Page 1

Honeywell

M9484 AND M9494 MODUTROL MOTORS ARE LOW

VOLTAGE, REVERSING PROPORTIONAL CONTROL

ACTUATORS FOR VALVES, DAMPERS AND AUXILIARY EQUIPMENT. THEY ARE ESPECIALLY DESIGNED

GAS BURNER CONTROL SYSTEMS.

•i Replace M941 motors.

0

formance and long life.

0

0

AC. Models available with factory installed transformer,

or internal transformer can be field added.

Cl

adapter available.

FORCOMMERCIALOR INDUSTRIALOILOR

Oil immersed motor and gear train for reliable per-

Wiring box provides NEMA 3 weather protection.

Actuator motor and circuitry operate from 24 volts

Quick-connect terminals standard - screw terminal

Cl

Adapter bracket for matching shaft height of older

motors is standard with replacement motors.

0

Field adjustable stroke (90” to 160’) models avail-

able.

q

Nominal timing of 30 seconds for 90” and 60 sec-

onds for

available.

0

Die-cast magnesium housing.

q Available accessories include valve and damper

linkages, explosion proof housing, and auxiliary

,

switches.

0

wiring box to upgrade actuator to Series 70 (electronic)

control.

•i

0

dard timings.

cl

minute timings for

160”

stroke is standard. Other timings are

Field addable interface modules can be mounted in

Models available with tapped output shaft.

M9481,

M9484 rated for 150 lb.-in. torque at stan-

M9491,

M9494 rated for 300 lb.-in. torque at 2 or 4

160“

stroke.

S.M.

Rev. 11-90

Form Number 63-2195-l

@Honeywell Inc. 1990

Page 2

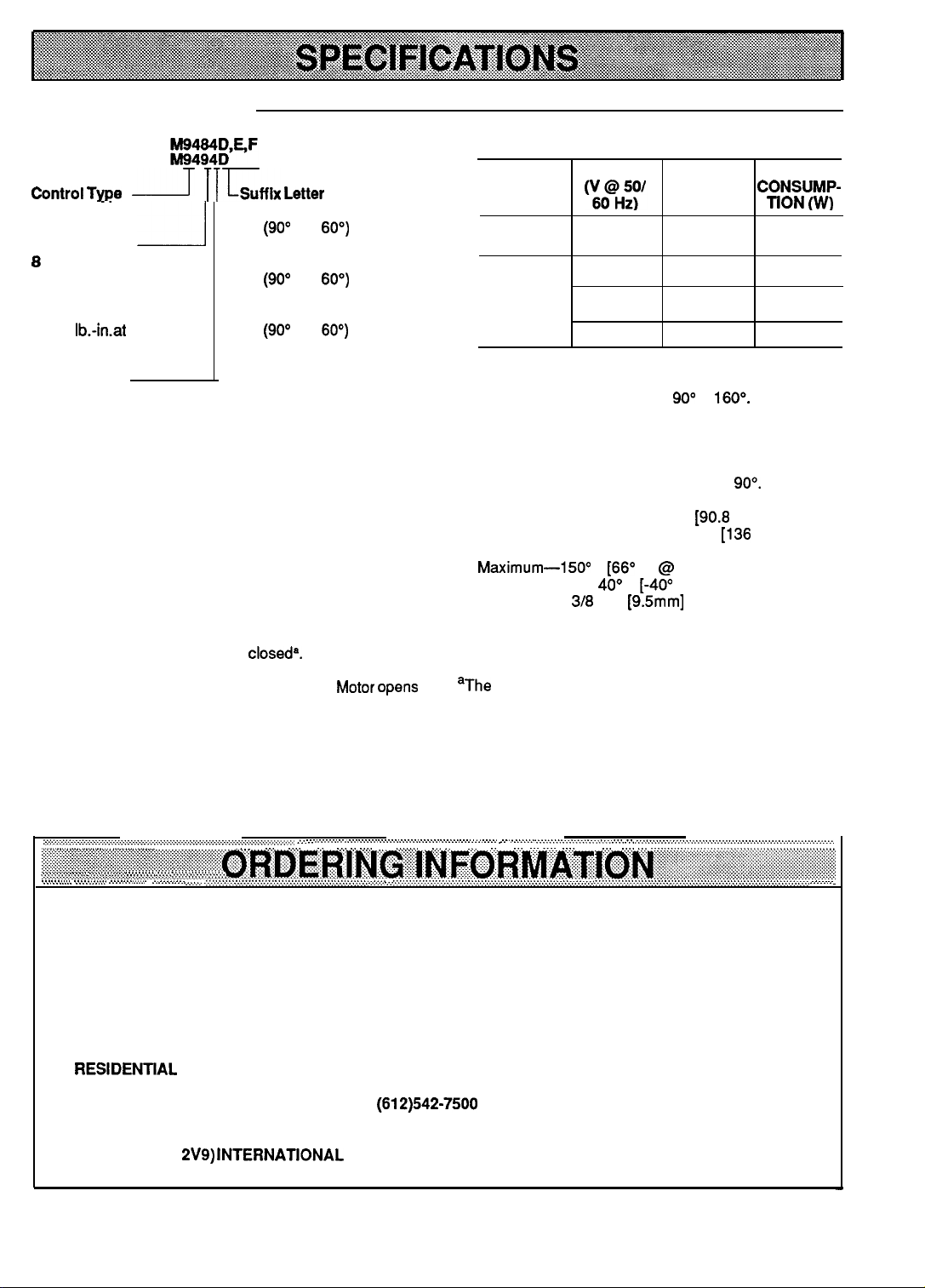

STANDARD MODELS

control Type

94 is Series 90

Power Rating

8

is high torque

150 lb.-in. at

standard timing

9 is high torque

300

2 or 4 min timing

Output Drive

4 is dual-ended shaft,

non-spring return

1 is single-ended shaft,

non-spring return

NOTE: Some motors furnished to equipment manufactur-

ers will have no adapter bracket, a single-ended shaft

and/or no wiring box.

CONTROLLER TYPE: Series 90 Control Circuit-135

ohm series 90 proportioning controller. Series 90 high

or low limit controller with manual minimum position po-

tentiometer (with a combined total resistance of up to

500 ohms) may also be used in the control circuit.

MOTOR ROTATION: Normally

tion is the limit of counterclockwise rotation as viewed

from the power end of the motor. See Fig 2.

clockwise (as viewed from the power end). Motors are

shipped in the closed position.

~~ I

lb.-in.at

T

TTLix

D:

is adjustable stroke

(90°

No auxiliary switches

E:

is adjustable stroke

(90°

1 auxiliary switch

is adjustable stroke

F:

(90°

2 auxiliary switches

closeda.

Letter

to 1

60°)

to 1

60°)

to 1

60°)

The closed posi-

Motor opens

ELECTRICAL RATINGS:

POWER

CONSUMP-

TfON

(W)

18

Without

VOLTAGE

CURRENT

DRAW (A)

24

0.8

Transformer

With internal

120

0.24

23

Transformer

208 0.14

240 0.12

STROKE: Field adjustable from

90”

to

160”.

23

23

Start position

of shaft changes with adjustment of stroke. (Midpoint of

stroke remains fixed as stroke is adjusted, as shown in

Fig. 2.) Stroke is adjusted by means of cams located in

wiring compartment. (See Stroke Setting Procedure.)

Motors are shipped with stroke set at

90”.

DEAD WEIGHT LOAD ON SHAFT:

Power or Auxiliary End-200 lb.

Maximum Combined Load-300 lb.

[90.8

kg] maximum.

[136

kg].

AMBIENT TEMPERATURE RATINGS:

Maximum-150°

Minimum-minus 40” F

CRANKSHAFT:

F [66” C] @ 25% duty cycle.

[-40°

318

inch

[9.5mm]

C].

square

M9484, M9494 have double-ended shaft.

M9481, M9491 have single-ended shaft.

aThe

normal position is the position the motor will assume

with controller disconnected.

. .. .. .. .. .. .. .. .. ..:. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::......... _....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

~~~~~~~~:~~I~~~~CYJ~~~:R.~~~~~~~~~~~~~

_..I........... .. .. .. .. .. . . .. . . _.... . . . ..i _......

..... .... .... . . . . . . .. . . . . . . . . . . . . ..i....

. .. ...i........... _........

..... .... .. ... . . . . . . . . . . . .

..i

..... .... . .. .

......‘.:.~~‘_~~::.~.

..- ___._.

. . . . . . .. .

___:_~~r~_“:.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:

. .. .

:.. ..... ... ....... ............. :.:..

... .......

.,.._...:.,.,.

. .. .. .. .. .. .. .. .. ...

.:

~_.:_:_._:_):_:_:.:.:.~.~.:.~.:.~.:.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~~.~.~~.~.~~~~

. . . . . . .

...:

. .. .. .. .. .. .. .. . . .. .

... .....

.......L.. -...................l..-...-....,-............

:.:..

...........,

_._..

....... :.:.. .......

..,........................................................................................................

:.:.: ....................................._...............,.,.,.....,.,.,.,.,.,.,.,.,.,.,.,.,.,.,.,.,.,.,

t_~_._._._._._._._.‘.............................................................................................................

WHEN PURCHASING REPLACEMENT AND MODERNIZATION PRODUCTS FROM YOUR AUTHORIZED

DISTRIBUTOR, REFER TO THE TRADELINE CATALOG OR PRICE SHEETS FOR COMPLETE ORDERING

NUMBER.

IF YOU HAVE ADDITIONAL QUESTIONS, NEED FURTHER INFORMATION, OR WOULD LIKE TO COMMENT

ON OUR PRODUCTS OR SERVICES, PLEASE WRITE OR PHONE:

1.2.YOUR LOCAL HONEYWELL RESIDENTIAL AND BUILDING CONTROLS SALES OFFICE (CHECK WHITE

PAGES OF PHONE DIRECTORY).

RESlDENTlAL AND BUILDING CONTROLS CUSTOMER SERVICE

HONEYWELL INC., 1885 DOUGLAS DRIVE NORTH

MINNEAPOLIS, MINNESOTA 55422-4386

(612)542-7500

(IN CANADA-HONEYWELL LIMITED/HONEYWELL LIMITEE, 740 ELLESMERE ROAD, SCARBOROUGH,

ONTARIO Ml P

2V9)

INTERNATfONAL SALES AND SERVICE OFFICES IN ALL PRINCIPAL CITIES OF THE

WORLD.

2

. .. .. .. .. .. .. ..

Page 3

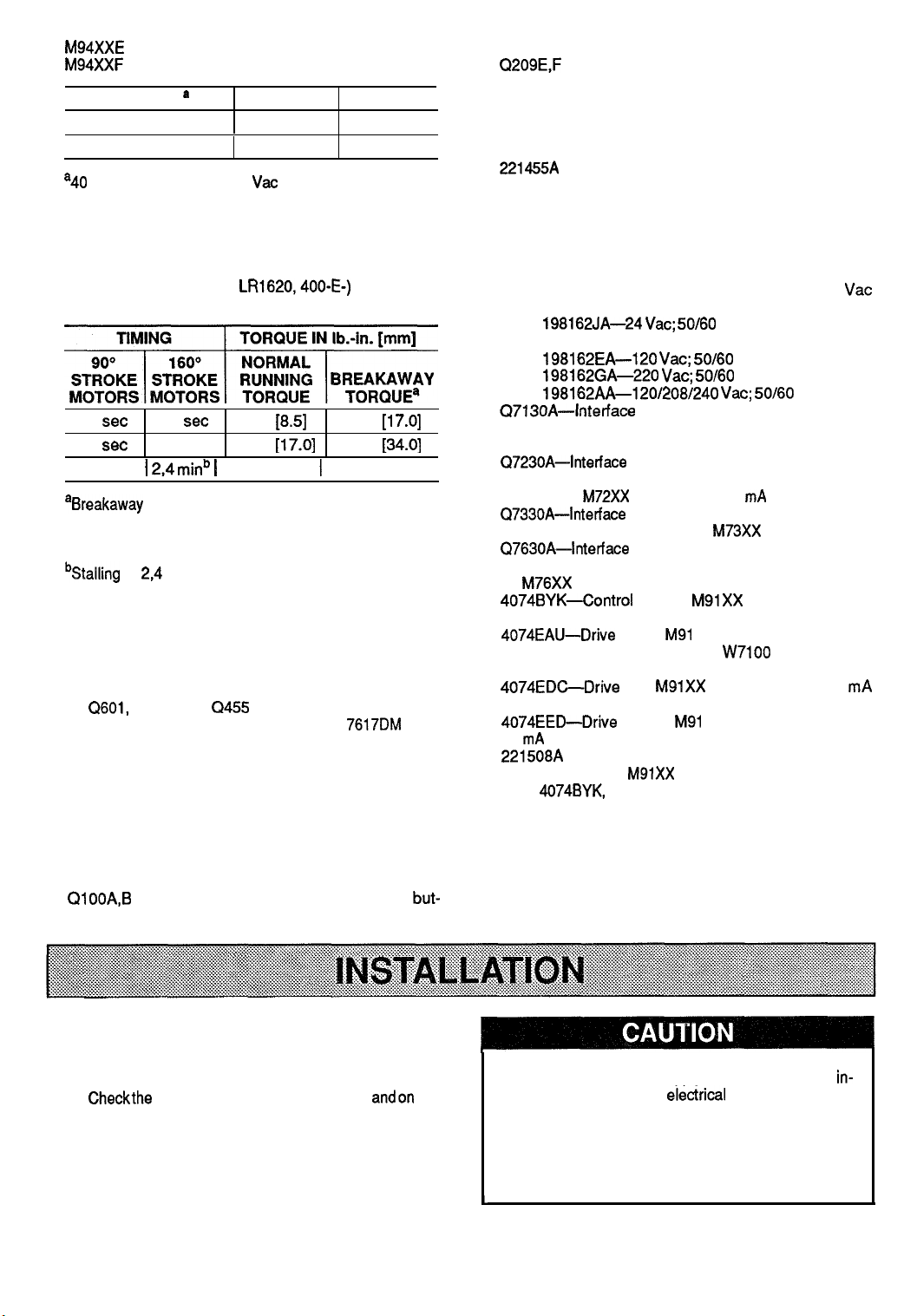

AUXILIARY SWITCH RATINGS (amperes):

M94XXE

M94XXF

ONE CONTACT

Full Load 7.2 3.6

Locked Rotor 43.2 21.6

a4O

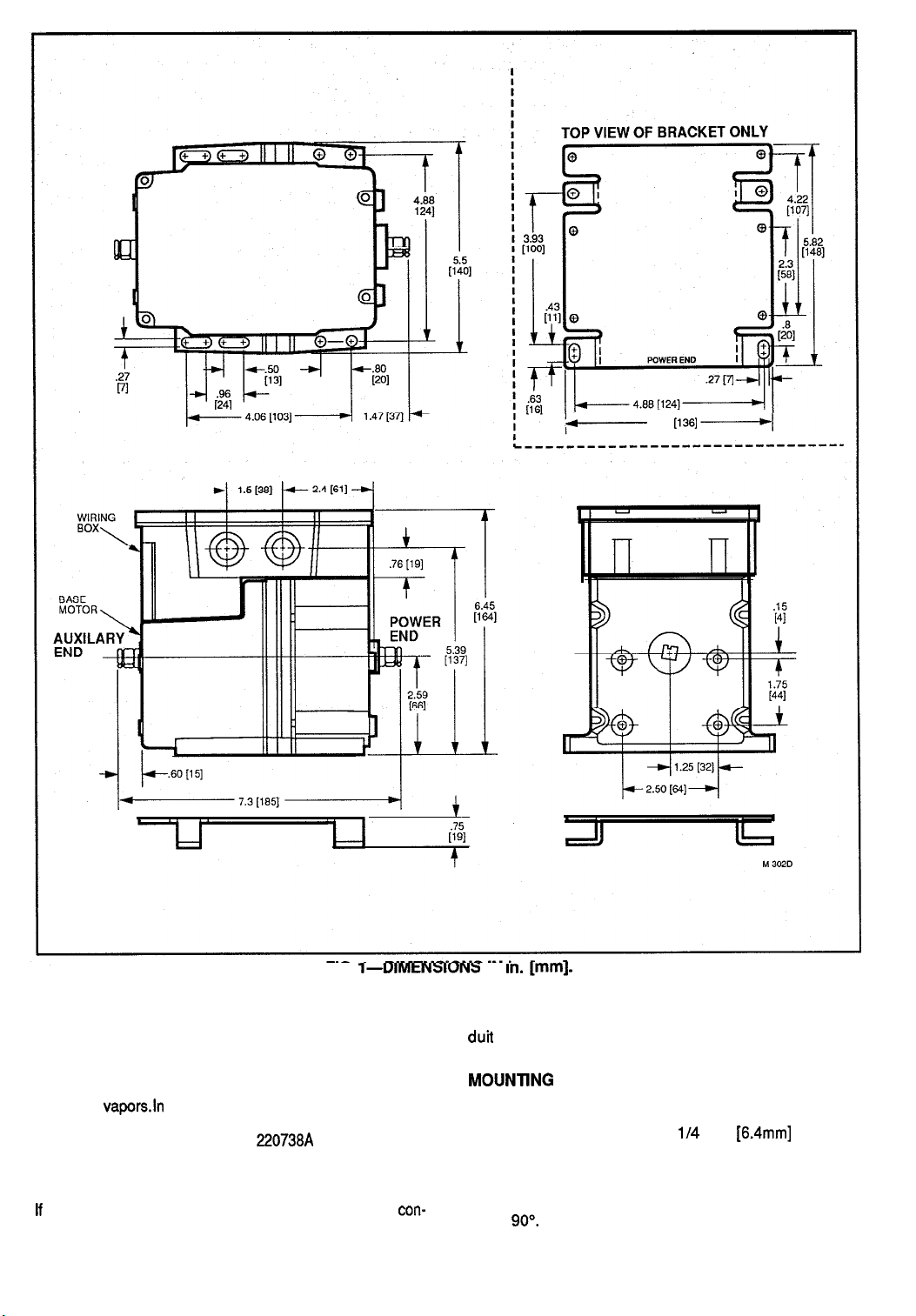

DIMENSIONS: See Fig. 1.

UNDERWRITERS LABORATORIES INC. LISTED

File No. E4436; Guide No. XAPX.

CANADIAN STANDARDS ASSOCIATION CERTIFIED:

General Listing File No.

has 1 spdt switch.

has 2 spdt switches.

a

VA pilot duty, 1201240

Vat

LR1620,400-E-)

120v 240v

on opposite contact.

‘U

STROKE STROKE RUNNING

15

set

30

set

1.2 min 1

aBreakaway

overcome occasional large loads such as a seized

damper or valve. MOTOR MUST NOT BE USED

CONTINUOUSLY AT THIS RATING.

bStalling

ACCESSORIES:

ES6501 17 Explosion-proof Housing-Encloses motor

for use in explosive atmospheres. Not for use with

Q601,

son Electric Co. Requires Honeywell

pling.

Q607 External Auxiliary Switch-Controls auxiliary

equipment as a function of motor position.

Q605 Damper Linkage-Connects motor to damper.

INCLUDES MOTOR CRANK ARM.

0618 Linkage-Connects Modutrol motor to water or

steam valve.

Q601 Bracket and Linkage Assembly-Connects

Modutrol motor to water or steam valve.

Ql OOA,B

30

set 7518.51

1 min 150

2,4 minD 1

torque is the maximum torque available to

of

2,4

min motor will damage motor.

Q618, and

Linkage-Connects Modutrol motor to

300 134.01 1 600 168.01

Q455

[17.0]

Linkages. Order from Nel-

BREAKAWtY

150

[17.0]

300

[34.0]

7617DM

Cou-

but-

terfly valve. Requires adapter bracket packed with

motor.

Q209E,F

Q68 Dual Control Potentiometer-Controls 1 through 9

Q181 Auxiliary Potentiometer-Controls 1 or 2 addi-

221455A

220741A Screw Terminal Adapter-converts the stanTransformers-mounted internally, provide 24 Vat

Q7130A-Interface Module with selectable voltage

Q7230A-Interface Module, selectable voltage or cur-

Q7330A-Interface Module, for W936 economizer ap-

Q7630A-Interface

4074BYK-Control up to 6 M9lXX motors in unison

4074EAU-Drive 2 or 3

4074EDC-Drive one

4074EED-Drive up to 4

221508A

7616ADW Motor Crank Arm-Approximately 0.75

Potentiometer-Limits minimum position of

motor.

additional motors.

tional motors.

Motor Crank Arm-Infinitely adjustable crank

arm. Approximately 0.75 inches shorter than the

4074ELY crank arm, can rotate through downward

position and clear base of motor without requiring

use of adapter bracket.

dard quick-connect terminals to screws terminals.

power to motor

198162JA-24 Vat;

lation).

198162EA-120

198162GA-220 Vat;

198162Al-120/208/240 Vat;

ranges (4-7 Vdc, 6-9 Vdc, and 10.5-13.5 Vdc).

Adapts motor to M71 XX function.

rent control, with adjustable null and span. Adapts

motor to

plications. Adapts motor to

with minimum position capability. Adapts motor to

M76XX

from one Series 90 controller.

Single-zone Logic Panel or

Controller.

Controller.

mA

in wiring box of M9lXX motor. Can be used in place

of

tions described above).

inches shorter than the 7616BR crank arm, can

rotate through the downward position and clear

base of motor without requiring use of adapter

bracket.

M72XX

function.

Controller.

Resistor Board-Plugs onto quick-connects

4074BYK,

EAU, EDC, or EED resistor kits (func-

50/60

Hz (for electrical iso-

Vat; 50160

function; 4 to 20 mA or 2 to 10 Vdc.

Module, 3-wire 14-17 Vdc control

M91

M91XX

M91

Hz.

50160

Hz.

50160

Hz.

M73XX

function.

XX motors from a W973

W7100

Discharge Air

motor from a 4-20

XX motors from a 4-20

mA

WHEN INSTALLING

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Checkthe

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

THIS PRODUCT...

ratings given in the instructions

andon

the

Disconnect power supply before beginning

1.

stallation to prevent

ment damage.

Never turn the motor shaft by hand or with a

2.

wrench-this will damage the motor.

Always conduct a thorough checkout when in-

3.

stallation is complete.

1

3

eiectrical

shock and equip-

in-

63-2195-l

Page 4

ADAPTER

BRACKET

f---

5.37 [136]

FIG.

1-UIMtNSIUNS

IN

NOTE: M9481, M9491 do not have auxiliary shaft. All other dimensions are the same.

LOCATION

install the Modutrol motor in any location

except where

acid fumes or other deteriorating vapors might attack the

metal parts, or in atmospheres of escaping gas or the

duit

weather protection.

MOUNTtNG

explosive vaporsin excessive salt environments, mount-

ing base and screws should be zincorcadmium plated, not

stainless steel or brass:

Use the

220738A

adapter bracket

for mounting on these surfaces.

Allow enough clearance for installing accessories and

servicing the motor when selecting a location. See Fig. 1.

If

located outdoors, mount upright and use liquid-tight

con-

motor housing are drilled for

screws or bolts.

(at the limit of counterclockwise rotation as viewed from the

power end of the motor, as shown in Fig. 2) with the stroke

set at

4

In.

connectors with wiring box to provide NEMA 3

Always install motors with the crankshaft horizontal.

Mounting flanges extending from the bottom of the

l/4

inch

[6.4mm]

machine

Motors are shipped from the factory in closed position

90”.

Page 5

NON SPRING RETURN MOTORS

E373C

FIG. 2-LIMITS OF MOTOR ROTATION.

ADAPTER BRACKET

The220738A

motor and the equipment, raises the shaft height

Adaptor Bracket, positioned between the

ptthe-

M9484 motor by 0.75 inch to match that of the M941 motor.

This is required on all valve linkage applications,

Q607

External Auxiliary Switch applications, and on some

damper linkage applications (either to provide clearance

for the crank arm to rotate through the downward position,

or to allow the damper linkage to reach the shaft).

To mount the motor with the bracket:

1. Mount the bracket to the equipment with existing or

standard bolts.

2. Mount the motor to the bracket using the bolts pro-

vided into the threaded holes of the bracket (see Fig. 3).

For valve linkage applications, the bracket should first

be mounted to the linkage (see Fig. 4). The bracket then

provides a convenient base on which the motor can be

positioned. After the motor shaft is aligned to the linkage,

it can then be attached to the bracket with the 4 bolts

provided. These bolts go through the inner set of holes in

the motor

flanae

BOLTS

PROVIDED (4)

and into the threaded holes of the bracket.

1

#12 OR

l/4”

n

FIG.

“MOUNTING

with standard bolts.

which thread into the threaded bracket holes.

ZINC PLATED MACHINE SCREWS OR BOLTS

M 3076

MOTOR WITH 220738A ADAPTER BRACKET. The

The motor is then mounted

to

DAMPER LINKAGES

A 220738A Adapter Bracket is packed with replace-

ment motors. Use of this bracket is optional for many

damper applications but may be needed in damper applications requiring the crank arm to rotate through the

bottom plane of the actuator. If the bracket is not used in a

replacement application, the damper linkage will have to

be adjusted to the new shaft position.

The motor comes without a crank arm. The crank arm

is included in the Q605 linkage or may be ordered separately (see Accessories).

For detailed instructions on the assembly of specific

linkages, refer to the instruction sheet packed with each

5

bracket is first mounted to the

the

bracket using the bolts provided with

equipmel

the

bracKet,

linkage. In general, however, check the following points of

operation when installing a motor and linkage.

1.

Linkages for valves and louver type dampers should

be adjusted so that the damper or valve moves through

only the maximum required distance when the motor

moves through its full stroke.

2. With modulating control, maximum damper

should be no more than

60”.

Little additional airflow is

opening

provided beyond this point.

3. The motor must be stopped at the end of its stroke

by the limit switch and must not be stalled by the damper

or valve. The motor will be damaged if it is not permitted to

complete its full stroke.

63-2195-l

Page 6

Y

BOLTS PROVIDED (4)

WIRING BOX

MOTOR

MACHINE SCREWS OR BOLTS.

M

31% TIGHTEN AFTER SECURING MOTOR TO THE BRACKET USING FOUR BOLTS PROVIDED.

FIG. 4-MOTOR

4.

Do not exceed the motor ratings in any installation.

5.

Do not turn motor shaft manually or with a

wrench-

this will damage the motor.

LTS SECURING BRACKET TO LINKAGE.

MOUNTING

ONVALVE LINKAGE,.

of theprintedcircuit boardshown in

adapter is standard on all Trade models and also may be

VALVE LINKAGES

The 220738A Mounting Bracket must be used with the

Ql

00,

Q601 and Q618 linkages in all valve applications.

WIRING

Disconnect power supply before wiring to prevent electrical shock or equipment damage. All wiring must agree with

applicable codes, ordinances, and regulations.

A transformer is required to supply 24

Vat power to the

motor. Make sure that the power requirements stamped on

the motor correspond to the characteristics of the power

supply.

added to all models. Access to the wiring compartment is

gained

and lifting off the cover.

WIRING BOX

When used with liquid-tight conduit connectors, the wiring

box provides NEMA 3 weather protection for the motor.

The box also provides knockouts for wiring conduits and

encloses terminals. The wiring box, standard with replace-

ment motors, is required for housing an internal trans-

former, internal auxiliary switches or Series 70 Interface

Modules.

Figs. 5 and 6 show internal schematics.

The motor terminals are quick-connects located on top

Fig.7.Ascrewterminal

byremovingthe4screws

inthetoppf the wiring box

6

Page 7

CLOSE

LIMIT

DIRECTION OF MOTOR TRAVEL AS VIEWED FROM POWER END.

&

CONNECT 24V POWER TO

POWER SUPPLY TO CONTROLLER TERMINALS. PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION AS REQUIRED.

3 TURN

LIMIT

n

COUNTERCLOCKWISEr?FOR 90’

FIG.

5-lNTERNAL

POT FULL

Tl-T2

TERMINALS ONLY. DO NOT CONNECT

CLOCKWISE~FOR 160’

WIRING OF

STROKE.

An9494

STROKE, FULL

MOTORS.

MODUTROL

A

BLUE LEAD

I

YELLOW LEAD

1

REDLEAD

2

‘n

1

WIRING SHOULD BE NEC CLASS 1 UNLESS POWER SUPPLY

n

MEETS CLASS 2 REQUIREMENTS. TAPE UNUSED LEADS. MAKE

CERTAIN THE CURRENT DRAW OF THE EXTERNAL CIRCUIT IS

LESS THAN CONTACT RATING OF SWITCH.

2

ON TWO-SWITCH MOTORS SECOND SWITCH HAS BLACK

n

LEADS WITH BLUE, YELLOW. AND RED TRACERS.

FIG.

6-AUXILIARY

SWITCH INTERNAL WIRING.

A

A

M

254

I

STROKE

MINIMUM

:zTloN

I

STROKE POT

NOTE: FEATURES AVAILABLE ON SOME MODELS ONLY.

ADJUSl

CAMS (YELLOW)

FIG. 7-TERMINALS AND ADJUSTMENTS.

INNER AUXILIARY

INNER AUXILIARY

SWITCH CAM (BLUE)

OUTER AUXILIARY

SWITCH CAM (RED)

OUTER AUXILIARY

*

M ml/\

63-2195-l

Page 8

AUXILIARY SWITCH

M9484E

The

wires are color-coded as follows: solid yellow-normally

closed (N.C.); solid red-common (COM.); solid

blue-normally open (N.O.).

SWITCH/CAM COLOR-CODING:

CONNECTIONS

supplies to de-energize the

has 1 internal auxiliary switch. The switch

CAM

SWITCH

LOCATlON’

Left

Right

aViewed

bSee

from power end of motor.

Fig. 6.

ASSEMBLY

LOCATIONa

Outer

Inner

CAM

COLOR CODE

Red

Blue

The

M9484F

may be used to prove low fire and high fire positions.

1.

To prove low fire use red (common) and yellow wires

connected to outer (left) switch. This switch makes red to

yellow and breaks red to blue as motor closes.

2.

Wires connected to the inner (right) switch are black

with colored tracers. To prove high fire, use red tracer

(common) and blue tracer wires. The right switch makes

red tracer to blue tracer and breaks red tracer to yellow

tracer as motor opens.

Color coding and switching action are tabulated below

to aid the installer.

TABLE 1

has 2 internal auxiliary switches which

SWITCH

COLOR

Solid Yellow

Solid Red

Solid Blue

Yellow Tracer

Red Tracer

Blue Tracer

WIRESb

DESIGNATION

Normally Closed (N.C.)

Common (COM.)

Normally Open (N.O.)

Normally Closed (N.C.)

Common (COM.)

Normally Open (N.O.)

SWITCHING ACTION:

SWITCH

LOCATIONa

Left

Right

aViewed

bSee

from power end of motor.

Fig. 9

NORMAL

FUNCTION

Proves

Low Fire

Position

Proves

High Fire

Position

MAKES

Red

to to

Yellow

Red Tracer Red Tracer

to

Blue Tracer

STROKE SEl-lING

On M94XXD,E,F motors, stroke is field adjustable and

can be set from 90” to 160”. Motors are shipped in 90”

position. In order to set stroke, both mechanical and electrical adjustments are required. The mechanical adjust-

n

ments (cams) establish the full open (clockwise,

viewed from the power end) and full closed (counterclockwise

0

)

positions of the motor shaft. The electrical

adjustment (trim pot) provides sufficient total stroke angle

to ensure that cams will actuate both limit switches.

STROKE SETTING PROCEDURE

See Fig. 8.

Detach linkage from motor before adjusting stroke.

as

TABLE 2

CAM

BREAKES

Red

Blue

to

Yellow Tracer

BEFORE SETTING STROKE:

1. Remove top cover from motor.

2. Disconnect controller from motor.

3. Connect

ter (Q209 or S963) to matching terminals on motor.

SETTING

(Q209 or

yellow cam and MOVE TOP OF SCREWDRIVER as far as

possible counterclockwise n (viewed from power

end). Repeat in successive cam slots until inner cam is

against counterclockwise

160”

1. Turn stroke pot fully clockwise

2. Drive motor to mid-position using 135 ohm pot

S963),

3. Insert

l/8

POSITIONb

High portion of cam

not in Contact

with Cam follower.

High portion of cam

in Contact

with Cam follower.

R,B,W

terminals on 135 ohm potentiome-

STROKE (Fig. 8):

or by jumpering B-R-W.

in. screwdriver blade into slot on inner

0

stop.

POSITION

f7

.

MOTOR

Closing

Opening

8

Page 9

MOVE SCREWDRIVER

ONLY TO ADJUST CAM:

AT TOP

l/8 IN. STRAIGHT BLADE

SCREWDRIVER

OUTER STROKE

ADJUST CAMS

RY SWITCH CAMS

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

A

OVERLOAD PROTECTION AS REQUIRED.

2 TRANSFORMER MAY BE EXTERNAL OR INTERNAL.

A

FIG.

M 3,3A

8-STROKE

ADJUSTMENT SETUP.

OUTER CAM

NOTE: CAMS ARE OFFSET

PROVIDE BETTER VIEW OF BACK CAM.

l/8

IN. STRAIGHT-BLADE

SCREWDRIVER

M305

STROKE ADJUST

CAMS (YELLOW)

INNER AUXILIARY CAM (BLUE)

OUTER AUXILIARY CAM (RED)

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

A

OVERLOAD PROTECTION AS REOUIRED.

2

TRANSFORMER MAY BE EXTERNAL OR INTERNAL.

A

FIG. O-AUXILIARY SWITCH ADJUSTMENT SETUP.

RIGHT/INNER

M 315c

NOTE: CAMS ARE OFFSET VERTICALLY TO

PROVIDE BETTER VIEW OF BACK CAM.

POWER END

9

OTOR CLOSE

M 3060

63-2195-l

Page 10

IMPORTANT

Set cams by moving top of screwdriver only. Pressing screwdriver against sides of cam slots could

cause damage to motor end switches.

4. Insert

yellow cam and MOVE TOP OF SCREWDRIVER as far as

possible clockwise

until outer cam is against clockwise q stop.

NOTE: Excessive force will damage cam stop on hub.

5. Check motor stroke before connecting linkage.

6. Disconnect 135 ohm pot, reconnect controller, re-

place top cover on motor.

7. Attach linkage to motor.

SETTING

1. Turn stroke pot fully counterclockwise

2. Drive motor to mid-position, using 135 ohm pot

(Q209 or

3. Insert

cam and MOVE TOP OF SCREWDRIVER as far as

possible clockwise

peat in successive cam slots until inner cam is against

clockwise stop.

NOTE: Excessive force will damage cam stop on hub.

4. Insert

yellow cam and MOVE TOP OF SCREWDRIVER as far as

possible counterclockwise

cam slots until outer cam is against counterclockwise stop.

NOTE: Excessive force will damage cam stop on hub.

5. Check motor stroke before connecting linkage.

6. Disconnect 135 ohm pot, reconnect controller, replace top cover on motor.

7. Attach linkage to motor.

AUXILIARY SWITCHES

The auxiliary switches in

ated by adjustable cams. The cams are mounted on the

motor shaft at the power end of the motor. The settings of

the cams determine the point in motor shaft rotation at

which the auxiliary equipment will be switched on or off.

These cams can be set to actuate switches at any angle

within the stroke of the motor. Also each cam provides a

fast rise portion for switching (1

rise portion for slow switching (10’ differential).

l/8

in. screwdriver blade into slot on outer

n

.

Repeat in successive cam slots

90”

STROKE (Fig. 8):

S963),

or by jumpering B-R-W.

l/8

in. screwdriver into slot on inner yellow

q

(viewed from power end). Re-

l/8

in. screwdriver blade into slot on outer

c

.

Repeat in successive

M9484E,F

motors are actu-

o

differential) and a slow

0

.

Switching action and color coding are shown in Tables

1 and 2 on page 8.

Motors with factory added auxiliary switches are

shipped in the closed position (counterclockwise

as viewed from power end) with auxiliary cams set to

actuate switches

provide 1” differential. Wiih motor in closed (full counter-

clockwise

AUXIUARY

terminals and cam adjustments.

ohm manual potentiometer with R-W-B terminals on pot

connected to corresponding terminals on motor (Fig. 9).

position where auxiliary equipment is to be switched.

cam associated with selected auxiliary switch. The inner

(blue) cam actuates the inner (right) switch, the outer (red)

cam actuates the outer (left) switch. MOVE TOP OF

SCREWDRIVER to set cams.

iliary switch R-B contacts and rotate cam as follows:

auxiliary switch R-B contacts and rotate cam as follows:

iaryequipmentby runningmotorthroughfullstroke (inboth

directions), using 135 ohm pot. Repeat adjustment if

necessary.

place top cover on motor.

NOTE: If differential is changed from

r\

Do not turn motor shaft by hand or with a wrench as

damage to the gear train and circuit board stroke

limit contacts will result.

1. Removetopcoverfrom motorto gain access to motor

2. Disconnect controller from motor and connect 135

3. Adjust 135 ohm pot so that motor shaft turns to

4. Insert a

5. For switch differential of 1 O, check continuity of auxa. lf

contacts are open, rotate cam clockwise n until

R-B contacts close.

b.

lf

contacts are closed, rotate cam counterclockwise

c

6. For switch differential of loo, check continuity of

a.

lf

contacts are open, rotate cam counterclockwise

0

until R-B contacts close.

b. lf contacts are closed, rotate cam clockwise

until R-B contacts open.

c. Final adjustment in the proper direction should be

made to obtain contact make or break at the desired

position.

7. Check for proper differential and switching of auxil-

8. Disconnect 135 ohm pot, reconnect controller, re-

ing action is reversed, thus: switch contacts R-B make

and R-W

30” from the closed position, and to

)

position, auxiliary switch breaks R-B.

IMPORTANT

SWlTCH SElllNG

l/8

in., straight-blade screwdriver into slot on

until R-B contacts open.

breakon

acounterclockwise (closed) rotation.

PROCEDURE (Fig. 9)

1”

to

lo”,

fi

r\.

the switch-

,

MODULATlNG

The potentiometers, one in the controller and one in the

motor, along with resistor network, form a bridge circuit. As

long as the value of the controlled medium remains at the

controller set point, the circuit is balanced, and the motor

does not run.

When the value of the controlled medium changes, the

potentiometer wiper in the controller is moved, which

unbalances the bridge circuit. This unbalance is amplified,

and energizes

direction necessary to correct the change in temperature

or pressure. The motor turns the feedback potentiometer

to rebalance the circuit and stop the motor.

SERIES 90 CIRCUIT

Triac switching to run the motor in the

10

CONNECTION DIAGRAMS (Figs. 10-13)

These motors are designed for use in series 90 proportioning control circuits employing a 135 ohm series 90

controller. Series 90 high or low limit controls or manual

minimum position potentiometers may also be used in the

control circuit.

The M9484 can also be used with some electronic

mA

controllers which provide a 4-20

necessary to use a resistor kii (4074EED for controlling up

to 6 motors) or Q7230 Interface Module to interface to the

4-20 mA source.

The standard series 90 controller has R, W, and B

terminals. As the controller reduces Rto W resistance, the

motor will drive closed (CCW as viewed from the power

end).

control output. lt is

Page 11

SERIES 99

CONTROLLER

OPTIONAL CONNECTIONS

WITH 2-135 OHM POTENTIOMETERS IN SERIES.

SERIES 90

CONTROLLER

-

MOTOR

MOTOR

1

POWER SUPPLY.

n

PROTECTION AS REQUIRED.

2

TRANSFORMER MAY BE INTERNAL OR EXTERNAL TO MOTOR.

n

PROVlDE

SPDT SWITCH

OR SERIES 60

CONTROLLER

USED ASA

DISCONNECT MEANS AND OVERLOAD

EJ74C

SERIES 90 HIGH

LIMIT CONTROL

1

POWER SUPPLY.

n

PROTECTION AS REQUIRED.

2

TRANSFORMER MAY BE INTERNAL OR EXTERNALTO MOTOR.

n

IG.

1 l-MOTOR

PROVIDE

USED

DISCONNECT MEANS AN,, OVERLOAD

WITH

ASERIESSO

LER AND A SERIES 90 LOW OR HIGH

CONTROL.

4.20 mA

SOURCE

TRANSFORMER

SINGLE MOTOR

E2rM4

CONTROI

LIMI

I

TRANSFORMER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

1

PROTECTION AS REOUIRED.

USE SOLID LINE CONNECTION FOR POSITIVE CLOSING TO

2

!h

MINIMUM POSITON. SUBSTITUTE DOTTED LINE CONNECTION

FOR POSITIVE FULL CLOSURE.

TRANSFORMER MAY BE INTERNAL OR EXTERNAL TO MOTOR.

3

!I

12-CONNECTIONS FOR MOTOR, SERIES 90

;.

CONTROLLER, MINIMUM POSITION POTENTIOMETER (ETC.).

M428

SLAVE MOTOR(S)

UP TO 4 ADDITIONAL SLAVE MOTORS (6 TOTAL,

A

RESISTOR (A) DEPENDS ON NUMBER OF SLAVES. SEE RESISTOR SELECT-

ION CHART IN TEXT.

2

SEE MOTOR SPECIFICATIONS FOR

n

ACTUAL TERMINAL ARRANGEMENT.

E474A

L

13-CONNECTlONS FOR MOTOR USED WITH 4

FIG.

11

TO 20 mA CONTROL.

63-2195-I

Page 12

4074EED

MOTORS

1

2 2.0

:

5

6

a

Not part of this kit, obtain separately.

b

These values represent the controller output voltage

required to drive the motors.

RESISTOR SELECTION CHART FOR

4-20

mA

MIINIMUM

OUTPUT

VOLTAGE

REQUIRED

(Vdc)b

RESISTOR (A)

(Ohms) Part No.

1.7 237 80213QCDHA

150

2.3 2.7 124 113 802139BCEA 802139BBDA

3.0

105a

3.3 97.6”

802139BFAA

-

-

CHECKOUT

After installation and linkage adjustment, check the entire

motor and control hookup to ensure that-

*

The motor operates the damper or valve properly.

l The motor responds properly to the controller.

Inspect the motor, linkage, and valve or damper to see

that all mechanical connections are correct and secure. In

damper installations, the

pushrod

should not extend more

than a few inches past the ball joints. Check to see that

there is adequate clearance for the linkage to move

through its stroke without binding or striking other objects.

Check to see that cams operate the auxiliary switches,

if used, at the desired point of motor rotation.

NOTE: Motors are shipped in the fully closed position (the

limit of counterclockwise rotation as viewed from the

power end of the motor) with the stroke set at

SERIES 90 MOTORS OPERATION CHECK WITH MODUTROL MOTOR DISCONNECTED FROM CONTROLLER

90”.

STEP ACTION

1.

2.

3.

4.

Apply 24

Vaca.

Open terminal B and short W to R. Motor drives closed. Proceed to Step 6.

Open terminal W and short B to R. Motor drives open.

Connect terminals R to B to W.

RESPONSE

None.

Motor must drive to

Mid-

IF NO OR LIMITED RESPONSE

-

Proceed to Step 6.

Proceed to Step 6.

position.

5.

Remove jumpers from R, B, and W.

17 to 20 Vdc.

Check voltage between B and R,

No voltage or out of range. Proceed

to Step 7.

and W and R.

6.

7.

Motor does not drive.

Voltage out of range.

Motor is defective.

Motor printed wiring board

Replace motor.

Replace motor.

is defective.

8.

Disconnect 24

Vat.

Spring return motors return

Spring mechanism defective

to their normal mechanical -replace motor.

position.

NOTES:

a

Ensure motor transformer is sized properly. If a common transformer is used to power multiple motors, ensure power

input is in phase with all motors.

b

Motors may operate in Series 90 or two-position control applications. However, checking voltage between terminals

R

to B and R to W is necessary to confirm proper operation in electronic (W973, 4 to 20 mA etc.) applications.

DAMPER APPLICATION

1. Turn off power and remove wiring from the old

actuator.

2. Remove crank arm from shaft of old actuator and

remove the old actuator.

3.

Checkto

see

whether or

not the mounting bracket is

needed. lf the linkage can reach the lowershaft position of

the new actuator and if the crank arm has clearance for the

needed rotation, then the bracket is not needed. Use

4b.ffthe

sections and see Fig. 3 as well as the INSTALLATION,

SETTINGS &ADJUSTMENTS, and

of these instructions.

5. Use old mounting bolts to mount the new actuator.

6. Mountthedampercrankarmandlinkagetotheshaft

of the new actuator.

8. Use the CHECKOUT procedures to test the proper

adjustment of the crank arm and linkage.

bracket is needed,

referto

the Adapter Bracket

CHECKOUTsections

.

220738A Adapter Bracket or 221455A crank arm if crank

arm must rotate through the bottom plane of the motor (for

damper applications).

4a.If

the bracket is not needed, mount the new actuator

directly to the equipment and refer to the INSTALLATION,

SETTlNGS&ADJUSTMENTS,andCHECKOUTsections

of these instructions as needed.

VALVE APPLICATION

When installing a M9484, M9494 motor in a valve ap-

plication which has a

QlOO,

Q601 or

0618

it will be

necessary to use the 220738A Adapter Bracket provided

to

raisethe

motor. Ensure motor stroke is

V5011

motorshafttothesame height asthatof

160”

to operate Honeywell

two-way or

V5013

three-way valves.

theold

Honeywell

U.S.A.:

1885 Douglas Drive N. Australia, Canada, Finland, Franc%, Germany, Japan, Mexico, Netherlands,

Inc.

International Sates Offices

in all

principal cities of the world. Manufacturing in

Golden Valley, MN 55422-4386 Spain, Taiwan, United Kingdom, U.S.A.

CANADA: 740 Ellesmere Road

Scarborough, Ontario Ml P

2V9

PRINTED IN U.S.A.

@

Lz3

QUALITY IS KEY

Loading...

Loading...