Page 1

MA

MD

MS

Application

Solenoid valves series M are used in general refrigeration

and for original equipment to cut off/activate the refrigerant

flow in a refrigerating plant.

The solenoid valves can be installed in the liquid line, hot gas

line and suction line of a refrigerating unit.

Materials

Body

Seal material

Connection tubes

Coil

brass, stainless steel

PTFE

solder: copper

flare: brass

copper, steel, Crastin

Series M

SOLENOID VALVES

NORMALLY CLOSED

PRODUCT DATA

Features

• MA: direct operated, angle construction

• MD: direct operated, two way construction

• MS: pilot operated, two way construction

• Normally closed

• Hermetic construction

• Low pressure drop

• High performance

• Direct operated: no minimum pressure differential

required to open the valve

• Pilot operated: minimum pressure differential of

0.05 bar required to open the valve

• Solder and flare connections

• Coils for AC and DC

• Refrigerants: all CFC, HCFC, HFC,

not for ammonia

Specification

Nominal capacity

Maximum pressure PS

Maximum test pressure PF

Min. pressure differential

Max. pressure differential

Max. opening pressure

differential MOPD

Max. medium temperature

Min. medium temperature

Max. ambient temperature

Min. ambient temperature

Number of operating cycles

Standard coil voltages

Voltage tolerance

see tables on page 2

35 bar(a)

50 bar(a)

MA, MD: 0 bar

MS: 0.05 bar

MS: 2 bar

AC-coil: MA, MD: 25 bar

MS: 30 bar

DC-coil: MA, MD: 21bar

MS: 21 bar

125 °C

-45 °C

80 °C

-40 °C

> 1,5 million

AC: 230V, 110V, 24V

DC: 230V, 24V

further voltages on request

AC: ±10%

DC: +10%, -5%

Copyright © 2009 Honeywell GmbH • Subject to change without notice EN0H-1917GE23 R0709

Page 2

SERIES M

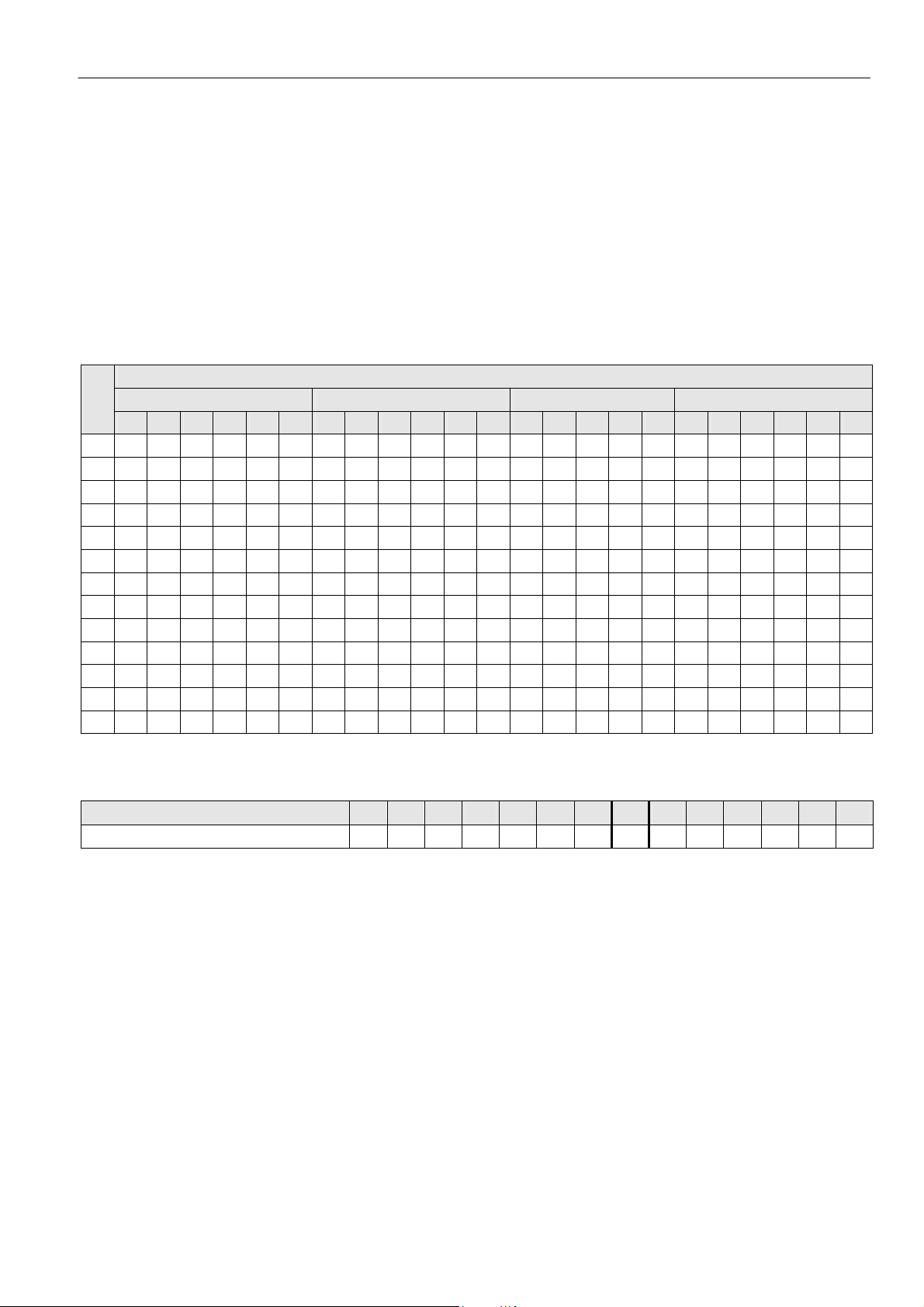

Nominal Capacity QN (kW)

Type

MA 062 0.17 5.21 5.62 5.39 3.87 1.14 1.47 1.45 1.29 - - - -

MD 062 0.17 5.21 5.62 5.39 3.87 1.14 1.47 1.45 1.29 - - - -

MD 102 0.22 6.74 7.27 6.98 5.01 1.48 1.90 1.88 1.67 - - - -

MD 103 0.23 7.05 7.61 7.29 5.24 1.54 1.99 1.96 1.75 - - - -

MS 103 0.9 27.6 29.8 28.5 20.5 6.04 7.78 7.67 6.83 1.54 2.06 1.92 1.80

MS 104 0.9 27.6 29.8 28.5 20.5 6.04 7.78 7.67 6,83 1.54 2.06 1.92 1.80

MS 124 1.6 49.0 52.9 50.7 36.4 10.7 13.8 13.6 12.1 2.74 3.66 3.42 3.19

MS 125 1.6 49.0 52.9 50.7 36.4 10.7 13.8 13.6 12.1 2.74 3.66 3.42 3.19

MS 165 2 61.3 66.1 63.4 45.5 13.4 17.3 17.1 15.2 3.42 4.57 4.27 3.99

MS 167 2 61.3 66.1 63.4 45.5 13.4 17.3 17.1 15.2 3.42 4.57 4.27 3.99

MS 227 4 123 132 127 91.1 26.8 34.6 34.1 30.4 6.85 9.14 8.54 7.98

The nominal capacity QN is based on the following conditions

Medium

Liquid -10 25 1 - 0.4

Hot gas -10 25 1 25 °C 1

Suction gas -10 25 1 - 0.15

Valve selection for other operating conditions see the following tables or consult the Honeywell software

kv-value

(m3/h)

Evaporating

temperature

R134a R22 R407C

t0 (°C) tc (°C)

Liquid Hot gas Suction gas

R404A

R507A

Direct operated

Pilot operated

Condensing

temperature

R134a R22 R407C

Subcooling

Δtc2u (K)

R404A

R507A

temperature

R134a R22 R407C

Hot gas

tH (°C)

Pressure loss

across valve

Δp (bar)

R404A

R507A

EN0H-1917GE23 R0709 2 Honeywell GmbH • Subject to change without notice

Page 3

SERIES M

Valve size calculation for the liquid line

Refrigeration capacity Q0, multiplied with correcting factor fTF,

multiplied with correcting factor f

nominal capacity Q

N.

ΔPF results in the required

QN = Q0 x fTF x fΔPF

QN nominal capacity (according to table on page 2)

Q

0 refrigeration capacity

TF correcting factor for evaporating and liquid

f

temperature

f

ΔPF correcting factor for pressure loss across the valve

Correcting factor fTF for the change of capacity according to the operating temperatures

tL*

(°C)

+10 ±0 -10 -20 -30 -40 +10 ±0 -10 -20 -30 -40 +10 ±0 -10 -20 -30 +10 ±0 -10 -20 -30 -40

0 - - 0.80 0.83 0.85 0.88 - - 0.82 0.83 0.85 0.88 - - 0.80 0.80 0.80 - - 0.73 0.76 0.79 0.83

+5 - - 0.83 0.86 0.89 0.93 - - 0.85 0.87 0.89 0.91 - 0.80 0.80 0.80 0.90 - - 0.77 0.8 0.84 0.88

+10 - 0.84 0.87 0.91 0.94 0.97 - 0.86 0.88 0.90 0.92 0.95 - 0.80 0.90 0.90 0.90 - 0.79 0.82 0.85 0.89 0.94

+15 - 0.88 0.91 0.94 0.98 1.02 - 0.90 0.92 0.94 0.96 0.99 0.90 0.90 0.90 0.90 1.00 - 0.84 0.87 0.91 0.95 1.00

+20 0.89 0.92 0.95 0.99 1.03 1.08 0.92 0.94 0.96 0.98 1.00 1.03 0.90 0.90 0.90 1.00 1.00 0.86 0.89 0.93 0.97 1.02 1.08

+25 0.94 0.96 1.00 1.05 1.09 1.14 0.96 0.98 1.00 1.03 1.05 1.09 0.90 1.00 1.00 1.00 1.10 0.92 0.96 1.05 1.05 1.11 1.18

+30 0.99 1.02 1.06 1.12 1.16 1.22 1.01 1.02 1.05 1.08 1.10 1.14 1.00 1.00 1.00 1.10 1.20 0.99 1.03 1.08 1.14 1.21 1.29

+35 1.04 1.08 1.12 1.18 1.24 1.30 1.05 1.07 1.10 1.13 1.16 1.20 1.10 1.10 1.10 1.20 1.20 1.08 1.13 1.19 1.26 1.34 1.44

+40 1.10 1.14 1.19 1.26 1.32 1.39 1.10 1.12 1.15 1.19 1.22 1.26 1.10 1.20 1.20 1.30 1.30 1.18 1.24 1.32 1.40 1.50 1.63

+45 1.18 1.22 1.28 1.35 1.42 1.50 1.17 1.19 1.22 1.26 1.29 1.34 1.20 1.30 1.30 1.40 1.40 1.32 1.39 1.48 1.59 1.72 1.88

+50 1.25 1.24 1.37 1.45 1.53 1.62 1.23 1.26 1.29 1.33 1.37 1.42 1.30 1.40 1.40 1.50 1.60 1.50 1.59 1.7 1.85 2.02 2.23

+55 1.35 1.41 1.48 1.58 1.67 1.78 1.30 1.33 1.37 1.42 1.46 1.52 1.40 1.50 1.60 1.70 1.80 1.74 1.87 2.02 2.22 2.47 2.79

+60 1.46 1.55 1.61 1.73 1.84 1.97 1.38 1.41 1.46 1.51 1.56 1.63 - - - - - - - - - - -

* Temperature of liquid refrigerant at valve inlet.

Correcting factor f

Pressure loss across valve Δp (bar)

Correcting factor fΔPF

R134a R22 R407C R404A, R507A

ΔPF for the change of capacity according to the chosen pressure loss across the valve

Evaporating temperature t0 (°C)

0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.55 0.60 0.65

2.83 2.00 1.63 1.41 1.26 1.15 1.07 1.00 0.94 0.89 0.85 0.82 0.78 0.76

0.70

Honeywell GmbH • Subject to change without notice 3 EN0H-1917GE23 R0709

Page 4

SERIES M

Valve capacity for the hot gas line

Type

MA 062

MD 062

MD 102

MD 103

MS 103

MS 104

MS 124

MS 125

MS 165

MS 167

MS 227

* Capacities are based on evaporating temperature t0 = -10 °C, hot gas temperature tH = +25 °C and 1 K subcooled refrigerant.

Pressure

loss

across

valve

Δp (bar)

0.2 0.54 0.55 0.57 0.58 0.57 0.68 0.70 0.74 0.76 0.78 0.62 0.65 0.68 0.70 0.60 0.60 0.58 0.53

0.5 0.83 0.86 0.89 0.90 0.89 1.06 1.10 1.15 1.19 1.22 0.98 1.02 1.08 1.11 0.93 0.93 0.90 0.83

1.0 1.12 1.17 1.23 1.25 1.24 1.46 1.51 1.60 1.67 1.70 1.39 1.44 1.52 1.57 1.29 1.29 1.26 1.16

1.5 1.31 1.38 1.47 1.50 1.50 1.74 1.81 1.93 2.01 2.06 1.71 1.77 1.87 1.93 1.54 1.55 1.52 1.41

2.0 1.44 1.52 1.64 1.70 1.70 1.94 2.04 2.19 2.29 2.34 1.96 2.04 2.15 2.22 - - - -

0.2 0.69 0.72 0.75 0.75 0.73 0.77 0.91 0.96 0.99 1.00 0.81 0.83 0.88 0.91 0.77 0.77 0.74 0.68

0.5 1.07 1.11 1.15 1.17 1.16 1.37 1.42 1.49 1.55 1.58 1.27 1.32 1.39 1.44 1.20 1.20 1.17 1.07

1.0 1.44 1.51 1.60 1.62 1.61 1.89 1.96 2.08 2.15 2.20 1.80 1.87 1.97 2.04 1.66 1.67 1.63 1.50

1.5 1.69 1.78 1.89 1.94 1.93 2.25 2.34 2.50 2.60 2.66 2.21 2.29 2.41 2.49 1.99 2.00 1.96 1.82

2.0 1.86 1.97 2.12 2.20 2.20 2.52 2.64 2.83 2.97 3.03 2.55 2.64 2.79 2.88 - - - -

0.2 0.72 0.75 0.78 0.78 0.77 0.80 0.95 1.00 1.03 1.05 0.84 0.87 0.92 0.95 0.80 0.80 0.78 0.71

0.5 1.12 1.16 1.21 1.22 1.21 1.43 1.48 1.56 1.62 1.65 1.33 1.38 1.46 1.50 1.26 1.26 1.22 1.12

1.0 1.51 1.58 1.67 1.69 1.68 1.98 2.05 2.17 2.25 2.30 1.88 1.95 2.06 2.13 1.74 1.74 1.70 1.57

1.5 1.77 1.86 1.98 2.03 2.02 2.35 2.45 2.61 2.72 2.78 2.31 2.39 2.52 2.61 2.08 2.09 2.05 1.90

2.0 1.94 2.06 2.22 2.30 2.30 2.64 2.76 2.96 3.10 3.17 2.66 2.76 2.91 3.01 - - - -

0.2 2.83 2.93 3.04 3.06 3.02 4.20 4.33 4.55 4.70 4.79 3.60 3.71 3.90 4.03 3.09 3.09 3.00 2.74

0.5 4.37 4.53 4.73 4.78 4.72 6.55 6.76 7.13 7.38 7.52 5.61 5.79 6.11 6.33 4.89 4.89 4.80 4.37

1.0 5.93 6.19 6.52 6.63 6.57 9.02 9.35 9.91 10.3 10.5 7.73 8.01 8.49 8.83 6.77 6.86 6.69 6.09

1.5 6.93 7.29 7.77 7.95 7.92 10.8 11.2 11.9 12.4 12.7 9.26 9.60 10.2 10.6 8.14 8.14 8.06 7.37

2.0 7.60 8.07 8.66 9.00 9.00 12.1 12.6 13.5 14.2 14.5 10.4 10.8 11.6 12.2 - - - -

0.2 5.04 5.21 5.40 5.44 5.36 6.40 6.60 6.94 7.17 7.30 5.86 6.07 6.41 6.62 5.60 5.60 5.44 4.96

0.5 7.77 8.07 8.40 8.50 8.39 9.97 10.3 10.9 11.2 11.5 9.27 9.6 10.1 10.5 8.76 8.76 8.52 7.80

1.0 10.5 11.0 11.6 11.8 11.7 13.7 14.3 15.1 15.7 16.0 13.1 13.6 14.3 14.8 12.1 12.1 11.8 10.9

1.5 12.3 13.0 13.8 14.1 14.1 16.4 17.1 18.2 19.0 19.4 16.1 16.6 17.6 18.1 14.5 14.6 14.3 13.2

2.0 13.5 14.3 15.5 16.0 16.0 18.4 19.2 20.6 21.6 22.1 18.5 19.2 20.3 20.9 - - - -

0.2 6.29 6.51 6.76 6.80 6.70 8.00 8.25 8.68 8.96 9.12 7.33 7.59 8.01 8.28 7.00 7.00 6.80 6.20

0.5 9.72 10.1 10.5 10.6 10.5 12.5 12.9 13.6 14.1 14.3 11.6 12.0 12.7 13.1 10.9 10.9 10.6 9.70

1.0 13.2 13.7 14.5 14.7 14.6 17.2 17.8 18.9 19.6 20.0 16.4 17.0 17.9 18.5 15.1 15.2 14.8 13.6

1.5 15.4 16.2 17.2 17.7 17.6 20.5 21.3 22.7 23.7 24.2 20.1 20.8 22.0 22.7 18.1 18.2 17.9 16.5

2.0 16.9 17.9 19.3 20.0 20.0 23.0 24.0 25.7 27.0 27.6 23.2 24.0 25.3 26.2 - - - -

0.2 12.6 13.0 13.5 13.6 13.4 16.0 16.5 17.4 17.9 18.2 14.7 15.2 16.0 16.6 14.0 14.0 13.6 12.4

0.5 19.4 20.1 21.0 21.2 21.0 24.9 25.8 27.1 28.1 28.6 23.2 24.0 25.3 26.2 21.9 21.9 21.3 19.5

1.0 26.3 27.5 29.0 29.5 29.2 34.4 35.6 37.8 39.2 40.0 32.8 33.9 35.8 37.0 30.3 30.4 29.7 27.3

1.5 30.8 32.4 34.5 35.3 35.2 41.0 42.6 45.4 47.4 48.4 40.1 41.6 43.9 45.3 36.3 36.5 35.8 33.1

2.0 33.8 35.9 38.7 39.9 40.0 45.9 48.0 51.5 53.9 55.2 46.3 48.0 50.7 52.4 - - - -

+25 +30 +40 +50 +60 +25 +30 +40 +50 +60 +25 +30 +40 +50 +25 +30 +40 +50

R134a R22 R407C R404A, R507A

Condensing temperature tc (°C)

Direct operated

Pilot operated

Capacity (kW)*

If the hot gas temperature is changed by ±10 °C the valve capacity changes (inversely proportional) by ±2,5 %.

With other evaporating temperatures t

t0 (°C) -50 -40 -30 -20 -10 ±0 +10

R134a - 0.85 0.90 0.95 1.00 1.05 1.09

R22 0.88 0.91 0.95 0.97 1.00 1.03 1.05

R407C 0.83 0.88 0.92 0.95 1.00 1.01 1.06

R404A,

R507A

EN0H-1917GE23 R0709 4 Honeywell GmbH • Subject to change without notice

0.75 0.81 0.88 0.13 1.00 1.05 -

0 the capacities above should be multiplied by the following correcting factors:

Page 5

SERIES M

Valve size calculation for the suction line

Refrigeration capacity Q0, multiplied with correcting factor fTS,

multiplied with correcting factor f

nominal capacity Q

N.

ΔPS results in the required

QN = Q0 x fTS x fΔPS

QN nominal capacity (according to table on page 2)

Q

0 refrigeration capacity

TS correcting factor for evaporating and liquid

f

temperature

fΔPS correcting factor for pressure loss across the valve

Correcting factor fTS for the change of capacity according to the operating temperatures

Evaporating

temperature

t0 (°C)

+60 +50 +40 +30 +20

+10 0.98 0.86 0.78 0.71 0.66

±0 1.19 1.05 0.95 0.86 0.79

-10 1.48 1.29 1.16 1.05 0.96

-20 1.88 1.62 1.44 1.31 1.19

-30 2.42 2.08 1.83 1.65 1.59

-40 3.20 2.71 2.37 2.13 1.92

+10 - 1.14 0.82 0.71 0.63

±0 - 1.24 1.01 0.87 0.77

-10 - 1.57 1.26 1.07 0.94

-20 - 2.02 1.60 1.35 1.17

-30 - 2.67 2.07 1.72 1.49

-40 - 3.62 2.74 2.25 1.93

Correcting factor fΔPS for the change of capacity according to the chosen pressure loss across the valve

Pressure loss across valve Δp (bar)

Correcting factor fΔPS

0.05 0.075 0.10 0.15 0.20 0.30 0.40 0.50 0.60

1.73 1.41 1.22 1.00 0.87 0.71 0.61 0.55 0.50

Condensating temperature tc (°C)

For refrigerant R134a, R22, R407C

For refrigerant R404A, R507A

Honeywell GmbH • Subject to change without notice 5 EN0H-1917GE23 R0709

Page 6

SERIES M

Type Code / Order Information

1. Solenoid Valve

M S 16 5 S 230 V AC

Series

Type:

A = direct operated, angle

D = direct operated

S = pilot operated

Valve size

Connection size in 1/8”

() = flare connection

MMS = solder, metric

S = solder, inch

Voltage

() = without coil

2. Solenoid Coil

Type of coil, capacity For Solenoid Valve Voltage, frequency Voltage tolerance

MC 062, 8 W MA 062(S)(MMS)

MC 102-227, 13 W MD 102(S)(MMS)

MC 102-227, 20 W MD 102(S)(MMS)

International protection rating IP65, coil incl. e.l.c.b.-protected plug to DIN 43650 with cable gland; conduit thread PG11.

230 V, 50/60 Hz

MD 062(S)(MMS)

MD 103(S)(MMS)

MS 103-227(S)(MMS)

MD 103(S)(MMS)

MS 103-227(S)(MMS)

110 V, 50/60 Hz

24 V, 50/60 Hz

230 V, 50/60 Hz

110 V, 50/60 Hz

24 V, 50/60 Hz

24 V DC

230 V DC

±10 %

±10 %

+10 %

-5 %

EN0H-1917GE23 R0709 6 Honeywell GmbH • Subject to change without notice

Page 7

Dimensions and Weights

SERIES M

For tube

(E)

MA 062MMS 6 mm ODF 6 mm 88 88 142 47 0.15 0.30

MA 062S 1/4" ODF 1/4" 88 88 142 47 0.15 0.30

MD 062 7/16" UNF 6 mm, 1/4" 65 17 57 47 0.19 0.33

MD 062MMS 6 mm ODF 6 mm 112 17 57 47 0.17 0.31

MD 062S 1/4" ODF 1/4" 112 17 57 47 0.17 0.31

MD 102 7/16" UNF 6 mm, 1/4" 68 19 64 54 0.19 0.33

MD 102MMS 6 mm ODF 6 mm 118 19 64 54 0.17 0.31

MD 102S 1/4" ODF 1/4" 118 19 64 54 0.17 0.31

MD 103 5/8" UNF 10 mm, 3/8" 71 19 64 54 0.28 0.52

MD 103MMS 10 mm ODF 10 mm 118 19 64 54 0.25 0.49

MD 103S 3/8" ODF 3/8" 118 19 64 54 0.25 0.49

MS 103 5/8" UNF 10 mm, 3/8" 84 12 79 54 0.51 0.75

MS 103MMS 10 mm ODF 10 mm 159 12 79 54 0.55 0.79

MS 103S 3/8" ODF 3/8" 159 12 79 54 0.55 0.79

MS 104 MMS 12 mm ODF 12 mm 159 12 79 54 0.56 -

MS 104S 1/2" ODF 1/2" 159 12 79 54 0.56 -

MS 124 3/4" UNF 12 mm, 1/2" 91 12 79 54 0.54 0.77

MS 124MMS 12 mm ODF 12 mm 159 12 79 54 0.56 0.79

MS 124S 1/2" ODF 1/2" 159 12 79 54 0.56 0.79

MS 125S

MS 165 7/8" UNF 16 mm, 5/8" 97 12 79 54 0.57 0.80

MS 165S

MS 167S

MS 227S

16 mm,

5/8" ODF

16 mm,

5/8" ODF

22 mm,

7/8" ODF

22 mm,

7/8" ODF

diameter

Direct operated

Pilot operated

16 mm, 5/8" 159 12 79 54 0.56 -

16 mm, 5/8" 159 12 79 54 0.59 0.82

22 mm, 7/8" 173 12 79 54 0.59 -

22 mm, 7/8" 262 22 88 54 1.45 1.65

Dimensions (mm) Weight (kg) Type Connections

A B C D

without coil

230 V AC

with coil

230 V AC

MD MS MA

Honeywell GmbH • Subject to change without notice 7 EN0H-1917GE23 R0709

Page 8

SERIES M

Installation

• Position of plunger tube should be from upright to

horizontal position.

• Arrow on valve body must correspond with flow direction.

• Keep 45 mm distance clear above the valve for

assembly/disassembly of coil.

• Fit solenoid valve so that it is drip proof.

• Solder valves:

Remove cap nut, coil and gaskets before soldering

Max. temperature of valve body: 125 °C.

When soldering, always point flame away from valve

body

When assembling after soldering, fit the coil’s top and

bottom seal rings.

• Flare valves:

When tightening flare nuts grip at wrench flats on the

valve body provided for this purposes

Do not use coil and plunger tube as lever (thin-walled

plunger tube).

When installing direct operated valves with 20 W DC

coil, the flare nut must be tightened in that way that one

flat of the nut is in parallel with the lower surface of the

coil.

• Voltage of coil and network must correspond.

• The flat spade terminals is the earth connection. The

protective conductor must also be connected at the plant.

• Do not energize the coil before assembling on the valve

body.

• All gaskets must be fitted carefully in order to achieve

protection to IP65.

• Tighten fixing screw of connector.

• Constructive modifications at the valve are not allowed.

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

74821 Mosbach/Germany

Phone: +49 (0)

Fax: +49 (0)

62 61 / 81-475

62 61 / 81-461

E-Mail: cooling.mosbach@honeywell.com

www.honeywell-cooling.com

KAT-MV-002

EN0H-1917GE23 R0709 8 Honeywell GmbH • Subject to change without notice

Manufactured for and on behalf of the

Environment and Combustion Controls

Division of Honeywell Technologies Sàrl,

1180 Rolle, Z. A. La Pièce 16, Switzerland

by its authorized representative Honeywell GmbH

Loading...

Loading...