IPC500

PROGRAMMABLE

TEMPERATURE

CONTROLLER

Installation Manual

To our valuable customers

Special attention to the manual

1. Keep the manual for the last user who can get easy access to the

manual.

2. Make sure you read and understand the content of the manual then

operate the product.

3. This manual only explains detail information on how to use the product

effectively. Honeywell disclaims the implied warranties for particular

purpose.

4. Our company, Honeywell Korea is not responsible for any damages

caused by the user with careless.

5. This manual is not to be duplicated, re-edited or rent without

permission given by Honeywell Korea. It is subject to change without

notice.

6. If you have any queries or thought about this manual, please do not

hesitate to contact Honeywell Korea. We’ll try our best to get you an

answer.

Thank you for purchasing our IPC500(Programmable Temperature Controller)

This manual explains suitable effective way of using and installing this product.

Please read carefully to apply IPC500 to controller of temperature chamber or

others.

Description on indicator diagram

Following diagrams indicate potential dangers that may damaged the product

and harm your body. Please make sure you read and understand meaning of

following symbols before you read this manual.

Example of indicator

It indicates “Handle with care” which designed to avoid any

dangers that may risk one’s life and harm the machine.

It is a Frame Ground which means protection earth terminal.

Provided for connection of the protective earth.

(1) Indicates “Operating with care”

Learn and understand before operating.

(2) Indicates “Operating warning”

It may damage software or hardware.

System down may happen.

The manual contains following indicators.

Indicates “set-up is not available”

It explains about learning method before actual operating and

also explains how to be able to set up the condition

(1) Indicates “Additional description”

It explains techinical part which may be refered when set up.

(2) Indicates "Referential Description”

It explains referential part that the user can refer when set up

Indicator that used in the manual

For the safety

Checks when Unpacking

IPC500 series consists of the units on the table below.

When unpacking the product, check the following :

1. Model and parts numbers to ensure that you have received the product you ordered.

2. Unit appearance for damage.

3. That all accessories are included.

Caution on installation

After unpacking, store any unused accessories in a safe to avoid loss or damage.

If any of the accessories listed in the table below are missing, or the product has

been damaged during in shipping, immediately contact your Honeywell sales/service

office or the dealer from whom you purchased the equipment.

Model and parts Model and Parts No. Qt'y Remarks

IPC500

Basic Model No. :

IPC500-RE

LonWorks option

Model No. : IPC500-L

1

Metal fitting 2

Communication Software CD 1

RS-232 Communication

Software

IPC500 User Manual

IPC500 Installation Manual

1. Product summary

1.1 Name of Model

1.2 Terminal Layout Chart

1.3 Backside Terminal Layout

2. Installation and Connection

2.1 Installation Environment

2.2 Installation Suggestions

2.3 Panel Cut Dimensions

2.4 Installation of fixed Bracket

2.5 Terminal Connection Chart

3. IPC500 Setup

3.1 Composition of the Display Screen

3.2 CONTROL SET display

3.3 Display Screen for Setup of PID ZONE

3.4 Display for Setup of PID CONSTANT

3.5 INNER SIGNAL Setup Display Screen

3.6 INPUT SET Display

3.7 OFFSET & LonWorks Setup Display Screen

3.8 LANGUAGE Setup Display

4. Specifications

4.1 General Specifications

4.2 Input/Output Specifications

4.3 Program specifications

4.4 Control output specifications

4.5 Control output specifications(INNER Signal)

4.6 Control mode and setup

4.7 Other specifications

4.8 Trouble Monitor

4.9 External Dimensions

1

1

1

2

3

3

4

4

5

5~10

11

11

12~15

15~18

18~19

19~25

26~27

28

29

30

30

31

32~33

CONTENTS

33~34

34~35

35

36

37

38

- 1 -

1. Product Summary

1.1 Name of Model : IPC500

1.2 Terminal Layout Chart

No Name No Name No Name

21

22

23

A

B

B

Dry-bulb

temperature

Pt100Ω/

JPt100Ω

1

2

3

4

FG

NC

Power

24

25

26

NC

NC

NC

27

28

NC

NC

Analog

Input

41

42

43

44

45

46

47

48

49

50

51

COM

RUN/STOP

Trouble, signal 1

Trouble, signal 2

Trouble, signal 3

Trouble, signal 4

NC

Trouble, signal 6

Trouble, signal 7

NC

NC

Digital

Input

signal input specification

29

30

31

32

NC

COMMON

Temperature

Control Output

SSR

NC

Digital

Control

Output

33

34 +-

Temperature

Control Outpu

t

35

36

NC

NC

37

38 +-

Temperature

Current Value

Output

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

COM

NC

NC

RUN

END

NC

DOWN

TROUBLE

INNER SIGNAL1

INNER SIGNAL2

INNER SIGNAL3

INNER SIGNAL4

TIME SIGNAL 1

TIME SIGNAL 2

TIME SIGNAL 3

TIME SIGNAL 4

Digital

Output

(SSR)

39

40

NC

NC

Analog

Output

( 4 ~

20mA )

Signal 1

Signal 2

Signal 3

Signal 4

Signal 5

Signal 6

Signal 7

Signal 8

Signal 9

Invert

BLOWER

OVER TEMP

DRY TEMP

No Used

Freezer 1

Freezer 2

No Used

No Used

Additional Description

If you choose I.S. in SIGNAL SE LECT item in the CONTROL SET

display (Figure 3.2.1), TIME SIGNALS 1, 2, 3, 4 are utilized

as INNER SIGNAL 5, 6, 7, 8 (Terminal number 17, 18, 19, 20).

AC 85 ~ 264V

- 2 -

1.3 Backside Terminal Layout

Additional Description:

LonWorks in Figure 1.3.1 is optional. LonWorks part does not

operate for models that do not have LonWorks option.

Installation W arning:

♦ in Figure 1.3.1 is a part that is to fix the terminal stand

and is not a part of connect ion. In case you connect to

the part of ♦, such abnormal opera tion as sy stem dama ge

or malfunction may occur. Please be cautious.

<Figure 1.3.1> Terminal Layout

NC 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

41 42 43 44 45 46 47 48 49 50 51

RS-232C

CAUTION

IPC500

♦

♦

LON

A B

LonWorks

FG

AC85~264V

- 3 -

2. Installation and Connection

2.1 Installation Environment

Caution

To enhance reliability of the system and for IPC500’ s smooth functioning, please do

not install it in and under the following locations and conditions .

— Where the surrounding temperature is — Where corrosive or combustible gas

higher than 50°C exists

— Where there are direct rays of light — Where there are conductible materials

— Outdoors such as lots of dust, salt and steel scraps,

and organic solvents

— Where the temperature is below 0°C — Conditions that would expose it to vibration

and shocks

— Where humidity is over 85% — Where a strong electromagnetic field

— Where due is generated due to rapid exists

change of temperature

— Where water, oil or chemical materials

exist

- 4 -

2.2 Installatio n Sug gestions

Here, items to be cautioned at the time of installation of IPC500 (temperature

controller) to panel are explained. Protection from the environment and

convenience of operation needs to be considered.

1) Allow sufficient distance for ventilation.

2) Do not install it right above of equipment (transformer, large capacity resistor, etc.) that

generates a lot of heat in the panel.

3) Install it as far as possible from high voltage equipment and power-driven machinery or

wiring. Otherwise, install it in a different panel.

4) To reduce and prevent noise, please use special purpose grounding. If wiring to the point

of grounding is far, please use heavy insulation wire as a special purpose grounding

cable and ground it through a conduit tube.

5) For IPC500’s communication cable and data lines, do not tie it up together with those

that cause noise such as the power supply wiring of a power-driven machine. In case it is

wired to the same duct, connect shield wire to FG terminal of the main frame.

6) When installing panel, use a flat panel that is not curved.

7) To prevent product damage, fasten screws just once when bracket does not move back

and forth.

8) The Cooling method of IPC500 is based on vertical installation which needs natural air

cooling. In case it is installed horizontally or on a slant, range of operating temperature is

somewhat limited.

9) If you want to use it after keeping it under 0°C, you need to warm it up for two

hours at room temperature before plugging it in. Otherwise, it may not function

normally and the product may be damaged.

2.3 Panel Cut Dimensions

199.5

119

<Figure 2.3.1>

Unit: mm

- 5 -

2.4 Installation of fixed Bracket

Caution at the time of connection:

Before connecting IPC500, please be sure that the po wer supply is shut off.

Otherwise, there might be electric shock. Please be cautious.

2.5 Terminal Connection Chart

1) Connection chart of power supply input terminal

<Figure 2.4.1>

NC

85 ~ 264 VAC 50/60Hz

<Figure 2.5.1>

FG

AC85~264V

- 6 -

Installation Warning:

Please be sure to ground Frame Ground (FG) in Figure 2.5.1

Otherwise, an abnormal operation might occur .

- 7 -

2) Connection chart of digital input (SSR) terminal

Explanation for Reference

1. RUN output

— Terminal number: 8

— Content : Output is ON, when it is being operated .

In case operating mode is "STOP", "END", "READY",

"BREAK", or "TROUBLE" mode, output is OFF;

in case operating mode is "RUN", "HOLD", "WAIT", "COLD",

"HOT" mode, output is ON.

2. END output

— Terminal number : 9

— Content: Output is ON, if program control operation

is completed; otherwise, it is OFF.

Caution

The open collector output

of IPC500 is specified in

MAX 30 VDC, MAX 50mA,

internal resistance 47

Ω.

When the load is relay,

INNER SIGNAL1

8

INNER SIGNAL2

9

INNER SIGNAL3

10

INNER SIGNAL4

11

RUN

12

END

13

NC

14

DOWN

15

TROUBLE

16

TIME SIGNAL1

17

TIME SIGNAL2

18

TIME SIGNAL3

19

TIME SIGNAL4

20

COM

5

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

-

-

-

-

-

-

-

-

-

-

-

-

DC V

/(INNER SIGNAL 5)

/(INNER SIGNAL 6)

/(INNER SIGNAL 7)

/(INNER SIGNAL 8)

<Figure 2.5.3>

- 8 -

3. DOWN output

— Terminal number : 11

— Content: While the patte rn contr ol is operated, output is ON if the

set temperature point decreases as in Figure 2.5.4. Output is

maintained as ON until WAIT is over and becomes OFF when

WA IT is over. If it is operated by a fixed command control , it is OFF.

4. TROUBLE output

— Terminal number : 12

— Content :

If any of the digital ALARM input (1~9) (terminal number 43,44,45,

46, 47, 48, 49, 50, 51) is ON, TROUBLE outp ut is ON . To make

TROUBLE output OFF, you need to make ALARM input OFF and

press the “Clear” key in the troubleshooting display screen. At the time

when TROUBLE output occurs, all output except auxiliary (Present

value) output becomes OFF.

5. Output of 4 different types of Inner signals and Time signals

— Terminal Number:

INNER SIGNAL 1 → terminal 13 TIME SIGNAL 1 → terminal 17

INNER SIGNAL 2 → terminal 14 TIME SIGNAL 2 → terminal 18

INNER SIGNAL 3 → terminal 15 TIME SIGNAL 3 → terminal 19

INNER SIGNAL 4 → terminal 16 TIME SIGNAL 4 → terminal 20

— Content:

See reference explanation of Inner signal from p a ges 19 to 25

See reference explanation of Time signal from pages 28 to 30 in

“User Manual”

ON

ON

OFF OFF

<

Figure 2.5.4> DOWN SSR output ON-OFF

- 9 -

3) Digital control main output (SSR) terminal connection chart (PID control output)

4) Analog current control main output terminal connection chart (PID control output)

5) Analog current auxiliary output terminal connection chart

Present value output of temperature current (-)

NC

Present value output of temperature current (+)

37

38

39

NC

40

DC 4~20 mA

Receiver

-

<Figure 2.5.7>

Temperature control output

NC

COM

30

LOAD

31

32

DC V

<Figure 2.5.5>

Temperature current control output(-)

NC

Temperature current control output(+)

33

34

35

NC

36

DC 4~20 mA

Receiver

-

<Figure 2.5.6>

- 10 -

6) Analog input terminal connection chart

7) Digital input terminal connection chart

Installation Warning:

At the time of connection, please be sure to connect to the correct polarity.

If there is an error in the polarity connection, operation of ON/OFF and

current input and output may not be normal.

44

45

RUN/STOP

46

47

48

49

TROUBLE 4

50

51

COM

41

TROUBLE 1

TROUBLE 2

TROUBLE 3

NC

TROUBLE 6

TROUBLE 7

NC

NC

42

43

<Figure 2.5.9>

A

B

22

B

23

24

25

26

Dry bulb temperature

RTD

<Figure 2.5.8>

NC

NC

NC

- 11 -

3. IPC500 Setup

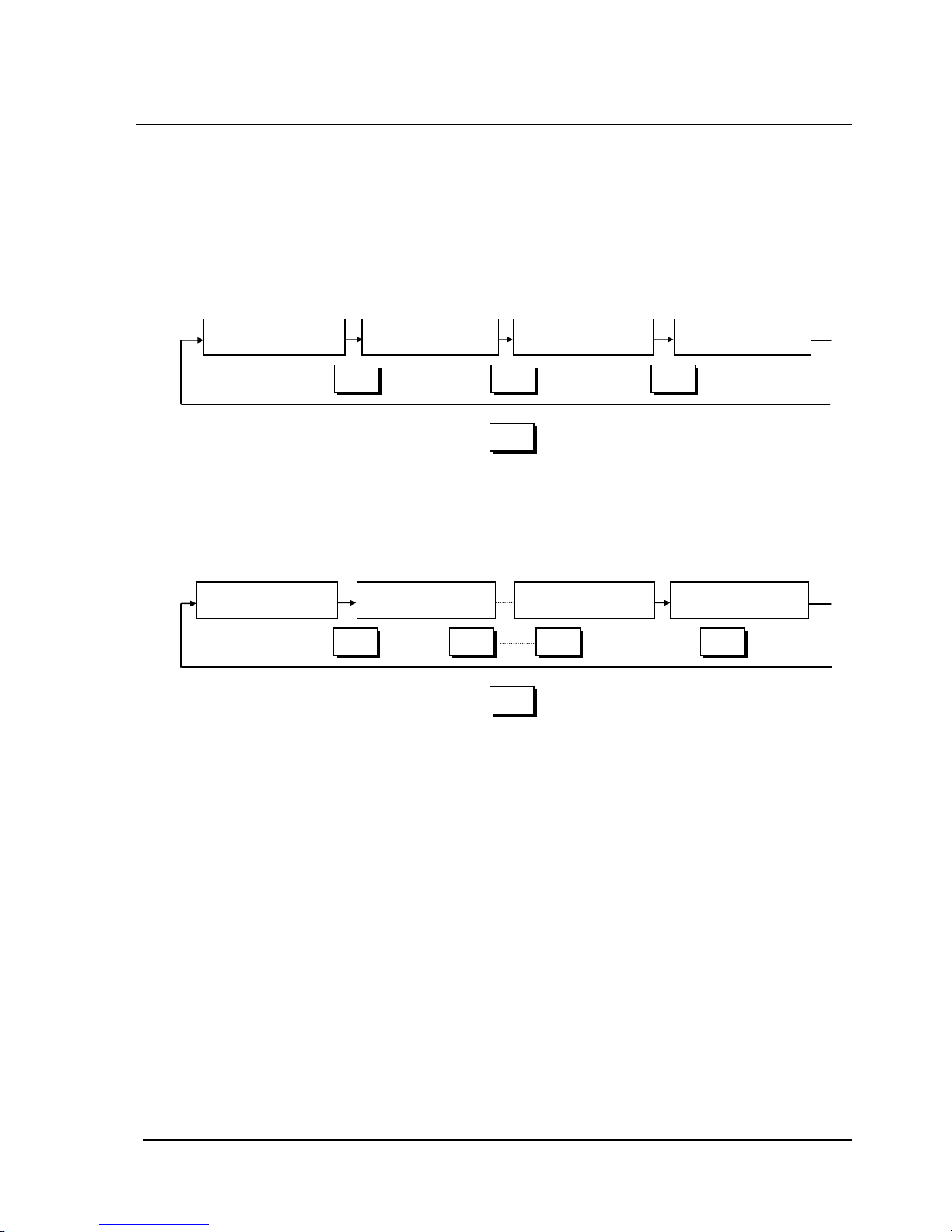

The initial setup should make it appropriate for the control of the function and capacity of the

temperature chamber. It is composed and operated as shown in Figure 3.1.1.

3.1 Composition of the Display Screen

Composition of the display screen is based on ROTATION mode (Figure 3.1.1).

T o enter into the init ial disp lay screen (Display to set CONT ROL SET), touch the

upper right in the main display screen and push the monitor key within one

second.

CONTROL SET screen

Main screen

Press MONITOR key in a second

after pressing the key on the top right

INPUT SET screen

OFFSET & LonWorks

screen

NEXT

NEXT

EXIT

EXIT

EXIT

<Fi

g

ure 3.1.1>

Menu screen

Korean/English/Chinese

conversion screen

Press the bottom left in a second

after pressing the key on the top

EXIT

NEXT

- 12 -

3.2 CONTROL SET display

This display screen is used to set up such items as the output mode of temperature

control, DIGITAL output, PID related items, and AUTO TUNING.

Sequence of Operation

1. Setting up the temperature control output mode

It allows you to choose to make the temperature control output mode either in direct or

reverse motion.

— To choose reverse motion

Enter REVERSE key (1). If you choose the REVERSE key, the key is reversed

from a white background with blue characters to a blue background with white

characters.

— To choose direct motion

Enter DIRECT key (1). If you choose the DIRECT key, the key is reversed.

Key to go to PID ZONE

setup screen

(1) Temperature reverse/direct

operation select key

(3) SIGNAL type select key

(4) SIGNAL output form display

(5) AUTO TUNING MAN/AUTO

select key

EXIT

CONTROL SET

REVERSE DIRECT

I.S/T.S I.S

I.S(4) T.S(4

)

PID

ZONE

PID

CONSTANT

INNER

SIGNAL

MAN AUTO

10

ESC

-

0 5 16273849. ENT

SEC

NEXT

<Figure3.2.1>

Return to menu screen

Converted to INPUT SET screen

Key to go to PID

constant setup

screen

Key to go to INNER SIGNA

L

setup screen

(6) TROUBLE delay time

setup key

- 13 -

Additional Description

Direct operation/ reverse operation explanation

1. Direct operation: freezing

2. Reverse operation: heating

Proportional band

SP

PV hi

g

h

Te mperature

Cycle Time

OFF time

ON time

<Figure3.2.2> Temperature Direct operation Output

Proportional band

SP

PV high

Temperature

Cycle time

OFF time

ON time

<Figure3.2.3> Temperature Reverse operation Output

- 14 -

3. Setting up INNER(4)/TIME(4) SIGNAL or INNER(8) SIGNAL

Generally, IPC500’s outputs are 4 INNER SIGNALs and 4 TIME SIGNALs.

However, you can use up to 8 INNER SIGNALs

(but 4 TIME SIGNALS cannot be utilized if 8 INNER SIGNALs are used).

— Setting up outputs as 4 INNER SIGNALs and 4 TIME SIGNALs

Push I.S/T.S key (3) shown in Figure 3.2.1. If you choose I.S/T.S, the key is

reversed and SIGNAL output mode indicator (4) is shown as "I.S(4) T.S(4)".

— Setting up output as 8 INNER SIGNALs

Push I.S key (3) shown in Figure 3.2.1. If you choose I.S, the key is reversed

and SIGNAL output mode indicator (4) is shown as "I.S(8)."

Additional Description

Terminal numbers by selecting I.S/T.S Terminal numbers by selecting I.S

INNER SIGNAL 1 → Terminal number : 13 INNER SIGNAL 1 → Terminal number : 13

INNER SIGNAL 2 → Terminal number : 14 INNER SIGNAL 2 → Terminal number : 14

INNER SIGNAL 3 → Terminal number : 15 INNER SIGNAL 3 → Terminal number : 15

INNER SIGNAL 4 → Terminal number : 16 INNER SIGNAL 4 → Terminal number : 16

TIME SIGNAL 1 → Terminal number : 17 INNER SIGNAL 5 → Terminal number : 17

TIME SIGNAL 2 → Terminal number : 18 INNER SIGNAL 6 → Terminal number : 18

TIME SIGNAL 3 → Terminal number : 19 INNER SIGNAL 7 → Terminal number : 19

TIME SIGNAL 4 → Terminal number : 20 INNER SIGNAL 8 → Terminal number : 20

4. Setting up AUTO TUNING MAN/AUTO

It allows you to set it up so that you can or cannot execute AUTO TUNING in the

operating display.

— To select AUTO TUNING MAN

Push MAN key (5) in Figure 3.2.1. If you choose MAN key, the key is

reversed.

When MAN key is selected, ( TEMP ) AUTO TUNING execution key

does not appear in the monitor screen and you cannot execute AUTO TUNING.

— To select AUTO TUNING AUTO

Push AUTO key (5) in Figure 3.2.1. If you choose AUTO key, the key is reversed.

If AUTO key is set up, ( TEMP ) AUTO TUNING execution key

appears in the monitor screen, which allows you to execute AUTO TUNING.

- 15 -

5. Setting up TROUBLE input delay time

If there are TROUBLE inputs, TROUBLE output and message operate after set delay

time. Range of delay time to be set is between 1 and 99 second(s).

— When key (6) is pressed, the numeric keyboard appears. If you enter delay

time and hit ENT key, it is set up; if you enter ESC key, it is cancelled.

3.3 Display Screen for Setup of PID ZONE

There can be up to 6 ZONEs for the range of temperature PID constant

and they are controlled by the PID constants in the ZONE field in which set points (SP)

of temperature exist.

Initial setup at the time of product shipment is ZONE 1 fields and all fields are controlled

by a single PID constant.

EXIT

PID ZONE

<Figure 3.3.1>

Return to CONTROL SET screen

T1

DISP

(1) Temperature ZONE

classifying constant T1

setup key

(2) Temperature ZONE

classifying constant T2

setup key

(6) ZONE range

redrawin

g

key

(3) Temperature ZONE

classifying constant T3

setup key

=

-50

T2 =

0

T3 =

50

T4 =

100

T5 =

200

(4) Temperature ZONE

classifying constant T4

setup key

(5) Temperature ZONE

classifying constant T5

setup key

- 16 -

Sequence of Operation

1. If each of T1 key (1), T2 key (2), T3 key (3), T4 key(4), T5 key(5) is entered,

the numeric keyboard appears in the lower-hand side of the display. If you enter

the temperature that you want to set and then hit the ENT key, it is set up; if you enter

the ESC key, it is cancelled.

2. If you enter DISP (6) key after executing the sequence of operation 1, it draws a figure

again that divides the field in Figure 3.3.1 according to the changed ZONE field.

3. Temperature range setup for T1 ~ T5 is between -100 and 300°C.

Additional Description

ZONE divisional setup screen

1. Case of maximum 6 Zones

Divided into 1 to 6 zones based upon the setup of T1,T2,T3,T4,T5 in the needs of 6 Zones.

2. Case of 1 ZONE

Setup: T1 = 300, T2 = 300, T3 = 300,T4 = 300,T5 = 300 (product prevalues)

1

T2

T3

300°C

-100°C

Divided into 6 zones and

setup temperature

Temperature SP → High

2 3 4 5 6

T1

T4

T5

1

T2

T3

300°C

-100°C

Temperature SP → High

T1

T4

T5

- 17 -

3. Case of 2 ZONE

Set T2=T3=T4=T5=300 and T1will be the temperature at the setup which distinguishes zone.

4. Case of 3 ZONE

Set T3=T4=T5=300 and T1 and T2 will be the temperature at the setup which distinguishes zone.

5. Case of 4 Zone

Set T4=T5=300 and T1, T2 and T3 will be the temperature which distinguishes zone.

1

T2

T3

300°C

-100°C

Temperature SP → High

T1

T4

T5

2

1

T2

T3

-100°C

Temperature SP → High

2 3

T1

T4

T5

300°C

1

T2

T3

300°C

-100°C

Temperature SP → High

2 3 4

T1

T4

T5

- 18 -

6. Case of 5 ZONE

Setup is T5 = 300. T1,T2,T3 and T4 will be the temperature which distinguishes zone.

Invalid Setup:

At the time of setting up T1,T2,T3,T4 and T5, T1 ≥ T2 ≥ T3 ≥ T4 ≥ T5 is

invalid and cannot be entered.

3.4 Display for Setup of PID CONST ANT

It sets up P, I, D, ARW constants in each ZONE field. The PID constant that results

after completion of AUTO TUNING is applied to the appropriate ZONE field.

1

T2

T3

300°C

-100°C

Temperature SP → High

2 3 4 5

T1

T4

T5

PID CONS

T

A

NT

<

>

Return to CONTROL SET screen

P(%) I(Min) D(Min) ARW(%)

TEMP 1.00 1.20 0.30 000

TEMP 1.00 1.20 0.30 100

TEMP 1.00 1.20 0.30 000

TEMP 1.00 1.20 0.30 000

TEMP 1.00 1.20 0.30 000

TEMP 1.00 1.20 0.30 100

1

3

5

Indicate that the PID constant of what

zone is controlling

EXIT

2

4

6

- 19 -

Sequence of Operation

1. When you press any of keys, you will see a numeric keyboard in the screen below

and when you will insert any of PID and ARW constants in the input and press

the enter key, the setup will be all set, but if you press the ESC key the task will be

cancelled.

2. Early PID and ARW constants of every zone are setup as below:

P = 1.00 %, I = 1.20 Min, D = 0.30 Min, ARW = 100 %

3. constant setup boundary

P (Proportional band) : 0.0 ~ 99.99 %

I (Integral time) : 0 ~ 36.00 Min

D (Derivative time) : 0 ~ 36.00 Min

ARW : 0 ~ 100 %

3.5 INNER SIGNAL Setup Display Screen

This is a part which setups the INNER SIGNAL output items among DIGITAL outputs.

<Figure3.5.1>

EXIT

INNER SIGNAL1

TEMP

ITEM

(2) Object

select key

(3) Object value

select key

(5) Output operation selection key

Return to CONTROL SET screen

P

V

SP

DV

A

BS DEV

RANG

LOW HIGH

LEVEL

ABS VALUE 0.0 -100 ~ 300°C

OPER DIFF 0.0 0 ~ ±9.9°C

DELAY(SEC) 0 0 ~ 99 SEC

PAGE

(1) Page conversion key

A

BS DEV

A

BS

LOW HIGH

OFF ON

(4) Operating point selection key

TYPE→ PV

TYPE→ SP or DV

TYPE → PV

TYPE → SP or DV

(6) Absolute value,

Deviation value,

Minimum value

setup key

(7) Operation differential,

Maximum value

setup key

(8) ON/OFF DELAY time

setup key

- 20 -

Sequence of Operation

1. Setting up temperature(TEMP)/PV/ABS/HIGH, Absolute value (ABS VALUE),

Operation Differential (OPER DIFF), and DELAY(SEC)

— Press PV at object value selection key (3). The PV key is reversed.

— Press ABS at operating point selection key (4). The ABS key is reversed.

— Press HIGH at output operation selection key (5). The HIGH key is reversed.

— Enter absolute value after pressing ABS VALUE setup key (6). Input of ABS

VALUE is allowed only within SET RANGE on the right-hand side.

(Set range : -100 ~ 300°C)

— Enter operation differential after pressing OPER DIFF setup key (7). Input of

OPER VALUE is allowed only within SET RANGE on the right-hand side.

(Set range : 0 ~ ±9.9°C)

— Enter delay time after pressing DELAY time setup key (8). Input of DELAY time

is allowed only within SET RANGE on the right-hand side.

(Set range : 0 ~ 99 SEC)

2. Setting up TEMP/PV/DEV/HIGH, deviation value (DEV VALUE), OPER DIFF, and

DELAY(SEC)

— Press TEMP at object selection key (2). The TEMP key is reversed.

— Press PV at object value selection key (3). The PV key is reversed.

— Press DEV at operating point selection key (4). The DEV key is reversed.

— Enter HIGH at output operation selection key (5). The HIGH key is reversed.

— Enter deviation value after pressing DEV VALUE setup key (6). Input of

deviation value is allowed only within SET RANGE on the right-hand side.

( Set range: -99.9 ~ 99.9°C)

— Enter operation difference after pressing OPER DIFF setup key (7). Input of

operation differential is allowed only within SET RANGE on the right-hand side.

(Set range : 0 ~ ±9.9°C)

— Enter delay time after pressing DELAY time setup key (8). Input of delay time

input is allowed only within SET RANGE on the right-hand side. (0 ~ 99 SEC)

3. Setting up TEMP/SP/ABS/ON, minimum value (MIN VALUE), maximum value(MAX

VALUE), and DELAY(SEC)

— Press TEMP at object selection key (2). The TEMP key is reversed.

— Press SP at object value selection key (3). The SP key is reversed.

— If you choose SP, the ABS key is automatically selected.

— Press ON at output operation selection key (5). The ON key is reversed.

— Enter minimum value after pressing MIN VALUE setup key (6). Input of MIN

VALUE is allowed only within SET RANGE on the right-hand side.

(Set range : -100 ~ 300°C)

- 21 -

— Enter maximum value after pressing MAX VALUE setup key (7). Input of MAX

VALUE is allowed only within SET RANGE on the right-hand side.

(Set range : -100 ~ 300°C)

— Enter delay time after pressing DELAY time setup key (8). Input of DELAY time

is allowed only within SET RANGE on the right-hand side. (0 ~ 99 SEC)

4. Setting up TEMP/DV/ABS/ON, MIN VALUE, MAX VALUE, and DELAY(SEC)

— Press TEMP at object selection key (2). The TEMP key is reversed.

— Press DV at object value selection key (3). The DV key is reversed.

— If you choose DV, the ABS key is automatically selected.

— Press ON at output operation selection key (5). The ON key is reversed.

— Enter minimum value by pressing MIN VALUE setup key (6). Input of MIN VALUE

is allowed only within SET RANGE on the right-hand side.

(Set range : -100 ~ 300°C)

— Enter maximum value by pressing MAX VALUE setup key (7). Input of MAX VALUE

is allowed only within SET RANGE on the right-hand side.

(Set range : -100 ~ 300°C)

— Enter delay time by pressing DELAY time setup key (8). Input of DELAY time is

allowed only within SET RANGE on the right-hand side. (0 ~ 99 SEC)

Invalid Setup

At the time of setting up MIN VALUE and MAX VALU E of SP and DV,

MIN VALUE > MAX VALUE is invalid and cannot be entered.

Please enter MIN VALUE after entering MAX VALUE.

- 22 -

6. PAGE Conversion for INNER SIGNAL Setup Screen

In the first conversion screen, it is converted to the display in which INNER SIGNAL

NO.1 is set up. To set up INNER SIGNALs of other numbers, you need to press

PAGE key in Figure 3.5.1. Sequence of conversion at the time of key operation is

shown in Figure 3.5.2 and Figure 3.5.3.

INNER SIGNAL1 INNER SIGNAL2 INNER SIGNAL3 INNER SIGNAL4

PAGE PAGE PAGE

PAGE

<Figure3.5.2> Screen conversion when selecting I.S/T.S

INNER SIGNAL 1 INNER SIGNAL 2 INNER SIGNAL 7 INNER SIGNAL 8

PAGE PAGE PAGE

PAGE

<Figure3.5.3> Screen conversion when selecting I.S

PAGE

- 23 -

Additional Description

INNER SIGNAL Explanation

1. Contents

— ON / OFF open collector output × 4 or × 8

— Can be used optionally for cooling and signal control output.

— Each output is independent and sets up temperature, present value/

set point / target value, absolute value / deviation, output operation

(LOW / HIGH), and output operation (ON / OFF)

2. Setup of various operations: Various operations can be set up by combining items below.

— Object : TEMP → It allows you to set up if the object of operation is temperature.

— Object value : PV / SP / DV → It allows you to set up at what point it is ON and OFF.

PV : Present Value

SP : Set Point (Target value that changes synchronously as the PROGRAM

proceeds)

DV : Step’s target value (within a step, a fixed value is maintained)

— Operating point : ABS / DEV → sets up absolute value(ABS) and deviation(DEV).

Only PV allows you to set up. When SP and DV are set, it is fixed

as ABS.

— Output operation : ON / OFF → ON/OFF is set up for operating point in absolute

value that is set up next in case object value is SP and DV.

TEMP PV

SP

DV

Present Value

Set Point

Step

target value

ABS

DEV

Absolute

value(operating

Deviation

HIGH

LOW

Absolute value

(ABS VALUE)

Operation

Differential

(OPER DIFF)

DELAY

HIGH

LOW

DELAY

ON

OFF

ABS

Absolute

value(operating

point)

Minimum value

(MIN VALUE)

DELAY

ABS

Absolute

value(operating

ON

OFF

Deviation

(DEVIATION)

1

2

3

4

5

6

7

8

<Figure5.3.4> Block chart when selecting INNER SIGANL

Maximum value

(MAX VALUE)

Operation

Differential

(OPER DIFF)

Minimum value

(MIN VALUE)

DELAY

Maximum value

(MAX VALUE)

- 24 -

LOW / HIGH → If object value is PV, direction in which it is

turned ON is set up for the point that is set up next.

LOW :

Output is OFF when the reverse operation (heating) PV is

at a high temperature output OFF.

HIGH : Output is ON when the direct operation (freezing) PV is

at a high temperature output ON.

3. Operation range : Setup items vary depending on the operation types.

— Case of PV / ABS (Setup : LOW or HIGH range)

Absolute value (operating point) , Operation differential, DELAY time.

— Case of PV / DEV (Setup: LOW or HIGH range)

Deviation, Operation differential, DELAY time.

— Case of SP and DV (Setup: ON or OFF range)

Maximum value, Minimum value, DELAY time.

— DELAY time : The delay time of setup is over-lapsed until it becomes ON or OFF

condition setup, the output comes out. Within DELAY time, if the

conditions are cancelled, there will be no output.

4. Example case of PV, DEV selection

— Operation direction = LOW

— Operation direction = HIGH

▲

SP

- deviation

OFF

ON

PV → high

▲

SP

+ deviation

OFF

ON

PV → high

Operation differential

Operation differential

▲

SP

- deviation

OFF

ON

PV → high

▲

SP

+ deviation

ON

PV → high

OFF

Operation differential

Operation differential

- 25 -

5. Example in Case of PV, ABS selection

— Operation direction = LOW — Operation direction = HIGH

6. Example in case of SP and DV selection

30

20

10

0

-10

-20

Maximum

value

IS4

IS3

IS2

IS1

ON

range

SP (°C)

DV

setup

SP

setup

IS1

IS2

IS3

IS4

IS1

IS2

IS3

IS4

Minimum

value

-30

-40

O

N

ON ONONONO

N

O

N

O

N

ABS

OFF

ON

Operation differential

PV → high

setup

ABS

OFF

ON

PV → high

setup

Operation differential

- 26 -

3.6 INPUT SET Display

It is the display in which the cycle time of the control output, output range of current

temperature value, temperature set range, sensor selection are setup.

Sequence of Operation

1. Setting up control cycle

— Numeric keyboard appears, if you press control cycle time setup key (1). It is set

up if you enter control cycle and push ENT key; it is cancelled if you enter ESC

key. Control cycle time is shown in Figure 3.6.2.

2. Setting up output range of current temperature value

— Numeric keyboard appears, if you press the left-hand side button of the

current temperature value output range setup key (2). Please enter minimum

value of scale which is 4mA.

O

N

ON

75%

25%

Control Cycle Time (Sec)

<Figure 3.6.2> MV = 75% out

OFF

EXIT

INPUT SET

(2) Temperature present

value output range

setup key

2

CONTROL CYCLE

SEC

NEXT

(4) Sense selection key

(1) Control cycle time

setup key

Return to the menu screen

Converted to RANGE SET screen

-100.0

SCALING

~

300.0

°C

Pt

SENSOR SELECT

JPt

<Figure 3.6.1>

ESC

-

0516273849.

ENT

-100.0

TEMP SET

300.0

~

°C

(3) Temperature input range

setup key

- 27 -

— Numeric keyboard appears, if you press the right-hand side key of key (2). Please

enter maximum value which is 20mA.

— The range of SCALING setup is between 4 and 20mA and output of temperature

current value depends upon current temperature(PV).

Example) When SCALING setup range is between 0°C and 90°C, output of

current temperature value is 4mA if current temperature is below 0°C;

output of current temperature value it is 20mA if the current temperature is

above 90°C; if the current temperature is between 0°C and 90°C, output of

current temperature value is between 4mA and 20mA. (Initial SCALING

setup at the time of product shipment is between -100.0°C and 300.0°C)

3. Setting up the range of temperature input

It allows you to limit the range of Set Point for fix control and program control. If the user

enters SP that is out of the range of input field, an OVER RANGE message appears and

indicates that it cannot be set up.

— If you press the left-hand side key of temperature input range setup key (3),

the numeric keyboard appears. Please enter the minimum value of the input limit

field.

— If you press the right-hand side key of temperature input range setup key (3),

the numeric keyboard appears. Please enter the maximum value of the input limit

field.

4. Selecting Sensor Input

It allows you to select if you want to input a dry bulb /a wet bulb temperature either as

Pt100 or JPt100

— Selecting Pt100

If you press Pt key (4), the Pt key is reversed.

— Selecting JPt100

If you press JPt key (4), the JPt key is reversed.

Invalid Setup

At the time of setting up MIN VALUE and MAX VALUE,

MIN VALUE > MAX VALUE is invalid and cannot be entered.

Please enter MIN VALUE after entering MAX VALUE.

- 28 -

3.7 OFFSET & LonWorks Setup Display Screen

The part is adjusting the dry bulb temperature OFFSET and sending service pin number.

Sequence of Operation

1. Adjusting temperature OFFSET of a dry bulb temperature

— If you press dry bulb temperature OFFSET setup key (1),

the numeric keyboard appears. Please enter OFFSET value of a dry bulb

temperature.

— If input mode is DRY/DC or DRY/WET mode, both are valid.

Example) Let’s say that the actual input is 50.0°C. If OFFSET value is set up as

+1.00°C, the current value PV becomes 51.00°C and is adjusted

upward for the +1°C.

If OFFSET is set up as -1.00°C, it becomes 49.00°C and is adjusted

downward for the -1°C. Adjusted PV value is indicated as adjusted

current value of dry bulb temperature key (3).

— Input range : -9.99 ~ +9.99°C

2. Sending service pin No.

— When the Host request the service pin No. of IPC500, you press Send key(2).

Then, IPC500 send the pin No.

(3) Display dry bulb

temperature adjusted

by adding OFFSET value

EXIT

OFFSET & LonWorks

NEXT

(1) Dry bulb temperature

OFFSET

Return to the menu screen

Converted to CONTROL SET screen

0.00

DRY TEMP

°C

50.0

°C

<Figure 3.7.1>

OFFS

ET DISPLAY

Send

Se

rvice

ESC - 0 5 16273849.

ENT

(2) Button sending service pin

- 29 -

3.8 LANGUAGE Setup Display

It is a display that enables you to choose the language.

EXIT

LANGUAGE

English / Korean / Chinese conversion key

Return to the menu screen

<Figure 3.9.1>

ENGLISH

KOREAN

CHINESE

- 30 -

4. SPECIFICATIONS

4.1 General Specifications

Item Specifications

Temperature input range -100.0~300.0°C

Indicator Dot matrix LCD module

Display screen 86.37(H)X115.17(W)mm

Number of dots 240(H)X320(W) dot

Back light CCFL cathode type fluorescent lamp (Brightness : 100 cd/m2)

Display size 40 lines X 30 lines ( case of 8X8 dot characters)

Display

device

Display color Blue characters on a white ground

Setup method Touch key method

A/D conversion

Dual integral method

15bit (0.01 resolution with 300°C span)

Indication temperature ± 0.1%FS ± 1digit

Measure display 0.01°C / 0.1°C display switch available

Input sampling cycle 0.5 second

Clock accuracy ± 10 PPM(25°C standard), temperature specificity -10~70°C:+10/-120 PPM)

Backup

Program data, control stated number : nickel manganese secondary battery

Data is preserved for 5 years after break-off of power supply (provided that

Full Charge is preceded)

Initial set value EEPROM storage, more than ten years

Power voltage

Power frequency

AC 85 ~ 264 V

50/60Hz

Isolation resistance 50MΩ min. between case and terminals using a 500V DC Mega

Withstand voltage AC1500V, 1 min, between case and power terminals

Ambient temperature 0 ~ 50°C

Exterior Case: steel painting (ivory), front panel : plastic

Mounting Panel-mount

Exterior size 210mm(H)X130mm(W)X188mm(D)

Panel cut 199.5mm(H)X119mm(W)

- 31 -

4.2 Input/Output specifications

Item Specifications

PV input Pt100 or JPt100

RUN/STOP input Contact input X 1 (Program RUN/STOP external signal)

Trouble signal

Contact input X 6 (Display 6 items per screen)

Control output all OFF with Trouble signal input

Individual measure message, maximum 6 screens

Temperature

PID

Open collector output X 1

Temperature

PID

DC 4~20mA output X 1(Within load resistance 500Ω)

Control

output

Note 1) Operation direction direct operation(freezing) / reverse operation(heating)

Changeable.

Note 2) Open collector /DC4~20mA simultaneous output.

INNER SIGNAL

ON / OFF open collector out X 4 or X 8

Inner signals can be used at the freezing and Alarm Control

Each output is independently temperature, PV / SP / DV,

Absolute value / Deviation, Output operation LOW / HIGH, Output

operation ON / OFF, expansion of output X4 or out X8 when selecting

output (In use of INNER SIGNAL 8 kind TIME SIGNAL can be out of

use)

RUN output Open collector output X 1

END output Open collector output X 1

TIME SIGNAL Open collector output X 4

DOWN output Open collector output X 1

TROUBLE output Open collector output X 1

Transmission output

(Auxiliary output)

Temperature : 4~20mA -100~300°C(range changeable)

Communication RS232(standard), LonWorks(OPTION)

Open collector out MAX DC30V, MAX50mA/1ch internal resistance 47Ω

- 32 -

4.3 program specifications

Item Specifications

Step registration number 0~799step (maximum 800steps)

Step times Maximum 99 hours and 59 minutes per step

Pattern registration number 0~29 (Maximum 30pattern)

Program link Maximum 6 patterns

Link program registration Maximum 10 links

Pattern REPEAT

1pattern all repeat X 1(Maximum repeat is 999 cycle)

Part repeat X 5(Maximum repeat is 999 cycle)

HOLD

Stops program operation, if HOLD key in the front panel is pressed

(Time counter stops and FIX control begins from that position)

Starts program operation, when HOLD key is pressed again.

(Time counter begins)

WAIT

1) Rear Wait

Time may exceed set time of the particular step. In this case,

remaining time is set as 0 and pending, if temperature

that was measured do not reach target value ± WAIT set point.

It proceeds to the next step after it is confirmed that temperature reach

the range of set point

(target value ± WAIT)

2) Front Wait

Proceeding of program is pending if temperature

that was measured do not reach the range of target

value ± WAIT set point.

Setup range : ± 0 ~ 9.9°C

ADVANCE

If you press ADVANCE key in the display, the remaining time of the step is

set as 0 and moves to the next STEP.

Note) Operation of Advance while waiting

1) Proceeds to the next step in the case of Rear Wait

2) Time is set as 0 and set point (SP) is equal to target value in

the case of Front Wait.

PROGRAM RUN

1) Operates with RUN key in the display

2) Starts external signal : Input RUN/STOP,ON / 1 pulse

3) Starts time : It is possible to reserve time, day, and month

Note 1) Control output is ON with program RUN.

Note 2) Time begins is effective after operation of RUN in 1) or 2)

Program STOP

1) Operates with STOP key in the display

2) Input STOP for external signal : RUN/STOP ON / 1 pulse

(Note) If it is STOP, program stops and control output of the

total is OFF

- 33 -

Item Specifications

POWER FAILURE

Controls right away after recovery of power failure, if the power failure

lasts less than 4 seconds.

For power failure that lasts longer than 4 seconds, setup modes below

will be followed.

BREAK : Stops program

HOT START : Controls at the state just before power

failure

COLD START : It starts again at the beginning of

program

(Note) It is HOT START for fix control

Output Open collector output X 4

SIGNAL

MODE

3 kinds of mode setup available (according to numerical inputs of 0-9)

1) ON-OFF mode

2) time mode

3) step mode

: 0 setup OFF (out is OFF at this step)

: 1 setup ON (out is ON at this step)

: Random time signal setup of 2-9 available (8 kinds)

TIME MODE

Setup of ON-DELAY time (ON time due to delay)

Setup of CUT-BACK time (beforehand OFF time)

TIME SIGNAL

STEP MODE Setup of ON-DELAY time (ON time due to delay)

4.4 control output specifications

Item

Specifications

PID control

PID time partition open collector output X 1

PID DC 4~20mA(load resistance 500Ω)X1

Temperature

ON/OFF control Open collector output(Maximum ON/OFF X 9) - INNER SIGNAL

Proportion (P) 0.0~99.99 %

Integral time (I) 0~36.00 Min

Derivative time

(D)

0~36.00 Min

Cycle time 1~99 seconds

PID Constants

ARW 0~100 %

- 34 -

Item Specifications

PID ZONE Setup

Up to six zones are classified for the field of temperature and input of

PID constant can be setup in each field (While program is being

executed, PID constant of the field is used automatically, if SP exists in

the field).

Note 1) 6 temperature fields

RUN Output

Open collector output ON/OFF X 1

"ON" when program is RUN; "OFF" when program is END

END Output

Open collector output ON/OFF X 1

"ON" when program is END; "OFF" when program is ON

TIME SIGNAL

Open collector output ON/OFF X 4

It is possible to set up to 10 ON/OFF times

Others

In the program mode, control operation starts for program start

(Control output of the total of the previous is OFF)

For those other than transmitted output (Power failure, Alarm, stop),

output of the total is OFF when the program stops.

4.5 Control output specifications (INNER Signal)

Item Specifications

Output points

Open collector output ON/OFF X 6

(MAX DC30V MAX 50mA / 1ch internal resistance 47Ω)

Object Temperature(TEMP)

Object value Set Point (SP) / Present value (PV) / Target value (DV)

Operating point Absolute value (ABS) / Deviation (DEV)

Output

operation

ZONE ON/OFF / Operation direction (LOW/HIGH)

Temperature

Absolute value -100.0 ~ 300.0 °C

Deviation value -99.9 ~ +99.9 °C

Operation

range

Action differential ± 0.0 ~ ± 9.9 °C

Setup item

ON delay time 0 ~ 99 seconds

- 35 -

Item Specifications

Object

TEMP

INNER SIGNAL output is to be setup at temperature output.

Object value

PV/SP/DV

Setup of which value determines the ON/OFF.

PV: Present value, SP: Set point interlocked with program operation

DV: target value of step (fixed value within step, Destination value)

Output

operation

LOW/HIGH

Setup for ABS or DEV

Setup

item

content

Output

operation

ON/OFF

In case of a setup by selecting object value as SP or DV, and then range

setup and operation direction (ON/OFF) setup are to be done.

range setup : Temperature 2 points MIN~MAX -100.0~300.0°C

ON/OFF setup :

Output On: when ON mode set point is within setup range

Output Off: when ON mode set point is out of setup range

Output On: OFF mode set point is within setup range

Output Off: OFF mode set point is out of setup range

4.6 Control mode and setup

Item Specifications

1) FIX control mode

Control mode

2) Program control mode

Control

mode

Mode selection

Selection available at the operation setup screen

Temperature

setup

-100.0 ~ 300.0°C

Slope

setup

0 ~ 9.9 °C/min

FIX

control

mode

Auto

tuning

Auto tuning of PID constant

Control

mode

setup

Program

control

mode

Temperature

setup

-100.0 ~ 300.0°C

- 36 -

4.7 Other specifications

Item Specifications

Display language

English, Korean and Chinese

(Conversion to English/Korean/ Chinese selection screen at the Menu

screen)

Temperature -100~300, -80~120, -50~150, -50~50, 0~100, 0~300°C of variability

Hours 4, 12, 24, 48, 96 hours, 8 days of variability

Graph

screen

Operation

Identification of program setup with a graph SP curve is possible.

PV value display, SP value display, total time display (color of graph is

to be inverted) in operation.

Month, date, time

correct

Month, date, time correctable (year 2000 display is possible)

LCD brightness LCD brightness adjustable

Accumulation of

operation time

(TOTAL TIME)

Accumulated time at the beginning of program RUN or control (FIX

control)

Recounting from END at the maximum of 9,999hours and 59mins

Counting from ‘0’ at the program or regular control start

Back light

ON/TIMER OFF conversion available (0~99min)

When back light is OFF and you press any part of the screen, backlight

will be turned on.

Run lock RUN/STOP key display is locked

Test name registration Test name registration is up to 10 patterns

- 37 -

4.8 T rouble Monitor

Item Specifications

Trouble input

ON / OFF contact point input X 6

(In case of operation when the trouble input is ON)

1) Automatic conversion from operation screen to trouble monitor

2) Control output and ON/OFF output are all to be OFF exclusive

of temperature present value output

Trouble monitor Display of maximum 6 of trouble items

Trouble message Trouble countermeasure message screen (6 screens)

Reset handling CLEAR handling performs when removing the causes of trouble.

- 38 -

4.9 External Dimensions

210.0

130.0

unit : mm

198.5

173.5

13.5

14

118

Honeywell Co., Ltd.

S&C Control Product

06F, Hanil Group Building 191,

Hangangro-2ga, Yongsan-gu,

Seoul, 140-702, Korea

Tel: 82-2-799-6176 Fax : 82-2-792-9013

Contents are subject to change without notice.

http://www.honeywell.co.k

r

Oct., 2002

Loading...

Loading...