Page 1

Triple Aquastat® Relay

The L8151A is a remote bulb controller for use

with hydronic heating systems that include domestic hot water service.

L8151A

■ Provides high limit, low limit, and circulator control

for maintaining boiler temperatures.

■ Can provide multizone control by using a separate

thermostat and R845 Relay for each zone.

■ An internal transformer powers the thermostat cir-

cuit.

■ Shielded capillary allows convenient mounting.

■ Consists of a diaphragm powerhead and micro switch

assembly that responds to temperature changes in

the boiler water.

CONTENTS

Specifications ................................................. 2

Ordering Information ..................................... 2

Installation ..................................................... 2

Operation and Settings...................................5

Checkout.........................................................6

J. H. • Rev. 1-95 • ©Honeywell Inc. 1995 • Form Number 60-2553—3

1 60-2553—3

Page 2

L8151A

SPECIFICATIONS • INSTALLATION • ORDERING INFORMATION

Specification

IMPORTANT: The specifications given in this publication

do not include normal manufacturing tolerances.

Therefore, this unit may not exactly match the listed

specifications. Also, this product is tested and calibrated under closely controlled conditions, and some

minor differences in performance can be expected if

those conditions are changed.

MODEL: L8151A Triple Aquastat® Relay for remote bulb

control of hydronic heating systems that include domestic

hot water.

ELECTRICAL RATINGS:

Power Supply: 120 Vac, 60 Hz; 220 Vac, 50 Hz and

240 Vac, 60 Hz operation.

Contact Ratings (A): See Table 1.

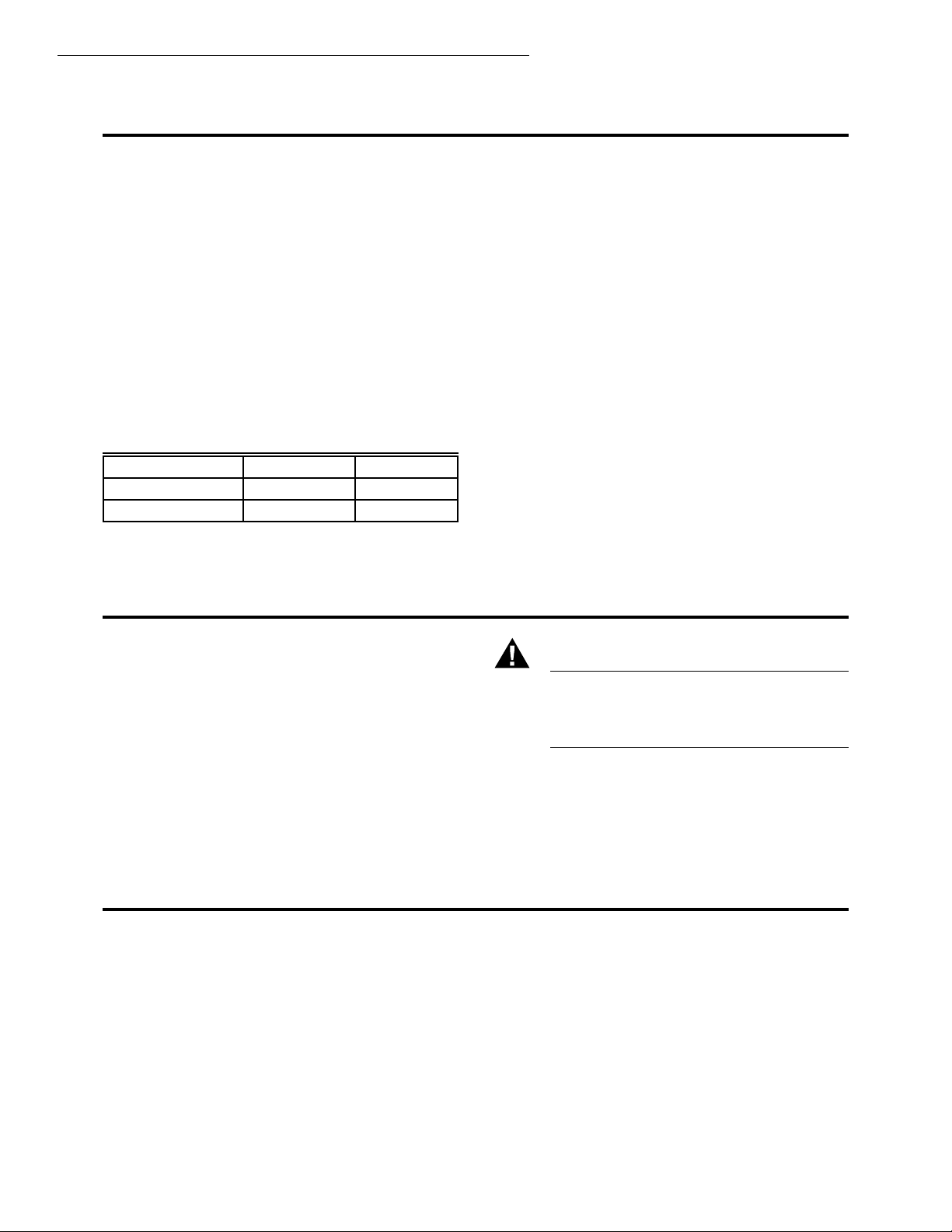

TABLE 1—CONTACT RATINGS.

120 Vac 240 Vac

Full Load 7.4 3.7

Locked Rotor 44.4 22.2

MAXIMUM POWER CONSUMPTION: 8W at 120 Vac,

60 Hz.

MAXIMUM AMBIENT TEMPERATURE: 150°F (66°C)

at case. 265°F (130°C) at sensing element.

PRESSURE RATING: 200 psi (1380 kPa) on outside of

immersion well.

THERMOSTAT HEAT ANTICIPATOR SETTING: 0.2A.

LOW LIMIT (Fig. 2):

Function: Maintains water temperature at setting during

thermostat off periods.

Setting: 110°F to 220°F adjustable (43°C to 104°C).

Differential: 10°F to 25°F adjustable (6°C to 14°C).

HIGH LIMIT (Fig. 2):

Function: Opens burner circuit if water temperature reaches

high limit setting.

Setting: 130°F to 240°F adjustable (54°C to 116°C).

Differential: 10°F fixed (6°C).

MOUNTING MEANS: Mounting lugs on back of case.

DIMENSIONS: See Fig. 1.

SENSING ELEMENT: 3/8 x 2-7/8 in. (10 x 73 mm).

CAPILLARY LENGTH: 36 in. (914 mm), armored

capillary.

UNDERWRITERS LABORATORIES INC. LISTED: File

No. MP466, Guide No. MBPR2.

Installation

WHEN INSTALLING THIS PRODUCT...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

WARNING

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY OR DEATH.

Product is for use only in a system with a pressure

relief valve.

Ordering Information

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the Tradeline

Catalog or price sheets for complete ordering number, or specify—

1. Order number. 3. Order additional system components and system

2. Accessories, if desired. accessories separately.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1. Your local Home and Building Control Sales Office (please check the white pages of your phone directory).

2. Home and Building Control Customer Logistics

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9. International Sales and

Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan, Mexico,

Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

®

60-2553—3 2

Page 3

CAUTION

• Disconnect power supply before beginning installation to prevent electrical shock or equipment damage.

• Avoid making sharp bends or kinks in the capillary. Bends should be no less than 1 in. (25 mm).

IMPORTANT: Terminals on these Aquastat® Relays are

approved for copper wire only.

Fig. 1—Approximate L8151 dimensions in in.

(mm).

1/8

(3)

L8151A

INSTALLATION

IMMERSION WELL MOUNTING

NOTE: Immersion well must be ordered separately. For a list

of available wells, refer to form 68-0040, Wells and

Fittings for Temperature Controllers.

The boiler manufacturer generally provides a tapping

for the immersion well. This tapping should be located at a

point where typical water temperature can be measured.

The immersion well must never be located close to a hot or

cold water inlet or a steam coil, or where the pressure

exceeds 200 psi (1380 kPa).

If the system is filled, drain to a point below the selected

installation location.

Fig 2— Internal view of L8151.

13/64 X 21/64 (4)

CAPILLARY

30 IN. (762)

KNOCKOUT

FOR 1/2 IN.

CONDUIT (5)

1-1/2

(38)

4-5/16 (110)

4-23/32 (120)

1-1/4

(32)

1-1/4

(32)

1-7/16

(37)

2-3/16

4-1/2

(114)

13/16

(21)

2-3/6

(56)

(56)

6-1/8

(156)

M8892

3-5/16

(84)

GROUNDING SCREW

HIGH LIMIT SETTING

VOLTAGE BARRIER

TRANSFORMER

FOR THERMOSTAT

CIRCUIT

DIFFERENTIAL

SETTING

CIRCULATOR

RELAY

LOW LIMIT SETTING

M8893

1. Screw the well into the boiler, tank, or pipe tapping.

2. Insert the bulb into the well, pushing tubing until bulb

bottoms in well. Avoid making sharp bends or kinks in the

capillary. Bends should be no sharper than 1 in. (25 mm)

radius.

MOUNTING THE CASE

Mount the case in a convenient location near the boiler.

Remember that the shielded capillary must reach from the

case to the immersion well. This maximum ambient temperature of the selected location must not exceed 150°F

(66°C) at the case, 265°F (130°C) at the sensing element.

3. Attach the retainer clamp to end of well spud. Loosen

draw nut and spread jaws of clamp with screwdriver if

necessary, Fig. 3.

3 60-2553—3

Page 4

L8151A

L1

(HOT)

L2

1

2

3

1

2

3

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

CONTROL CASE MUST BE CONNECTED TO EARTH GROUND.

USE GROUNDING SCREW PROVIDED.

B1 IS 1/4 IN. TAB TERMINAL.

M8886

T

T

ZC

ZR

B1

B2

C1

C2

1

2

G

THERM.

BURNER

LINE

2

1

CIRC.

LOW VOLTAGE

THERMOSTAT

LINE VOLTAGE

CIRCULATOR

X

X

X

X

X

X

OR

OIL BURNER

RELAY

LINE TERMINAL

LINE VOLTAGE

GAS VALVE

INSTALLATION

Fig. 3—Remote bulb installation.

JAWS

SPREAD JAWS

TO FIT OVER

RIDGE ON SPUD

OF WELL

SCREWDRIVER

INSERT— MOUNTING CLAMP

DRAW

NUT

B

TUBING

MOUNTING

CLAMP

SPUD

BULB

WELL

M8777

A

4. With part no.121371AA Retainer Clamp attached to

well spud (be sure jaws of clamp hook over ridge at end of

spud, as shown at points A), adjust tubing to fit through

retainer clamp groove, as shown at point B.

5. Tighten draw nut so that retainer clamp is firmly

attached to well spud and tubing is held securely in place. Be

careful not to damage the capillary.

6. Carefully coil the excess capillary at the bottom of the

Aquastat® case.

All wiring must comply with local electrical codes and

ordinances. The limits given in the Specifications section

must not be exceeded when applying this control. Use

manufacturer instructions when wiring controlled equipment or refer to typical hookups in Fig. 4 through 6.

When the B1 terminal on the device being replaced is

1/4 in. tab terminal, use the existing wiring harness terminals to install the replacement device. When the B1 terminal on the device being replaced is a screw terminal, insert

the provided tab terminal to screw terminal adapter on the

1/4 in. tab terminal of the replacment device. After the

adapter is installed, the existing wraparound wire end can

be reused to make an electrical connection to the B1 terminal.

NOTE: Do not use a push type ratchet screwdriver.

1. Strip 7/16 in. of insulation from the wire end.

2. Wrap the wire at least three-fourths of the distance

around the screw as shown.

3. Using a standard, flat-headed screwdriver, tighten the

screw until the wire is snugly in contact with the screw and

contact plate.

4. Tighten the screw an additional one-half turn.

Fig. 4—Typical hookup for L8151A in a single

zone system.

WIRING

CAUTION

• Disconnect power supply before wiring to avoid

electrical shock or equipment damage.

• Be sure the terminal connections are inside an

IMPORTANT: Terminals on the L8151A Aquastat® Relay

60-2553—3 4

enclosure that meets local codes.

are approved for use only with copper wire. The

terminals allow wraparound wiring only.

1. Strip 7/16 in. of insulation

from the wire end.

2. Wrap the wire at least three

fourths of the distance around

the screws as shown.

3. Use a standard flat-headed

screwdriver to tighten the

screw until the wire is snugly

in contact with the screw and contact plate.

4. Tighten the screw an additional one-half turn.

NOTE: Do not use a push-type ratchet screwdriver.

M8843

Page 5

HIGH LIMIT

LOW LIMIT

AND

CIRCULATOR

SETTING

HIGH LIMIT

SETTING

SWITCH BREAKS ON

TEMPERATURE RISE.

BURNER TURNS OFF.

CIRCULATOR OPERATES

ON A CALL FOR HEAT.

SWITCH MAKES ON

TEMPERATURE FALL.

BURNER OPERATES ON A

CALL FOR HEAT.

SWITCH MAKES R-W

AND BREAKS R-B ON

TEMPERATURE RISE.

SWITCH MAKES R-B AND

BREAKS R-W ON

TEMPERATURE FALL.

BURNER IS ON TO

MAINTAIN MINIMUM

WATER TEMPERATURE.

CIRCULATOR IS OFF.

110°F (43°C)

240°F (116°C)

M1523

SWITCH MAKES R-W

AND BREAKS R-B ON

TEMPERATURE RISE.

WHEN WATER REACHES PROPER TEMPERATURE, THE BURNER

SHUTS OFF OR THE CIRCULATOR PUMP STARTS (WHEN CALLING

FOR HEAT).

1

1

10°F (6°C)

DIFFERENTIAL

25°F (14°C)

DIFFERENTIAL

10°F (6°C)

DIFFERENTIAL

The high limit opens and turns off the burner when the

water temperature reaches the setpoint. The high limit

automatically resets after the water temperature drops past

the setpoint and through the 10°F (6°C) differential.

L8151A

OPERATION AND SETTINGS

Operation and Settings

Fig. 6—L8151A internal schematic.

21

WARNING

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY OR DEATH.

Product is for use only in a system with a pressure

relief valve.

LOW LIMIT AND CIRCULATOR CONTROL

On a temperature rise, with the adjustable differential at

the minimum setting of 10°F (6°C), the low limit circuit

(RB) breaks and the circulator circuit (R-W) makes at the

control setpoint. On a temperature drop of 10°F (6°C)

below the setpoint, the R-B circuit makes and the R-W

circuit breaks.

Fig. 5—Typical hookup for the L8151A in a

multizone system.

TO ADDITIONAL

R845A RELAYS

FOR OTHER ZONES

T

THERM.

T

ZC

THERMOSTAT

ZONE 1

R845A RELAY

2

1

THERMOSTAT

ZONE 2

T

1K

T

B2 B1

HIGH LIMIT

C1C2

ZR

ZC

1K1

1K2

R

B

CIRCULATOR

CONTROL

W

LOW

LIMIT

M8884

Fig. 7—Relationship of setpoints and differential.

ZR

4

B1

BURNER

B2

C1

CIRC.

C2

1

LINE

2

G

HYDRONIC HEATING

CONTROL TERMINALS

1

2

3

4

3

CIRCULATOR

ZONE 1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

CONTROL CASE MUST BE CONNECTED TO EARTH GROUND.

USE GROUNDING SCREW PROVIDED.

LINE VOLTAGE OIL BURNER CONTROL OR GAS VALVE.

B1 IS 1/4 IN. TAB TERMINAL.

2

4

3

5

6

CIRCULATOR

ZONE 2

L1

(HOT)

1

L2

IF CONTROLLING TWO LOADS USE:

—TERMINALS 3 AND 4 FOR LINE

VOLTAGE LOAD.

—TERMINALS 5 AND 6 FOR LINE

OR LOW VOLTAGE LOAD.

M8885

At any differential setting greater than 10°F (6°C), the

R-B make and R-W break temperatures remain the same

(control setting minus 10°F (6°C). The R-B break and R-W

make temperatures are the setpoint temperatures plus the

difference between the differential setting and 10°F (6°C).

5 60-2553—3

Page 6

L8151A

OPERATION AND SETTINGS • CHECKOUT

EXAMPLE: Setpoint of 140°F (60°C) differential set at

25°F (14°C). On a temperature rise, R-B breaks and

R-W makes at 155°F (68°C). On a temperature fall,

R-B makes and R-W breaks at 130°F (54°C); see

Fig. 7.

THERMOSTAT ANTICIPATOR

Set the thermostat heat anticipator at 0.2A.

Checkout

Put the system into operation and observe each function through at least one complete cycle. Be sure the control operates

as intended.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

60-2553—3 6

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Scarborough, Ontario M1V 4Z9

Loading...

Loading...