Page 1

31-00118EFS-01

LCBS Connect Solution

APPLICATION MANUAL

TABLE OF CONTENTS

Introduction .................................................................................................................................................................. 2

Background....................................................................................................................................................................................... 3

Automatic Building Schedules ................................................................................................................................ 4

Scheduling a Holiday .................................................................................................................................................................... 5

Heating, Heat Pump Control .................................................................................................................................... 6

Heating Theory and Operation ................................................................................................................................................. 6

Basic Gas and Electric Heating ................................................................................................................................................ 6

Air to Air Heat Pump ...................................................................................................................................................................... 6

Droop, Comfort and Saving Heat Pump Mode ................................................................................................................... 7

Discharge Air Temperature High Limit Control.................................................................................................................. 7

Cooling, Dehumidification, Economizer Control ................................................................................................7

Cooling Theory and Operation .................................................................................................................................................. 7

Cooling Operation .......................................................................................................................................................................... 8

Dehumidification Theory and Operation .............................................................................................................................. 8

Method #1: Cooling On, Cycle Heating ................................................................................................................................. 8

Method #2: Simple Humidification......................................................................................................................................... 8

Method #3: Dehumidification extended cooling minimum run time ....................................................................... 9

Fresh Air Economizer Control .................................................................................................................................. 9

Theory and Operation Economizer ......................................................................................................................................... 9

General Economizer Operation ................................................................................................................................................ 9

Honeywell Integrated Economizer Control Described .................................................................................................... 10

Honeywell Integrated Economizer Control, Climate Zones .......................................................................................... 12

Honeywell Integrated Economizer Control - High Limit and Changeover Strategies........................................ 12

Strategy 1: Differential Enthalpy with Fixed Dry Bulb Temperature Limit .............................................................. 12

Strategy 2: Outdoor Air Enthalpy.............................................................................................................................................. 12

Strategy 3: Differential Temperature ...................................................................................................................................... 12

Strategy 4: Outdoor Temperature ............................................................................................................................................ 12

Low Limit Temperature Override Control ............................................................................................................................. 13

Freeze Stat Operation ................................................................................................................................................................... 13

Advanced Temperature Control Fundamentals..................................................................................................13

Proportional Control and the Concept of Differential and Throttling Range......................................................... 13

Proportional Control...................................................................................................................................................................... 13

Set point and Differential Refresher - On Off, Digital Control...................................................................................... 14

Integral Action Primer and Refresher Course for Some.................................................................................................. 15

Derivative Control........................................................................................................................................................................... 17

Demand Controlled Ventilation............................................................................................................................... 17

Theory and Operation Demand Controlled Ventilation .................................................................................................. 17

DCV Operation ................................................................................................................................................................................. 17

Adaptive Intelligent Recovery..................................................................................................................................18

Page 2

LCBS CONNECT SOLUTION

Multispeed Fan ............................................................................................................................................................ 20

Multispeed Fan Theory and Operation................................................................................................................................... 20

Two speed motor .............................................................................................................................................................................20

VFD application................................................................................................................................................................................20

Direct drive "ECM" motor..............................................................................................................................................................20

Theory and Operation Accessory Loops ............................................................................................................... 23

How do Accessory Loops work?.................................................................................................................................................23

Service Alerting Theory and Fundamentals ........................................................................................................24

How does service alerting work?...............................................................................................................................................25

Terminal Load, Zone Demand Alert. ........................................................................................................................................ 25

Space Humidity Alert.....................................................................................................................................................................25

Space Zone Carbon Dioxide Level Alert .................................................................................................................................26

Differential Pressure Alerting, Filter Loading ......................................................................................................................26

Alerting Details................................................................................................................................................................................. 27

Appendix, Wiring Diagrams ...................................................................................................................................... 30

1. Master Points List - Configurable and Fixed Function Points.................................................................................30

2. Master Application Inventory - All Wiring Diagrams....................................................................................................30

3. Configurable Input and Output Assignments Wiring Diagram ...............................................................................31

4. Fixed Input and Output Assignments Wiring Diagram ...............................................................................................32

5. Two Heat Two Cool Integrated Economizer Single Temperature Changeover Limit ......................................33

6. Two Heat Two Cool Integrated Economizer Differential Enthalpy Changeover and

Temperature Limit.....................................................................................................................................................................34

7. Two Heat Two Cool Integrated Economizer Differential Enthalpy Changeover and Temperature

Limit and Demand Controlled Ventilation.......................................................................................................................35

8. Three Heat Three Cool Multispeed Fan with Variable Frequency Drive ...............................................................36

9. Single Stage Heat Pump with Economizer Differential Enthalpy Changeover and

Temperature Limit.....................................................................................................................................................................37

10. Two Stage Heat Pump with Economizer Differential Enthalpy Changeover and Temperature Limit ...38

11. Simple Dehumidification......................................................................................................................................................39

12. Two Speed Fan with Discrete Fan Outputs Two Heat and Two Cool ...................................................................40

13. Outdoor Ambient Lighting Control with Photosensor Input to Control Outdoor Light Level ..................41

14. Sylk Sensor Installation Relating to LCBS Connect Controller .............................................................................42

INTRODUCTION

The LCBS Connect Solution features controllers that support multiple CVAHU applications, including rooftop units, split

systems and air to air heat pumps and a new Gateway that permits controller data to be sent from individual CHAHU

controllers via the internet to the new LCBS Connect Cloud. The new Honeywell Cloud capability gives our control system

users unprecedented access to data remotely via standard smart phones, tablets, and personal computers. Honeywell

also performs data analysis, called “analytics,” that will permit service contractors and building owners to effectively and

efficiently manage HVAC assets. Here are a few specific features of the new LCBS Connect solution.

— Occupancy Control. Daily and holiday schedules are available to ensure that building occupants, employees, and

visitors are comfortable when they are in the building and that owners achieve maximum energy savings when no

one is occupying the building. Honeywell patented Adaptive Intelligent Recovery monitors outdoor and indoor climate conditions to ensure comfortable conditions when building occupants arrive.

— Advanced Sensing. Supports multiple space temperature sensors (Up to five) for effective temperature value

(Average, Minimum, Maximum, and Smart) and options for return air sensing. Supports space and return air temperature, humidity, and CO2 sensing.

— Heating and Cooling Control. Provides three stages of heating and cooling for conventional equipment and up to

three compressor stages for air to air heat pumps. LCBS Connect heat pump controllers support up to two (2)

stages of auxiliary heat.

— Economizer Control. Supports nine different economizer strategies that address all climatological zones in North

America.

— Dehumidification Control. Three (3) dehumidification strategies for dehumidification control are supported.

First, if the equipment is capable, a reheat mode can be programmed to provide precise dehumidification operation. Second, dehumidification equipment can be controlled through a direct LCBS Connect output to provide

dehumidification. Third, extended minimum cooling runtime can be selected supporting the dehumidification

process.

31-00118EFS—01 2

Page 3

LCBS CONNECT SOLUTION

— Accessory Loop, Multispeed Fan Control. Each LCBS Connect controller provides the ability to configure custom

control loops to control other equipment including exhaust fans, exhaust pressurization loops, cabinet unit heaters, blower coils, and outdoor lighting circuits based on ambient light level. These loops are called "Accessory

Loops." LCBS Controllers also provide unprecedented control of CVAHU fans that we call Multispeed Fan. This feature not only ensures building occupant comfort, but when applied properly, results in energy cost avoidance to

building owners.

— Honeywell Cloud Based Remote Control and Service Analytics… A New Honeywell Feature! Data is sent

securely from a building site via the internet to the Honeywell Cloud where extensive analysis is performed. The

output of this analysis is useful information that will allow service contractors to do service more efficiently and

effectively and retain valuable service contracts.

Background

The LCBS Connect system provides comprehensive control options for constant volume air handling units (CVAHU). In

addition to heating, air conditioning, dehumidification, and ventilation applications, critical data from LCBS Connect

controllers is collected, stored, and analyzed in the Honeywell Cloud. The data can be used for logging, sophisticated

graphic display, advanced service alerting and "big data" analytics. Honeywell data scientists and engineers are relying

on hundreds of years of control and service experience to write analytics that will help service contractors assist building

owners to predict and prevent service issues from occurring, resulting in superior equipment uptime and extended HVAC

equipment life. These analytics run in the cloud 24 hours a day, 365 days a year.

Honeywell has an incomparable industry reputation for providing precise temperature control, superior remote and local

operator interface experience. With the addition of cloud based data collection and data analytics, Honeywell steps to the

front again.

The primary focus for LCBS Connect is control of CVAHU rooftop units and split systems. Over 60% of commercial

buildings in North America are heated and cooled by CVAHU packaged and split systems. The average age of this HVAC

equipment is approximately eight (8) to 10 years. Due to lack of appropriate service, many suffer from operational

problems including temperature, pressure, humidity sensing devices that are out of calibration, refrigeration circuits

improperly under and overcharged for a variety of reasons, economizer ventilation cycles that have ceased to function, air

flow systems improperly sized delivering substandard air flow, and thermostats in common buildings that "fight" each

other due to improper occupant intervention.

LCBS Connect. Extending HVAC Equipment Life

The average estimated life of packaged constant volume air handling systems is about 17-25 years, depending on where

the system is located. At eight (8) years, these systems are ripe for 1] restorative service and 2] re-control for reasons

listed above. With service contractor assistance, a user of these systems can delay capital appropriation and expenditure

by up to five (5) years by restoring these units to initial, "as built" specified operation. Restored equipment operates less

resulting in lower energy costs. Ongoing maintenance costs are reduced as "tuned up" equipment operates efficiently and

effectively. After this work is done, Honeywell offers LCBS Connect Cloud Services that will help HVAC service contractors

keep HVAC equipment operating in a highly efficient manner and delivering extended equipment life.

What you will learn by reading this document

Each section consists of three (3) sections. First, "theory and operation" includes a short description about

why we do what we do and how it works. Second, a more complete description of "how it works" is provided.

Third, wiring diagrams are provided to demonstrate how an installer wires up the application. Technically, this

is in the "appendix" of this document.

Controls in Small Commercial Buildings

In commercial buildings, it is essential that heating and air conditioning systems operate in a properly configured,

automatic manner. In a small commercial building, HVAC operational experts are often HVAC service contractor

specialists or by a few subject matter experts within the building. Additionally, control performed in a small commercial

buildings is typically more complex than in a residential dwelling. Heating, cooling, fan operation, ventilation, indoor air

quality, dehumidification, and various other functions can all operate successfully in a small commercial building but due

to economics, we can't count on an experienced controls experts to be present to troubleshoot building controls

problems.

Herein lies a point of concern for servicing contractors and building owners as we strive to effectively control small

commercial buildings. Honeywell and our contractor business partners need to provide basic local control for building

owners. The more power and authority that building occupants have is desirable, but can also lead to undesirable system

operation, particularly higher energy use and HVAC equipment wear and tear. It is important that Honeywell LCBS

Connect contractors to educate building owners about key control requirements.

3 31-00118EFS—01

Page 4

LCBS CONNECT SOLUTION

Here is a typical case of how control systems are designed to work and how building

occupant's well intentioned efforts can cause facility operational problems.

Typical CVAHU systems observe a control operation strategy called "automatic heating and cooling changeover." This

operation ensures that mandatory, building code compliant heating, cooling, and ventilation occurs in a commercial

building. If the system permits, a building occupant can change this operational to "cooling" or "heating" only. A well

intentioned building occupant may simply be hot or cold and may change settings to achieve personal comfort.

This action is not without consequences. If this setting is erroneously left in the "cooling" or "heating" position, when

climate changes, mechanical heating and cooling is locked out. This will lead to an inevitable service call at 1] will cost the

building owner hundreds of dollars due to service contractor interaction or 2] a service contractor who can't bill for the

call due to service contractor type.

Enter LCBS Connect

A contractor that has adopted LCBS Connect will have remote access to the customer's site and will allow

remote remediation of the problem and will save a truck roll to the customer's site. Providing local access to

building occupants should be weighed and discussed carefully with the building owner and those paying for

maintenance and utility bills.

AUTOMATIC BUILDING SCHEDULES

Automatic Occupancy Control Theory and Operation

For building owners and operators, we assume two basic things: indoor commercial building environments need to be

heated, cooled, and ventilated for human health and comfort during the time humans occupy a building. There are

important secondary issues relating to occupancy including management and protection of assets during periods when

humans don't occupy building spaces including protection of plants, precious artwork, plumbing, paper products, and

wall and floor coverings. Excessive heat, cooling, and humidity conditions can cause damage to building.

Ensuring that building space is conditioned to make sure building occupants are comfortable is quite different than

making sure that it is warm or cool enough to protect plumbing from freezing and from wall paper and paint from peeling

off the wall. In general, the energy required to operate systems to provide human comfort is 2-5X the cost to protect

assets in a building without humans present.

How does occupancy methodology work?

LCBS Connect allows HVAC service contractor and customers to develop schedules via LCBS Connect tools including

local operator interface or remote cloud based tool to match building occupancy schedules. These schedules can be also

be set to accommodate occurrence of special events and holidays.

To ensure that proper comfort conditions are achieved by desired occupancy, Honeywell has developed an algorithm to

meet these needs. Honeywell's answer to this recovery process is called "Adaptive Intelligent Recovery™" Implementing

this correctly will require knowledge by the HVAC professional regarding the rate at which the HVAC system can provide

restorative heat injection (heating), heat removal (cooling) in a building space. This recovery algorithm also keeps HVAC

systems from starting suddenly and creating an excessive electrical in-rush that can result in undesirable utility demand

control charges. The payoff to getting this "right" is huge. We want to keep building occupants and patrons comfortable

and control energy usage and associated costs. Honeywell Adaptive Intelligent Recovery permits us to meet this

requirement.

LCBS Connect controllers also have the ability to control temperature to "standby" set points. This set point technique is

typically applied to building spaces that are randomly and infrequently occupied. A good example of the application of

the standby set point is for an office or meeting room. The standby heating set point is always set the same or slightly

below the standard occupied set point and the standard cooling set point is always set the same or slightly above the

standard occupied set point. If the space temperature is being controlled at the standby set point, it is assumed that the

building space being controlled is unoccupied. The benefit of using the standby strategy is twofold… 1] to make sure that

building occupants are comfortable when they enter randomly occupied spaces and 2] reduce energy usage by altering

HVAC control and reducing ventilation when building occupants aren't in the randomly occupied building space. The

transition of standby set points from "standby" to "occupied" is typically initiated by a "motion sensor" detecting

occupancy in the building space. Likewise, if the motion sensor does not detect motion, the set point is transitioned from

"standby" to "unoccupied."

In order to comply with building codes, during scheduled "occupied" periods, the supply fan will run 100% on. Why? Most

prevailing building codes require "continuous fresh air ventilation" and a specific requirement of fresh air, outdoor air

based on an aggregate CFM per hour or CFM per person in the building space. Without going into detail, it is literally

31-00118EFS—01 4

Page 5

LCBS CONNECT SOLUTION

impossible to provide minimum fresh air ventilation without supply fan moving air. During "standby" and "unoccupied"

periods, the supply fan operates in conjunction with a call for heating or cooling and ventilation is disabled, as we assume

that people are not in the building space.

LCBS Connect users can permit the supply fan to run only on a call for heating or cooling during "occupied" periods, but it

is discouraged and defies prevailing the building ventilation code. Further, cycling the fan on a call for heating or cooling

can degrade the life of the fan motor, fan belts, and associated fan accessories.

LCBS Connect controllers have the ability to control local equipment based on an eight (8) day scheduling strategy, seven

days of the week featuring four events per day and a "holiday" schedule featuring four events per day.

Let's get into some specific details.

There are four (4) programmable events that are available for each event.

— Occupied. This indicates the beginning of a time period, associated with an "on" condition or observance of "occu-

pied" set points when building occupant typically occupy building zones.

— Unoccupied. This indicates the beginning of a time period, associated with an "off" condition or observance of

"unoccupied" set points when building occupants typically leave the building.

— Standby. This indicates the beginning of a time period, associated with observance of "standby" set points, were

ventilation and fan are controlled conforming to unoccupied control behavior. Using "standby" set points and process can result in energy savings during traditional occupied hours. During the standby period, if an occupancy

sensor is assigned to the controlled zone, and it detects people in the controlled zone, occupied set points and

occupied ventilation practice is observed. If this occupancy sensor does not detect movement, unoccupied set

points and ventilation practice is observed. Tip: Use standby set points in infrequently occupied building zones

including meeting rooms and break rooms.

— Available. This is a fourth condition indicating that a change of event state can be programmed, configured, exe-

cuted. This is also referred to as "un-configured."

How it works

Date and Time is available for each LCBS Connect controller. Each LCBS controller can support for events. For example,

assume that I open my store at 7:00 AM and close it at 7:00 PM Monday through Friday. My store is open at 7:00 AM and

closes at 1:00 PM on Saturday. I'm closed on Sunday. Find constructed table of required schedules below:

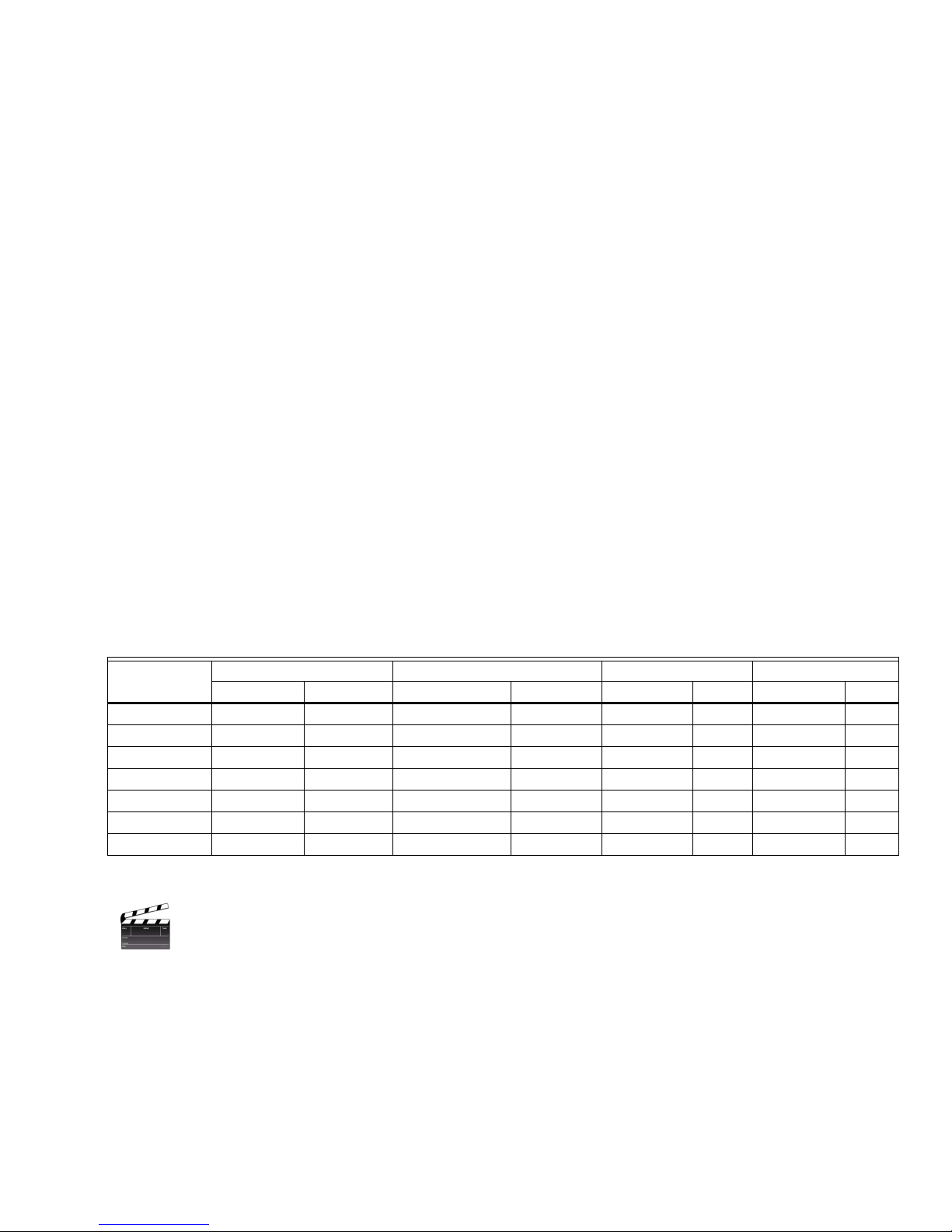

Table 1.

EVENT 1 EVENT 2 EVENT 3 EVENT 4

DAY

MONDAY OCCUPIED 7:00AM UNOCCUPIED 7:00PM AVAILABLE AVAILABLE

TUESDAY OCCUPIED 7:00AM UNOCCUPIED 7:00PM AVAILABLE AVAILABLE

WEDNESDAY OCCUPIED 7:00AM UNOCCUPIED 7:00PM AVAILABLE AVAILABLE

THURSDAY OCCUPIED 7:00AM UNOCCUPIED 7:00PM AVAILABLE AVAILABLE

FRIDAY OCCUPIED 7:00AM UNOCCUPIED 7:00PM AVAILABLE AVAILABLE

SATURDAY OCCUPIED 7:00AM UNOCCUPIED 7:00PM AVAILABLE AVAILABLE

SUNDAY AVAILABLE AVAILABLE AVAILABLE AVAILABLE

EVENT TYPE TIME EVENT TYPE TIME EVENT TYPE TIME EVENT TYPE TIME

Scheduling Summary

LCBS Connect controllers have a default schedule built into them. The LCBS Connect controller will work

when you pull them out of the box. The default schedule is 6:00 AM to 6:00 PM Monday through Sunday. If

you want to set up different occupancy schedules, it's a good idea to refer to appropriate documentation

form in your support package, print it out, and write out the schedules you want to implement. Go to LCBS Connect wall

module or LCBS Connect Remote User Interface and program desired times.

Scheduling a Holiday

LCBS Connect controllers support the following holiday scenarios for one event schedule. This will be improved in the

future, particularly when we implement "Cloud Based Scheduling":

Date specific: A good example of this is July 4 for our national holiday and December 25 for Christmas. This could be

obvious, but isn't intended to be insulting to the reader. July 4th never changes as a date, but the day of week does.

5 31-00118EFS—01

Page 6

LCBS CONNECT SOLUTION

Day specific: A good example of this is Thanksgiving. This date is always on the last Thursday of the month of November.

Thursday, as the day we celebrate American Thanksgiving, never changes, but the date does.

Extended date: Establish a specific day or date. The ability to extend this holiday any number of days is offered. For

example, if we celebrate Thanksgiving and our establishment will be closed on the day following Thanksgiving, enter two

(2) days in the proper configuration field.

Holiday Scheduling Summary

LCBS Connect controllers do NOT have a default holiday schedule built into them. If you want to set up

different occupancy schedules on various holiday dates and times, please do so. Go to LCBS Connect wall

module or LCBS Connect Remote User Interface and program desired times.

HEATING, HEAT PUMP CONTROL

Heating Theory and Operation

There are two key theoretical objectives for heating. First, we have an objective to keep building occupants comfortable by

providing heat during heating seasons during periods when occupants occupy buildings. Second, we need to keep

building assets warm enough so that no building damage occurs to valuable assets, particularly when it's very cold

outdoors. LCBS Connect controllers are designed so they don't operate heating system in an inefficient manner, on in a

manner where damage occurs to the heating systems. Some examples to protect heating equipment are minimum on

and off times for gas and electric heating elements and heat exchangers, high limit heating controls, and lockout based

on low sensed ambient or outdoor air temperature.

Basic Gas and Electric Heating

There are two basic systemic direct heating methods that LCBS Connect supports; standard staged heating that features

natural gas heat exchangers and staged electric heat that typically include electric duct heaters. For gas heating option,

LCBS Connect can either be set to energize supply fan operation on a call for heating directly or the supply fan can be

controlled by a fan and limit device. The latter is quite common with gas heating systems. We support control of three

stages of heat, three stages of cool. Further, electric heat can typically be cycled more frequently and aggressively than

gas heat. LCBS Connect accounts for both methods and all settings.

Air to Air Heat Pump

In North America, there are areas where natural gas is not available or where electrical energy is relatively inexpensive.

This makes Air to Air Heat Pumps financially and operationally viable. The air to air heat pump features mechanics and

electronics that reverse the refrigeration cycle in an air conditioning unit and pumps warm refrigerant into the evaporator

coil to provide heat. Another heat pump that we find in North America is the "water source" or "geothermal" heat pump.

The Air to Air Heat Pump is a widely used solution that spans residential and commercial applications in North America

and is the focus of this release. We will be able to control Water Source Heat Pumps and associated boiler and cooling

tower plans in the 2.0 release of LCBS Connect.

A standard method of controlling the flow of refrigerant in a heat pump system is by controlling the position of the

"reversing valve." There are two prevalent methods are 1] energizing the reversing valve on a call for cooling and 2]

energizing the reversing value of a call for heating. For the former, the terminal designation on the low voltage terminal

strip on the heat pump is "O" and for heating, "B." Please note! There is a third method of heat pump control, popularized

by Carrier and Carrier brands. This method features standard Y1 and W1 cooling and heating control with the reversing

valve internally controlled. It may be necessary to adjust heating minimum on times to protect heating compressor cycle.

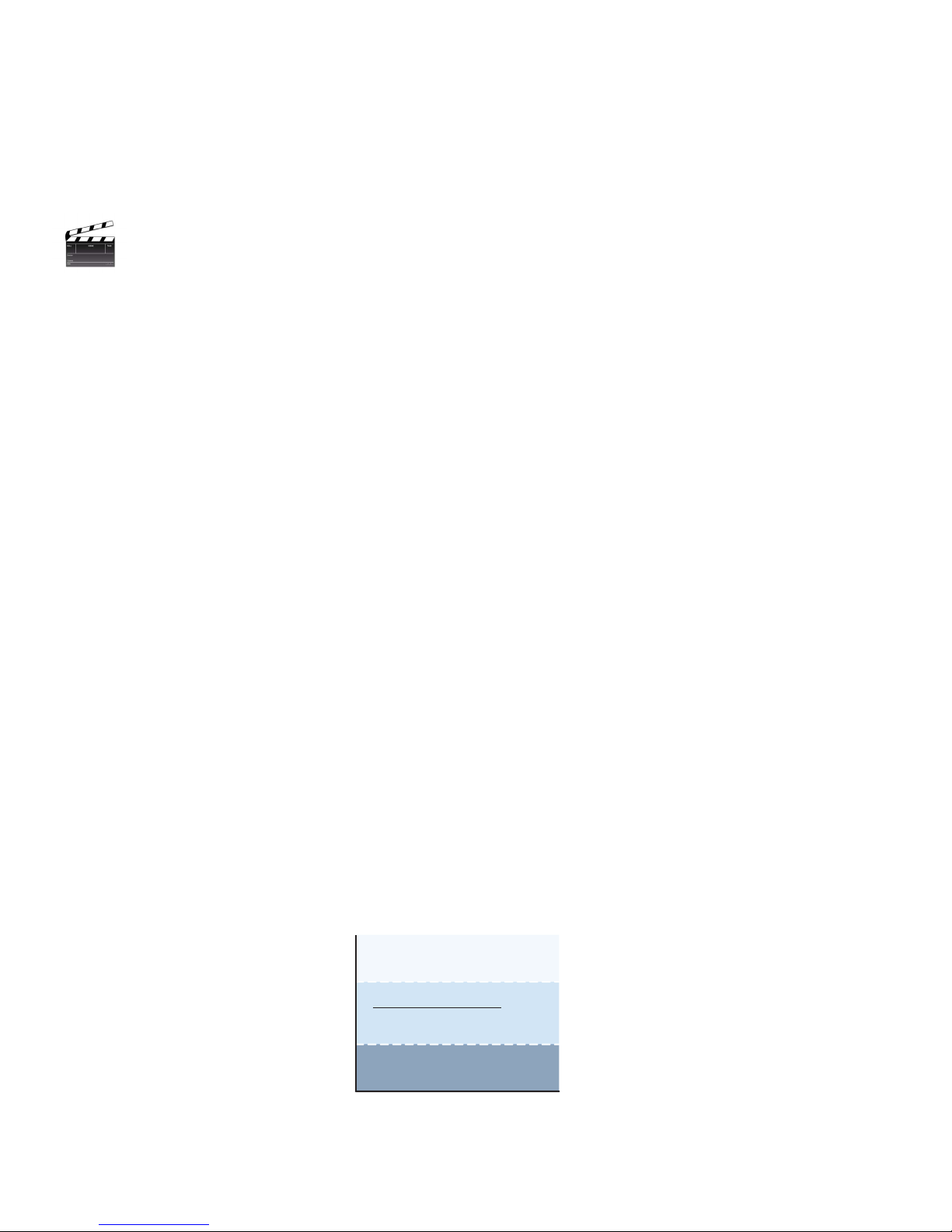

50°F

OUTDOOR

AIR

TEMPERATURE

ADJUSTABLE

PARAMETERS

35°F

SYSTEM COMPRESSOR ONLY OPERATING

IF INDOOR AIR TEMPERATURE “DROOPS”

BELOW HEATING SETPOINT, SHUT OFF

COMPRESSOR AND USE AUX HEAT

SYSTEM FURNACE AND AUXILIARY

HEAT ONLY OPERATING

ADJUSTABLE

OUTDOOR

TEMP

AUXILIARY

LOCKOUT

ADJUSTABLE

OUTDOOR

TEMP

BALANCE

POINT

31-00118EFS—01 6

TIME

Fig. 1.

MCR36696

Page 7

LCBS CONNECT SOLUTION

Depending on the geographical location of our customer's building and of an air to air heat pump, electric auxiliary heat

may be required. In northern United States, if a heat pump compressor is not protected with a compressor heater, the

compressor must be locked out to prevent damage to it and electric heat must be used to heat building space. The latter

can be expensive, thus we provide adjustable settings to attempt to help contractors and building owners avoid excessive

electricity use. The LCBS Controller has an adjustable outdoor air limit sensor that can lockout heat pump compressor if

outdoor air temperature falls below an adjustable level. Given this potential extraordinary expense, we've developed

several techniques to attempt to reduce the cost of operation of electric heat. Honeywell provides an option to operate

electric heat in a standard manner; this concentrates on traditional comfort. It's called the "comfort" mode. Look for this

as you configure your air to air heat pump; it's a selectable option. If the building owner can tell their employees, staff to

have a sweater ready on very cold days, Honeywell offers the "savings" mode. This automatically depresses the heating set

point and results in electric heat cycling less, maintaining a lower heating set point.

Droop, Comfort and Saving Heat Pump Mode

What is "droop?" Simply put, it's a temperature value that "droops" below standard occupied or unoccupied heating set

point. Heat pumps do a super job of heating as long as it's not too cold outdoors. As we've described a few times,

sometimes the pump just loses the battle to provide adequate heating. When this happens, the LCBS Connect control

system supplements the compressor and begins using "fossil fuel" heating, typically electric strip heaters. So, standard

heat pump cycle is designed to terminate heat pump usage below established outdoor air temperature where the

efficiency is less than electric or gas heat.

Here's a summary of the "Comfort" and "Savings" mode:

"COMFORT" MODE "SAVINGS" MODE

Depending on outdoor limits set, the compressor, the

compressor acting in unison with auxiliary heat, or auxiliary

heat operates to maintain heating setpoint.

COMMENTS. BENEFITS, SHORTCOMINGS

Comfort is our prevailing concern for our employees,

guests, and patrons.

If "savings" mode is selected and if auxiliary heat is not

locked out, the heating sepoint is depressed by "x" degrees.

this minimimzes the use of auxiliary heat and avoids energy

cost.

Pushes pump operation thus saves energy. the more

aggressive the "savings" setpoint is, the more likely that

building zones will become cold. take care to select

parameters properly.

Discharge Air Temperature High Limit Control

While heating, it is possible that discharge air temperature may increase beyond an unacceptable limit. To avoid this, the

LCBS Connect controller features discharge air temperature high limit control. When discharge air temperature increases

above the discharge air high limit set point, the heating equipment is controlled to maintain the discharge air

temperature to the set point. Let's assume that the discharge air set point is 120°F. If the discharge air temperature

increases above 120°F then the heating equipment is cycled off. When it falls back below the limit minus the switching

differential, it will be allowed to cycle back on. Please note: Your HVAC unit will feature a high limit heating control.

Ensure that the LCBS Connect setting is HIGHER than that of the unit being controlled.

Heating Summary

LCBS Connect controllers have a wide array of heating options. As with most functions, if you are

commissioning a simple single heat conventional system, the LCBS Controller will work "out of the box." It

will be designed to work at 68°F occupied setting and 62°F unoccupied setting. You will have access to

changing proportional band, integral gain, and derivative gain if you wish. It is HIGHLY RECOMMENDED that you

DON'T alter these parameters unless a Honeywell LCBS Connect support professional tells you to do so. You will need to

make some basic changes to the device if you are commissioning a heat pump. There are a number of options described

in this document that will allow you to alter basic heat pump operation; most are provided so that the heat pump operates

in an efficient manner. It is recommended that you don't change preconfigured parameters.

COOLING, DEHUMIDIFICATION, ECONOMIZER CONTROL

Cooling Theory and Operation

There are two key operational objectives for cooling. First, we have an objective to keep building occupants comfortable

during assumed cooling seasons during periods when occupants occupy buildings. A close following objective is to keep

building assets cool and dehumidified enough so that no building damage occurs when it's very warm and humid

outdoors. LCBS Connect controllers need to protect cooling systems so they don't operate in an inefficient manner, on in

a manner where damage occurs to the cooling systems. Some typical examples to protect cooling equipment are

7 31-00118EFS—01

Page 8

LCBS CONNECT SOLUTION

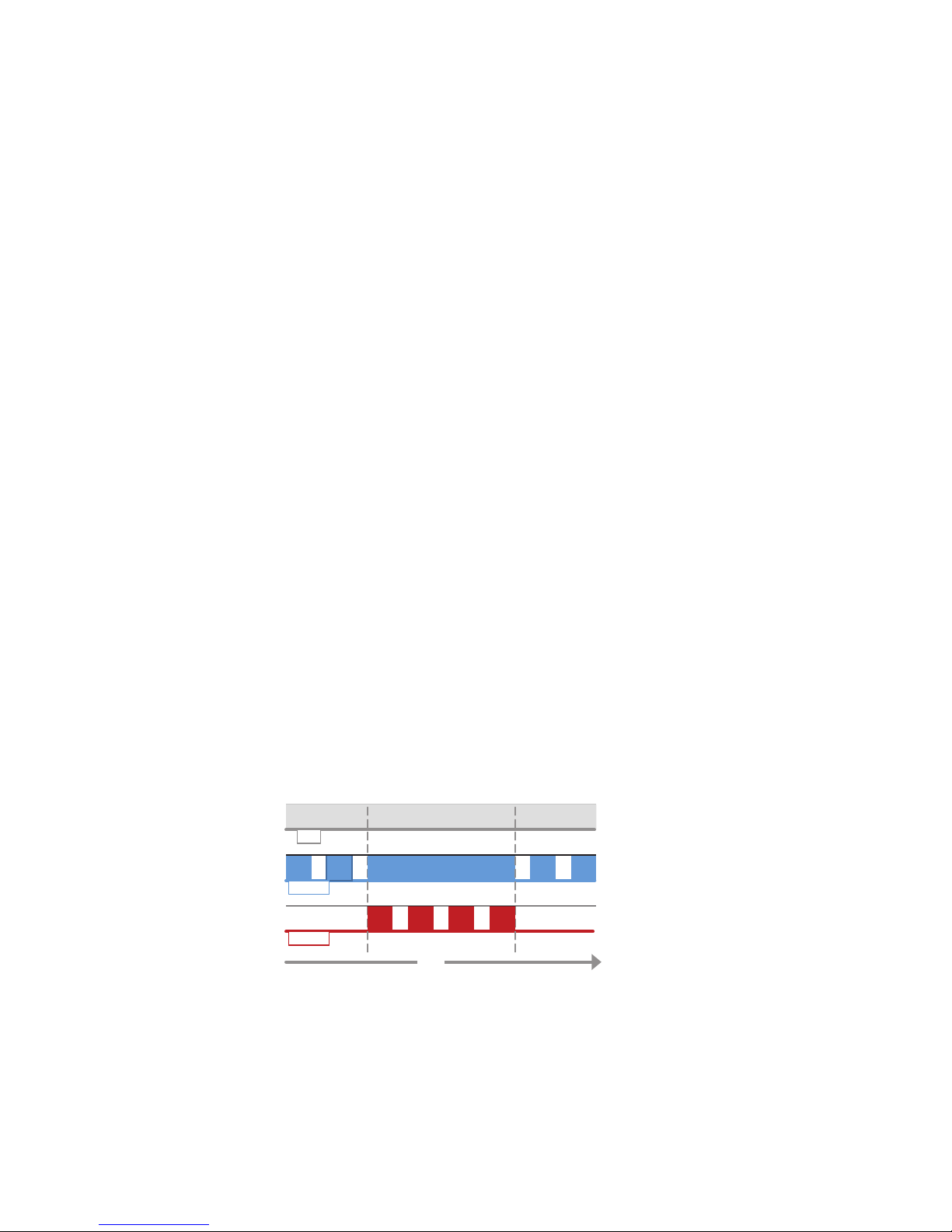

ON

OFF

ON

OFF

ON

OFF

DEHUMIDIFICATION CONTROL

WORKS IN “COOLING MODE” ONLY, DOES NOT WORK IN “HEATING MODE”

TIME

HUMIDITY LIMIT,

SETPOINT EXCEEDED

HUMIDITY LIMIT,

SETPOINT ABATES

FAN

COOLING

HEATING

FAN ON CONTINUOUSLY (OCCUPIED, STANDBY PERIOD)

COOLING CYCLING, LOCKED ON, CYCLING

HEATING OFF, CYCLING, OFF

MCR36697

minimum on and off times for compressor operation and lockouts based on low sensed ambient or outdoor air

temperature. Freeze stat operation protects HVAC system from being damaged as systems are cycled off if system

freezing conditions are detected.

Cooling Operation

LCBS Connect controllers support control of compressor stages and DX refrigeration circuits. Up to three stages of

cooling can be controlled by LCBS Connect controllers. There is a freeze stat sensor control input that monitors potential

freezing temperatures and serves as a low limit. The sensor is typically mounted against the cooling coil and protects it

from freezing, resulting in coil damage and can also make sure that unheated outdoor compressors aren't "slugged." The

LCBS Connect controller shuts off the supply fan, the compressor and closes the outdoor air damper if a frozen coil

condition is detected. Also the discharge air sensor utilizes a control tactic called a "low limit", where if the discharge air

temperature falls below the low limit, compressor stages will be turned off until the condition goes away or all stages are

off.

Dehumidification

Dehumidification Theory and Operation

Dehumidification is an important part of control operation in many parts of the United States. High humidity can result in

two major problems. First, high relative humidity can result in uncomfortable conditions for building occupants. Second,

relative humidity is destructive to architectural elements like carpeting, wallpaper, paint, and art work.

How does LCBS Connect dehumidification work?

Three (3) dehumidification strategies for dehumidification control are supported. First, cooling and heating can be

programmed to operate in a reheat sequence to provide precise dehumidification operation. Second, dehumidification

equipment can be controlled through a direct LCBS Connect output to provide dehumidification. Third, extended cooling

extended runtime can be selected that can enhance and augment the dehumidification process. These are described in

detail below.

Method #1. Cooling On, Cycle Heating

The reheat dehumidification control algorithm works only when system in in cooling mode. The call for dehumidification

occurs as a result of humidity level rising above the dehumidification limit. If cooling is not operating, it becomes

energized. A single stage of heating is energized in conjunction with the call for dehumidification. When humidity drops

below set point less differential, hysteresis, the heating stage is cycled off and cooling cycles off. If a call for cooling

continues, cooling remains on and cycles per temperature control algorithm. Method #1 can be augmented with Method

#3, described below.

NOTE: It's important to observe the configuration of heating and cooling coils in the constant volume that you intend to

apply the dehumidification algorithm. The heating coil must be downstream of the supply fan and cooling coil for

the dehumidification algorithm to work properly.

Method #2: Simple Humidification

In the "simple dehumidification method," the algorithm simply senses space or return air humidity and energizes a

designated digital output until the call for dehumidification abates. Method #2 can be augmented with Method #3,

described below.

31-00118EFS—01 8

Fig. 2.

Page 9

LCBS CONNECT SOLUTION

Method #3: Dehumidification extended cooling minimum run time

This alternate dehumidification sequence works in conjunction with the dehumidification strategy described above. If

there is a call for dehumidification and there is also a call for cooling, the DX refrigeration will continue to operate and

functionally runs for specified time. We are ensuring that a cooling stage is on long enough so that it reaches a cold

enough temperature to remove moisture. This will cause fewer compressor cycles of longer duration, which may result in

slightly larger temperature swings around the set point.

Cooling and Dehumidification Summary

LCBS Connect controllers have numerous cooling and dehumidification options as described in this section.

If you are commissioning a simple single cool conventional system, the LCBS Controller will work "out of the

box." It will be designed to work at 76°F occupied setting and 82°F unoccupied set point setting. You will

have access to changing proportional band, integral gain, and derivative gain if you wish. It is HIGHLY RECOMMENDED

that you DON'T alter these parameters unless a Honeywell LCBS Connect support professional tells you to do so. You will

need to make some basic changes to the device if you are commissioning a dehumidification loop. There are a number of

options described in this document that will allow you to alter basic dehumidification operation. Do not change

preconfigured parameters unless you discuss this with an LCBS Connect support professional.

FRESH AIR ECONOMIZER CONTROL

Theory and Operation Economizer

There are two key operational objectives for economizer. First, we have an objective to keep building occupants alert,

healthy, and safe by making sure that fresh outdoor air is continually provided to the building space. Technically, this is

referred to as "ventilation." In the North American geography, there are many areas that cool, dry outdoor air can be used

to cool building spaces and augment the mechanical cooling process. This apparatus, system, collection of sheet metal

and controls is called an "economizer system. "

Economizer Function

Three high level strategies are supported by LCBS Connect to address control economizer functions.

— None. First, for units that do not feature integrated economizer at all, LCBS connect offers a "none" selection.

There are some parts of North America that allow make up air to be provided to building spaces in an alternate

manner; not using the economizer apparatus. Please refer to ASHRAE Standard 90.1 - 2010 Section 6.5.1 or to

your local building code for ventilation and economizer codes. This choice would also be used for systems that

aren't connected to a fresh air, ventilation function, like many commercial split systems.

— Enable Economizer Function. Second, there are hundreds of thousands of economizers that are "controlled" by a

stand-alone collection of economizer controls, typically provided by Honeywell for the last 20 years through companies like MicroMetl, Cambridgeport, and Canfab to name a few. The resulting control sequence is super simple.

If there is a call for cooling via a thermostat of contractor and building owner's choice and the economizer control

system indicates that outdoor air is cool and dry enough, the economizer controls operate, providing as much as

100% outdoor air to cool the building space. If outdoor air becomes unacceptably warm, the electronic thermostat

takes over control and controls mechanical cooling. Lastly, a time of day signal is provided to the economizer control system so that the outdoor air damper is able to close 100% to avoid equipment damage and potential excessive energy use.

— Integrated Economizer. The third strategy that is supported is full control of the economizer function by the LCBS

Connect controller. If this option is suggested, you have also enabled the LCBS Connect controller to perform

"Demand Controlled Ventilation (DCV)." DCV will be described in the next section. This is clearly the preferred

selection. This results in optimum comfort for customers and can also result in efficient operation, supporting

cost avoidance for building owners. Service contractors also benefit from full Cloud based remote control of the

economizer function, allowing him or her to troubleshoot the economizer from the ground, rooftop unit, or their

service truck.

General Economizer Operation

We refer to the economizer section of a rooftop in many ways. When we refer to the "economizer damper," we're typically

referring to the combination of outside air damper and return air damper. In our area of interest in the light commercial

marketplace and more specifically, 3 to 25 ton CVAHU units, the outside air damper system is typically operated by an

actuator directly coupled to mechanical linkages and to dampers. The outdoor air damper is normally closed and return

air damper is normally open. For most installations, the outdoor air damper is interlocked mechanically to the return air

damper. The outdoor air actuator is almost exclusively a "spring return device" that is designed to "spring closed" in event

of a loss of control signal power failure. The spring return apparatus in an actuator is provided to combat the potential

damage to HVAC coils, compressors, and to building plumbing.

9 31-00118EFS—01

Page 10

LCBS CONNECT SOLUTION

NOTICE

Minimum Ventilation

Let's examine the minimum ventilation requirement first. The notion of minimum ventilation is now driven by building

codes and is tied to providing "fresh air" to building dwellers. The code typically provides a guideline that is driven by

number of people in a building space, multiplied by CFM per person. This is further mitigated by the operation going in

the building, but that's simply too complex for this paper.

A Simple Example

We are retrofitting the controls on a five (5) ton rooftop unit in a commercial application. We are assuming that there will

be an average of 20 people in the space served by this unit. Our local code dictates that we need to provide 5 CFM of

"fresh air" per person to the building occupants. Our customer would like to make sure there is a rich supply of fresh air in

their building space, so we'll increase this to 10 CFM per hour. Simply put, this requires us to ventilate the building space

at a rate of 200 CFM per hour. The rooftop unit that we've installed has the capability to supply 2,000 CFM air per hour

and further, has the capability to ventilate our space at that rate. In conclusion, we need to ventilate the space at a

maximum rate of 200 CFM per hour. Divide 200 CFM by 2,000 CFM and we'll need to provide minimum ventilation rate of

10%. Don't panic! Hysteresis that occurs from damper and actuator linkage, plus the relatively poor accuracy of OEM

dampers will make it easy for you to estimate 10% damper position. Use the LCBS Connect service mode to help you set

the 10% air flow target.

Naturally, when folks leave the building at the end of the day, we aren't required to provide any fresh air and we close the

outdoor air dampers, shut off the system fan and operate at "unoccupied set points" that result in customer energy cost

avoidance.

Enable Economizer Function

There are literally millions of economizers installed in North America that are integrated through a simple integration to a

time of day signal and call for cooling.

How it works. A digital "enable economize" signal must be configured on the LCBS Connect controller. Again, typically this

"dry" digital output can be used to carry 24 VAC to a packaged economizer system. By definition, during building

unoccupied schedule, the contact is open, disabling the economizer. This typically allows a spring return actuator to close

to 100% position.

Opportunity to upgrade your customer's system and provide trusted advisor service! Using the "integrated"

techniques described above, you will be able to 1] improve economizer operation 2] provide full remote access of

settings, configuration information, 3] permit access to interesting and useful graphics, trending, and service

mode capability and 4] enable full Title 24, economizer analytics that will allow you to provide heroic service to key

service customers.

Honeywell Integrated Economizer Control Described

In addition to making sure that fresh air is provided to building occupants, the economizer function consists of two more

basic control loops. First is a "mixed air control loop." This is a direct acting control loop that is enabled by a call for

cooling and positions an outdoor air damper actuator based on mixed air temperature and set point. Second is a

changeover or "high limit" control function. In our industry, these terms are sometimes used interchangeably. This

control loop senses outdoor air temperature, or outdoor air temperature and humidity (enthalpy). If this loop senses high

temperature or high enthalpy, the control system drives the outdoor air damper actuator to minimum position. The high

limit controls make sure that warm or moist air is prohibited from getting into the building space.

There is another changeover strategy that is associated with the economizer function called "differential" control. On a

call for cooling, if the system return air sensor senses a temperature less than the system outdoor air sensor, and a call for

cooling exists, the economizer is disabled.

outdoor air, I'm going to use return air to provide "free cooling." Likewise, on a call for cooling, if the outdoor air

temperature is less that the return air temperature, the system economizer continues to be enabled. This is called

"differential temperature changeover." There is an equivalent "differential enthalpy changeover" described in this

document. Applied properly, differential control can provide substantial customer energy cost avoidance.

The test is simple… if there is a call for cooling and return air is cooler than

31-00118EFS—01 10

Page 11

LCBS CONNECT SOLUTION

NOTICE

WARNING

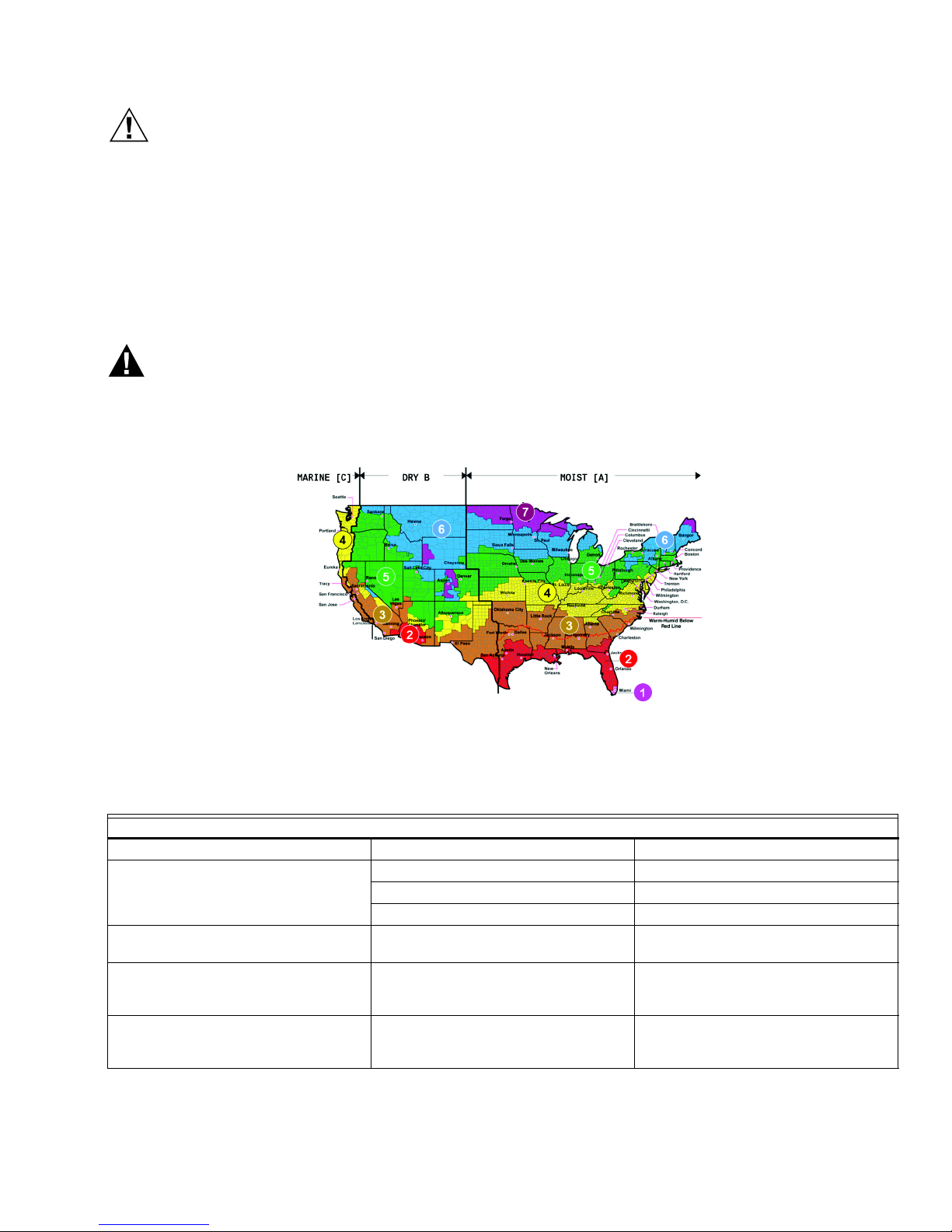

Some economizer strategies are not applicable for all climates in the United States. ASHRAE Standard 90.1 - 2010

Table 6.5.1.1.3 A describes what economizer strategies should be used in various climate regions in the United

States. For example, the fixed enthalpy economizer strategy is not permitted in U.S. climate zones 1b, 2b, 3b, 3c,

4b, 4c, 5b, 5c, 6b, 7, and 8 and fixed dry bulb and differential dry bulb economizer strategy is not permitted in U.S.

climate zones 1a, 2a, 3a, and 4a.

Honeywell Integrated Economizer Control, Climate Zones, Getting

Tactical!

If outdoor air is cool enough, our integrated economizer system begins to control our outdoor air actuator to attempts to

control to mixed air set point. The control is mitigated by a throttling range set point.

Unless you are instructed to do so by your Honeywell or LCBS Connect control system distributor, you should

NEVER have to change mixed air set point and throttling range. Over 8M of the control systems we've

provided to the HVAC industry have these set points "hard coded" in the devices with literally no complaints,

callbacks, or service interventions.

Fig. 3.

Pacific Northwest National Laboratory & Oak Ridge National Laboratory August 2010

http://www1.eere.energy.gov/buildings/publications/pdfs/building_america/ba_climateguide_7_1.pdf

Table 2.

ASHRAE 90.1 PERMISSABLE ECONOMIZER CONTROL TYPES, HIGH LIMIT, CHAGEOVER OPTIONS

CONTROL TYPE ALLOWED IN CLIMATE ZONES HIGH LIMIT, CHANGEOVER SETPOINT

FIXED DRY BULB TEMP 1B, 2B,3B,3C,4B,4C,5B,5C,6B,7,8 OUTDOOR AIR TEMP > 75°F

5A, 6A OUTDOOR AIR TEMP > 70°F

1A,2A,3A,4A OUTDOOR AIR TEMP > 65°F

DIFFERENTIAL DRY BULB TEMP 1B, 2B, 3B, 3C, 4B, 4C, 5B,5C,6B,7,8 OUTDOOR AIR TEMP > RETURN AIR

FIXED ENTHALPY WITH FIXED DRY

BULB TEMP

DIFFERENTIAL ENTHALPY WITH

FIXED DRY

When the mixed air control system has captured all the cooling value from outdoor air it can, the system will begin to

augment that call for cooling with mechanical cooling. An integrated low limit is also offered.

ALL OUTDOOR AIR ENTHALPY > 28

ALL OUTDOOR AIR ENTHALPY > RETURN

TEMP

BTU/LB OR OUTDOOR AIR TEMP >

75°F

AIR ENTHALPY OR OUTDOOR AIR

TEMP > 75°F

11 31-00118EFS—01

Page 12

LCBS CONNECT SOLUTION

NOTICE

Honeywell Integrated Economizer Control - High Limit and Changeover

Strategies

North America features widely different climates. ASHRAE and other code bodies recognize this fact and provide control

guidance. These organizations drive application and use of economizer systems regionally. These different climate zones

drive different economizer application practices. For example, air in Honolulu and Miami is far hotter, higher dew point

and has almost no capability to be used to augment the HVAC cooling process.

As a service contractor, you probably know what your customer's needs are. Continue to set controls how you see

fit. We haven't seen any building code or ASHRAE police roaming any U.S. streets, yet!

The information below describes the use of the following economizer strategies.

Strategy 1: Differential Enthalpy with Fixed Dry Bulb Temperature Limit

This technique can be used in all ASHRAE climate zones. Successfully applied, excellent energy savings can accrue to

building owners. LCBS Connect remote services alerting and analytics can help you fine tune settings to maximize

customer energy savings and maintain comfort.

How does it work? If there is a call for cooling and return air enthalpy is less than outdoor air enthalpy and the outdoor air

temperature is below high limit, changeover set point, RETURN air will be used to cool your customer's building. If there is

a call for cooling and return air enthalpy is GREATER than outdoor air enthalpy and the outdoor air temperature is below

high limit, changeover set point, OUTDOOR air will be used to cool your customer's building.

Enthalpy hysteresis is adjustable to make sure that you don't experience excessive enabling and disabling of the

economizer cycle potentially overusing the economizer actuator. It is advised that you don't change this value unless you

talk to a Honeywell distributor or customer support professional.

Strategy 2: Outdoor Air Enthalpy

This technique can be used in all climate zones. HVAC professionals like this method as it's relatively simple to deploy. As

with all economizer limit and changeover strategies, LCBS Connect remote services alerting and analytics can help you

fine tune setting to maximize customer energy savings and maintain comfort. There is an ASHRAE prescriptive value

suggestion at 28 LB/BTU changeover. Many folks find this a bit warm and could result in customer, client comfort issues.

How does it work? If there is a call for cooling and outdoor air enthalpy is less than outdoor air enthalpy set point and the

outdoor air temperature is below high limit, changeover set point, outdoor air will be used to attempt to cool your

customer's building.

Again, enthalpy hysteresis is adjustable to make sure that you don't experience excessive enabling and disabling of the

economizer cycle potentially overusing the economizer actuator. It is advised that you don't change this value unless you

talk to a Honeywell distributor or customer support professional.

Strategy 3: Differential Temperature

This technique is suggested to be used in zones 1B, 2B, 3B, 3C, 4B, 4C, 5A, 5B, 5C, 6A, 6B, 7, and 8. See map on page 16.

HVAC professionals like this method as it's relatively simple to deploy and understand. As with all economizer limit and

changeover strategies, LCBS Connect remote services alerting and analytics can help you fine tune setting to maximize

customer energy savings and maintain comfort.

How does it work? If there is a call for cooling and outdoor air temperature is less than return air temperature and the

outdoor air temperature is below high limit, changeover set point, outdoor air will be used to attempt to cool your

customer's building. If there is a call for cooling and outdoor air temperature is GREATER than return air temperature and

the outdoor air temperature is below high limit, changeover set point, RETURN air will be used to attempt to cool your

customer's building.

Temperature hysteresis is adjustable to make sure that you don't experience excessive enabling and disabling of the

economizer cycle potentially overusing the economizer actuator. It is advised that you don't change this value unless you

talk to a Honeywell distributor or customer support professional.

Strategy 4: Outdoor Temperature

This technique is suggested to be used in zones 1A, 2A, 3A, 4A, 5A, 6A, 1B, 2B, 3B, 3C, 4B, 4C, 5B, 5C, 6B, 7, and 8. See map

on page 16.

31-00118EFS—01 12

Page 13

LCBS CONNECT SOLUTION

HVAC professionals like this method as it's probably the simplest strategy to deploy and understand. This technique was

widely used before humidity sensing technology became cost effective. As with all economizer limit and changeover

strategies, LCBS Connect remote services alerting and analytics can help you fine tune setting to maximize customer

energy savings and maintain comfort.

How does it work? If there is a call for cooling and outdoor air temperature is less than outdoor air temperature is below

high limit, changeover set point, outdoor air will be used to cool your customer's building.

Temperature hysteresis is adjustable to make sure that you don't experience excessive enabling and disabling of the

economizer cycle potentially overusing the economizer actuator. It is advised that you don't change this value unless you

talk to a Honeywell distributor or customer support professional.

Low Limit Temperature Override Control

HVAC coil protection is offered as a feature as part of integrated economizer control. Please note that this feature does

not work with the "simple" digital input, digital output economizer control sequence described above.

How it works. The low limit control overrides the economizer damper position to prevent the economizer control sensor,

mixed air temperature or discharge air temperature from falling below the low temperature override limit by closing the

economizer, outdoor air damper. The low limit temperature override control is disabled when DCV is enabled as heating

will allow to cycle on.

Freeze Stat Operation

The capability to apply and install an electromechanical freeze stat as an ultimate redundant control is available. Simply

select freeze stat function by configuring the appropriate digital input on the LCBS Connect controller. A freeze stat

contact must be installed and an output from the device needs to be terminated to the LCBS controller. If the freeze stat is

configured and the LCBS Connect controller input is closed, the CVAHU system will be shut down. The freeze stat

function can also be used to shut down the CVAHU system for smoke or fire alert, alarm.

Economizer Control Summary

LCBS Connect controllers feature an "ASHRAE Complete" range of economizer control, changeover, and

high limit options. If you are attempting to commission a "direct drive" economizer system, read this

description carefully. LCBS Connect remote services will be a great help to you as you fine tune economizer

control.

ADVANCED TEMPERATURE CONTROL FUNDAMENTALS

If you would like to learn how to "fine tune" control loops, you may want to take some time to learn about more advanced

control fundamentals. This will also be important for you if you chose to construct "Accessory Loops" as part of your

control business. Please read the following about proportional, integral, and derivative control operation. Contact your

Honeywell LCBS Connect professional for assistance.

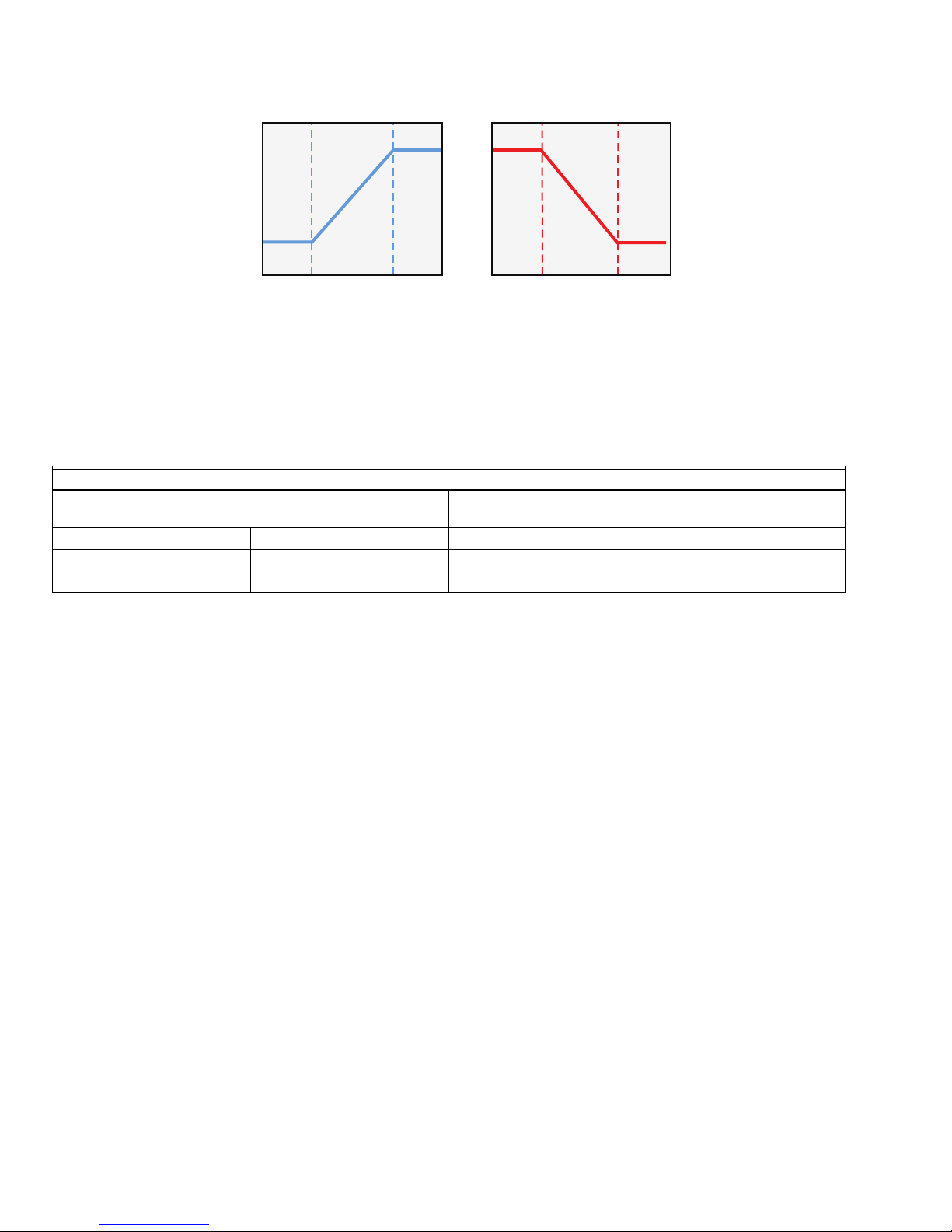

Proportional Control and the Concept of Differential and Throttling Range

Let's start with basic control. Feedback control uses the "error", defined as the sensed value minus the set point, to

determine how to drive the output. Proportional Control commands the output as a direct proportion of the current error.

This is typically configured with a "Proportional Band" or a "Throttling Range" that defines the value of the error that will

result in the control output going to 100%. These terms are typical when we are describing modulating output. If we are

driving a digital output, the difference that is observed between the controlled load being energized and de-energized is

typically referred to as Differential.

So, if we are driving a modulating output, then the output is set to the percent calculated from the ratio of the error to the

Throttling Range (TR, e.g. if the error is ½ the TR, the output would be 50%, and if the error is equal to the TR then it would

be 100%).

Proportional Control

Proportional control is the function that determines the output setting required to meet the load conditions.

13 31-00118EFS—01

Page 14

LCBS CONNECT SOLUTION

THROTTLING

100%

80%

60%

40%

20%

0%

CONTROLLER OUTPUT %

70°F 72°F 74°F 76°F 78°F

EXAMPLE: COOLING – DIRECT ACTING

SETPOINT 72°F THROTTLING RANGE 4°F

RANGE

SENSOR INPUT VALUE

100%

80%

60%

40%

20%

0%

CONTROLLER OUTPUT %

70°F 72°F 74°F 76°F 78°F

EXAMPLE: HEATING – REVERSE ACTING

SETPOINT 76°F THROTTLING RANGE 4°F

THROTTLING

RANGE

SENSOR INPUT VALUE

MCR36698

Fig. 4.

A direct acting control loop is one where the output increases as the input sensor value rises above the set point. A reverse

acting control loop is one where the output increases as the input falls below the set point. Direct or reverse acting should

be selected based on the application requirements with the consideration that set point is the "no load" value of the

measured variable and with 0% output the energy input should be the closed or off. The physical outputs can be

configured to match the controlled devices (normally open, normally closed, energized on, energized off, etc.).

APPLICATION EXAMPLES

DIRECT ACTING. CONTROL DEVICE INCREASES AS

MEASURED VALUE INCREASES

REVERSE ACTING. CONTROLLED DEVICE DECREASES

AND MEASURED VALUE INCREASES

COOLING STATIC PRESSURE HEATING LIGHTING

DEHUMIDIFICATION CHILLED WATER PUMP HUMIDIFICATION STATIC PRESSURE

MIXED AIR CONDENSER WATER PUMP HOT WATER PUMP

The proportional calculation determines proportional error (Ep). Proportional error is the deviation from set point of the

sensed medium (input sensor) divided by the throttling range expressed in units of the input sensor. The set point is the

value of the input sensor at which the control loop is satisfied. When the input sensor value is at set point there is no

proportional error and the output is 0%. The throttling range is the amount of change in the sensed medium required to

drive the output from 0 to 100%. By definition, in proportional control the input value must deviate from set point to

initiate a change in the output.

Selected Throttling Range must be narrow enough to provide good control without becoming unstable. The throttling

range is determined by a number of factors such as the control application, the response time to the equipment being

controlled, and the control algorithm being used. The narrower (smaller) the throttling range, the more precise the control

and the wider (larger) the throttling range, the more stable the control. The objective is setting the throttling range to

achieve the optimum balance between precision and stability.

Set point and Differential Refresher - On Off, Digital Control

The following is a refresher course for you and describes the relationship between set point and differential for heating

and cooling. These settings are typically programmed for each control loop and each on off output.

In heating mode, the differential is below the set point. The output relay de-energizes when the temperature rises to the

set point. As the temperature drops to the set point minus the differential, the relay energizes. You will also see this

referred to as "direct acting," where increased control action is in direct relationship to increased temperature value.

31-00118EFS—01 14

Page 15

LCBS CONNECT SOLUTION

PROPORTIONAL ON OFF CONTROL HEATING (REVERSE ACTING)

TYPICAL HEATING CIRCUIT

LOAD (HEATING) ON

“ERROR” =

SETPOINT PLUS

MEASURED

VALUE

HEATING

SETPOINT

“ON” WHEN “MEASURED VALUE” REACHES SETPOINT, OFF WHEN

“SETPOINT” PLUS “DIFFERENTIAL” EQUALS “MEASURED VALUE.”

REPEAT AS LOAD CHANGES.

LOAD (HEATING) OFF

MCR36699

LOAD

(HEATING) ON

PROPORTION AL CONTROL

– HEATING – REVERSE ACTING

MEASURED VALUE

“DIFFERENTIAL

PROPORTION AL ON OFF CON TROL COOLIN G

(DIRECT ACTING) TYPICAL COOLING CIRCUIT

MEASURED VALUE

LOAD (COOLING) ON

LOAD (COOLING) OFF

“DIFFERENTIAL

“ERROR” =

SETPOINT

LESS

MEASURED

VALUE

COOLING

SETPOINT

PROPORTIONAL CONTROL – COOLING – DIRECT ACTING

“ON” WHEN “MEASURED VALUE” REACHES SETPOINT, OFF WHEN

“SETPOINT” LESS “DIFFERENTIAL” EQUALS “MEASURED VALUE.”

REPEAT AS LOAD CHANGES.

MCR36700

Fig. 5.

In cooling mode, the differential is above the set point. The output relay de-energizes when the temperature falls to the

set point. As the temperature rises to the set point plus the differential, the relay energizes. You will also see this referred

to as "reverse acting, where increased control action is in direct relationship to reduced temperature value.

Integral Action Primer and Refresher Course for Some

The purpose of the integral function is to eliminate the offset inherent in proportional control, in other words, integral

control functions to hold the input sensor value at set point.

The integral function is a function of proportional error and time.

When the proportional error is greater than 0 the integral error will be calculated and added to proportional error to

determine the control loop output. The integral error is cumulative and will continue to increase as long as the

proportional error is greater than 0. The increase in the output signal will drive the controlled device further open and the

controlled medium will be brought closer to set point. While the proportional error is reduced, the integral error will

continue to increase until the proportional error is eliminated.

Fig. 6.

15 31-00118EFS—01

Page 16

LCBS CONNECT SOLUTION

NOTICE

T0 T1 T2 T3 T4

PROPORTIONAL PLUS INTEGRAL CONTROL

EI = INTEGRAL ERROR

EP = PROPORTIONAL ERROR

V=TOTAL ERROR IMPACT, P PLUS I

OUTPUT

%

100%

80%

60%

40%

20%

0%

THROTTLING

RANGE

INPUT

SENSOR

DEGREES F

80°F

75°F

70°F

SETPOINT

V=EI + E

P

E

P

E

I

MCR36701

Fig. 7.

When the proportional error equals 0 the calculated integral error is 0 and no change is made to the output.

When the proportional error is less than 0 the integral error is calculated as a negative value resulting in decrease in the

integral error.

The integral time value is set in seconds based on the lag time of the controlled process. A slow process such as space

temperature control requires a long integral time (600 seconds or more) while a fast process such as static pressure

control requires a short integral time. An integral time value of 0 (default) eliminates implementation the integral

function.

P+I control can decrease stability of a control loop. Stability of the control loop is a balance of the throttling range and the

integral time. If a P+I control loop is unstable it is necessary to increase the throttling range and/or increase the integral

time. In general, the throttling range required for P+I control is greater than that for proportional only.

A bit of good news. Honeywell has utilized "proportional plus integral control" in analog and digital temperature

control devices for residential and commercial customers for 40 years. LCBS Connect controllers are

preconfigured with proper settings as they have been for 40 years. You simply don't have to do a thing to take

advantage of this sophisticated control.

If you decide to use LCBS Connect controller "accessory loop" function, you may want to ask your Honeywell LCBS

Connect distributor for a hand. If you decide to control something other than temperature with the accessory loop

function, you may need to provide integration timing factor. For example, if you want to control outdoor lights, the

integration feature doesn't add to the quality of control and the integration timer should be set to zero (0). Simple set

point and differential are the only parameters that need to be set.

Do You Want to Know More about Integral Control?

As a starting point, the LCBS Connect controller uses the dependent gains form of the PID equation. This means that you

specify an integral time and the actual integration gain is dependent on the Throttling Range (TR). Specifically the

integral time is the time in seconds that it should take for the integration result to be 100% if the error is held constant at

the TR. For room control integral time typically ranges from 1,000 to 2,500 seconds given the standard throttling range

used. Note that the LCBS Connect controller integral gain for the thermostat function is predefined for optimal

performance and should generally not be changed! The purpose of integral action is to reduce the offset from set point

during steady state control that can be experienced using proportional only control. Again, as general information,

control action is impacted by throttling range selection and adjustment. It's a good idea to adjust the throttling range first

before making any adjustment to integral time. It's a good idea to adjust throttling range to be as wide as possible

because this will provide the most stable control. Remember that the integral will eliminate the steady state error so you

do not need to have a small throttling range to have accurate control. Integral action allows for controlling to set point

even with a wide throttling range.

31-00118EFS—01 16

Page 17

LCBS CONNECT SOLUTION

Derivative Control

Proportional-integral-derivative (PID) control adds the derivative function to PI control. The derivative function opposes

any change and is proportional to the rate of change. The more quickly the control point (actual sensed temperature)

changes, the more corrective action the PID system provides. The higher the derivative setting, the greater the effect. In

LCBS Connect controllers, the derivative default value is factory set to zero resulting in no control. It is strongly

recommended that the derivative remain at zero (0) unless you have a very good reason to adjust it. Derivative

control is not needed in the vast majority of HVAC applications.

DEMAND CONTROLLED VENTILATION

Theory and Operation Demand Controlled Ventilation (DCV).

As energy costs increased in the last half of the 20th century, coupled with the cost of providing ventilation to building

spaces during height and depth of winter and summer, ventilation codes have been altered. It is acceptable to supply

ventilation at a rate equivalent to the number of building occupants as opposed to a fixed minimum ventilation rate of

outdoor air actuator and dampers.

DCV Operation

As energy consumption continues to be a driving part the economics to operate HVAC systems, we continue to support

HVAC strategies that will allow systems to dynamically "decrease" fresh air ventilation rates if there are a few occupants in

a building space. Unfortunately, many building owners and operators have figured this out and have purposefully

restricted fresh air ventilation flow to building occupants. Incorrectly executed, this can result in sluggish behavior and

illness directly caused by stale, recirculated air.

Without writing an HVAC physics paper, scientists have determined that the presence of carbon dioxide gas is

proportional to oxygen content in air due to human respiration. Fact is that the "primary function (of human respiration)

is to obtain oxygen for use by body's cells and eliminate carbon dioxide that cells produce." The less content of carbon

dioxide in the air, the less presence of human respiration (and humans) exists. This makes people drowsy, ill, and worse.

Find levels and associated human impact of CO2 in confined building spaces provided by "Engineering Tool Box:"

SITUATION CO2 PPM LEVELS

NORMAL OUTDOOR AIR PPM LEVEL 350-450 PPM

ACCEPTABLE PPM LEVEL <600 PPM

COMPLAINTS OF DISCOMFORT, ODORS BY BUILDING OCCUPANTS 600-1,000 PPM

ASHRAE AND OSHA STANDARD, EXPECTATION 1,000 PPM

GENERAL DROWSINESS 1,000-2,500 PPM

ADVERSE HEALTH EFFECTS EXPECTED 2,500-5,000 PPM

MAXIMUM ALLOWED CONCENTRATION WITHIN AN EIGHT (8) HOUR WORKING

PERIOD

Source: http://www.engineeringtoolbox.com/

The Honeywell LCBS Connect control can reduce ventilation in a building space with feedback from a CO2 sensor. As you

can see from the table above, it is desirable to keep interior building space CO2 levels at 1,000 PPM or below during

building occupancy periods. If sensed CO2 level falls, it is acceptable to reduce outdoor air damper minimum position

and still conform to building code. The LCBS Connect controller will reduce outdoor air damper position until sensed CO2

begins to rise. Again, if it is very cold or very warm outdoors, reducing outdoor air position can save substantial negative

energy consumption and associated cost outlay.

5,000 PPM

First "law" of ventilation

The bigger the rate is, the more my energy bills will be. The more extreme the climate, the more damaging high rates of