Honeywell IQ8Control C, IQ8Control M Installation Instruction

Installation Instruction

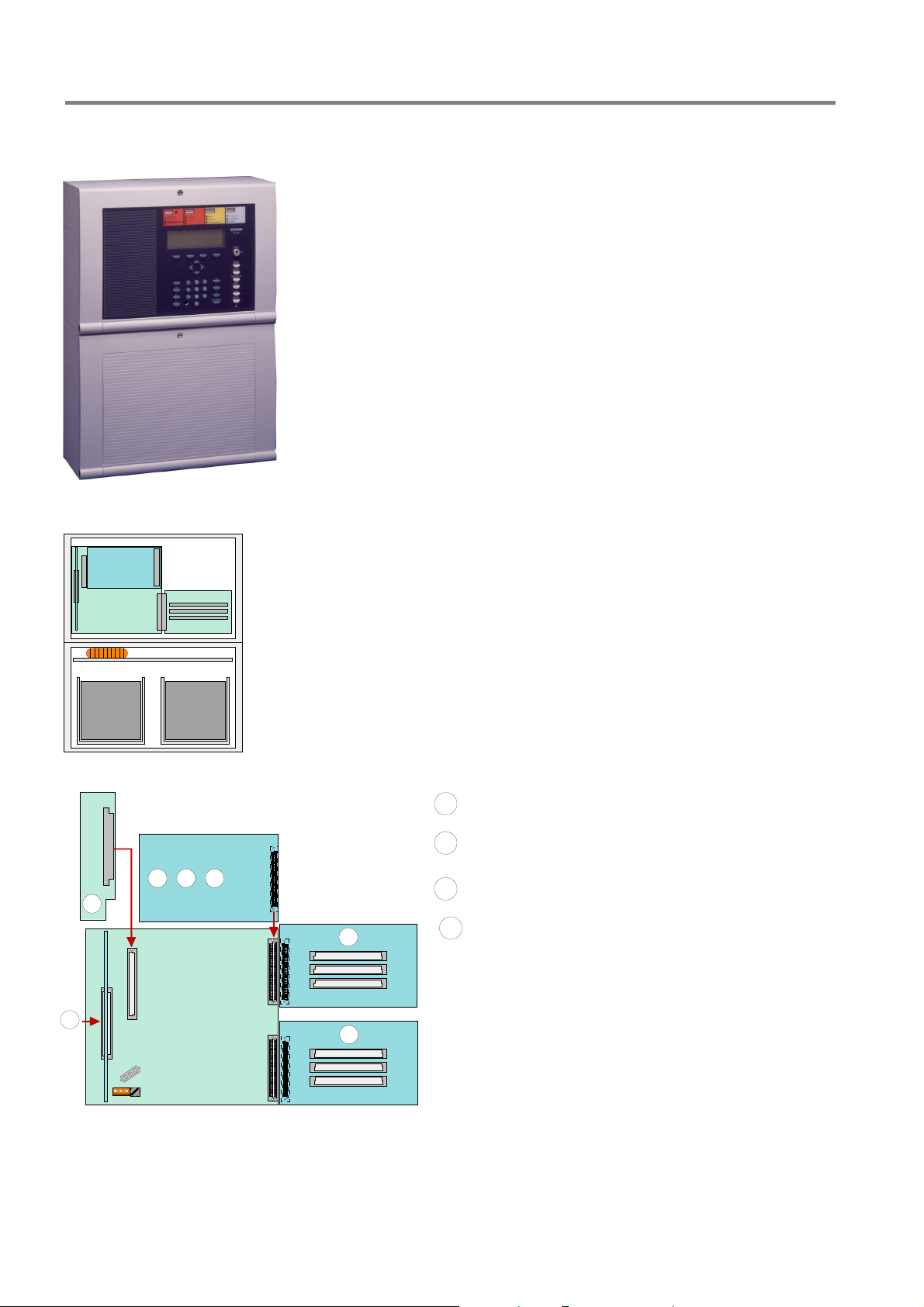

Fire Alarm Control Panel IQ8Control C/M

798951.GB0 G 299044

01.2009

G 205129

GB

Technical changes reserved!

© 2009 Honeywell International Inc.

Fire Alarm Control Panel IQ8Control C/M

Intended purpose

This product must only be used for the applications outlined in the catalogue and the technical description

and in combination with external components and systems which have been approved or recommended by

Esser by Honeywell.

Warning

In order to ensure correct and safe operation of the product, all guidelines concerning its transport, storage,

installation, and mounting must be observed. This includes the necessary care in operating the product.

Safety-relevant user information

This manual includes all information required for the proper use of the products described.

The term 'qualified personnel' in the context of the safety information included in this manual or on the

product itself designates:

project engineers who are familiar with the safety guidelines concerning fire alarm and extinguishing

systems.

trained service engineers who are familiar with the components of fire alarm and extinguishing systems

and the information on their operation as included in this manual.

trained installation or service personnel with the necessary qualification for carrying out repairs on fire

alarm and extinguishing systems or who are authorised to operate, ground and label electrical circuits

and/or safety equipment/systems.

Safety warnings

The following information is given in the interest of your personal safety and to prevent damage to the

product described in this manual and all equipment connected to it.

Safety information and warnings for the prevention of dangers putting at risk the life and health of user and

maintenance personnel as well as causing damage to the equipment itself are marked by the following

pictograms. Within the context of this manual, these pictograms have the following meanings:

Dismantling

In accordance with Directive 2002/96/EG (WEEE), after being dismantled, electrical and

electronic equipment is taken back by the manufacturer for proper disposal.

Designates risks for man and/or machine. Non-compliance will create risks to man and/or

machine. The level of risk is indicated by the word of warning.

Important information on a topic or a procedure and other important information!

This is an important guideline issued by VdS Schadenverhütung GmbH, Cologne.

If the hazard alarm system is programmed in compliance with VdS, this section must be read very

carefully and all instructions must be adhered to.

2 FB 798951.GB0 / 01.09

Fire Alarm Control Panel IQ8Control C/M

1

Installation Instruction................................................................................................................................................. 5

2 System overview........................................................................................................................................................ 7

3 Configuration options................................................................................................................................................. 8

3.1 Special configuration – Swiss option

3.2 FACP IQ8Control C........................................................................................................................................... 10

3.3 FACP IQ8Control M........................................................................................................................................... 12

3.4 Definition of the Primary loop number.............................................................................................................. 17

3.5 Central housing.................................................................................................................................................. 19

3.6 Assembly............................................................................................................................................................ 20

3.7 Cable glands ...................................................................................................................................................... 25

3.8 Panel buzzer ...................................................................................................................................................... 25

4 Module ......................................................................................................................................................................26

4.1 Power supply module (Part No. 802426 index G or higher)........................................................................... 26

4.1.1 Mains connection and earth connections .................................................................................... 28

4.1.2 Protective and Functional earth ................................................................................................... 29

4.1.3 Emergency power supply ............................................................................................................ 30

4.1.4 Specification Power supply module (Part No. 802426) ............................................................... 33

4.2 Basic module...................................................................................................................................................... 34

4.3 Software.............................................................................................................................................................. 37

4.3.1 Firmware Update ......................................................................................................................... 37

4.3.2 Customer data programming .......................................................................................................39

4.3.3 Housing contact ........................................................................................................................... 40

4.3.4 Serial interface ............................................................................................................................. 41

4.3.5 Micro module slot......................................................................................................................... 44

4.3.6 Technical data Basic module....................................................................................................... 45

4.3.7 Connecting a fire department operating panel ............................................................................ 50

4.3.8 Connecting the master box (Relay K1)........................................................................................ 51

4.3.9 Connecting the Relays K2, K3, K4 .............................................................................................. 55

4.3.10 Technical data Field device module .................................................................................... 57

4.4 Extension module ..............................................................................................................................................58

4.4.1 Technical Data Extension module ............................................................................................... 59

CH

......................................................................................................... 9

5 Micro module............................................................................................................................................................62

5.1 Analog loop modules......................................................................................................................................... 62

5.1.1 esserbus® Analog loop module (Part No. 784382 / 784382.10 / 784382.D0) ............................. 64

5.1.2 esserbus®-PLus Analog loop module (Part No. 804382 / 804382.10 / 804382.D0) ................... 65

5.1.3 Technical Data Analog loop module............................................................................................ 68

5.2 essernet® module............................................................................................................................................... 69

5.2.1 essernet® micro module (Part No. 784840 / 784840.10 and 784841 / 784841.10) .................... 70

5.2.2 Technical data essernet® micro module ...................................................................................... 72

6 Relay module............................................................................................................................................................76

6.1 3-relay module / 3-relay common trouble module........................................................................................... 76

6.2 4- Relay module.................................................................................................................................................81

6.2.1 Technical Data Relay module...................................................................................................... 83

6.3 Serial interface module......................................................................................................................................84

6.3.1 RS 232 / TTY module .................................................................................................................. 84

6.3.2 Technical data interface modules ................................................................................................86

FB 798951.GB0 / 01.09

3

Fire Alarm Control Panel IQ8Control C/M

7

Master box activation module ................................................................................................................................. 87

7.1 Technical Data Master box activation module (Part No. 784385) ................................................................. 91

8 Installer level............................................................................................................................................................. 96

9 Diagnostic display.................................................................................................................................................. 108

9.1 Diagnostic display IQ8Control C/M ................................................................................................................ 108

10 Meaning of the three digit error codes / test mode.............................................................................................. 115

11 Functionality for fire alarm control panels............................................................................................................. 126

11.1.1 Use of the analog loop module in door control systems.................................................... 126

12 IQ8Wireless devices.............................................................................................................................................. 127

13 Top hat rail mounting kit (Part No. 788652) ......................................................................................................... 129

14 esserbus® transponder.......................................................................................................................................... 131

15 Extension housing.................................................................................................................................................. 132

15.1 Extension housing for two batteries (Part No. 789300 / -01) ................................................................... 134

16 Power supply for the built-in printer ...................................................................................................................... 135

17 Mounting / Replacing of the Panel front + Printer................................................................................................ 136

17.1 Heat transfer Printer without paper take-up unit (Part No. 7868xx / 7869xx)........................................ 136

17.2 Printer with paper take-up reel (Part No. 7863xx) .................................................................................... 139

18 Fire protection housing (F30)................................................................................................................................ 141

Danger – Electrical shock !

Remove all power from the panel before carrying out any installation work!

ESD protection

While handling electronic assemblies, the necessary precautions against electrostatic discharge

must be taken.

Protective and functional earth

The PE conductor must be connected to the corresponding terminal at the mains supply. Connect

the FE terminal of the panel’s cabinet with the PE rail of the power distributor panel from which the

fire alarm system will be powered.

Commissioning

A complete system check must be carried out after commissioning and for each modification of the

customer data programming!

Additional and updated Informations

The described features, specifications and product related informations in this manual correspond

to the date of issue (refer to date on the front page) and may differ due to modifications and/or

amended Standards and Regulations of the System design, Installation and Commissioning.

Updated informations and declaration of conformity are available for comparison on the

www.esser-systems.de homepage.

®

esserbus

and essernet® are registered trademarks in Germany.

4 FB 798951.GB0 / 01.09

Fire Alarm Control Panel IQ8Control C/M

1 Installation Instruction

Operation of the Fire Alarm Control Panel IQ8Control is governed by the national version of the operating

system software used and the country version programmed in the customer data. The terminal assignment and

wiring illustrated in these installation instructions refer exclusively to the facilities of the operating system

D

software for the Federal Republic of Germany

The fire alarm panel may only be installed in a dry, clean room with controlled access and appropriate

lighting. The environmental conditions must comply with DIN EN 60721-3-3, class 3k5.

The panel must be mounted on a flat surface using appropriate hardware (screws and dowels). Avoid

mechanical stressing. It may only be commissioned after correct mounting on a wall or other mounting

surface of sufficient strength to support the weight of the unit.

Avoid strong electric or magnetic fields as well as mechanical influences. This applies especially to the

presence of fluorescent lighting or energy cabling in the close vicinity of the panel, its components and the

associated cabling. Do not mount on vibrating, unstable surfaces such as light partitioning walls.

Do not install the system in places where adverse conditions prevail. Parts and components of the system

may only be installed in or led through locations which allow compliance with DIN VDE 0800.

Control panels and visual indicators mounted on a wall should be installed at a height of 800 to 1800 mm

above the floor.

.

The fire alarm system is not suitable for connection to IT power supply systems.

It is highly recommended for correct ESD protection that the dummy plug (factory supplement) of the

programming interface plug is inserted into the front of the operation panel.

This documentation applies to the following products:

Fire Alarm Control Panel IQ8Control C/M

Standard system software (without special customer-dependent functionality)

Country function >Germany<

Configuration and Commissioning

For the configuration and commissioning of the system, the programming software tools 8000 is required in

each case in the current program version.

Installer / Installation Specialist

The fire alarm control panel must be installed by a skilled electrician (according to DIN VDE 0833), who, as a

result of the appropriate training and experience, can evaluate the work to be carried out and recognise

potential dangers. In addition to the specialist qualifications, knowledge of the validity and application of the

relevant standards and their use and compliance with is required.

Operator of the Fire Alarm System / Trained Person

For the operation of the fire alarm control panel, a qualified person must be trained in the basic functioning of

the system and its technical requirements. A trained person (according to DIN VDE 0833) must be able to

operate the fire alarm control panel and to recognise faults. If a fault signal occurs or the functionality is limited,

arrangements must be made for the checking and rectification of the cause of the fault.

Maintenance / Service

Maintenance is necessary for the proper operation of the fire alarm control panel. The function of the system

parts can be affected by environmental conditions and ageing. For an application within the area of validity of

the European Union (EU) the maintenance is defined in EN 54. In addition to the safety directives and notes in

this documentation, the country-specific requirements for the operational location of the fire alarm control panel

must be observed.

FB 798951.GB0 / 01.09

5

Fire Alarm Control Panel IQ8Control C/M

1.1 Standards and guidelines

The general technical rules must be observed when installing fire alarm systems. Any deviation from those rules

is only admissible if the same degree of safety can be ensured with different means. Installations within the

European Community are primarily subject to all EU regulations defining the current standards for security

systems.

In Germany, systems are considered to be in compliance with the general technical rules or the standards of the

EU for security systems if they meet the technical guidelines of the VDE (Verband Deutscher Elektrotechniker,

Association of German Electrical Engineers). They may also be considered to be in compliance with the

standards of the EU for security systems if they meet the technical guidelines of another comparable institution

within the European Community which have been accepted in accordance with directive 73/23 EEC of the

Council dd. 19 February 1973 – directive on low-voltage systems- (ABL. EG No. L 77 page 29). The same must

be applied for all applications of additional, product relating guidelines, e.g. EMI-Guideline 2004/108/EC and the

Construction Products Directive (CPD) 89/106/CE.

These are examples:

Standards of the DIN EN 54 “Fire alarm systems“, particulary DIN EN 54-2 „Fire alarm control panels" and

DIN EN 54-4 „Power supply units".

Standards of the DIN VDE 0100 issue, particulary DIN EN 0100-410 „Installation of high-voltage sytems with

rated voltage up to 1000 V“, DIN VDE 0105-100 „Operation of electrical system: General commitments“ and

DIN VDE 0108 „Installation and Operation of high-voltage systems in buildings for public gathering“.

Standards of the DIN EN 62305 or DIN VDE 0185 issue, particulary DIN VDE 0185-1 „Lightning protection:

General standards. DIN VDE 0185-2 „Risk-Management“, DIN VDE 0185-3 „Protection of buildings and

persons“ and DIN VDE 0185-4 „Eletrical and electronic systems in buildings“.

DIN VDE 0701-1 „Maintenance, Modification and Test of electrical devices: General commitments“.

Standards of the DlN VDE 0800 issue, particulary DIN VDE 0800-1 „General commitments, Requirements

and Tests for system security“, DIN VDE 0800-1 „Communication systems, Earthing and potential

compensation“, DIN VDE 0800-174-2 .Information systems – design and installation of communication

cabling in buildings“.

DIN VDE 0815 „Cables for communication and information systems“.

Standards of the DIN VDE 0833 issue Hazard alarm systems for Fire, Intruder and Hold-up, particulary DIN

VDE 0833-1 „General commitments“, DIN VDE 0833-2 „Commitments for fire alarm systems (FAS)“, DIN

VDE 0833-3 „Commitments for Intruder and Hold-up systems“ and DIN VDE 0833-4 „Commitments for

Voice alarm systems within fire protection“.

Standards of the DIN VDE 0845 issue, particulary DIN VDE 0845-1 „Protection of Communication systems

against Lightning, electrostatic charge and overvoltage from high-voltage systems; Actions to avoid overvoltage“.

DIN 14675 Fire alarm systems – Design and Commissioning.

Standards of the DIN EN 120094 issue, localized fire fighting systems – components of extinguishing

systems with gaseous extinguishing agents“, particulary DIN EN 120094-1 „Requirements and test

procedures for automatic electrical Control- and Delay systems“ and DIN EN 12094-3 „ Requirements and

test procedures for Manual release systems and Stop units.

DIN 14675 Fire alarm systems – mounting and operation.

These technical guidelines must be observed within the European Community. The VDE guidelines must be

observed within Germany. In other countries (e.g. U.S.A.: NFPA and UL requirements), the relevant national

standards, guidelines and legislation must be observed.

In addition to the above, the guidelines of the German VdS Schadenverhütung GmbH (VdS) may apply for

systems installed in Germany.

VdS 2046 Safety rules for electrical power systems with voltages up to 1000 V

VdS 2015 Electrical appliances and systems – rules for damage prevention

VdS 2095 Design and installation of fire alarm systems

VdS 2833 Overvoltage protection measures for Hazard Alarm Systems

6 FB 798951.GB0 / 01.09

Fire Alarm Control Panel IQ8Control C/M

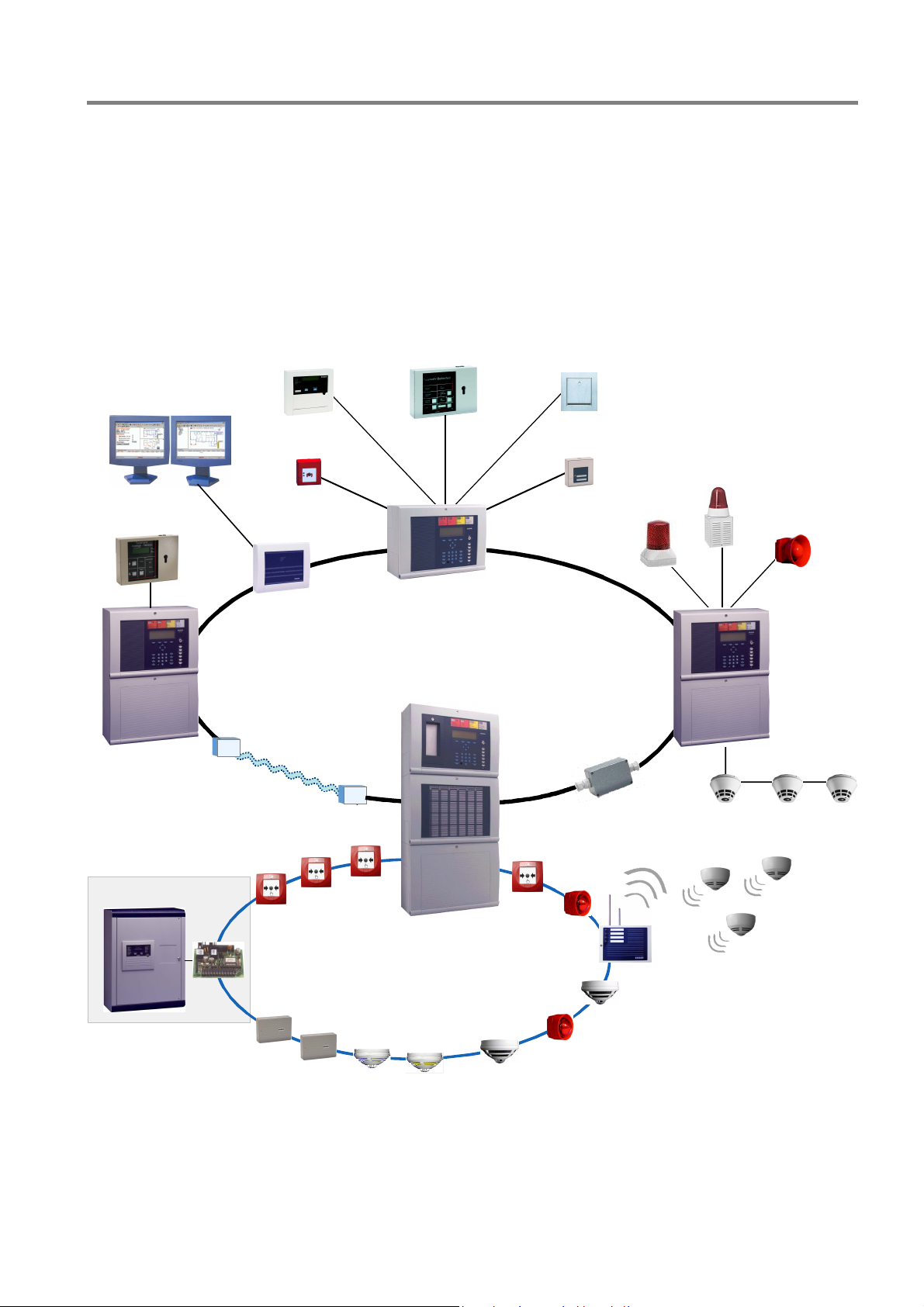

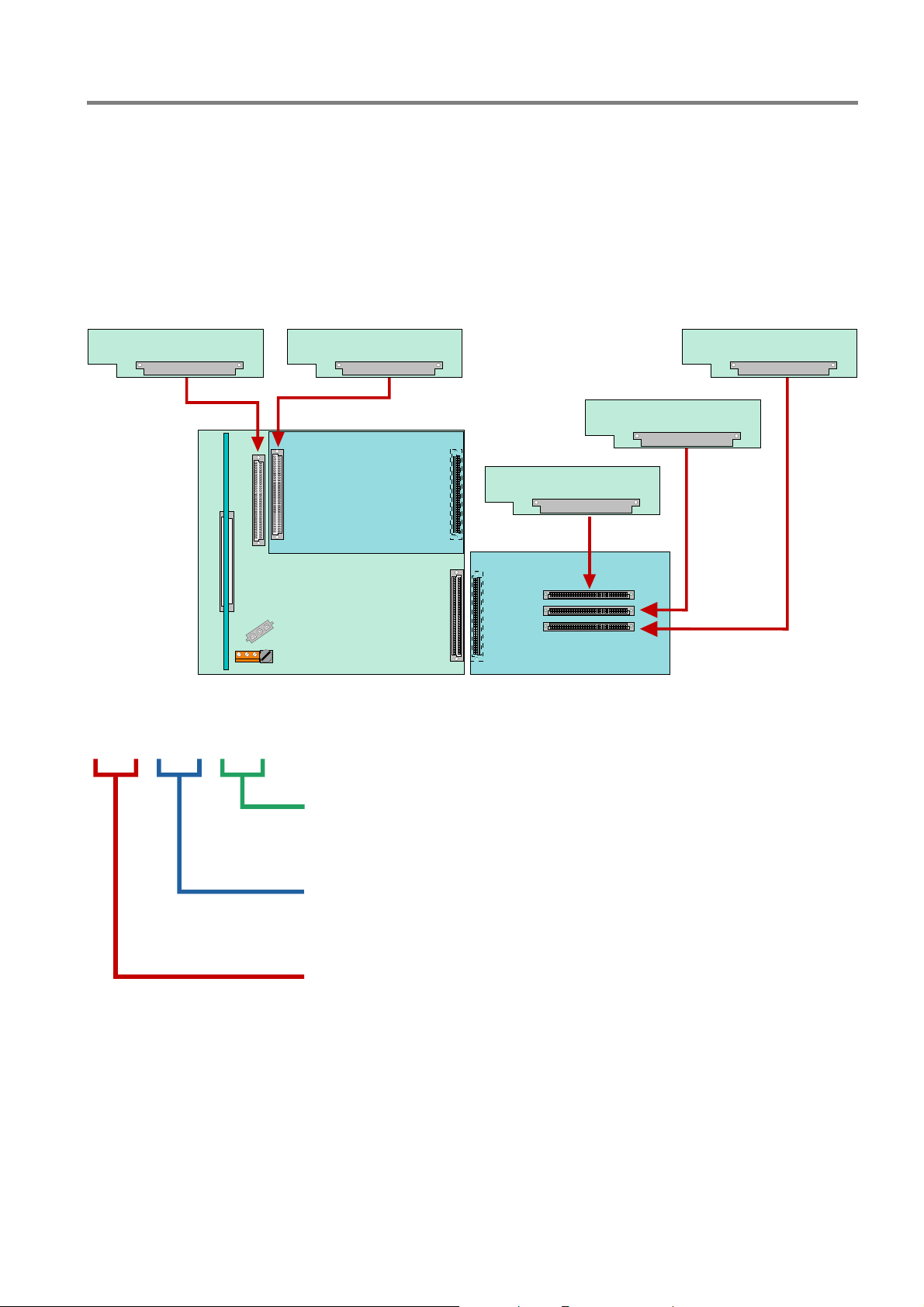

2 System overview

The modular design with different micro modules and individual extension concepts allow the Fire Alarm

Computer IQ8Control C and IQ8Control M to be easily adapted to special requirements. This provides the range

from a stand-alone panel up to 31 Fire Alarm Control Panels Computer or other network subscribers such as

supervising system WINMAG, Fire department indicator panel or Intruder Alarm Panels Series 5000 by using

the essernet

The Field device modules required in order to configure a stand-alone FACP in accordance to the appropriate

standards and guidelines. The connections for the Fire Alarm Control Panel, the master box and the three freely

programmable relays are integrated on the Field device module. If several Fire Alarm Control Panels are

connected together in the essernet

®

safety network.

WINMAG

®

LCD

display panel

MFAB

, the master box can be connected to one of the other FACPs.

FDOP

Fire dept.

key box

TAL

module

Fire department

indicator panel

Fibre optical cable

LWL

Fire alarm and extinguishing

computer 8010

essernet

Serial

®

-Interface

essernet

LWL

max. 1 km

®

max. 1 km

max. 1 km

Repeater

esserbus

Fig. 1: System overview

®

-PLus

Additional extensions

The FACP panel configuration may be extended to suit requirements by adding supplementary input/ output

modules, esserbus

®

transponders. Transponders may be installed at special integrated slots or on standard

C-Top rails in the housing. Optional plastic housings conforming to protection class IP 40 are available for the

decentralized installation of transponders on the analog loop.

FB 798951.GB0 / 01.09

7

Fire Alarm Control Panel IQ8Control C/M

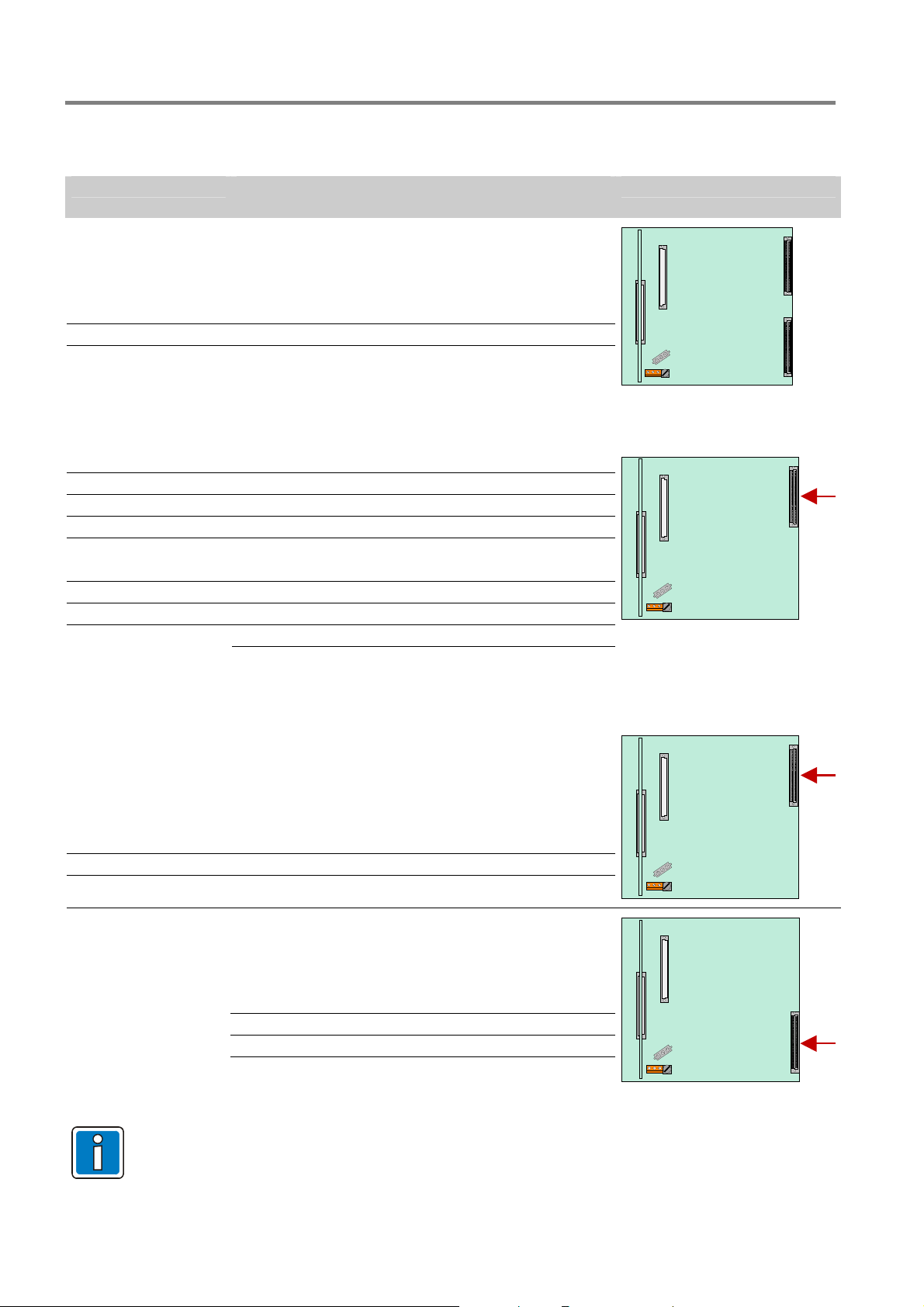

3 Configuration options

The operating module front (7860xx) is available in various language versions. The language is defined with the

2-digits of the part number, e.g. 786002

= English lettering.

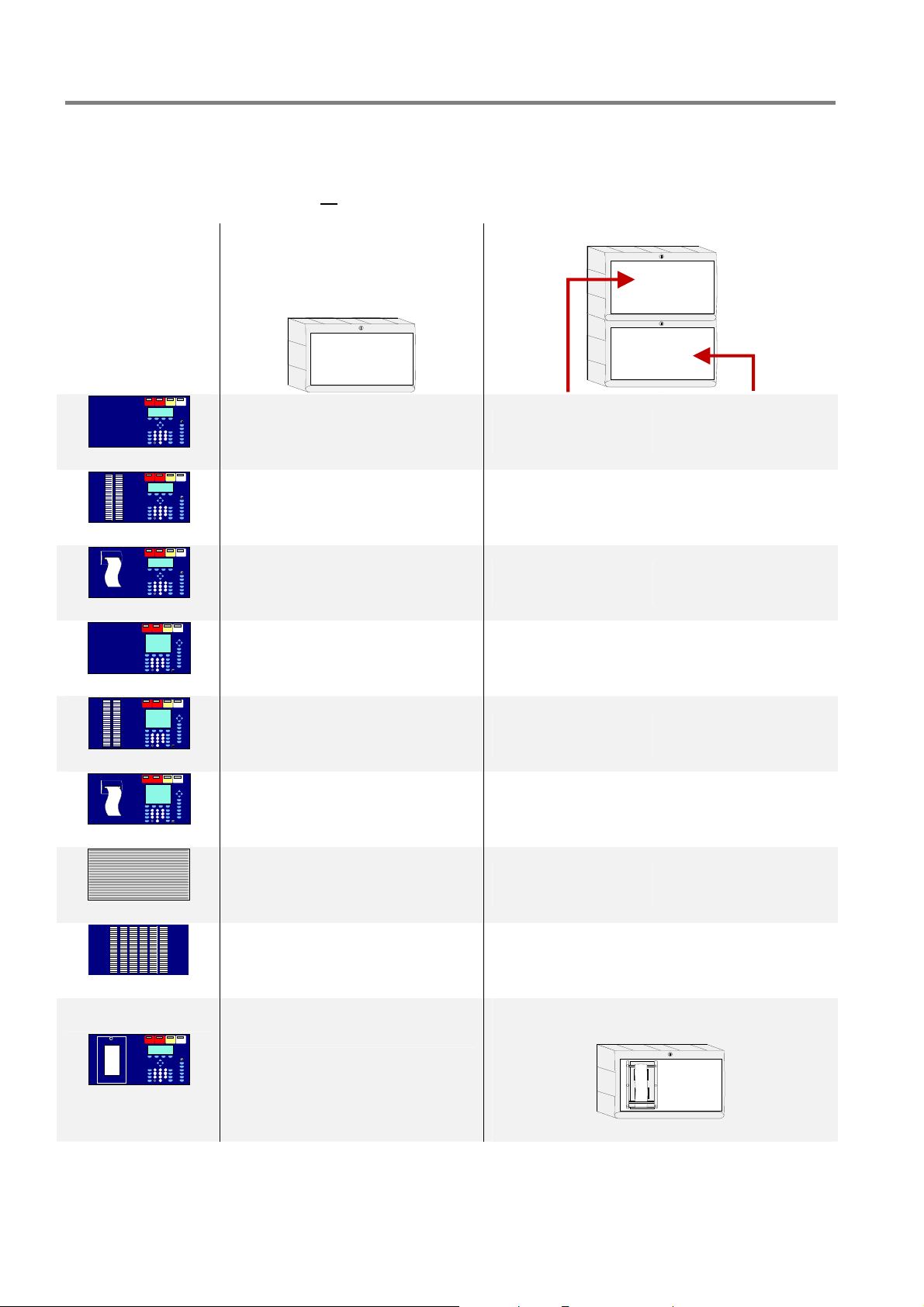

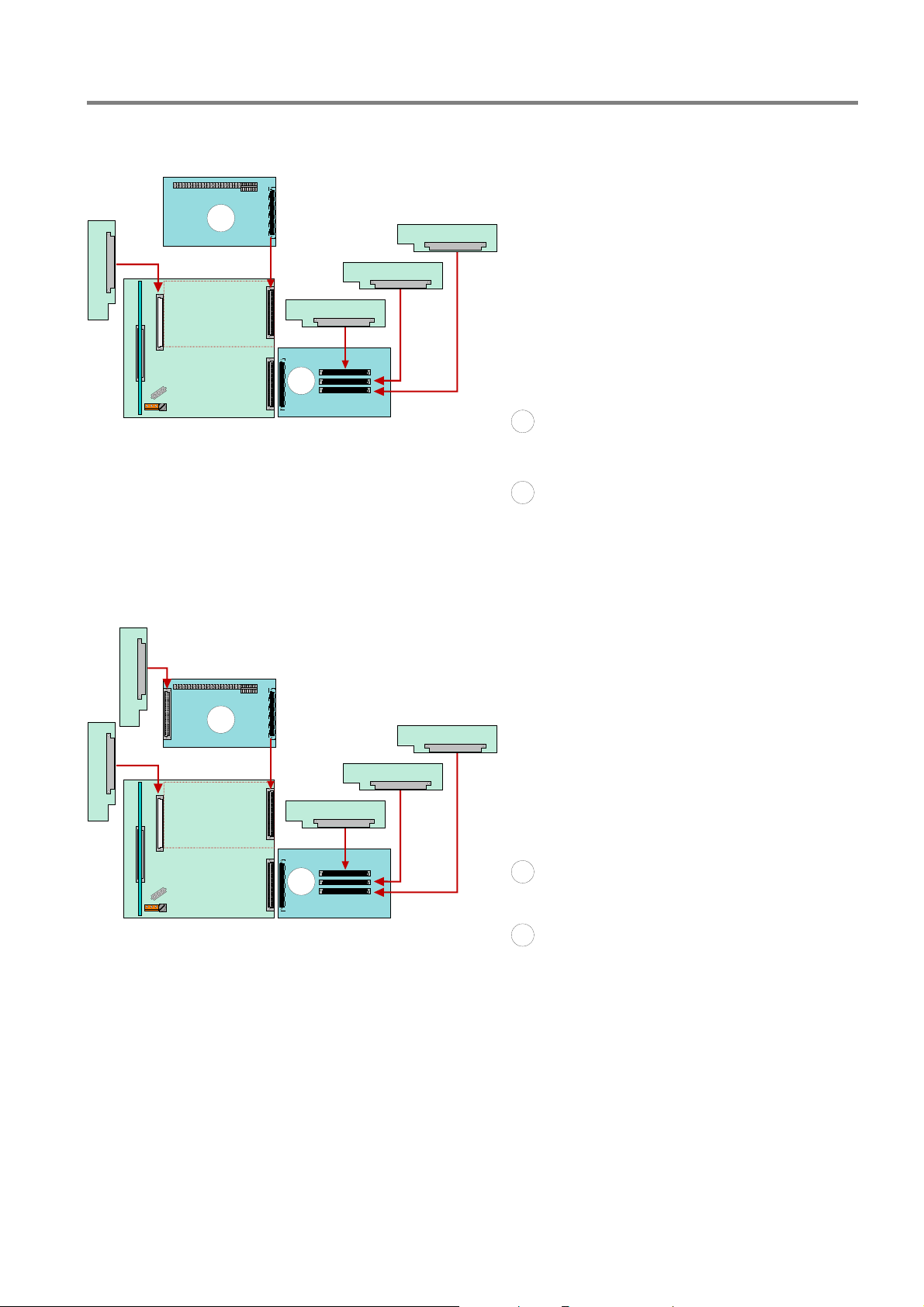

IQ8Control C IQ8Control M

Operating module

7860_ _

7861_ _

7868_ _

7864_ _

7865_ _

7869_ _

9 9

9 9

9 9

9 9

9 9

9 9

---

---

---

---

---

---

742100

786000

9 9 9

9

1)

---

9

2)

9

1)

7863_ _

Fig. 2: Configuration options

1)

Extension housing required

2)

Not available for operating module 7861 _ _ or 7865 _ _

9

8 FB 798951.GB0 / 01.09

Extension housing 789304

Fire Alarm Control Panel IQ8Control C/M

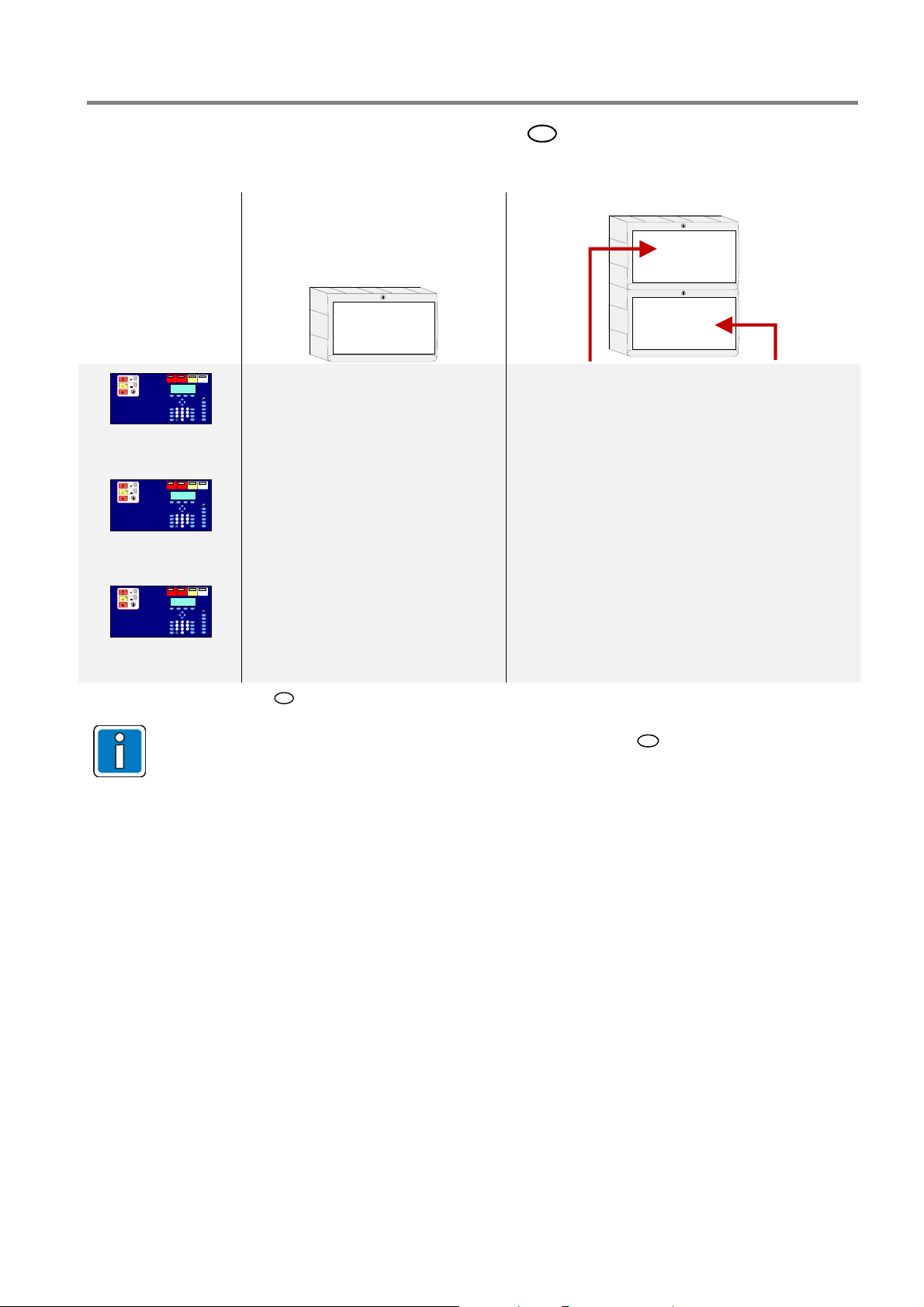

3.1 Special configuration – Swiss option CH

IQ8Control C IQ8Control M

Operating module

786261

786262

786263

Fig. 3: Operating module – Swiss CH with integrated Fire department operating panel (FBA)

For country-specific displays and labels as well as further information

instructions FACP IQ8Control C/M (Part No. 798950.GB0).

9 9

9 9

9 9

CH

refer to operating

---

---

---

FB 798951.GB0 / 01.09

9

Fire Alarm Control Panel IQ8Control C/M

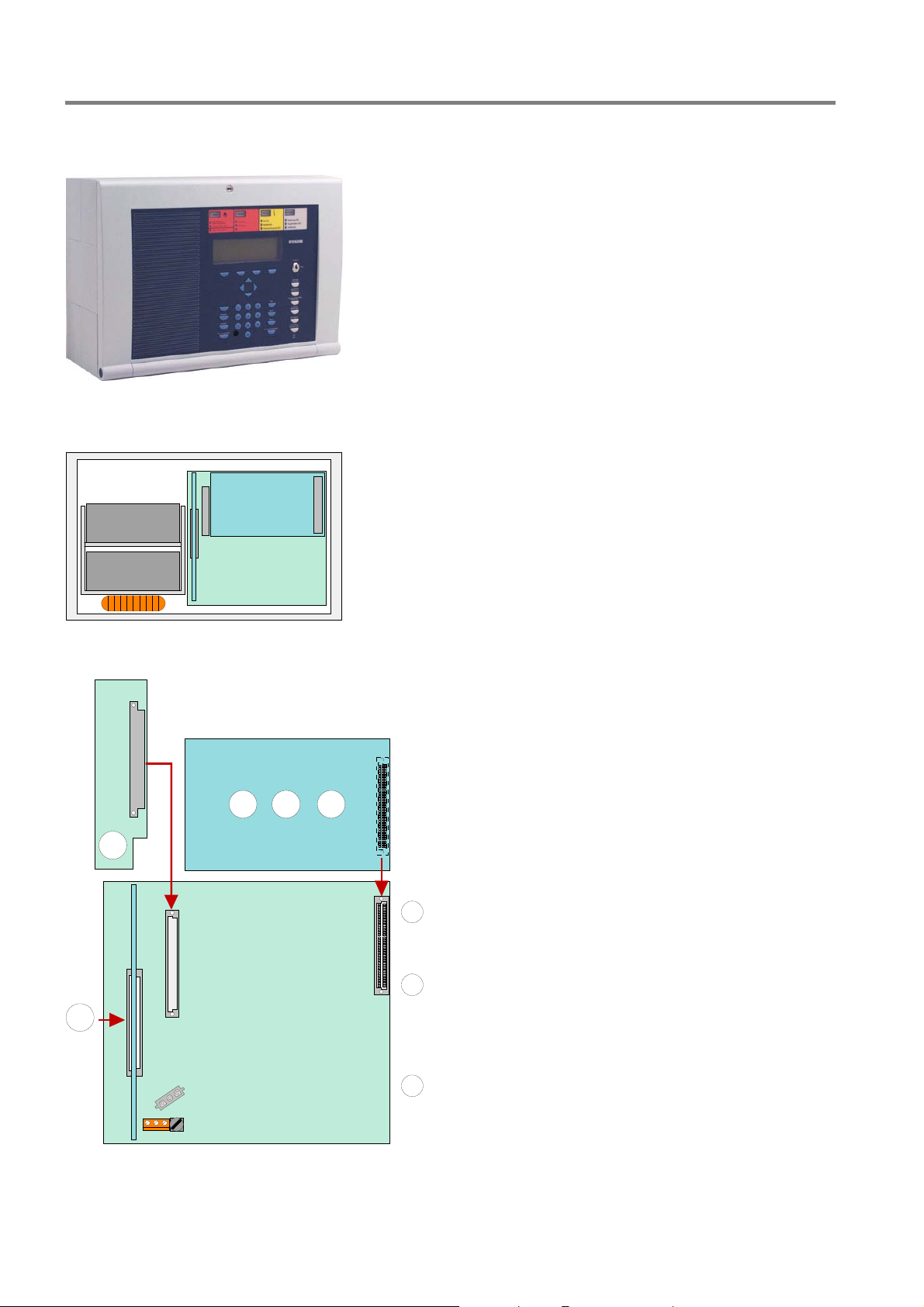

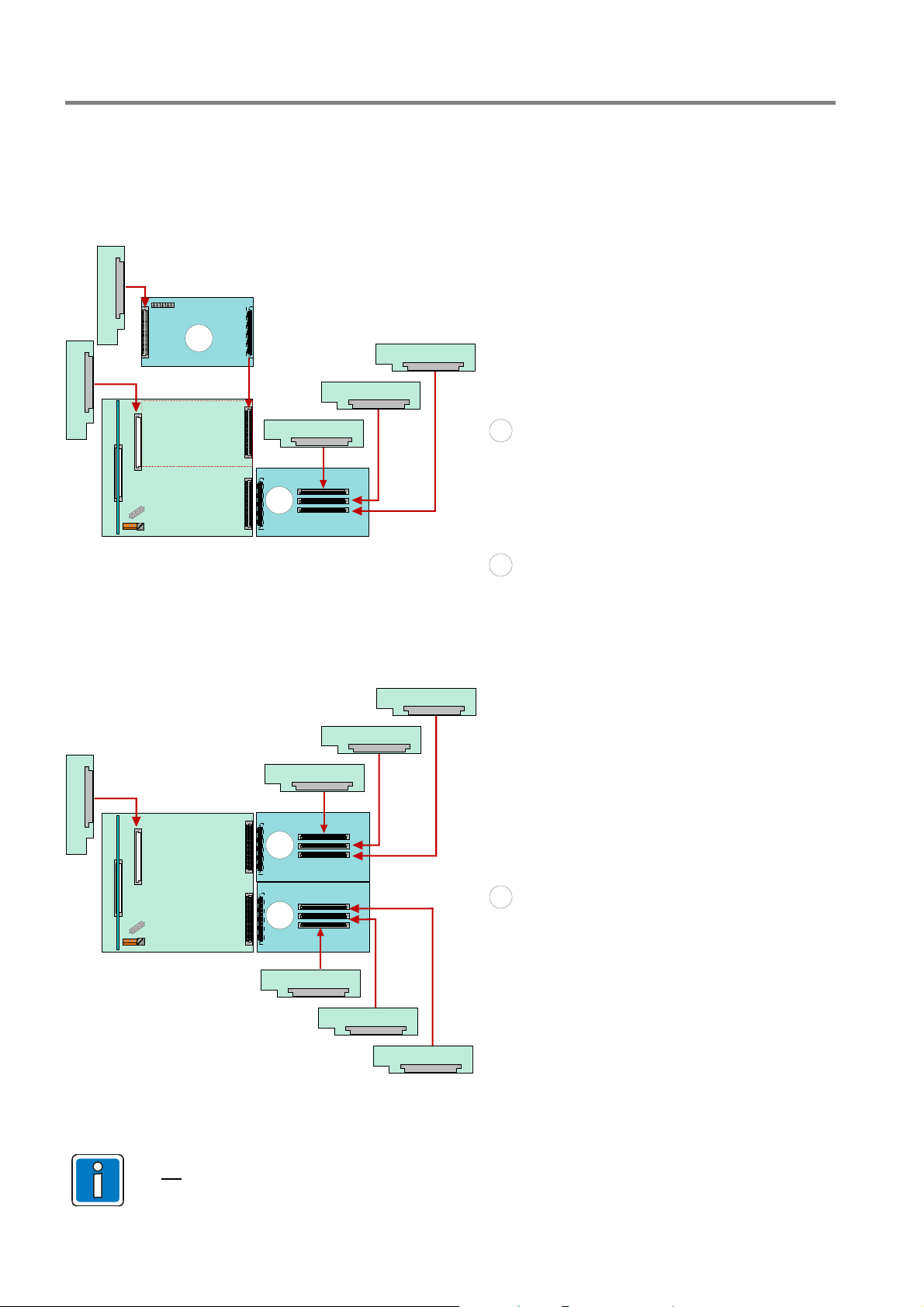

3.2 FACP IQ8Control C

The configuration of the FACP IQ8Control C includes:

1 Basic module

1 Power supply module

1 Field device module or 1 Extension module

In the full configuration, two freely selectable micro modules

can be employed.

On the Basic module only the upper slot (slot 1) of can be

used for a Field device or Extension module.

The lower slot (slot 2) of the FACP IQ8Control C is not used.

Micro module

c

A B C

Power supply module Part No. 802426

d

1

Field device module Part No. 772479

A

Connector 1

Field device module

B

with one micro module slot

Part No. 772477

2

Fig. 4: Configuration FACP IQ8Control C

Extension module

C

with one micro module slot

Part No. 772478

10 FB 798951.GB0 / 01.09

Configuration of FACP IQ8Control C

Fire Alarm Control Panel IQ8Control C/M

MM 1

MM 1

MM 2

A

B

Connector 1

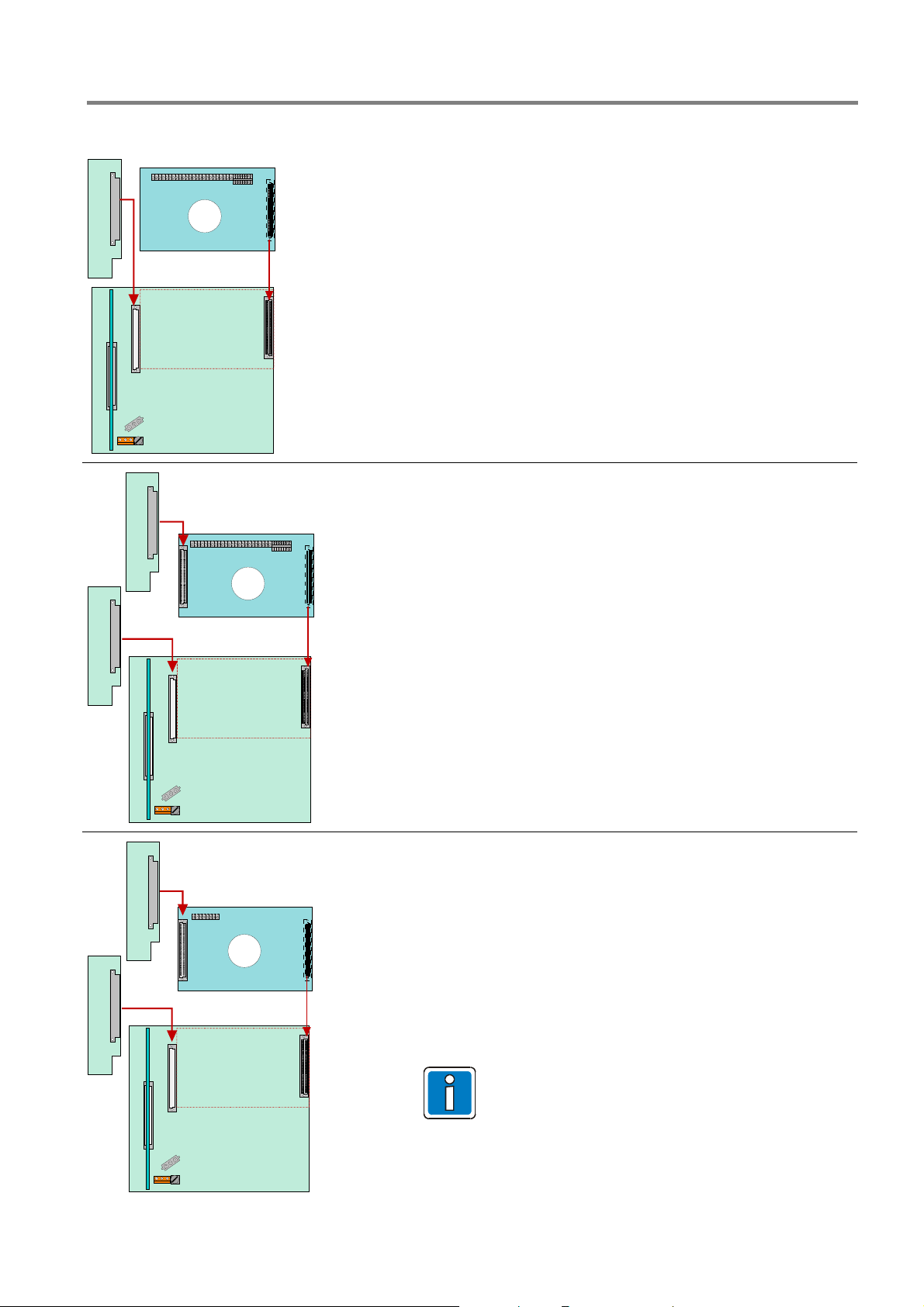

Example 1:

Basic module with a micro module and a Field device module

(Part No.772479 without micro module slot) on slot 1 of the

Basic module.

Application:

With this configuration, for example, a single control panel

with an analog loop and max. 127 bus devices can be

implemented.

Example 2:

Basic module with a micro module and a Field device module

(Part No.772477 with micro module slot) on slot 1 of the Basic

module

Application:

MM 1

MM 2

C

Connector 1

Connector 1

With this configuration, for example, a single control panel

with two analog loops and max. 254 bus devices can be

implemented

or

This configuration is usually employed in essernet

with an analog loop and max. 127 bus devices.

Example 3:

Basic module with a micro module and a Extension module

(Part No.772478 ) on slot 1 of the Basic module.

Application:

This configuration is usually employed in essernet

with an analog loop and max. 127 bus devices.

Without the Field device module, no connection is

available for the fire department key pad and the

master box. These devices can be connected to a

different control panel of the essernet

®

networks

®

networks

®

.

Fig. 5: Configuration FACP IQ8Control C

FB 798951.GB0 / 01.09

11

Fire Alarm Control Panel IQ8Control C/M

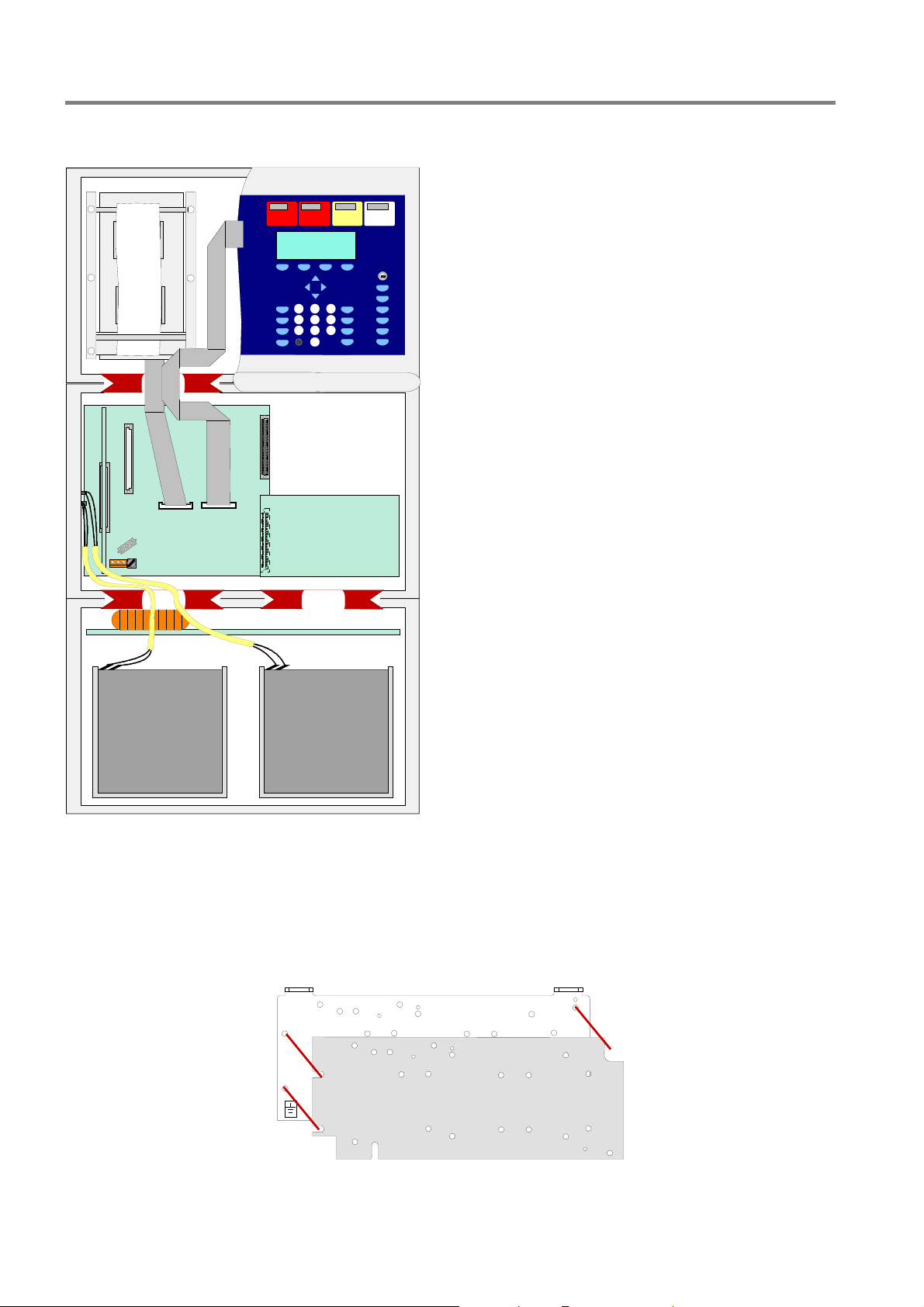

3.3 FACP IQ8Control M

The configuration of the FACP IQ8Control C includes:

1 Basic module

1 Power supply module

1 Field device module or 1 Extension module 1

or

max. 2 Extension modules - each with three micro

module slots

In this full configuration, a total number of slots for 7

(3 + 3 + 1) freely selectable micro module are available.

A B C

1

Slot 1

On the Basic module only the upper slot (slot 1) can be

used for a Field device or Extension module.

The Field device module must be installed in Slot 1 of

the Basic module.

Slot 2

The lower slot (slot 2) can be used for a Extension

D

module only.

Field device module Part No.772479

A

Field device module with one

B

additional micro module slots

Extension module with one

C

additional micro module slots

Extension module with three

D

additional micro module slots

Part No.772477

Part No.772478

Part No.772476

Connector 1Connector 2

2

D

Fig. 6: Configuration FACP IQ8Control M

12 FB 798951.GB0 / 01.09

Example: Configuration of FACP IQ8Control M

Fire Alarm Control Panel IQ8Control C/M

Example 1:

MM 1

MM 2

A

Basic module with a Field device module

MM 4

(without micro module slot) on slot 1 and one

Extension module (with 3 micro module slots)

MM 3

on slot 2.

MM 2

Connector 1

Application:

With this configuration, e.g. a single control

panel with 4 analog loops and max. 508 bus

D

Connector 2

devices can be implemented.

Field device module (Part No.772479)

A

Extension module with three additional micro

D

module slots (Part No.772476)

Example 2:

MM 1

B

D

Connector 2 Connector 1

Fig. 7: Configuration FACP IQ8Control M

MM 3

MM 4

MM 5

Basic module with a Field device module

(without micro module slot) on slot 1 and one

Extension module (with 3 micro module slots)

on slot 2.

Application:

With this configuration, e.g. a single control

panel with 5 analog loops and max. 635 bus

devices can be implemented

Field device module with 1 additional micro

B

module slot (Part No.772477)

Extension module with three additional micro

D

module slots (Part No.772476)

FB 798951.GB0 / 01.09

13

Fire Alarm Control Panel IQ8Control C/M

Example: Configuration of FACP IQ8Control M

MM 2

MM 1

C

MM 4

MM 3

D

Connector 2 Connector 1

MM 5

Example 3:

Basic module with a Field device module

(without micro module slot) on slot 1 and

one Extension module (with 3 micro module

slots) on slot 2.

Application:

With this configuration, e.g. a security

network panel with 4 analog loops and max.

508 bus devices can be implemented.

Extension module with one additional micro

C

module slot (Part No.772478)

MM 1

Extension module with three additional micro

D

module slots (Part No.772476)

MM 4

MM 3

MM 2

Example 4:

Basic module with two Extension modules

(with 3 micro module slots) on slot 1 + 2.

Application:

With this configuration, e.g. a security

network panel with 6 analog loops and max.

D

762 bus devices can be implemented.

Extension module with three additional micro

D

module slots (Part No.772476)

D

Connector 2 Connector 1

MM 5

MM 6

MM 7

Fig. 8: Configuration FACP IQ8Control M

install Field device and Extension modules series 01 FACP 8000 C/M (Part No. 772418, 772419,

Do not

772420, 772421) at FACP IQ8Control C/M.

14 FB 798951.GB0 / 01.09

Fire Alarm Control Panel IQ8Control C/M

Three part housing with integrated printer

The integrated printer and the operating module front are mounted in the upper housing. Due to the depth of the

printer, the Basic module and all of the plug-in cards are integrated into a separate housing beneath. The

emergency power supply with max. two 24Ah batteries can be installed into the lowest housings.

Extension housing 789304

or

Extension housing 789303

Fig. 9: Three part housing with integrated printer

Assembly area for esserbus® transponders

1

1

2

Fig. 10: Location of the components in a three part housing

Ensure that the arrangement of the assemblies corresponds with the presentation shown here during

this configuration. Another distribution is not

front, the integrated printer and the battery connection cable.

3

4

c

Basic module / power supply module /

d

slot for micro module

Alternatively Field device module

e

(without micro module slot)

or Field device module (with 1 micro module slot)

or Extension module (with 1 micro module slot)

or Extension module (with 3 micro module slots)

on slot 1

Extension module (with 3 micro module slots)

f

on slot 2

Part No. 772479

Part No. 772477

Part No. 772478

Part No. 772476

Part No. 772476

possible due to the cable length of the operating module

FB 798951.GB0 / 01.09

15

Fire Alarm Control Panel IQ8Control C/M

Location of the components in a three part FACP housing IQ8Control M

Fig. 11: Location of the components in a three part housing

Mounting plate for master boxes DS 7500 / DS 8800

The mounting plate (Part No. 057633) allows installation of two esserbus

®

transponders or one master box Type

DS 7500 / DS 8800 in the extension housing (Part No. 789303).

Protect the devices against short circuits with the metal mounting plate with the plastic spacers and the

insulation foil.

Mounting plate

Insulation foil

Fig. 12: Mounting plate (Part No. 057633)

16 FB 798951.GB0 / 01.09

Fire Alarm Control Panel IQ8Control C/M

3.4 Definition of the Primary loop number

Individual assemblies of the FACP IQ8Control can be switched on/off with the internal primary loop number

through the control panel keyboard or programmed with programming software . This internal primary loop

number is composed of the control panel number, the slot and the assembly number.

Example: Stand-alone FACP (= Panel No. 01)

0113 0123 0133

0132

0131

Fig. 13: FACP IQ8Control

0 1 X X

2

1

3

Subassembly number of the Basic-, Field device or Extension module

(ref. follow pages)

Slot number: Basic module = No. 1

Basic module Slot 1 = No. 2

Basic module Slot 2 = No. 3

(only FACP IQ8Control M)

Number of the Fire Alarm Control Panel

Stand-alone FACP = 01

Security network FACP = 01 - 31

FB 798951.GB0 / 01.09

17

Fire Alarm Control Panel IQ8Control C/M

Example: Primary Loop No. (Panel No. 01)

Primary Loop No. Subassembly

Basic module

0111

0112

0113

Field device module

0121

0122

0123

0124

Extension module with 1 micro module slot Part No. 772478

---

---

0123

---

Common Fault Relay (SaS-Relay)

Interface - RS485-1 or TTY

Micro module slot

Relay K2, K3 and K4

Master box (MB) Relay K1

Micro module slot (only module Part No. 772477)

Internal primary loop

no module available

no module available

Micro module slot

no module available

Position of modules

Connector 1Connector 2

Connector 1

Extension module

(only IQ8Control M)

0121

0122

0123

Extension module

(only IQ8Control M)

0131

0132

0133

The Field device module (if available) must be installed in >Slot 1< of the Basic module.

>Slot 2< of the Basic module is unused on the FACP IQ8Control C.

with 3 micro module slots Part No. 772476

Micro module slot 1

Micro module slot 2

Micro module slot 3

with 3 micro module slots Part No. 772476

Micro module slot 1

Micro module slot 2

Micro module slot 3

Connector 1

Connector 2

18 FB 798951.GB0 / 01.09

Fire Alarm Control Panel IQ8Control C/M

3.5 Central housing

1. Remove the central housing of the FACP IQ8Control from the box.

The cover contact and both connecting cables for the rechargeable batteries have already been attached to

the Basic module.

2. Pull the ribbon cable of the operating module and of the built-in printer (if present) off the connectors of the

Basic module.

3. Remove the four connecting screws between the base plate and the housing frame which were screwed in

for transport.

4. The housing door (operating module and variants) has already been connected to the housing frame at the

factory. To detach the housing door from the housing frame, pull out both retaining pins of the housing door

holder.

5. The housing must be mounted on a stable, clean and dry wall surface without mechanical stress. The

function of the snap-type connection for the housing door can be impaired if the housing is not correctly

mounted.

Only flat-head screws and dowels with a diameter of 8 mm should be used to secure the central unit’s

housing. Here, make sure that the screw head fits into the hole of the wall compensation element and does

not project.

6. To compensate for slight wall unevenness, you can screw the four wall compensation pieces of the base

plate in or out. The central unit’s additional pack contains a special spanner for the adjusting the wall

compensation elements.

The three unused fastening points between the base plate and the housing frame are not necessary on the

FACP IQ8Control C/M. This fastening is intended for a different housing use.

Danger - Electrical shock !

Disconnect all power from the panel before carrying out any installation work. The panel may only be

operated while the cabinet is closed. Operation is not allowed while the cabinet is open.

Risk of short circuit

All voltage and signal lines connected to the Basic module must be secured to prevent slipping by

using a suitable attachment materials such as plastic cable binders. Make sure the voltage cable will

not move and touch the signal lines (SELV). Work on the FACP IQ8Control may only be carried out

when it is de-energised (mains and emergency power supply).

FB 798951.GB0 / 01.09

19

Fire Alarm Control Panel IQ8Control C/M

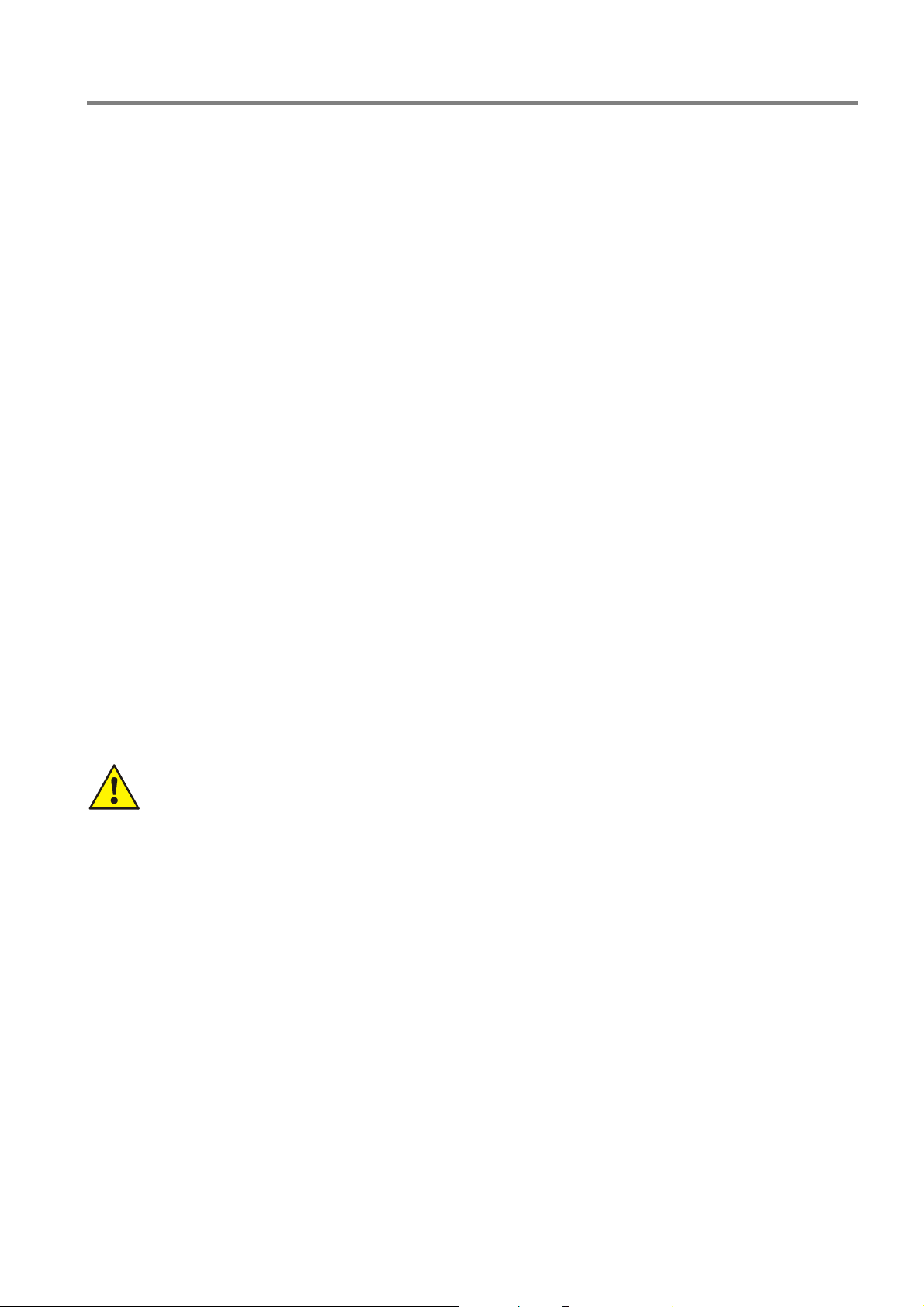

3.6 Assembly

The housing is pre-assembled by factory delivery. To ease the further assembling and mounting please observe

the given mounting sequence.

1

2

3

Fig. 14: Exploded illustration

c

d

e

f

g

h

i

4x wall compensation pieces

1 x Metal sheet of the base plate for shielding and the PE connection (functional earth)

1x rear panel

1x back box

1x housing contact (up to four contacts possible)

1x front frame with operating module and housing door

4x connecting screws

The Basic module is connected to the central housing’s rear metal panel via the metal spacers and

the metal screws. Without this electrically conductive connection between the Basic module and the

rear metal panel, sufficient EMC protection for the FACP IQ8Control is not guaranteed.

4

5

7

6

20 FB 798951.GB0 / 01.09

Fire Alarm Control Panel IQ8Control C/M

Operating module / Housing door

The operating module/the housing door is installed by the manufacturer on the front housing part. If required for

dismantling, loosen the 4 fixing screws and remove the front part of the housing.

Depending on the panel configuration, e.g. with or without an installed printer or an individual zone display,

deviation from the illustration here is possible.

For correct ESD protection it is highly

recommended to insert the dummy plug

123

456

789

0

(insert pack) of the programming interface

plug into front of the operation panel.

8

Fig. 15: Operating module / Housing doo

The operating module is not required for programming the FACP IQ8Control. The service PC can

also be directly connected to the programming connector of the Basic module. Using the service

program TEDIS (optional) enables the operating module to be completely simulated on the service

PC with all functions.

Opening

The front door key is always required to open the housing front.

It can be opened with the key vertical

Closing

To close the front door, the lock must be in the horizontal position. The key is not

required. The front door can

simply be pushed closed and engaged in the snap-type fastener.

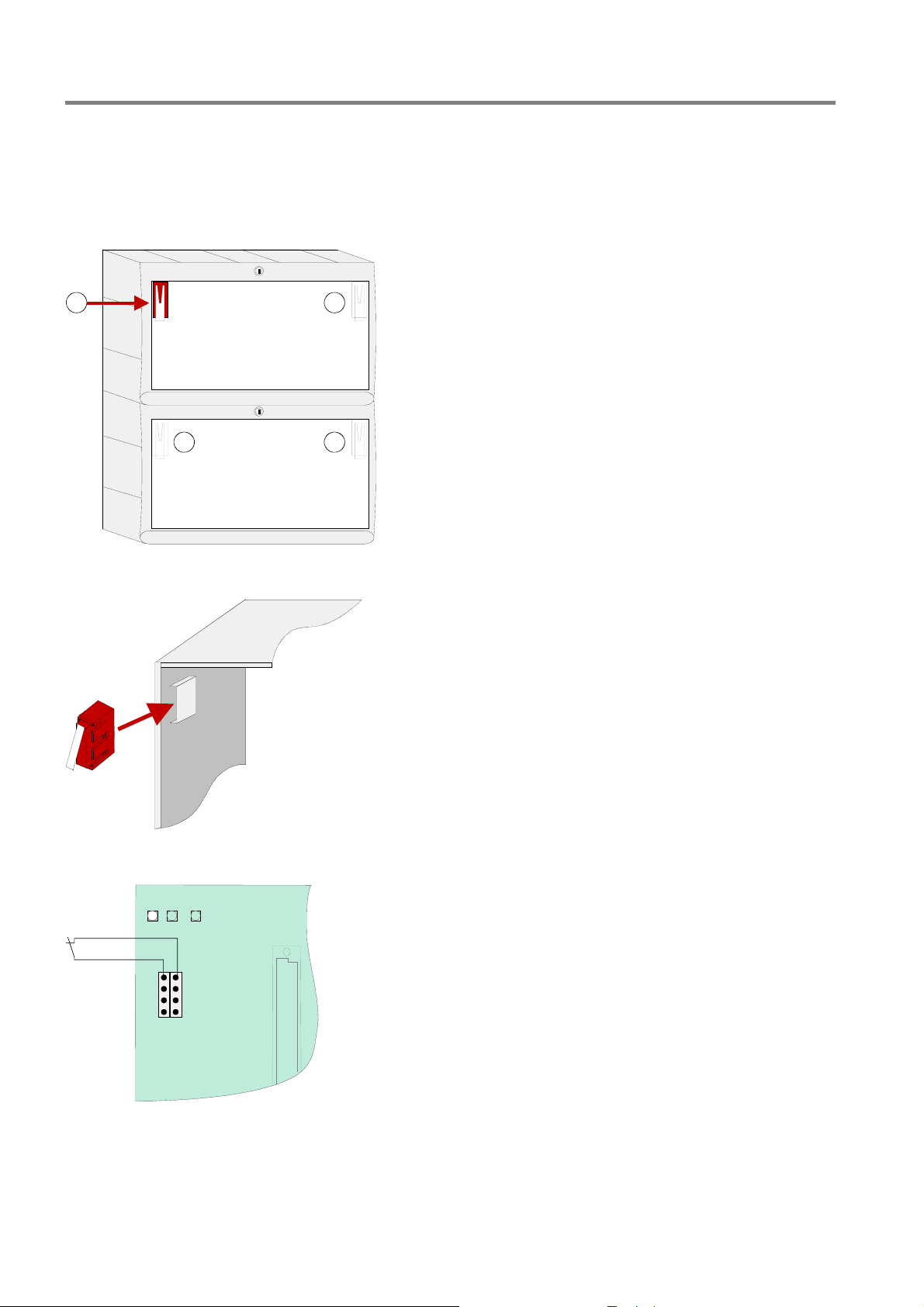

Example: Housing IQ8Control C

1. Place front frame with integrated door carefully onto the back box.

Take care to ensure that no cables are pinched or damaged when installing or removing the assembly.

2. Insert the four screws between the back box and the front frame and tighten carefully.

3. Insert housing contact in the upper place of the housing with the contact tab downwards. The contact is

connected to the Basic module by factory settings and may be removed for service or maintenance work.

4. Connect the ribbon cable of the operation panel to the corresponding connector on the Basic module.

5. This completes assembly of the housing

FB 798951.GB0 / 01.09

21

Fire Alarm Control Panel IQ8Control C/M

Housing contact

The housing contact provides the monitoring of the panels housing and may be used additionally for control

function by means of service or maintenance work, e.g. to disconnect devices whilst the contact is open.

Max. 2 contacts per housing

(1 integrated contact by factory configuration)

1 1

Max. 4 contacts per FACP

Select contact operation via the panels data

configuration, e.g.

- Disconnect master box whilst open contact

- Access of Service-PC whilst open contact

- und additional features

11

The housing contact must be place to the appropriate

insert on the top corner of the housing.

Housing contact / contact tab points downwards

Housi ng

open

V2

8

7

6

5

X7 X8

1

2

3

4

Housing contact

Connect to Basic module

(refer to section “Basic module”)

Fig. 16: Housing contact

22 FB 798951.GB0 / 01.09

Fire Alarm Control Panel IQ8Control C/M

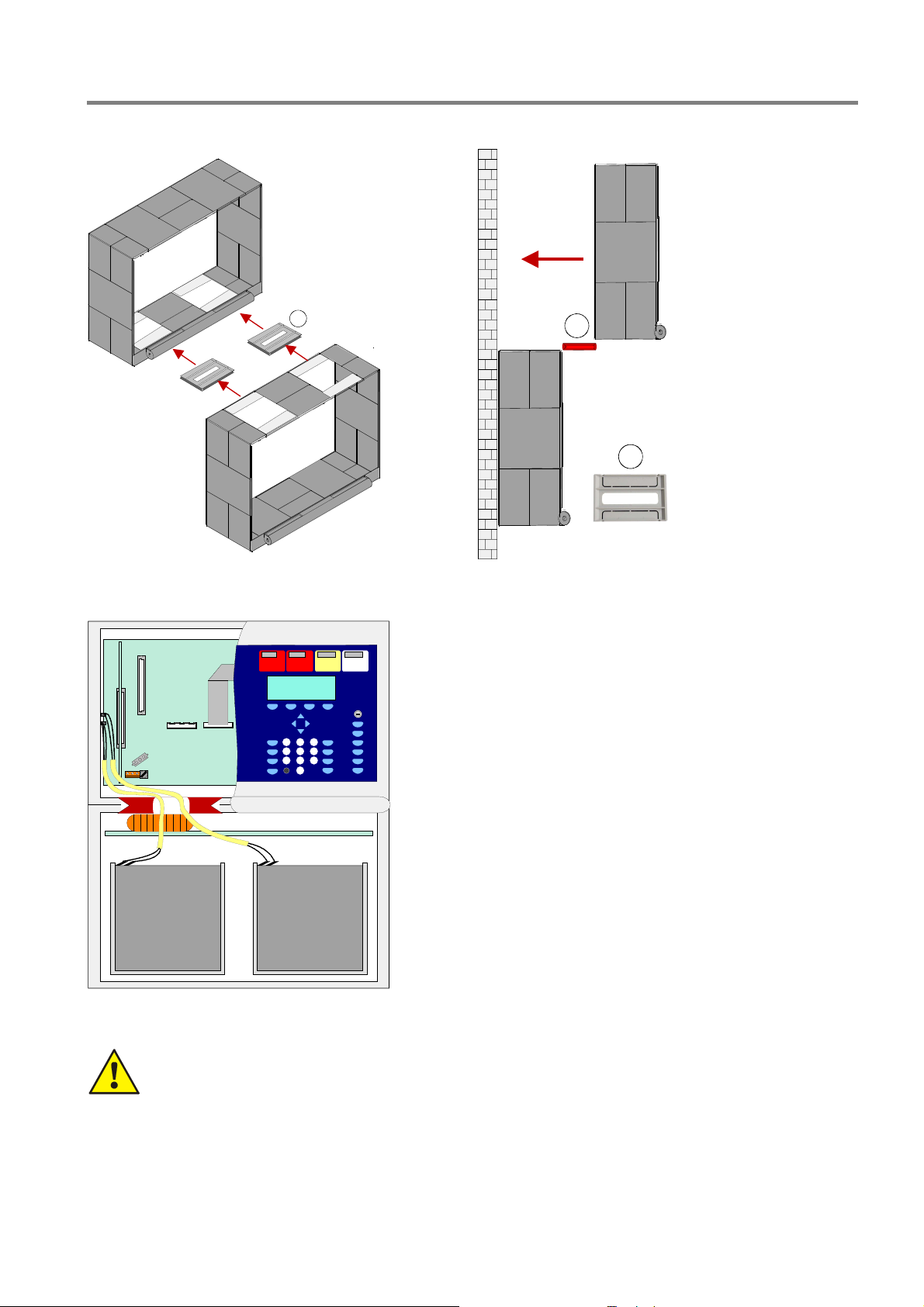

Connection between the central housing and the extension housing

1

1. Remove the appropriate 2 plastic plates from

panels and extension housing

2. Push the plastic connector bracket in each

originated gap. Observe the arrows on the bracket

for the right direction.

1

1

2x connection pieces

with cable glands

Fig. 17: Knockouts for battery cable

Damage to the system!

Take care to ensure that no cables are pinched or damaged.

Each housing part must be separately fixed to the mounting place. The plastic connection brackets are

not suited to carry the weight of the lower housing alone.

3. Push the upper housing via the guide way of the

brackets towards the wall.

4. Align both connection brackets to ensure that the

cables between the housings may be lead through

the openings of the brackets.

5. Each housing must be fixed with suited screws

(4x) and dowels without twisting stress.

FB 798951.GB0 / 01.09

23

Fire Alarm Control Panel IQ8Control C/M

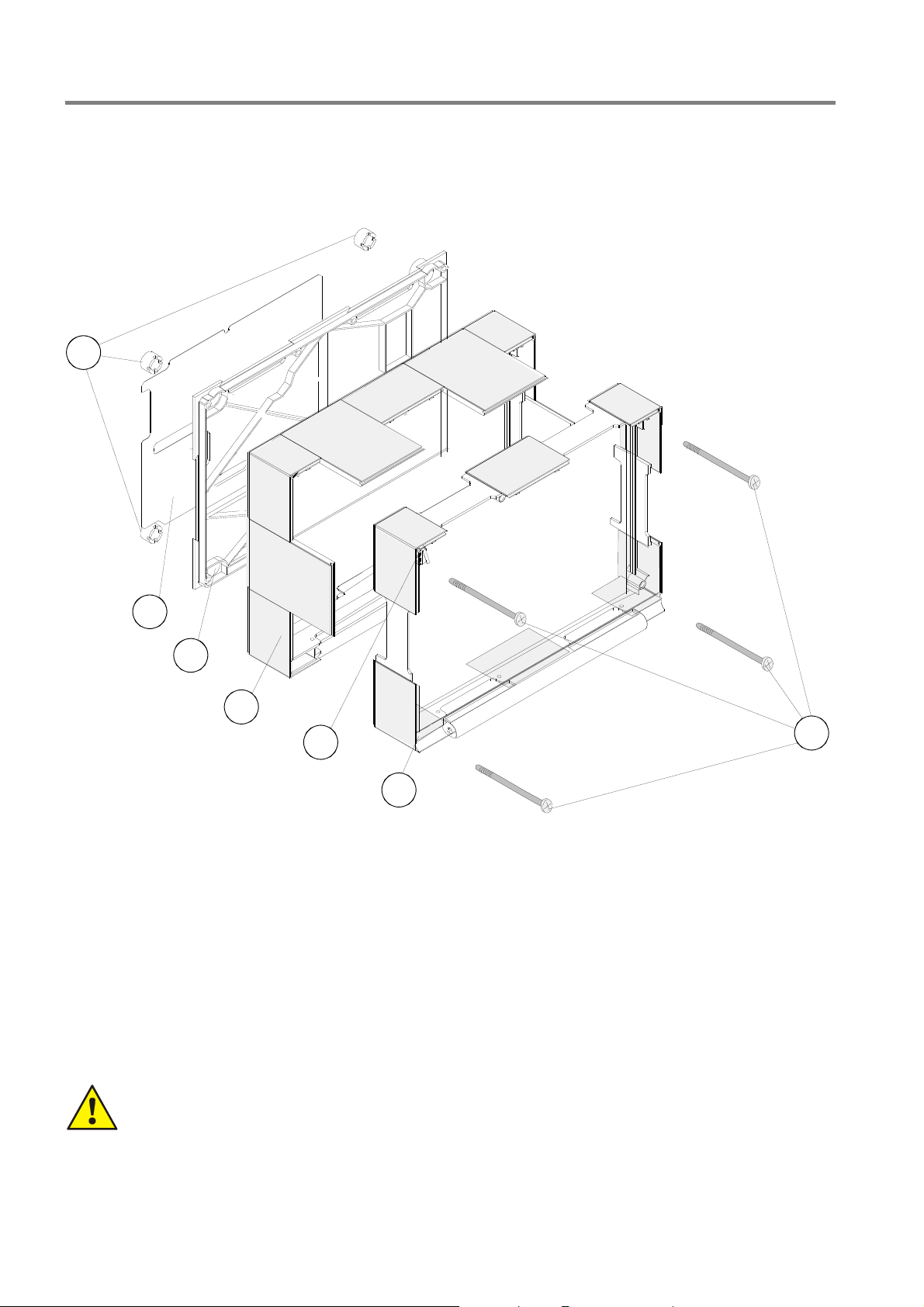

Wall mounting

The panel must be mounted on a flat surface using appropriate hardware (screws and dowels). Avoid

mechanical stressing. It may only be commissioned after correct mounting on a wall or other mounting surface

of sufficient strength to support the weight of the unit. Minor unevenness of the mounting surface may be

adjusted by the wall compensation device. Apply the delivered key tool from the inside of the housing to adjust

the wall compensation devices.

1

Fig. 18: Rear side of the Standard back box

Fig. 19: Wall compensation element for adjusting and key tool

Damage to the system !

Please note that depending on the rechargeable batteries used, a significant weight must be

supported by the fastening screws of the extension housing.

Plastic key is enclosed.

24 FB 798951.GB0 / 01.09

Fire Alarm Control Panel IQ8Control C/M

3.7 Cable glands

Lead the 230V main power cord through the wall and the cable entry c provided in the rear of the unit (see

illustration). Fasten it using appropriate devices, e.g. plastic cable straps.

Make sure that the mains and signal cables don’t interfere with the rear panel of the cabinet or the cabinet frame

which is mounted on the rear panel.

Signal cables must only be led through the other cable entries

IQ8Control C

d.

IQ8Control M

1

Fig. 20: Cable glands

Danger - Electrical shock !

Disconnect all power from the panel before carrying out any installation work. The panel may only be

operated while the cabinet is closed. Operation is not allowed while the cabinet is open.

Risk of short circuit

All voltage and signal lines connected to the Basic module must be secured to prevent slipping by

using a suitable attachment materials such as plastic cable binders. Make sure the voltage cable will

not move and touch the signal lines (SELV). Work on the FACP IQ8Control may only be carried out

when it is de-energised (mains and emergency power supply).

Insulation of connecting cable

Make sure to lead all cables complete with their outer sheaths intact into the cabinet. Only remove the

insulation from those sections which are inside the cabinet.

3.8 Panel buzzer

2

1

2

If required the internal panel buzzer may be disabled with the solder jumper BR2 on the rear side of the

operating panel PCB.

BR2

BR2

closed, buzzer enabled (factory setting)

BR2

open, buzzer disabled

If the buzzer is permanently disabled (BR2 open), the transmission of this audible warning signal to

must be ensured (e.g. by indicating this condition at a panel within the network)!

FB 798951.GB0 / 01.09 25

Fire Alarm Control Panel IQ8Control C/M

4 Module

The FACP IQ8Control C / M has a modular design so that modules can be replaced/extended at any time.

Only remove or insert modules when the FACP is voltage free.

Switch off the power and battery supply.

Wait for at least 10 seconds before the modules are replaced or supplemented.

Take suitable measures to discharge static electricity.

Check correct installation (modules and connection cables).

Switch on the power and battery supply.

If necessary, check/supplement the customer data using the programming software tools

8000.

4.1 Power supply module (Part No. 802426 index G or higher)

The power supply module is installed on the Basic module of the FACP. This module accommodates the entire

voltage supply for the Fire Alarm Control Panel and the +12 V DC supply voltage for external devices. Maximum

current load from external users will depend on control panel configuration. If necessary, additional supply is

possible from a monitored external power supply unit. The power supply module is suited to connect 2 batteries

(2 x 12 V / 24 Ah). In case of an AC power (230 V DC) loss the panel operation will be supplied without

discontinuation (refer chapter 4.1.3).

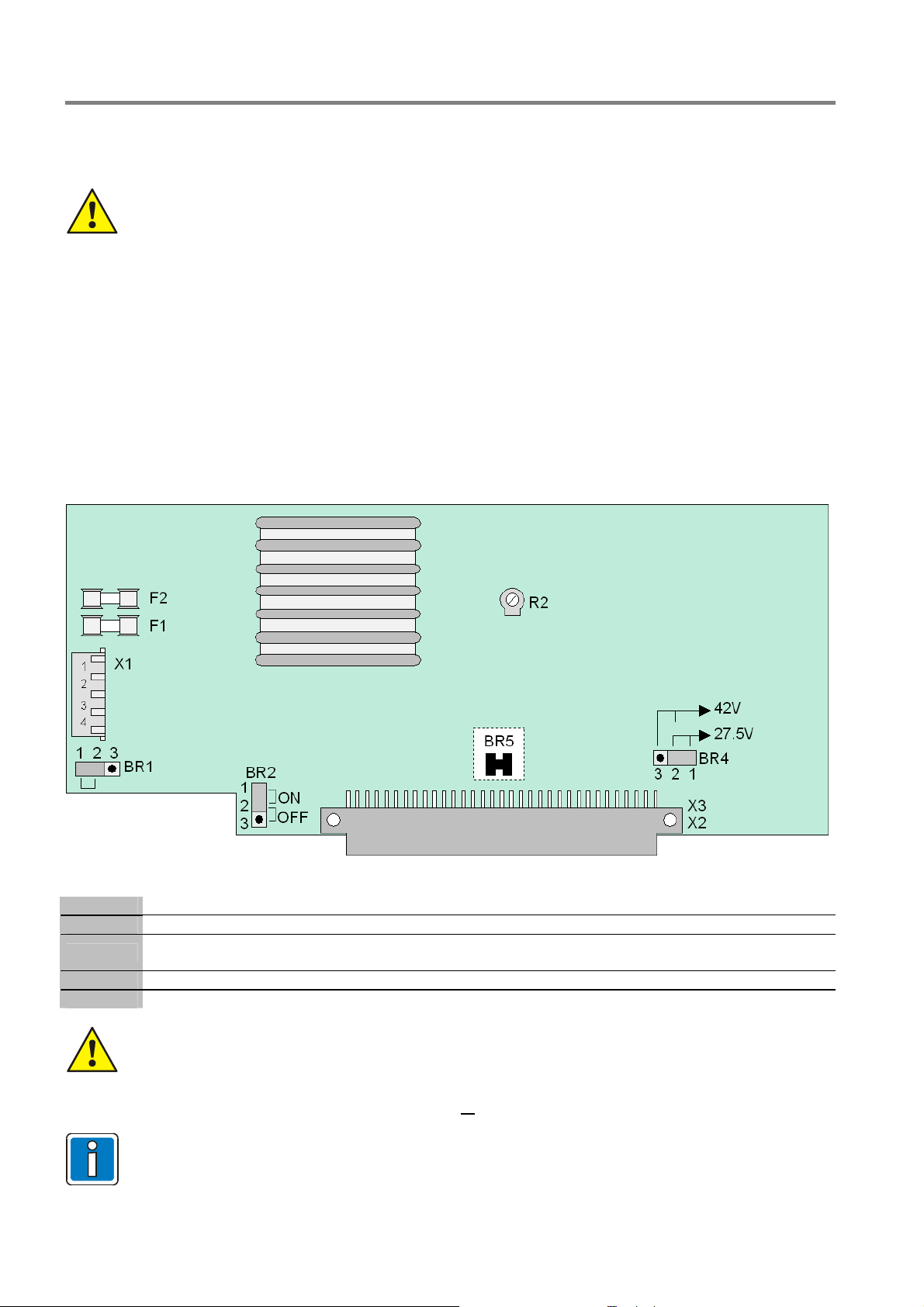

Fig. 21: Power supply module (Part No. 802426 from index G)

X1

X 2/3

F1

F2

R 2

Plug connector for transformer (secondary)

Basic module connector

Fuse for the FACP internal power supply: T 4 A

to the analog loop 27,5 V (esserbus

Fuse for secondary side: T 5 A

Potentiometer for adjusting the battery charging voltage to +13.65 V DC (@ 25 °C)

The power supply module must only be installed or removed with the Fire Alarm Control Panel in a

de-energised state.

When you are installing or replacing the power supply module, observe the BR5 solder

bridge/jumper (on the rear side of the circuit board). This jumper is used to set whether the power

supply unit is installed in an FACP 8000C/M or

this could damage the Fire Alarm Control Panel or the power supply unit.

The battery charging voltage is set to the abovementioned values by the manufacturer. If the FACP

is used at other ambient temperatures (refer to technical data), then the battery charging voltage

must be adjusted accordingly using potentiometer R2.

®

) or 42 V (esserbus® PLus)

an IQ8Control C/M. If the jumper is set incorrectly,

26 FB 798951.GB0 / 01.09

Earth fault monitoring

Fire Alarm Control Panel IQ8Control C/M

BR 1

Earth fault monitoring enabled (factory default = ON)

Earth fault monitoring disabled (not VdS appropriate)

Information for powered loop systems

In case of an earth fault with +U

message "U

<" will be displayed for each analog loop. In the alarm condition, the zone voltage

zone

is lower than the required 42 V. The audible alarm loop device may not sound an alarm at full

volume.

Undervoltage protection (U

BR2

Undervoltage protection activated (factory setting = ON)

The panel switches off automatically if, in case of charging, the

battery voltage is

Under voltage protection disabled

< 9,5 V DC)

Batt

9.5 DC.

ON

1 2 3

OFF

1 2 3

a ground fault message occurs and additionally the fault

zone

1

ON

2

3

1

2

OFF

3

Selection of the analog loop voltage

BR 4

esserbus® System with 27,5 V analog loop voltage

esserbus® PLus System with 42 V analog loop voltage

esserbus

devices with Part No.

®

PLus module Part No. 804382 and appropriate loop

80xxxx required

Damage to the system !

Mixed operation with esserbus® and esserbus® PLus functionality is not possible!

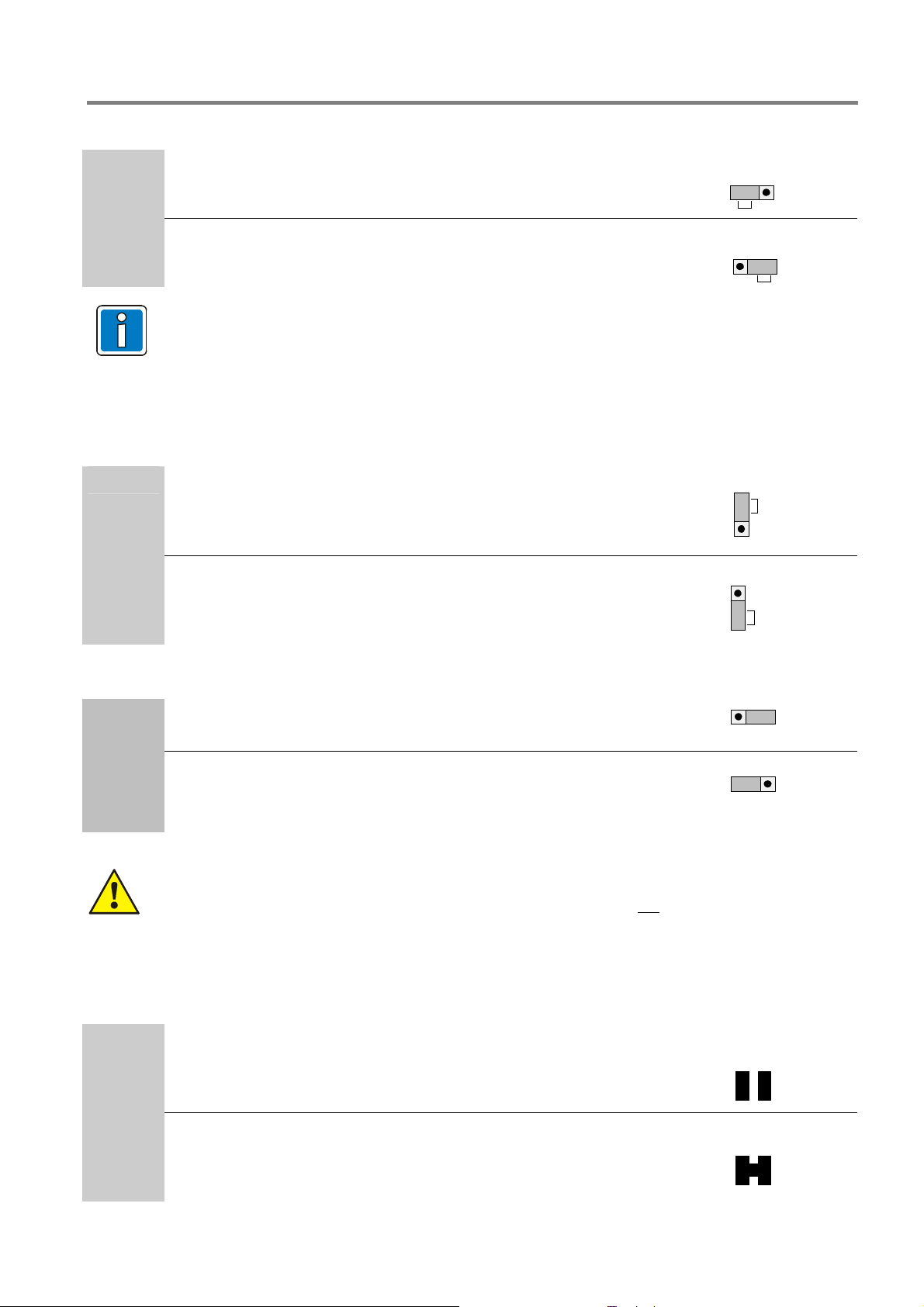

Selection of the Fire Alarm Control Panel

Solder jumper on the rear side of the PCP to select the CPU power supply voltage.

BR5

Factory default of a separately delivered power supply module

(Prepared for mounting in the FACP 8000 C / M)

3 2 1

3 2 1

BR5

Operation in FACP IQ8Control C/M Î Jumper BR 5 closed

BR5

FB 798951.GB0 / 01.09 27

Fire Alarm Control Panel IQ8Control C/M

4.1.1 Mains connection and earth connections

L1

F1

T1.25A

H/230V~

X2

N

U

Main

230V~

N

Housing mantle

terminal

PE

L1

FE

Fig. 22: Connection of the rated voltage (230 V AC) and earth connections on the basic module

The mains supply must be installed in accordance with local regulations by a qualified technician. The AC

connection terminals are located on the Basic module.

Requirements

Use an appropriate mains cable, e.g. NYM 3 x 1.5 mm2 or a cable type with similar specifications.

The installation must comply with local regulations on electrical safety.

Overvoltage fine protection is integrated into the FACP according to EN 54 and the VdS guidelines. Should

coarse protection be required this should be installed by the installer for the specific object.

The fire alarm system must be supplied from the 230 V mains through a separate isolator or an

appropriately labelled safety switch. The required mains voltage (230 V AC) is given on the panels

nameplate.

In buildings fitted with earth fault devices (FI protection), a separate device must be installed for the fire

alarm system.

The fuse for the power supply of the fire alarm system must be clearly labelled with the red marking ‘FACP’.

Observe national standards and guidelines.

The protective earth conductor of the mains cable must be connected to the corresponding screw terminal

at the fire alarm panel (ref. to section Protective and Functional earth).

AC mains voltage

Cable corss section at least

> 4mm² to PE rail

The required mains voltage (230 V AC) is given on the panels nameplate.

Cable insulation

Make sure to lead all cables complete with their outer sheaths intact into the cabinet. Only remove the

insulation from those sections which are inside the cabinet!

Power supply

The fuses of the panel or external power supply units cannot prevent an unexpected fault in electrical

modules; rather, these fuses are intended to protect users and their surroundings from damage.

Therefore, never repair or bridge the fuse that is installed (e.g. T1A H/250V) or replace it with anything

other than the stated type!

28 FB 798951.GB0 / 01.09

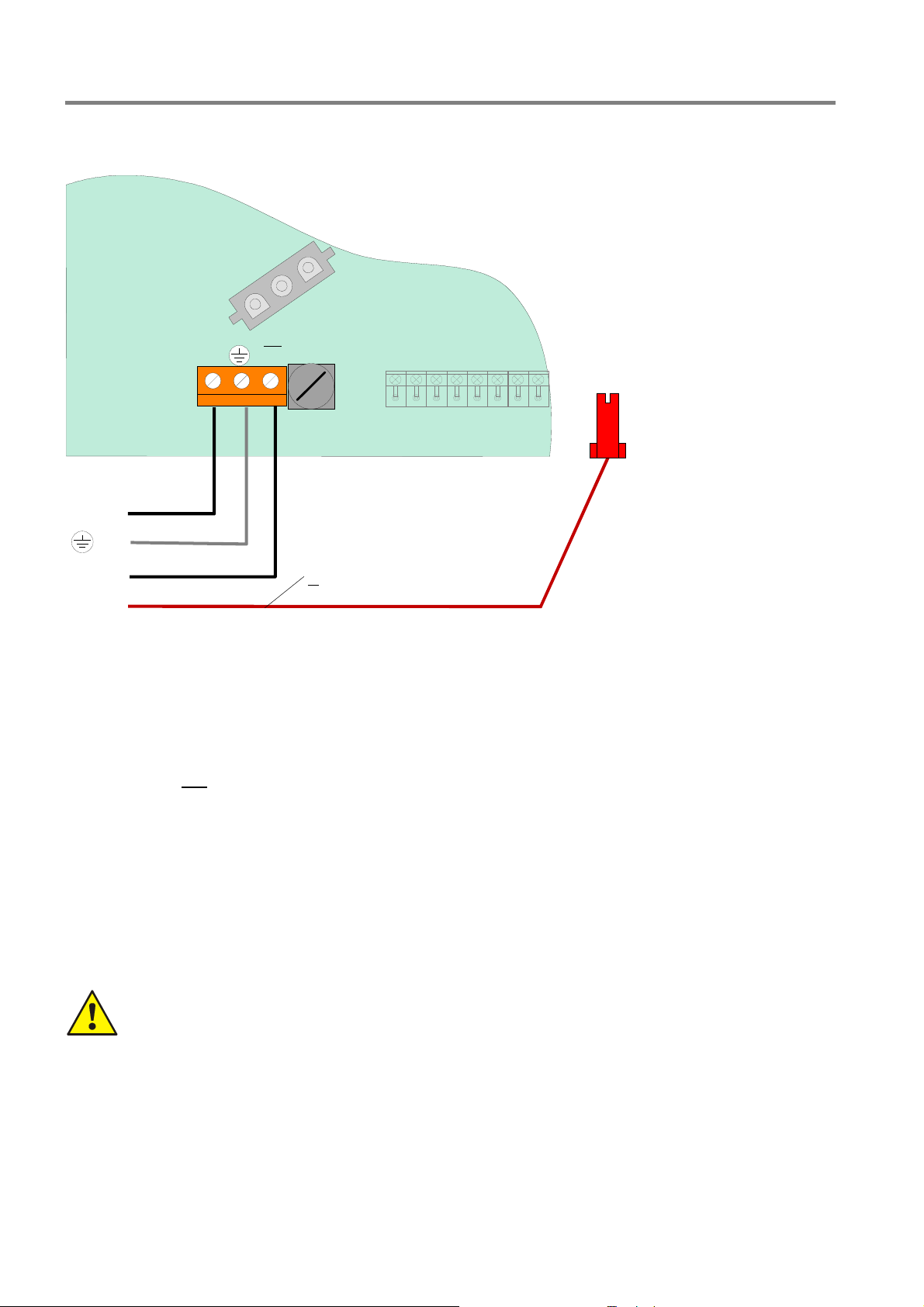

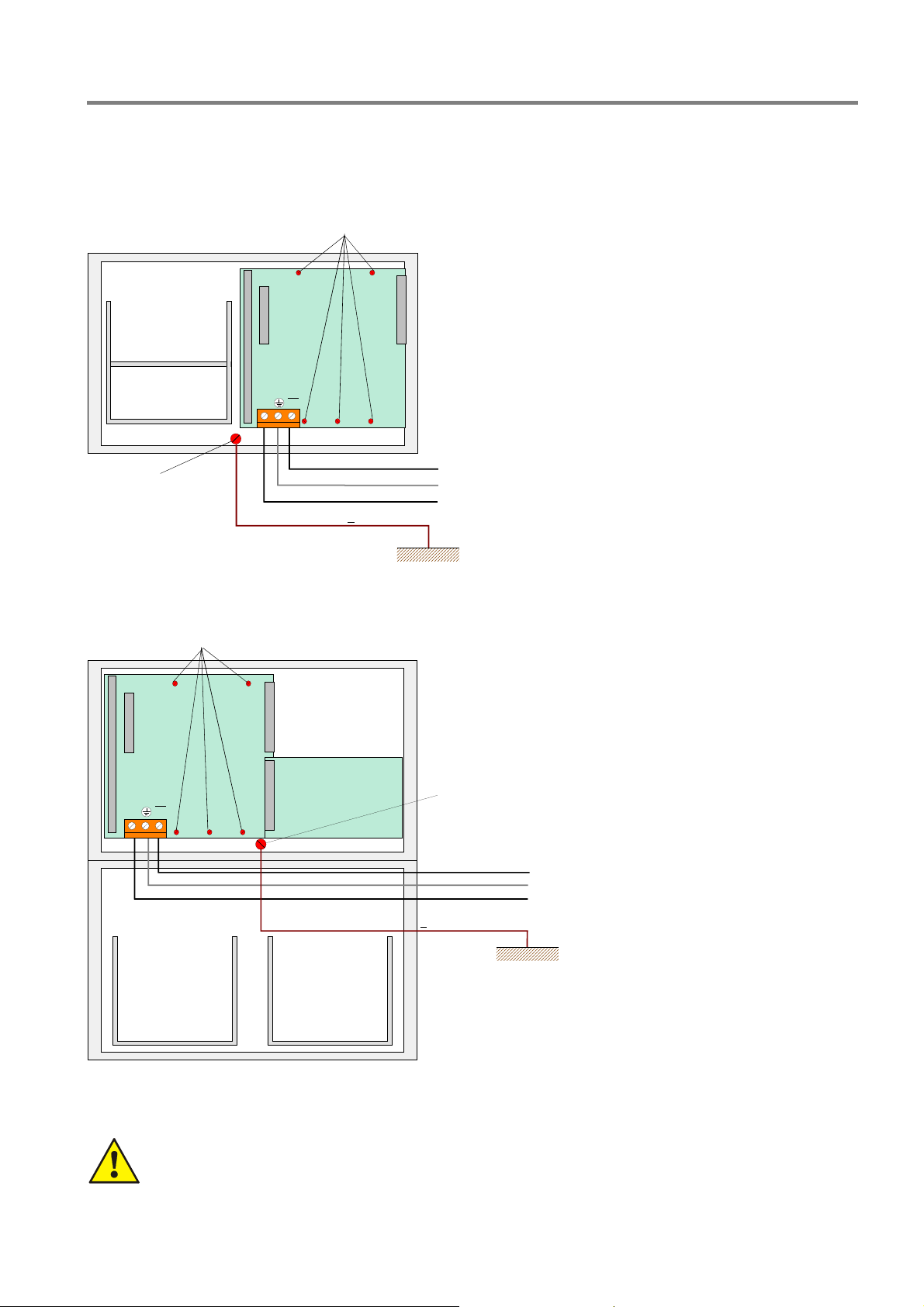

4.1.2 Protective and Functional earth

Fire Alarm Control Panel IQ8Control C/M

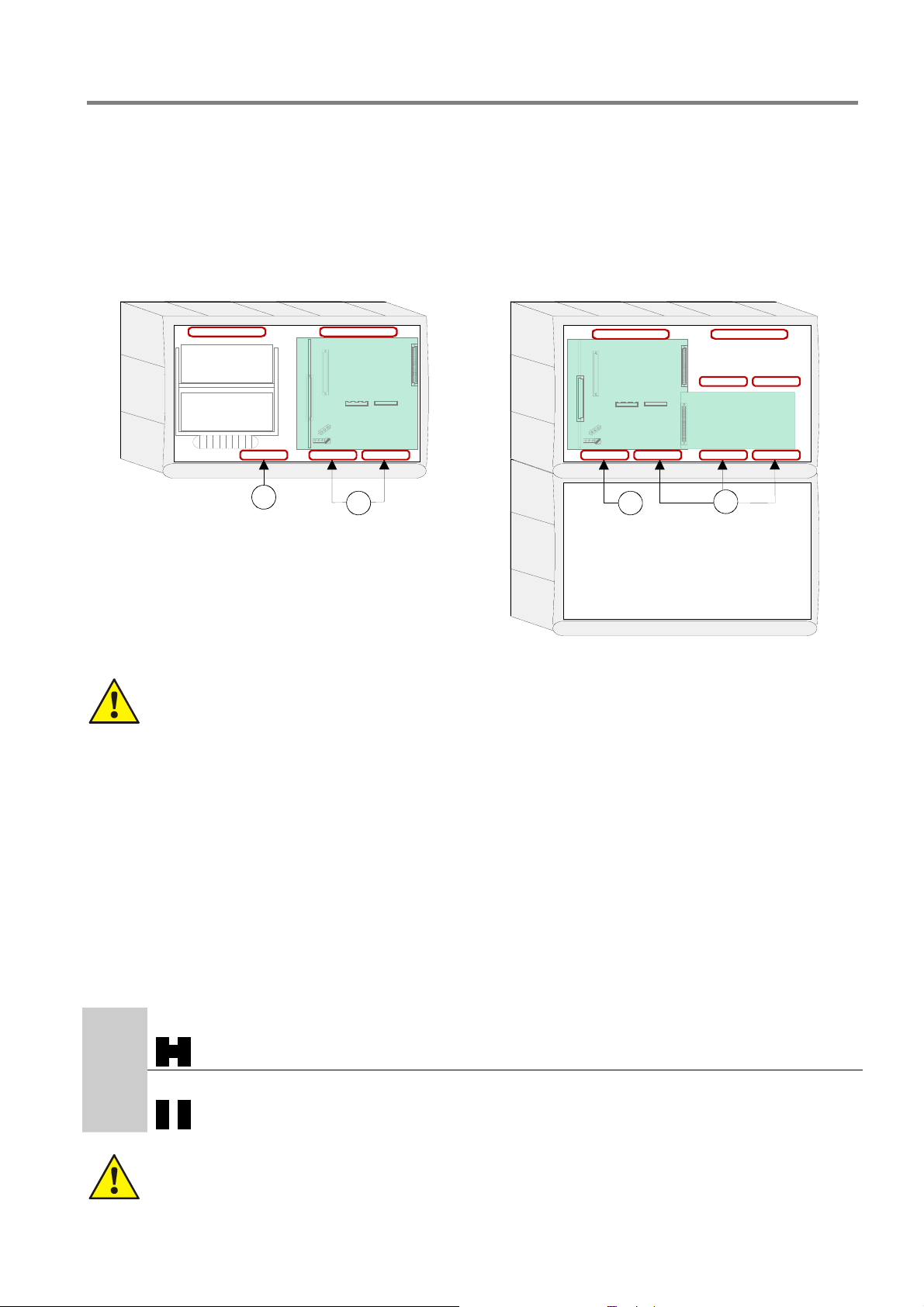

Wiring FACP IQ8Control C

rear wall plate of the central unit's housing

Battery bag 2

Battery bag 1

Housing mantle terminal

Basic

module

N

Cable cross section at least > 4mm² to PE rail

Wiring FACP IQ8Control M

Metal screws to the

rear wall plate of the central unit's housing

Metal screws to the

L1

U

L1

PE

N

FE

The primary PE-connection (protective

earth) of the mains supply must be

connected to the appropriate terminal of

the FACP to ensure a proper operation of

the system.

The FE (functional earth) and PE

(protective earth) terminals of the panel’s

housing must be connected with the PE

rail of the power distributor panel from

which the fire alarm system will be

powered.

Use copper cable with a cross section of

at least ≥ 4 mm

2

depending on the length

of the cable run.

The FACP IQ8Control is a protection

>class I DIN EN 60950< device.

Basic

module

L1

U

N

Battery bag 1

Fig. 23: Protective and Functional earth

The base module is connected to the rear panel of the cabinet by means of metal spacers and

screws. This electrically conducting connection between base module and rear panel is essential

for correct functional earthing of the FACP IQ8Control C/M.

Battery bag 2

Housing mantle terminal

Cable cross section at least

> 4mm² to PE rail

L1

PE

N

FE

FB 798951.GB0 / 01.09 29

Fire Alarm Control Panel IQ8Control C/M

Several alarm circuits on one power supply unit

If several visual/acoustic alarm devices are switched on e.g. via the 3 relay micro module (part no.

787531), 4 relay micro module (part no. 787530), the 4 zone/2 relay esserbus

no. 808613/808613.10) or the 12 relay esserbus

their power supply is provided by a joint power supply unit

®

transponder (part no. 808610/808610.10) and

, then the installer must ensure that there

®

transponder (part

is a staggered backup concept.

As a rule, several fuses with different fuse values and different response characteristics are

connected in series. The response behaviour also always depends on the preload of the fuses.

In order to carry out this wiring according to the standard, it must be ensured that in the case of a

short circuit, it is not the power supply unit fuse that responds but instead a fuse for the respective

alarm area.

It is thefore paramount

that every single alarm area is protected via a separate external fuse. The

8-fold fuse card (part no. 382040), for example, can be used for this purpose.

The fuse values depend on the number and type of the devices used and must always be

determined for the specific object.

Recommendation: Small fuse value

¼ quick response behaviour.

4.1.3 Emergency power supply

In case of loss of the mains voltage the control panel will be powered without a interruption by the connected

battery. Depending on the capacity of the battery a backup time of up to 72 hours can be realised. After that

time the external alarm devices must be still operable in an alarm condition. The activation of these devices

must be still possible with a minimum battery voltage of 10.5V DC.

First Commissioning

New batteries must be charged at least 24 hours before operation. If the date of manufacturing is dated back

about more than 9 month a battery charge time of min. 48 hours is required.

Deep discharging

The power supply unit periodically monitors the charge of the batteries connected. If this battery test reveals a

battery voltage of below 10.0 V DC under load, battery trouble will be signalled. The battery charge is controlled

by means of a temperature-dependent resistor (NTC). As soon as the voltage of the batteries goes below 9.5V

the battery backup will get disconnected to protect the control panel. The control panel is no longer operational!

Eliminate the trouble condition of the mains power supply and turn/switch on the control panel. The connected

batteries will get charged automatically if the voltage of the batteries during the battery test without external load

is higher than 10.5V DC. A battery failure will be indicated if the voltage of the batteries does not exceed this

level. Discharged batteries have to be recharged with an external power supply or need to be replaced. This

Function can be enabled / disabled with the

jumper BR2 on the basic circuit board.

Exhausted batteries (off-load voltage U

< 10,0V DC) will not charge correctly!

battery

Only the battery types approved by the Esser by Honeywell Fire Alarm Control Panel may be used

for supplying the Fire Alarm Control Panels with backup power. Observe the information and

technical specifications of the battery manufacturer and the VdS-guidelines for deep charged

batteries.

30 FB 798951.GB0 / 01.09

Loading...

Loading...