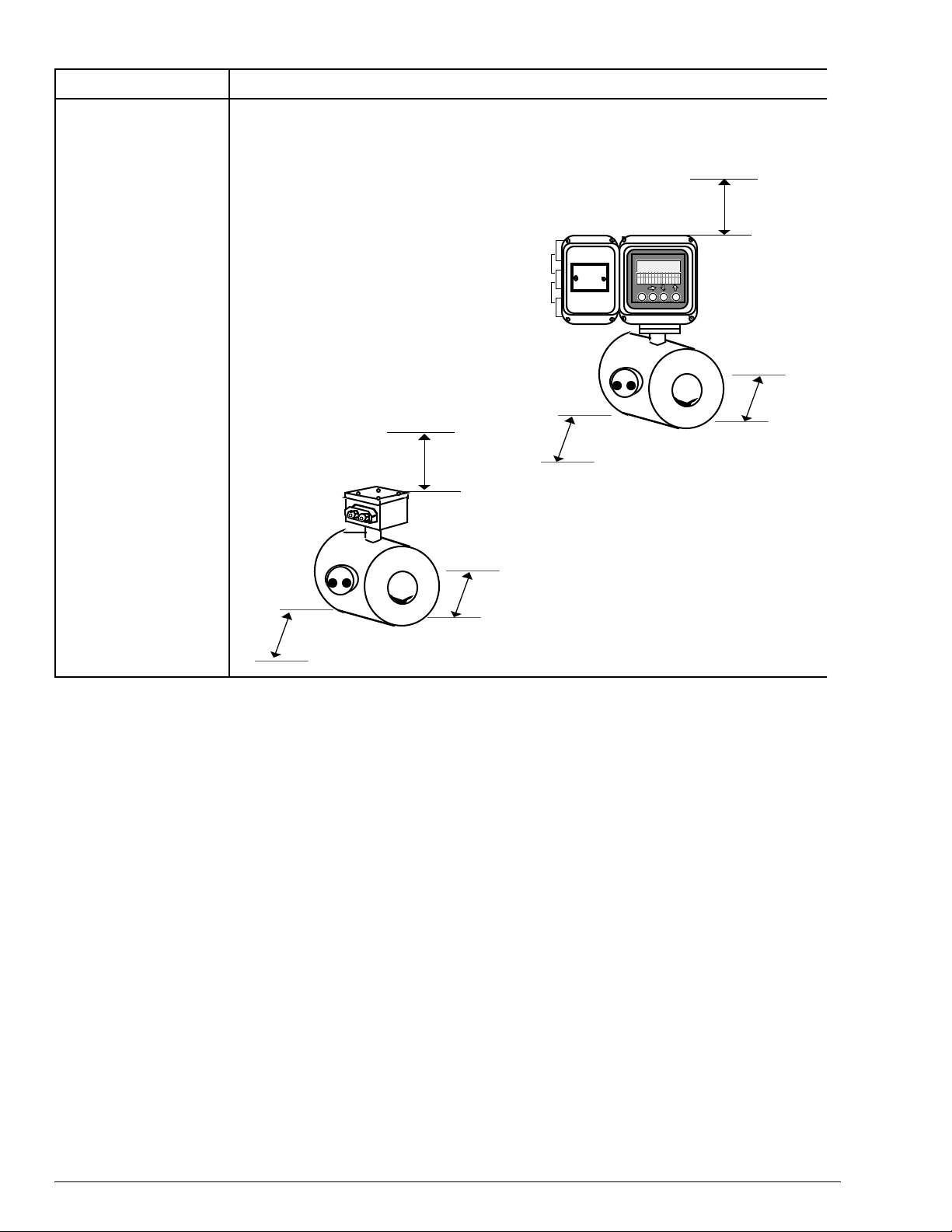

Clearance for

maintenance

Sufficient space must be provided for maintenance of the electrodes and inspection of the

terminals, and for operation of the converter with an integral type flowmeter.

Suggested minimum clearances are provided below.

500 mm

19.7 in.

400 mm

15.8 in.

500 mm

19.7 in.

400 mm

15.8 in.

Integral type

400 mm

15.8 in.

400 mm

15.8 in.

Remote detector

23456

18 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 25

Specifications

Table 6 summarizes pertinent specification data for the MagneW 3000

Table 6—Specifications for MagneW 3000

PLUS

Performance

Accuracy Refer to the following tables.

Diameters 2.5 mm to 15 mm (0.1 in. to 0.6 in.):

Vs (m/s) Accuracy at Vs ≥40% Accuracy at Vs ≤ 40%

1.0 ≤ Vs ≤ 10 ±0.5% of indicated value ±0.2% of Vs

0.1 ≤ Vs ≤ 1.0 ±(0.1/Vs + 0.4%) of indicated ±0.4 (0.1/Vs + 0.4)% of Vs

value

Diameters 25 mm to 600 mm (1 in. to 23.6 in.):

Vs (m/s) Accuracy at Vs ≥20% Accuracy at Vs ≤20%

1.0 ≤ Vs ≤ 10 ±0.5% of indicated value ±0.1% of Vs

0.1 ≤ Vs ≤ 1.0 ±(0.1/Vs + 0.4%) of indicated ±0.2 (0.1/Vs + 0.4)% of Vs

value

Design

Flow Velocity Ranges 0-0.1 m/s to 0-10 m/s (0-0.3 ft/s to 0-30 ft/s)

The range can be set locally through the DOP or remotely through the SFC.

See Table 7 for minimum and maximum ranges by diameter.

PLUS

.

Upper limit value of Vs = set velocity range

Upper limit value of Vs = set velocity range

Electrical Conductivity of

Liquid

Liquid Pressure and

Temperature Ranges for

Detector

Damping Time Constant Variable from 0.5 to 199.9 seconds.

Low Flow Cutoff Current output corresponding to 0-10% of set range (variable integer)

Dropout Pulse output corresponding to 0-10% of set range (variable integer) for 20 kHz maximum

Lightning Protection 12 kV, 1000A

Power Failure EEPROM retains data record of total flow volume when pulse output is used (retention period

Input (Transmitter) Detector flow signals plus external selections that drive a semiconductor or no-voltage open-

300 microsiemens/m (3 micromhos/cm) minimum.

See Table 5, Page 14.

Incorporated into the power source and external input and output terminals.

approximately 10 years).

close contact signal for any one of the following functions:

External 0% lock:

•

pulse output via contact input.

External automatic zero adjustment:

•

External range changeover:

•

Built-in counter reset (optional for pulse output model):

•

the built-in counter by contact input.

Enables 0% stop of the flow indication, analog output, digital output, and

Adjusts the zero point by contact input.

Switches dual range or forward/reverse range by contact input.

Resets the total flow volume value of

1/98 MagneW 3000

PLUS

Specification and Application Guide 19

Page 26

Table 6—Specifications for MagneW 3000

PLUS

, continued

Design (continued)

Outputs (Transmitter) • Detector’s coil excitation current

Current output without SFC communications requirement:

•

load with external 24 Vdc power supply.

Current output with SFC/DE communications requirement:

•

ohms load with an external 24 Vdc power supply.

1460

620

300

Load Resistance (Ω)

250

•

Contact output:

following condition states:

– Alarm actuating contacts for

Self-diagnosis alarm —Outputs an alarm-actuating contact when the self-diagnosis function

detects an error.

No-load detection alarm (with empty-status detection) —Outputs an alarm-actuating

contact when the fluid level in the detector goes below the electrode level.

Upper/lower flow limit value alarm —Outputs an alarm-actuating contact when the flow

volume exceeds the upper/lower limit values.

Two-stage flow value alarm (with two contact outputs) —Outputs an alarm-actuating contact

when the flow value exceeds the two upper limits (H and HH) or the two lower limits (L and

LL).

– Range identification output—Outputs a contact for large and small ranges, forward and

reverse direction ranges.

– Counter preset status (for pulse output model)—Outputs a contact when the built-in

counter reaches the preset value.

For a maximum external load of 30 Vdc/200 mA, indicating any one of the

Load Resistance (Ω) =

16.0 24.0 45

Supply Voltage (Vdc)

4 to 20 mA dc into a 0 to 600 ohms

4 to 20 mA dc into a 250 to 1460

Supply voltage 8.5

0.025

Operating

Range

21703

Display Display card can rotate 90° for installation on vertical pipe.

Backlit liquid crystal display (LCD).

Display board:

One line with six 7-segmented digits—Main display

Dot matrix, two lines with 16 columns—Auxiliary display

Display contents:

• instantaneous flow rate in percent

• instantaneous actual flow rate in a variety of engineering units

• total volume (with pulse output model)

• engineering data

Operator Interface Four infrared touch sensor keys OR

Hand-held communicator with keyboard and LCD. Connects anywhere in the 4-20 mA output line.

Mounting

Converter:

• Integral mounts directly on detector

• Remote mounts on wall or 2-inch pipe

Detector:

20 MagneW 3000

A variety of piping connections are offered–flange, wafer, hose, sanitary coupling, etc.

PLUS

Specification and Application Guide 1/98

Page 27

Table 6—Specifications for MagneW 3000

Flange Rating •

25 to 50 mm (1 to 2 in.) diameters:

150, ANSI 300, DIN PN10, DIN PN16, DIN PN25, DIN PN40

80 to 200 mm (3.2 to 7.9 in.) diameters:

•

ANSI 150, ANSI 300, DIN PN10, DIN PN16, DIN PN25, DIN PN40, JIS G3451 F12

250 to 600 mm (9.8 to 23.6 in.) diameters with PFA lining:

•

JPI3 00, ANSI 150, ANSI 300, DIN PN10, DIN PN16, DIN PN25, JIS G3451 F12

250 to 600 mm (9.8 to 23.6 in.) diameters with chloroprene rubber lining:

•

ANSI 150, DIN PN10, JIS G3451 F12

PLUS

, continued

Design (continued)

JIS 10K, JIS 16K, JIS 20K, JIS 30K, JPI 150, JPI 300, ANSI

JIS 10K, JIS 20K, JIS 30K, JPI 150, JPI3 00,

JIS 10K, JIS 16K, JIS 20K, JPI 150,

JIS 10K, JPI 150,

Structure

Finish

Color

Material

Converter:

• Converter can rotate 180°.

NEMA 4X, IEC IP66, JIS C 0920 waterproof model

Detector:

• NEMA 4X, IEC IP67, JIS C 0920 watertight model

• NEMA 6, IEC IP68, JIS C 0920 submersible model

Electrode

• Watertight—External insertion (electrode can be removed)

• Submersible—Internal insertion (electrode cannot be removed)

Converter:

acrylic resin

Detector:

• Watertight:

2.5 to 200 mm (0.1 to 7.9 in.) diameters, terminal box only of remote model—corrosionpreventive acrylic resin

250 to 600 mm (9.8 to 23.6 in.) diameters, terminal box of remote model and case of

remote/integral models—Corrosion-preventive polyurethane resin

•

Submersible:

15 to 200 mm (0.6 to 7.9 in) diameters, terminal box only; and 250 to 600 mm (9.8 to 23.6 in.)

diameters, terminal box and case—Corrosion-preventive tar epoxy

Converter:

light beige

Detector:

• Watertight: light beige

• Submersible: black

Converter:

• Main body—Aluminum alloy

• Display cover—Tempered glass, 5 mm thick; aluminum alloy

Detector:

• Flange

25 to 65 mm (1 to 2.6 in.) diameters—SUS304 stainless steel

80 to 600 mm (3.2 to 23.6 in.) diameters—carbon steel plus corrosion-preventive coating

• Case

2.5 to 15 mm (0.1 to 0.6 in) diameters—SCS13 stainless steel

25 to 200 mm (1 to 7.9 in.) diameters—SUS304 stainless steel

250 to 600 mm (9.8 to 23.6 in.) diameters—SS400 carbon steel

• Terminal box—Aluminum alloy (remote model)

1/98 MagneW 3000

PLUS

Specification and Application Guide 21

Page 28

Table 6—Specifications for MagneW 3000

PLUS

, continued

Design (continued)

Wetted Materials

Electrical Conduit 1/2 inch NPT, G1/2, CM20, Pg13.5 internal threads, optional plastic and brass waterproof glands

Lining:

• 2.5 to 600 mm (0.1 to 23.6 in.) diameters—PFA

• 25 to 200 mm (1 to 7.9 in.) diameters—polyurethane rubber

• 250 to 600 mm (9.8 to 23.6 in.) diameters—chloroprene rubber

Electrode:

Platinum/Iridium

Ground ring:

Union joint for diameters 2.5 to 15 mm (0.1 to 0.6 in.):

Hose for diameters 2.5 to 15 mm (0.1 to 0.6 in.):

IDF clamp:

Tri-clamp:

Gasket:

Tantalum, and Platinum. For ground rings made of SUS316, gaskets are supplied by customer;

non-rubber, such as PTFE or joint sheet, is recommended.

O-ring:

(G1/2 only)

SUS316L, Hastelloy C, Titanium, Zirconium, Tantalum, Tungsten-Carbide,

SUS316, Hastelloy C, Titanium, Zirconium, Tantalum, Platinum

SUS316

SUS316

SUS316

SUS316

PTFE gaskets are supplied with ground rings of Hastelloy C, Titanium, Zirconium,

Viton rubber (with union joints)

Nuts and Bolts For wafer construction models only

Electrical Connection

S20C carbon steel, SUS304 stainless steel

Integral:

M4-12P screw terminals

Remote:

• Converter—M4-19P screw terminals

• Detector—M4-5P screw terminals

Cables

Cable Length 300 meters (984 feet) maximum

Grounding Category 3

Dimensions See Figures 12 through 20, as applicable.

Weight

Signal cable:

Coil excitation current cable:

100 ohms maximum ground resistance

Converter:

Detector:

2-core individually double-shielded cable

2-core chloroprene cabtyre cable

3.7 kg (8.2 lbs)

Refer to Table 8, 9, or 10, as applicable.

22 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 29

Table 6—Specifications for MagneW 3000

PLUS

, continued

Environmental and Operating Conditions

Ambient Temperature

Relative Humidity 5 to 100%

Power Requirements •

Power Consumption 13W (17 VA)

Approval Bodies Model No. Approval Body Approval Type and Classification

CE Mark Conformity

(Europe)

Converter:

–25 to +60°C (–13 to +140°F)

Detector:

• Integral model: –25 to +60°C (–13 to +140°F)

• Remote model, PFA lining: –30 to +80°C (–22 to +176°F)

• Remote model, polyurethane rubber lining/chloroprene rubber lining:

–30 to +60°C (–22 to +140°F)

Voltage (Vac) ±10%:

Voltage (Vdc) ±10%:

•

Frequency:

•

MGG14C CSA and FM Nonincendive – Class I, II, III, Division 2,

Remote Converter Groups A, B, C, D, E, G

MGG17D, F, U CSA and FM Special Protection – Class I, II, III, Division 1,

Remote Detector Groups B, C, D, E, F, G

MGG18D, F, U CSA and FM Nonincendive – Class I, II, II, Division 2,

Remote Detector Groups A, B, C, D, F, G

(Water Tight)

MGG19D, F, U CSA and FM Nonincendive – Class I, II, III, Division 2,

Remote Detector Groups A, B, C, D, F. G

(Submersible)

MGG14C (Converter) CSA and FM Nonincendive – Class I, II, III, Division 2,

MGG18D, F, U Groups A, B, C, D, F, G

Integral Unit

MGG16D, F, U CENELEC EEx de ia II CT4

Remote Detector

MagneW 3000

for EN 50082-2-1995.

50 or 60 Hz

PLUS

100, 110, 115/120, 200, 220, 230/240

24

meets the emission limits for EN 50081-1-1993 and the immunity standards

1/98 MagneW 3000

PLUS

Specification and Application Guide 23

Page 30

Table 7—Minimum and Maximum Ranges

Diameter

mm (inches)

2.5

(0.1)

5

(0.2)

10

(0.4)

15

(0.6)

25

(1)

40

(1.6)

50

(2.0)

65

(2.6)

80

(3.1)

100

(3.9)

Minimum Range—m

[Minimum constant flow speed of

0 to 0.1 m/s (0 to 0.3 ft/s)]

0 to 0.00177

(0 to 0.625)

0 to 0.00707

(0 to 0.2498)

0 to 0.0283

(0 to 1)

0 to 0.0636

(0 to 2.24)

0 to 0.177

(0 to 6.25)

0 to 0.452

(0 to 15.97)

0 to 0.707

(0 to 24.98)

0 to 1.19

(0 to 42.04)

0 to 1.81

(0 to 63.95)

0 to 2.83

(0 to 100)

3

/h (ft3/h)

Maximum Range—m3/h (ft3/h)

[Maximum constant flow speed of

0 to 10 m/s (0 to 30 ft/s)]

0 to 0.177

(0 to 6.25)

0 to 0.707

(0 to 24.98)

0 to 2.83

(0 to 100)

0 to 6.36

(0 to 224.73)

0 to 17.7

(0 to 625.44)

0 to 45.2

(0 to 1, 597.17)

0 to 70.7

(0 to 2,498.23)

0 to 119

(0 to 4,204.94)

0 to 181

(0 to 6,395.75)

0 to 283

(0 to 10,000)

125

(4.9)

150

(5.9)

200

(7.9)

250

(9.8)

300

(11.8)

350

(13.8)

400

(15.8)

450

(17.7)

500

(19.7)

600

(23.6)

0 to 4.42

(0 to 156.18)

0 to 6.36

(0 to 224.73)

0 to 11.31

(0 to 399.64)

0 to 17.67

(0 to 624.38)

0 to 25.45

(0 to 899.29)

0 to 34.64

(0 to 1,224.02)

0 to 45.24

(0 to 1,598.58)

0 to 57.26

(0 to 2,023.32)

0 to 70.70

(0 to 2,498.23)

0 to 101.79

(0 to 3,596.81)

0 to 442

(0 to 15,618.37)

0 to 636

(0 to 22,473.49)

0 to 1,131

(0 to 39,964.66)

0 to 1,767

(0 to 62,438.16)

0 to 2,545

(0 to 89,929.32)

0 to 3,464

(0 to 122,402.82)

0 to 4,524

(0 to 159,858.65)

0 to 5,726

(0 to 202,332.15)

0 to 7,070

(0 to 249,823.32)

0 to 10,179

(0 to 359,681.97)

24 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 31

Dimensions

Figures 12 through 20 and Tables 8 through 10 list reference dimensions for the

various MagneW 3000

PLUS

styles and sizes.

3.2

0.1

103

4

128

5

248

9.8

216

8.5

Plate

130

5.1

82

3.2

15.5

0.6

150

5.9

110

4.3

14

0.5

Terminal

box

Tag

number

plate

Dimensions:

FOR REFERENCE ONLY

Figure 12—Wall Mounting Dimensions

millimeters

inches

34

1.3

30

1.2

25

25125125

1

1

23671

1/98 MagneW 3000

PLUS

Specification and Application Guide 25

Page 32

50 mm

(2-inch) pipe

Bracket

Material: SPCC

(zinc-plated)

Bolt

Material: SUS304

44.3

1.75

128

5

216

8.5

130

5.1

82

3.2

150

5.9

14

0.5

Terminal

box

Tag

number

plate

Dimensions:

FOR REFERENCE ONLY

millimeters

inches

103

15.5

4

34

1.3

30

1.2

0.6

25

1

25125125

1

23672

Figure 13—2-inch Pipe Mounting Dimensions

26 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 33

Dimensions:

FOR REFERENCE ONLY

millimeters

128

5

34

1.3

inches

25

25

216

8.5

82

3.2

1

1

130

5.1

øD

W

25

25

1

1

159

6.3

L

23673

Figure 14—Dimensions for Integral Model—Refer to Table 8

1/98 MagneW 3000

PLUS

Specification and Application Guide 27

Page 34

Dimensions:

FOR REFERENCE ONLY

millimeters

47

1.9

inches

84

3.3

30

1.2

max

84

3.3

190

7.5

71

2.79

72

2.83

110

4.3

96

3.8

98

3.9

52

2

100

3.9

23457

Figure 15—Union Joint Dimensions – 2.5 mm to 15 mm (0.1 in. to 0.6 in.) Sizes

28 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 35

Dimensions:

FOR REFERENCE ONLY

millimeters

47

1.9

inches

84

3.3

30

1.2

max

84

3.3

190

7.5

71

2.79

72

2.83

110

4.3

96

3.8

98

3.9

52

2

100

3.9

23458

Figure 16—Hose Joint Dimensions – 2.5 mm to 15 mm (0.1 in. to 0.6 in.) Sizes

1/98 MagneW 3000

PLUS

Specification and Application Guide 29

Page 36

Dimensions:

FOR REFERENCE ONLY

millimeters

47

1.9

inches

84

3.3

30

1.2

max

84

3.3

190

7.5

71

2.79

72

2.83

110

4.3

96

3.8

98

3.9

52

2

100

3.9

23459

Figure 17—IDF/Tri-Clamp Dimensions – 2.5 mm to 15 mm (0.1 in. to 0.6 in.) Sizes

30 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 37

Dimensions:

FOR REFERENCE ONLY

millimeters

inches

Sizes 2.5 to 15 mm (0.1 to 0.6 inches)

84

3.3

47

1.9

øD

H1

H3

H2

110

W

4.3

Sizes 25 to 200 mm (1 to 7.9 inches)

84

3.3

30

1.2

H4

30

1.2

max

84

3.3

L

52

2

max

84

3.3

47

1.9

H4

H3

Figure 18—Wafer Dimensions – 2.5 mm to 15 mm (0.1 in. to 0.6 in.) and 25mm to 200 mm (1 in. to 7.9 in.) Sizes—Refer to Table 8

H1

H2

øD

W

L

23460

1/98 MagneW 3000

PLUS

Specification and Application Guide 31

Page 38

Table 8—Dimensions for Figures 14 and 18

e

6

6

6

6

6

8

4

5

2

1

7

4

2

0

8

Detector

Diameter

mm (in.)

2.5

(0.1)

5

(0.2)

10

(0.4)

15

(0.6)

25

(1)

40

(1.6)

50

(2)

65

(2.6)

Face to

Face

Dimension

mm (in.)

L H1 H2H3H4WøD

56

(2.2)

56

(2.2)

56

(2.2)

56

(22)

56

(2.2)

80

(3.2)

86

(3.4)

96

(3.8)

71

(2.79)

71

(2.79)

71

(2.79)

71

(2.79)

77

(3)

84

(3.3)

93

(3.7)

100

(4)

72

(2.83)

72

(2.83)

72

(2.83)

72

(2.83)

34

(1.3)

43.5

(1.7)

52

(2)

62

(2.4)

Height

mm (in.)

190

(7.5)

190

(7.5)

190

(7.5)

190

(7.5)

158

(6.2)

174.5

(6.9)

192

(7.6)

209

(8.2)

96

(3.8)

96

(3.8)

96

(3.8)

96

(3.8)

102

(4)

109

(4.3)

118

(4.7)

125

(5)

Width

mm (in.)

98

(3.9)

98

(3.9)

98

(3.9)

98

(3.9)

106

(4.2)

125

(5)

135

(50)

148

(5.8)

Outer

Diameter

mm (in.)

49.5

(1.95)

49.5

(1.95)

49.5

(1.95)

49.5

(1.95)

68

(2.7)

87

(3.4)

104

(4.1)

124

(4.9)

Inner

Diameter

mm (in.)

2.5 ±0.2

(0.098 ±0.007)

5 ±0.3

(0.196 ±0.011)

10 ±0.5

(0.393 ±0.019)

15 ±0.5

(0.590 ±0.019)

24 ±0.5

(0.944 ±0.019)

38.5 ±1

(1.515 ±0.039)

50 ±1

(1.968 ±0.039)

63 ±1

(2.480 ±0.039)

W

kg

2.

(5.

2.

(5.

2.

(5.

2.

(5.

2.

(5.

2.

(6.

3.

(7.

4.

(9.

80

(3.1)

100

(3.9)

125

(4.9)

150

(5.9)

200

(7.9)

106

(4.2)

120

(4.7)

140

(5.5)

160

(6.3)

200

(7.90)

108

(4.3)

120.5

(4.7)

133

(5.2)

160

(6.3)

185

(7.3)

67

(2.6)

79.5

(3.1)

95

(3.7)

110

(4.3)

135

(5.3)

222

(8.7)

247

(9.7)

275

(10.8)

317

(12.5)

367

(14.5)

133

(5.2)

145.5

(5.7)

158

(6.2)

240

(9.5)

210

(8.3)

164

(6.5)

189

(7.4)

214

(8.4)

240

(9.5)

290

(11.4)

134

(5.3)

159

(6.3)

190

(7.5)

220

(8.7)

270

(10.6)

75 ±2

(2.952 ±0.078)

100 ±2

(3.937 ±0.078)

123 ±3

(4.842 ±0.118)10(2

147 ±3

(5.787 ±0.118)13(3

195 ±3

(7.677 ±0.118)22(4

5.

(1

6.

(1

32 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 39

Dimensions:

FOR REFERENCE ONLY

47

1.9

187

7.36

77

3

63

2.5

millimeters

inches

84

3.3

96

3.8

30

1.2

max

84

3.3

106

4.2

Inner diameter: 24 ±0.5 mm (0.944 ±0.019 in.)

Weight: 5.5 kg (12.1 lbs.)

Figure 19—Flange Dimensions – 25 mm (1 in.) Sizes

200

7.9

23461

1/98 MagneW 3000

PLUS

Specification and Application Guide 33

Page 40

Dimensions:

FOR REFERENCE ONLY

millimeters

inches

Sizes 40 to 100 mm (1.6 to 3.4 inches)

84

3.3

47

1.9

H4

30

1.2

max

84

3.3

H3

H1

H2

Sizes 150 to 600 mm (5.9 to 23.6 inches)

84

3.3

47

1.9

H1

H4

30

1.2

L

max

84

3.3

H3

H2

L

23462

Figure 20—Flange Dimensions – 40 mm to 100 mm (1.6 in. to 3.9 in.) and 150 mm to 600 mm (5.9 in. to 23.6 in.) Sizes—Refer to Table 9

34 MagneW 3000

PLUS

Specification and Application Guide 1/98

Page 41

Table 9—Dimensions for Figure 20

h

s

Detector

Diameter

mm (in.)

40 (1.6) 200

50 (2) 200

65 (2.6) 200

80 (3.1) 200

100 (3.9) 250

125 (4.9) 250

150 (5.9) 300

200 (7.9) 350

250 (9.8) 450

Face to Face

(7.9)

(7.9)

(7.9)

(7.9)

(9.8)

(9.8)

(11.8)

(13.8)

(17.7)

Dimension

mm (in.)

L H1H2H3 H4

84

(3.3)

93

(3.7)

100

(3.9)

108

(4.3)

120.5

(4.7)

133

(5.2)

160

(6.3)

185

(7.3)

212

(8.3)

85

(3.35)

90

(3.5)

102

(4)

105

(4.1)

115

(4.5)

143

(5.6)

158

(6.2)

175

(7.1)

221

(8.7)

Height

mm (in.)

216

(8.5)

230

(9.1)

249

(9.8)

260

(10.2)

167.5

(6.6)

323

(12.7)

365

(14.4)

411

(16.2)

480

(18.9)

109

(4.3)

118

(4.7)

125

(4.9)

133

(5.2)

45.5

(5.7)

158

(6.2)

185

(7.3)

210

(8.3)

237

(9.3)

Inner

Diameter

mm (in.)

38.5 ±1

(1.515 ±0.039)

50 ±1

(1.968 ±0.039)

63 ±1

(2.480 ±0.039)10(22.1)

75 ±2

(2.952 ±0.078)

100 ±2

(3.937 ±0.078)

123 ±3

(4.842 ±0.118)26(57.3)

147 ±3

(5.787 ±0.118)

195 ±3

(7.677 ±0.118)48(105.8)

245 ±4

(9.645 ±0.157)60(132.3)

Weig

kg (lb

6.5

(14.3)

8.5

(18.7)

12.6

(27.8)

18.4

(40.6)

32.6

(71.9)

300 (11.8) 500

(19.7)

350 (13.8) 550

(21.7)

400 (15.8) 600

(23.6)

450 (17.7) 600

(23.6)

500 (19.7) 600

(23.6)

600 (23.6) 650

(25.6)

235

(9.3)

259

(10.2)

287

(11.3)

339

(13.3)

343

(13.5)

392

(15.4)

250

(9.8)

273

(10.8)

321

(12.6)

364

(14.3)

383

(15.1)

446

(17.6)

532

(20.9)

579

(22.8)

655

(25.8)

750

(29.5)

773

(30.4)

885

(34.8)

260

(10.2)

298

(11.7)

312

(12.3)

364

(14.3)

368

(14.5)