Honeywell IP-AK2 Installation And Configuration Manual

Honeywell

IP-AK2

Access Control Unit

Installation and Configuration Guide

© 2009 Honeywell International Inc. All rights reserved.

http://www.security.honeywell.com/

Document 800-03522 Rev. A1

Warnings and Cautions

Fire Safety and Liability Notice: Never connect card readers to any critical entry, exit door,

barrier, elevator or gate without providing an alternative exit in accordance with all fire and

life safety codes pertinent to the installation. These fire and safety codes vary from city to

city and you must get approval from local fire officials whenever using an electronic product

to control a door or other barrier. Use of egress buttons, for example, may be illegal in

some cities. In most applications, single action exit without prior knowledge of what to do is

a life safety requirement. Always make certain that any required approvals are obtained in

writing. Verbal approvals are not valid.

Honeywell never recommends using WIN-PAK or related products for use as a primary

warning or monitoring system. Primary warning or monitoring systems should always meet

local fire and safety code requirements. The installer must also test the system on a regular

basis by instructing the end user in appropriate daily testing procedures. Failure to test a

system regularly could make installer liable for damages to the end user if a problem

Warnings

occurs.

Earth ground all enclosures for proper installation.

Use suppressors on all door locks. Use S-4 suppressors for installation. Honeywell Access

Systems (HAS) recommends only DC locks.

Personal injury or death could occur, and the equipment could be damaged beyond repair,

if this precaution is not observed!

• Before installation, turn off the external circuit breaker which supplies power to the

system, including door locks.

• Before connecting the device to the power supply, verify that the output voltage is

within specifications of the power supply.

• Do not apply power to the system until after the installation has been completed.

Honeywell

Cautions

If any damage to the shipment is noticed, a claim must be filed with the commercial carrier

responsible.

Electro-static discharge (ESD) can damage CMOS integrated circuits and modules. To

prevent damage always follow these procedures:

• Use static shield packaging and containers to transport all electronic components,

including completed reader assemblies.

• Handle all ESD sensitive components at an approved static controlled workstation.

These workstations consist of a desk mat, floor mat and an ESD wrist strap.

Workstations are available from various vendors.

i

Honeywell

Limited Warranty

All product and brand names are the service marks, trademarks, registered trademarks,

or registered service marks of their respective owners. Printed in the United States of

America. Honeywell reserves the right to change any information in this document at any

time without prior notice.

All Products sold or licensed by Honeywell Access Systems (HAS) include a warranty

registration card which must be completed and returned to HAS by or on behalf of the

end user in order for Honeywell to provide warranty service, repair, credit or exchange.

All warranty work shall be handled through the Customer which shall notify Honeywell

and apply for a Return Merchandise Authorization (RMA) number prior to returning any

Product for service, repair, credit or exchange.

Honeywell warrants that its Products shall be free from defects in materials and

workmanship for a period of one year from date of shipment of the Product to the

Customer. The warranty on Terminals, Printers, Communications, Products and Upgrade

kits is 90 days from date of shipment. Satisfaction of this warranty shall be limited to

repair or replacement of Products which are defective or defective under normal use.

Honeywell’s warranty shall not extend to any Product which, upon examination, is

determined to be defective as a result of misuse, improper storage, incorrect installation,

operation or maintenance, alteration, modification, accident or unusual deterioration of

the Product due to physical environments in excess of the limits set forth in Product

manuals.

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THIS PROVISION. THIS

WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS,

IMPLIED OR STATUTORY, INCLUDING IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. NO

REPRESENTATION OR WARRANTY OF THE DISTRIBUTOR SHALL EXTEND THE

LIABILITY OR RESPONSIBILITY OF THE MANUFACTURER BEYOND THE TERMS

OF THIS PROVISION. IN NO EVENT SHALL HONEYWELL BE LIABLE FOR ANY REPROCUREMENT COSTS, LOSS OF PROFITS, LOSS OF USE, INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES TO ANY PERSON RESULTING FROM

THE USE OF HONEYWELL PRODUCTS.

ii

Contents

Honeywell

1 About This Document ..................................................................................................................................1

2 Introduction..................................................................................................................................................3

3 Installation ...................................................................................................................................................5

4 Connecting to IP-AK2 Access Control System..........................................................................................14

5 Configuring via IP-AK2 Web Server ..........................................................................................................15

6 Specifications and Panel Wiring ................................................................................................................48

7 Maintenance ..............................................................................................................................................50

8 Troubleshooting.........................................................................................................................................51

Appendix A Miscellaneous ...........................................................................................................................52

Overview of Contents.........................................................................................................................1

Special Font and Symbols .................................................................................................................2

How to Use This Document ...............................................................................................................2

IP-AK2 Access Control Panel ............................................................................................................4

Power Supply .....................................................................................................................................4

Battery................................................................................................................................................4

Mounting ............................................................................................................................................6

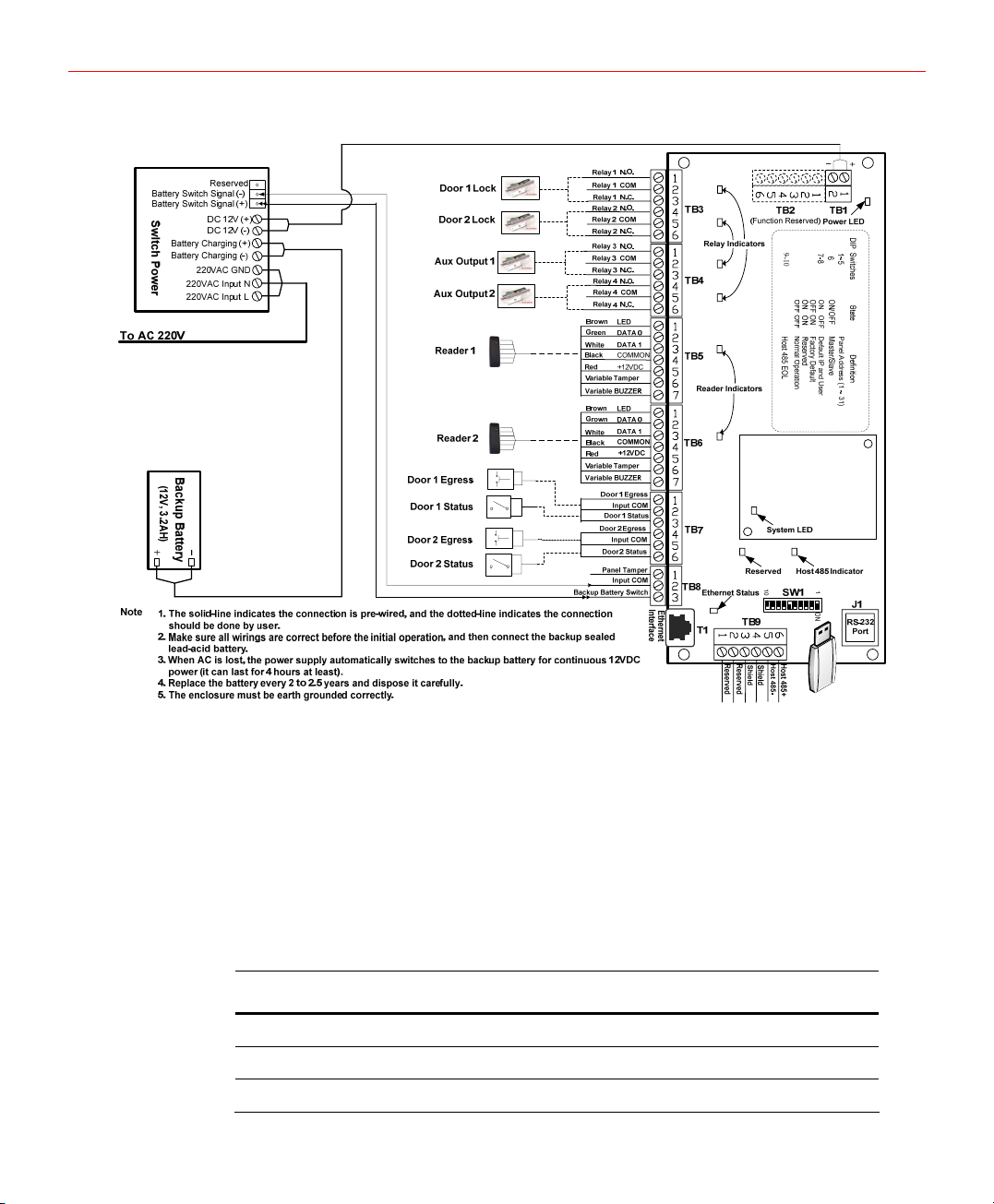

Wirings ...............................................................................................................................................8

Cabinet Wiring.............................................................................................................................8

Reader Wiring .............................................................................................................................9

Supervised Input Wiring ............................................................................................................10

Output Wiring ............................................................................................................................11

DIP Switch Settings..........................................................................................................................11

LED Status .......................................................................................................................................13

Connecting to IP-AK2 Web Server...................................................................................................15

Connecting Panel to Computer .................................................................................................15

Configuring Network Connection...............................................................................................16

Login to IP-AK2 Web Server ............................................................................................................17

Security Alert .............................................................................................................................17

Login..........................................................................................................................................18

Configuring via Web Server .............................................................................................................19

Time Configuration ....................................................................................................................21

Panel Configuration...................................................................................................................23

Door Configuration ....................................................................................................................29

Access Configuration ................................................................................................................34

System Configuration ................................................................................................................40

Monitor .............................................................................................................................................43

Alarms .......................................................................................................................................43

Events .......................................................................................................................................44

Door View..................................................................................................................................45

Input View..................................................................................................................................45

Output View...............................................................................................................................46

System Status ...........................................................................................................................47

Report ..............................................................................................................................................47

Specifications...................................................................................................................................48

IP-AK2 Panel Wiring Diagram..........................................................................................................49

Basic Standalone Operations...........................................................................................................52

Card Read / Door Lock Operation.............................................................................................52

Door Egress / Door Lock / Door Status Operation ....................................................................52

IP-AK2 Panel Defaults .....................................................................................................................52

Reader Ports .............................................................................................................................52

Reader Tamper Inputs ..............................................................................................................53

Door Egress Inputs....................................................................................................................53

Door Status Inputs.....................................................................................................................53

AC FAIL and Panel Tamper Inputs ...........................................................................................54

Additional Generic Outputs .......................................................................................................54

i

Honeywell

Figures

Figure 2-1 IP-AK2 Access Control Unit ...................................................................................................................... 3

Figure 3-1 IP-AK2 Panel Cabinet - Top View ............................................................................................................. 6

Figure 3-2 IP-AK2 Panel Cabinet - Bottom View ........................................................................................................ 6

Figure 3-3 IP-AK2 Panel Cabinet - Left View ............................................................................................................. 7

Figure 3-4 IP-AK2 Panel Cabinet - Right View ........................................................................................................... 7

Figure 3-5 IP-AK2 Panel Cabinet - Back View ........................................................................................................... 8

Figure 3-6 Cabinet Wiring........................................................................................................................................... 9

Figure 3-7 Typical Supervised Input Wiring Diagram ............................................................................................... 10

Figure 3-8 LED Indicators......................................................................................................................................... 13

Figure 4-1 IP-AK2 Panel Connections in IP-AK2 Access Control System ............................................................... 14

Figure 5-1 IP-AK2 Web Server Hub Connection ...................................................................................................... 15

Figure 5-2 IP-AK2 Web Server Direct Connection ................................................................................................... 16

Figure 5-3 Local Area Connection Properties........................................................................................................... 16

Figure 5-4 Network Configuration............................................................................................................................. 17

Figure 5-5 Security Alert 1 ........................................................................................................................................ 17

Figure 5-6 Security Alert 2 ........................................................................................................................................ 18

Figure 5-7 Security Alert 3 ........................................................................................................................................ 18

Figure 5-8 Security Alert 4 ........................................................................................................................................ 18

Figure 5-9 IP-AK2 Web Server Login Page.............................................................................................................. 18

Figure 5-10 IP-AK2 Web Server Main Page............................................................................................................. 19

Figure 5-11 IP-AK2 System Configuration Flow Chart ............................................................................................. 20

Figure 5-12 Configuration Menu in IP-AK2 Web Server........................................................................................... 20

Figure 5-13 Time Zones Page .................................................................................................................................. 21

Figure 5-14 Current Loop Time ................................................................................................................................ 21

Figure 5-15 Update Loop Time................................................................................................................................. 21

Figure 5-16 Add Time Zone...................................................................................................................................... 21

Figure 5-17 Modify Time Zone.................................................................................................................................. 22

Figure 5-18 Holidays Page ....................................................................................................................................... 22

Figure 5-19 Add Holiday ........................................................................................................................................... 23

Figure 5-20 Modify Holiday....................................................................................................................................... 23

Figure 5-21 Select a Different Panel 1...................................................................................................................... 23

Figure 5-22 Select a Different Panel 2...................................................................................................................... 24

Figure 5-23 Panel Attributes Page............................................................................................................................ 24

Figure 5-24 Interlocks Page...................................................................................................................................... 26

Figure 5-25 Add Interlock ......................................................................................................................................... 26

Figure 5-26 Modify Interlock ..................................................................................................................................... 27

Figure 5-27 Data Management Page ....................................................................................................................... 28

Figure 5-28 Select a Different Door 1 ....................................................................................................................... 29

Figure 5-29 Select a Different Door 2 ....................................................................................................................... 29

Figure 5-30 Input Settings Page ............................................................................................................................... 30

Figure 5-31 Door Status 1 ........................................................................................................................................ 30

Figure 5-32 Door Status 2 ........................................................................................................................................ 30

Figure 5-33 Door Status 3 ........................................................................................................................................ 30

Figure 5-34 Output Settings Page ............................................................................................................................ 32

Figure 5-35 Reader Settings Page ........................................................................................................................... 32

Figure 5-36 Site Codes Page ................................................................................................................................... 34

Figure 5-37 Add Site Code ....................................................................................................................................... 34

Figure 5-38 Modify Site Code ................................................................................................................................... 34

Figure 5-39 Access Levels Page .............................................................................................................................. 35

Figure 5-40 Add Access Level.................................................................................................................................. 35

Figure 5-41 Modify Access Level.............................................................................................................................. 36

Figure 5-42 Card Formats Page ............................................................................................................................... 36

Figure 5-43 Card Format Data Layout...................................................................................................................... 37

Figure 5-44 Card Management Page ....................................................................................................................... 38

Figure 5-45 Add Card ............................................................................................................................................... 38

Figure 5-46 Modify Card ........................................................................................................................................... 39

ii

Honeywell

Figure 5-47 Search Card .......................................................................................................................................... 40

Figure 5-48 User Configuration Page ....................................................................................................................... 40

Figure 5-49 Add User ............................................................................................................................................... 40

Figure 5-50 Modify User ........................................................................................................................................... 41

Figure 5-51 Change Password 1 .............................................................................................................................. 41

Figure 5-52 Change Password 2 .............................................................................................................................. 41

Figure 5-53 Networking Settings Page ..................................................................................................................... 42

Figure 5-54 Web Configuration................................................................................................................................. 42

Figure 5-55 Unacknowledged/ Acknowledged Alarm Number ................................................................................. 43

Figure 5-56 Monitoring->Alarm ................................................................................................................................. 43

Figure 5-57 Monitoring->Alarms->“Acknowledged” .................................................................................................. 43

Figure 5-58 Monitoring->Events ............................................................................................................................... 44

Figure 5-59 Monitoring->Doors................................................................................................................................. 45

Figure 5-60 Door Action............................................................................................................................................ 45

Figure 5-61 Monitoring->Inputs ................................................................................................................................ 45

Figure 5-62 Input Action ........................................................................................................................................... 46

Figure 5-63 Monitoring->Outputs.............................................................................................................................. 46

Figure 5-64 Output Action......................................................................................................................................... 47

Figure 5-65 Monitoring->System Status ................................................................................................................... 47

Figure 5-66 Reports Page ........................................................................................................................................ 47

Figure 6-1 IP-AK2 Panel Wiring Diagram ................................................................................................................. 49

iii

Honeywell

Tables

Table 3-1 Cabinet Electrical Entries ........................................................................................................................... 6

Table 3-2 Reader Wiring............................................................................................................................................. 9

Table 3-3 Default Supervised Input Assignments..................................................................................................... 10

Table 3-4 DIP Switch Definition ................................................................................................................................ 11

Table 3-5 DIP Switch Settings .................................................................................................................................. 12

Table 5-1 Panel Attributes Description ..................................................................................................................... 25

Table 5-2 Interlock Settings Description ................................................................................................................... 26

Table 5-3 Database Categories................................................................................................................................ 27

Table 5-4 Auto Backup Description .......................................................................................................................... 28

Table 5-5 Input Settings Description......................................................................................................................... 31

Table 5-6 Output Settings Description...................................................................................................................... 32

Table 5-7 Reader Settings Description..................................................................................................................... 33

Table 5-8 Card Format Description .......................................................................................................................... 37

Table 5-9 Card Fields Description ............................................................................................................................ 38

Table 5-10 Networking Settings Description............................................................................................................. 42

Table 5-11 Alarms Field Descriptions....................................................................................................................... 44

Table 5-12 Alarms Field Descriptions....................................................................................................................... 44

Table 5-13 Door Icon Description ............................................................................................................................. 45

Table 8-1 Troubleshooting Problems and Solutions................................................................................................. 51

Table A-1 Default Reader Ports................................................................................................................................ 53

Table A-2 Default Reader Tamper Inputs................................................................................................................. 53

Table A-3 Default Door Egress Inputs ...................................................................................................................... 53

Table A-4 Default Door Status Inputs ....................................................................................................................... 53

Table A-5 Default AC FAIL and Panel Tamper Inputs.............................................................................................. 54

Table A-6 Additional Generic Outputs ...................................................................................................................... 54

iv

1 About This Document

Thank you for purchasing the IP-AK2 Access Control Unit!

This user guide is designed to be a reference for the installation and configuration of IPAK2 Access Control Unit.

Overview of Contents

This document contains the following chapters:

• Chapter 1, About This Document, a brief introduction of “IP-AK2 Access Control

Unit User Guide”.

• Chapter 2, Introduction, general information about IP-AK2 Access Control Unit

components, including IP-AK2 Access Control Panel, Power Supply, Battery, and

Enclosure.

• Chapter 3, Installation, describes how to install IP-AK2 panel, mount the cabinet,

wire the components, set dip switches, and so on.

• Chapter 4, Connecting to IP-AK2 Access Control System, gives a diagrammatical

instruction on how to connect IP-AK2 panel to Access Control System.

• Chapter 5, Configuring via IP-AK2 Web Server, introduces how to configure IP-AK2

panel settings through IP-AK2 Web Server.

• Chapter 6, Specifications and Panel Wiring, shows IP-AK2 Access Control Unit

specifications and panel wiring diagram.

• Chapter 7, Maintenance, introduces the maintenance information.

• Chapter 8, Troubleshooting, introduces troubleshooting problems and resolutions.

• Appendix A, Miscellaneous, introduces basic standalone operations and IP-AK2

panel defaults.

Honeywell

1

About This Document

Special Font and Symbols

Italic

【】

Note

Caution

references

a button, tab or menu item

the important notice should pay attention to

important operating alerted

How to Use This Document

• Pictures in the manual are for reference only, so please see the actual items.

• The products will be updated and the information shall not be distributed.

• Please read the book before operation and keep it properly for future use.

• The manual has been reviewed and the accuracy is guaranteed. If there is any

uncertainty or controversy, please refer to the final explanation of Honeywell.

Honeywell does not take any responsibility for any consequences caused by

misunderstanding of the manual or improper operations.

2

2 Introduction

The IP-AK2 Access Control Unit is one part of Access Control System (see Figure 4-1

IP-AK2 Panel Connections in IP-AK2 Access Control System

protects and preserves enterprise’s resources by providing authentication, authorization,

and administration services.

The IP-AK2 Access Control Unit consists of:

• An IP-AK2 Access Control Panel

• A Power Supply

• A Sealed Lead-acid Battery

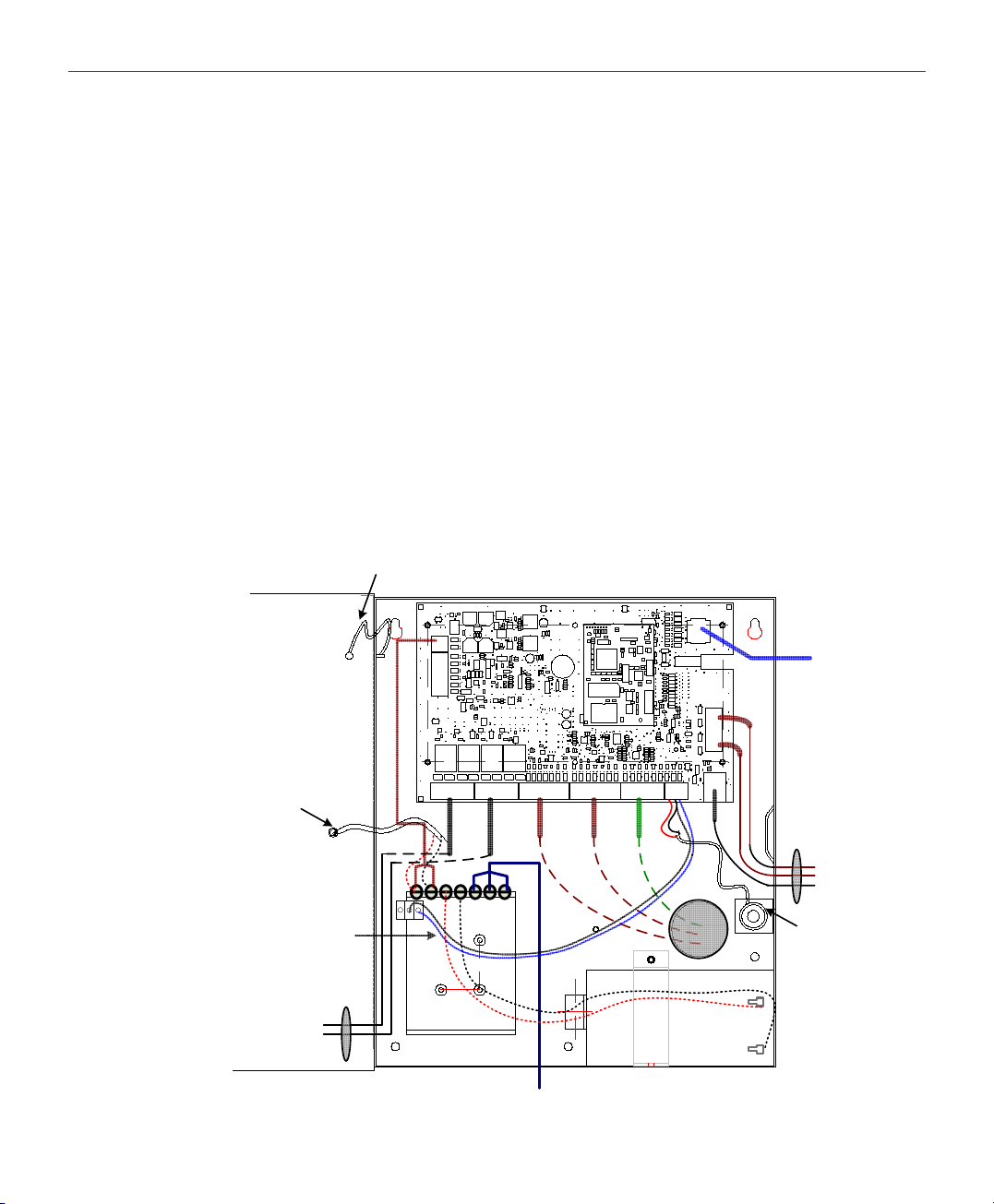

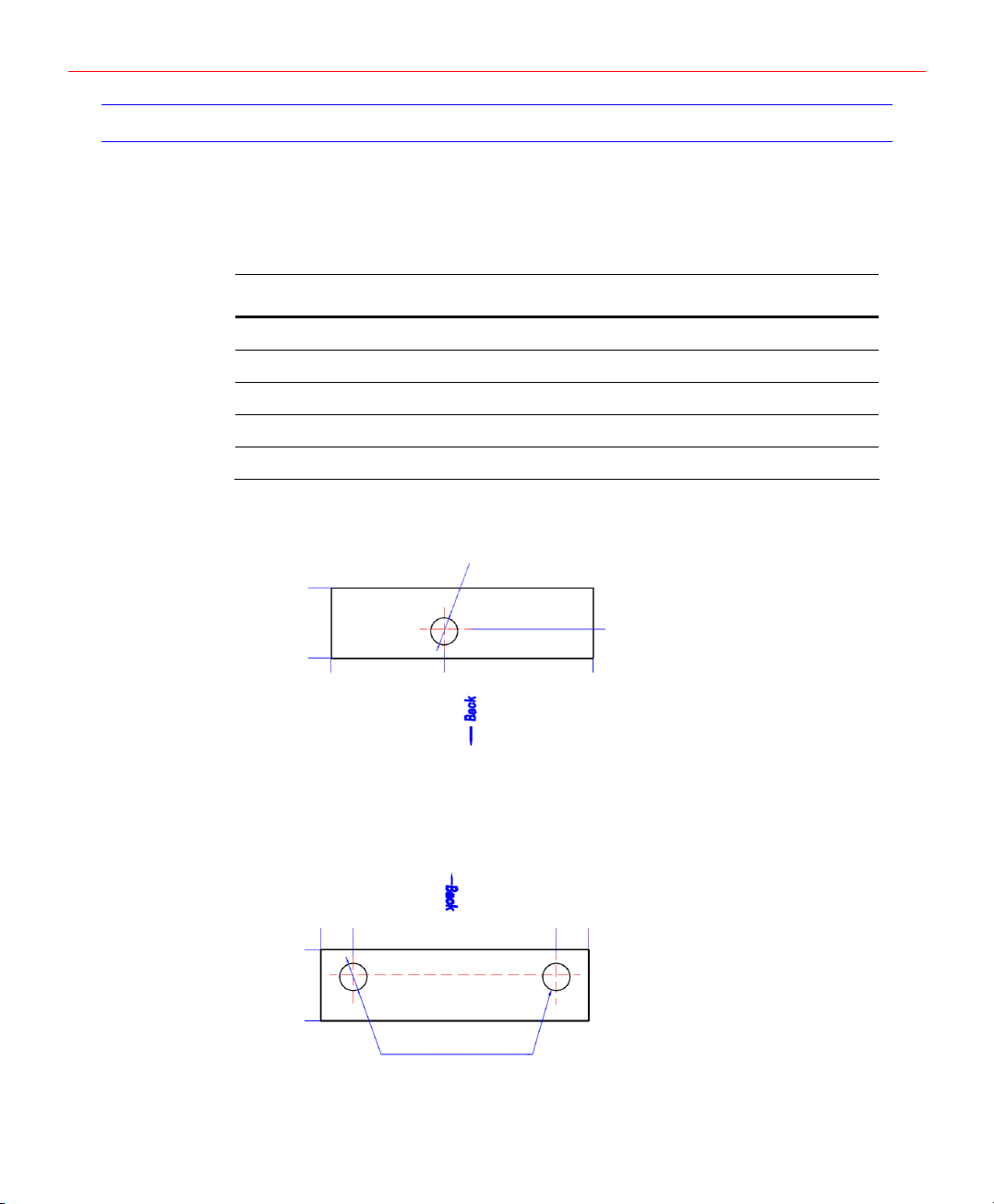

The following figure shows the IP-AK2 Access Control Unit components in the cabinet.

Figure 2-1 IP-AK2 Access Control Unit

Honeywell

on page 14), which

Chassis Ground

Connected Cable

RS232

Indictor LED

connected 12VDC

LED

Backup power loss

alarm input

Relay 1, 2 Relay 3, 4

POWER SUPPLY

220VAC Power Input

Reader1

Reader2

SVS input

BATTERY

Host 485

Reserved

Ethernet

Panel Tamper

Contact

3

Introduction

IP-AK2 Access Control Panel

The IP-AK2 Access Control Panel (shorted for “IP-AK2 panel” hereafter) is a two-reader

access controller that controls up to 2 doors by providing up to 8 inputs and 4 outputs. It

can be used as a stand-alone system (Up to 10 panels). User can configure and monitor

it through standard web browser. The IP-AK2 panel has the following features:

Real-Time Clock Protection

The panel RTC is backed up using a super capacitor, which will power the real-time

clock for one week in the absence of primary power or backup battery.

Memory Protection

The IP-AK2 panel continuously saves database and event information in non-volatile

FLASH memory. This activity prevents the panel from losing data when power is lost.

Reader Power

Reader power is supplied at 12VDC nominal with a maximum current distribution of

150mA. The maximum draw of two readers is less than 300mA.

Caution IP-AK2 panel and Reader Power must not be used to power locks.

Power Supply

The IP-AK2 panel uses an internal 220VAC (110VAC) to 12VDC regulated power supply

(Hengfu Model HF20W-SB-12). The supply uses 220VAC (110VAC), 60Hz, 0.2(0.4)Amp

input, and provides 12VDC at 1.5Amps for the system power. It also charges and

monitors the condition of the batteries.

Input power indicator is supplied for illuminating when board input voltage is present. If

the indicator is off, it means the input voltage is off or it is too low to operate the system.

Battery

For the IP-AK2 panel, one Long-way 6FM3.2AJ, 12VDC, 3.2AHr sealed lead-acid battery

(Honeywell order number 300-03271) must be used to have backup battery capability.

The battery will provide standby backup power, depending upon system configuration

and activity. The battery is wired and connected to the BAT and COM terminals on the

12VDC power supply in the IP-AK2 enclosure. When AC is lost, the power supply

automatically switches to the backup batteries for continuous 12VDC power.

The power supply has deep discharge protection, and it can shutdown battery backup

output when discharge voltage is below 9.4V. Refer to the system wiring diagram for

details. Replace the batteries every 2 to 2.5 years, or more often if the system has a high

rate of backup use.

4

3 Installation

Perform the following steps to install IP-AK2 panel:

Caution

1. Check the panel layout, cable runs, and power needs.

2. Mount the enclosure at the proper location on the wall. Use appropriate anchors for

the mounting material.

3. Run all I/O wires to the enclosure, and properly mark each wire for its use (Remove

each terminal plug one at a time to wire the properly labeled cables).

Figure 6-1 IP-AK2 Panel Wiring Diagram on page 49. Leave enough shield drain

See

length to secure to the grounding stud. Also, maintain a distance of at least 6.35mm

between the non-power limited wiring (220VAC/60Hz input wiring, power line filter wiring,

12VDC wiring, and battery backup/charger wiring) and all other wirings.

Honeywell

Use a static strap whenever touching the panel to ensure protection from

Electrostatic Discharge (ESD).

Caution Do not apply power at this moment.

4. Connect the shield to the grounding studs.

5. Set DIP switch settings for the panel address (see Table 3-5 DIP Switch Settings on

12).

page

6. Check all wirings.

Caution

Improper wiring can cause damage to the IP-AK2 panel when power up and

result in a loss of warranty.

7. Apply power to the panel, and then POWER LED will turn green meanwhile. The

POWER LED is close to 12VDC power connector (TB1). After several minutes,

RUN LED will flash per second. The RUN LED is close to 80-pin Connector (J2).

8. Place one 3.2A-Hr battery in the enclosure. Attach the positive (red) Power Supplyto-Battery cable to the remaining positive (red) battery terminal; and the negative

(black) Power Supply-to-Battery cable to the remaining negative (black) battery

terminal.

Note

For panels using the Ethernet connection, the cable clamp must be used for the

panel to pass the FCC Part 15 Class B requirements. Snap the clamp around

any portion of the Ethernet cable that is inside of the enclosure.

5

Installation

Mounting

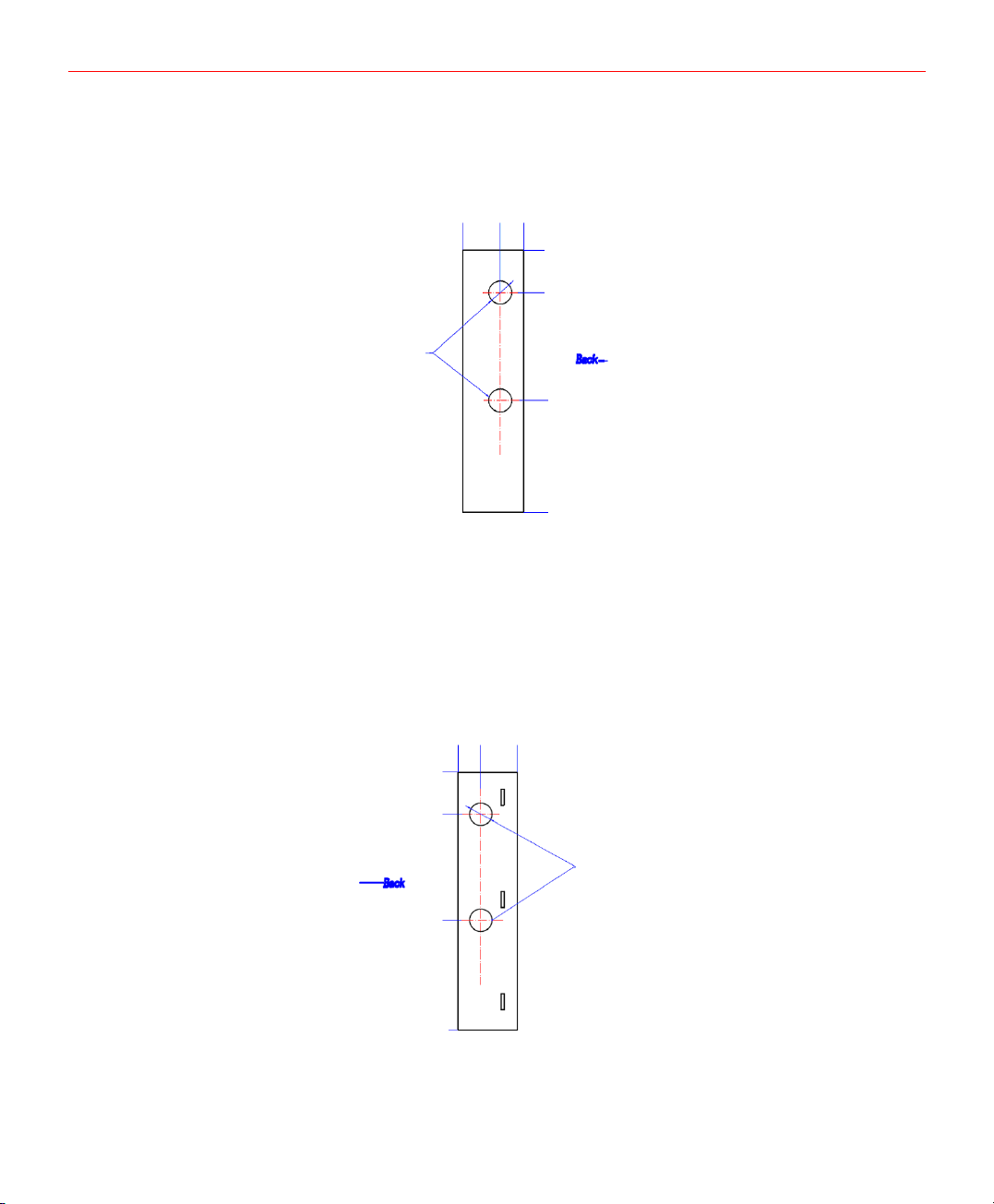

The following five figures show the back, top, bottom, right, and left views of the IP-AK2

panel cabinet. Each view includes the dimensions and knockout placement to mount the

cabinet. See the table below for dimensions of the conduit entries into the cabinet.

Table 3-1 Cabinet Electrical Entries

ENCLOSURE CONDUIT 1” (30mm) CONDUIT 2” (40mm)

Top 2 N/A

Bottom N/A 1

Right 2 N/A

Left 2 N/A

Back 1 N/A

Figure 3-1 IP-AK2 Panel Cabinet - Top View

78mm [3.071”]

φ30mm [φ1.181”] Diameter Knockout

0mm [0.000”]

0mm [0.000”]

125mm [4.921”]

Figure 3-2 IP-AK2 Panel Cabinet - Bottom View

0mm [0.000”]

0mm [0.000”]

78mm [3.071”]

35mm [1.378”]

φ30mm [φ1.181”] Diameter Knockout

255mm [10.039”]

32.44mm [1.277”]

290mm [11.417”]

290mm [11.417”]

6

Figure 3-3 IP-AK2 Panel Cabinet - Left View

78mm [3.071”]

φ30mm [φ1.181”] Diameter Knockout

0mm [0.000”]

30mm [1.181”]

0mm [0.000”]

55mm [2.165”]

195mm [7.677”]

Honeywell

340mm [13.386”]

Figure 3-4 IP-AK2 Panel Cabinet - Right View

30mm [1.181”]

0mm [0.000”]

55mm [2.165”]

195mm [7.677”]

340mm [13.386”]

0mm [0.000”]

78mm [3.071”]

φ30mm [φ1.181”] Diameter Knockout

7

Installation

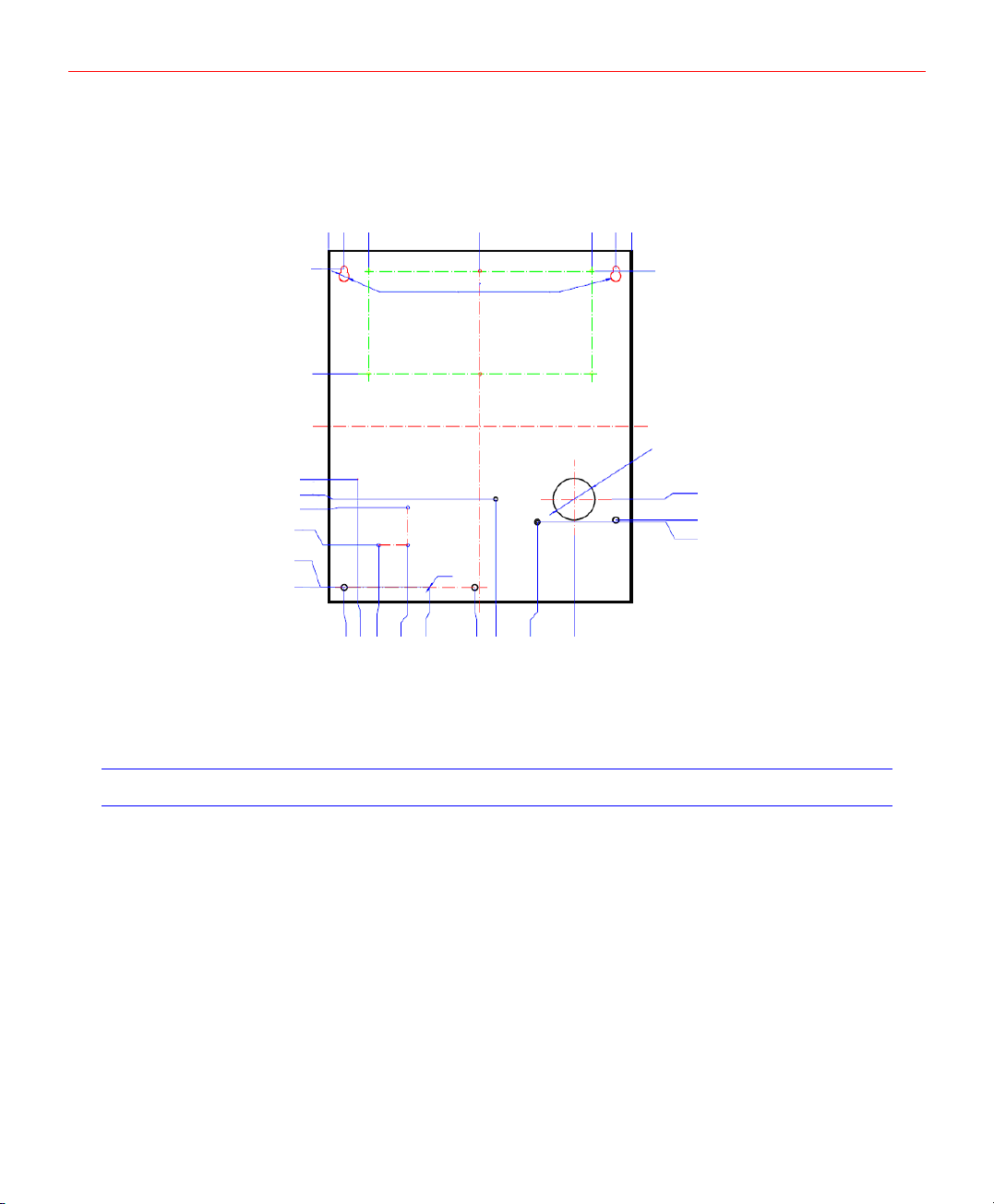

Figure 3-5 IP-AK2 Panel Cabinet - Back View

0mm [0.000”]

18mm [0.709”]

119mm [4.685”]

221mm [8.701”]

240mm [9.449”]

248mm [9.764”]

284mm [11.181”]

324.5mm [12.776”]

325mm [12.795”]

15mm [0.591”]

38.25mm [1.506”]

φ10mm [φ0.394”] Diameter (2 holes)

2-N3

144.92mm [5.706”]

290mm [11.417”]

251.75mm [9.911”]

275mm [10.827”]

20mm [0.787”]

φ40mm [φ1.575”] Diameter Knockout

240mm [9.449”]

260mm [10.236”]

262mm [10.315”]

Wirings

This section describes how to wire the IP-AK2 panel cabinet, the reader, the supervised

input and output.

Cabinet Wiring

The picture below shows how to connect the IP-AK2 panel and the inputs, outputs,

power supply in cabinet.

8

15mm [0.591”]

76mm [2.992”]

28mm [1.102”]

48mm [1.890”]

140mm [5.512”]

97.1mm [3.823”]

160mm [6.299”]

200mm [7.874”]

235.06mm [9.254”]

Figure 3-6 Cabinet Wiring

Honeywell

Reader Wiring

Each reader port supports a single 12-volt reader with Wiegand output format. The

maximum power draw is 300 mA for readers.

To fully utilize each reader port, a shielded 7-conductor cable (18-22 AWG) is required. If

the optional reader buzzer feature is not needed, you can use the standard 6-conductor

cable. The cable shield should be grounded at the panel only. Grounding at both ends

can cause ground loops which can be disruptive. The maximum recommended length of

wiring is 500 feet per reader.

Table 3-2 Reader Wiring

Terminal Wire Color Wiegand Reader

TB5-1, 6-1 Brown LED Control

TB5-2, 6-2 Green Wiegand Data 0 or Data

TB5-3, 6-3 White Wiegand Data 1 Or Clock

9

Installation

Terminal Wire Color Wiegand Reader

TB5-4, 6-4 Black Common

TB5-5, 6-5 Red 12VDC Power

TB5-6, 6-6 Variable Tamper

TB5-7, 6-7 Variable Buzzer

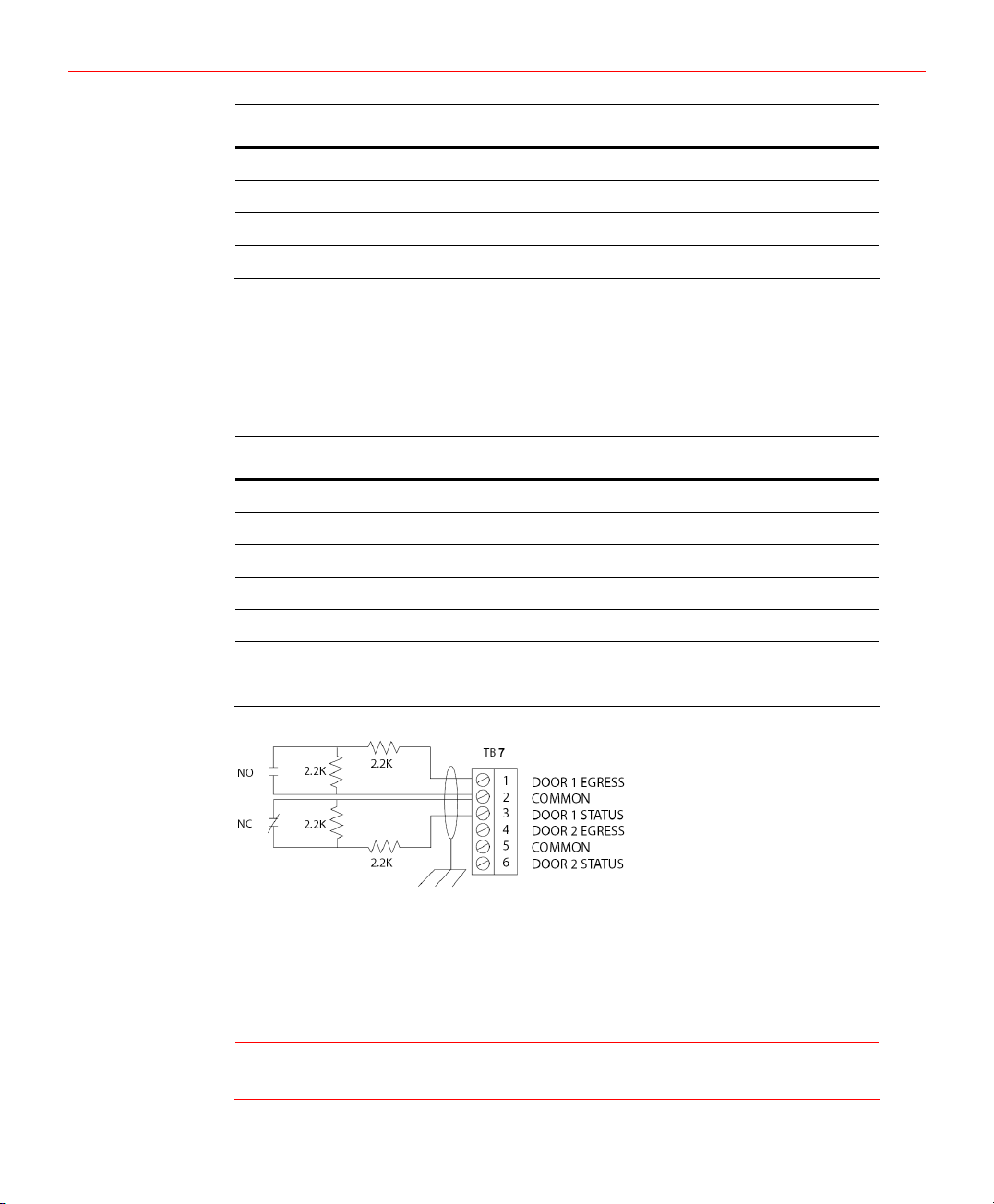

Supervised Input Wiring

The supervised inputs are located on TB5, TB6, TB7 and TB8. Input 1 through Input 4

may be configured for normally open or normally closed contacts as supervised or nonsupervised. Inputs 5 and 6 are on TB8.

Table 3-3 Default Supervised Input Assignments

Terminal Position Input Number Default Function

TB7-1 Input 1 Door 1 REX (Egress)

TB7-3 Input 2 Door 1 Status

TB7-4 Input 3 Door 2 REX (Egress)

TB7-6 Input 4 Door 2 Status

TB8-1 Input 5 Panel Tamper

TB8-3 Input 6 External Power Supply AC FAIL

TB 5-6, 6-6 Input 7/8 Reader Tamper

Figure 3-7 Typical Supervised Input Wiring Diagram

The figure above shows the typical wiring for a supervised input using standard 2,200

ohm resistors. The IP-AK2 panel accepts 1,000, 2,200, 4,700, or 10,000 ohm values.

Note that both resistors must have the same value.

In addition, the Panel Tamper and External Power Fail can be supervised and capable of

being used as additional inputs if the default functionality is not needed. They also share

a single common.

Caution

Supervised input wiring must be used if Input 6 is used for “External Power

Supply AC Failed”.

10

Honeywell

The wire used for the inputs should be shielded and cannot exceed 20 ohms over the

entire length of the cable. Remember that the distance from the panel to the door must

be doubled to determine the total resistance.

Caution

The cable shield should be grounded only at the panel. Grounding at both ends

can cause ground loops disruptive.

Output Wiring

Relay 1 is defaulted for controlling Door 1 lock, Relay 2 is defaulted for controlling Door 2

lock, Relay 3 and Relay 4 are used as auxiliary outputs.

IP-AK2 panel is connected to the nominal 12VDC power supply and cannot be used to

power the access control door strikes/locks or other auxiliary loads. The voltage range of

the relay outputs is 12VDC to 28VDC.

Each relay also has a green indicator LED, which indicates the relay state. If the relay is

triggered, the LED will be on.

Caution

The cable used must be sized for the current load and should be shielded. Do

not bundle these wires with communication, reader, or supervised input wiring.

DIP Switch Settings

IP-AK2 panel includes 10 DIP switches. The table below shows DIP Switch Definition.

Table 3-4 DIP Switch Definition

DIP Switches State Definition

1-5 Panel Address (1 ~ 31)

6 ON/OFF Master/Slave

ON OFF Default IP and User

7-8

9-10 Host 485 EOL

OFF ON Factory Default

ON ON Reserved

OFF OFF Normal Operation

Position 1 to position 5, whose panel address from 1 to 31; they are must not been set 0,

which is invalid.

Position 6 will be set with the Host RS485 Master & Slave mode. For Multidrop RS-485

line, Position 6 MUST be set “ON” for RS-485 gateway in Master mode.

Position 7 and position 8 have four combinations. When both of them are “OFF”, it

means normal operation; When position 7 is “ON” and position 8 is “OFF”, it means the

11

Loading...

Loading...