Page 1

Mastertrol® Automatic Balancing System™

(MABS®) EZ Zone (EZ-2 and EZ-4)

Control Panels

PRODUCT DATA

FEATURES

• MABS EZ-2 controls two zones and MABS EZ-4 control

four zones. For systems requiring five or more zones,

the TotalZone series of control panels is used.

• Uses standard four-wire (R,W,Y,G) thermostats.

• Any zone thermostat changeover is based on first call.

• Bank of eight DIP switches provides easy system

configuration.

• Adjustable purge timing of two minutes or three and

one-half minutes.

• Adjustable heating and cooling limit with optional

ZoneMAX Sensor.

APPLICATION

The MABS EZ-2 and EZ-4 are microprocessor-based forced

air zone control panels that provide automatic or manual

changeover control of single- and two-stage heating and

cooling and heat pumps with or without auxiliary heat.

• Stage control allows built-in timer to control heating

and cooling stages.

• Use any four-wire thermostat.

For Internet access: www.trolatemp.com or

www.honeywell.com/yourhome/zoning/zoning_home.htm

For technical support, call 1-800-TAT-Temp (1-800-828-8367).

To download Zoning literature: http://hbctechlit.honeywell.com

Contents

Application ........................................................................ 1

Features ............................................................................ 1

Specifications .................................................................... 2

Ordering Information ......................................................... 2

Installation ......................................................................... 3

Startup and Checkout........................................................ 8

Operation........................................................................... 9

Troubleshooting................................................................. 12

® U.S. Registered Trademark

Copyright © 2001 Honeywell • All Rights Reserved

69- 1360- 2

Page 2

MASTERTROL® AUTOMATIC BALANCING SYSTEM™ (MABS®) EZ ZONE (EZ-2 AND EZ-4) CONTROL PANELS

SPECIFICATIONS

Electrical: 24 Vac, 60 Hz.

Dimensions: 9-3/8 in. high x 7-5/8 in. wide x 1-5/8 in. deep.

Mounting: Mount with screws (supplied) through holes in

cabinet back.

Wiring: 18-gauge wire for all equipment and system connec-

tions

Wiring Connections:

Thermostat: L, G, Y, R, W.

Dampers: M6 (Closed); M4 (Open); M1 (Common) Zone-

MAX TL, TL

Transformer: TR1 (Common), TR2 (Hot)

Equipment: Y2, Y1, O, R, G, B, W1, E, W2

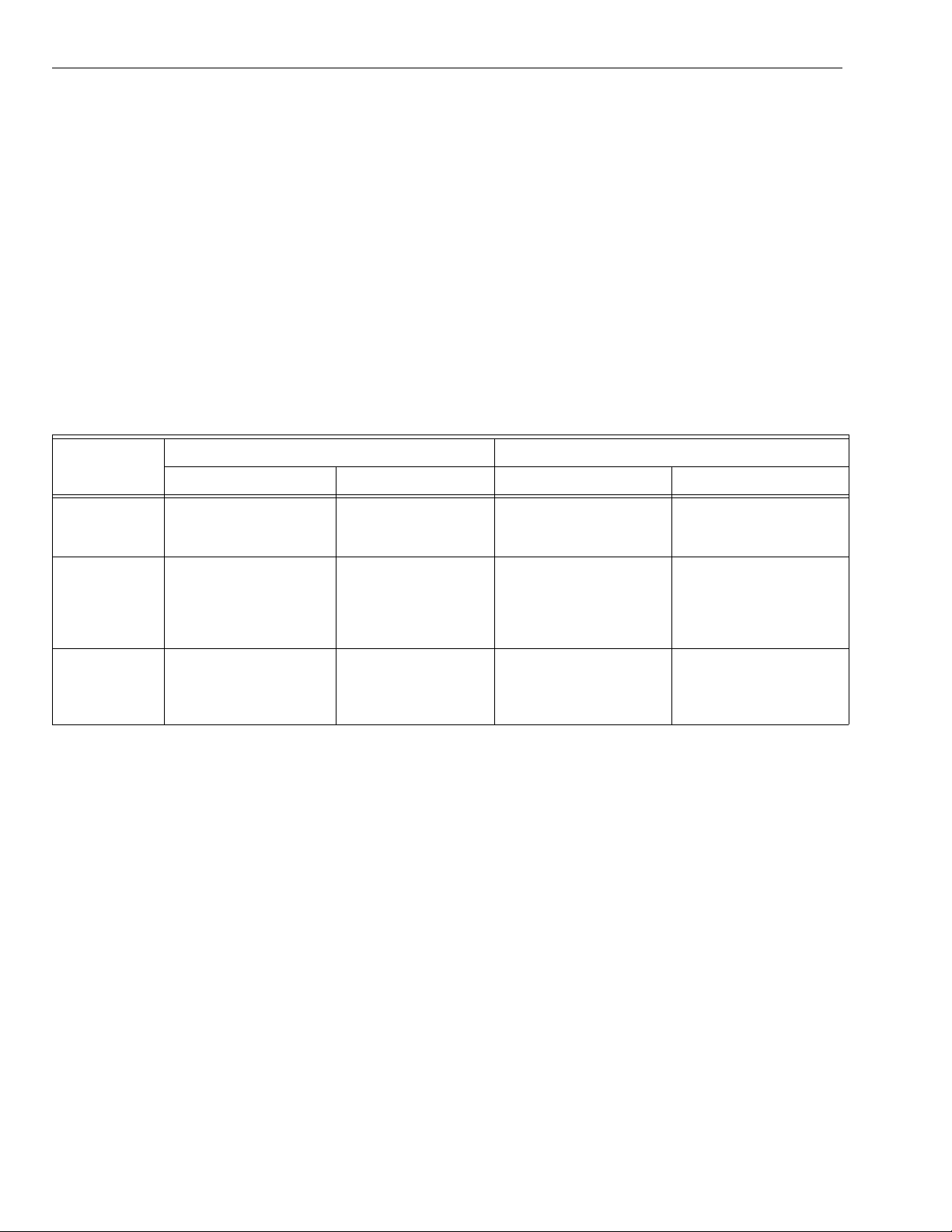

Table 1. Recommended Thermostats.

Trol-A-Temp Logo Honeywell Logo

System

Manual

Changeover

Auto

Changeover

Mechanical Programmable Non-Programmable Programmable

T87F3715/Q539A1436

T87F3707/Q539A1428

T8131C1020 T87F1859/Q539A1014

T8601D2027 Y594D1347 T8600D2069

Thermostats (See Table 1):

Conventional four-wire (R,W,Y,G) thermostats.

Manual or automatic changeover switching subbase for

each zone thermostat.

MABS EZ second-stage timer and emergency heat switch

replace multi-stage or heat pump thermostat.

MABS EZ with heat pump thermostat controls Emergency

Heat mode from thermostat and MABS EZ panel switch.

• Requires separate W1 and Y1 outputs for the heat

and cool calls.

• Requires L terminal energized when Emergency

Heat switch is on.

• W2 thermostat terminal is not used.

• MABS EZ panel timer turns on auxiliary heat when

not in Emergency Heat mode.

Q87F4010/Q539A4026

T8400R

T8000C1002

T8000C1010

T8600D2028

T8601D2019

T8602D2018

T8602D2000

Heat Pump T8011R1006

T8011R1014

T8411R1002

T8411R1028

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

69-1360–2 2

Page 3

MASTERTROL® AUTOMATIC BALANCING SYSTEM™ (MABS®) EZ ZONE (EZ-2 AND EZ-4) CONTROL PANELS

Dampers: See Fig. 3-7 for hookup drawings. See Table 2 for

recommended dampers.

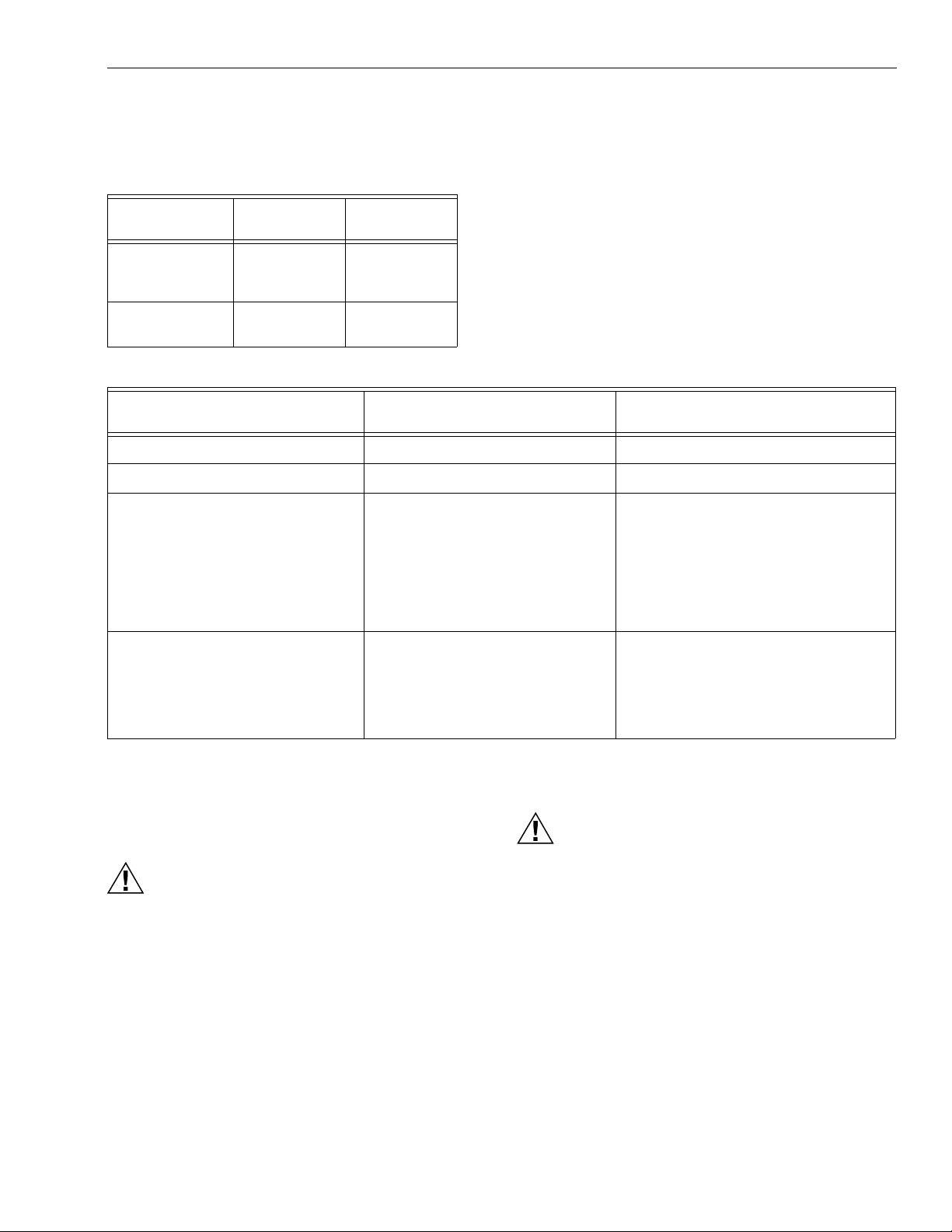

Table 2. Recommended Dampers.

Honeywell

Damper Types Round Rectangular

Power-open/

power-closed

Spring-open/

power-closed

40 VA Transformer AT140D1046 (PMT-40) _

Capacity Protector ZMS/C7735 _

Round Static Pressure Regulator

Damper (SPRD)

MARD AOBD

AOBD-BM

CDO-51

ARD ZDB

ZDS

Table 3. Required Accessories (Not Supplied With Panel).

Accessory Description

7 SPRD

8 SPRD

9 SPRD

10 SPRD

12 SPRD

14 SPRD

16 SPRD

18 SPRD

Accessories:

For required accessories, see Table 3.

Bypass Rated Capacity

(cfm)

300

400

600

750

1200

1800

2400

3200

Rectangular Static Pressure Regulator

Damper (SPRD)

12 x 8 SPRD

12 x 10 SPRD

12 x 12 SPRD

20 x 8 SPRD

20 x 10 SPRD

20 x 12 SPRD

INSTALLATION

Mounting

CAUTION

Equipment Damage Hazard.

Do not mount MABS EZ inside HVAC equipment.

Mount only on wall or on cold air return

1. Mount the thermostats in each zone of the living space

using the installation instructions provided with each

thermostat.

2. Mount the dampers in the ductwork using the installation instructions provided with each damper.

3. Mount the MABS EZ Zone Panel near the HVAC equipment; locate it on a wall or on the cold-air return.

4. Level the MABS EZ for appearance only.

1000

1200

1400

1600

2000

3000

Wiring

CAUTION

Vol tage H a zard.

Can cause electrical shock or equipment damage.

Disconnect power before continuing installation.

Wiring must comply with applicable codes, ordinances, and

regulations.

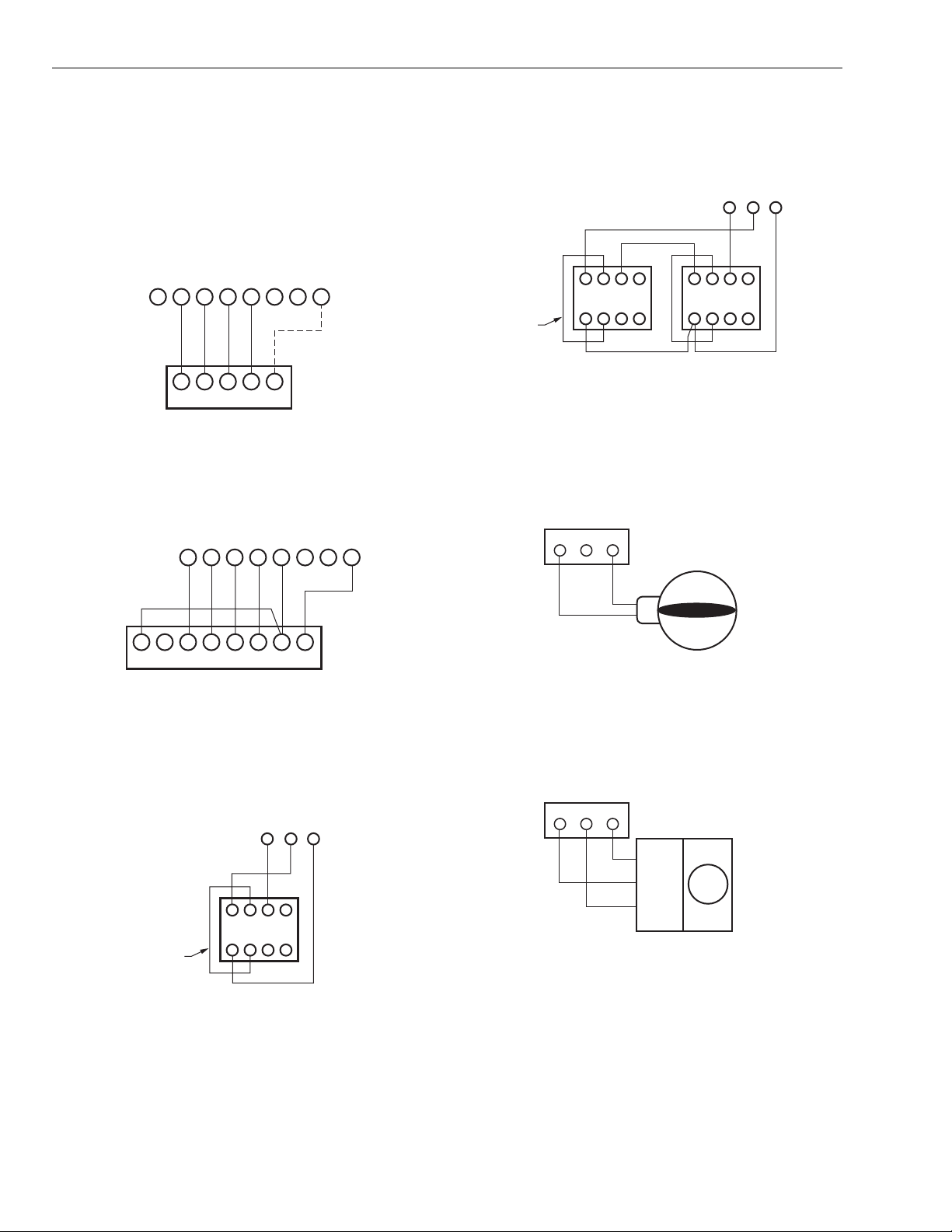

1. Connect thermostats as shown in Fig. 1 and 2.

2. Connect dampers as shown in Fig. 3-7.

3. Connect the ZMS (not supplied) to the TL terminals.The

wires are not polarized. See Fig. 9.

4. Connect the HVAC equipment to the equipment terminals on the left side of the panel. See Figures 10-13.

5. Connect a 40 VA, 24 volt transformer (not supplied) to

TR1 (common) and TR2 (hot). This must be a dedicated

transformer. See Fig. 8.

3 69-1360–2

Page 4

MASTERTROL® AUTOMATIC BALANCING SYSTEM™ (MABS®) EZ ZONE (EZ-2 AND EZ-4) CONTROL PANELS

Wiring Diagrams

See Table 1 for recommended thermostats. See Fig. 1-15 for

wiring appropriate wiring diagrams.

NOTE: The common wire (C to M1) is used only on thermo-

stats that require it.

ZONE CONNECTIONS ON PANEL

THERMOSTAT

L G Y R W M6

GYR WC

ZONE THERMOSTAT

Fig. 1. Typical single-stage thermostat hookup diagram.

ZONE CONNECTIONS ON PANEL

THERMOSTAT

LGYR W M6

MOTOR

M4 M1

M19033

MOTOR

M4 M1

NOTE: Wiring is the same for AOBD, AOBD-BM and IOBD

Dampers.

MOTOR TERMINALS

M6 M4 M1

4

5 6

123

M19036

FIELD

JUMPER

4 5 6

123

DAMPER MOTORS

Fig. 4. AOBD Damper wiring (multiple).

NOTE: For three or more AOBD dampers on one zone, a

Slave Damper Control Relay (SDCR) is required.

DAMPER TERMINALS

ON PANEL

M6 M4 M1

E W2 L G Y1 R W1 C/X

ZONE THERMOSTAT

M19034

Fig. 2. Heat pump thermostats with separate heat and

cool outputs.

Use only thermostats listed in Table 1.

MOTOR TERMINALS

M6 M4 M1

4

5 6

123

FIELD JUMPER

DAMPER MOTOR

M19035

Fig. 3. AOBD damper wiring (single).

POWER CLOSE

SPRING OPEN

C MODEL ARD, ZDS, ZDB

M19037

Fig. 5. ARD or ZD Damper wiring diagram.

NOTE: Multiple dampers can be wired in parallel, with up to

five dampers wired to each panel.

DAMPER TERMINALS

ON PANEL

M6 M4 M1

COM/M1

CL/M6

OP/M4

M19038

Fig. 6. MARD and CDO-51 Damper wiring diagram.

69-1360–2 4

Page 5

MASTERTROL® AUTOMATIC BALANCING SYSTEM™ (MABS®) EZ ZONE (EZ-2 AND EZ-4) CONTROL PANELS

CONTROL PANEL CONNECTIONS

2

1

M6

M4

M1

R8222

24V SPDT RELAY

CW

COM

CCW

ML6161A

MOTOR

M19039

Fig. 7. ML6161 Damper Motor Actuator wiring diagram.

NOTE: The R8222 relay is not required for operation, but if it

is not used, the zone damper LED will be constantly

green.

TR2

TR1

OUTDOOR CONDENSING UNIT

COMPRESSOR RELAY

C

24V TRANSFORMER

FAN RELAY

HEAT RELAY

HVAC CONTROLS

Y

R

G

W

MABS EZ

PANEL

Y2

Y1

O

R

G

B

W1

E

W2

M19042

Fig. 10. Single-stage heating and cooling equipment

wiring diagram.

NOTES:

— Electric Furnace: Set DIP switch 8 to On to ener-

gize the fan with a call for heat.

— Oil Furnace: See Fig. 11 for hookup.

— Hydro-Air: Wired similarly except the zone valve

or circulator relay is connected to the W1. (If the

circulator relay has powered terminals, an isola-

tion relay may be needed. See Fig. 11.) DIP

switch 8 must be set to On to energize the fan

with a call for heat.

24V, 40 VA

TRANSFORMER

MODEL PMT-40

CR

M19040

Fig. 8. Transformer wiring diagram.

NOTE: A dedicated 40 VA, 24 Vac transformer must be

used.

ZMS

SENSOR

or C7735

TL

TL

M19041A

Fig. 9. ZoneMAX or C7735 Sensor wiring diagram.

MABS EZ

PANEL

HVAC CONTROLS

COOLING RELAY

C

24V TRANSFORMER

FAN RELAY

OIL

PRIMARY

T

T

R8222 24V

ISOLATION

RELAY

Y1

R

G

Y2

Y1

O

R

G

B

W1

E

W2

M19043

Fig. 11. Oil furnace and air conditioning wiring diagram.

NOTE: The isolation relay is required to isolate the cooling

transformer from the heating transformer.

5 69-1360–2

Page 6

MASTERTROL® AUTOMATIC BALANCING SYSTEM™ (MABS®) EZ ZONE (EZ-2 AND EZ-4) CONTROL PANELS

HVAC CONTROLS

SECOND STAGE

COOLING RELAY

FIRST STAGE

COOLING RELAY

C

24V TRANSFORMER

FAN RELAY

FIRST STAGE

HEATING RELAY

SECOND STAGE

HEATING RELAY

Y2

Y1

R

G

W1

W2

MABS EZ

PANEL

Y2

Y1

O

R

G

B

W1

E

W2

M19044

Fig. 12. Two-stage heating and cooling wiring diagram.

NOTE: The stage timer energizes the second stage equip-

ment.

C

24V TRANSFORMER

FAN RELAY

FIRST STAGE

HEATING RELAY

SECOND STAGE

HEATING RELAY

HEAT PUMP CONTROLS

IMPORTANT

Y1 must be jumped to W1 for compressor control.

Set DIP switch 8 to On to energize the fan with a call

for heat.

OUTDOOR CONDENSING UNIT

COMPRESSOR RELAY

MABS EZ

COMPRESSOR

RELAY

REVERSING

VALV E

Y

O

R

G

E

W2

PANEL

Y2

Y1

O

R

G

B

W1

E

W2

DIP SWITCH

CONFIGURATION

NO. 8 - ON

2 STAGE

EM. HT.

Fig. 13. Heat pump wiring diagram.

M19045A

NOTES:

— Fossil Fuel Kits with Heat Pumps: The wiring for

these heat pumps is similar but the manufacturer's fossil fuel control must be used. The EZ

equipment terminals are wired using the thermostat terminals shown on the heat pump manufacturer's wiring diagrams.

— Two-speed Compressors: For two-speed com-

pressors or two-speed compressors with auxiliary

heat, the EMM-3U or TotalZone panels are recommended. Call Honeywell Zoning at 800-8288367 for assistance.

69-1360–2 6

Page 7

MASTERTROL® AUTOMATIC BALANCING SYSTEM™ (MABS®) EZ ZONE (EZ-2 AND EZ-4) CONTROL PANELS

OPTIONAL ZoneMAX

OR C7735 SUPPLY AIR

TEMPERATURE

HVAC CONTROLS

SECOND STAGE COOLING RELAY

FIRST STAGE COOLING RELAY

REVERSING VALVE (COOLING)

24V TRANSFORMER (HOT)

REVERSING VALVE (HEATING)

FIRST STAGE HEATING

EMERGENCY HEAT RELAY

SECOND STAGE HEATING RELAY

THIS DIAGRAM SHOWS TYPICAL

SINGLE-STAGE THERMOSTAT

AND DAMPER MOTOR CONNECTIONS.

TM

SENSOR

FAN RELAY

ZoneMAX

FIH

TM

TL

TL

Y2

Y1

O

R

G

B

W1

E

W2

2ND STG. EMG.

HEAT

COOL PURGE FAN EM.HT ZONE 1 ZONE 2

BOOT

YRWM6M4M1

GL

THERMOSTAT MOTOR

ZONE 1

LGYRWM6M4M1

THERMOSTAT MOTOR

ZONE 2

EZ2 REV. F

PURGE

OVERRIDE

GRN - DAMPER OPEN/MOVING

OFF - DAMPER CLOSED

ON

1

2 3 4 5 6 7 8

TR1 TR2

ON

EM HEAT

OFF

ZONE THERMOSTAT

ZONE DAMPERS

Fig. 14. MABS EZ-2 wiring diagram.

GYRW

ZONE 1 THERMOSTAT

4567

123X

OPPOSED BLADE

DAMPERMOTOR

C

GYRWC

ZONE 2 THERMOSTAT

AUTOMATIC ROUND DAMPER

POWERE CLOSED (ARD-PC)

CR

24V, 40 VA

TRANSFORMER

M19046A

7 69-1360–2

Page 8

MASTERTROL® AUTOMATIC BALANCING SYSTEM™ (MABS®) EZ ZONE (EZ-2 AND EZ-4) CONTROL PANELS

OPTIONAL ZoneMAX

OR C7735 SUPPLY AIR

TEMPERATURE

HVAC CONTROLS

SECOND STAGE COOLING RELAY

FIRST STAGE COOLING RELAY

REVERSING VALVE (COOLING)

24V TRANSFORMER (HOT)

REVERSING VALVE (HEATING)

FIRST STAGE HEATING

EMERGENCY HEAT RELAY

SECOND STAGE HEATING RELAY

THIS DIAGRAM SHOWS TYPICAL

SINGLE-STAGE THERMOSTAT

AND DAMPER MOTOR CONNECTIONS.

TM

SENSOR

FAN RELAY

HEAT

TM

ZoneMAX

TL

TL

Y2

Y1

O

R

G

B

W1

E

W2

2ND STG. EMG.

YRWM6M4M1

GL

THERMOSTAT MOTOR

ZONE 1

COOL PURGE FAN EM.HT ZONE 1 ZONE 2 ZONE 3 ZONE 4

GRN - DAMPER OPEN/MOVING

OFF - DAMPER CLOSED

THERMOSTAT MOTOR

ZONE 2

LGYRWM6M4

THERMOSTAT MOTOR

ZONE 2

BOOT

M1

GL

THERMOSTAT MOTOR

ON

1

2 3 4 5 6 7 8

PURGE

OVERRIDE

YRWM6M4M1 LGYRWM6M4

ZONE 1

TR2

TR1

EM HEAT

ON

OFF

M1

ZONE THERMOSTAT

ZONE DAMPERS

GYRW

ZONE 1 THERMOSTAT

4567

123X

OPPOSED BLADE

DAMPERMOTOR

C

GYRWC

ZONE 2 THERMOSTAT

AUTOMATIC ROUND DAMPER

POWERE CLOSED (ARD)

Fig. 15. MABS EZ-4 wiring diagram.

STARTUP AND CHECKOUT

After the installation is complete, verify the operation:

1. Put the Em Heat switch in the off (down) position.

2. Be sure the DIP switches are set correctly. See

Sequence of Operation and Table 6 for correct configuration. The default position is in the off (down) position.

3. Power up the MABS EZ and set the thermostats so no

zones are calling. Verify that the board? enters the

Purge mode.

NOTE: During the two- or three and one-half- minute Purge,

the Purge LED should be amber. During this mode,

the dampers are open and the damper LEDs are

lighted green.

C

GYRW

ZONE 3 THERMOSTAT

4567

123X

OPPOSED BLADE

DAMPERMOTOR

GYRWC

ZONE 4 THERMOSTAT

AUTOMATIC ROUND DAMPER

POWERE CLOSED (ARD)

CR

24V, 40 VA

TRANSFORMER

M19047A

4. Set the zone one thermostat to heat and raise the setpoint to call for heat. The Heat LED is red and the zone

one damper remains green while the other damper

LEDs turn off.

5. Lower the setpoint in zone one and raise the setpoint in

zone two to call for heat. Verify that zone one LED turns

off (also zones three and four turn off when used on

MABS EZ-4) and zone two damper is green.

6. When using a MABS EZ-4, repeat for zones three and

four and verify correct operation.

7. Alternately, the setpoint can be lowered to call for cooling. Then the green cool LED lights.

69-1360–2 8

Page 9

MASTERTROL® AUTOMATIC BALANCING SYSTEM™ (MABS®) EZ ZONE (EZ-2 AND EZ-4) CONTROL PANELS

OPERATION

Sequence of Operation

On a call for heating or cooling, the zone damper to the calling

zone stays open, and the dampers close to the zones that are

not calling. The MABS EZ panel brings on the heating or

cooling and conditioned air is delivered to the calling zone

until the zone is satisfied. When the call is satisfied, the

system enters the Purge mode. This holds open the damper

of the last zone calling and purges into that zone. The Purge

time can be set to three and one-half or two minutes.

Individual Zone Fan Control

When all zones are satisfied, each zone thermostat Fan

switch controls the fan operation for each zone. When

circulation is desired, place the Fan switch in the On position.

The fan runs and closes the dampers to the zones where the

Fan switch is set to Auto.

Multi-Stage Operation

MABS-EZ can control up to two stages of heating and cooling

using singe-stage thermostats. The panel uses a timer to

control the second stage and is adjustable from five minutes

to 30 minutes using DIP switches 5, 6, and 7. See Table 4.

When a call for heating or cooling is not satisfied within the

time set on the stage time, the panel energizes the second

stage of heat or cool and both stages remain on until the call

is satisfied.

Table 4. Stage timer configuration.

Minutes DIP Switch 5 DIP Switch 6 DIP Switch 7

5 Off Off Off

8On Off Off

10 Off On Off

Table 4. Stage timer configuration.

Minutes DIP Switch 5 DIP Switch 6 DIP Switch 7

12 On On Off

15 Off Off On

20 On Off On

25 Off On On

30 On On On

Changeover Operation

The MABS EZ panel uses a standard heating and cooling

thermostat for each zone to allow any zone to call for heating

or cooling. When opposite calls are made from different

zones, MABS EZ accepts the first call. Once the first call is

satisfied, or a maximum of 20 minutes elapses from the start

of an opposite call, MABS EZ allows the opposite call.

Automatic changeover thermostats can also be used to

provide automatic zone changeover.

When opposite calls occur, the panel ensures that both calls

are acknowledged. If the first call is not satisfied within 20

minutes, the panel drops the existing call and goes into the

Purge mode. After completion of the Purge, the panel

switches to the opposite mode until it is satisfied or until 20

minutes elapses.Then it goes back into the Purge mode and

back to the original call. The system continues to switch back

and forth until both calls are satisfied.

Purge Mode

At the end of every call for heat or cool, the panel enters a

Purge mode that holds the last zone damper open for three

and one-half or two minutes. During this time, the panel or

HVAC equipment can operate the fan. Purge is a time delay

that prevents short cycling of the heating and cooling

equipment after each call. The Purge LED lights when the

system is in Purge mode. Press Purge Override button when

the purge LED is lighted to override Purge.

9 69-1360–2

Page 10

MASTERTROL® AUTOMATIC BALANCING SYSTEM™ (MABS®) EZ ZONE (EZ-2 AND EZ-4) CONTROL PANELS

ZoneMAX Sensor Leaving Air Temperature Sensor

Table 5. Purge DIP switch settings.

DIP Switch No. Setting Action

1 Off 3.5 minutes

1 On 2 minutes

2 Off Panel control of

2OnHVAC control of

fan in Purge

fan in Purge

LED Indicators

The panel features several LED status indicators visible

through a window in the cover. See Table 6.

Table 6. LED Status Indicators.

Status

LED Color

Heat Red Heat call Not in heat

Lighted

Not

Lighted Flashing

ZMS high

call

temperature limit

tripped

The ZMS (not included) is a duct-mounted temperature probe

that monitors the supply of air temperature to control capacity

and prevent over-heating or coil icing. The sensor attaches to

the TL terminals at the upper left corner of the panel. See Fig.

9.

IMPORTANT

The ZMS wires must be at least 12 in. away from line

voltage wiring to ensure correct operation. When not

possible, shielded cable must be used.

ZoneMAX Sensor Configuration

DIP switches 2 and 3 set the ZoneMAX Sensor temperature

limit. See Table 7. The recommended setting for fossil fuel/

heat pump systems is 160°F (71°C). For heat pump systems,

the recommended setting is 120°F (49°). The cooling

temperature limit can be set to 40°F (4°C) or 48°F (9°C).

Table 7. ZoneMAX Sensor Configuration.

DIP Switch

No.

2 ZMS 160°F (71°C)

3 ZMS 40°F (4°C)

Off (Default) On

heating limit

cooling limit

Setting

ZMS 120°F (49°C)

heating limit

ZMS 48°F (9°C)

cooling limit

Cool Green Cool call Not in cool

Purge Amber Purge

Fan Green Fan only

Em

Heat

Zone

1,2,

3,4

Red Emergency

Green Damper

mode

call

heat switch

on or thermostat in

emergency

heat

open or

moving

call

Not in

Purge

mode

No fan only

calls

Not in

emergency

heat mode

Damper

closed

ZMS low

temperature limit

tripped

_

_

_

_

Re-Booting the Microprocessor

When conditions hang up the microprocessor, press and

release the Boot button to re-boot the system and enter the

Purge mode.

OPERATION

If the system trips due to exceeding a high or low temperature,

the heating or cooling system shuts down and the fan

continues running to dissipate the conditioned air from the

plenum. If the low limit was tripped, the cool LED flashes

continuously until it resets. If the high limit was tripped, the

Heat LED flashes continuously until it resets.

The ZoneMAX Sensor resets and allows normal system

operation when the supply air temperature rises ten degrees

in cooling mode, or falls ten degrees in heating mode. The ten

degrees provide adequate time to prevent short cycling of the

unit.

Circuit Breaker Protection

A built-in thermal circuit breaker protects the panel against

shorts in the thermostat and damper wiring and the remote

occupied/unoccupied switch. It does not protect against shorts

in the HVAC equipment wiring into the panel.

OPERATION

None of the LEDs light when the circuit breaker tripped. The

fuse is a yellow square or rectangular disk located right of the

TR1 and TR2 terminals. If it is hot to touch, remove panel

power for ten seconds to allow the circuit breaker to cool off

and reset.

69-1360–2 10

Page 11

MASTERTROL® AUTOMATIC BALANCING SYSTEM™ (MABS®) EZ ZONE (EZ-2 AND EZ-4) CONTROL PANELS

Thermostats

The panel can use almost any four-wire (R,W,Y,G) thermostat.

Each zone requires its own switching subbase with either

manual or automatic changeover. See Table 1 for

recommended thermostats.

HEAT PUMP OR MULTI-STAGE THERMOSTATS

Heat pump or multi-stage thermostats are not required for the

MABS EZ panels because a timer in the panel brings on the

second stage. A heat pump thermostat is used only when

emergency heat control from the thermostat is desired. Use

only Table 1 recommended heat pump thermostats.

EMERGENCY HEAT MODE

An emergency heat switch is located on the side of the panel

and can be accessed without removing the cover. A heat

pump thermostat is used only when emergency heat control is

desired from the thermostat instead of from the panel.

Energizing the L terminal on the zone thermostat or switching

the Emergency Heat switch to the On position places the

system in Emergency Heat mode. This switch does not initiate

a call for emergency heat and prevents the first stage (heat

pump) from being used on a call for heat.

Fan On In Heat

The system fan can be set to come on with a heat call, as

required, with a hydro-air, heat pump, or electric heat system.

Set DIP switch 8 to the On position to activate this mode.

Otherwise, leave it in the default Off position.

Second Stage Emergency Heat Jumper

A jumper is installed on the jumper block to energize W2

output during a call for emergency heat. If there are two forms

of auxiliary heat, one can be connected to W2 as the second

stage of heat and the other to E as the emergency heat stage.

See Fig. 4.

Table 8. DIP Switch Settings.

Switch Function

DIP Switch

NO.

1 3.5 minute Purge

2 ZMS 160°F (71°C)

3 ZMS 40°F (4°C)

4 Normal operation Test mode;

5 See Table 4. _.

6 See Table 4. _

7 See Table 4. _

with DIP Switch

Off (Default)

with fan on

heating limit

cooling limit

Switch Function

with DIP Switch

On

2 minute Purge

with fan off

ZMS 120°F (49°C)

heating limit

ZMS 48°F (9°C)

cooling limit

accelerated

timings

8HVAC unit-

controlled fan

Fan on with call for

Heat

11 69-1360–2

Page 12

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

MASTERTROL® AUTOMATIC BALANCING SYSTEM™ (MABS®) EZ ZONE (EZ-2 AND EZ-4) CONTROL PANELS

TROUBLESHOOTING

The primary diagnostic tools are the system and damper status LEDs. See Table 9 for troubleshooting guide.

Table 9. Troubleshooting Guide.

Symptom Problem Solution

No LEDs light No power to the panel. • Check for 24 Vac across TR2.

• Check circuit breaker; if hot, a short exists in

thermostat or damper wiring.

Erratic operation Insufficient voltage.

Incorrect configuration

Check for 24 Vac ±10% across TR1 and TR2.

Verify jumpers and DIP switch setting for correct

configuration.

Heat or Cool LEd flashes

Panel in Emergency Heat mode

Panel needs resetting.

Heat LED flashing.

Check position of Em Heat switch.

Press Boot button and recheck system operation.

ZoneMAX Sensor tripped on high limit.

continuously

Heat pump works in

Cool LED flashing.

Incorrect thermostat.

ZoneMAX Sensor tripped on high limit.

Install the correct thermostat.

Heat but not in Cool or in

Cool but not in Heat

Incorrectly wired.

If equipment is heat pump, be sure there is a Y1 or

W1 jumper installed.

Emergency heat not

Incorrectly wired.

Verify thermostat and equipment wiring.

coming on

Incorrect thermostat.

Verify correct thermostat is used.

+RPHDQG%XLOGLQJ&RQWURO +RPHDQG%XLOGLQJ&RQWURO

+RQH\ZHOO +RQH\ZHOO/LPLWHG+RQH\ZHOO/LPLWpH

'RXJODV'ULYH1RUWK '\QDPLF'ULYH

*ROGHQ9DOOH\01 6FDUERURXJK2QWDULR

69-1360–2 G.H. Rev. 9-01 www.honeywell.com/yourhome

09=

Loading...

Loading...