Honeywell Integrated Pressure Transducer

IPT User’s Manual

ADS-14152 Rev. 7/16

Customer Service Email: quotes@honeywell.com

www.pressuresensing.com

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or mechanical, including

photocopying and recording, for any purpose, without the express written permission of Honeywell, Inc.

Honeywell reserves the right to make changes to improve reliability, function or design. Honeywell does not assume any

liability arising out of the application or use of any product or circuit described herein; neither does it convey any license

under its patent rights nor the rights of others.

2

IPT User’s Manual Contents

1 Introduction ..................................................................................................................................................... 4

1.1 Overview .................................................................................................................................................. 4

2 Specifications ................................................................................................................................................. 4

2.1 Block Diagram ................................................................................................................................ ......... 4

2.2 Specifications/Performance ..................................................................................................................... 5

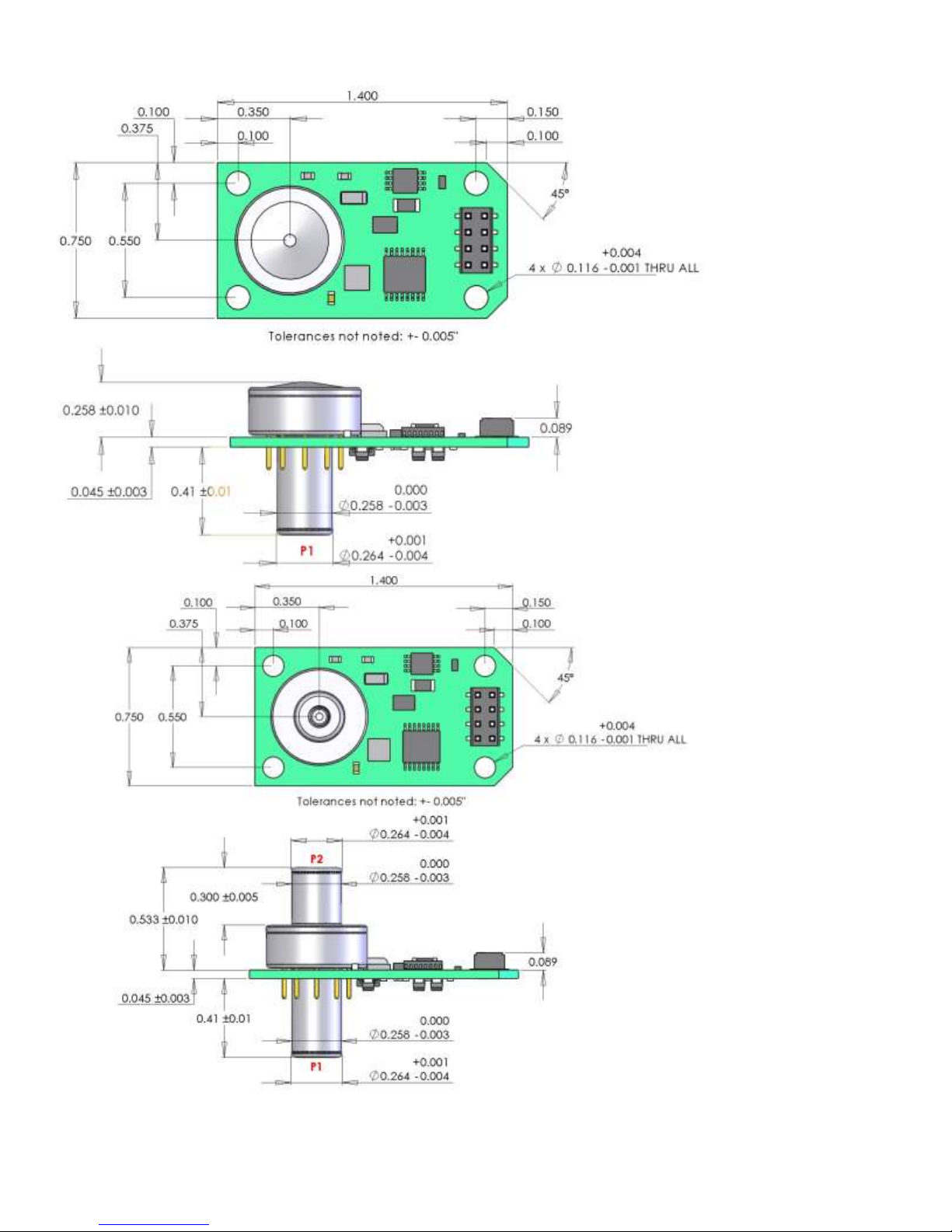

2.3 Outline/Dimensions (inches) .................................................................................................................... 6

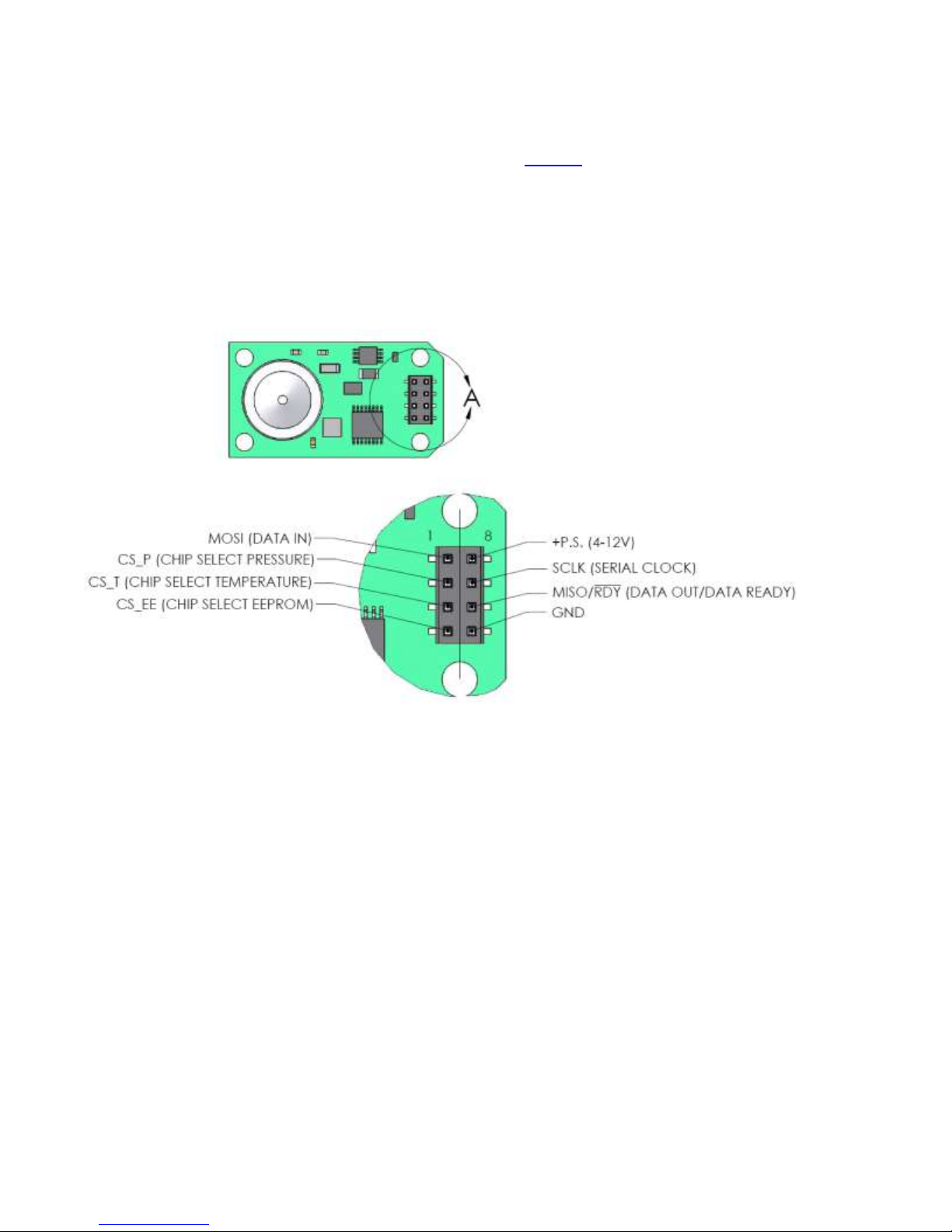

2.4 Electrical Connections ................................................................................................ ............................. 7

2.4.1 Connector ......................................................................................................................................... 7

3 Operation ........................................................................................................................................................ 8

3.1 Commands and Format ........................................................................................................................... 8

3.1.1 Initialization ....................................................................................................................................... 8

3.1.2 Normal Operation (Polling) .............................................................................................................. 10

3.1.3 Other Modes ................................................................................................................................ ... 11

3.2 Correction Algorithms ............................................................................................................................ 12

3.2.1 Pressure ......................................................................................................................................... 12

3.2.1.1 Algorithm #1 ................................................................................................................................. 12

3.2.1.1.1 Horner’s Method, Algorithm #1 .................................................................................................. 12

3.2.1.2 Algorithm #2 ................................................................................................................................. 13

3.2.1.2.1 Horner’s Method, Algorithm #2 .................................................................................................. 13

3.2.2 Pressure Sensor Temperature ........................................................................................................ 14

3.2.2.1 Algorithm ...................................................................................................................................... 14

3.2.2.1.1 Horner’s Method........................................................................................................................ 14

3.3 EEPROM Storage .................................................................................................................................. 15

3.3.1 EEPROM Format ............................................................................................................................ 15

3.3.2 Contents ......................................................................................................................................... 15

4 Installation Recommendations ...................................................................................................................... 19

4.1 Installation Examples ......................................................................................................................... 19

4.1.1 Flexible Tubing and Double-wire Hose Clamps .......................................................................... 19

4.1.2 Static Radial O-ring Seals .......................................................................................................... 20

4.1.3 Static Radial and Face O-ring Seals ........................................................................................... 20

5 Marking ........................................................................................................................................................ 20

6 Fletcher Checksum ....................................................................................................................................... 21

6.1 Calculation ................................................................................................................................ ............. 21

3

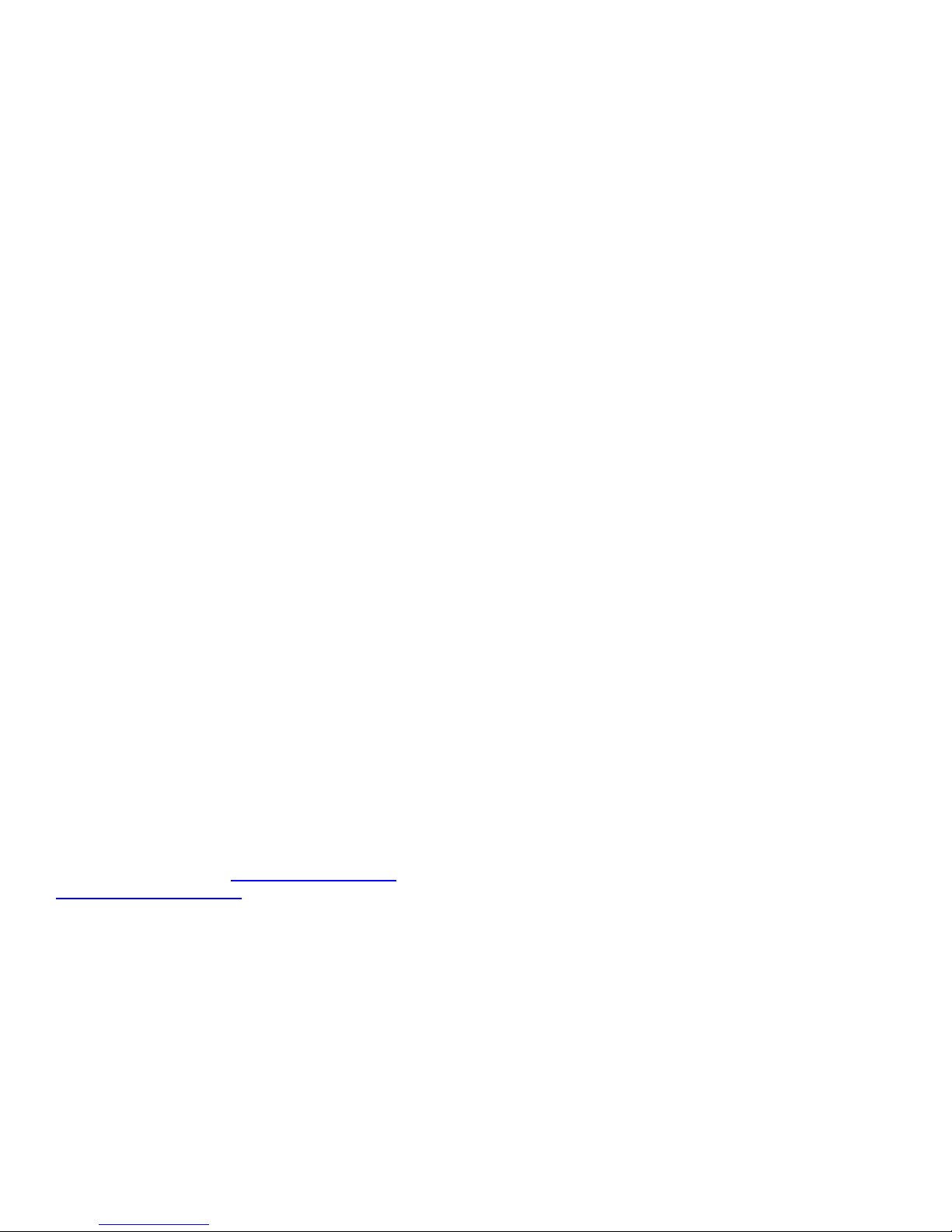

Sensor

-- Temperature -Op-Amp

3.3V Output

LDO Regulator

256 X 8 EEPROM

SPI Serial

Connector

3.3V Analog and

Digital Supply

4-12V

-- Pressure -Op-Amp

24-bit ADC, SPI

18+ ENOB @ 250 sps

+ P.S.

DIN

SCLK

CS_ADC_P

CS_EE

GND

16-bit ADC, SPI

~16 ENOB @ 20 sps

CS_ADC_T

DOUT/RDY

1 Introduction

1.1 Overview

The Honeywell IPT provides high accuracy pressure data in an industry standard SPI digital format. The core

of the IPT is a proven Honeywell silicon piezo-resistive pressure sensor with both pressure and temperature

sensitive elements. The IPT is both small and lightweight and can be easily integrated into a wide variety of

applications that require high performance in a small package.

Applying coefficients stored in the on-board EEPROM to normalized IPT pressure and temperature output

yields accurate pressure readings over a -40 to 85°C compensated temperature range.

2 Specifications

2.1 Block Diagram

4

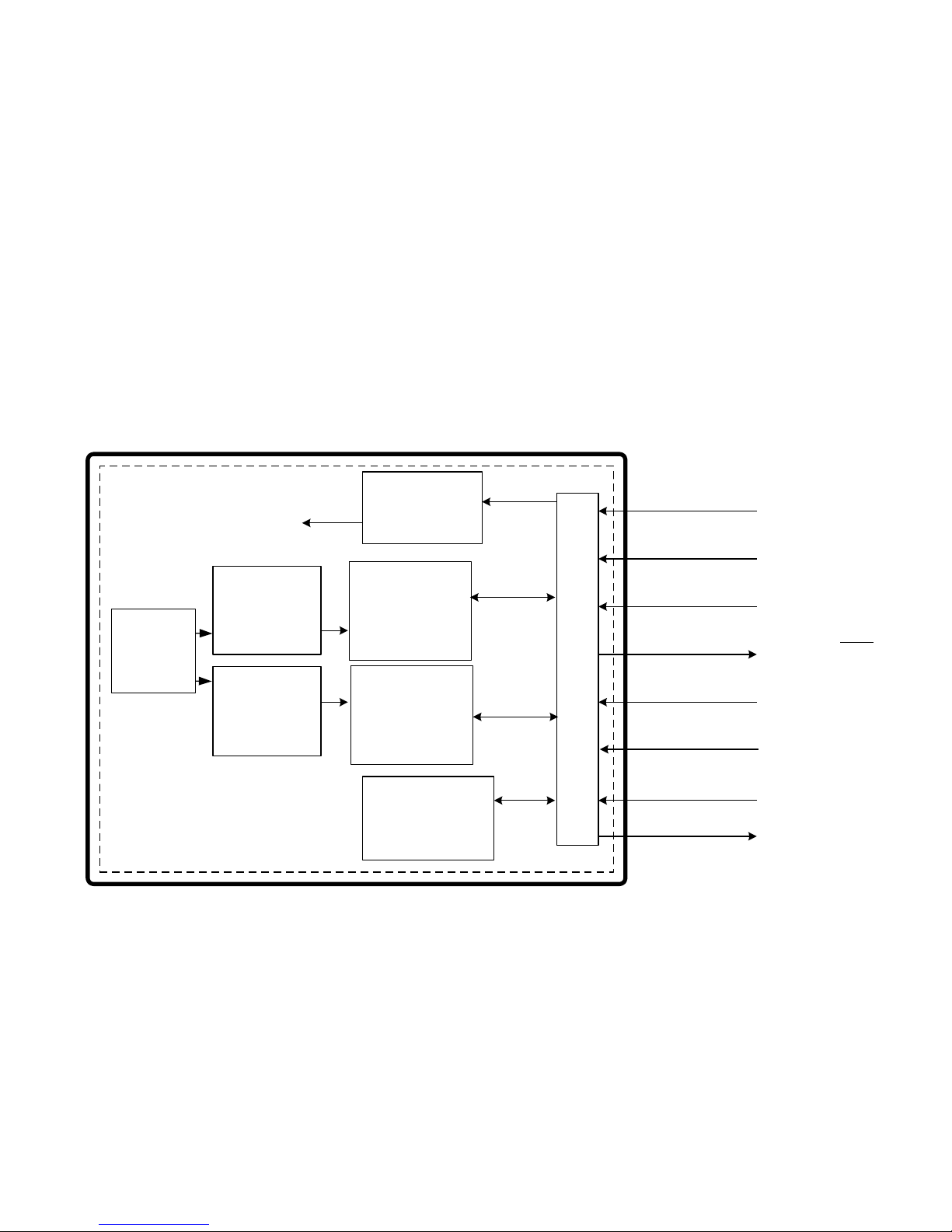

2.2 Specifications/Performance

Total Error Band

(1)

±0.04%FS absolute

±0.10%FS gauge, differential

±0.20%FS 1 psi gauge

Supply Voltage

4 to 12 VDC

Current Consumption

6 mA typical, 7.5 mA max

Operating Temperature Range

-40 to 85°C (-40 to 185°F)

Storage Temperature Range

-55 to 125°C (-67 to 257°F)

Sample Rate

See section 3.1.2

Long Term Stability

0.025%FS max per year typical

Pressure Ranges/Type

20, 50 psia

1, 2, 5, 10, 20 psig

1, 2, 5, 10, 20 psid

Pressure Units

PSI

(2)

Media Compatibility

Non-condensing, non-corrosive,

non-combustible gases

Weight

(3)

~ 8.0 grams (absolute)

~ 9.7 grams (gauge, differential)

Size

See section 2.3

(3)

Interface

3.3V SPI (mode 1,1)

(4)

SCLK ≤ 5 MHz

Output

24-bit pressure value

16-bit temperature value

256 x 8 EEPROM configuration

Overpressure

3X FS

Burst Pressure

3X FS

Humidity Sensitivity of Pressure Ports

DO-160E, Section 6.0, category A

(5)

Electromagnetic Immunity/Emissions

(6)

Mechanical Shock

DO-160E Section 7.0, Category A,

Figure 7.2, Operational Standard

Thermal Variation

Storage Temperature Cycling per

JESD22-104, Section 5.0: -55°C to

+125°C,

Vibration

DO-160E Section 8, Category H,

Aircraft Type 2, Aircraft Zones 1 & 2.

ESD

Class 3A, Table III, MIL-STD-883G,

Method 3015.7, section 3.4

RoHS Compliant (2011/65/EU)

Yes

(1)

Total Error is the sum of worst case linearity, repeatability, hysteresis, thermal effects, and calibration errors over the operating

temperature range. Accuracy is only achieved after applying the correction coefficients and algorithm as shown in section 3.2. (FS =

Full Scale) For total error calculations of differential units, “Full Scale” is the pressure difference between the minimum and maximum

pressures. For example, full scale for a 1 psid PPT is 2 psi (-1 to +1 psi).

(2)

After applying the correction coefficients stored in EEPROM, the resultant pressure reading is expressed in PSI (pounds per square

inch).

(3)

Not including any mounting hardware. Dimensions in section 2.3 do not include Humiseal 1A33 conformal coating which is typically

applied to the PWB assembly at a thickness of 1-3 mils.

(4)

Operation with a digital interface > 3.3V can damage the IPT and cause shifts in the ADC output.

(5)

IPT electronics require protection from humidity.

(6)

IPT requires shielding from EMI.

5

2.3 Outline/Dimensions (inches)

6

2.4 Electrical Connections

2.4.1 Connector

2mm, 2x4 Low Profile Bottom & Top-Entry Connector, Samtec P/N CLT-104-02-L-D-A-K-TR

Connector centered on circuit board and aligned with mounting holes.

Compatible Samtec mating connectors: TMM, MMT, TW, TMMH, MTMM

7

3 Operation

3.1 Commands and Format

3.1.1 Initialization

The IPT piezo-resistive pressure sensing die contains two bridge circuits; one for pressure, one for

temperature. The IPT provides two serial (SPI-compatible) Analog-to-Digital Converters (ADCs), one

for each of these data channels. The pressure channel uses a 24-bit ADC from Analog Devices, P/N

AD7799. The temperature channel uses a 16-bit ADC from Analog Devices, P/N AD7790. After

applying power to the IPT and before obtaining data, each data channel needs to be initialized.

As per the manufacturer’s data sheets, the SPI serial clock for each ADC should be ≤ 5 MHz. During

reads and writes to the ADC’s as detailed below, the appropriate chip-select line must be brought low

(CS_P or CS_T).

3.1.1.1 Pressure Channel

The pressure channel ADC is controlled and configured via a number of on-chip registers. ALL

communication to the pressure channel ADC starts with a write operation to the 8-bit write-only

communication register.

Initializing the pressure channel ADC requires writing data to a sequence of four registers; the

Communication register, the Mode register, the Communication register, and the Configuration

register.

3.1.1.1.1 Communication Register

Sending 0x10 to the Communication register tells the ADC the following write will be to

the 16-bit Configuration register.

3.1.1.1.2 Configuration Register

Sending 0x1020 to the Configuration register sets the ADC’s gain and buffering.

3.1.1.1.3 Communication Register

Sending 0x08 to the Communication register tells the ADC the following write will be to

the 16-bit Mode register.

3.1.1.1.4 Mode Register

Sending 0x3001 to the Mode register places the ADC into a single conversion mode

and sets the update rate, f

From the AD7799 manufacturer’s datasheet:

“When single-conversion mode is selected, the ADC powers up and performs a single

conversion. The oscillator requires 1 ms to power up and settle. The ADC then performs

the conversion, which takes a time of 2/f

the data register, RDY goes low, and the ADC returns to power-down mode. The

to 470 Hz.

ADC

[4.26 ms]. The conversion result is placed in

ADC

conversion remains in the data register and RDY remains active (low) until the data is

read or another conversion is performed.”

8

3.1.1.1.5 Reading

Note: after initialization is complete, reading the Configuration and Mode Registers is

recommended to ensure they have been set as desired. See the AD7799 manufacturer’s

datasheet for information regarding reads of the Configuration and Mode registers.

3.1.1.2 Temperature Channel

The temperature channel ADC is controlled and configured via a number of on-chip registers.

ALL communication to the temperature channel ADC starts with a write operation to the 8-bit

write-only Communication register.

Initializing the temperature channel ADC requires writing data to a sequence of four registers;

the Communication register, the Mode register, the Communication register, and the Filter

register.

3.1.1.2.1 Communication Register

Sending 0x20 to the communication register tells the ADC the following write will be to

the 8-bit Filter register.

3.1.1.2.2 Filter Register

Sending 0x03 to the Filter register sets the ADC’s update rate (f

3.1.1.2.3 Communication Register

Sending 0x10 to the Communication register tells the ADC the following write will be to

the 8-bit Mode register.

3.1.1.2.4 Mode Register

Sending 0x80 to the Mode register places the ADC into a single conversion mode.

From the AD7790 manufacturer’s datasheet:

“When single conversion mode is selected, the ADC powers up and performs a single

conversion, which occurs after a period 2/f

in the data register, RDY goes low, and the ADC returns to power-down mode. The

) to 20 Hz.

ADC

[100 ms]. The conversion result in placed

ADC

conversion remains in the data register and RDY remains active (low) until the data is

read or another conversion is performed.”

3.1.1.2.5 Reading

Note: after initialization is complete, reading the Filter and Mode registers is

recommended to ensure they have been set as desired. See the AD7790 manufacturer’s

datasheet for information regarding reads of the Filter and Mode registers.

9

3.1.2 Normal Operation (Polling)

3.1.2.1 Pressure Channel

After initializing the Mode register per section 3.1.1.2, a new 24-bit pressure value will be available in ~

5.26 ms (1 ms settle time + 4.26 ms conversion).

The pressure conversion remains in the data register and DOUT/ RDY remains active (low) until the

data is read or another conversion is performed.

The process of reading the conversion and reconfiguring the ADC for single conversion mode requires

repeated cycling through the following steps:

1. Wait > 5.26 ms for the conversion to complete, and/or monitor the status of the

DOUT/ RDY line.

2. Send 0x58 to the Communications register to indicate a subsequent read of the 24-bit

Data register.

3. Send 24 clock cycles to read the 24-bit Data register.

4. Send 0x08 to the Communications register to indicate a subsequent write to the 16-bit

Mode register.

5. Send 0x3001 to the Mode register to place the ADC into a single conversion mode and

set the update rate to 470 Hz.

6. Repeat

3.1.2.1 Temperature Channel

After initializing the Mode register per section 3.1.1.1, a new 16-bit temperature value will be available

in ~ 100 ms. (As temperature is generally a more slowly changing input than pressure, and has a

modest impact on the pressure output, this conversion rate should be adequate for most applications.)

The temperature conversion remains in the data register and DOUT/ RDY remains active (low) until

the data is read or another conversion is performed.

The process of reading the conversion and reconfiguring the ADC for single conversion mode requires

repeated cycling through the following steps:

1. Wait 100 ms for the conversion to complete and/or monitor the status of the

DOUT/ RDY line.

2. Send 0x38 to the Communications register to indicate a subsequent read of the 16-bit

Data register.

3. Send 16 clock cycles to read the 16-bit Data register.

4. Send 0x10 to the Communications register to indicate a subsequent write to the 8-bit

Mode register.

5. Send 0x80 to the Mode register to place the ADC into a single conversion mode.

6. Repeat

10

3.1.3 Other Modes

The Honeywell IPT has been tested using the “Initialization” and “Normal Polling” as described in

sections 3.1.1 and 3.1.2. above.

Both pressure and temperature channel ADCs may also be configured to operate in Continuous

Conversion and Continuous Reads modes. Performance should be substantially the same in these

alternate modes. However, they have not been thoroughly tested.

11

3.2 Correction Algorithms

3.2.1 Pressure

One of 2 similar algorithms for converting IPT temperature and pressure channel ADC values into

corrected pressure readings is identified for each IPT. (Section 3.3.2.7 describes how the applicable

algorithm identity is documented in the IPT EEPROM contents.)

Coefficients (A, a1, a2, etc.) for the identified algorithm are stored in the IPT EEPROM. The algorithm

result (Y) is a corrected pressure reading in pounds per square inch (PSI). ADC values from the

temperature channel (normalized) are used to correct the readings for thermal effects.

3.2.1.1 Algorithm #1

Y = A + (F1 × p) + (F2 × p2) + (F3 × p3) + (F4 × p4) + (F5 × p5) + (F6 × p6)

Where:

F1 = a1 + (b1 × t) + (c1 × t2) + (d1 × t3) + (e1 × t4) + (fa1 × t5)

F2 = a2 + (b2 × t) + (c2 × t2) + (d2 × t3) + (e2 × t4) + (fa2 × t5)

F3 = a3 + (b3 × t) + (c3 × t2) + (d3 × t3) + (e3 × t4) + (fa3 × t5)

F4 = a4 + (b4 × t) + (c4 × t2) + (d4 × t3) + (e4 × t4) + (fa4 × t5)

F5 = a5 + (b5 × t) + (c5 × t2) + (d5 × t3) + (e5 × t4) + (fa5 × t5)

F6 = a6 + (b6 × t) + (c6 × t2) + (d6 × t3) + (e6 × t4) + (fa6 × t5)

Output: Y = pressure value in PSI

Inputs: p = 24-bit pressure channel ADC value, normalized 0 – 1

Normalized pressure channel ADC value = pressure channel ADC value / 16,777,215

t = 16-bit temperature channel ADC value, normalized 0 - 1

Normalized temperature channel ADC value = temperature channel ADC value / 65,535

3.2.1.1.1 Horner’s Method, Algorithm #1

Horner’s method is a suggested microcontroller-friendly alternative for evaluating the above equations:

Y = A + p(F1 + p(F2 + p(F3 +p(F4 + p(F5 + p(F6)))))) (6 multiplies, 6 additions)

F1 = a1 + t(b1 + t(c1 + t(d1 + t(e1 + t(fa1))))) (5 multiplies, 5 additions)

F2 = a2 + t(b2 + t(c2 + t(d2 + t(e2 + t(fa2))))) (5 multiplies, 5 additions)

F3 = a3 + t(b3 + t(c3 + t(d3 + t(e3 + t(fa3))))) (5 multiplies, 5 additions)

F4 = a4 + t(b4 + t(c4 + t(d4 + t(e4 + t(fa4))))) (5 multiplies, 5 additions)

F5 = a5 + t(b5 + t(c5 + t(d5 + t(e5 + t(fa5))))) (5 multiplies, 5 additions)

F6 = a6 + t(b6 + t(c6 + t(d6 + t(e6 + t(fa6))))) (5 multiplies, 5 additions)

Total: 36 multiplies, 36 additions

12

3.2.1.2 Algorithm #2

Differences from Algorithm #1 are highlighted in blue

Y = A + (F1 × p) + (F2 × p2) + (F3 × p3) + (F4 × p4) + (F5 × p5) + F6

Where:

F1 = a1 + (b1 × t) + (c1 × t2) + (d1 × t3) + (e1 × t4) + (fa1 × t5)

F2 = a2 + (b2 × t) + (c2 × t2) + (d2 × t3) + (e2 × t4) + (fa2 × t5)

F3 = a3 + (b3 × t) + (c3 × t2) + (d3 × t3) + (e3 × t4) + (fa3 × t5)

F4 = a4 + (b4 × t) + (c4 × t2) + (d4 × t3) + (e4 × t4) + (fa4 × t5)

F5 = a5 + (b5 × t) + (c5 x t2) + (d5 × t3) + (e5 × t4) + (fa5 × t5)

F6 = a6 + (b6 × t) + (c6 × t2) + (d6 × t3) + (e6 × t4) + (fa6 × t5)

Output: Y = pressure value in PSI

Inputs: p = 24-bit pressure channel ADC value, normalized 0 – 1

Normalized pressure channel ADC value = pressure channel ADC value / 16,777,215

t = 16-bit temperature channel ADC value, normalized 0 - 1

Normalized temperature channel ADC value = temperature channel ADC value / 65,535

3.2.1.2.1 Horner’s Method, Algorithm #2

Horner’s method is a suggested microcontroller-friendly alternative for evaluating the above equations:

Y = A + p(F1 + p(F2 + p(F3 +p(F4 + p(F5))))) + F6 (5 multiplies, 6 additions)

F1 = a1 + t(b1 + t(c1 + t(d1 + t(e1 + t(fa1))))) (5 multiplies, 5 additions)

F2 = a2 + t(b2 + t(c2 + t(d2 + t(e2 + t(fa2))))) (5 multiplies, 5 additions)

F3 = a3 + t(b3 + t(c3 + t(d3 + t(e3 + t(fa3))))) (5 multiplies, 5 additions)

F4 = a4 + t(b4 + t(c4 + t(d4 + t(e4 + t(fa4))))) (5 multiplies, 5 additions)

F5 = a5 + t(b5 + t(c5 + t(d5 + t(e5 + t(fa5))))) (5 multiplies, 5 additions)

F6 = a6 + t(b6 + t(c6 + t(d6 + t(e6 + t(fa6))))) (5 multiplies, 5 additions)

Total: 35 multiplies, 36 additions

13

3.2.2 Pressure Sensor Temperature

Starting in the May 2011 timeframe, coefficients for converting 16-bit Pressure Sensor Temperature

values to °C have been appended to the EEPROM contents of new IPT transducers. This supplemental

information allows users, if desired, to separately monitor the temperature of the pressure sensor. The

algorithm is a simple 3rd order polynomial as described below:

3.2.2.1 Algorithm

Y = g1 + (g2 × t) + (g3 × t2) + (g4 × t3)

Output: Y = pressure sensor temperature in °C

Inputs: t = 16-bit temperature channel ADC value, normalized 0 – 1:

Normalized temperature channel ADC value = temperature channel ADC value / 65,535

Coefficients (g1, g2, g3 and g4) for the identified algorithm are stored in the IPT EEPROM.

3.2.2.1.1 Horner’s Method

Horner’s method is a suggested microcontroller-friendly alternative for evaluating the above equation:

Y = g1 + t(g2 + t(g3 + t(g4))) (3 multiplies, 3 additions)

14

3.3 EEPROM Storage

3.3.1 EEPROM Format

The IPT transducer uses a 2 Kbit serial EEPROM from Microchip, P/N 25LC020AT-E/MC.

The EEPROM is organized as 256 x 8. Reads/writes to the EEPROM should be per the manufacturer’s

data sheet. Note: values are stored “big-endian”; most significant bit first.

3.3.2 Contents

3.3.2.1 Pressure Correction Coefficients

The 37 correction coefficients (A through fa6) are stored in 32-bit IEEE 754 format in

locations 00 through 93.

Example: -7.2467064 = C0E7E504

3.3.2.2 Full Scale Pressure Range

The IPT full scale pressure range (FS) is stored in 32-bit IEEE 754 format in locations 94

through 97.

Example: 20 = 41A00000

3.3.2.3 Minimum/Maximum Operating/Storage Temperature Limits

IPT operating/storage temperature limits (Min/Max Op/Stor Temp) are stored as 8-

bit signed integers in locations 98 through 9B.

Examples: Min Operating -40 = D8

Max Operating 85 = 55

Min Storage -55 = C9

Max Storage 125 = 7D

3.3.2.4 Minimum Pressure Output

The minimum pressure output value (Pmin) is the minimum value observed from the

pressure channel ADC over the IPT operating temperature/pressure range and is stored

as a 24-bit unsigned integer. Location 9C is padded with 00 and Pmin is stored in

locations 9D through 9F.

Example: 1213487 = 12842F

3.3.2.5 Maximum Pressure Output

The maximum pressure output value (Pmax) is the maximum value observed from the

pressure channel ADC over the IPT operating temperature/pressure range and is stored

as a 24-bit unsigned integer. Location A0 is padded with 00 and Pmax is stored in

locations A1 through A3.

Example: 11021407 = A82C5F

15

Note: These values can be used to determine if the IPT is being used within its specified

operating range. If samples from the pressure ADC are outside this range, the accuracy

of the correction algorithm cannot be guaranteed.

3.3.2.6 Minimum/Maximum Temperature Output

The minimum and maximum temperature output values (Min/Max Tout) are the

minimum and maximum values observed from the temperature channel ADC over the

IPT operating temperature/pressure range and are stored as 16-bit unsigned integers.

The minimum value is stored in locations A4 through A5 and the maximum value in A6

through A7.

Examples: Min 40175 = 9CEF

Max 60503 = EC57

Note: These values can be used to determine if the IPT is being used within its specified

operating range. If samples from the temperature ADC are outside this range, the

accuracy of the correction algorithm cannot be guaranteed.

3.3.2.7 Algorithm/Type, Date

Four unsigned bytes are used to identify the correction Algorithm, IPT transducer Type

and the manufacturing Date Code (Algorithm/Type/Date Code) at locations A8

through AB.

The most significant byte is used to identify both the correction Algorithm and IPT type

with high nibble for Algorithm and low nibble for Type (shown here in binary).

Algorithm is: #1 = 0000b

#2 = 0001b

Type is defined as: Absolute = 0001b

Gauge = 0010b

Differential = 0011b

Date is stored using the three remaining bytes in the format of mmddyy.

Example: 010C1B07 = Algorithm #1, Absolute, December 27, 2007

Example: 13060B0A = Algorithm #2, Differential, June 11, 2010

3.3.2.8 Serial Number

The IPT’ serial number (Serial No.) is stored as an unsigned 32-bit value in locations

AC through AF.

Example: 1100009827 = 4190D163

3.3.2.9 Honeywell Part Number

The Honeywell part number (Hon. P/N) stored in EEPROM is encoded to form a P/N in

the form of 22xxxxxx-0xx or 58xxxxxx-xxx with a special-order code of –Tyyy.

xxxxxxxx is 24-bit unsigned value from 000000 to 16777215 and yyy is an 8-bit

unsigned value from 00 to 255.

16

xxxxxxxx is stored in locations B0 through B2. yyy is stored in location B3.

Examples:

2FDDE901 = Honeywell Part Number 22031370-001

Special-order code –T001.

37107D07 = Honeywell Part Number 58036087-001

Special-order code –T007.

3.3.2.10 Checksum Bytes

Two checksum bytes (Checksum Bytes) are stored in locations B4 and B5. The

checksum bytes are stored such that an 8-bit Fletcher checksum calculation (Modulo

256) on the primary storage area (00 through B5) yields a zero for each of the calculated

8-bit Fletcher Checksum values.

In the case of the example Table 1 below, the checksum bytes are B4 and 64.

See section 6 for a description of the Fletcher Checksum.

3.3.2.11 Supplemental Information: Pressure Sensor Temperature to °C Coefficients

The 4 correction coefficients (g1 through g4) are stored in 32-bit IEEE 754 format in

locations B8 through C7.

Example: -1796.9403 = C4E09E17

3.3.2.12 Supplemental Information: “Seed” Values and Corresponding Corrected Pressure

To aid in development and debug of the Pressure Correction Algorithms found in section

3.2.1, a transducer-specific 24-bit Seed Pressure Count (spc), a 16-bit Seed

Temperature Count (stc) and the corresponding 32-bit IEEE 754 Corrected Seed

Pressure reading (csp) have been stored in the IPT EEPROM:

The 24-bit spc value is stored in locations C8 through CB with leading zero’s.

The 16-bit stc value is stored in locations CC through CF with leading zero’s.

The 32-bit csp value is stored in locations DO through D3 in IEEE 754 format.

3.3.2.13 Supplemental Information: Checksum Bytes

Two checksum bytes (Checksum Bytes) are stored in locations D4 and D5. The

checksum bytes are stored such that an 8-bit Fletcher checksum calculation (Modulo

256) on the supplemental storage area (B8 through D5) yields a zero for each of the

calculated 8-bit Fletcher Checksum values.

In the case of the example Table 1 below, the supplemental checksum bytes are CB and

1A. See section 6 for a description of the Fletcher Checksum.

3.3.2.14 Unused Locations

Locations B6, B7 and D6 through FF are unused and available for storage of customer

information.

17

Table 1. EEPROM Map w/ Example Values

Description

Inputs

ADDR

Stored Values

A

-10.251645

00

C1

24

06

BD

a1

-1796.9403

04

C4

E0

9E

17

a2

-4162.3979

08

C5

82

13

2F

a3

6.8445935

0C

40

DB

06

E9

a4

-2651.1321

10

C5

25

B2

1D

a5

-5778.0547

14

C5

B4

90

70

a6

10801.397

18

46

28

C5

97

b1

14889.769

1C

46

68

A7

13

b2

18248.301

20

46

8E

90

9A

b3

20223.174

24

46

9D

FE

59

b4

-4042.4363

28

C5

7C

A6

FB

b5

66986.164

2C

47

82

D5

15

b6

-93110.602

30

C7

B5

DB

4D

c1

-46230.684

34

C7

34

96

AF

c2

-28188.965

38

C6

DC

39

EE

c3

-83723.297

3C

C7

A3

85

A6

c4

20603.07

40

46

A0

F6

24

c5

-216138.38

44

C8

53

12

98

c6

295352.34

48

48

90

37

0B

d1

70067.305

4C

47

88

D9

A7

d2

20100.578

50

46

9D

09

28

d3

107100.88

54

47

D1

2E

71

d4

45148.465

58

47

30

5C

77

d5

268675.63

5C

48

83

30

74

d6

-438418.22

60

C8

D6

12

47

e1

-51952.816

64

C7

4A

F0

D1

e2

-10252.898

68

C6

20

33

98

e3

-31521.736

6C

C6

F6

43

79

e4

-148898.56

70

C8

11

68

A4

e5

-108588.63

74

C7

D4

16

50

e6

306424.84

78

48

95

9F

1B

fa1

15124.948

7C

46

6C

53

CB

fa2

4531.3633

80

45

8D

9A

E8

fa3

-13495.57

84

C6

52

DE

48

fa4

92770.586

88

47

B5

31

4B

fa5

-7349.3057

8C

C5

E5

AA

72

fa6

-80684.555

90

C7

9D

96

47

FS

50

94

42

48

00

00

Min/Max Op/Stor Temp

-40

85

-55

125 98

D8

55

C9

7D

Pmin

2336726

9C

00

23

A7

D6

Pmax

13173153

A0

00

C9 1 A1

Min/Max Tout

39393

50413

A4

99

E1

C4

ED

Algorithm/Type, Date

Code

1

7

31

10 A8

01

07

1F

0A

Serial No.

1464

AC

00

00

05

B8

Hon. P/N

3137201

0 B0

2F

DE

B1

00

Checksum Bytes

byte1

byte2

B4

B4

64

g1

-2882.41

B8

C5

34

26

8F

g2

11581.7

BC

46

34

F6

CD

g3

-16459.2

C0

C6

80

96

66

g4

8494.38

C4

46

04

B9

85

spc

10086589

C8

00

99

E8

BD

stc

41487

CC

00

00

A2

0F

csp

13.9968

DO

41

5F

F2

E5

Checksum Bytes

byte1

byte2

D4

CB

1A

18

4 Installation Recommendations

1. IPT media compatibility is non-condensing, non-corrosive, non-combustible gases. To ensure the best

transducer performance it is strongly suggested that IPT transducers and associated plumbing be

oriented to prevent accumulation of debris or condensation in the pressure ports.

2. Pressure ports P1 and P2 should be shielded from direct light due to a strong photoelectric effect on

the sense element.

3. Although conformally coated, electronics should be protected from humidity exposure.

4. Transducer should be mounted to minimize mechanical stress between circuit board and on-board

pressure sensor.

5. Although there is no official specification for the SPI interface (a defacto standard), it is intended for

short distance on-board communications between a microcontroller or microprocessor (Master) and a

peripheral (Slave). To help ensure signal integrity, minimize signal path distance between any Master

and the IPT.

4.1 Installation Examples

The three examples below are for illustrative purposes only and do not represent all possible methods

of installing the IPT.

4.1.1 Flexible Tubing and Double-wire Hose Clamps

Considerations:

1. Select tubing size/material for the application’s temperature and pressure extremes.

2. Ensure hose clamps do no contact any IPT circuitry.

3. Shield port P2 from light due to strong photoelectric effect upon the sense element.

4. Minimize mechanical stress between the circuit board and the on-board pressure sensor.

19

4.1.2 Static Radial O-ring Seals

Considerations:

1. Select o-ring size/material for the application’s temperature and pressure extremes.

2. Minimize mechanical stress between the circuit board and the on-board pressure sensor.

4.1.3 Static Radial and Face O-ring Seals

Considerations:

1. Select o-ring size/material for the application’s temperature and pressure extremes.

2. Minimize mechanical stress between the circuit board and the on-board pressure sensor.

5 Marking

An adhesive label on the O.D. of the IPT sensor contains the unit’s model code, serial number, and

date code (MMDDYY).

Example: IPT0020A33R-T003 S/N 2376 081710

20

6 Fletcher Checksum

Example: 4 bytes of data, 2 check bytes, no errors

Hex

Binary

Decimal

SUM1

SUM2

Data

C0

11000000

192 192

192

Data

E7

11100111

231 167

103

Data

E5

11100101

229 140

243

Data

04

00000100

4 144

131

Check Byte #1

ED

11101101

237 125

0

Check Byte #2

83

10000011

131

0

0

Example with single-bit error

Hex

Binary

Decimal

SUM1

SUM2

Data

C0

11000000

192 192

192

Data

E7

11100111

231 167

103

Data

C5

11000101

197 108

211

Data

04

00000100

4 112

67

Check Byte #1

ED

11101101

237 93

160

Check Byte #2

83

10000011

131

224

128

Example with two single-bit errors

Hex

Binary

Decimal

SUM1

SUM2

Data

C2

11000010

194 194

194

Data

E5

11100101

229 167

105

Data

E5

11100101

229 140

245

Data

04

00000100

4 144

133

Check Byte #1

ED

11101101

237 125 2 Check Byte #2

83

10000011

131

0 2 Example with multiple errors

Hex

Binary

Decimal

SUM1

SUM2

Data

64

01100100

100 100

100

Data

E7

11100111

231 75

175

Data

E5

11100101

229 48

223

Data

BC

10111100

188 236

203

Check Byte #1

ED

11101101

237 217

164

Check Byte #2

83

10000011

131

92

0

6.1 Calculation

The Fletcher checksum calculation results in two sums:

SUM1[R-1] = D[0] + D[1] + …D[R-1]

SUM2[R-1] = SUM1[0] + SUM1[1] + …SUM1[R-1]

where R = number of bytes in the EEPROM storage area from 00 through B5 (182d), including the

check bytes, and where all additions are modulo 256.

If no errors are found, SUM1[R-1] = SUM2[R-1] = 0

21

ADS-14152 Rev. 6/16

Customer Service Email: quotes@honeywell.com

www.pressuresensing.com

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or mechanical, including

photocopying and recording, for any purpose, without the express written permission of Honeywell, Inc.

22

Honeywell reserves the right to make changes to improve reliability, function or design. Honeywell does not assume any

liability arising out of the application or use of any product or circuit described herein; neither does it convey any license

under its patent rights nor the rights of others.

Honeywell

12001 Highway 55 ADS-14152

Plymouth, MN 55441 Rev. July 2016

www.pressuresensing.com © 2016 Honeywell International Inc.

23

Loading...

Loading...